Seawater desalination reverse osmosis membrane support and preparation method

A reverse osmosis membrane, seawater desalination technology, applied in chemical instruments and methods, reverse osmosis, seawater treatment, etc., can solve the problems of poor structure and performance stability, increased hydrolysis performance, membrane support shape stability and apparent smoothness Guarantee and other issues, to achieve excellent seawater resistance, strong loss and structural stability, and improve seawater resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

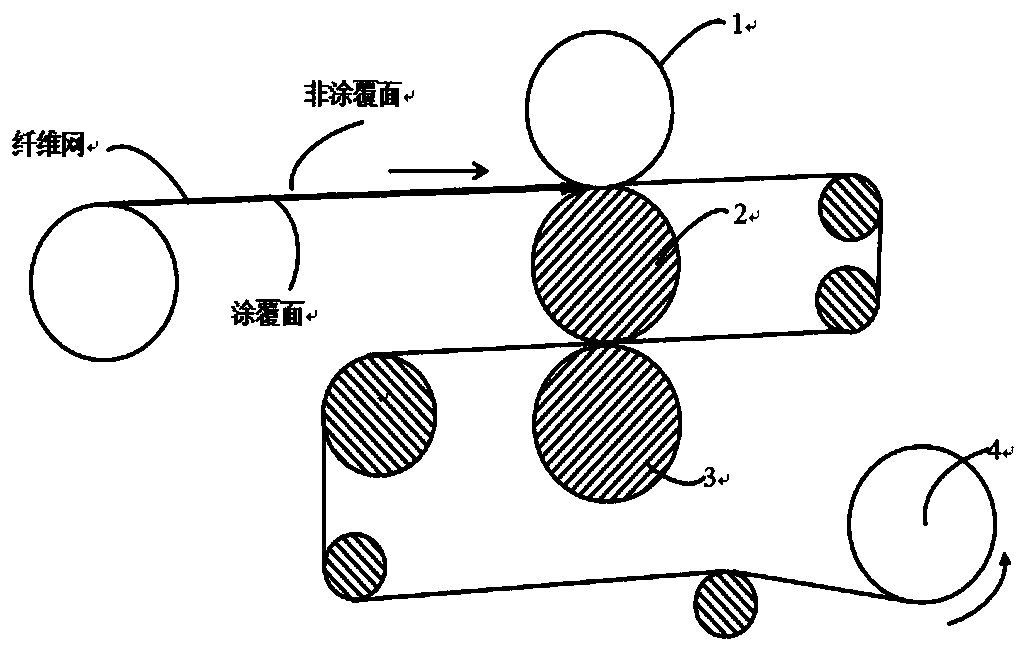

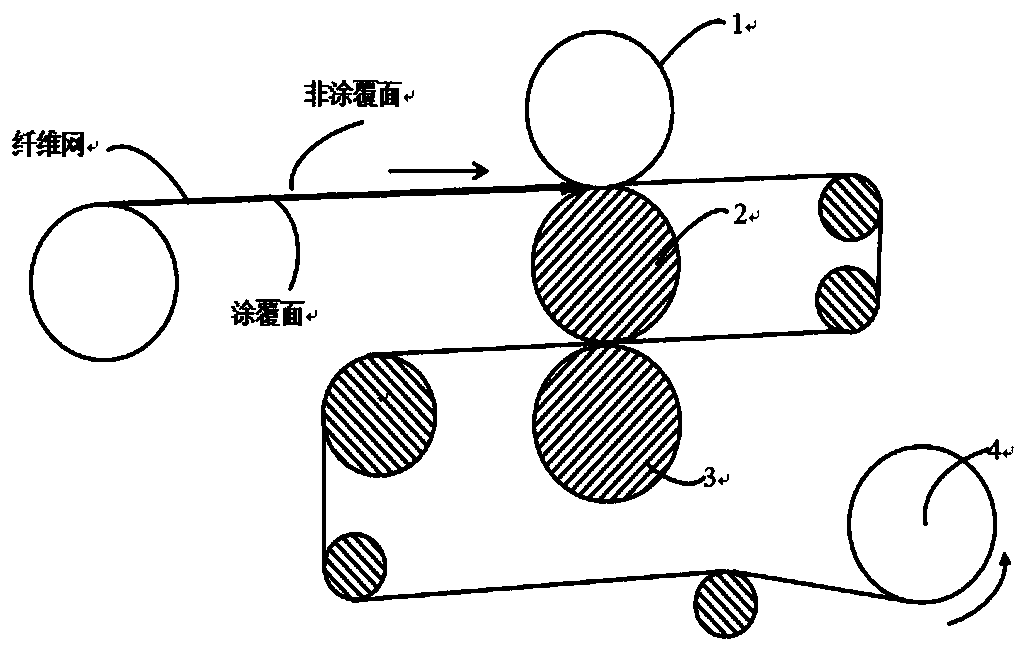

Image

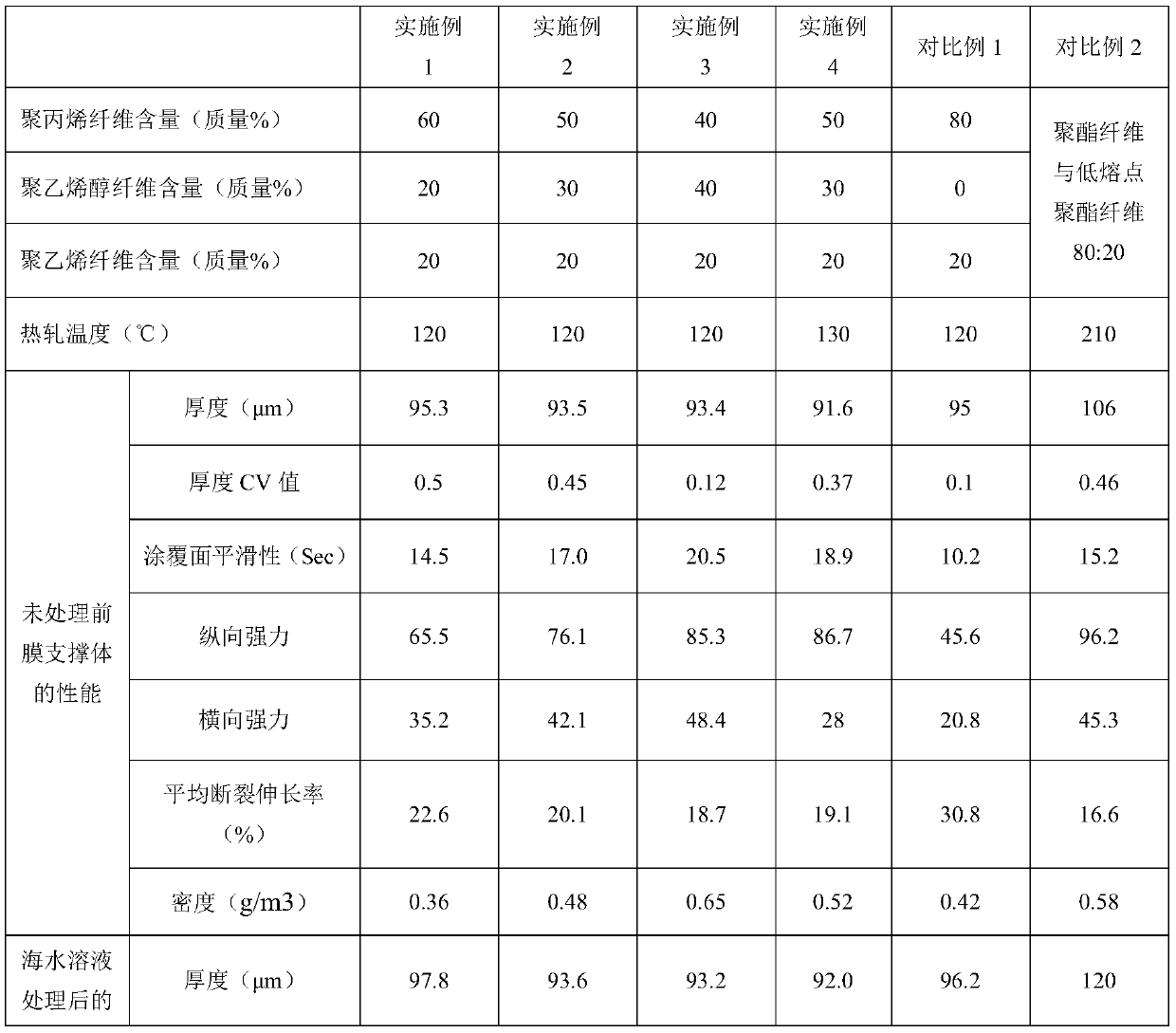

Examples

Embodiment 1

[0033] The preparation of seawater-resistant reverse osmosis membrane support mainly includes the following steps:

[0034] 1. Form a network

[0035] Mix polypropylene fibers (fiber diameter 6.5 μm, fiber length 5 mm), polyvinyl alcohol fibers (fiber diameter 7.2 μm, fiber length 5 mm), and polyethylene fibers (3.2 μm, fiber length 5 mm) at a ratio of 60:20:20 Proportionally disperse in water, control the fiber concentration to 2%, disperse for 40 minutes, put it into the slurry mixing tank, add water and polyacrylamide dispersant and stir evenly, make the concentration 0.03, the viscosity is 60 seconds, and make a slurry; the slurry passes through the inclined screen Forming machine copy forming.

[0036] 2. Dry

[0037] In order to prevent the water-containing polyvinyl alcohol fibers from dissolving during drying, the drying is carried out in two steps. First, the formed fiber web enters the drying cylinder in the first zone for dehydration. In the second zone drying zo...

Embodiment 2

[0041] Other processing procedures and processes are as described in Example 1, adjusting the ratio of polypropylene fiber, polyvinyl alcohol fiber and polyethylene fiber to 50:30:20 to prepare a seawater desalination reverse osmosis membrane support.

Embodiment 3

[0043] Other processing procedures and processes are as described in Example 1, adjusting the ratio of polypropylene fiber, polyvinyl alcohol fiber and polyethylene fiber to 40:40:20 to prepare a seawater desalination reverse osmosis membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com