Transformer or reactor oil temperature detection and simulation device

An oil temperature detection and simulation device technology, which is applied to measurement devices, thermometers using electrical devices, and thermometers that are directly sensitive to heat, can solve problems such as inability to accurately check data, difficulty in troubleshooting, and inconvenience. Achieve obvious safety benefits, eliminate defects, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

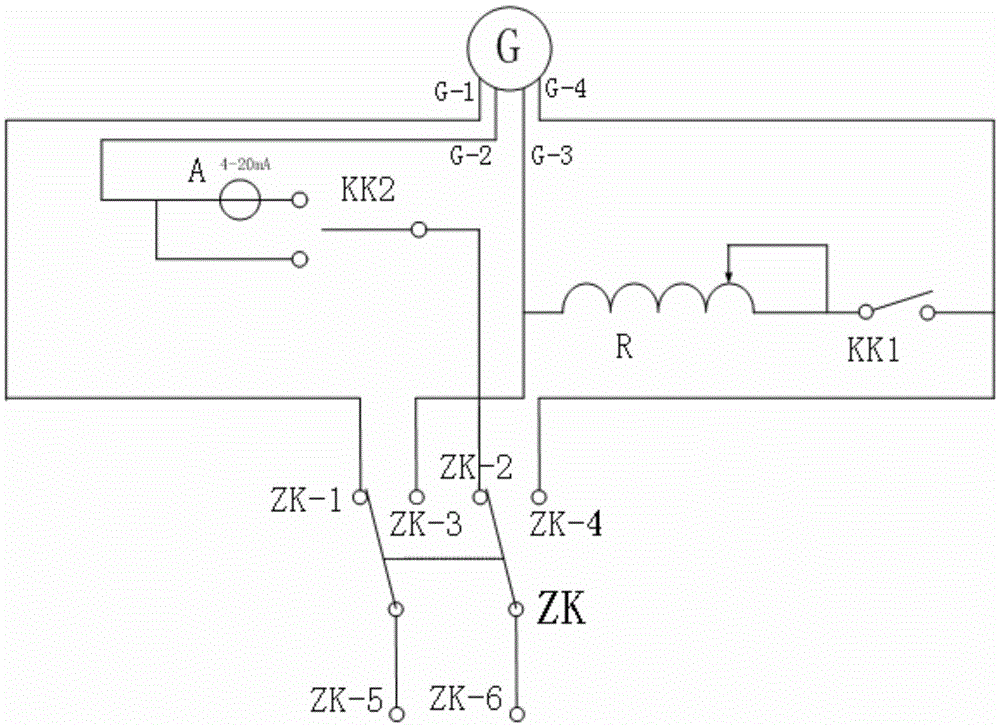

[0009] Such as figure 1 As shown, the present invention is a transformer or reactor oil temperature detection and simulation device, including a multi-function meter G, the first detection terminal G-1 and the third detection terminal G-3 of the multi-function meter G are sequentially converted into functions The first output terminal ZK-1 of the switch ZK is connected to the third output terminal ZK-3, and the second detection terminal G-2 and the fourth detection terminal G-4 of the multi-function meter G are sequentially connected to the first output terminal of the function changeover switch ZK. The second output terminal ZK-2 is connected to the fourth output terminal ZK-4, while the first input terminal ZK-5 and the second input terminal ZK-6 of the function changeover switch ZK are floating.

[0010] Among them, an adjustable resistance R is connected in parallel between the third detection terminal G-3 and the fourth detection terminal G-4 of the multi-function meter G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com