In-cylinder braking type automobile engine retarding system

An automobile engine and retarding technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of long braking time, insufficient braking force, affecting driving safety, etc. High resistance, safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0020] The standard parts used in the present invention can be purchased from the market, the special-shaped parts can be customized according to the description in the description and the drawings, and the specific connection methods of each part are all mature bolts, rivets, welding in the prior art. , pasting and other conventional means will not be described in detail here.

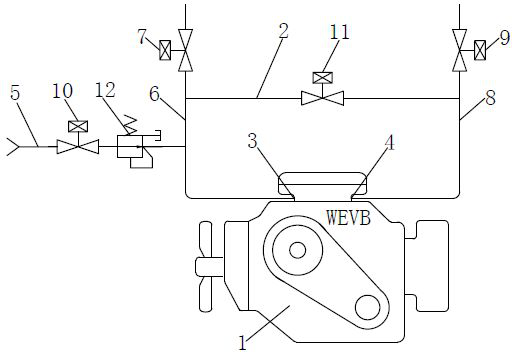

[0021] Depend on figure 1 It can be known from the illustrated embodiment that this embodiment includes an in-cylinder brake type automobile engine 1, an in-cylinder brake type automobile engine inlet and exhaust port circulating boosting channel and a retarding control device;

[0022] The in-cylinder brake type automobile engine intake and exhaust port circulation supercharging channel includes an intake and exhaust port circulation pipe 2 and a compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com