Cement mill dust collecting and discharging system

A technology of cement grinding and cement, which is applied in the direction of dust removal, disperse particle filtration, cleaning methods and utensils, etc., which can solve the problems of poor dust collection effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

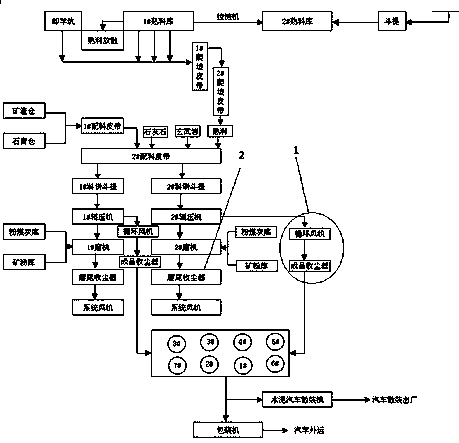

[0030] figure 1 , figure 2 , image 3 It shows a cement grinding dust collection and unloading system, which includes a roller press dust collection mechanism 1 and a grinding tail dust collection mechanism 2 arranged in sequence on the new cement production line. The roller press dust collection mechanism 1 includes a double cyclone Dust suction cylinder and main pulse spray bag dust collector 3, the double cyclone dust suction cylinder is arranged at the outlet of the air-powder mixture of the roller press, and the double cyclone dust suction cylinder connects with the main pulse spray bag dust collector 3 through the air duct The feed end is connected, and the dust collection mechanism 2 at the end of the mill includes a secondary pulse spray bag dust collector 4, and the secondary pulse spray bag dust collector 4 is connected with the cement mill through an air duct.

[0031] The roller press dust collection mechanism and the grinding tail dust collection mechanism are ...

specific Embodiment 2

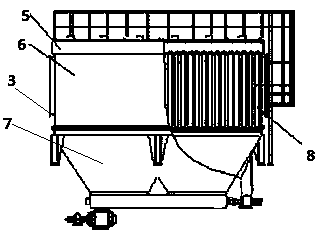

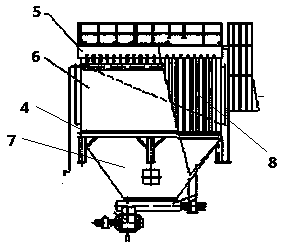

[0033] This embodiment further explains the main pulse spray bag dust collector on the basis of specific embodiment 1, and the main pulse spray bag dust collector 3 is a double series pulse spray bag dust collector.

[0034] The double-series pulse jet bag dust collector is one of the new pulse jet bag dust collectors of FDM. It is based on the original MC type pulse dust collector for reference from the latest technology at home and abroad, and combined with the actual situation of the current pulse dust collector in my country. situation, developed a new generation of bag type dust collector.

[0035] The dust collector adopts the technology of high-pressure (0.4-0.7MPa) large-flow pulse airflow to blow and clean the filter bags one by one. It has the characteristics of large cleaning kinetic energy, high cleaning efficiency, compact structure, and less maintenance workload. The characteristics of line cleaning can make the dust collector run continuously, which overcomes the...

specific Embodiment 3

[0042] This embodiment further explains the structure of the double-series pulse jet bag dust collector on the basis of specific embodiment 2. The double series pulse jet bag dust collector includes bag chambers 5 arranged in sequence from top to bottom , clean air chamber 6 and ash hopper 7, said clean air chamber 6 is provided with row filter bag 8, each top of row filter bag 8 is equipped with a blowing hose, blowing hose and pulse valve and compression The air main pipes are connected, the two ends of the clean air chamber 6 are respectively provided with an air inlet and an air outlet, the outlet of the ash hopper 7 is provided with a grid wheel, and the double-series pulse spray bag dust collector There are two clean air chambers 6 and ash hoppers 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com