Arrangement method for double-empty-hole rhombic cutting holes in drift filling mining

A technology of approach filling and layout method, applied in earth-moving drilling, discharging machinery, blasting, etc., can solve the problems of high blasthole inclination angle, limitation of blasting footage, low blasthole utilization rate, etc., to achieve high blasthole utilization rate, blasting The effect of improving efficiency and reducing the cost of rock drilling and blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

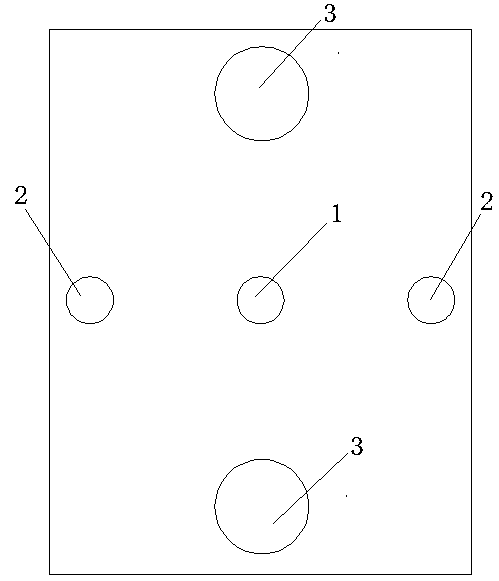

[0016] In order to better understand the present invention, the method for arranging double hollow diamond-shaped cut holes of the present invention will be further described in detail below through a specific case in conjunction with the accompanying drawings.

[0017] 50 times of excavation and blasting tests were carried out in the layered roadway of the third middle section of Baiyin Xiaotieshan according to the above-mentioned cutting hole arrangement method, and the excavation and blasting tests were carried out in combination with production.

[0018] In the cut blasting design, the first charging hole 1 and the second charging hole 2 are 3.2m long, and the empty hole 3 is 0.2m deeper than the first charging hole 1 and the second charging hole 2, which is 3.4m. For various reasons, the blastholes often do not actually reach the above-mentioned depths. The Swedish-made H128 double-arm electric full-hydraulic rock drilling jumbo is used for rock drilling. The machine is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com