SCR catalyst blockage removing device

A SCR catalyst and catalyst technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of affecting reaction effect, increasing running resistance, impact damage of catalyst, etc. Great, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

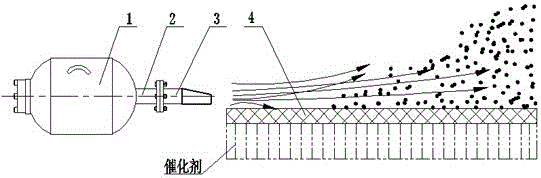

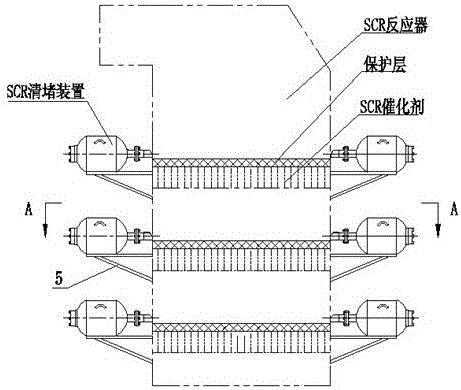

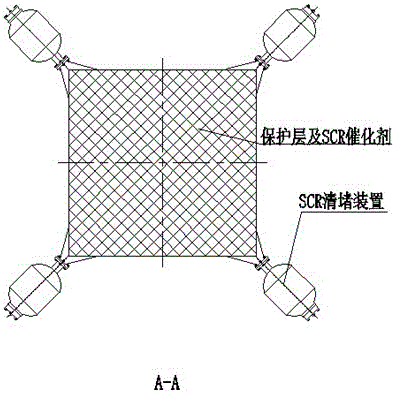

[0031] like figure 1 As shown, the SCR catalyst unclogging device comprises an air cannon (1), a spray pipe (2), a "duckbill" nozzle (3), a protective layer (4) and a bracket (5). The air cannon (1) and the blowing pipe (2) are connected by welding; the blowing pipe (2) and the "duckbill" nozzle (3) are connected by flange connection or welding.

[0032] like figure 1 As shown, the technical solution designs the protective layer (4) according to the external dimensions of the catalyst and the opening size, shape, quantity and distribution characteristics, and the protective layer (4) adopts positioning clamping connection with the SCR catalyst layer and the SCR reactor, and the two There must be a close fit between them, and the catalyst layer corresponds to the hole or slot position of the protective layer (4).

[0033] like figure 2 As shown, the "duckbill" nozzle (3) is sealed and welded with the SCR reactor shell; the whole set of unclogging device is supported by a br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com