Gantry assembly for electric fork lift truck

A technology of electric stacker and mast, which is applied in the direction of lifting device, etc., which can solve the problems of cargo detaching from the fork, easy to fall, and non-adjustable, so as to prevent derailment and broken chain, not easy to fall, and improve the performance of the forklift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

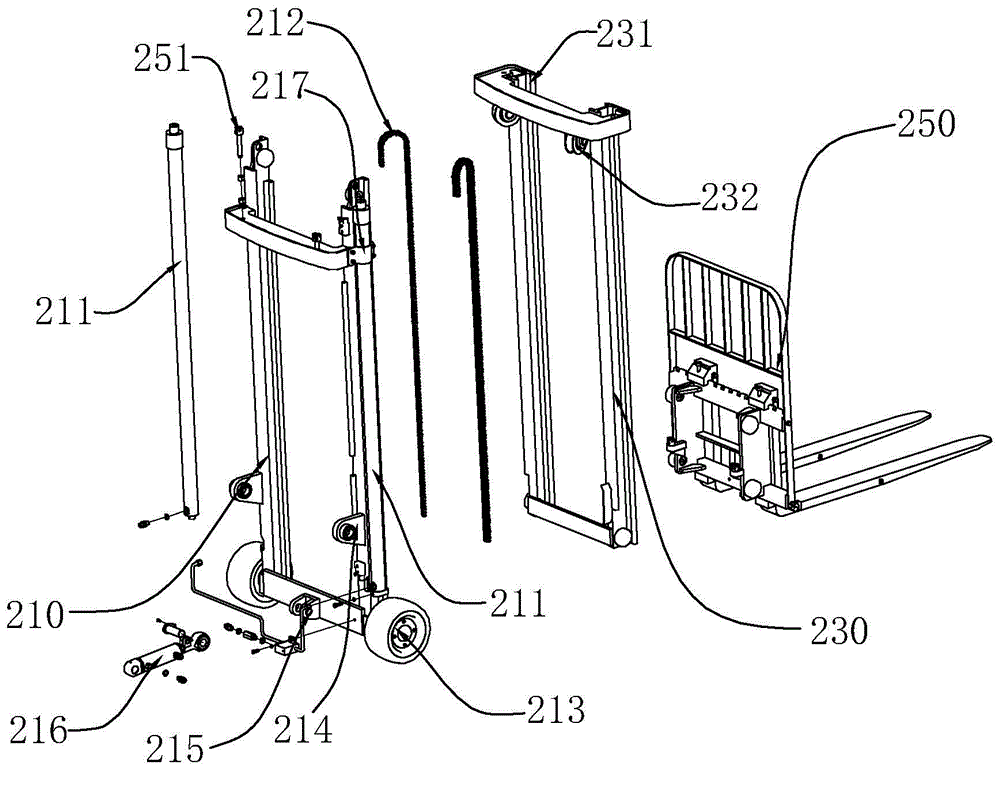

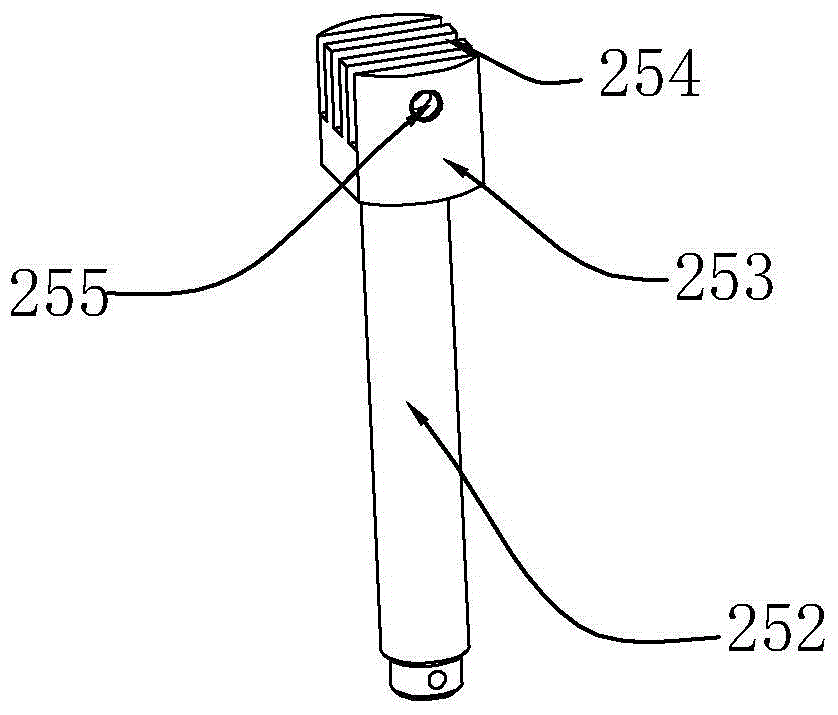

[0011] Such as Figure 1 ~ Figure 2 The mast assembly of an electric stacker shown includes an outer mast 210, an inner mast 230, and a fork frame 250. The outer mast 210 is connected to the front end of the vehicle body. Specifically, the outer mast 210 is two Two bearing seats 214 are arranged at the same height on the side, and a bearing rod is arranged between the two bearing seats 214, and the outer door frame 210 is hinged with the front end of the vehicle body through the bearing rod; the middle position of the lower end of the outer door frame 210 is provided with A hinged seat 215, on which a tilting oil cylinder 216 is hinged, and the other end of the tilting oil cylinder 216 is fixed on the front end of the vehicle body. The outer mast 210 is hinged to the front end of the vehicle body through a bearing rod, and a til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com