Coal chute with air-returning preventing device

A coal falling pipe and anti-return technology, which is applied in the field of coal falling pipe, can solve problems such as unstable water level of the steam drum or separator, frequent coal cutoff, unplanned shutdown of the unit, etc. Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

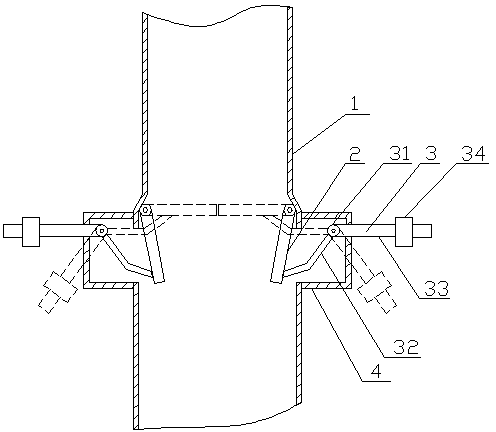

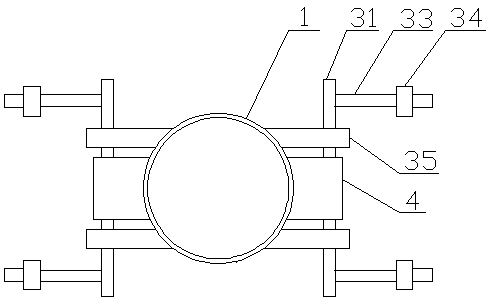

[0011] Such as figure 1 and figure 2 As shown, a coal falling pipe with an anti-return device, the coal falling pipe 1 is provided with a baffle group, a weight mechanism 3 and a sealing chamber 4, and the baffle group is composed of at least one baffle 2, The baffle plate 2 is hinged on the inner wall of the coal falling pipe 1, the sealing chamber 4 is arranged on the outer wall of the coal falling pipe 1, and communicates with the inside of the coal falling pipe 1 through the opening provided on the wall of the coal falling pipe 1, and the weight mechanism 3 includes a rotating shaft 31, a connecting rod 32 fixed in the middle of the rotating shaft 31, and two balance arms 33 fixed at both ends of the rotating shaft 31. A weight 34 is arranged on the balancing arm 33. The rotating shaft 31 is arranged in the sealed chamber 4. The rotating shaft 31 The two ends stretch out the sealing chamber 4, and are fixed on the outer wall of the coal drop pipe 1 by the bearing bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com