Medium-length hole controlled blasting construction method of underground large chamber

A construction method and technology of controlled blasting, which is applied in underground chambers, earthwork drilling, mining equipment, etc., can solve problems such as difficult safety management, poor working conditions, and low efficiency, so as to reduce the difficulty of roof management and improve construction safety , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

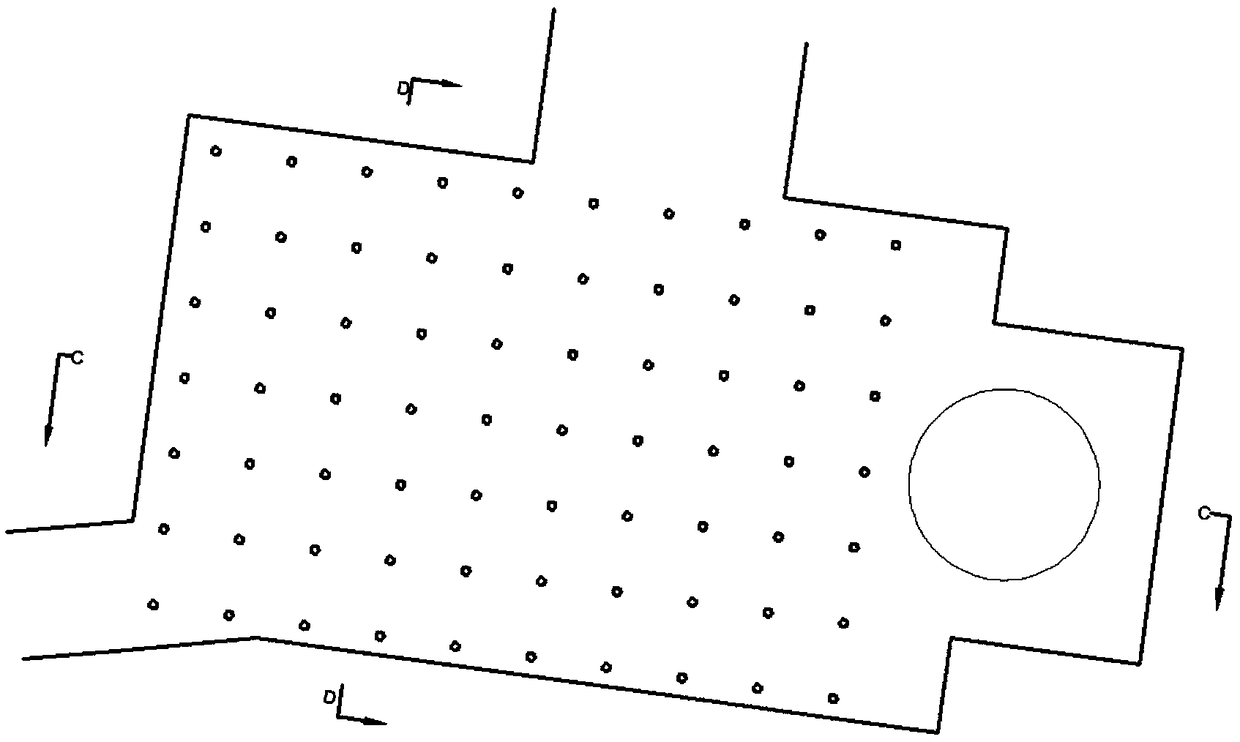

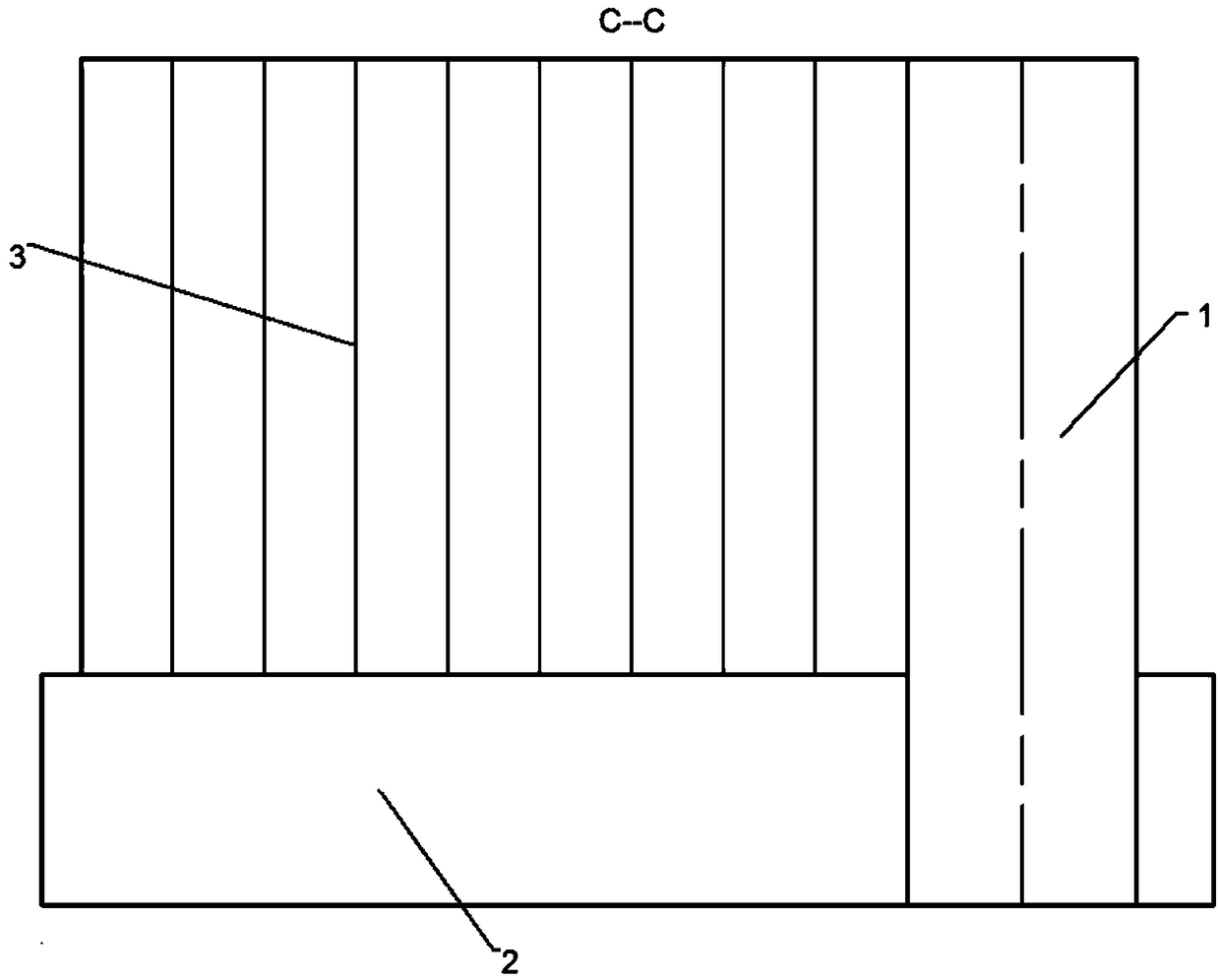

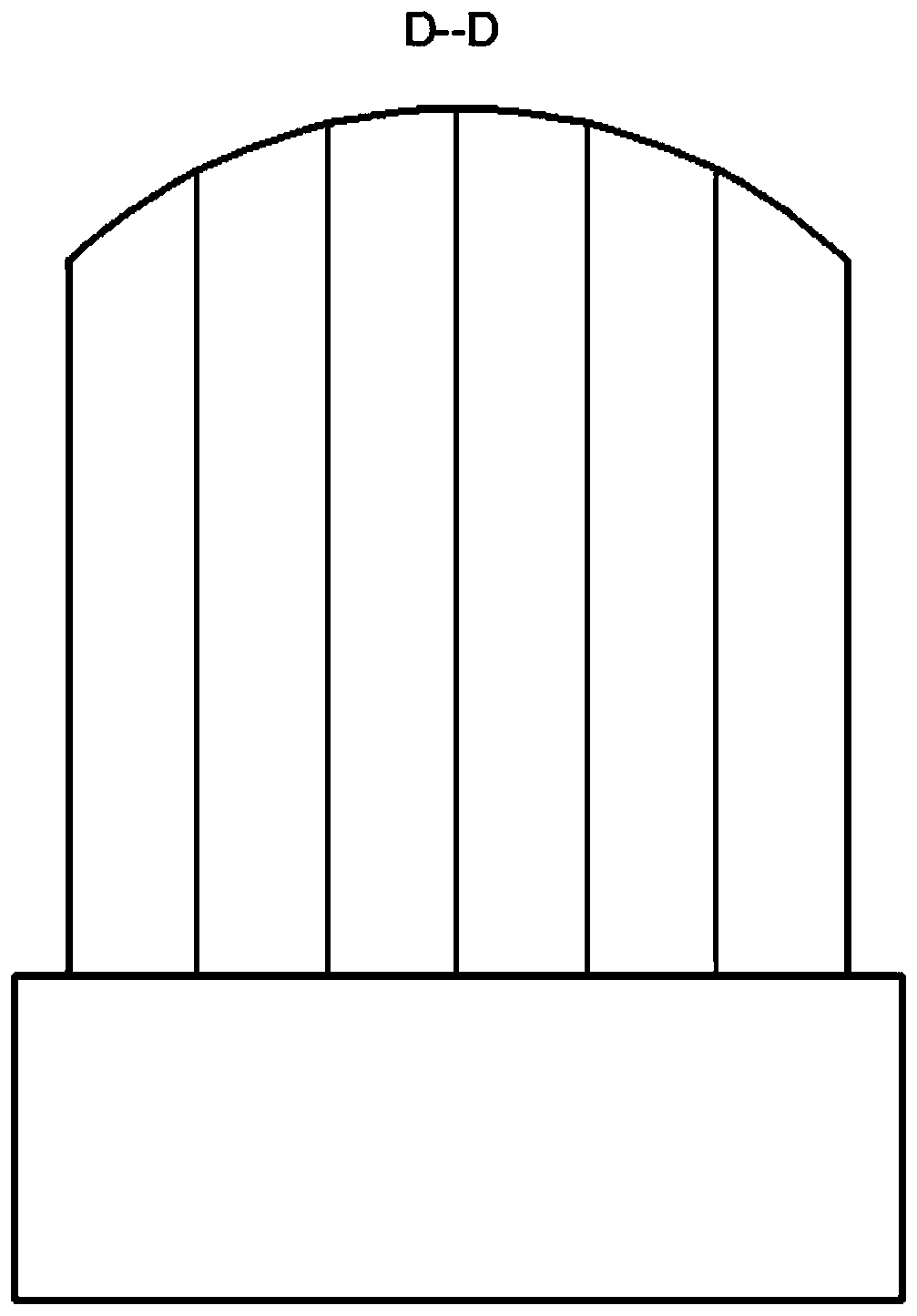

[0047] Taking the horizontal crushing chamber at -480 meters in an iron mine as an example, the chamber is 13 meters long, 8 meters wide, and 11 meters high. According to the size characteristics of the chamber, such as Figure 1-Figure 3 As shown, the construction method of deep hole controlled blasting in the large underground chamber is applied, including:

[0048] Step S1: Determine that the length of the large chamber is 13 meters, the width is 8 meters, and the height is 11 meters. The height of the arching line of the vault of the large chamber is 1.4 meters. The amount of slag and rock on the vault of the chamber, and the height of the wellhead for cutting the patio is determined according to the height of the large chamber;

[0049] Step S2: Construct the bottom roadway at the bottom of the large chamber. The bottom roadway was originally used for bottom excavation during mining, and here it is used for the roadway excavated at the bottom of the large chamber. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com