Automatic roller type sand blasting machine

A drum type, sandblasting machine technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of complex structure, lifting, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

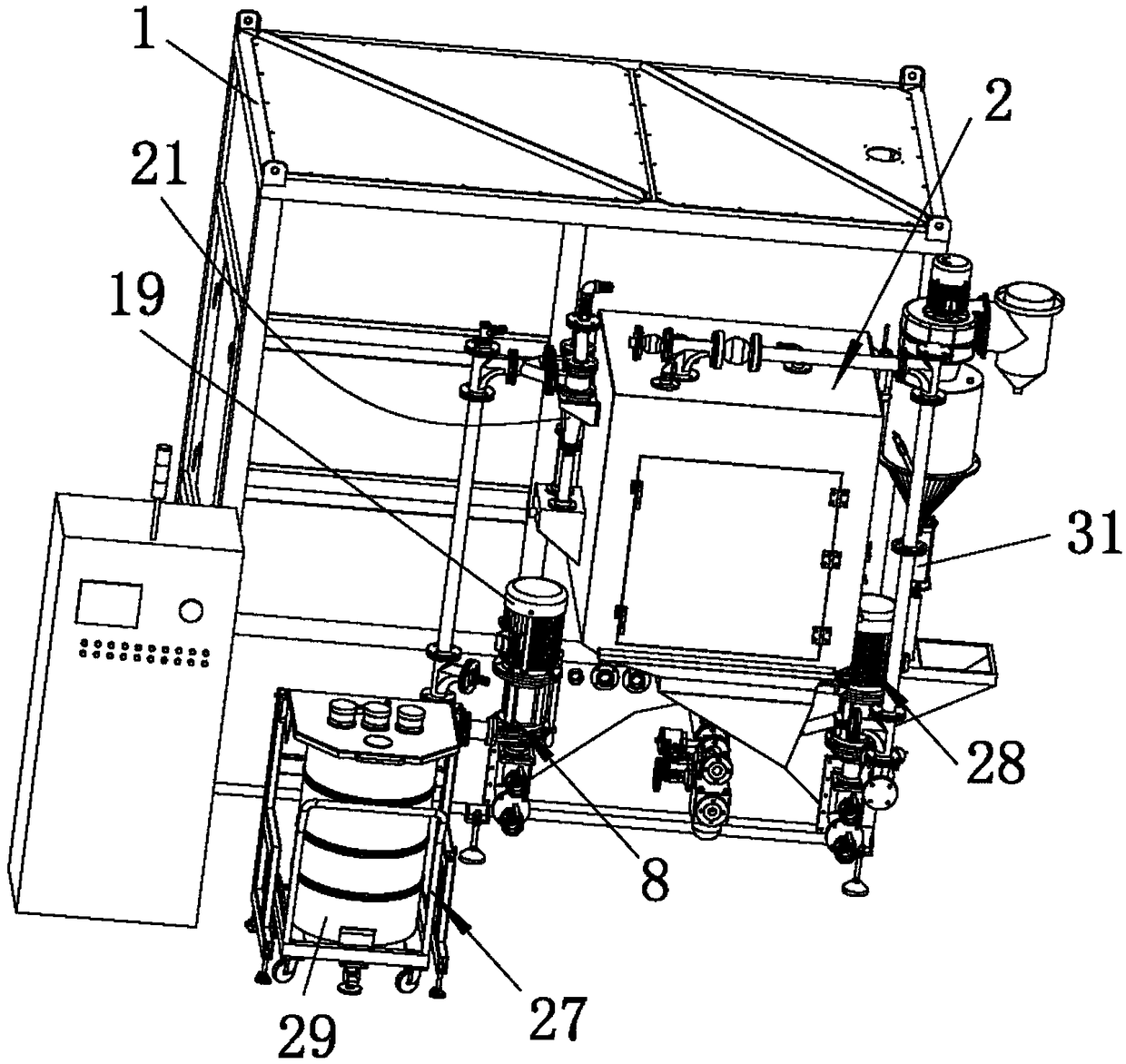

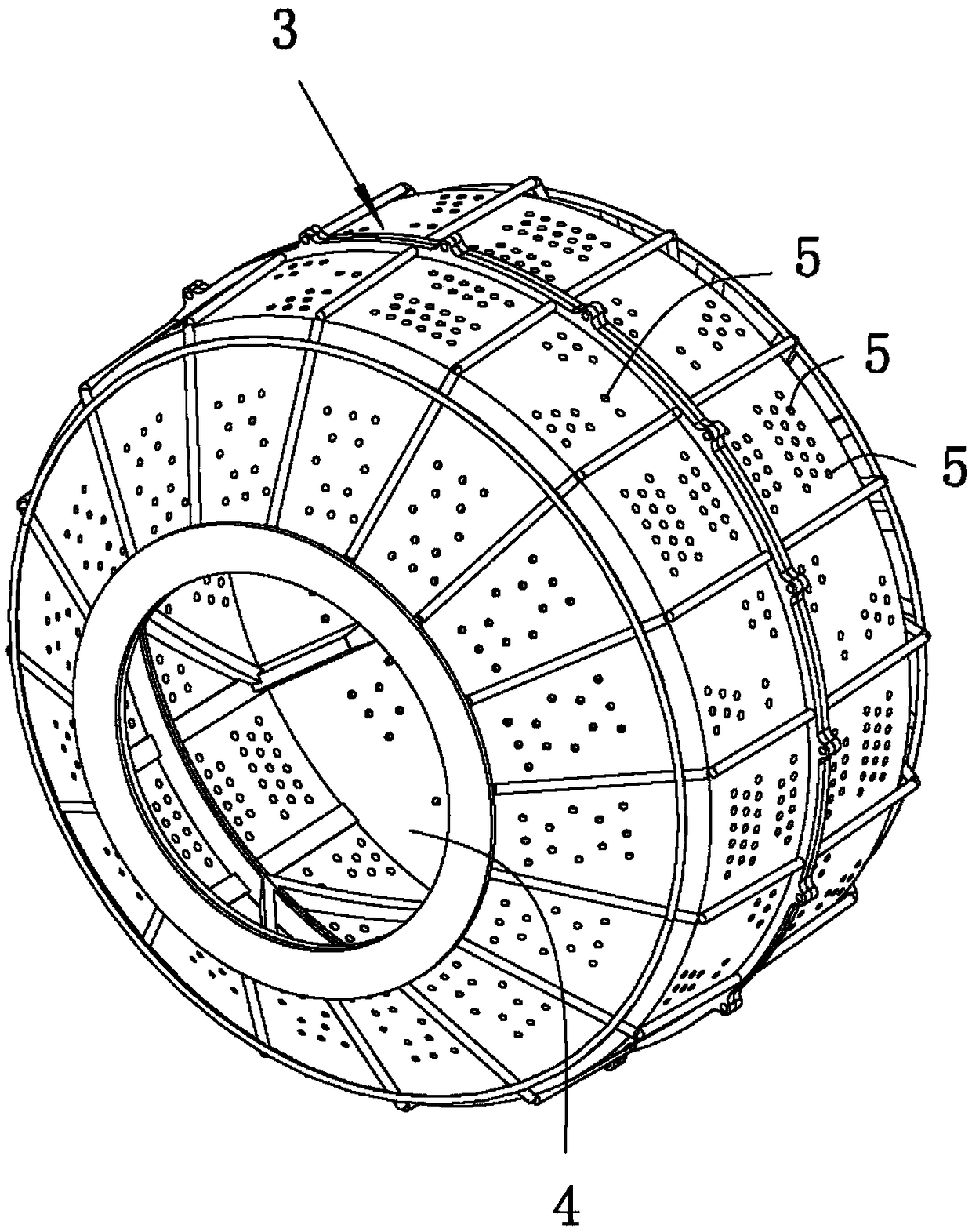

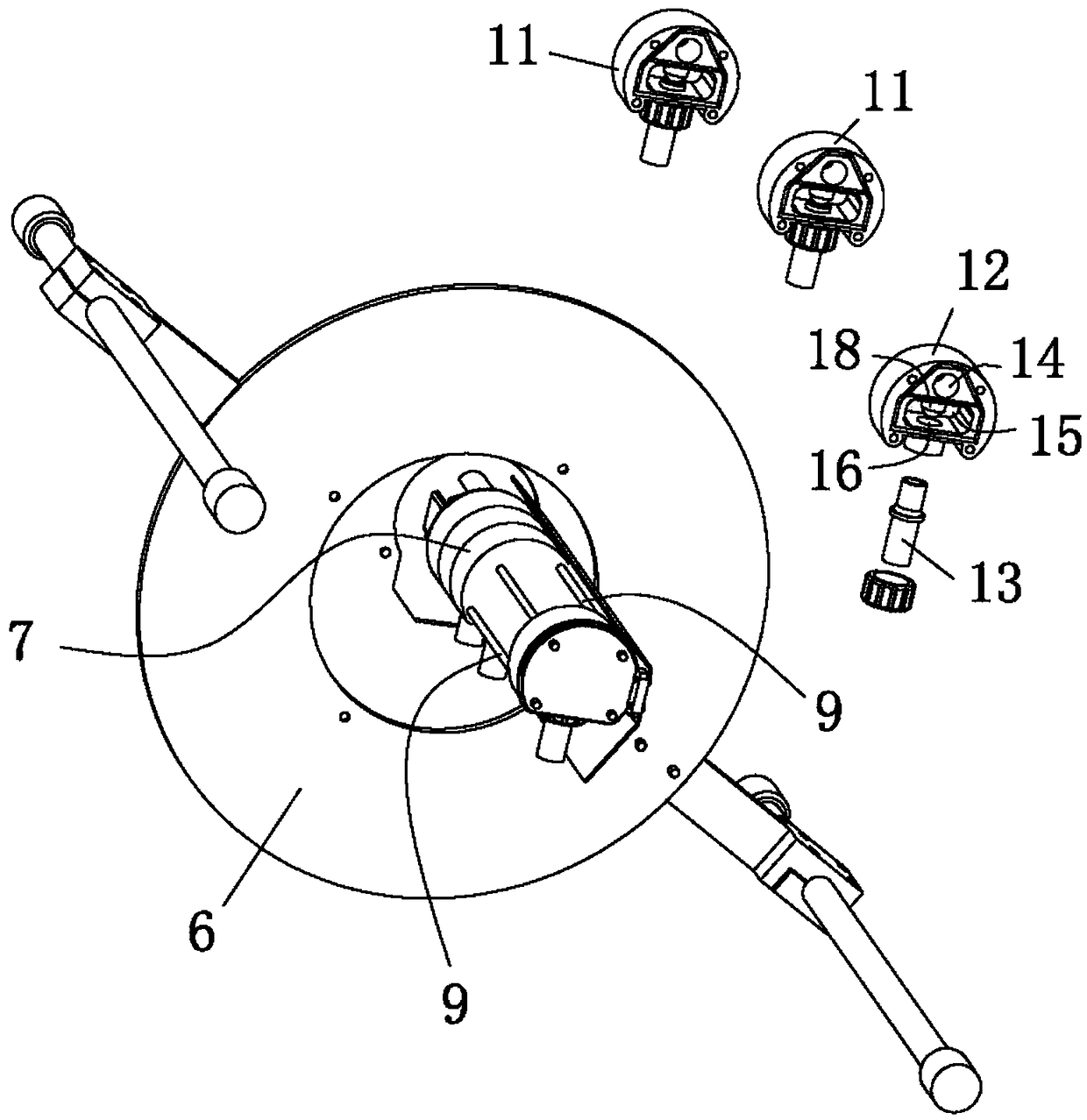

[0041] see Figure 1 to Figure 4 Shown, a kind of automatic drum sandblasting machine of the present invention comprises frame 1, and frame 1 adopts metal material to make, is arranged on the blasting room 2 on frame 1, and blasting room 2 is installed on frame It is composed of a plurality of metal plates on 1; it also includes a drum 3 that is rotatably arranged on the frame 1 and located in the sandblasting room 2. For example, the drum 3 is hinged on the frame 1 via a bearing, and the drum 3 is provided with a material Cavity 4 and a plurality of sand leakage holes 5 communicating with the material chamber 4, the material chamber 4 is recessed from the outer surface of one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com