Hydraulic railhead track jack and use method thereof

A technology of rail lifter and rail head, applied in the field of hydraulic rail head lifter, can solve the problems of waste of time cost and labor cost, unable to place the rail lifter base, unable to use the rail lifter, etc., so as to reduce maintenance time, Significant management benefits and high operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

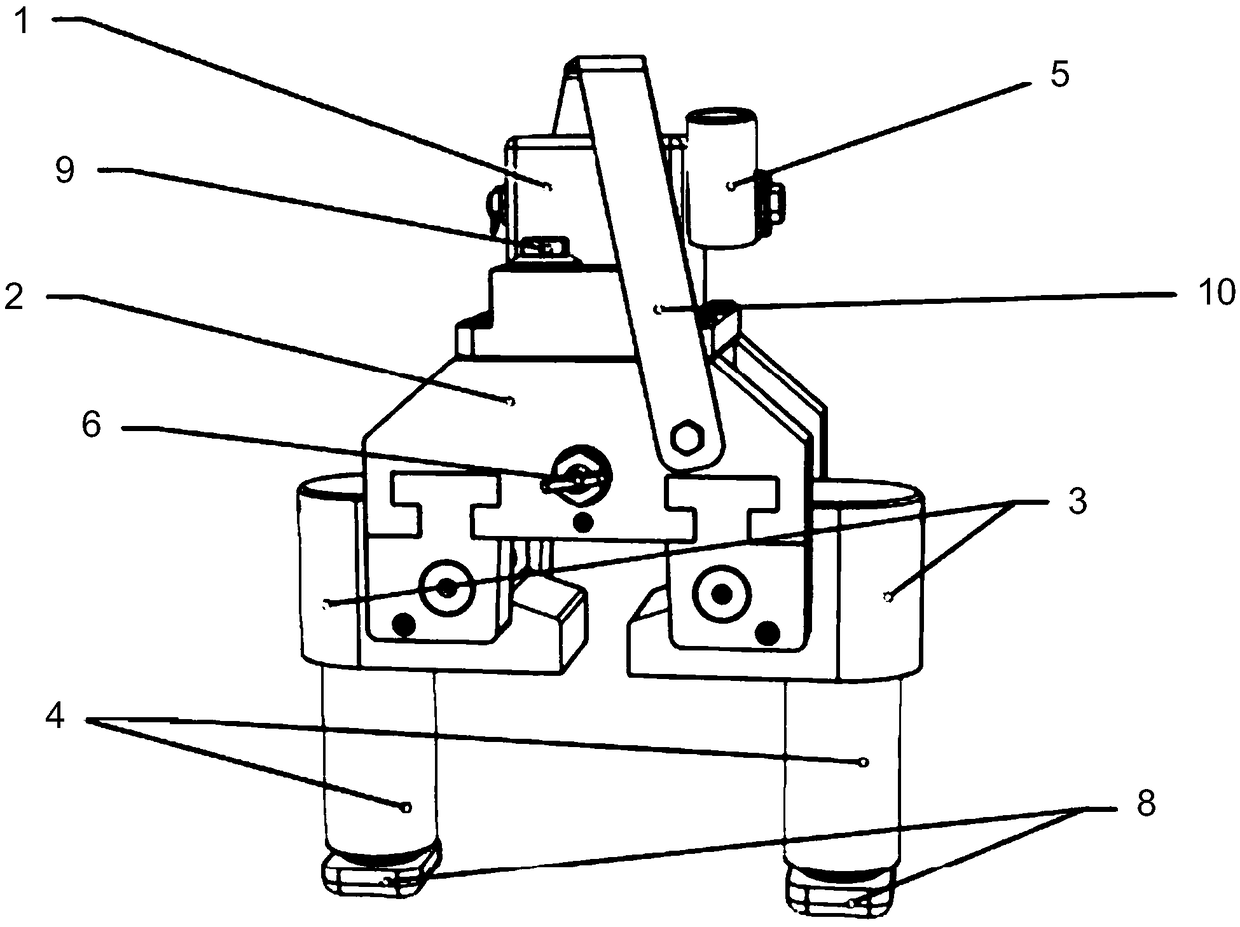

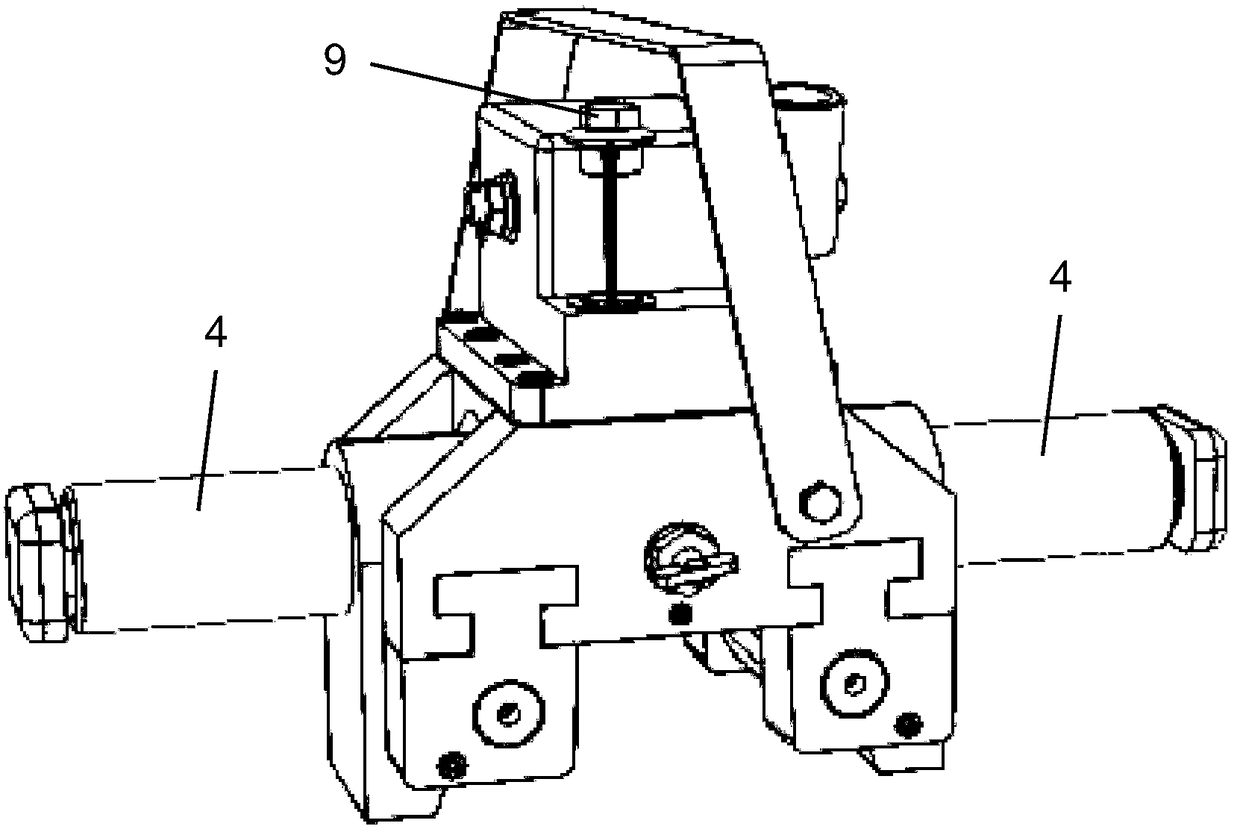

[0037] Please combine Figure 1 to Figure 2 As shown, a hydraulic rail head lifter provided by the present invention includes: a fuel tank 1 and a base 2, the fuel tank 1 is arranged on the top of the base 2, a pressing handle 5 is connected to the fuel tank 1, and the base 2 is also provided with Manual oil return valve 6, the bottom of the base 2 is provided with a channel structure. The lifting structure is designed with symmetrical double oil cylinders. This design is a key point to solve the lifting operation in small space in the wide sleeper area. On the one hand, it reduces the volume and weight of the whole machine, and on the other hand, it eliminates the unbalanced load of the existing lifting device.

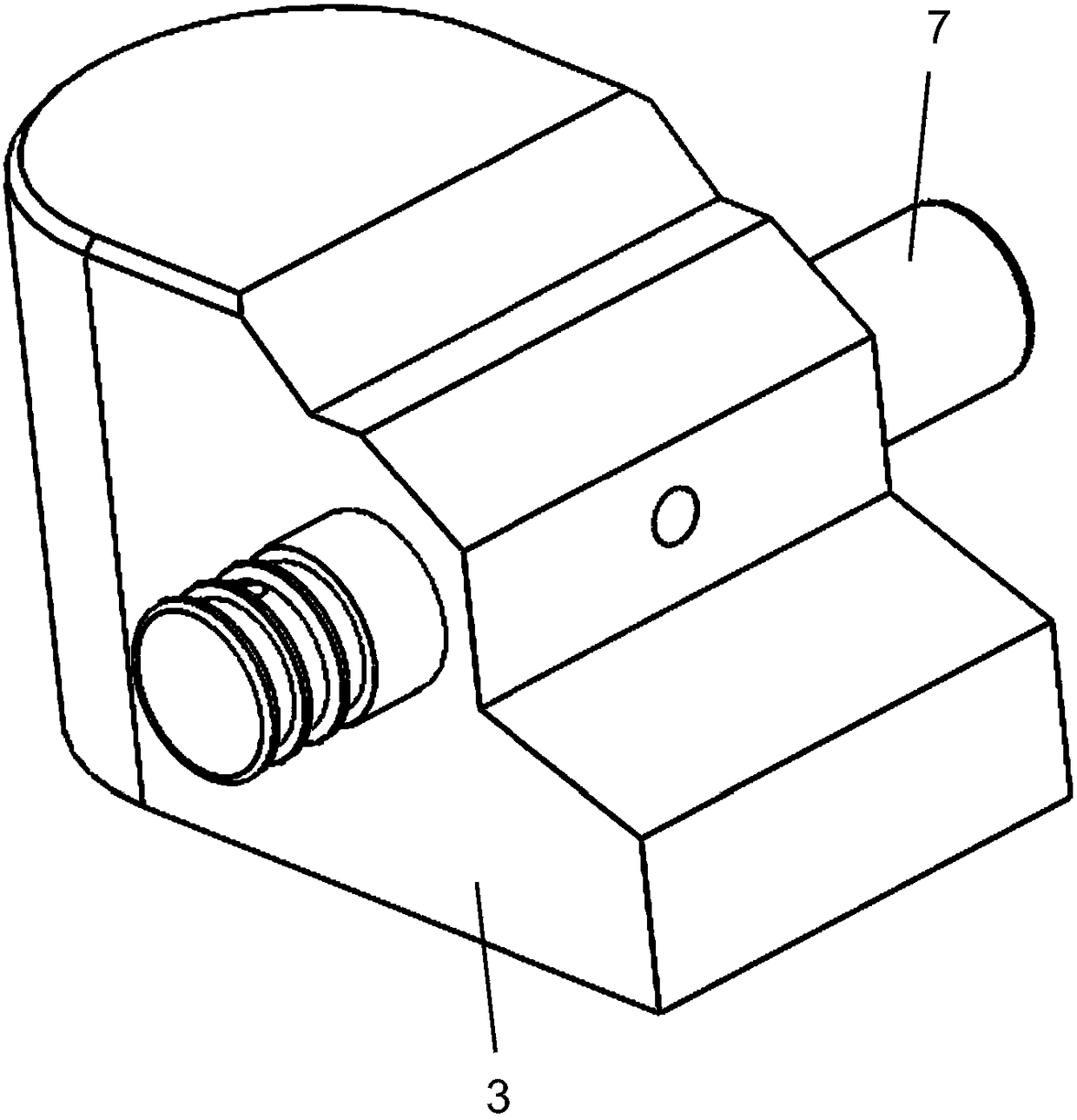

[0038] Preferably, the track lifting structure includes: a pair of track lifting hooks 3 that are symmetrically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com