Air-locking feeding device with drying function

A technology of feeding device and air lock, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of increasing the gap between the blade and the shell, aggravating the wear of the rotating blade, and the large running resistance of the rotating rotor. To achieve the effect of preventing wear and running resistance increase, reducing energy consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

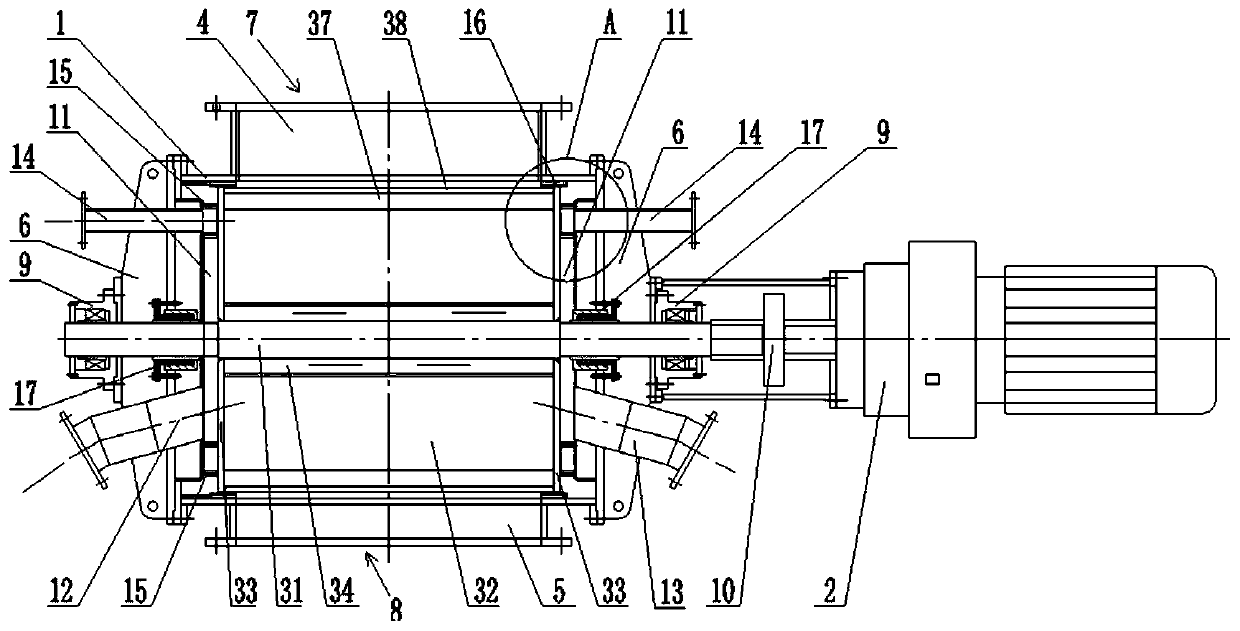

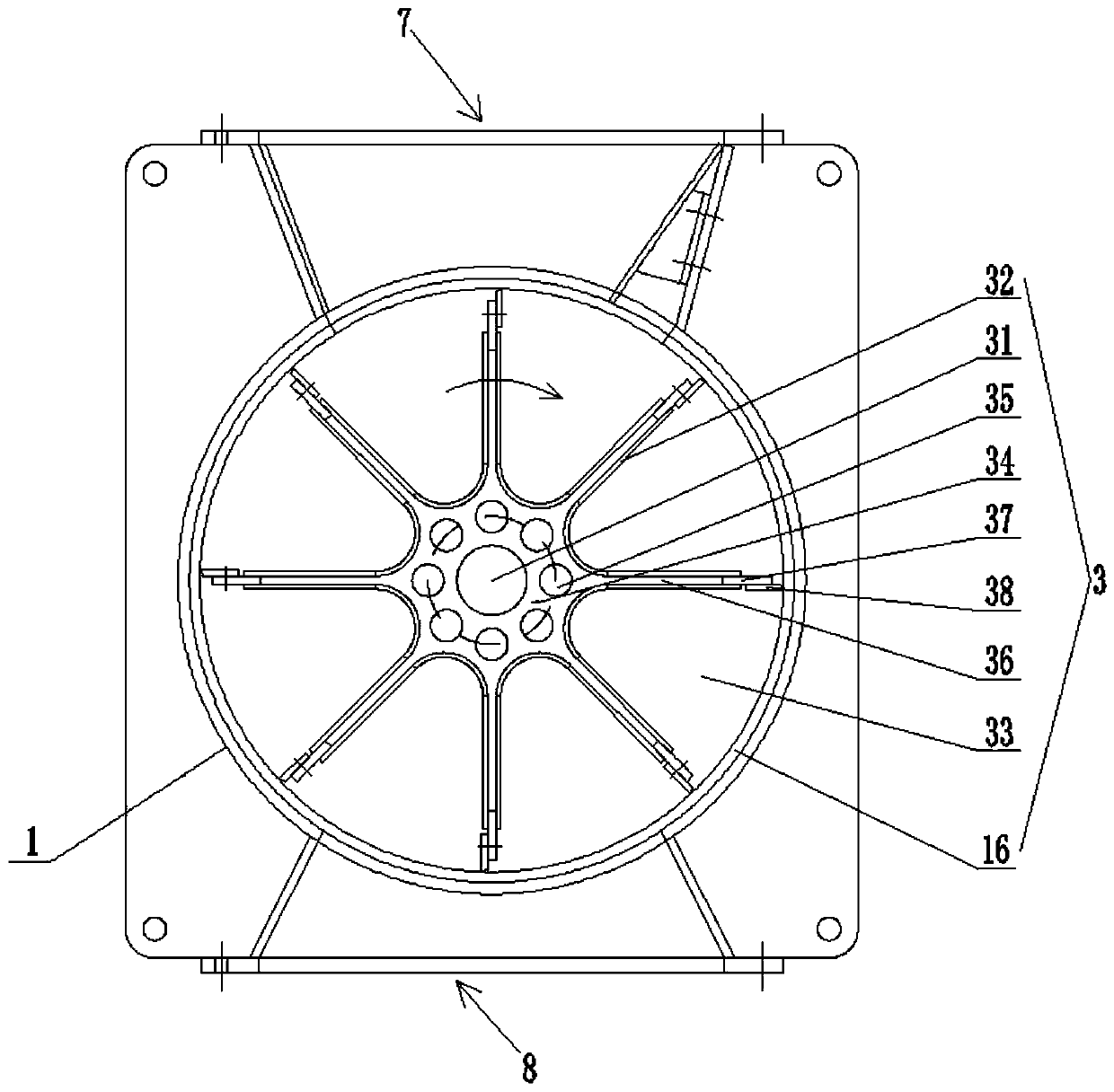

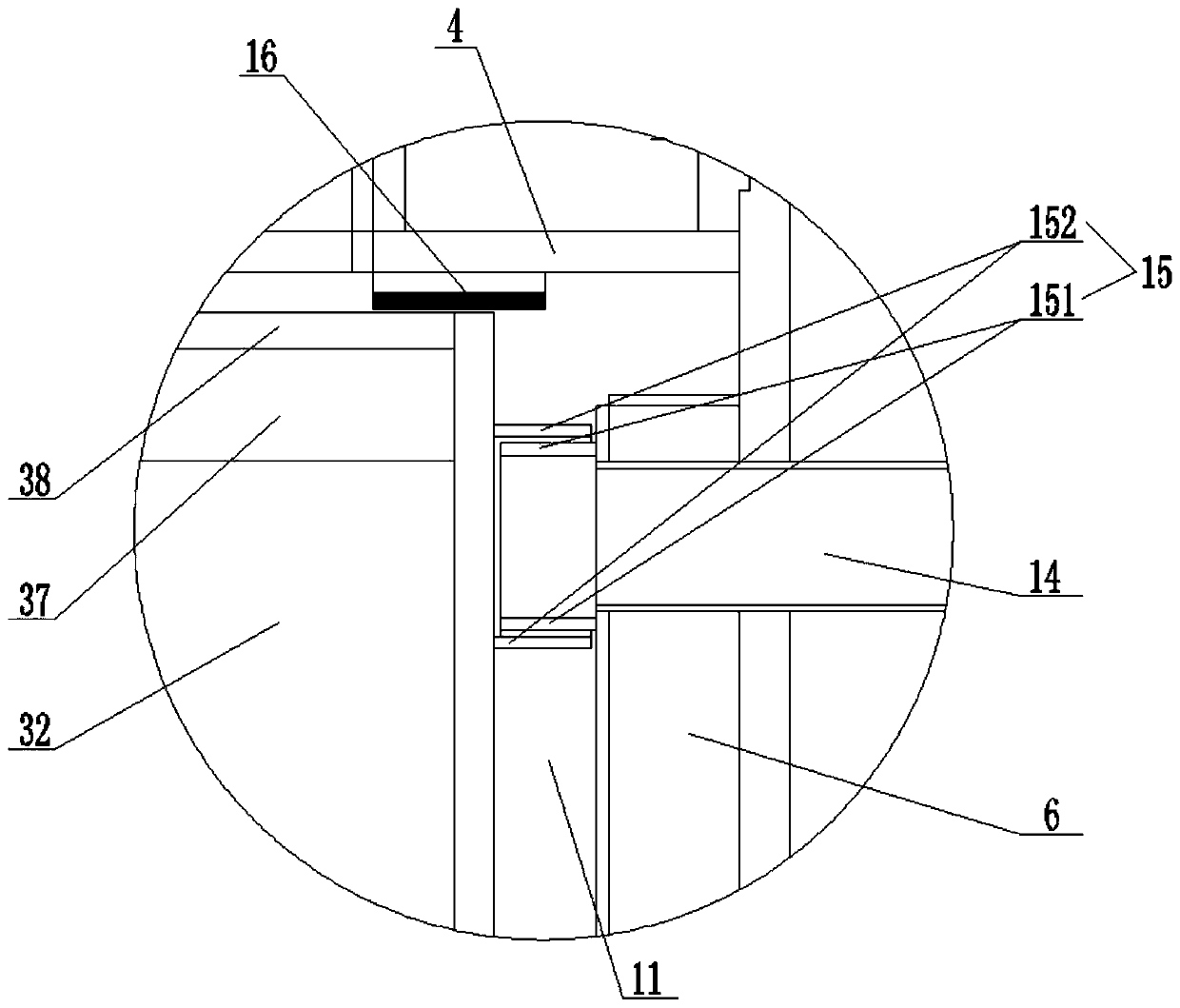

[0021] Such as figure 1 As shown, the embodiment of the present invention provides an airlock feeding device with a drying function, the device includes a housing 1, a power unit 2 and a rotary rotor 3, and the middle part of the rotary rotor 3 is arranged in the housing 1, the upper and lower ends of the shell 1 are respectively provided with an upper end flange 4 and a lower end flange 5, and the two sides of the shell 1 are respectively provided with a side end flange 6, an upper end flange 4, and a lower end flange 5 Both the side flange 6 and the housing 1 are preferably bolted tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com