Live-line insulator W-shaped pin electric pin remover

A live line and insulator technology, applied in the field of live line insulator W-type pin electric pin remover, can solve the problems of the influence of the pin removal operation, the W-type pin falling to the ground, and the lack of protection of the locking pin, so as to avoid insulator damage and operation Convenience, safety, and remarkable safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

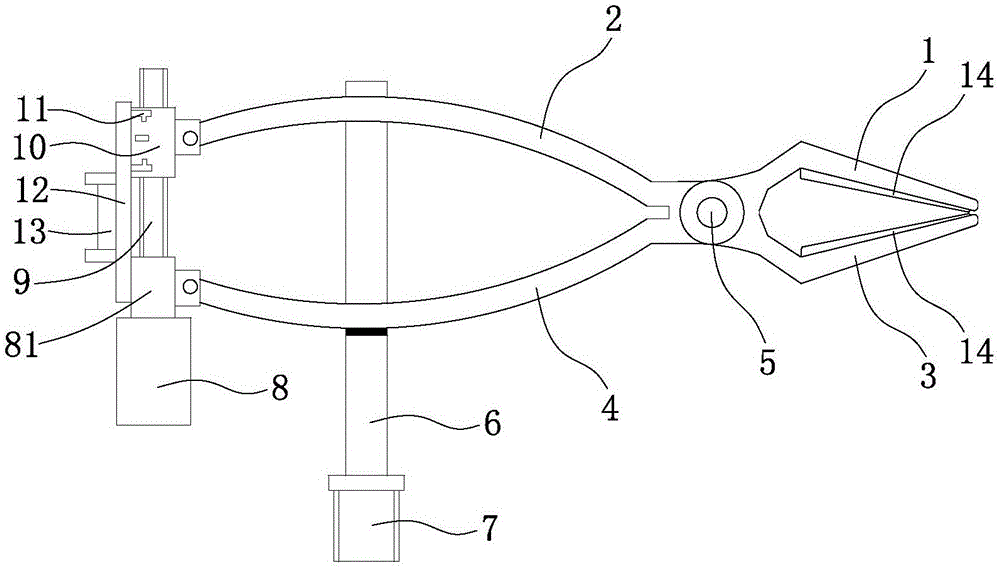

[0013] like figure 1 As shown, Embodiment 1 of a live line insulator W-type pin electric pin remover of the present invention includes an upper clip and a lower clip, and the upper clip and the lower clip are hinged by a rotating shaft 5, and the rotating shaft 5 is equipped with a spring, the upper clamp includes an upper clamp 1 and an upper clamp handle 2, the lower clamp includes a lower clamp 3 and a lower clamp handle 4, and the lower clamp 4 is connected to the insulating rod 6 through a connecting rod 6. The tops of the operating rods 7 are connected, and the inner sides of the upper chuck 1 and the lower chuck 3 are provided with anti-slip pads 14, which can prevent the W-shaped pin from slipping and causing it to be damaged or slip off and fall off.

[0014] The pin remover also includes an electric driving device, the electric driving device includes a motor 8, a screw 9 connected to the output end of the motor 8, and a nut 10 sleeved on the screw 9, and the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com