Live-working drainage wire bracket

A technology for live operation and drainage lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of distance not meeting the safety distance, personal equipment safety threats, and no control, etc., to increase electricity sales, significant safety benefits, and reduce power outages effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

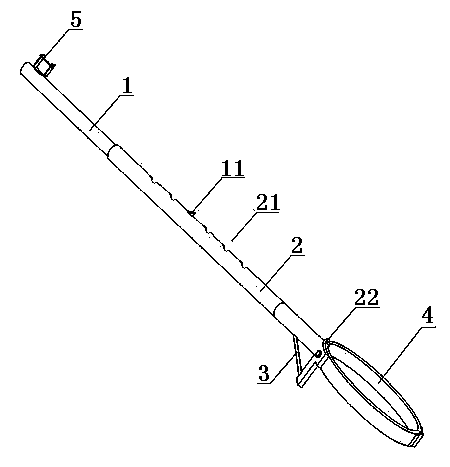

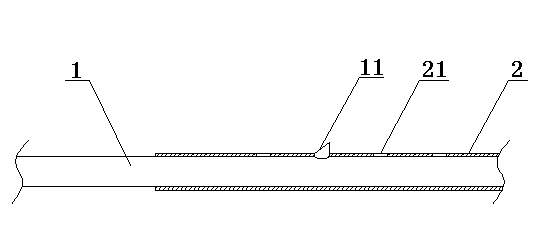

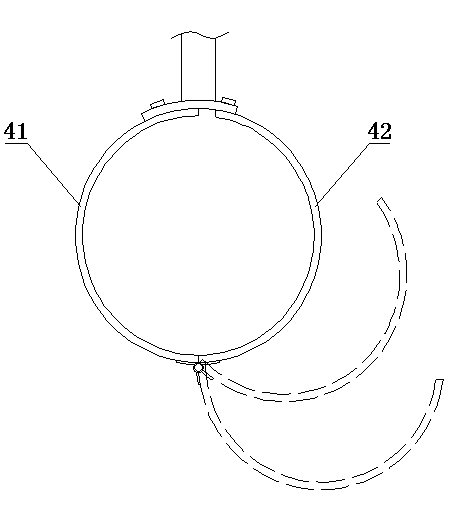

[0012] As shown in Figures 1 and 2, a live work drainage wire support includes a movable rod 1 and a sleeve 2, the movable rod 1 is placed in the sleeve 2, and the feature is that the sleeve 2 A number of through holes 21 are evenly arranged on the top, and the rear end of the casing 2 is connected to the fixing device 4 through a T-shaped plate 22; the movable rod 1 is provided with an elastic pin 11 adapted to the through hole 21, and the There is a fixed clip 5 at the end; when carrying out the drainage line bypass live operation method, the movable rod 1 is moved to a certain length, so that the elastic pin 11 pops out of the corresponding through hole 21, and the length is fixed. When the length needs to be adjusted, press the elastic Pin 11 is sufficient, and finally the drainage wire is passed through the fixing clip 5 at the end of the movable rod 1 to fix it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com