Long-stroke heavy drag chain operating device

A technology with a running device and a long stroke, applied in the field of drag chains, can solve the problems of high maintenance cost, short service life, easy arching of the bearing bracket, etc., and achieve the effect of reducing maintenance and replacement costs, quick and convenient maintenance, and reducing driving force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

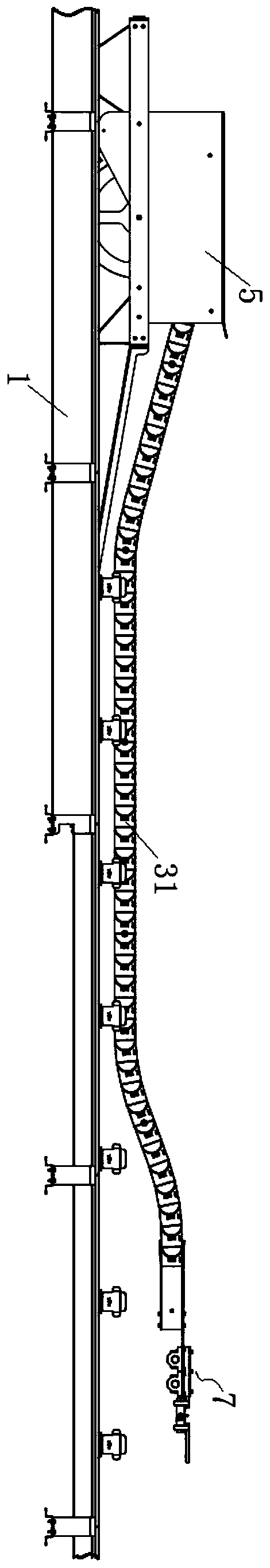

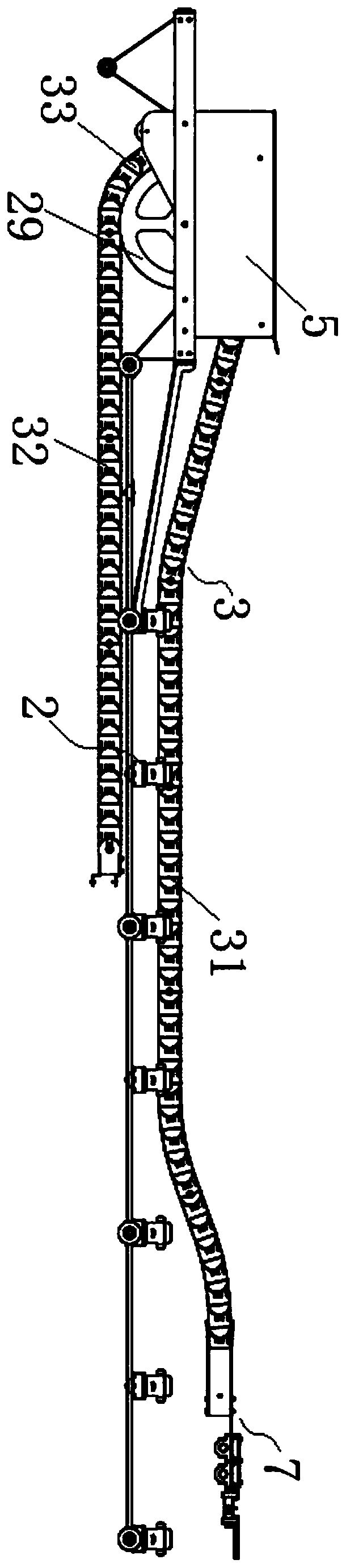

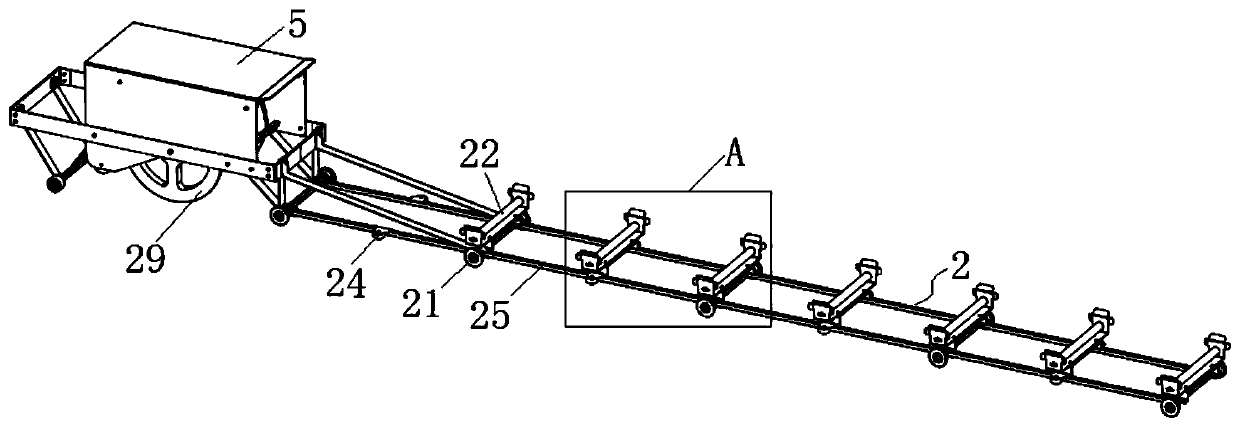

[0058] This embodiment provides a long-stroke heavy drag chain running device, such as figure 1 with 2 As shown, it is suitable for supporting and driving the drag chain 3 to reciprocate. The drag chain 3 includes an upper segment 31 of the drag chain, a steering ring segment 33 of the drag chain and a lower segment 32 of the drag chain, and the long-stroke heavy drag chain running device includes guide rails 1, Supporting wheel support 2 and driving mechanism.

[0059] Rail 1, such as Figure 13 As shown, it includes a first guide groove 11 for the rolling fit of the first support roller 21 and a second guide groove 12 for the rolling fit of the third support roller 29 .

[0060] The support roller bracket 2 is arranged between the upper section 31 of the drag chain and the lower section 32 of the drag chain, and includes a support roller assembly, a connecting rod 25 , a third support roller 29 and a fourth support roller 63 .

[0061] Such as Figure 4-6 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com