Patents

Literature

53results about How to "Increase running resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blending and treating system for ventilation air methane and drainage methane in coal mine

ActiveCN105381694APlay the role of energy saving and emission reductionNormal operation impactGas treatmentAuxillary pretreatmentAtmospheric airProcess engineering

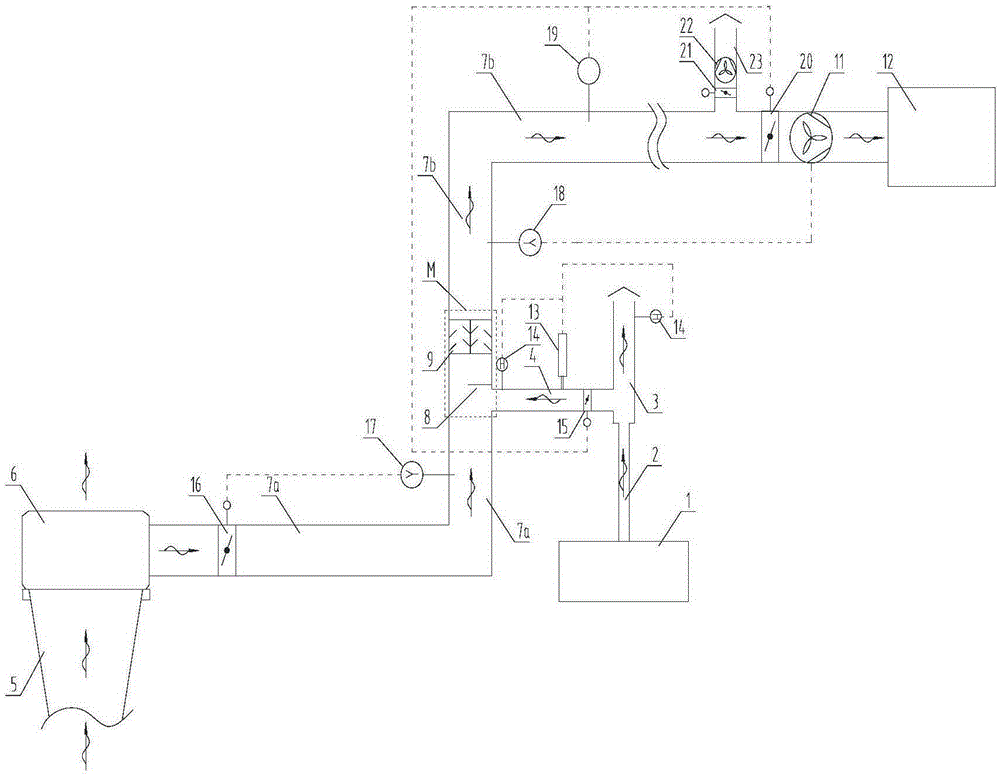

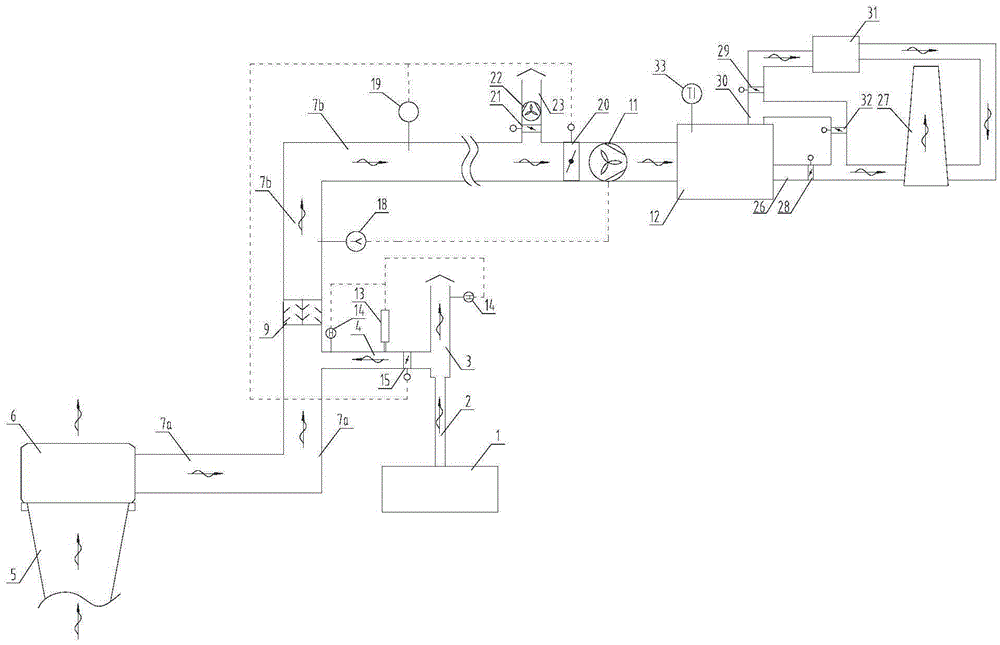

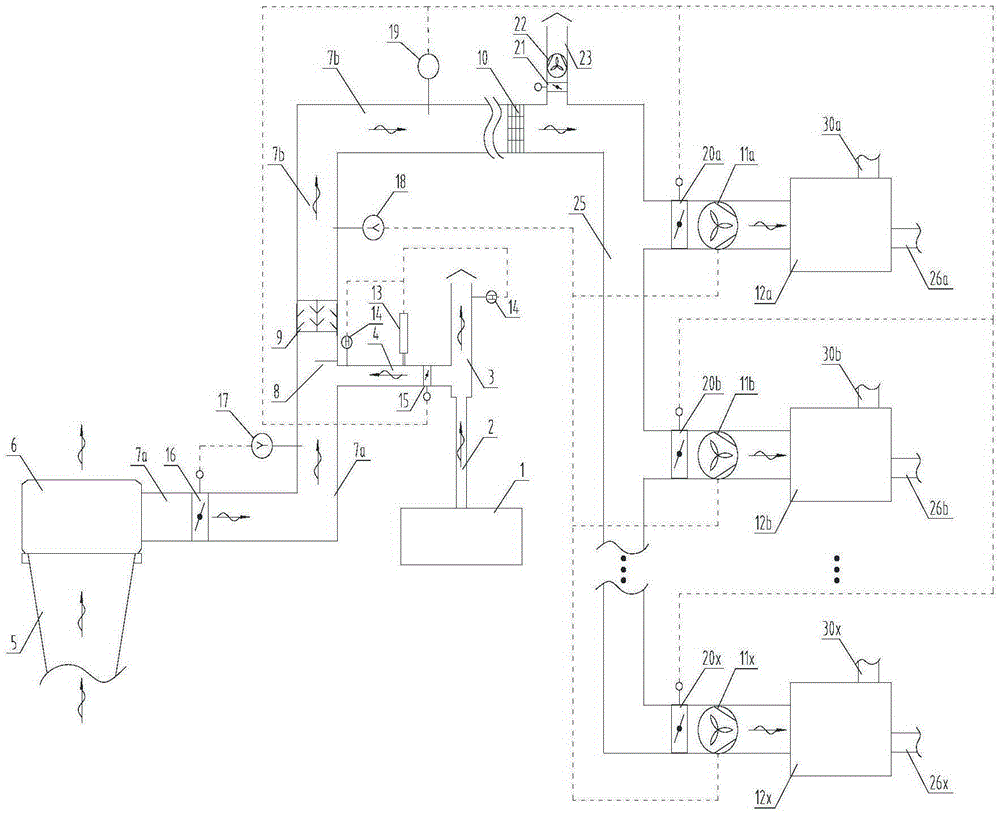

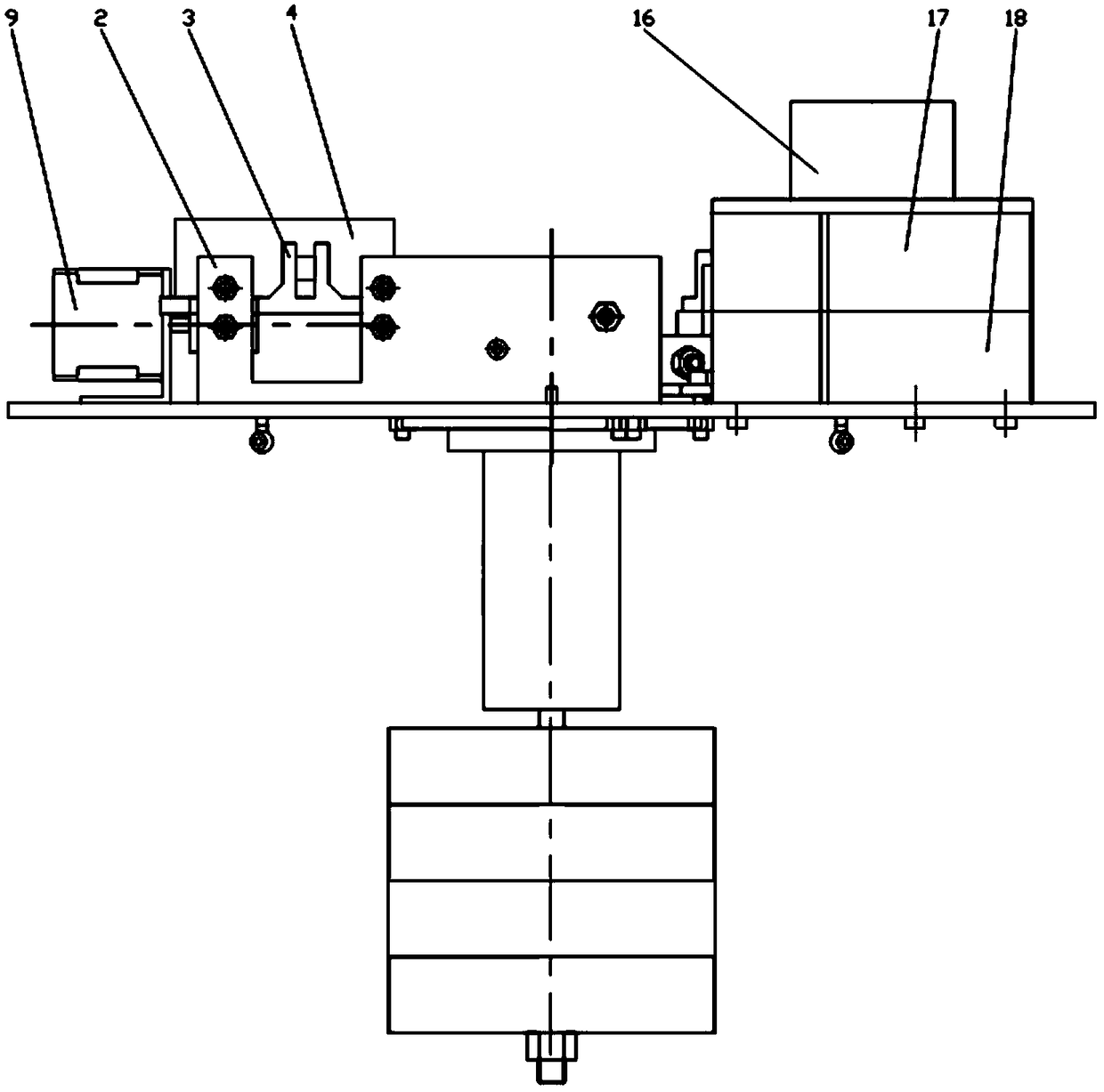

The invention provides a blending and treating system for ventilation air methane and drainage methane in a coal mine. The blending and treating system comprises a ventilation air methane inducing cover (6), a ventilation air methane conveying pipeline (7a), a drainage methane connection pipeline (4), a mixer (M), a mixed gas conveying pipeline (7b), an induced draught fan (11) and a heat-accumulating type high-temperature oxidation apparatus (12). A gas outlet of the drainage methane connection pipeline (4) is communicated with the ventilation air methane conveying pipeline (7a), so the drainage methane is sucked into the ventilation air methane conveying pipeline (7a) from the drainage methane connection pipeline (4) and uniformly blended with the ventilation air methane in the ventilation air methane conveying pipeline (7a); and the obtained mixed methane is conveyed to the heat-accumulating type high-temperature oxidation apparatus (12) by the mixed gas conveying pipeline (7b) for oxidation treatment. The blending and treating system can realize safe acquisition, blending and conveying of the ventilation air methane and the drainage methane in the coal mine, provides a safe gas source for subsequent utilization projects like heat-accumulating type high-temperature oxidation and discharges thoroughly oxidized products into the atmospheric environment.

Owner:兴边富民(北京)清洁能源技术有限公司 +1

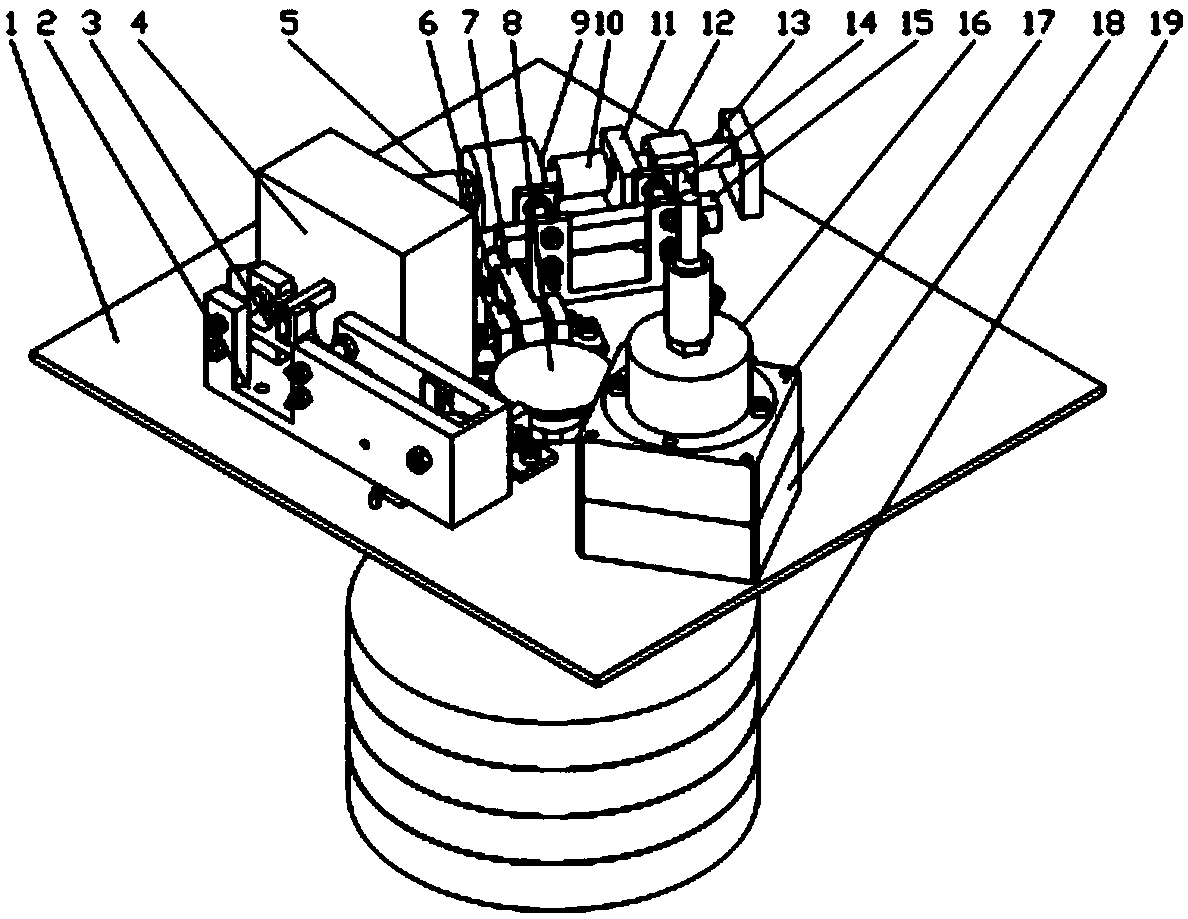

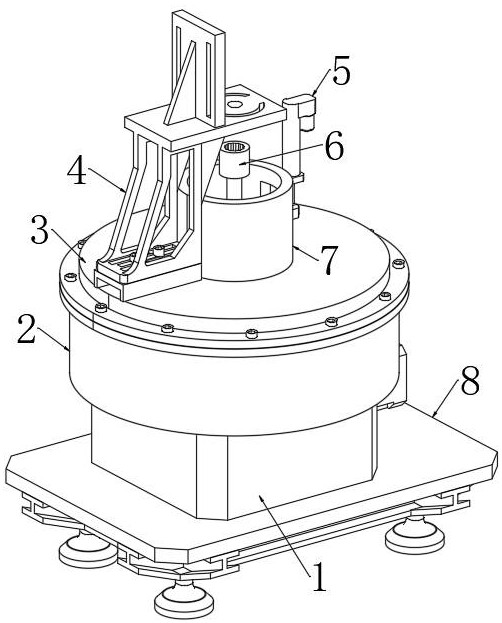

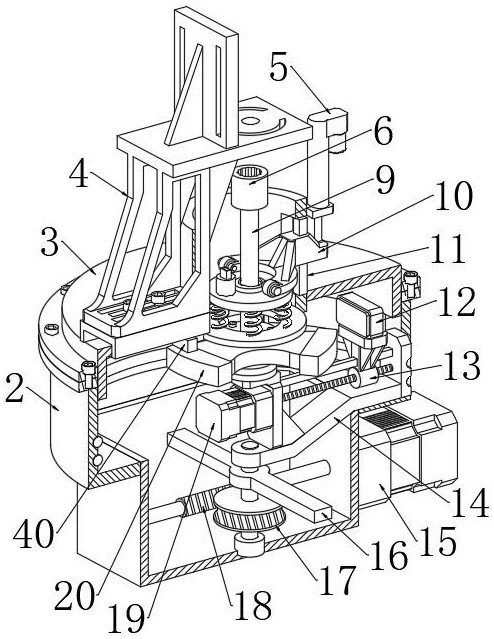

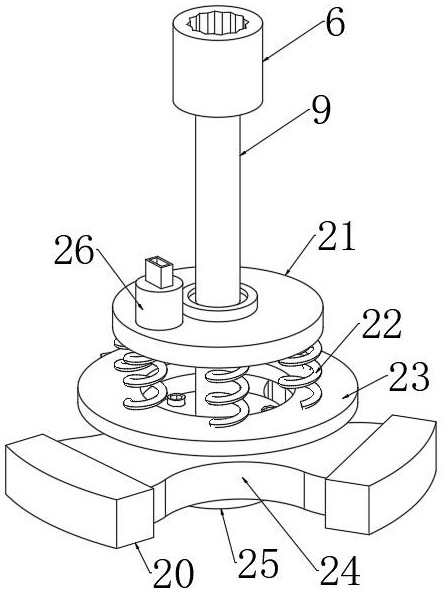

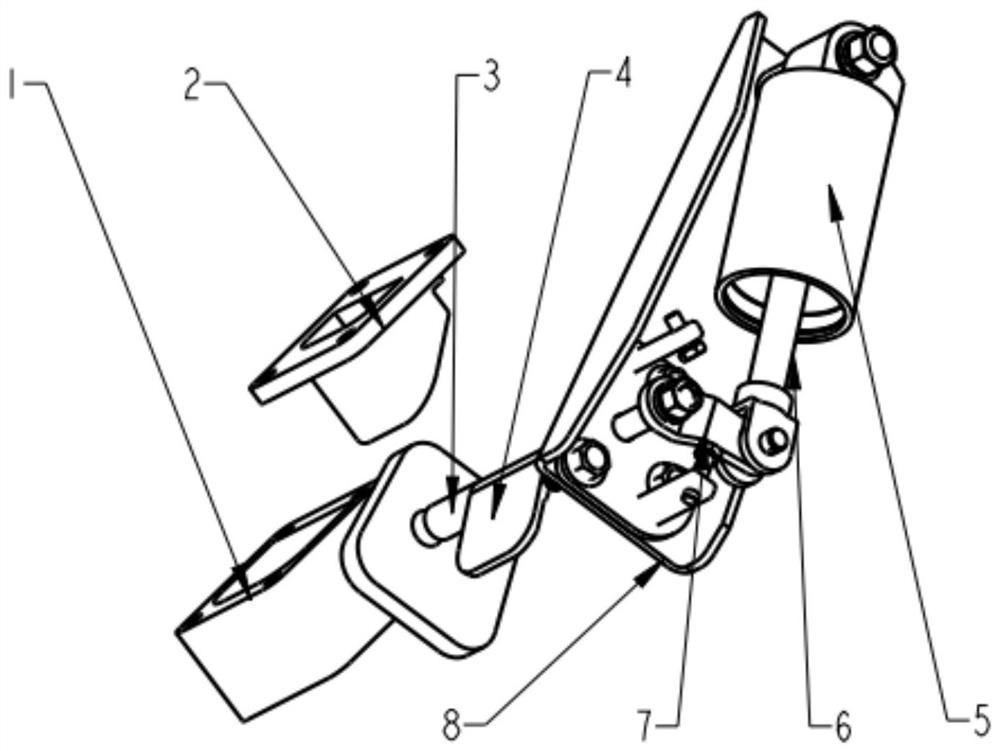

Underwater robot multi-mode jettison device

ActiveCN109131802AImprove reliabilityDoes not involve disassemblyUnderwater vesselsUnderwater equipmentMotor driveMarine engineering

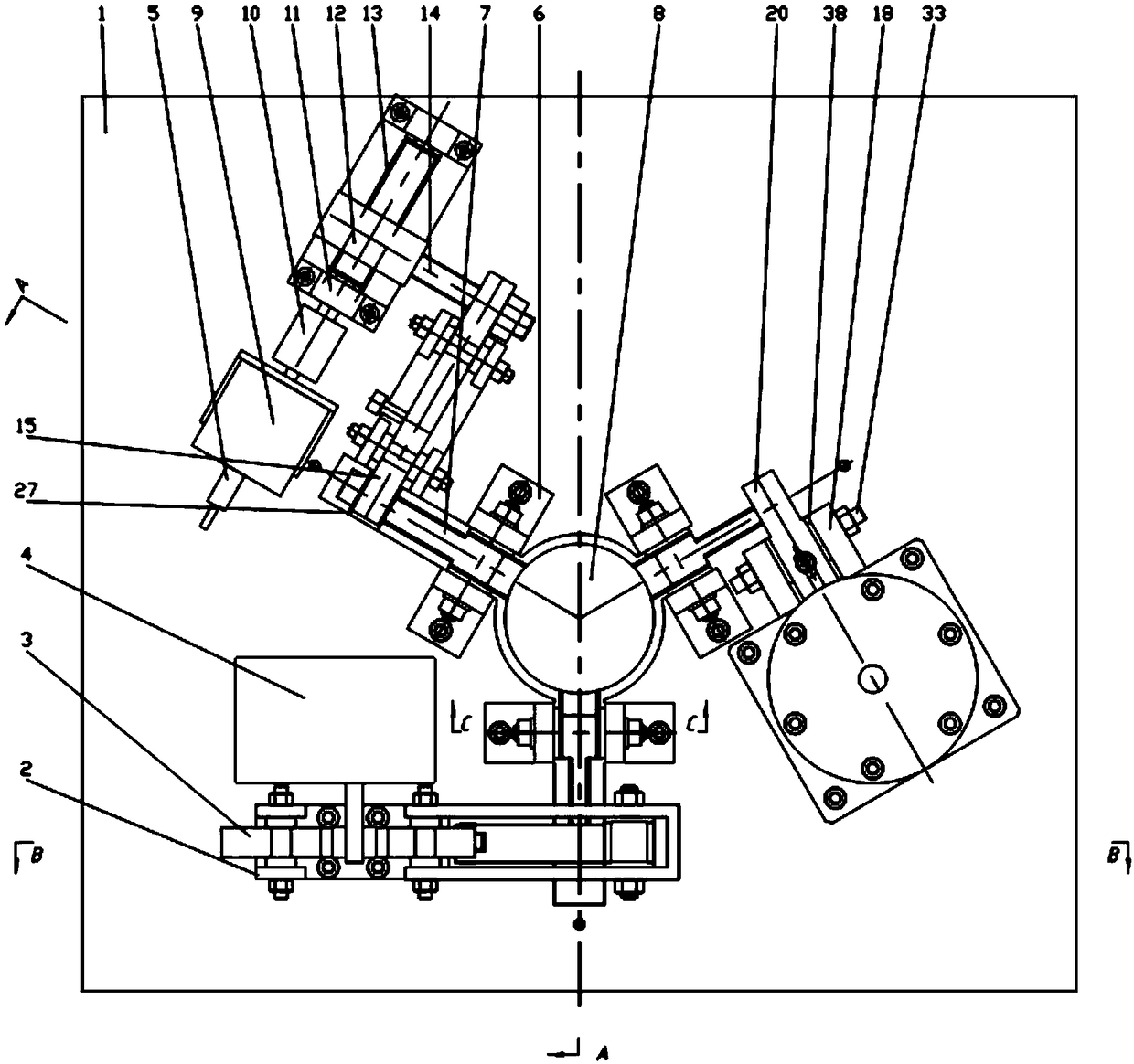

The invention relates to an underwater robot multi-mode jettison device, which is mainly composed of an electromagnetic driving mechanism, a motor driving mechanism, a pure mechanical timing driving mechanism and a releasing mechanism. Three kinds of driving mechanisms respectively act on the releasing mechanism to restrict the releasing mechanism to carry out the throwing action. Each drive mechanism is composed of a drive element and its corresponding actuator. The actuator reliably releases the ballast when the ballast needs to be released and reliably fixes the ballast when the ballast does not need to be released through the action of the actuator on the release mechanism. The device realizes the convenient installation of the ballast through the release mechanism, the automatic limitof the ballast after the installation of the ballast, and the guidance of the ballast in the process of the jettison. The device not only can reliably release the ballast, but also can reliably fix the ballast when the equipment works normally. It is especially suitable for autonomous underwater vehicle, underwater construction machinery and other underwater equipment.

Owner:HARBIN ENG UNIV

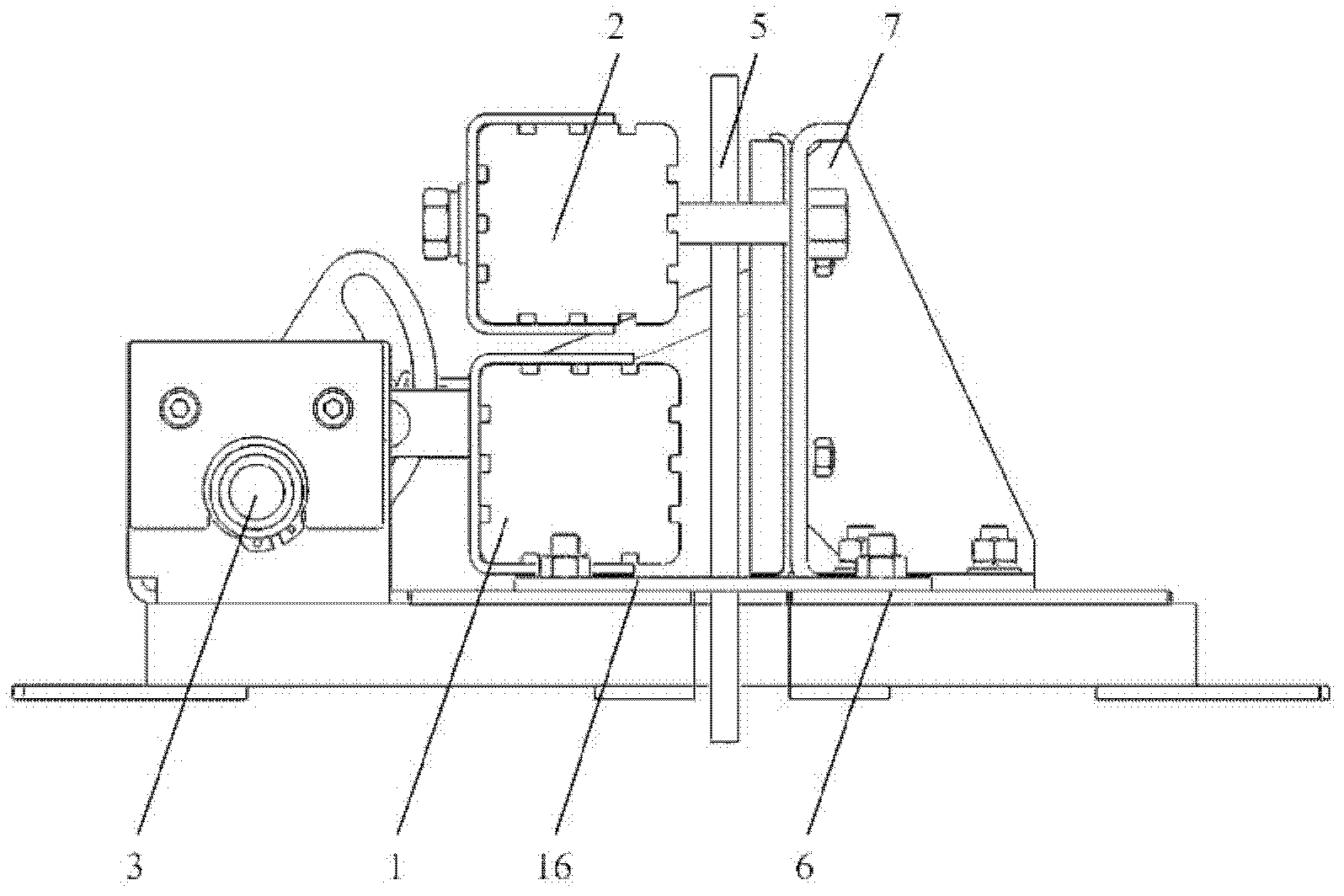

Rope-clamping device for installing steel wire rope of elevator

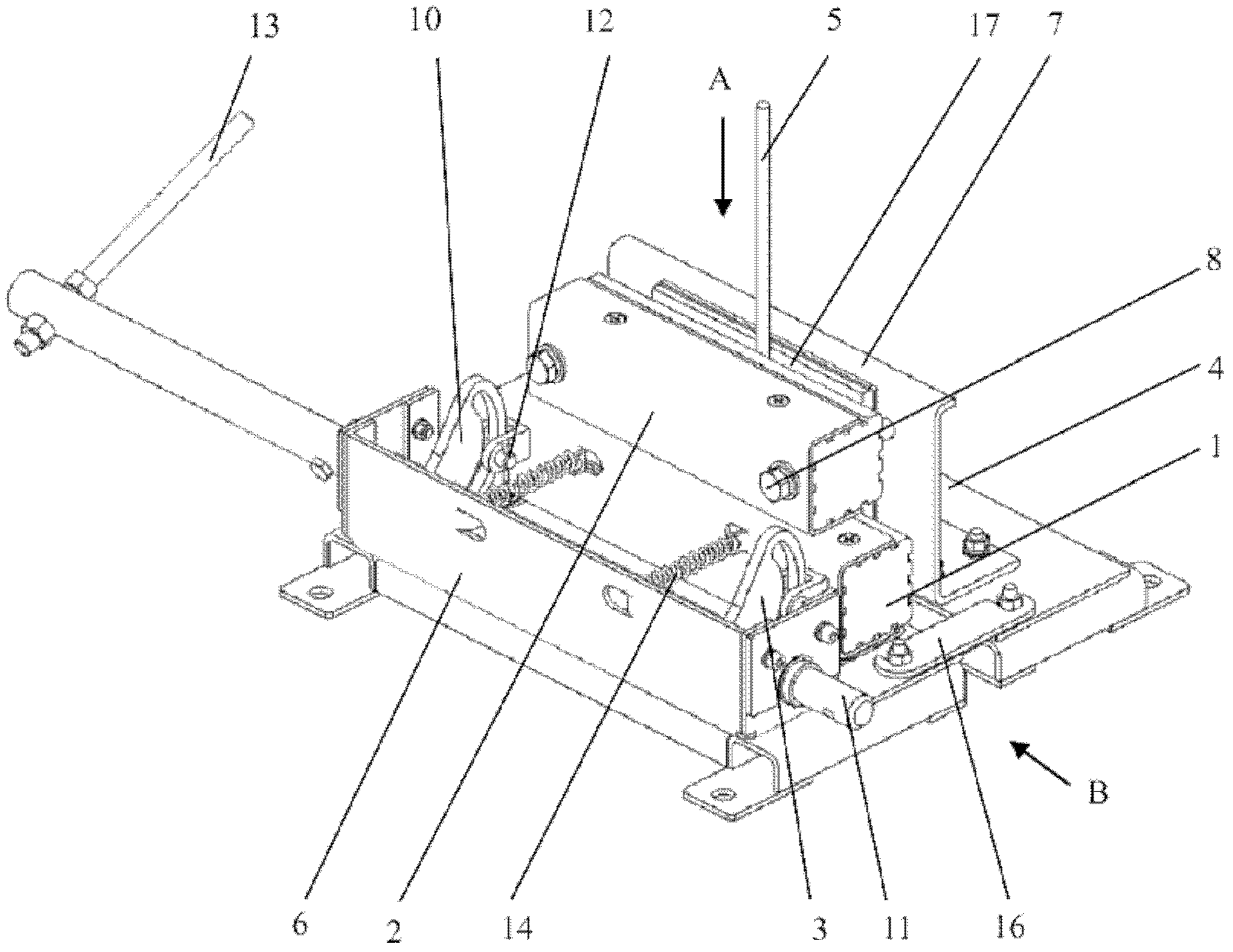

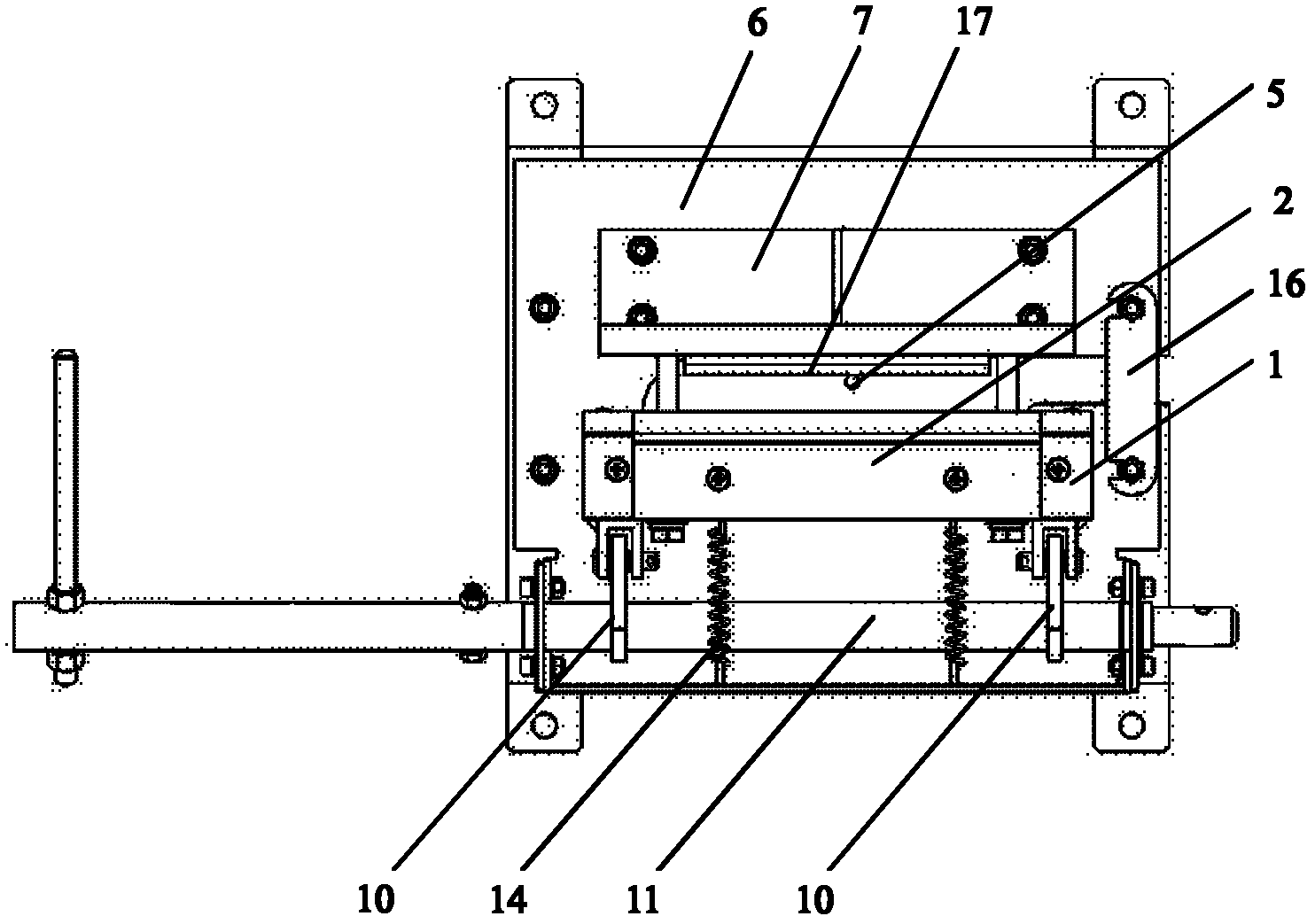

The invention relates to a rope-clamping device for installing a steel wire rope of an elevator, and belongs to the technical field of mechanical control for a lifting system. The rope-clamping device for installing the steel wire rope of the elevator comprises a movable clamp, a static clamp and a fixed support with a trigger mechanism, wherein the movable clamp is connected with the trigger mechanism as well as clamped and matched with the fixed support to adjust the descending speed of the to-be-installed steel wire rope, and the static clamp is movably connected with the fixed support; and the fixed support comprises a bottom plate, a fixed frame and the trigger mechanism for triggering the movable clamp, the fixed frame and the trigger mechanism are arranged on the bottom plate respectively, and the fixed frame is movably connected with the static clamp as well as clamped and matched with the static clamp to fix the steel wire rope. The rope-clamping device for installing steel wire rope of the elevator disclosed by the invention is simple in structure, convenient in operation, reliable in clamping, and wide in application range.

Owner:THYSSENKRUPP ELEVATORS SHANGHAI CO LTD

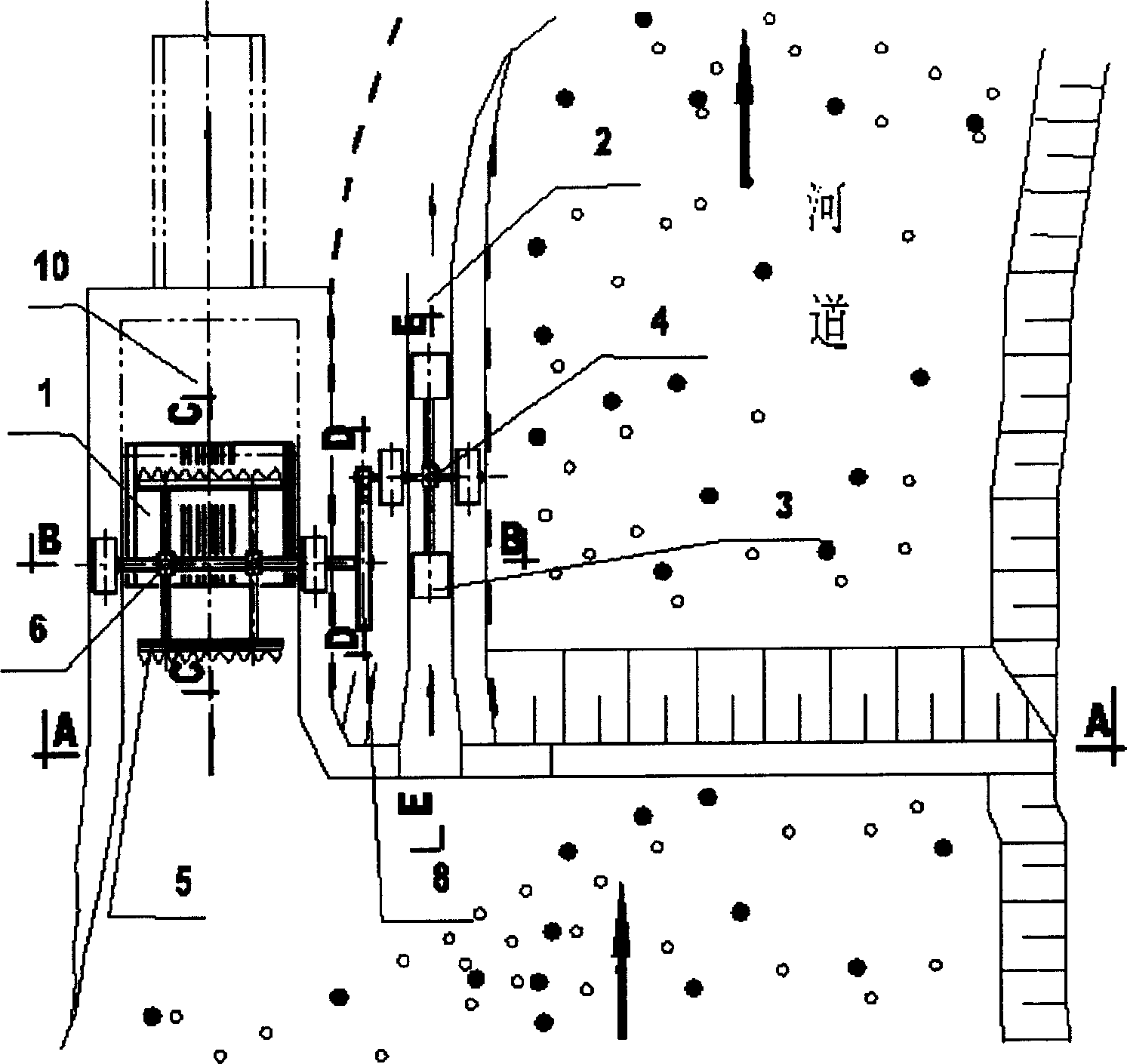

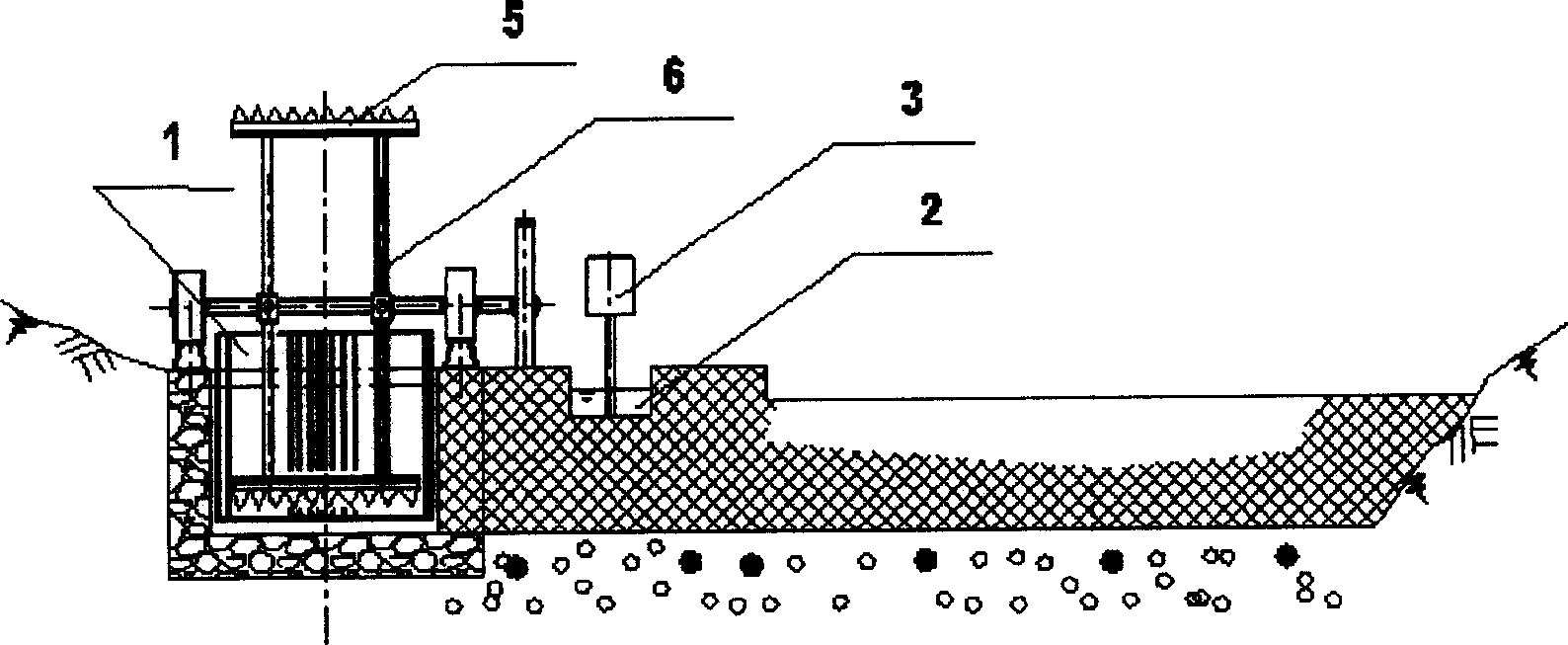

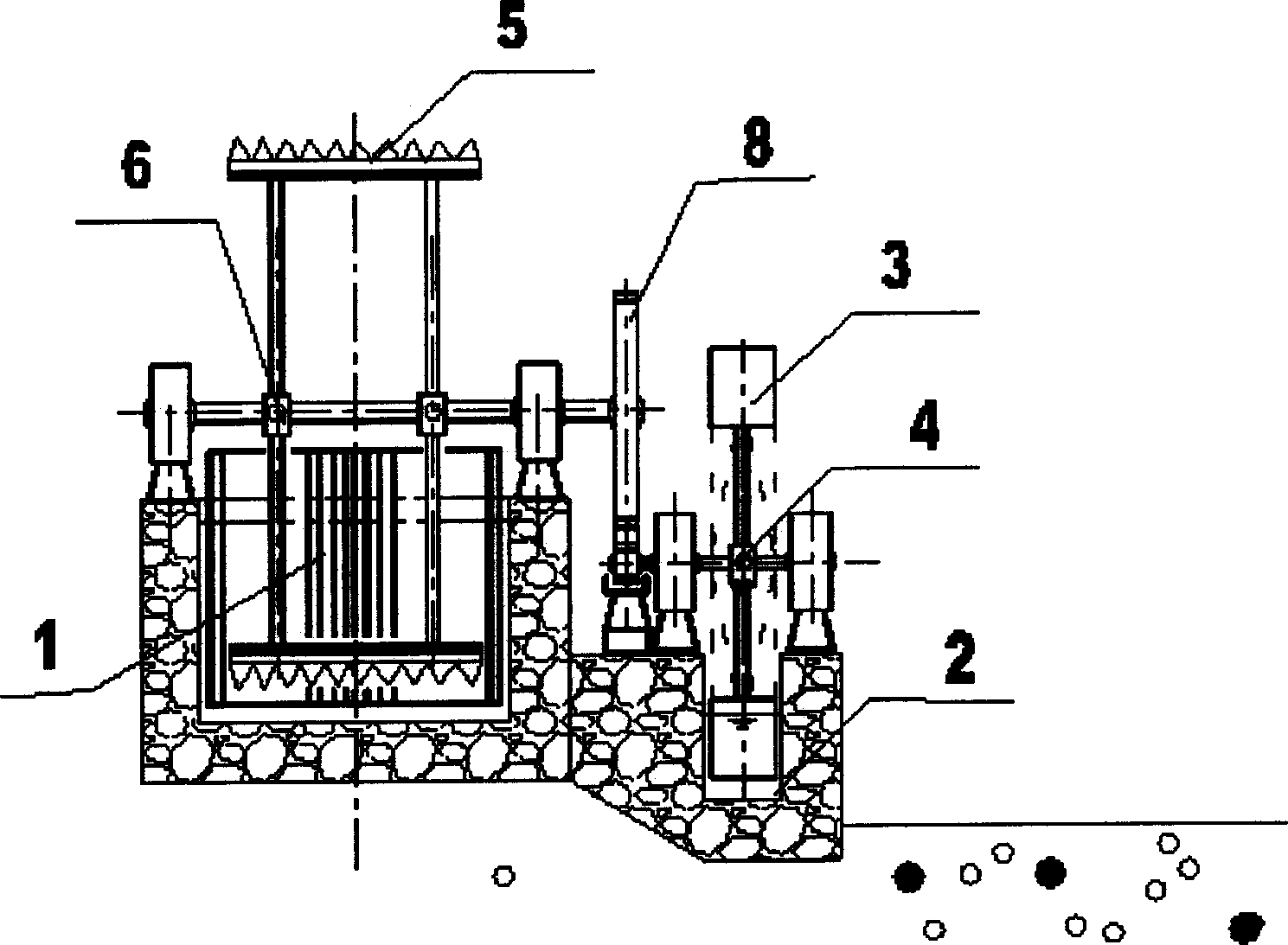

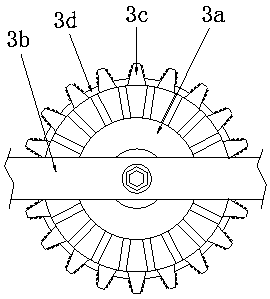

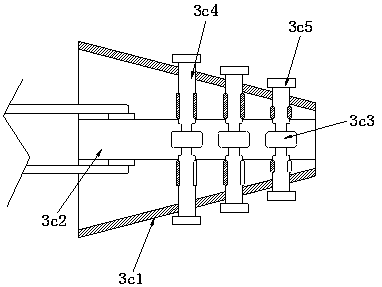

Method and device for automatically removing sewage in grid of water intake of river channel

The invention discloses an auto-clearing estuary water intake grid sewage method and device, which is characterized by the following: the gutter is installed on the barrage beside water intake, which can let a river flow and the floor have difference in elevation; the rotation device is installed on the gutter, which can be attacked by the current its pulpboard to rotate; the rotation gear with scumming rake is installed before the grid at intake; using river flowing in the gutter motivates pulpboard of rotating device and make rotating device rotate; scumming rake removals the sewage from the grid by rotating device makes the rotation gear rotate. The invention reduces the cost, which simplifies the structure.

Owner:GUIYANG AL-MG DESIGN & RES INST

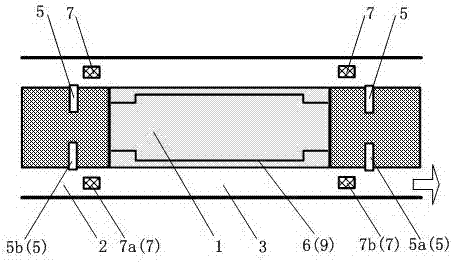

Subway-wind-power regulating and controlling system

ActiveCN107060864AEnhance piston wind strengthBlocking or reducing air flowWind energy with garvitational potential energyEnergy storageControl systemWind force

A subway-wind-power regulating and controlling system is disclosed. The subway-wind-power regulating and controlling system comprises a platform / station hall area (1), a subway tunnel (2), a station rail-mounted area (3) and a platform shield door (6). The subway-wind-power regulating and controlling system is characterized in that one or more tunnel shield doors (5) used for blocking air flowing are arranged in the subway tunnel (2) next to the station rail-mounted area (3), and the tunnel shield doors (5) have states of being opened, partially closed and closed. Subway piston flow is regulated and controlled and utilized reasonably through the tunnel shield doors (5).

Owner:NANJING KULANG ELECTRONICS

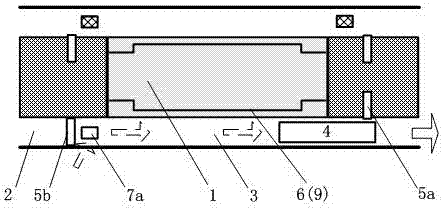

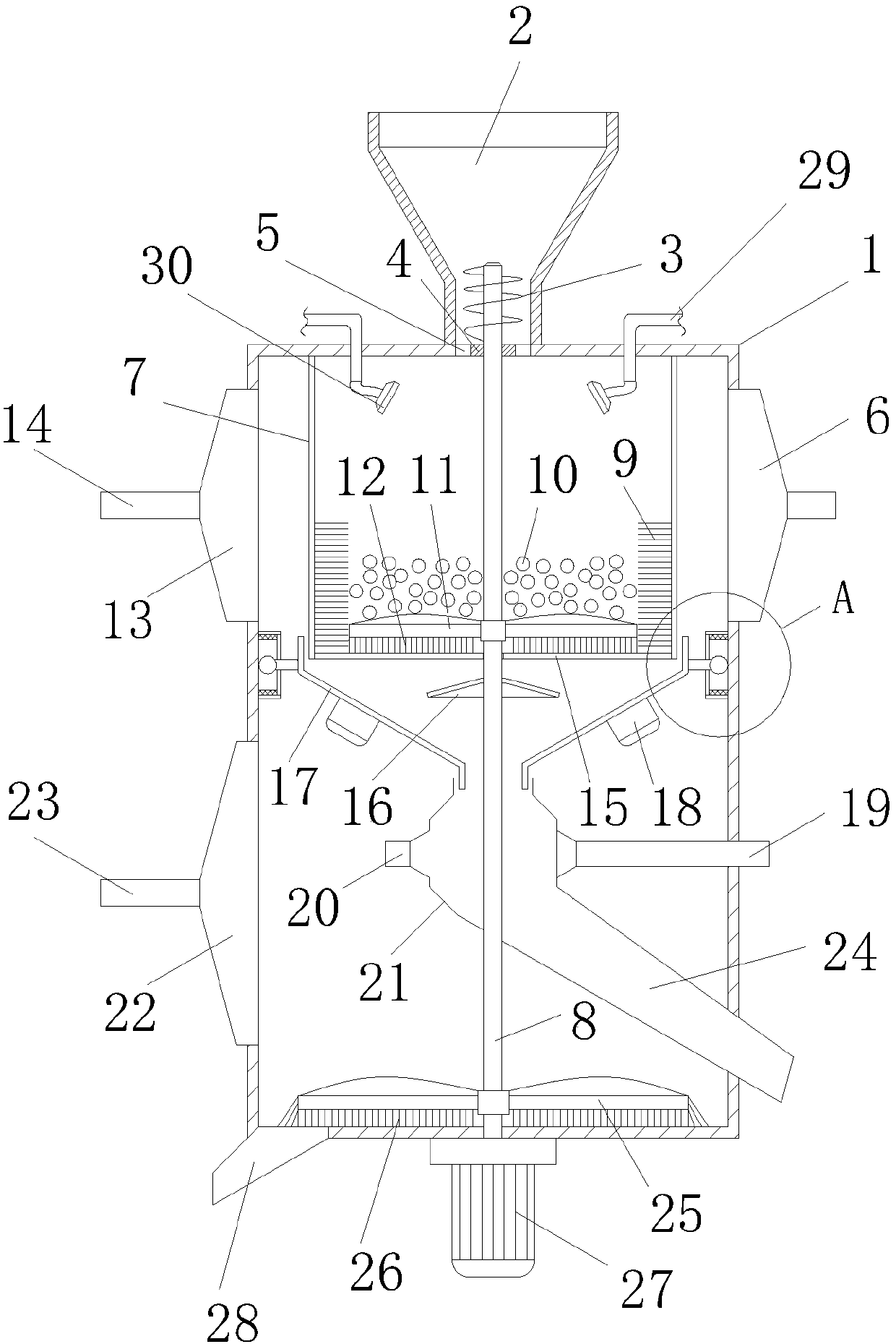

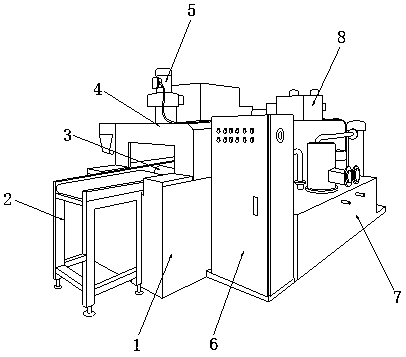

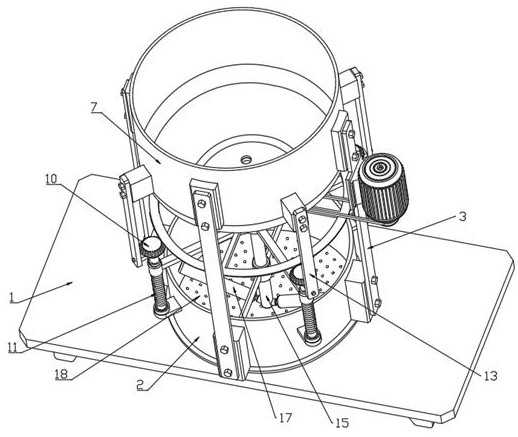

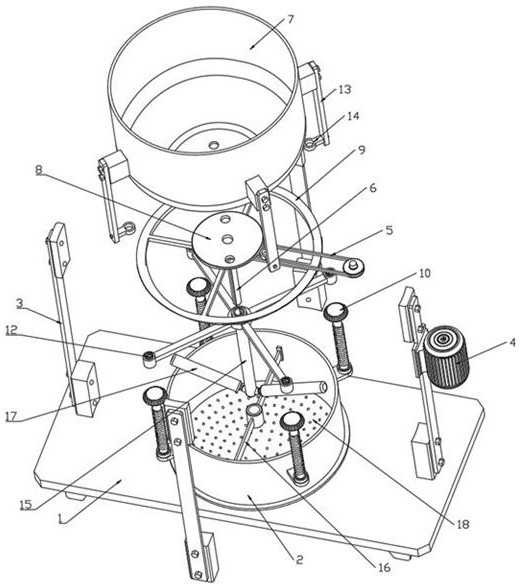

High-quality fine rice efficient polishing device

InactiveCN107583709AAvoid cloggingAvoid generatingGrain huskingGrain polishingBroken ricePulp and paper industry

The invention discloses a high-quality fine rice efficient polishing device. The high-quality fine rice efficient polishing device comprises a cylinder body, a feeding hopper, a bran and dust screen cylinder body, a polishing bottom screen, a broken rice screen conical cylinder and a rice collecting bin which is fixed to the inside of the cylinder body, the bran and dust screen cylinder body is fixedly arranged at the upper end inside the cylinder body, annular dust cleaning brushes are distributed at the middle lower end of the inner wall of the bran and dust screen cylinder body, a bran anddust cavity is arranged between the bran and dust screen cylinder body and the inner wall of the cylinder body, an air inlet hood and a bran suction hood which are communicated with the bran and dustcavity are arranged on outer walls of the two sides of the cylinder body respectively, the polishing bottom screen is fixedly arranged at the bottom of the bran and dust screen cylinder body in a sealing mode, a polishing chamber enclosed by the bran and dust screen cylinder body and the polishing bottom screen is filled with polishing pills, and the broken rice screen conical cylinder is arrangedinside the cylinder body below the bran and dust screen cylinder body. The high-quality fine rice efficient polishing device is reasonable in structural design, simple in overall design structure, good in work safety performance and good in polishing effect, the generation of broken rice is reduced, and the separating effect and separating efficiency of the broken rice and rice are drastically improved at the same time.

Owner:王旭君

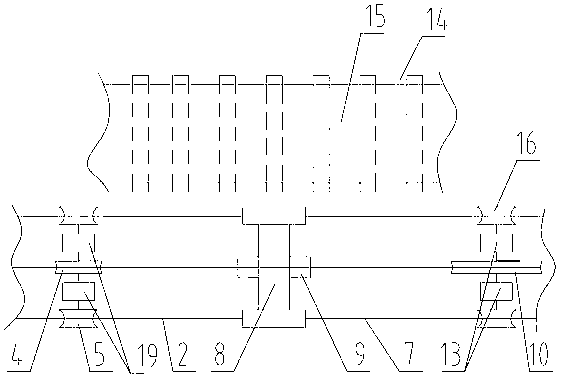

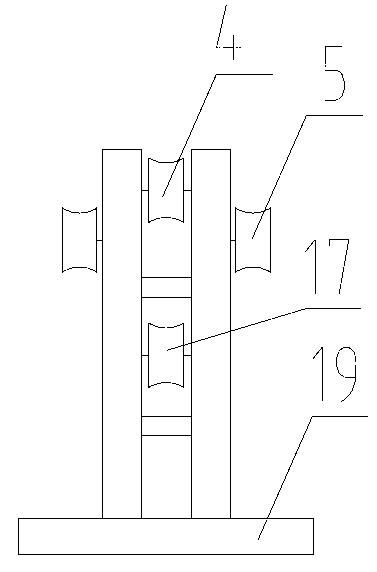

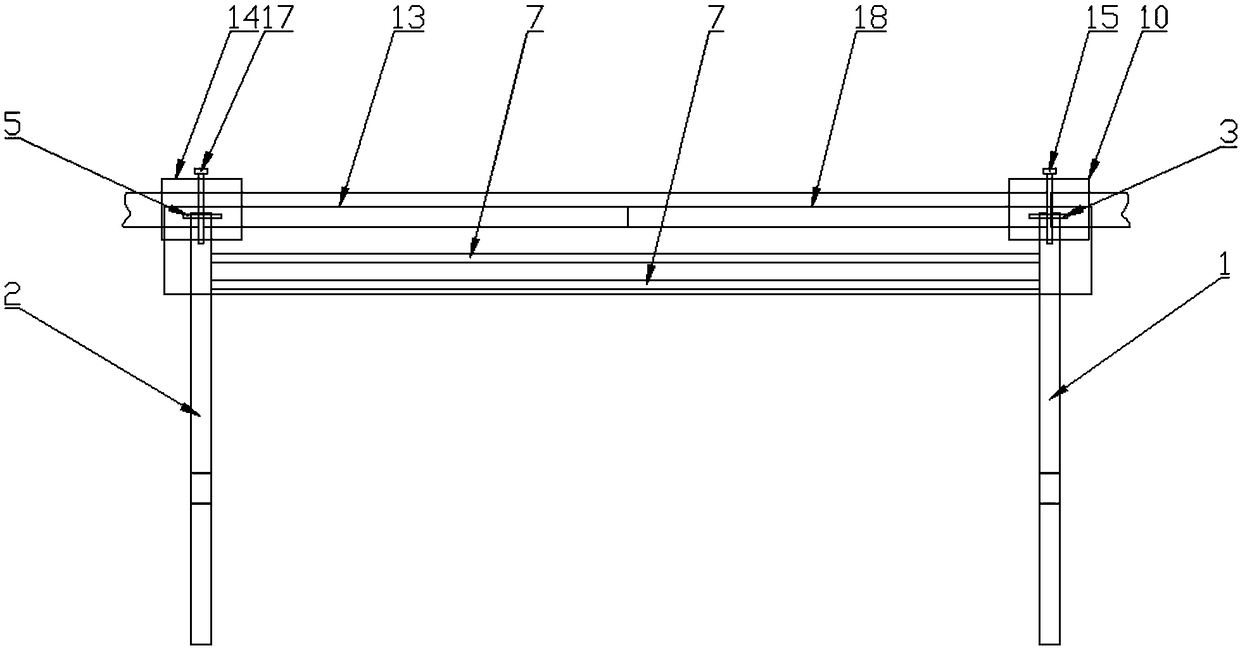

Automatic inspection system of suspension belt conveyer

ActiveCN102923466ARealize automatic inspectionSmall running resistanceControl devices for conveyorsState parameterBelt conveyor

The invention discloses an automatic inspection system of a belt conveyer and is suitable for monitoring an operation state of the belt conveyer. The automatic inspection system is composed of a drive device, a guide device, a rope tightener, a drag rope, suspension lead rails and an inspection warehouse, wherein the drive device drives the drag rope; two suspension lead rails guided by the guide device are arranged on left and right support wheels connected with two support saddles; an upper pulley, a lower pulley and a right pulley for guiding the drag rope are respectively arranged at the upper ends of the two support saddles; the guide device is connected with the inspection warehouse by a connection link; the drag rope is provided with a slide block capable of sliding up and down through the connection link; and the inspection warehouse moves to the side of an any roller of the belt conveyer, and the inspection warehouse collects a state parameter of the roller. Thus, the function of automatically inspecting the abnormality of the belt conveyer is achieved; and the abnormal condition of the roller is timely found out, and the automatic inspection system is simple in structure, good in detection effect, convenient to install and easy to maintain.

Owner:CHINA UNIV OF MINING & TECH

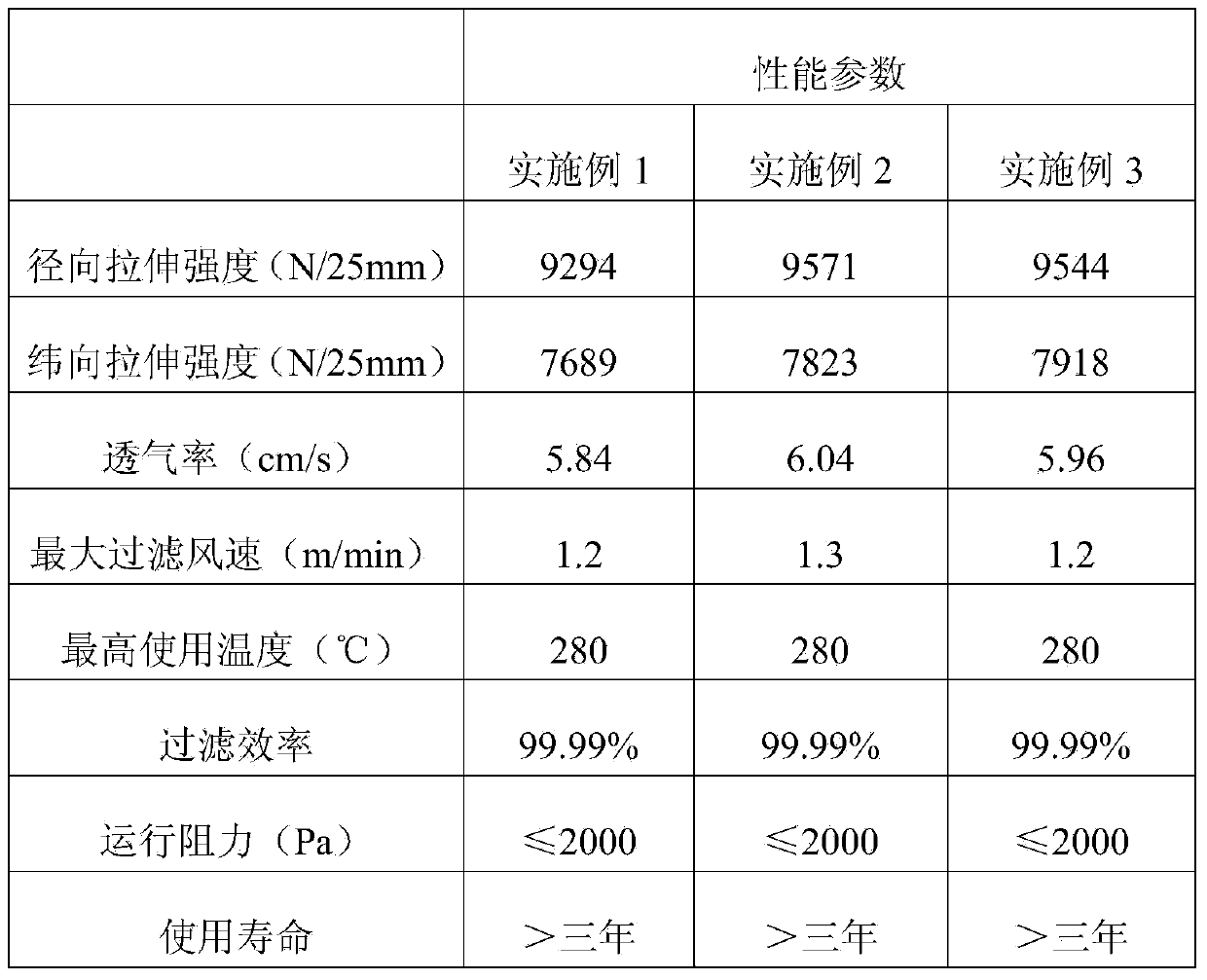

Method for preparing modified basalt fiber/polyphenylene sulfide compound filter material through dip coating

InactiveCN104191738ASmooth appearanceRaise the crystallization temperatureFiltration separationNatural mineral layered productsCooking & bakingPolymer science

A method for preparing a modified basalt fiber / polyphenylene sulfide compound filter material through dip coating comprises the following steps: the blended spinning is performed on linear polyphenylene sulfide and hyperbranched polyphenylene sulfide, so that modified polyphenylene sulfide fibers are prepared; a compound base fabric is prepared from the basalt fibers and the modified polyphenylene sulfide fibers through a needling technology; a fluoropolymer, a fluoride-containing silane coupling agent and deionized water are uniformly mixed through ultrasonic to prepare into a fluoropolymer emulsion; the compound base fabric is dipped in the emulsion and processed by the processes of padder rolling, pre-drying, baking, tension bracket processing and winding, so that the finished product is prepared. The compound filter material prepared through the preparing method has good thermostability, great corrosion resistance and high mechanical strength, the dispersibility and the compactness of the finished product fibers are improved, and the preparing process is simple, the cost is relatively low and the compound filter material is suitable for large-scale industrial production.

Owner:TAICANG SULUN TEXTILE CHEM FIBER

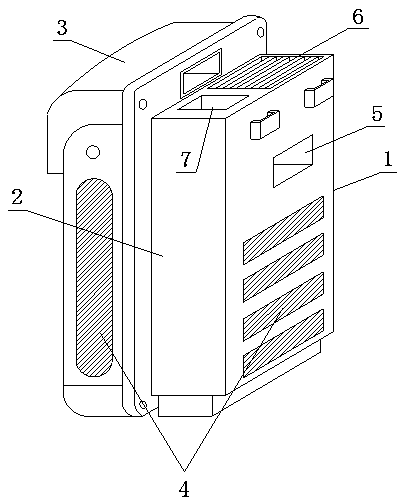

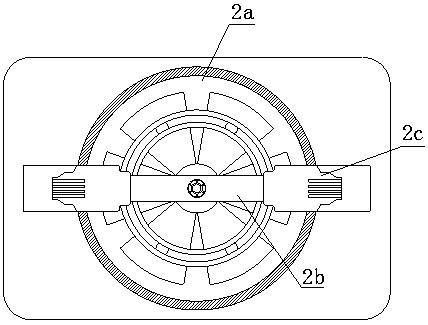

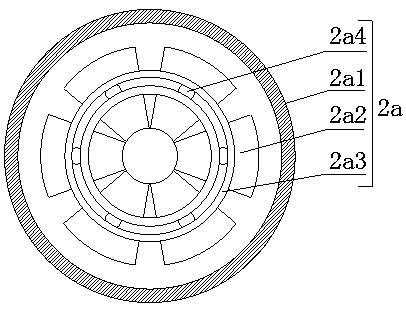

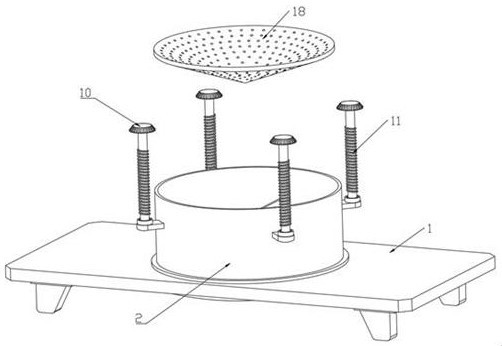

Motor equipment performance testing device

ActiveCN114859225AIncrease running resistanceEasy to useMeasurement instrument housingDynamo-electric machine testingMotor testingElectric machine

The invention relates to the technical field of motor testing, and discloses a motor equipment performance testing device which comprises a base, a speed sensor, a vibration sensor, a pressure sensor, an electromagnet, a shell, an outer shell and a cover plate, a sleeve is fixedly connected to the center of the upper end of the cover plate through a round opening, and a load mechanism is connected into the sleeve. The load mechanism is used for being connected to an output shaft of a to-be-tested motor to provide load force, a rotating shaft is vertically arranged in the shell, a transmission mechanism is connected to the shaft wall of the rotating shaft, and the transmission mechanism is connected with the electromagnet and used for changing the acting force of the electromagnet on the load mechanism so that the load mechanism can generate vibration force of different magnitudes. According to the motor equipment performance testing device, the operation steps during motor performance testing can be simplified, the speed of motor performance testing can be improved, load forces of different magnitudes and different directions can be applied to the motor, and then the mechanical performance of the motor can be tested at multiple angles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

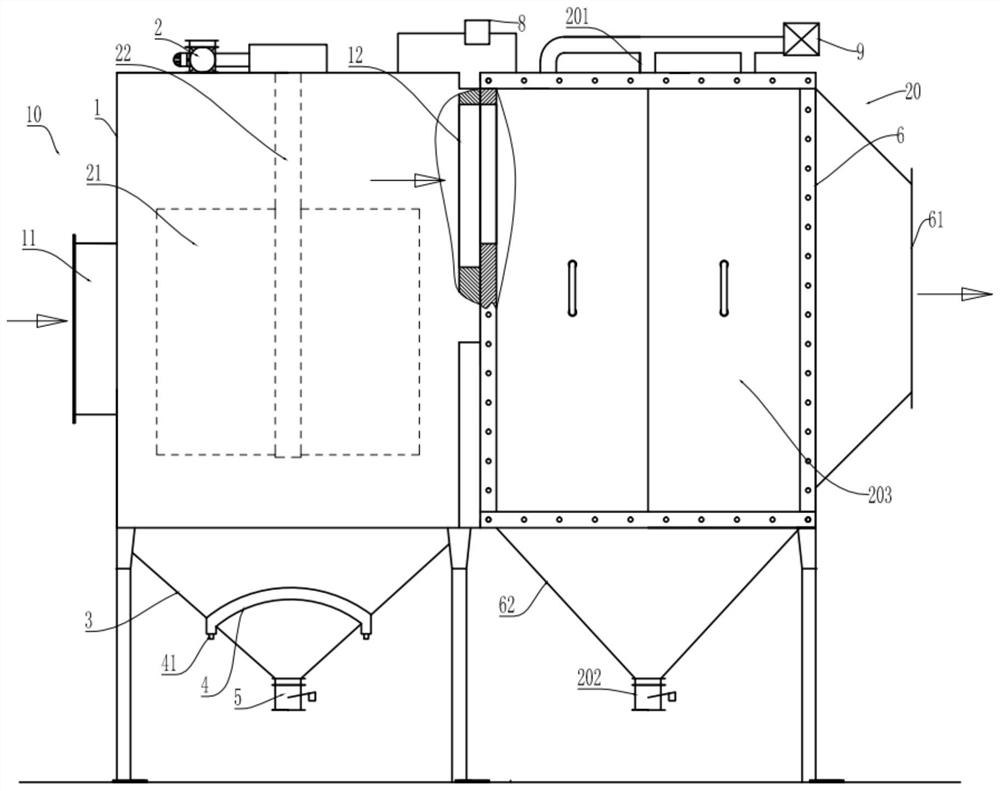

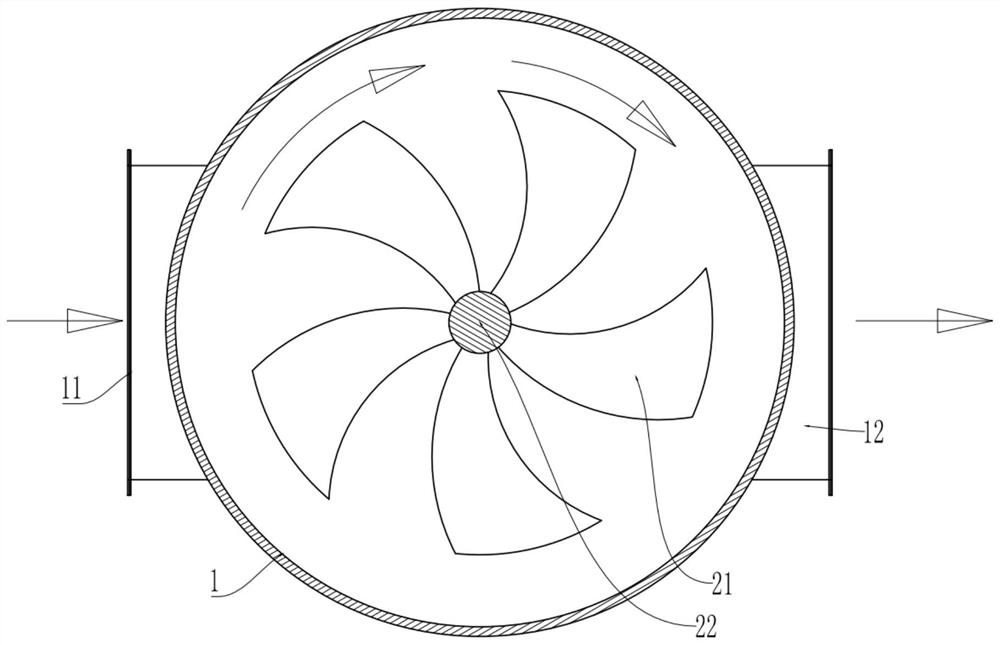

Oil-containing smoke intercepting equipment

PendingCN113731057AReduce oil contentImplement interceptionHuman health protectionGas treatmentDust controlOil mist

The invention relates to the technical field of oil-smoke separation, and particularly discloses oil-containing smoke intercepting equipment which comprises an oil-smoke separation unit, the oil-smoke separation unit comprises a separation chamber, the separation chamber comprises an air inlet and an air outlet, the oil-smoke separation unit further comprises a rotator, the output end of the rotator is connected with blades, and the blades are located in the separation chamber; after the rotator drives the blades to rotate, smoke entering from the air inlet can impact the inner wall of the separation chamber and then is discharged from the air outlet; the equipment further comprises an oil filtering unit, the oil filtering unit comprises a filtering plate for intercepting oil mist, the input end of the oil filtering unit is communicated with the air outlet of the separation chamber, and the output end of the oil filtering unit is connected with a cloth bag dust removal and purification equipment. According to the scheme, oil mist in waste gas is separated twice through the oil-smoke separation unit and the oil filtering unit, the oil content in the waste gas is greatly reduced, and the problems that in the prior art, after the waste gas enters cloth bag dust removal and purification equipment, a bag is pasted, dust removal is difficult, and the running resistance of the equipment is increased are solved.

Owner:重庆华光环境工程设备有限公司

Air-locking feeding device with drying function

PendingCN109748106AEasy to replaceEasy to wearDrying gas arrangementsBulk conveyorsEnergy consumptionFlange

The invention discloses an air-locking feeding device with a drying function. The device comprises a casing, a power device and a rotary rotor; the rotary rotor comprises a rotating shaft connected with the power device, a plurality of blades arranged on the periphery of the middle of the rotor at intervals, and two end plates fixed between the two side ends of the blades and the rotating shaft correspondingly; a heating channel is defined by the multiple blades, the end plates and the outer surface of the rotating shaft; the end plates on the two sides of the heating channel are each providedwith a plurality of venting holes; spaced air channels are formed by the two end plates and the inner sides of flanges of the two side ends; the air channels communicate with the heating channel through the venting holes; and the outer sides of the two end plates are sequentially provided with a drying air inlet pipe and a drying air outlet pipe which communicate with the air channels. An abrasion-resistant lining plate is convenient to replace, by arranging a drying mechanism, abrasion of material sticking to the rotor and increase of operation resistance are effectively prevented, the system energy consumption is reduced, the service life is longer, and the air-locking feeding device is more environmentally friendly.

Owner:NANJING XIPU CEMENT ENG GROUP

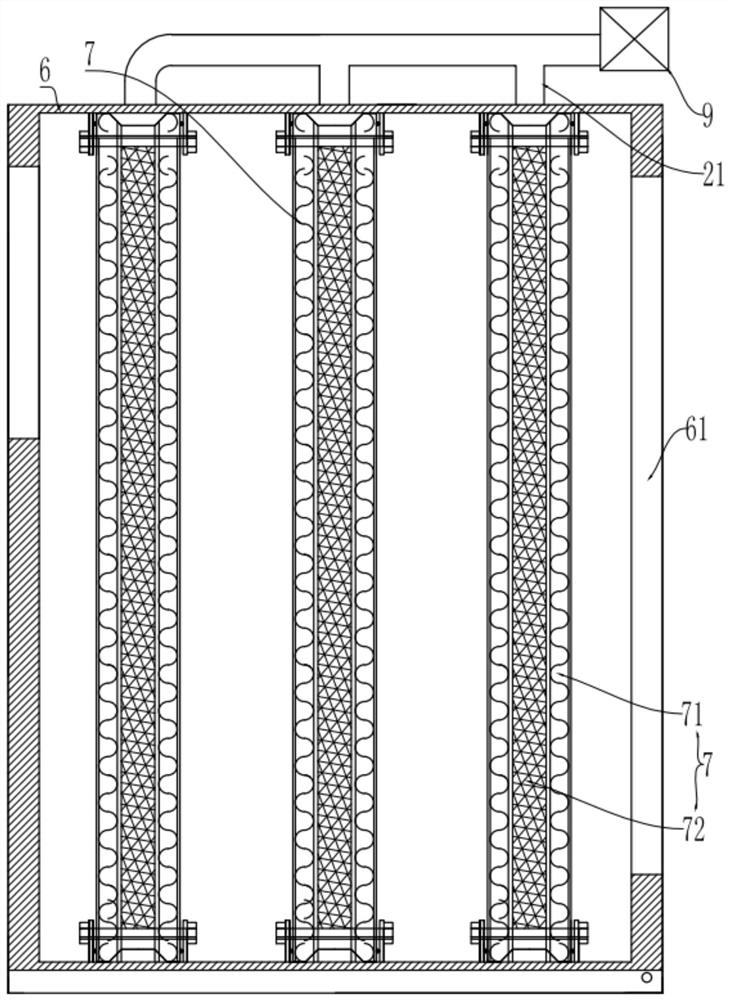

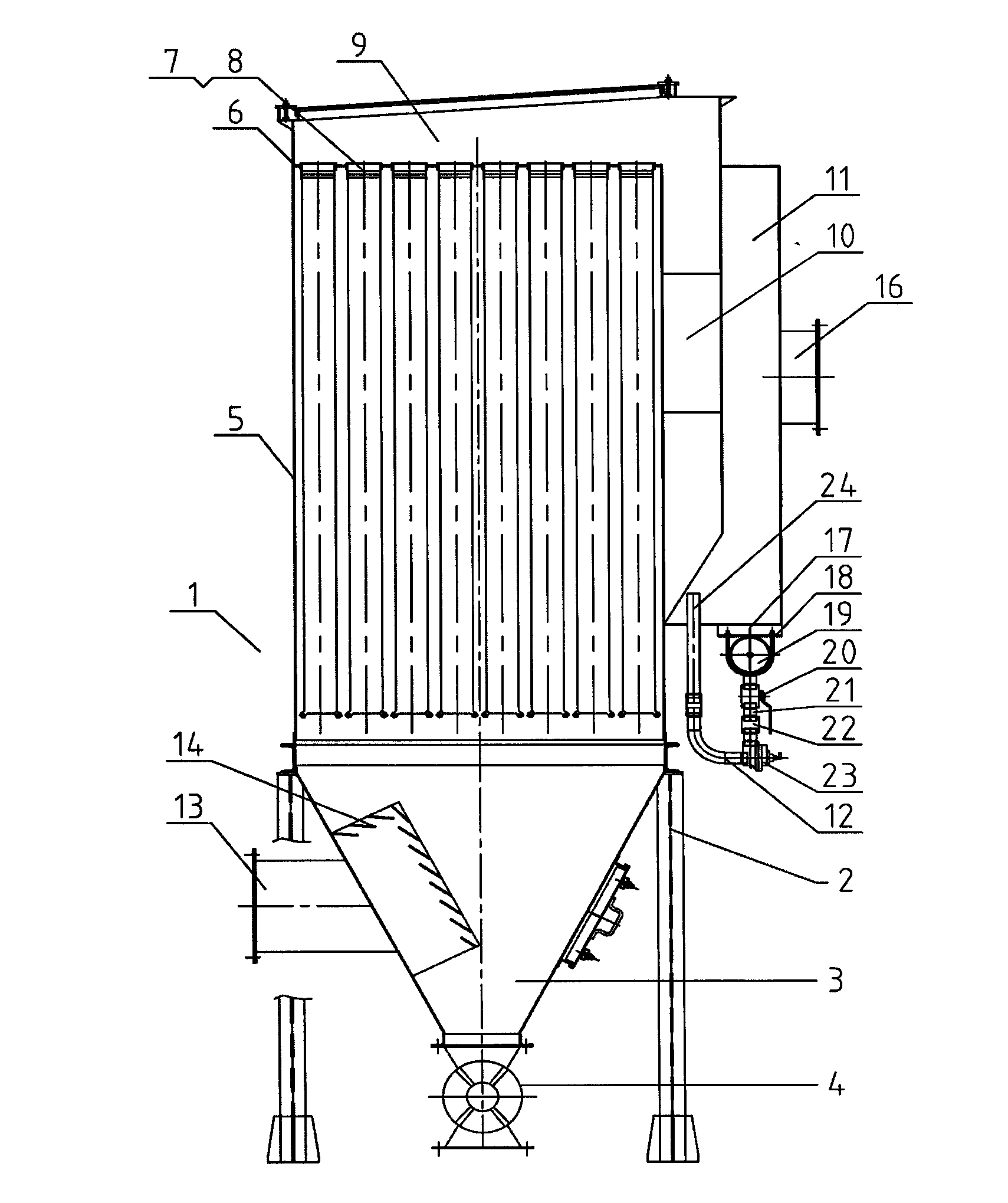

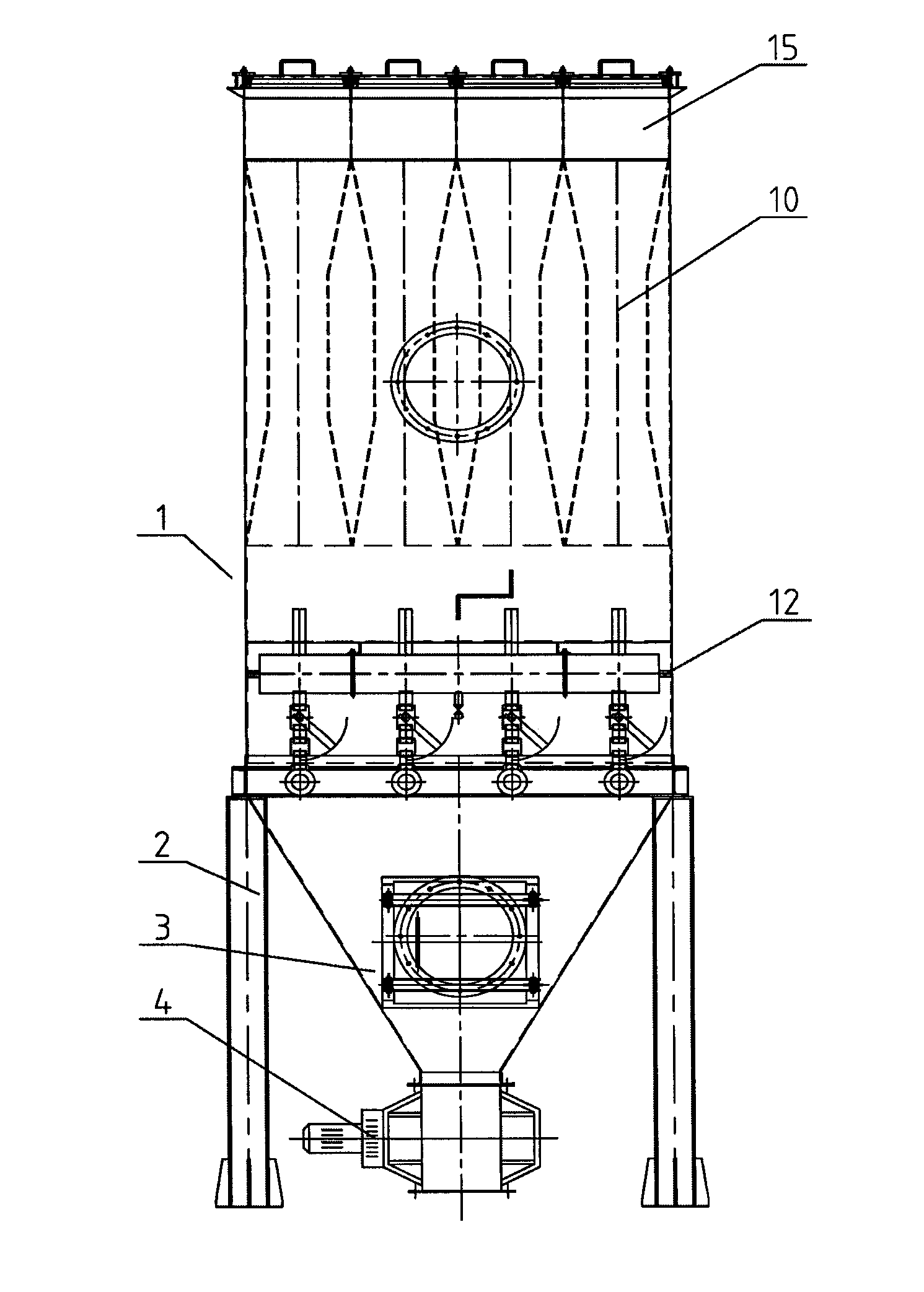

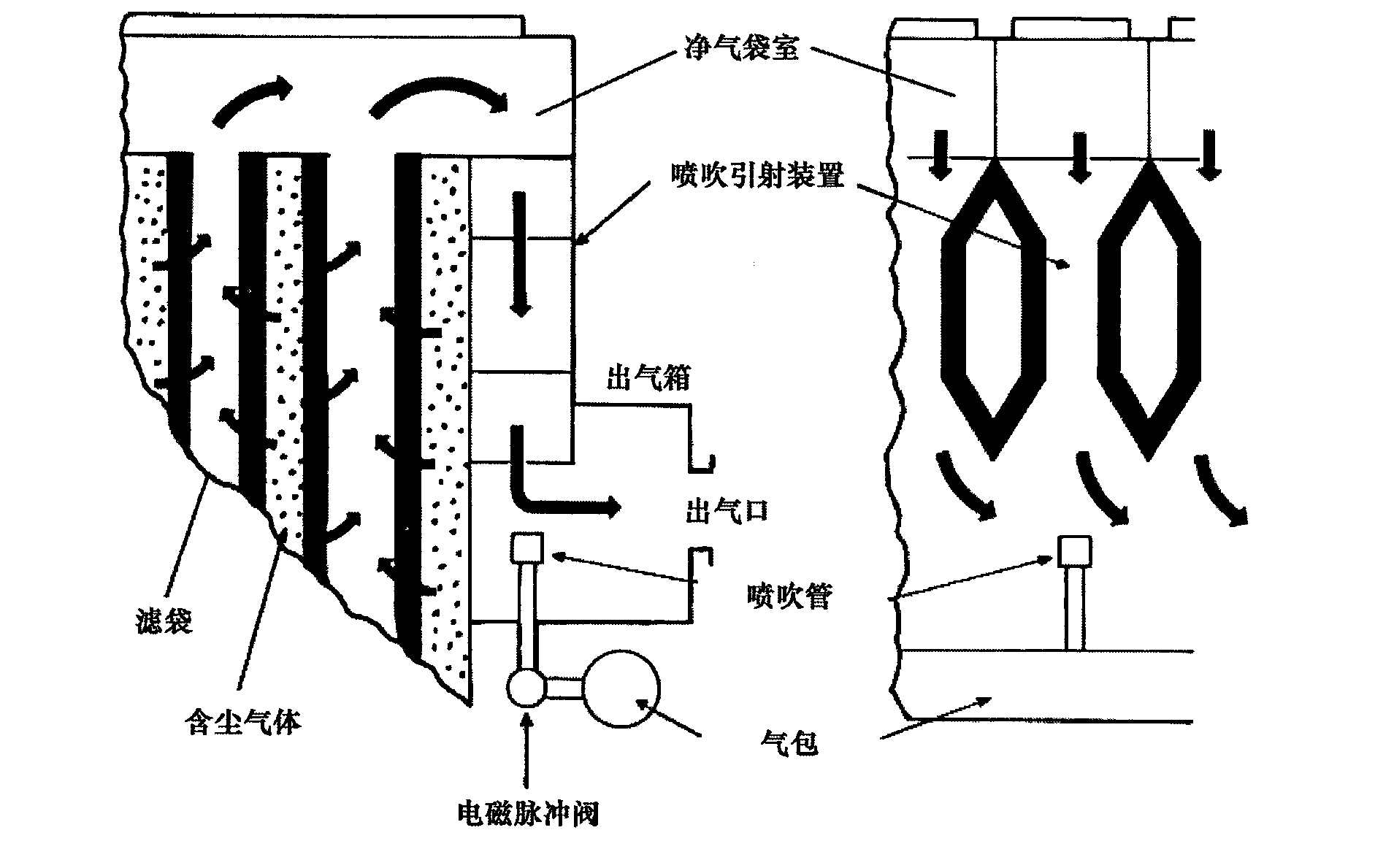

Deduster provided with underlying blowing system and capable of clearing away ashes offline without offline valve

InactiveCN104208955AEasy maintenanceAvoid crossingDispersed particle filtrationProcess engineeringElectromagnetic pulse

The invention discloses a deduster provided with an underlying blowing system and capable of clearing away ashes offline without an offline valve. The deduster comprises a deduster shell composed of an ash bucket, a bag chamber, and gas purifying chambers, a gas outlet cabinet, and a blowing system; the ash bucket is provided with a gas inlet and an electric cinder valve, the bag chamber and the gas purifying chamber are separated by a card, a gas outlet is arranged in the gas outlet cabinet, a plurality of blowing and ejecting devices are arranged in the gas outlet cabinet, each blowing and ejecting device is corresponding to a gas purifying chamber, and the blowing system is arranged in the bottom of the gas outlet cabinet. The gas blowing system comprises a gas bag, a plurality of blowing pipes arranged in the gas outlet cabinet are connected to the gas bag, a connecting pipe, a movable connector, and an electromagnetic valve are arranged between each blowing pipe and the gas bag in sequence; and each blowing pipe is corresponding to one blowing and ejecting device. The deduster has the advantages that the blowing system is convenient for recondition and maintenance, the ash clearing force is large, at the same time the filter bag is prevented from being broken in advance, the filter bag and the bag cage are easy to install and change, the offline valve is cancelled, thus the equipment cost is reduced, the equipment operation becomes more stable, and the equipment manufacture is turned into modularization.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

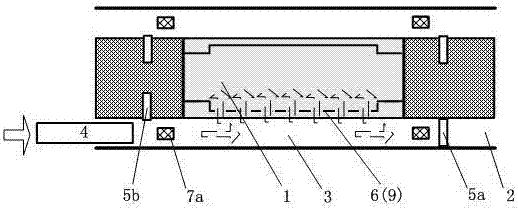

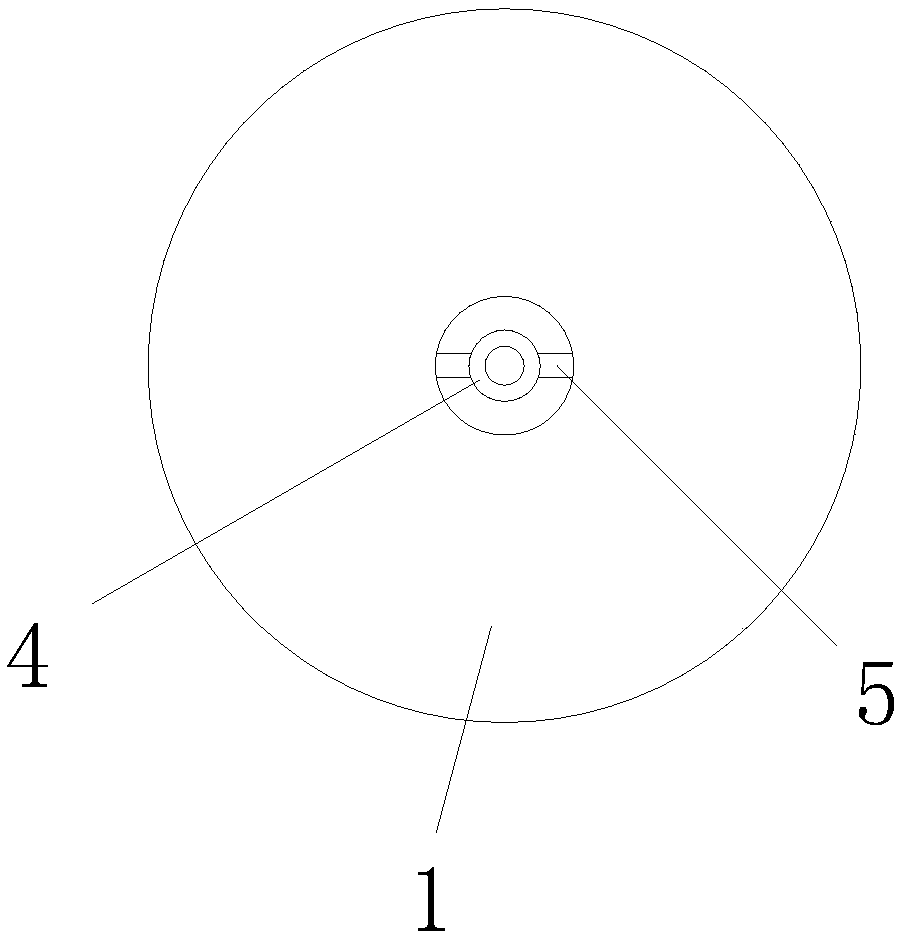

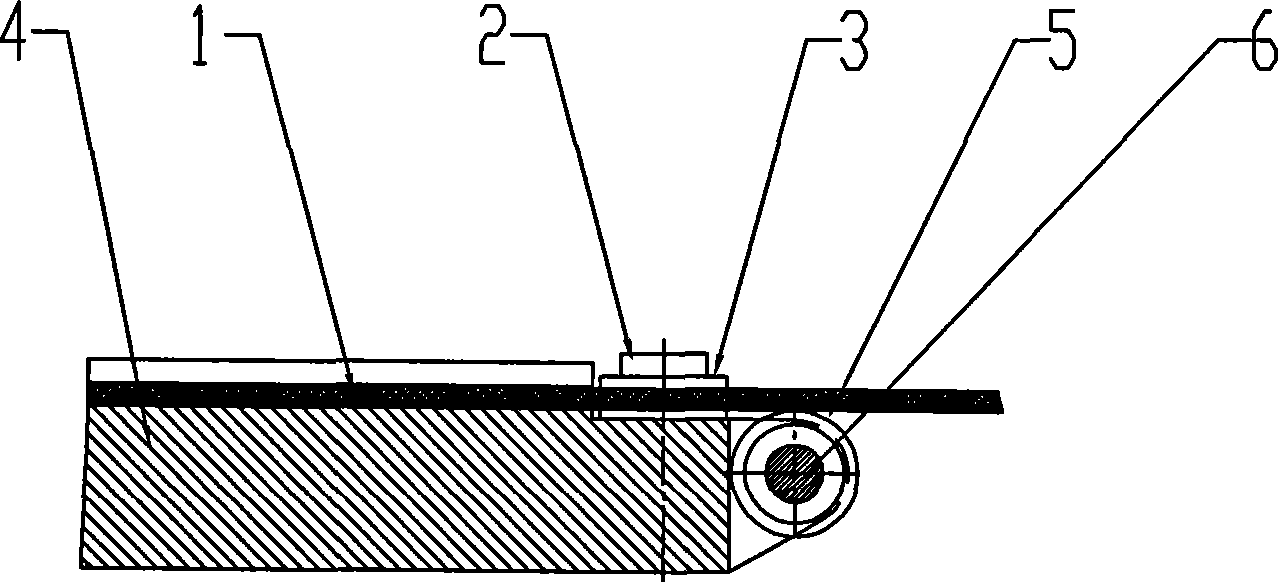

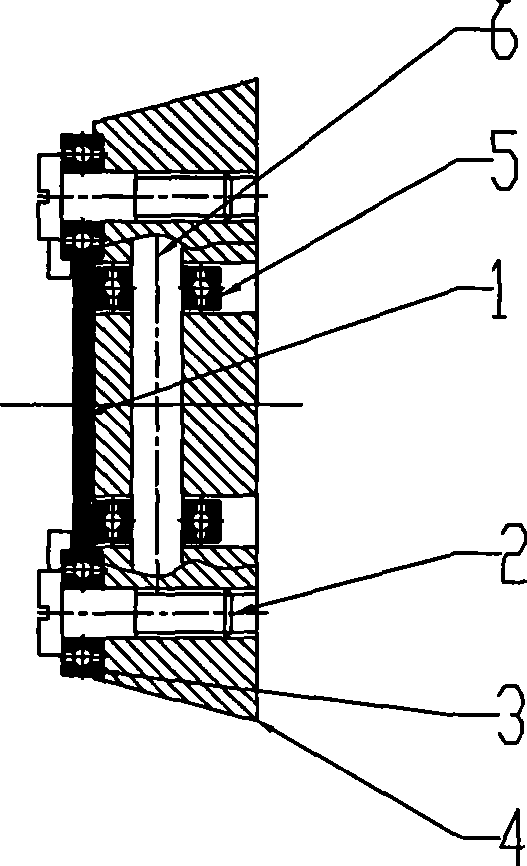

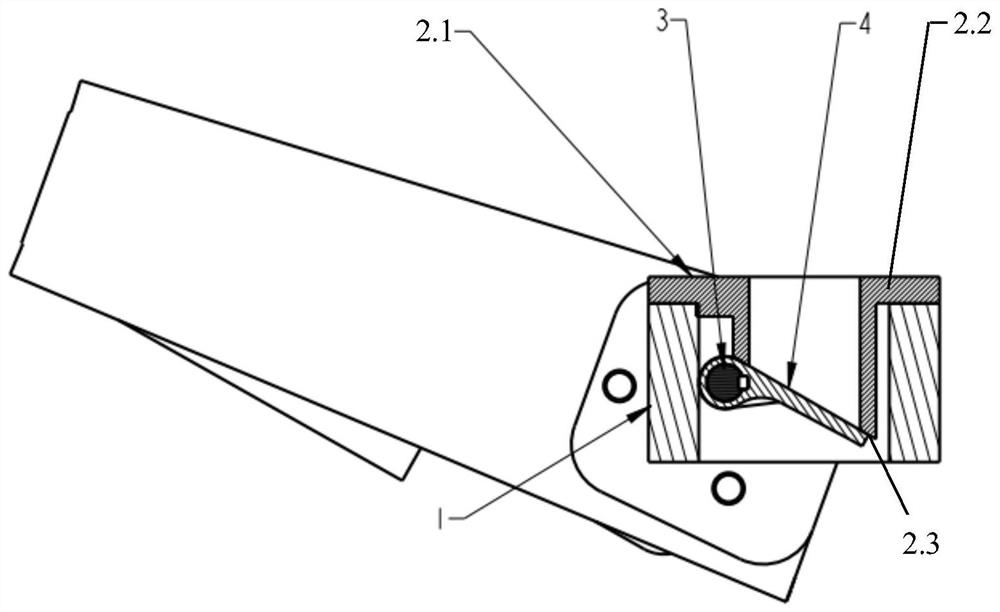

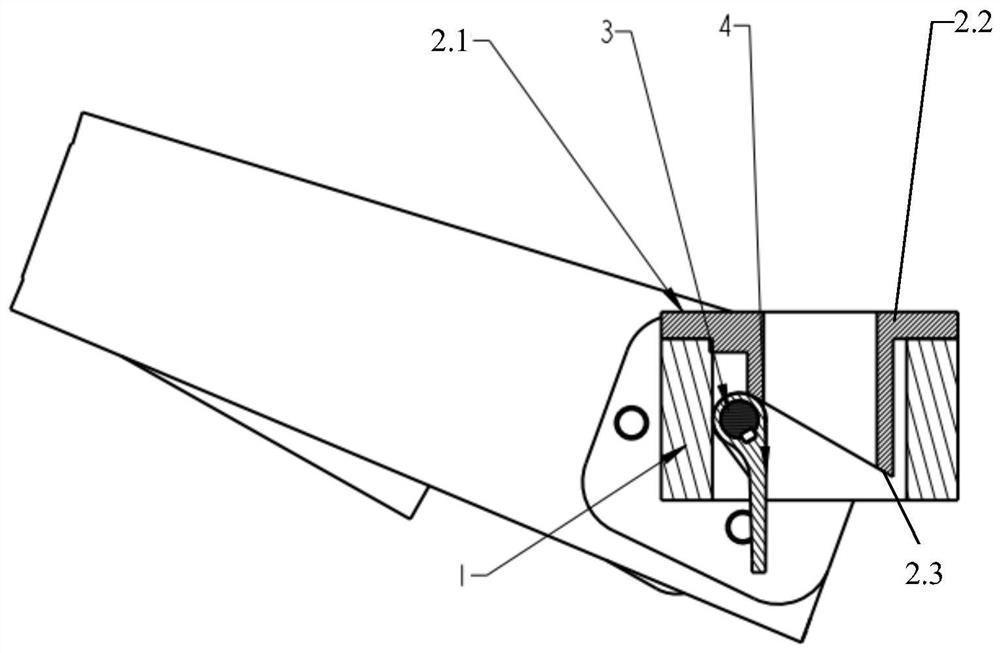

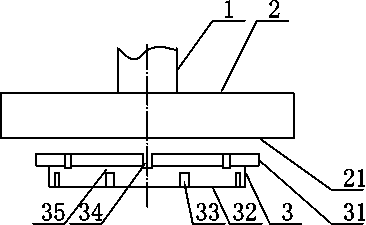

Trolley type rapier tape guide rail of rapier loom

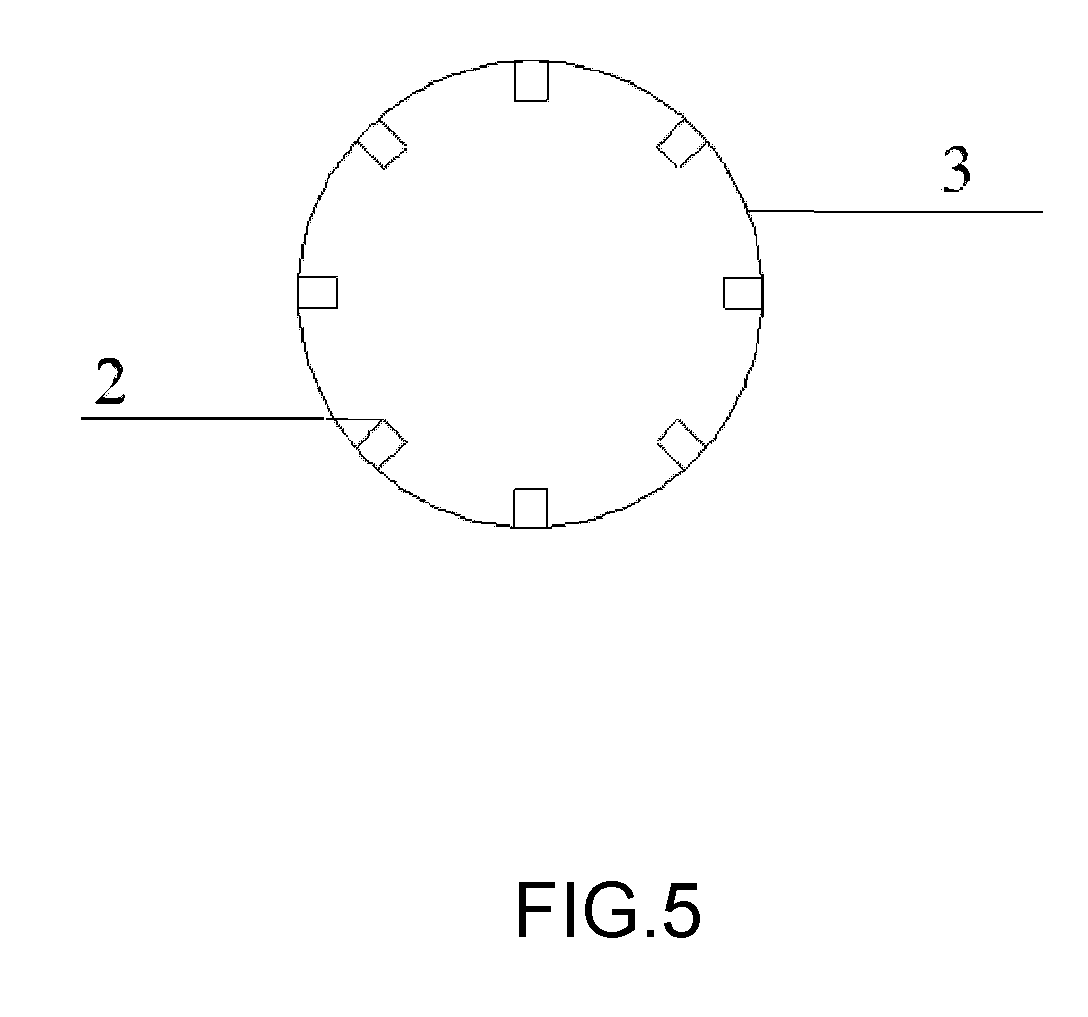

The invention relates to a roller type rapier belt guide rail for a rapier loom, which comprises a rapier belt (1), pins (2), lateral guiding rollers (3), a rapier belt guide rail (4), a lower supporting roller (5) and a pin shaft (6). The roller type rapier belt guide rail is characterized in that the lateral guiding rollers (3) are arranged at left and right sides of the rapier belt guide rail (4) through the pins (2), the lower supporting roller (5) is arranged at the lower part of the rapier belt guide rail (4) through the pin shaft (6), the rapier belt (1) is arranged on the rapier belt guide rail (4) and the lower supporting roller (5) and arranged inside the lateral guiding rollers (3), and the rapier belt (1) is glidingly connected with the rapier belt guide rail (4), the lower supporting roller (5) and the lateral guiding rollers (3). The roller type rapier belt guide rail has the advantages that the roller type rapier belt guide rail has small running resistance and low energy consumption, solves the problems of positioning and abrasion in the rapier belt running process of the high-speed rapier loom, is favorable for improving running speed of the loom, and can prolong the service life of the rapier belt.

Owner:经纬纺织机械股份有限公司榆次分公司

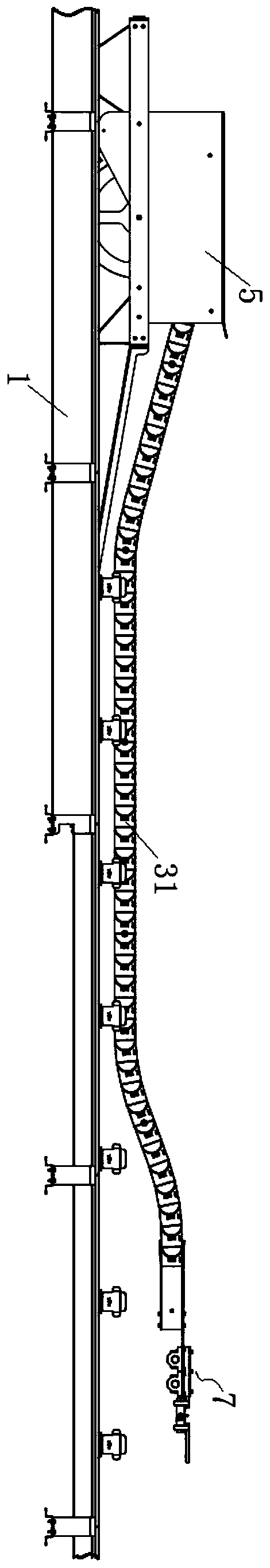

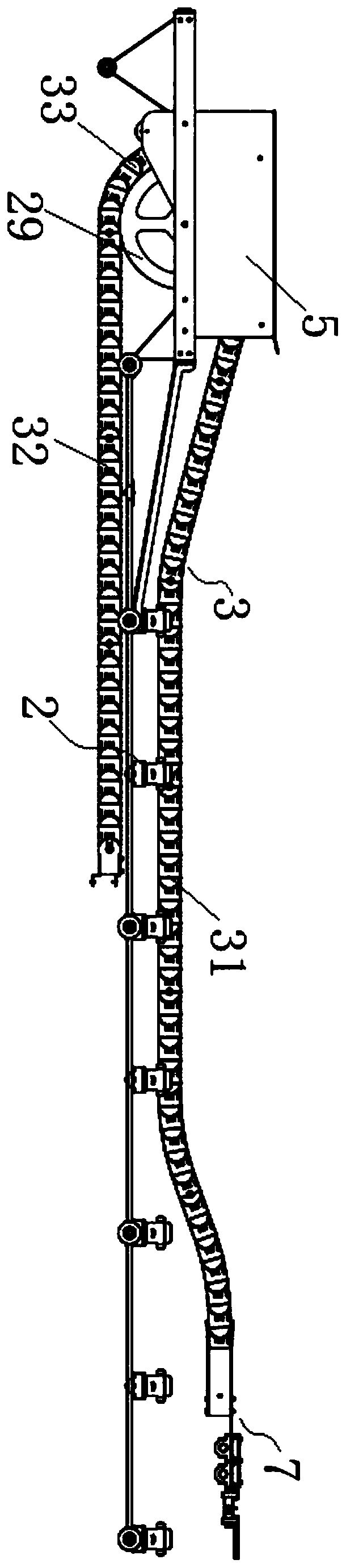

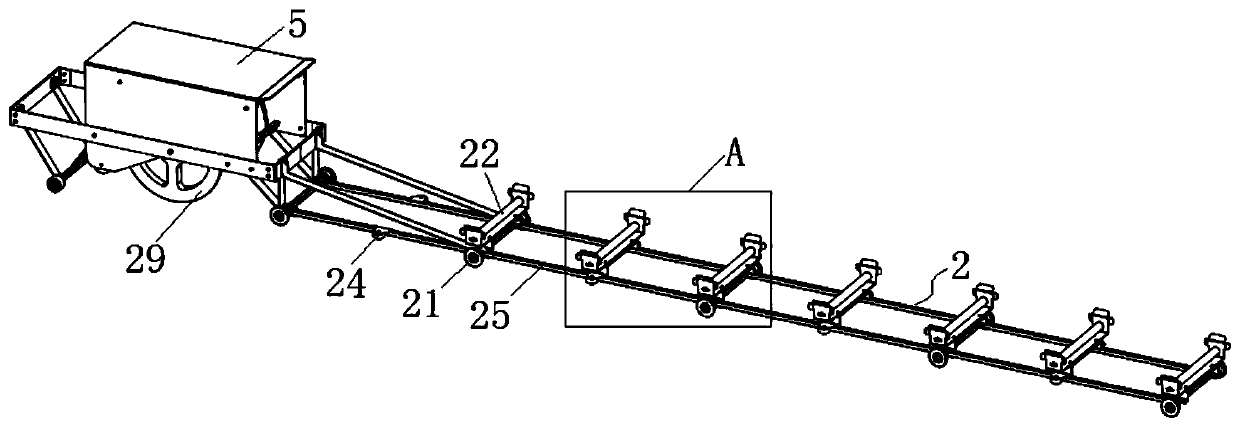

Long-stroke heavy drag chain operating device

PendingCN111196527APrevent derailmentSmall driving forceFilament handlingControl engineeringMechanical engineering

The invention provides a long-stroke heavy drag chain operating device. The long-stroke heavy drag chain operating device comprises a guide rail and a supporting roller bracket. The supporting rollerbracket is arranged between an upper drag chain segment and a lower drag chain segment and is provided with first supporting rollers matched with the guide rail and second supporting rollers suitablefor supporting the upper drag chain segment. As the upper drag chain segment is in rolling connection to the second supporting rollers, compared with the prior art, the friction force between the supporting roller bracket and the upper drag chain segment is reduced, so that on the one hand, the supporting roller bracket is unlikely to deform, conditions that a drag chain is derailed and a drag chain body is damaged are prevented effectively, the service life is prolonged and the maintenance and replacement costs are lowered, and on the other hand, the driving force for drag chain operation isreduced.

Owner:ZHEJIANG JINFULONG MACHINE TOOL ACCESSORIES

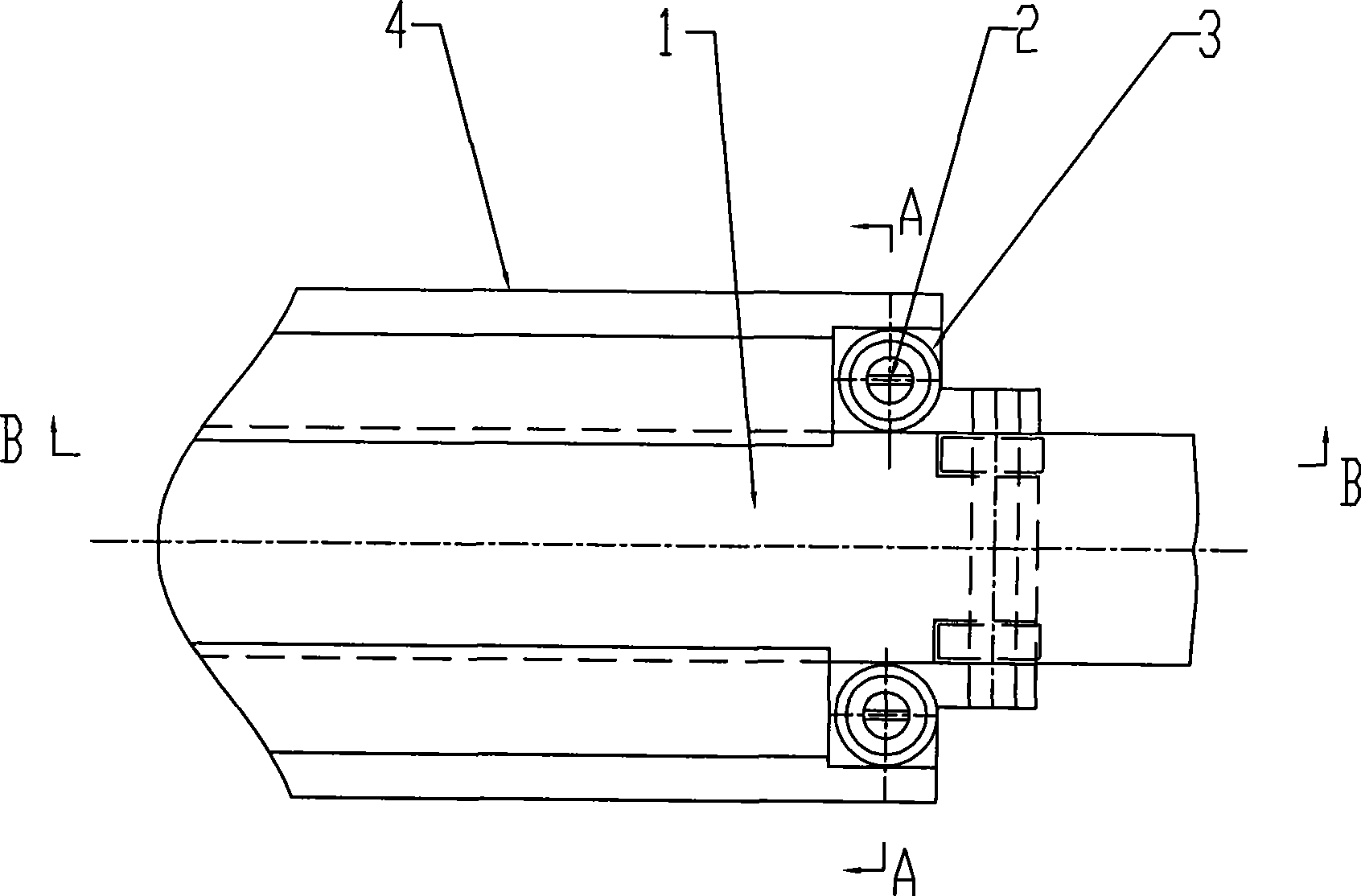

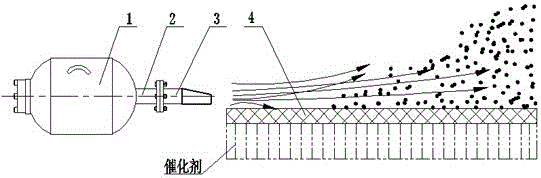

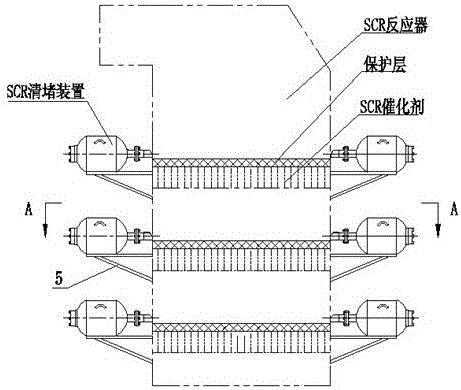

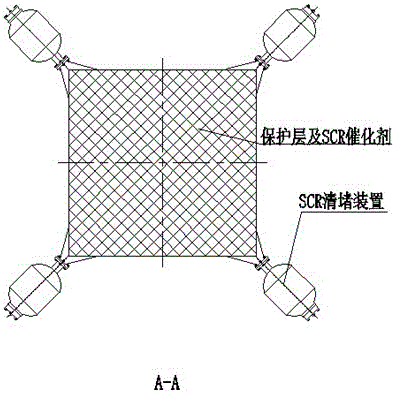

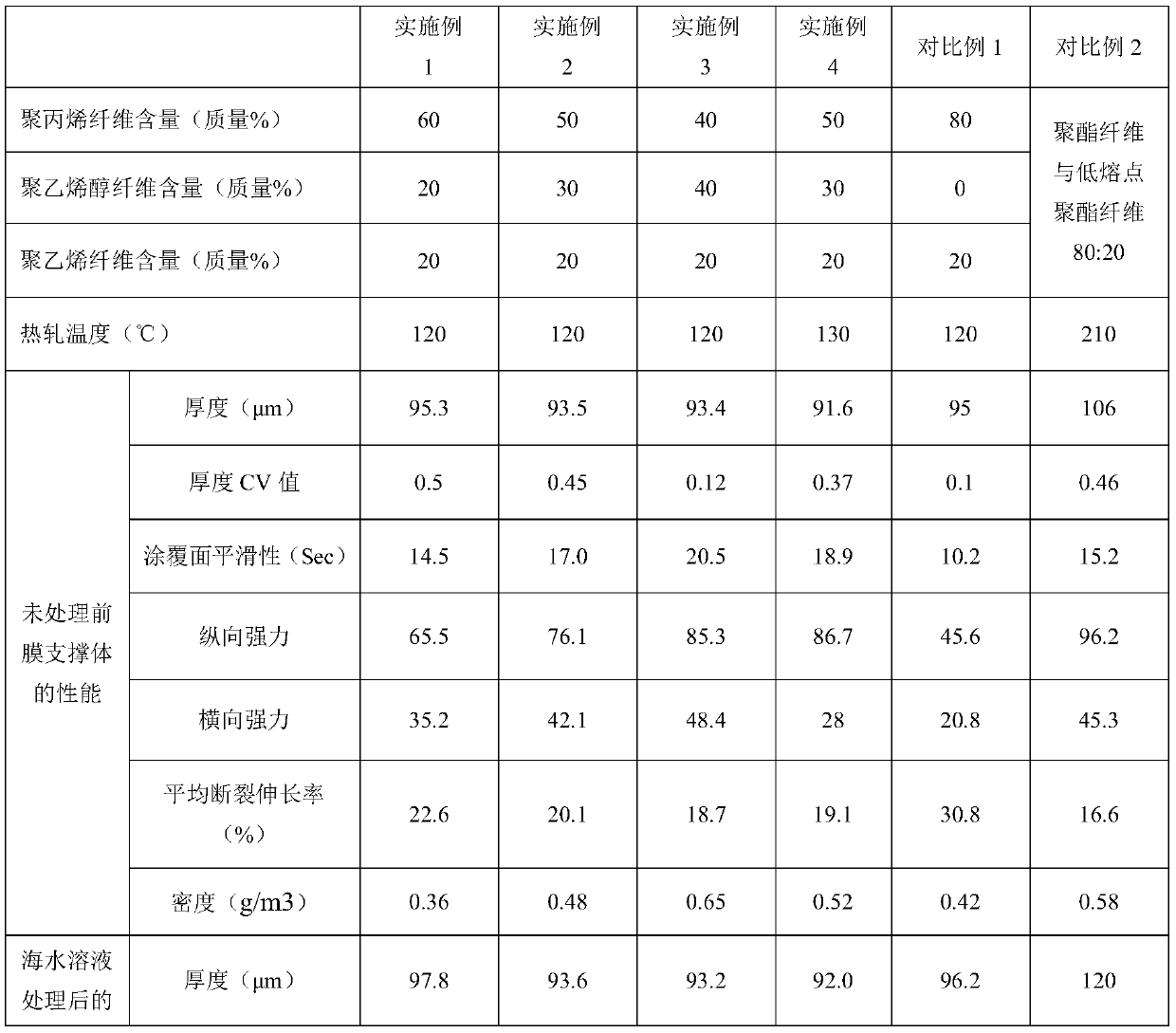

SCR catalyst blockage removing device

InactiveCN105833726AGreat cleaning powerClean up thoroughlyGas treatmentDispersed particle separationShock waveProduct gas

An SCR catalyst blockage removal device, which utilizes the shock wave principle of pulse injection to perform strong blockage removal on the SCR catalyst through "explosive" jet air flow, and is characterized in that: the compressed gas stored in the air cannon (1) instantaneously removes the blockage of the SCR catalyst. It is released to form an "explosive" high-pressure air mass, which is transported into the SCR reactor through the injection pipe (2) and the "duck-bill" nozzle (3), and the SCR catalyst and the protective layer (4) are deposited and blocked. Horizontal spray to clear blockage. According to the catalyst of different specifications, the blocking removal device can be evenly arranged around each layer of catalyst, and can be automatically opened and closed according to the resistance change of the catalyst layer to realize the blocking function, so as to ensure the performance of the catalyst, prolong the service life of the catalyst, and reduce the energy consumption of the equipment. The technical solution has significant advantages such as strong blocking ability, no damage to the catalyst, no influence on the normal operation and maintenance of the SCR, low cost, and convenient installation and maintenance.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

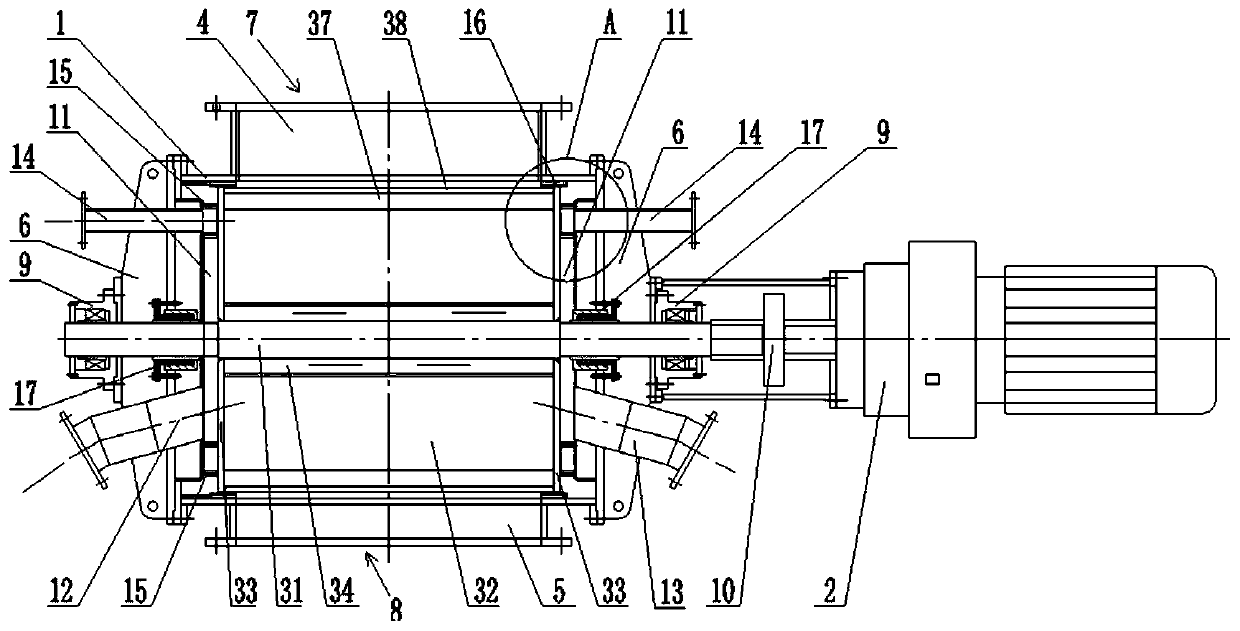

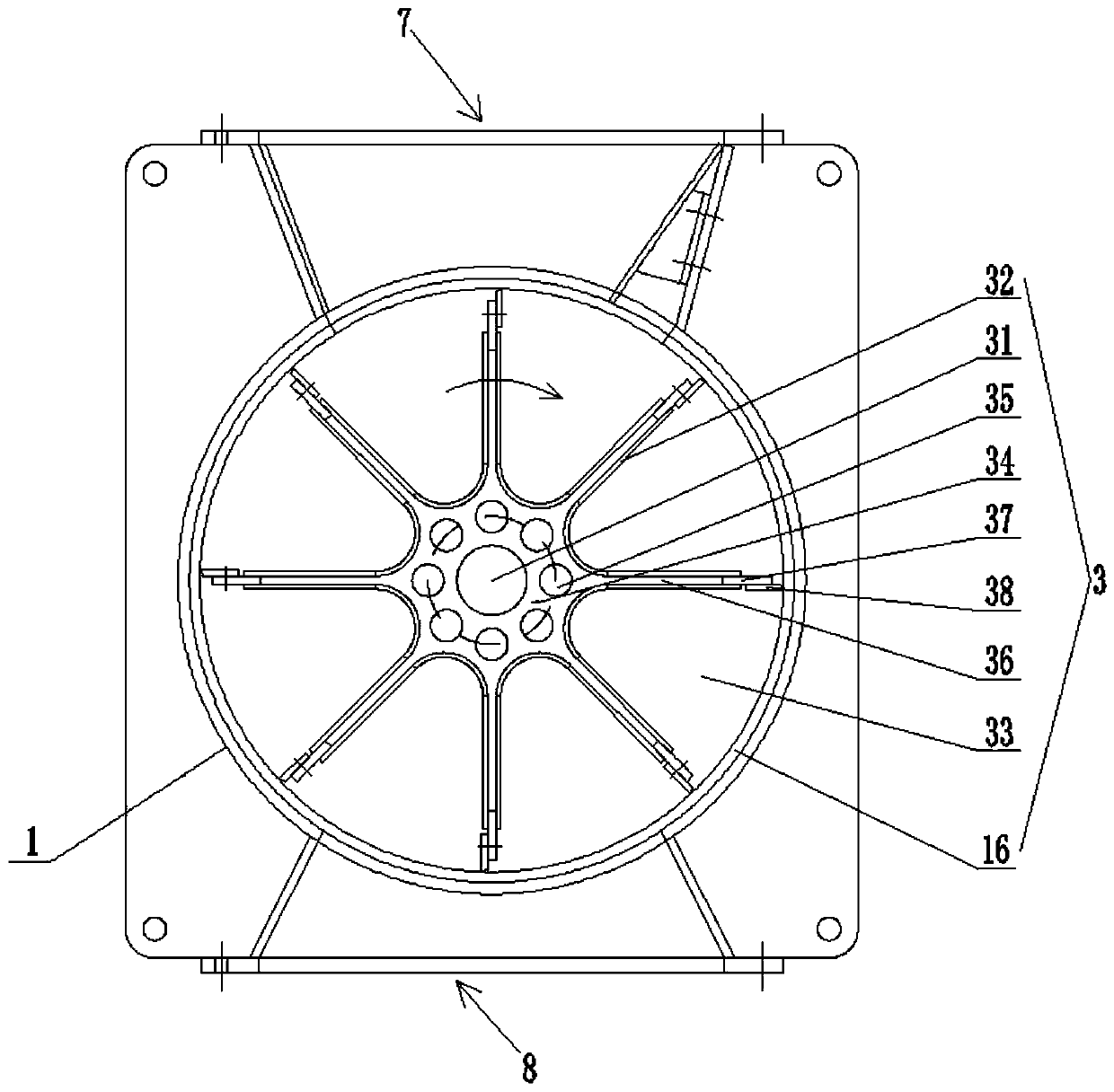

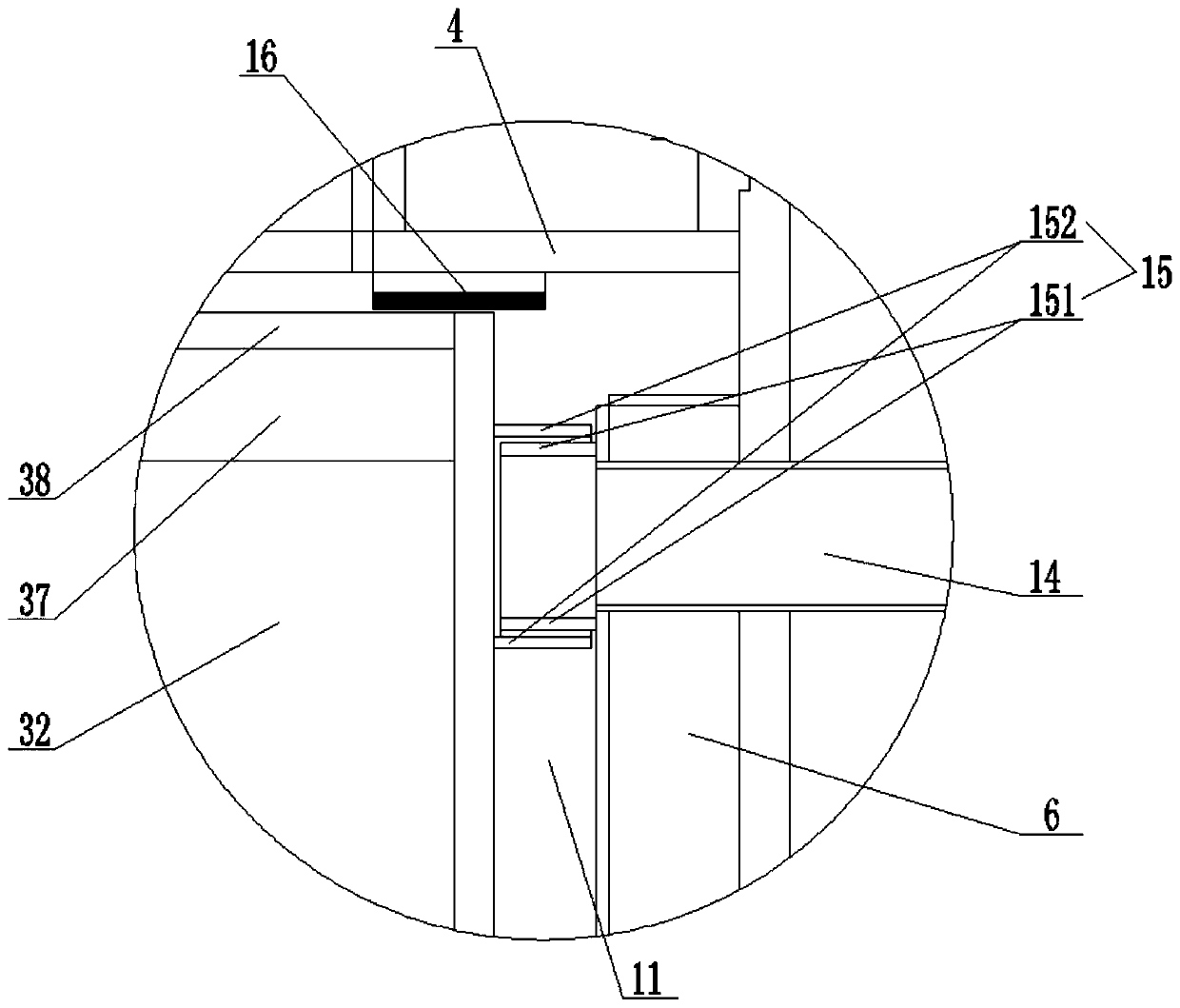

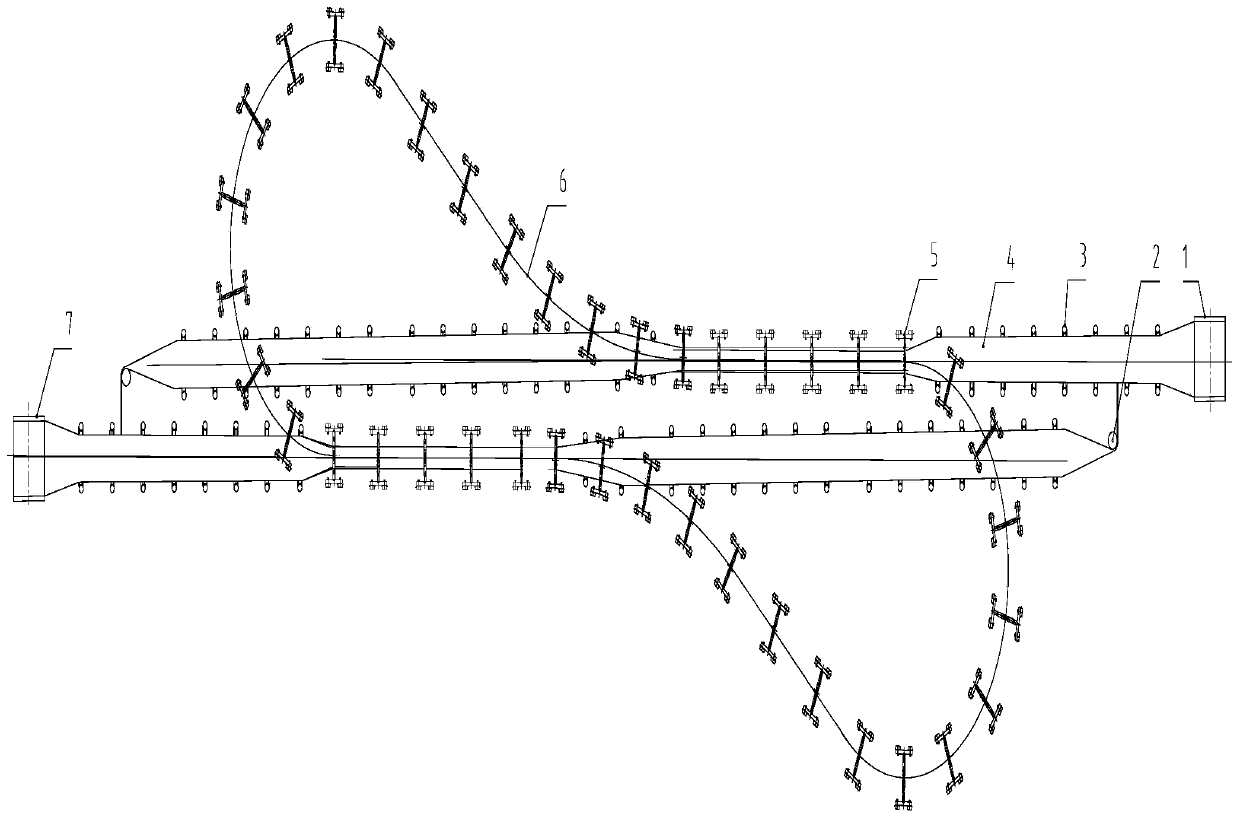

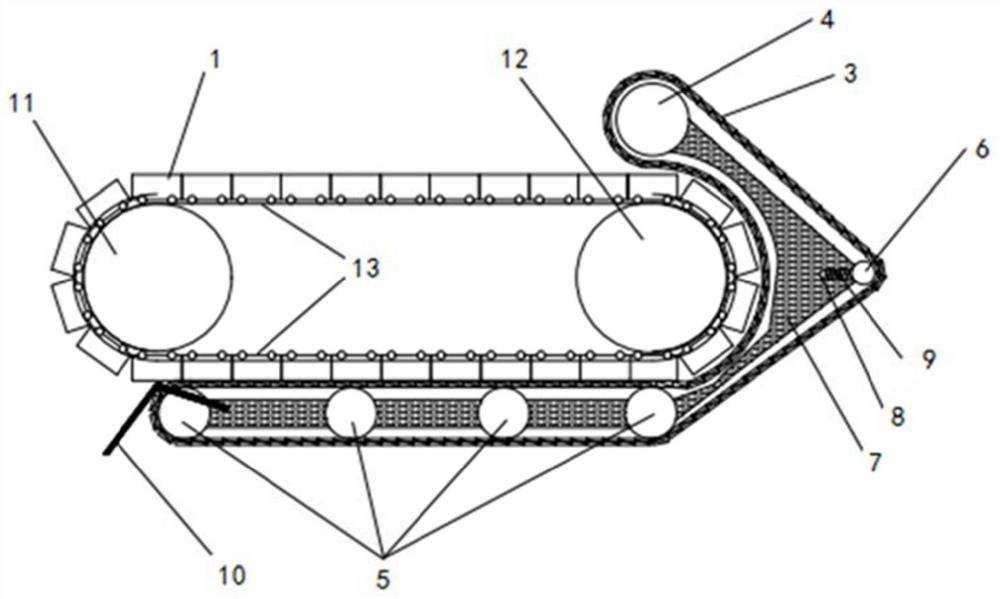

Novel low-resistance circular tube belt conveyor

ActiveCN109941689AImprove reliabilityExtended service lifeMechanical conveyorsClosed loopEngineering

The invention relates to a novel low-resistance circular tube belt conveyor which comprises a machine frame, a driving roller, redirecting roller groups, a carrier roller group, a conveying belt, a plurality of moving trolleys, a steel wire rope and a tail roller, wherein the driving roller, the redirecting roller groups, the carrier roller group, the conveying belt, the moving trolleys, the steelwire rope and the tail roller are installed on the machine frame; the driving roller and the tail roller are respectively positioned at two ends of the machine frame; the two redirecting roller groups are arranged at the end, close to the driving roller, of the machine frame and the end, close to the tail roller, of the machine frame respectively; the conveying belt surrounds the driving roller,the redirecting roller groups and the tail roller to be connected end to end to form a closed loop, and the conveying belt is further supported by the carrier roller group; and the plurality of movingtrolleys are arranged on the steel wire rope at equal distances. The novel low-resistance circular tube belt conveyor has the advantages that the reliability of the conveyor is improved, and the service life of the conveyor is prolonged. The moving trolleys and the conveying belt are combined to operate, so that the structural optimization of the conveyor is achieved, the using cost is reduced, and the complementation of advantages is achieved.

Owner:LIBO HEAVY MACHINE TECH

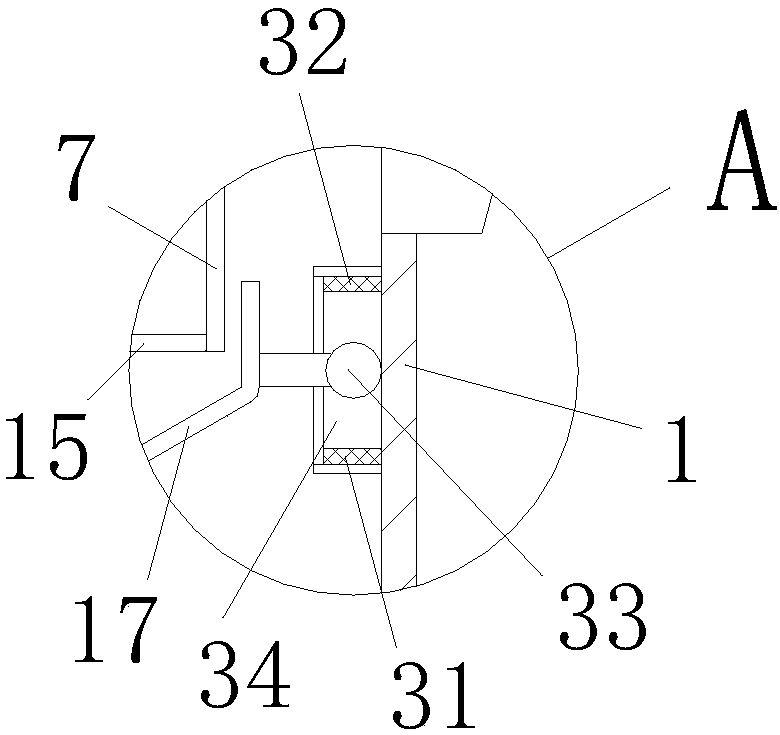

Friction intelligent direction-changing rolling tube

PendingCN108861412AIncrease running resistanceReduce drum speedConveyorsControl devices for conveyorsElectro hydraulicEngineering

The invention discloses a friction intelligent direction-changing rolling tube. The rolling tube comprises a tube body, the two sides of the interior of the tube body are fixedly connected with outershaft sleeves, the inner sides of the outer shaft sleeves are fixedly connected with an installing frame, bearings are installed between the outer shaft sleeves and the installing frame, a main shaftis installed on the inner sides of the bearings, an electro-hydraulic push rod and a controller are fixedly connected with the middle of the interior of the tube body, friction heads are installed onthe upper portions of the electro-hydraulic push rod and the controller, speed measuring devices are arranged on the left sides of the electro-hydraulic push rod and the controller, the speed measuring devices, the electro-hydraulic push rod and the controller are provided with data wires, and a cable passage is formed in the left side of the main shaft. The invention relates to the technical field of direction-changing rolling tubes, according to the rolling tube, the rotation rate of the rolling tube is automatically detected in the operating process of a delivery belt, the operating resistance of the rolling tube can be increased when the rotation rate reaches or exceeds a preset rotation rate to reduce the operating speed of the delivery belt, and runaway accidents are reduced.

Owner:ANHUI MINING ELECTROMECHANICAL EQUIP

Peculiar smell remover with self-reduced operation load and good air permeability

InactiveCN110639301APromote circulationAvoid gatheringDispersed particle filtrationTransportation and packagingThermodynamicsEngineering

The invention discloses a peculiar smell remover with a self-reduced operation load and a good air permeability. The peculiar smell remover structurally comprises a device main body, a wall dust removing device, an electric control box, an air inlet, a vibration measuring box, an air outlet plate and a humidifying opening. A scraping column arranged in the invention rotates, sticking substances onthe outer surface of a filter cylinder are movably scraped under the interaction of a scraper and burrs to ensure good liquidity of a gas, and dusts gathered on the surface of the filter cylinder areavoided, so the operating resistance of the remover is increased; and a gravity sensing structure and a dust collection assembly cooperate with each other, and dusts scraped off by a rotating assembly are uniformly collected and treated, so negative pressure and poor air permeability in peculiar smell purification due to poor fluidity of the gas, caused by adherence of dusts to the surface of thefilter cylinder, are avoided, and expansion and storage of the dusts are achieved under the self-induction gravity action of the gravity sensing ball in order to prevent mixing of oily dusts and filtered impurities and bonding to the bottom of the filter cylinder.

Owner:刘月金

Mechanical chain surface oily matter cleaning equipment for rotating cleaning during meshing

InactiveCN110639855AAchieve flexibilityAvoid wear and tearDirt cleaningCleaning using toolsPhysicsElectric machinery

The invention discloses mechanical chain surface oily matter cleaning equipment for rotating cleaning during meshing. The equipment structurally comprises an equipment body, a conveying frame, an in-chain cleaning device, a dust blocking cover, a driving motor, a control cabinet, a liquid tank box and a drying machine. The equipment has the beneficial effects that under the cooperation of a roughlayer and an S-bend pipe, oily matter in meshed rotating chains is removed through continuous rotation of rotating columns, and the loosening and falling oily matter is treated in a centralized mode under the action of adsorption airflow inside the S-bend pipe, so that the oily matter is prevented from adhering to equipment parts. Meanwhile, the oily matter adhering to the edge walls of the chainsis further scraped through scraping plates, so that the inner walls of the chains are prevented from being abraded when brushes are cleaned. According to the equipment, caking in a seam of the jointof the two chains falls off under the friction action of an iron coil by using an arranged inner rubbing structure, so that the flexibility of the joint of the chains is achieved, and the situation that when the chains are used, the chain running resistance is large due to the oily matter in the seam of the joint is avoided.

Owner:凌金霞

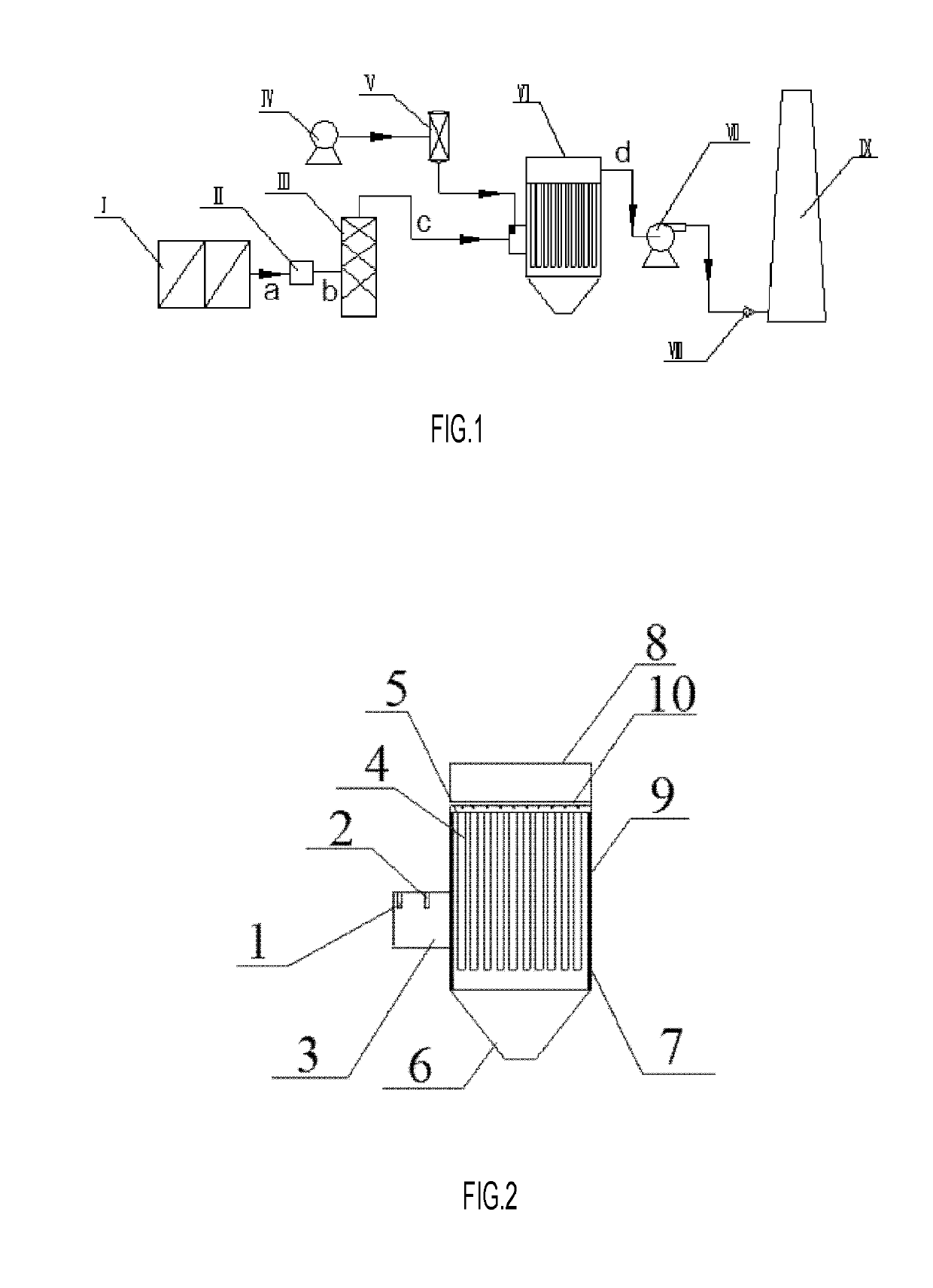

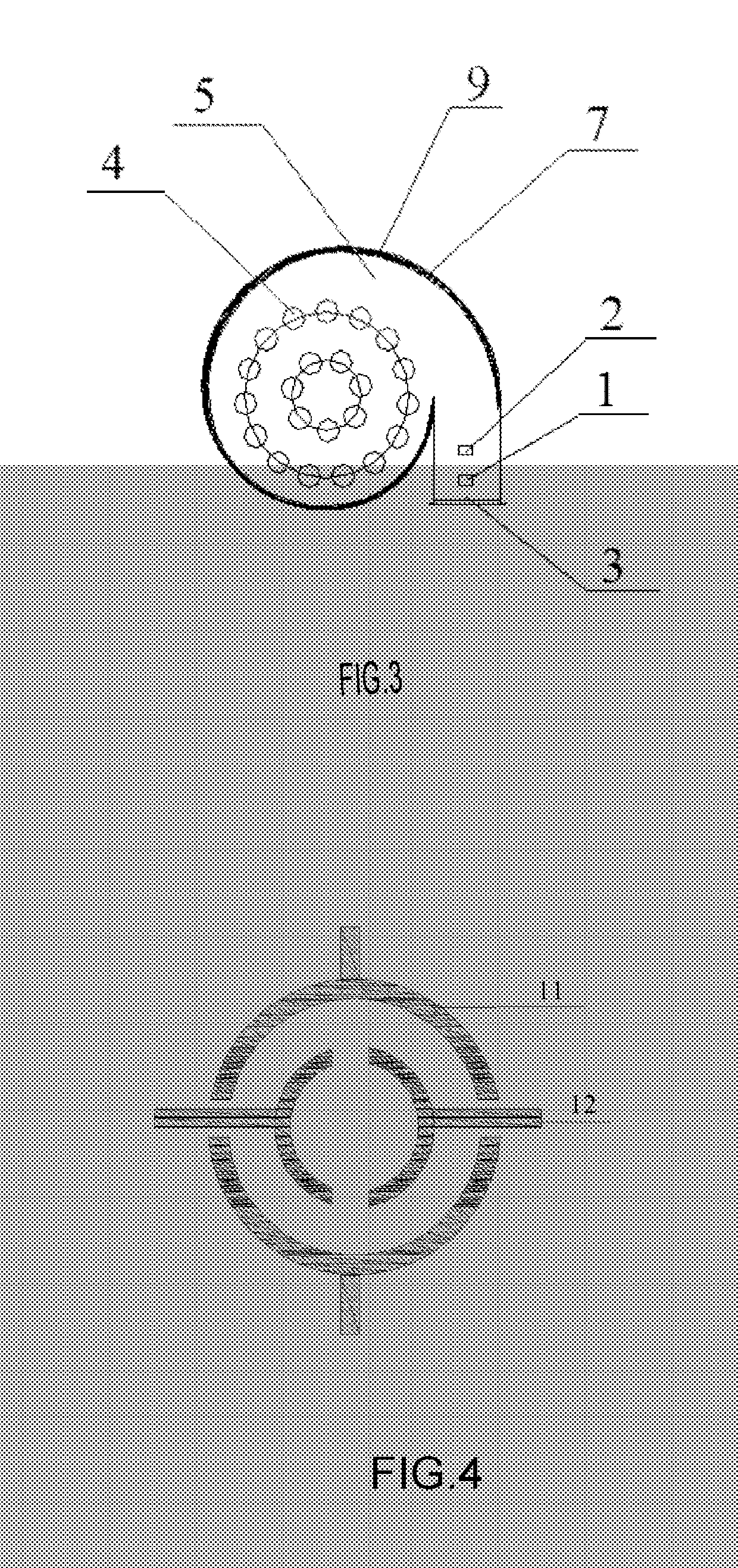

Membrane method processing system and process for high-concentration salt-containing organic waste liquid incineration exhaust gas

ActiveUS20190201830A1Increase running resistanceReduced service lifeGas treatmentDispersed particle filtrationHigh concentrationInorganic salts

A membrane method processing system and process for a high-concentration salt-containing organic waste liquid incineration exhaust gas is described. The system consists essentially of a waste liquid incinerator (I), a gas-solid separator (II), a heat exchanger (III), an air blower (IV), an anti-caking agent storage tank (V), a membrane method dust cleaner (VI), an induced draft fan (VII), a check valve (VIII), and a desulfurization tower (IX). The present invention introduces the dust collecting membrane into the tail gas treatment system and utilizes the small pore size and high porosity of the dust collecting membrane to prevent inorganic salt particles from entering the internal of the filter material and agglomerating there. When the humidity of the gas entering the dust collector increases during the dust removing process, the anti-caking agent is also introduced into the tail gas treatment system to change the surface structure of the inorganic salt crystal to prevent the crystal from agglomeration.

Owner:JIANGSU JIULANG HIGH TECH CO LTD

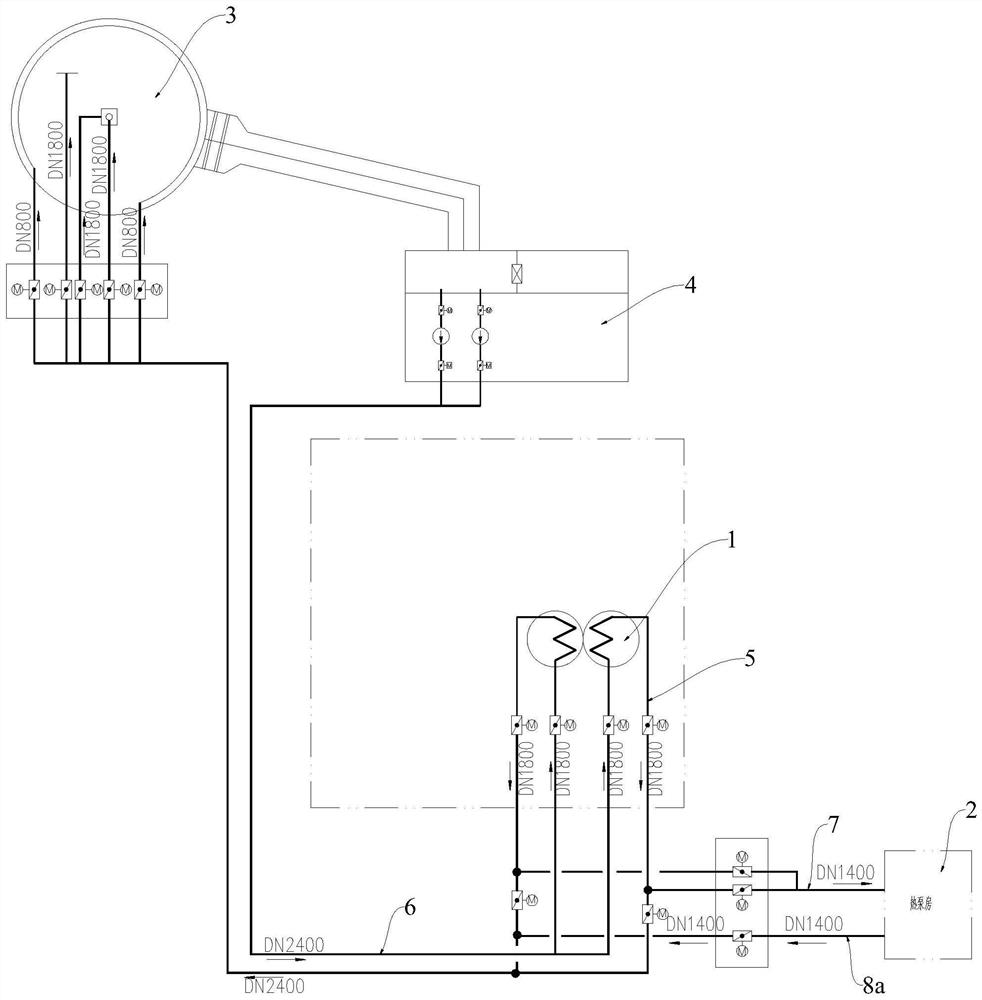

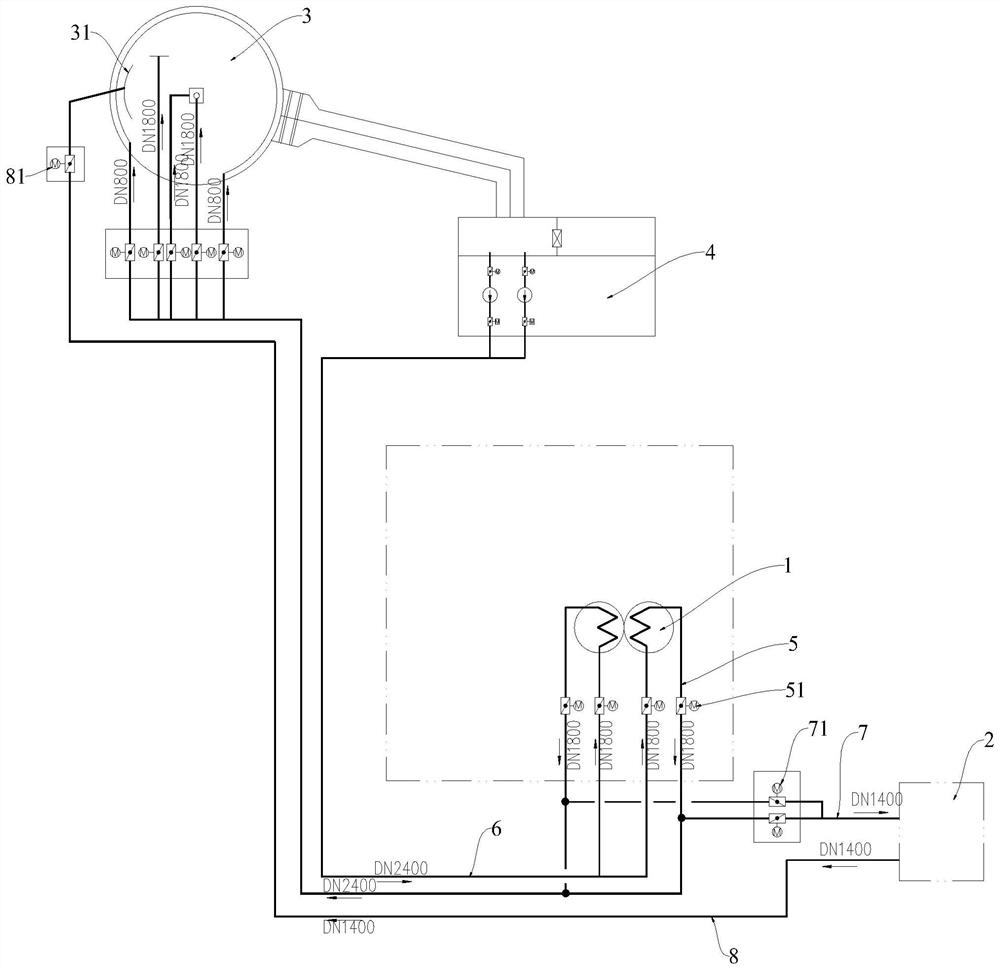

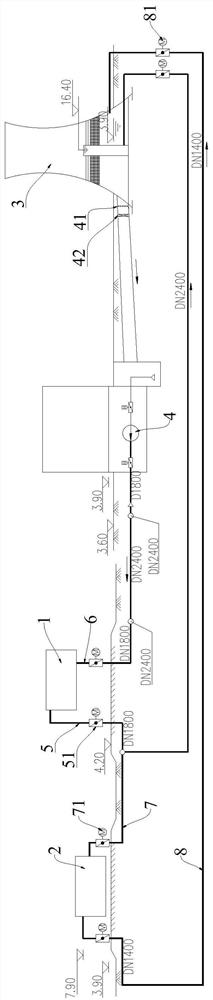

Pipeline arrangement system for extracting waste heat of circulating water of power plant

PendingCN113883748AReduce heat consumptionSimplify operation control methodHeat pumpsHeat recovery systemsProcess engineeringEnvironmental geology

The invention relates to the technical field of waste heat utilization of power plants, in particular to a pipeline arrangement system for extracting waste heat of circulating water of a power plant. The system comprises a steam turbine condenser, a heat pump, a cooling tower and a circulating water pump, wherein an outlet of the steam turbine condenser is connected into the cooling tower through a circulating cooling water return pipeline, and an outlet of the cooling tower is communicated with an inlet of the steam turbine condenser through a circulating cooling water supply pipeline via the circulating water pump; and the outlet of the steam turbine condenser is further communicated with an inlet of the heat pump through a waste heat water supply pipeline, and an outlet of the heat pump is connected into the cooling tower through a waste heat water return pipeline. According to the pipeline arrangement system, under the conditions that original output (lift and flow) of the circulating water pump is not affected, output of the circulating water pump meets the requirements of various operation conditions of a turboset, and safe and stable operation of the turboset is ensured, exhaust steam waste heat of the power plant is recycled to the maximum extent, and heat consumption of the power plant is reduced.

Owner:国能龙源蓝天节能技术有限公司上海分公司

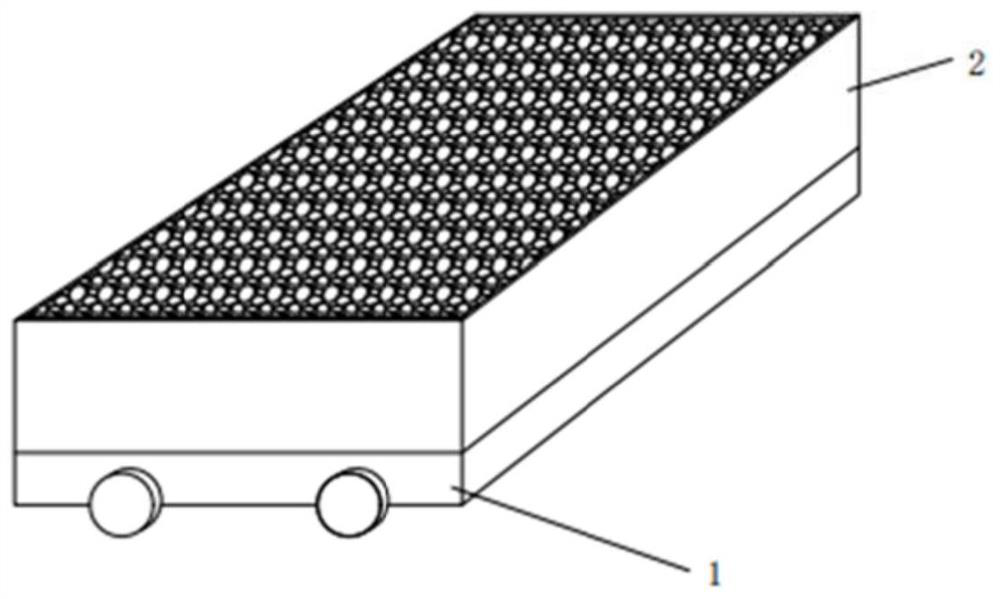

A high-utilization belt-type sintering machine

ActiveCN110726306BReduce in quantityAnti-leakage materialCharge manipulationFurnace typesStructural engineeringMachine

The invention relates to a belt-type sinterer with a high utilization rate. The sinterer comprises a trolley, a trolley running rail device and a crawler belt device. The trolley running rail device comprises a concentric-square-shaped rail. An upper-layer rail and a lower-layer rail of the concentric-square-shaped rail are parallel up and down. The trolley runs cyclically on the concentric-square-shaped rail, and a material opening is formed in the top of the trolley. The crawler belt device comprises crawler belt plates, a crawler belt driving wheel and crawler belt driven wheels. The crawler belt driving wheel and the crawler belt driven wheels are rotationally connected to a fixed support. The crawler belt driving wheel is located at the position, above the trolley, of the ending position of the upper-layer rail. The crawler belt driven wheels is located at the preset position, below the trolley, of the lower-layer rail. The multiple crawler belt plates are hinged in sequence to form a crawler belt chain, the crawler belt driving wheel and the crawler belt driven wheels are sleeved with the crawler belt chain, the crawler belt chain and the trolley are driven by the crawler belt driving wheel to move synchronously and cyclically, and the width of the crawler belt chain is not smaller than that of the material opening of the trolley. The outer side of the crawler belt chainis connected with the material opening of the trolley in a closed manner. According to the belt-type sinterer, the problems that sintered ore is too close, and holes are small are effectively solved,and the requirement for air extraction pressure is reduced.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

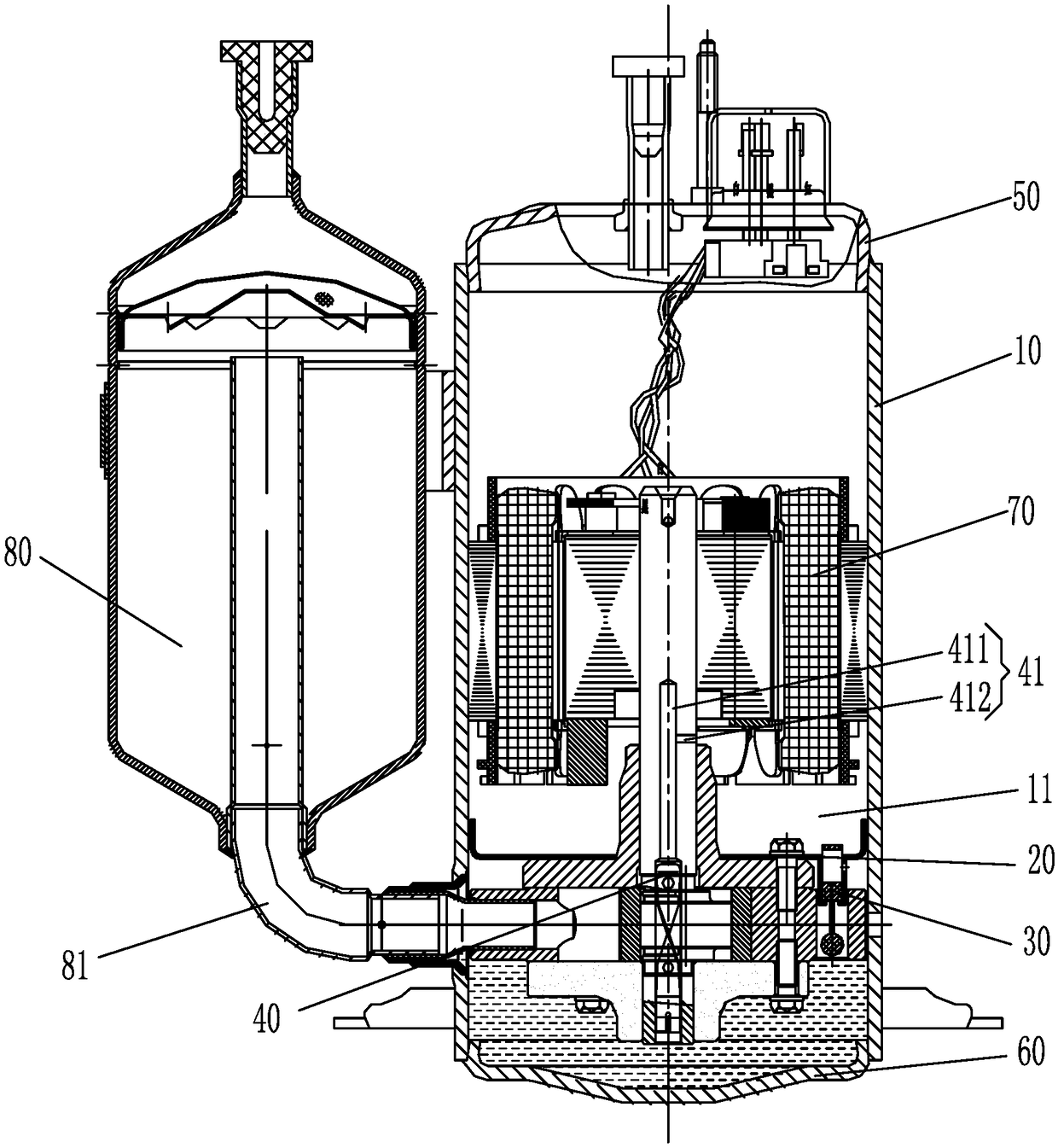

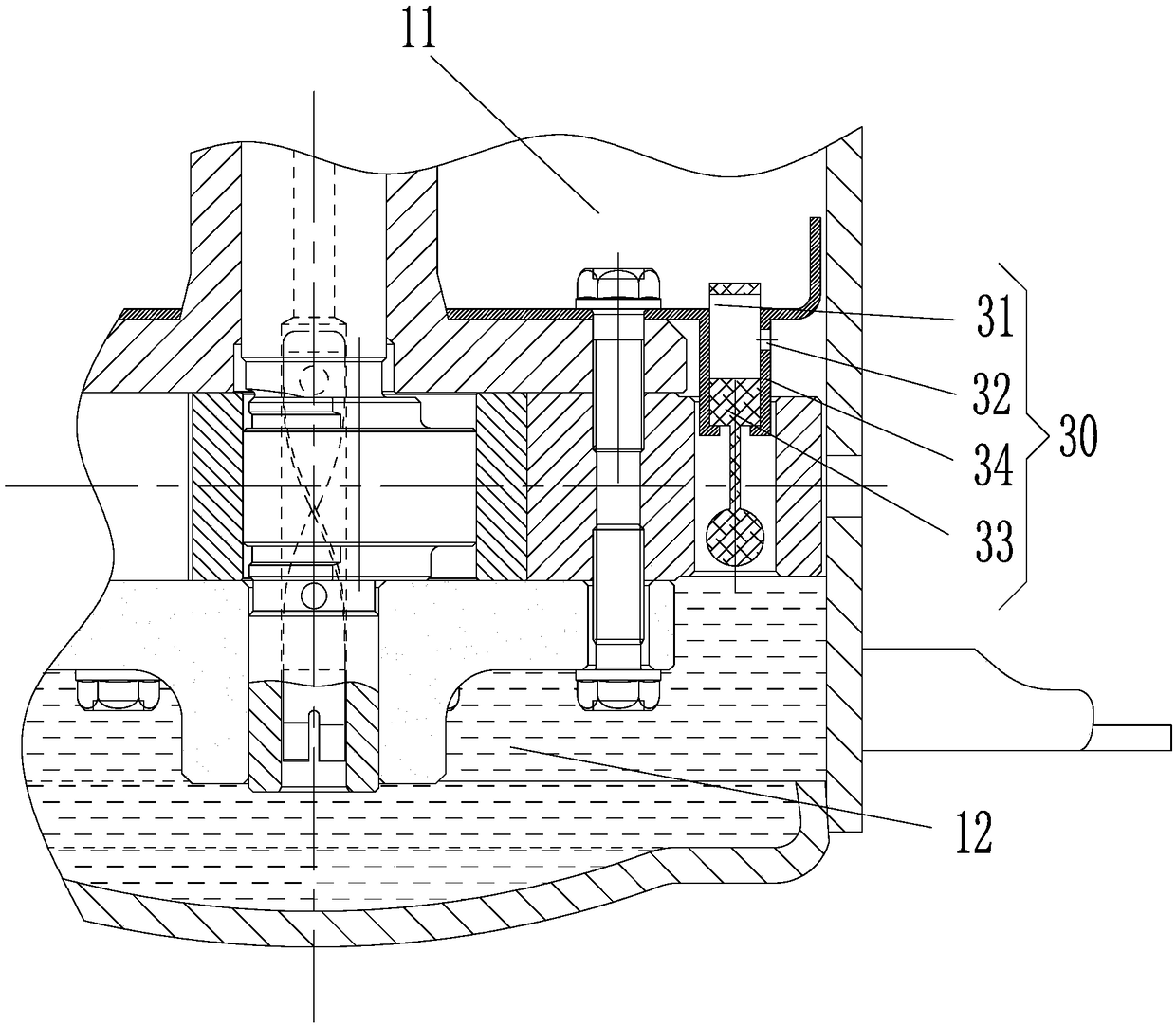

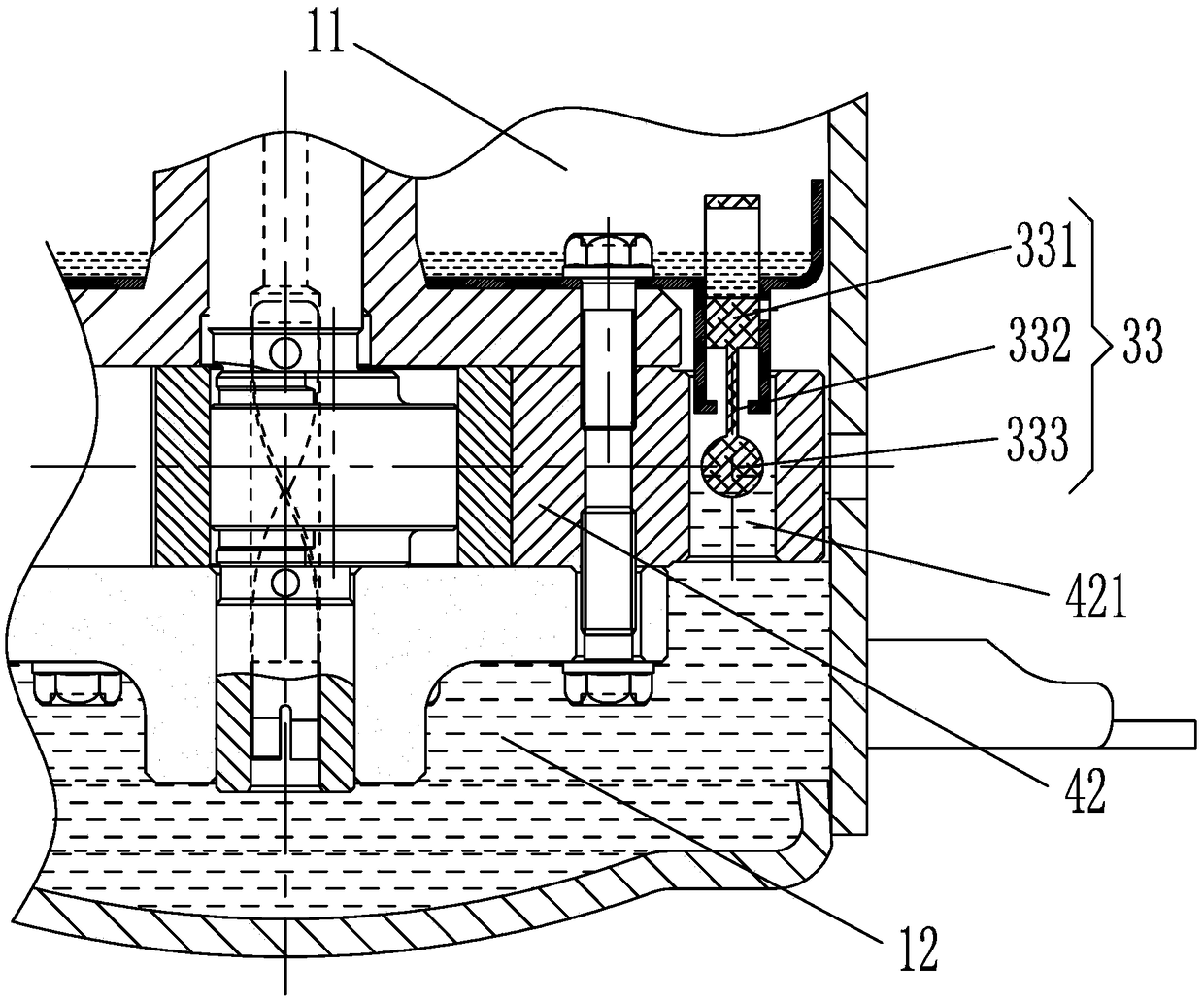

Oil return methods for compressors and compressors

ActiveCN106979159BIncrease running resistanceRotary/oscillating piston pump componentsLiquid fuel engine componentsOil storage

The invention provides a compressor and an oil return method of the compressor. The compressor comprises a shell, an oil storage disc arranged in the shell and used for dividing the space in the shell into an upper cavity and a lower cavity, and an oil return mechanism used for controlling communication or insulation between the upper cavity and the lower cavity. By means of the compressor, the problem that oil supply is insufficient or too much is solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

A high temperature and high back pressure exhaust brake valve

ActiveCN111963324BFit clearance is smallGood pressure holding effectEngine controllersMachines/enginesThermal dilatationExhaust brake

An exhaust brake valve with high temperature resistance and high back pressure, comprising a valve body, a valve shaft and a valve plate, the valve plate is arranged in the cavity of the valve body, and the valve plate is fixed on the valve shaft to rotate around the shaft hole of the valve body, and is characterized in that : The valve plate is eccentrically arranged in the inner cavity of the valve body; the inlet of the valve body is installed with a stepped first insert and a second insert, and the stepped parts of the first insert and the second insert are respectively Fitting with the inlet end face of the valve body and leaving a gap between the first insert, the second insert and the wall surface of the valve body; the first insert is in close contact with the part of the valve plate fixed on the valve shaft; the second insert is provided with a The inclined surface is in contact with the valve plate surface when the valve plate is closed to form a sealed cavity. The invention solves the problems that the existing exhaust brake valve has low pressure-holding capacity and structural stuck due to the thermal expansion of the sealing part; Piston section gas pressure, significantly improve engine auxiliary braking power.

Owner:DONGFENG COMML VEHICLE CO LTD

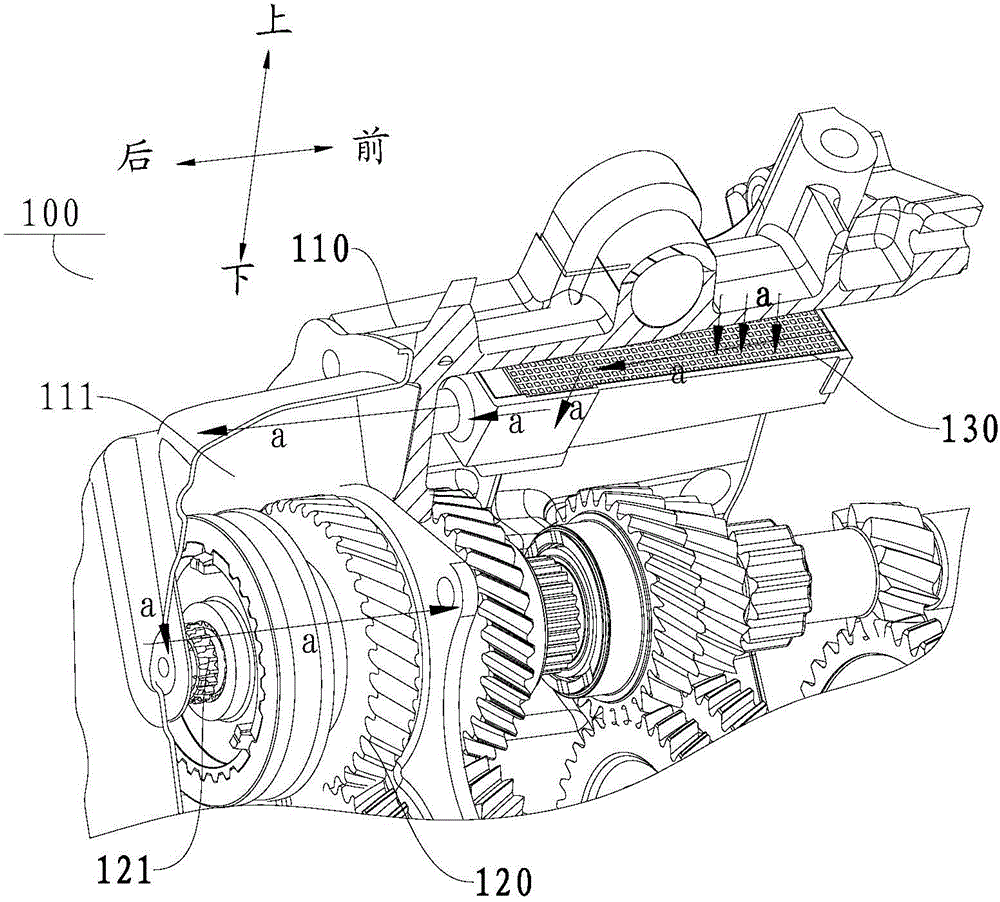

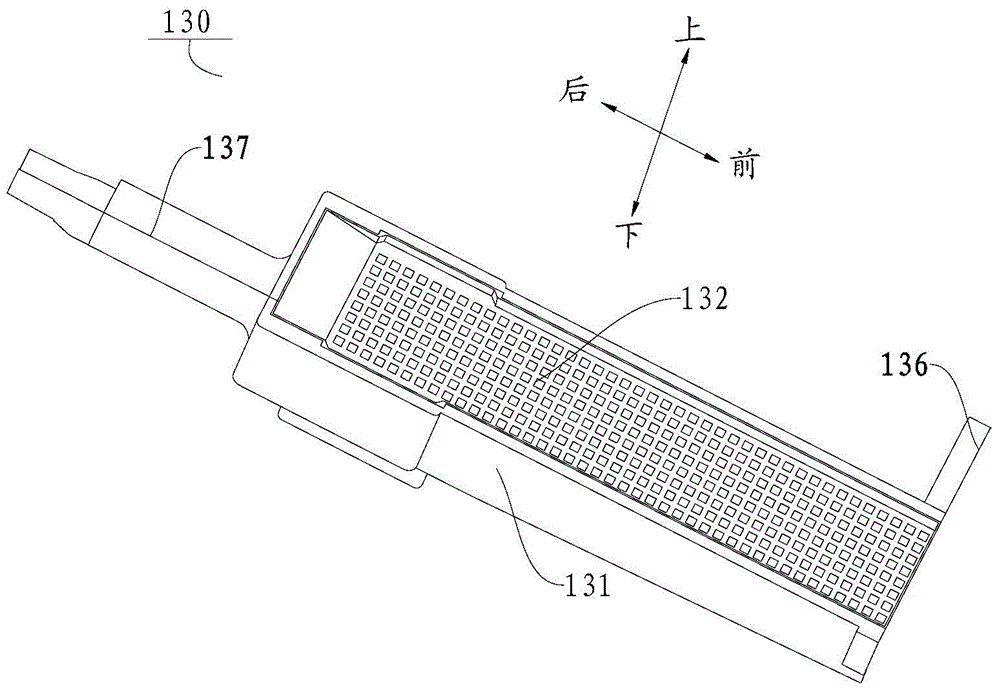

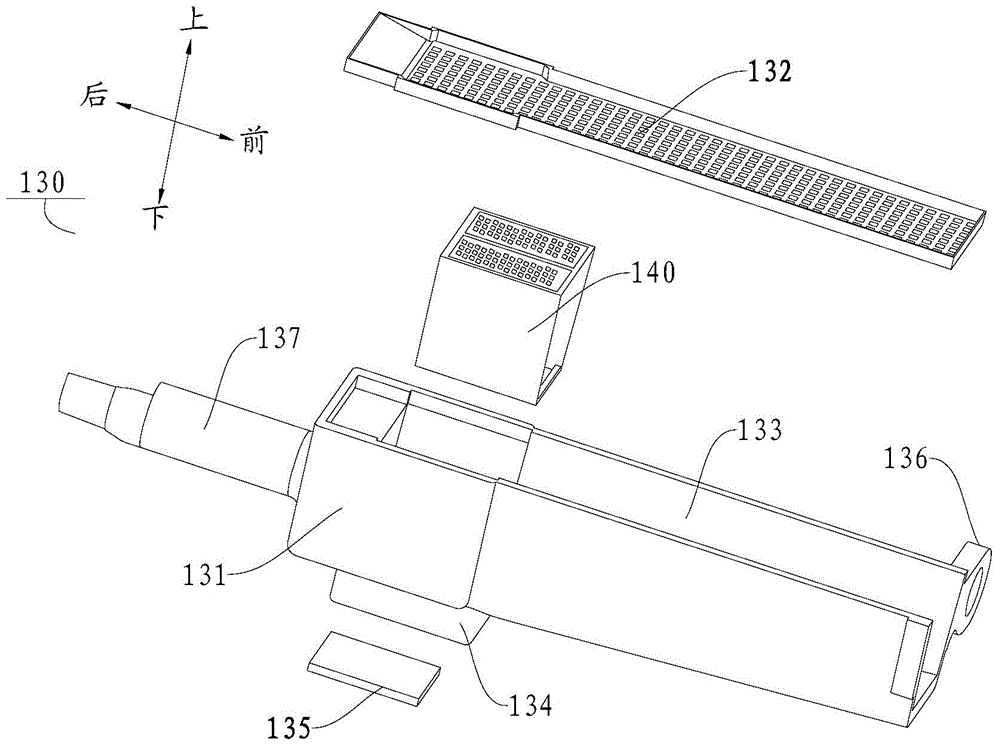

Gearbox and vehicle with the same

ActiveCN104613164AImprove job stabilityHigh working reliabilityGear lubrication/coolingImpurityPetroleum engineering

The invention provides a gearbox and a vehicle with the gearbox. The gearbox comprises a shell, a transmission assembly and an oil guide assembly, wherein a chamber is limited in the shell, an oil guide groove is formed in the side wall of the chamber, the oil guide assembly is arranged on the side wall of the shell and comprises an oil guide base and a first filter screen, the top of the oil guide base is opened, the first filter screen is arranged on the top of the oil guide base, an oil guide passageway is limited in the oil guide base, and the rear end of the oil guide passageway is communicated with the oil guide groove through an oil guide nozzle. According to the gearbox, the oil guide assembly with the first filter screen is arranged in the shell so that filtered lubricating oil can be guided to the transmission assembly, the oil guide assembly can have the lubricating oil guide effect, lubricating oil entering the transmission assembly can be filtered, scrap iron, impurities and the like generated in the gearbox can be prevented from entering the transmission assembly and damaging the transmission assembly, the work stability and reliability of the gearbox are improved, and the service life of the gearbox is prolonged.

Owner:GREAT WALL MOTOR CO LTD

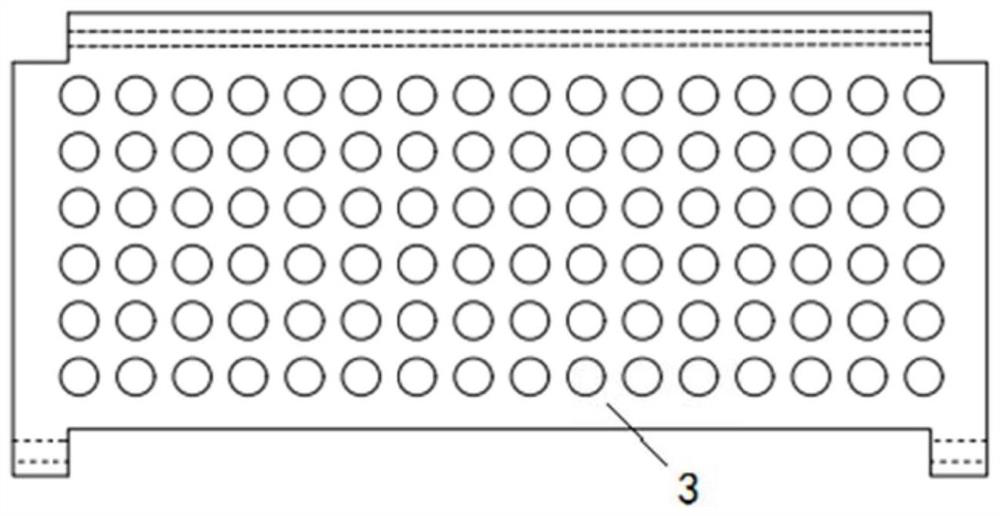

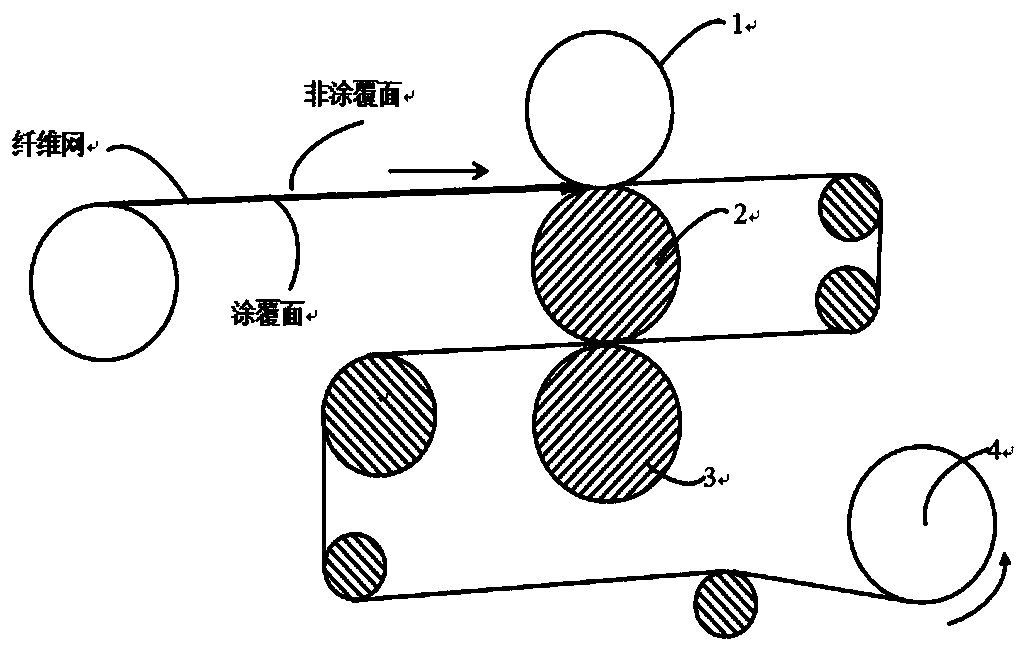

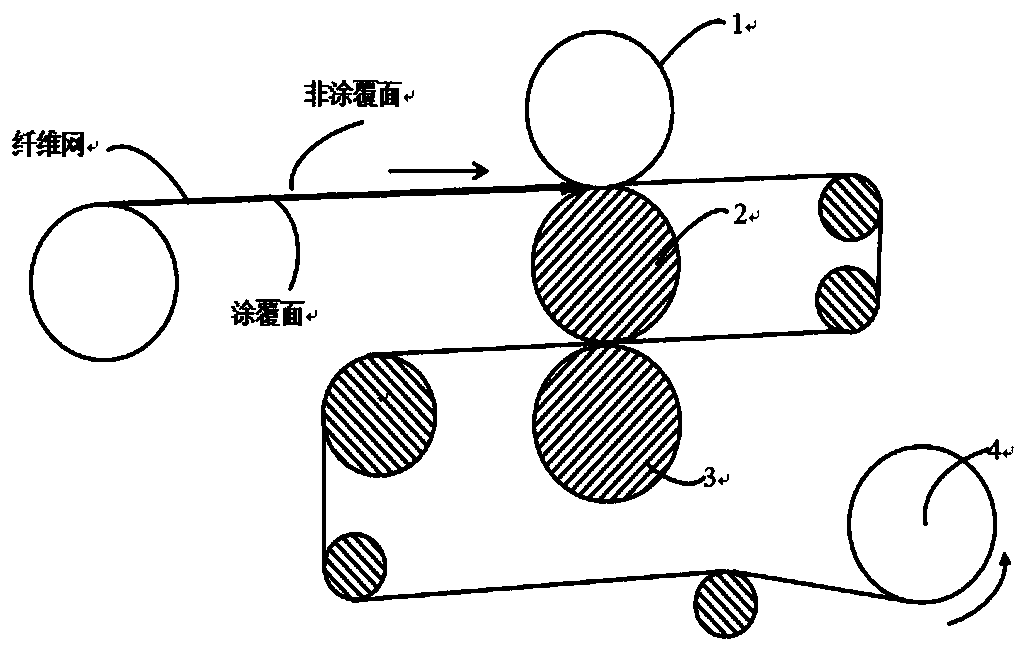

Seawater desalination reverse osmosis membrane support and preparation method

ActiveCN106823838BImprove smoothnessImprove flatnessGeneral water supply conservationSeawater treatmentPolymer sciencePolyvinyl alcohol

The invention discloses a reverse osmosis membrane support for seawater desalination and a preparation method. The reverse osmosis membrane support comprises, in percentage by weight, 40%-60% of polypropylene fibers serving as main fibers, 20%-40% of polyvinyl alcohol fibers serving as supporting fibers and 10%-30% of binding fibers, and the amount of the reverse osmosis membrane support is determined to be 40g / m<2>-120g / m<2>. According to the high salinity and high alkalinity characteristics of to-be-desalinated seawater, the support is mainly prepared from the polypropylene fibers serving as the main fibers, the polyvinyl alcohol fibers serving as the supporting fibers and ES (ethylene propylene) fibers or polyethylene fibers as the binding fibers which all have excellent seawater resistance in technical steps including proportional blending, beating, net forming through wet-process twill weaving, drying and calendering. The coating of the reverse osmosis membrane support has good smoothness and high flatness, the reverse osmosis membrane support has low strength loss in seawater and good structural stability, can be used in a reverse osmosis membrane for seawater desalination stably for a long time and can be widely used for reverse osmosis membrane assemblies for seawater desalination in different temperature environments, and the production process is simple.

Owner:FOSHAN S L P SPECIAL MATERIALS +1

In-cylinder braking type automobile engine retarding system

PendingCN114776496AIncrease piston running resistanceIncrease vehicle driving resistanceMechanical controlMachines/enginesAutomatic controlCompressed air

The invention discloses an in-cylinder braking type automobile engine retarding system, and belongs to the technical field of automobile braking. Comprising an in-cylinder braking type automobile engine, an in-cylinder braking type automobile engine air inlet and exhaust port circulation pressurization channel and a retarding control device. The in-cylinder braking type automobile engine air inlet and outlet circulating pressurization channel comprises an air inlet and outlet circulating pipe and a compressed air conveying pipe. One end of the air inlet and outlet circulating pipe is communicated with an air inlet of the in-cylinder brake type automobile engine, and the other end of the air inlet and outlet circulating pipe is communicated with an air outlet of the in-cylinder brake type automobile engine; one end of the compressed air delivery pipe is communicated with an automobile compressed air source, and the other end of the compressed air delivery pipe is communicated with an air inlet of the in-cylinder brake type automobile engine; the retarding control device comprises a controller and an execution element; the execution element comprises an air inlet pipe opening and closing automatic control valve, an exhaust pipe opening and closing automatic control valve, a circulating pipe opening and closing automatic control valve and a compressed air conveying pipe opening and closing automatic control valve. The device has the characteristics of reasonable structure, good braking performance, high safety and reliability and the like.

Owner:闫胜波

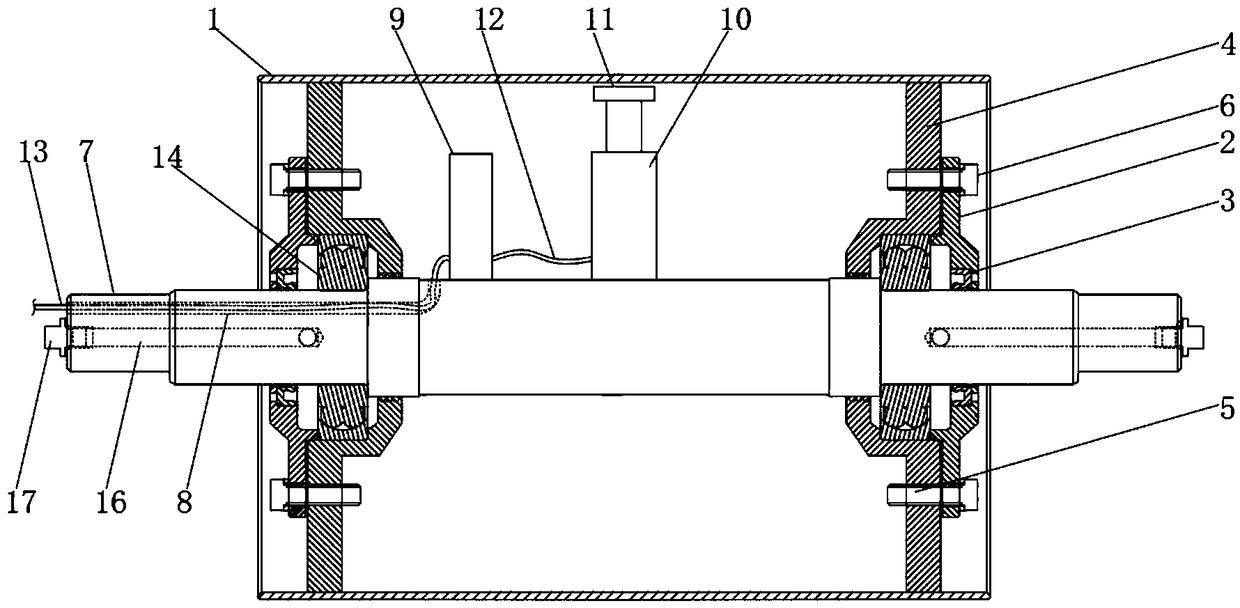

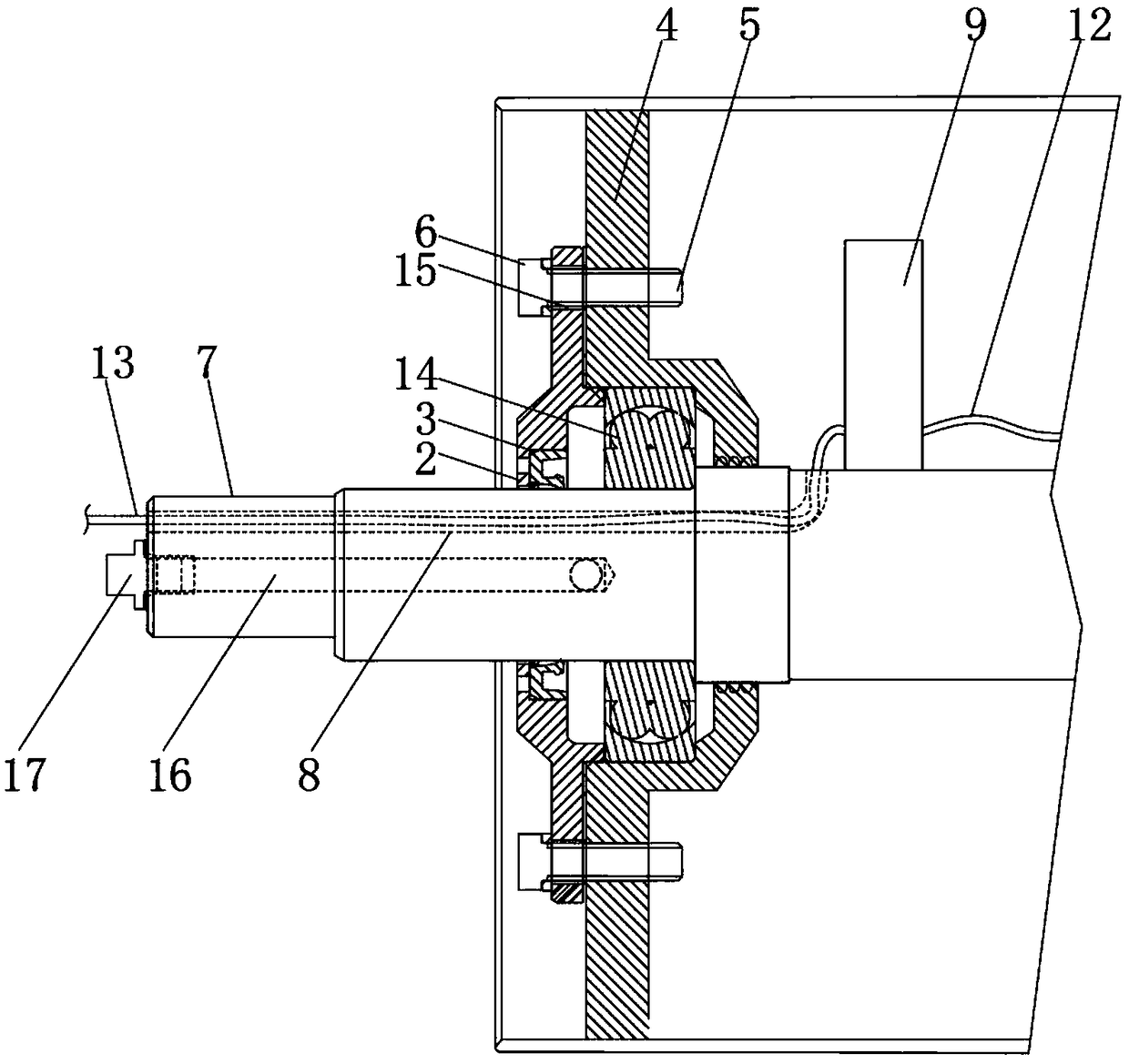

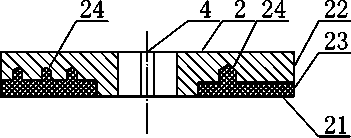

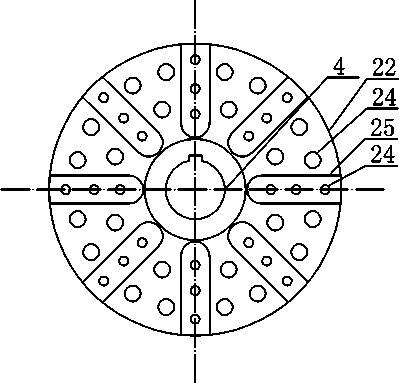

A water-lubricated thrust bearing assembly

InactiveCN105673547BStrong axial bearing capacityStrong wear resistancePump componentsPumpsWater channelHard metal

The invention discloses a water-lubricated thrust bearing assembly. The assembly comprises a thrust disc and a stainless steel thrust disc, wherein the thrust disc comprises a hard metal substrate, the annular end surface of the metal substrate at the contact sides of the thrust disc sector-ring shaped friction blocks is covered with a non-metal wear-resisting layer, the stainless steel thrust disc comprises a stainless steel annular substrate and a plurality of sector-ring shaped friction blocks on one side of the annular substrate, a lubrication water channel is formed between the adjacent sector-ring shaped friction blocks, the corresponding number of the stainless steel sector-ring shaped support blocks with the sector-ring shaped friction blocks are arranged on the other side of the annular substrate, a cool water channel is formed between the adjacent sector-ring shaped support blocks, the sector-ring shaped support blocks and the sector-ring shaped friction blocks are arranged in the circumferential direction in the staggered way, the symmetry axis of the sector-ring shaped support block coincides with the projection of the middle line of the lubrication water channel in the annular end surface of the substrate. The water-lubricated thrust bearing assembly has features of great axial bearing capacity, good cooling effect, great wear resisting capacity, high corrosion resistance, low operation resistance, and long service life.

Owner:衡水凯达模压制品有限公司

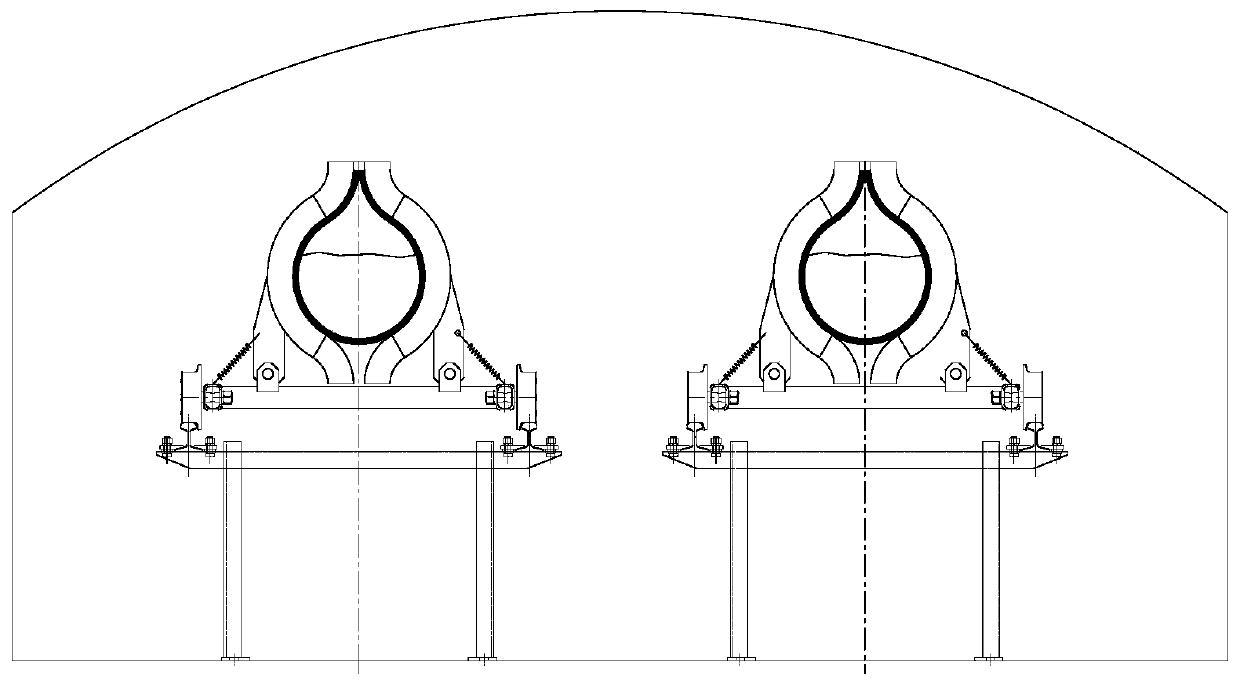

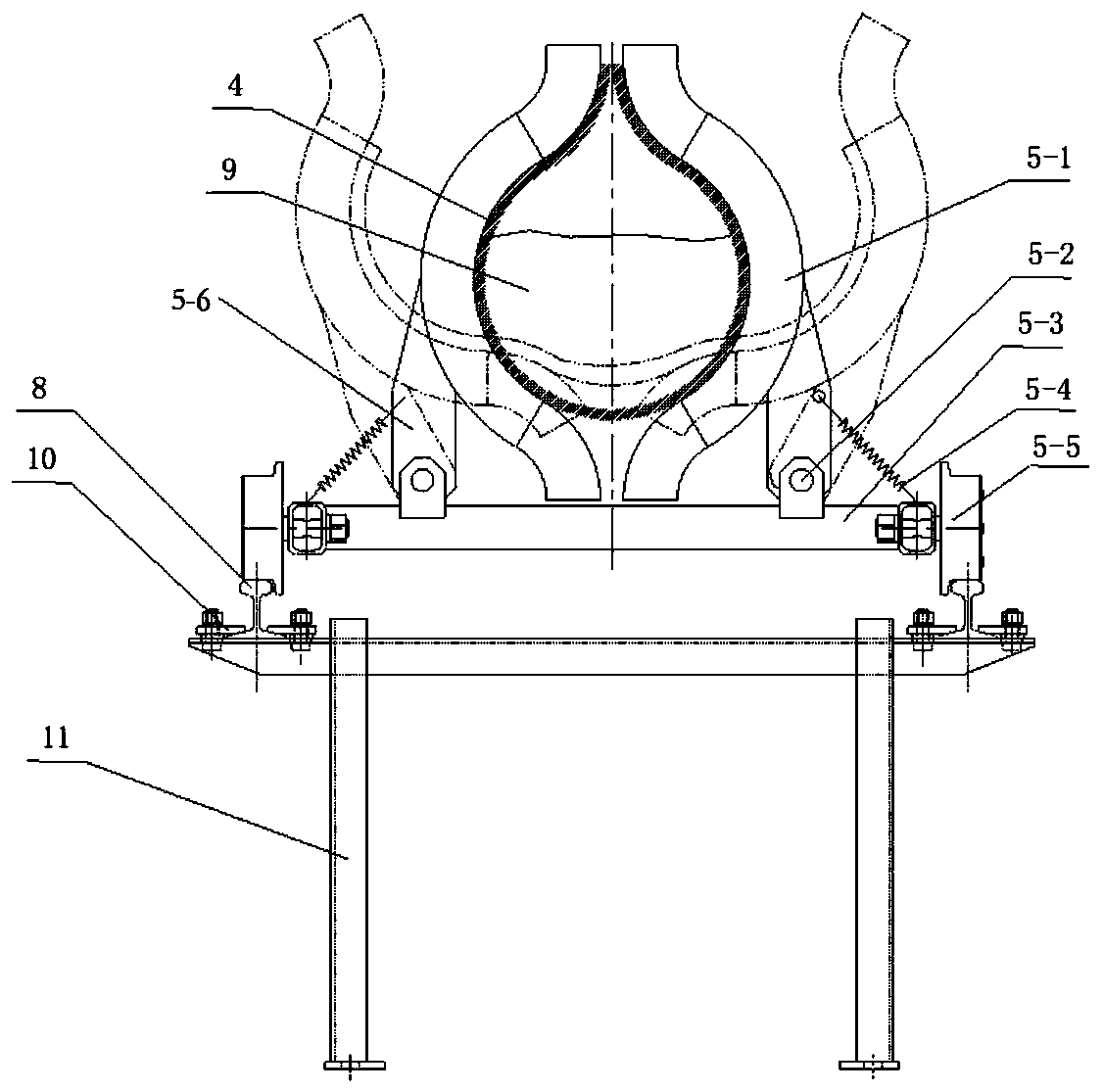

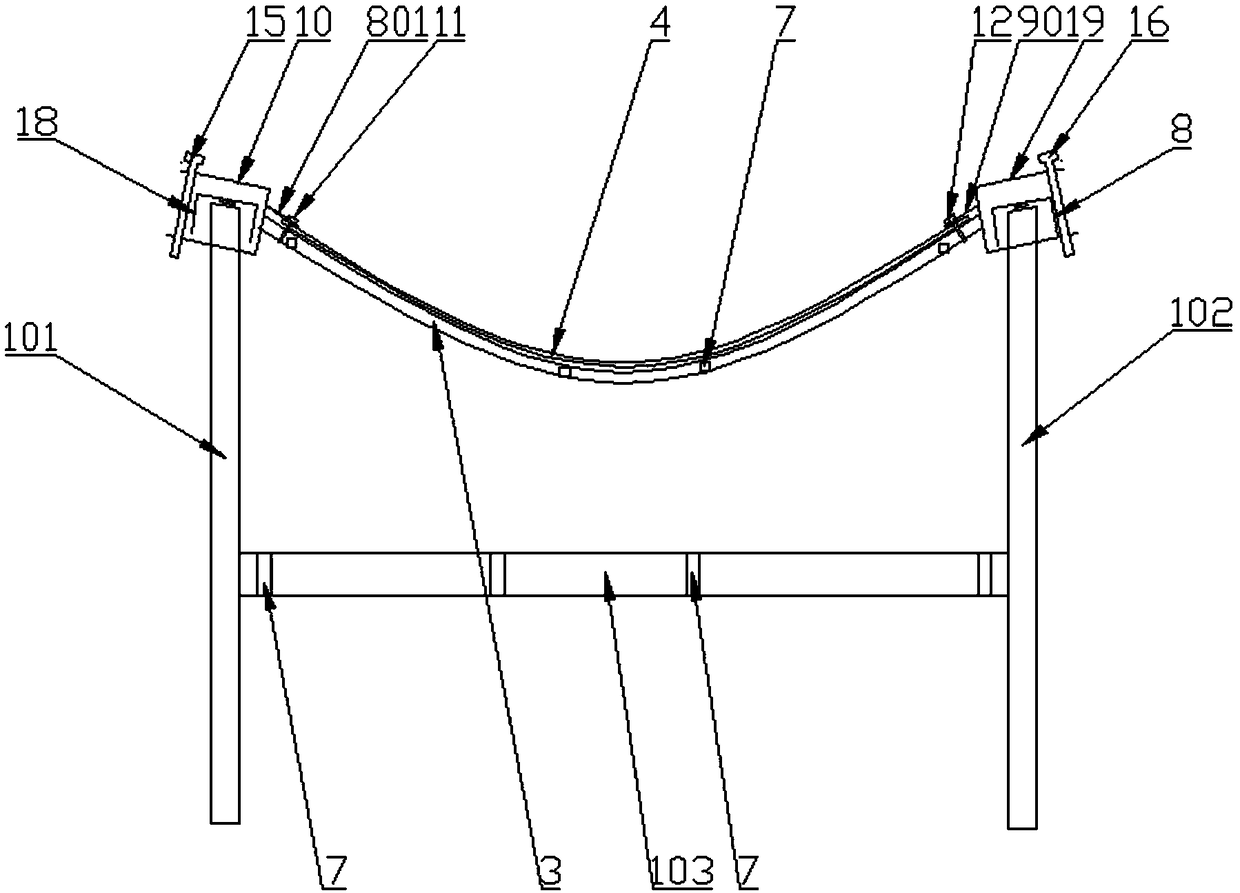

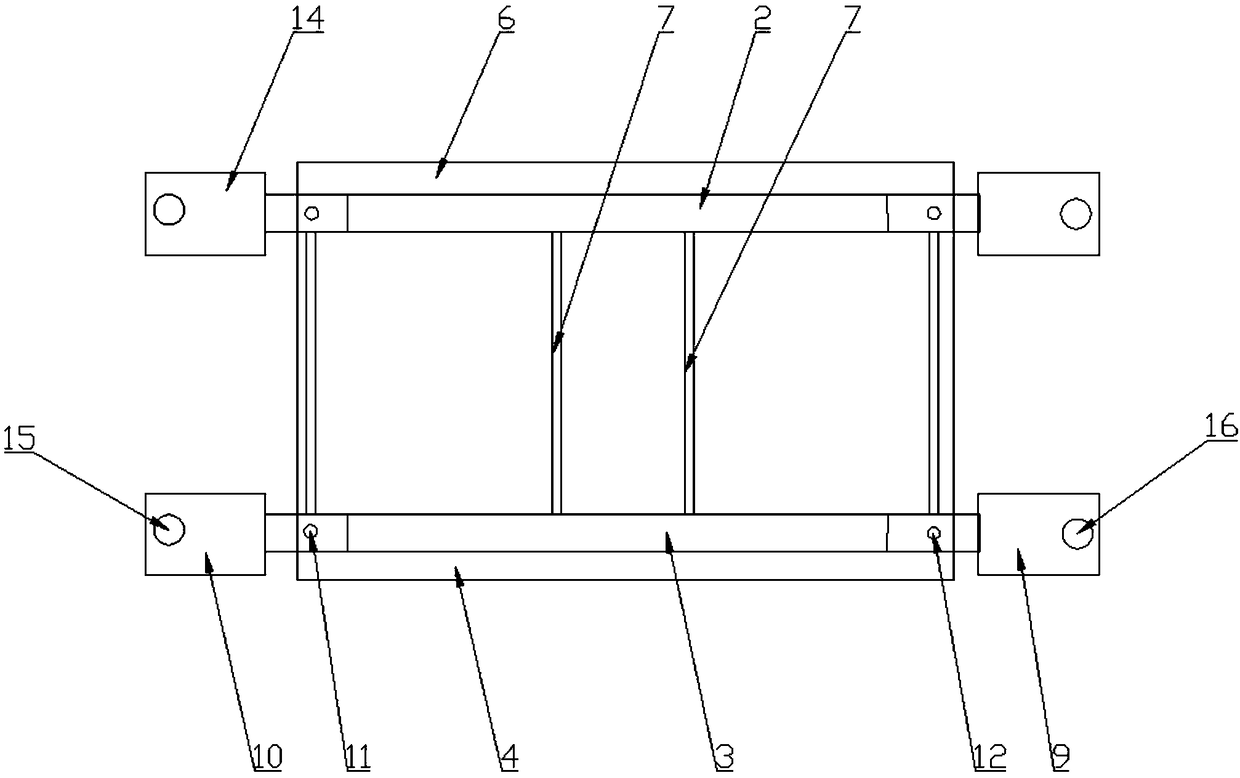

Belt mechanism with anti-derailing function under large-dip-angle underhand stoping condition

The invention provides a belt mechanism with an anti-derailing function under a large-dip-angle underhand stoping condition, and relates to the technical field of large-dip-angle underhand stoping belt coal transportation galloping prevention. The belt mechanism comprises a first belt H frame and a second belt H frame, wherein the first belt H frame and the second belt H frame are parallel to eachother and spaced. A first semicircular belt bracket is arranged above the first belt H frame, first damping skin is arranged above the first semicircular belt bracket, and the first damping skin is fixedly connected with the first semicircular belt bracket. A second semicircular belt bracket is arranged above the second belt H frame, second damping skin is arranged above the second semicircular belt bracket, and the second damping skin is fixedly connected with the second semicircular belt bracket. A belt of a belt conveyor is arranged above the first damping skin and the second damping skinand slidingly connected with the first damping skin and the second damping skin. Friction between the belt and the damping skin is improved by increasing the damping skin, friction force is generatedbetween the belt and the damping skin, and the purpose of large-dip-angle transportation galloping prevention of the belt conveyor is completely solved.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

A grinding device for chemical product processing

ActiveCN114177997BIncrease running resistanceAvoid overgrindingGrain treatmentsControl engineeringProcess engineering

The present invention relates to chemical production equipment, in particular to a grinding device for processing chemical products, which includes a mounting base and a grinding bucket that passes through the mounting base and is fixed thereto. The device also includes a filter bucket, a rolling assembly, a lifting assembly, and a feeding The material component, the rolling component is rotated and set above the filter bucket, the rolling component cooperates with the filter bucket, and rotates around the axis of the grinding barrel to break the chemical materials in the filter bucket and filter them out through the filter holes; the lifting component is connected with the rolling component , the lifting component is used to drive the rolling component to alternately lift up and down along the axis of the grinding bucket in the grinding barrel; the feeding component is located at the top of the lifting component and the rolling component, and is connected with the rolling component. The chemical materials to be processed are intermittently discharged into the filter hopper in the grinding barrel through the feeding component, and the feeding component also drives the rolling component to run, which has the effect of automatically adding chemical materials, and batch feeding prevents the grinding barrel Excessive material build-up increases the running resistance of the rolling assembly.

Owner:新沂市永诚化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com