Oil-containing smoke intercepting equipment

A flue gas and equipment technology, which is applied in the field of oily flue gas interception equipment, can solve the problems of increased equipment running resistance and difficulty in dust removal, and achieves the effect of avoiding frequent replacement and facilitating treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

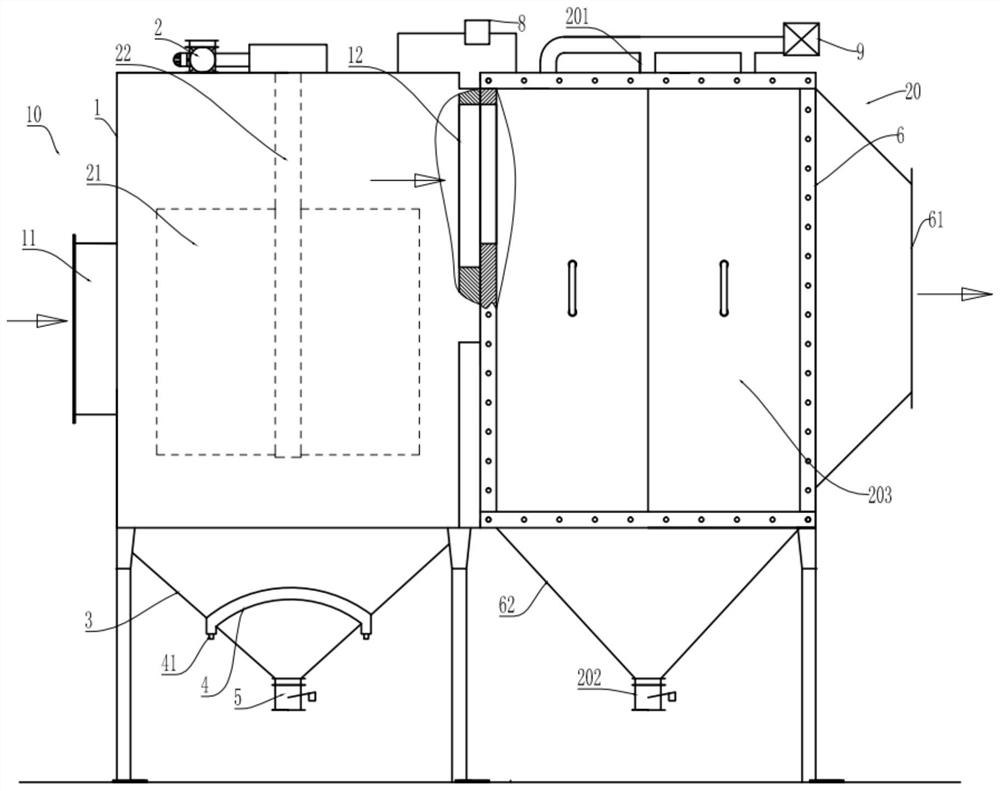

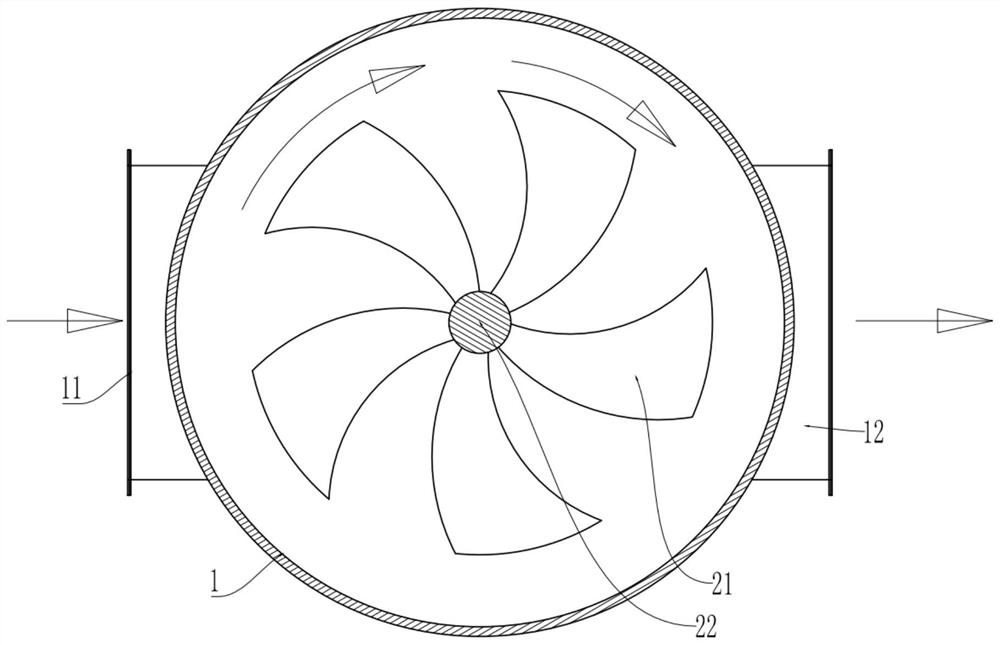

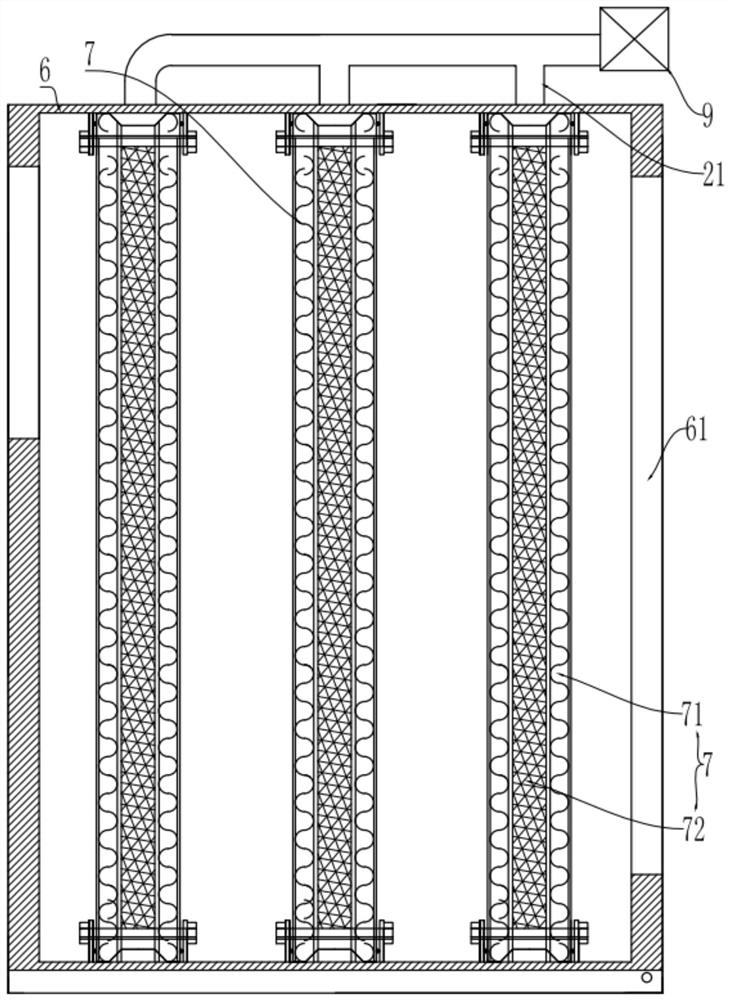

[0035] Embodiment one is basically as attached Figure 1 to Figure 3 As shown, an oily fume interception device is installed at the front end of the bag dust removal and purification equipment, and includes a fume separation unit 10 and an oil filter unit 20. Oil and gas are separated, and the output end of the oil filter unit 20 is connected to the bag dust removal and purification equipment.

[0036] The oil fume separation unit 10 includes a cylindrical separation chamber 1 and a rotator 2. The separation chamber 1 is formed with an air inlet 11 and an air outlet 12. The bottom of the cylindrical separation chamber 1 is welded with an inverted cone-shaped collection bucket 3. The collection bucket 3 An oil storage tank 4 is processed on the inner side wall of the oil storage tank 4, and an oil outlet 41 is opened on the lowest position of the oil storage tank 4, and the oil outlet 41 communicates with the outside of the separation chamber 1; the oil storage tank 4 extends o...

Embodiment 2

[0050] combine Figure 4 The difference between the second embodiment and the first embodiment is that the shape of the oil storage tank 4 of this embodiment is different, and the oil storage tank 4 of this embodiment is a spiral groove. In addition, the situation that the oil storage tank 4 is a zigzag type or a multi-curve connection type will not be elaborated one by one, but as long as the oil storage tank 4 can extend all the inner walls of the collecting bucket 3, it can be ensured that the collected oil will not flow over the oil storage tank 4 to the The bottom of the collection bucket 3 realizes the separate collection of dust and oil.

Embodiment 3

[0052] combine Figure 5 The difference between the third embodiment and the first embodiment is that the oil storage tank 4 of this embodiment is arranged at the cylindrical bottom of the separation chamber 1, and this embodiment can also realize the separate collection of oil and dust falling into the collection bucket 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com