Washing method of power station boiler temperature reducing water system and washing pipeline connection structure

A technology for power station boilers and desuperheating water, which is applied to boiler cleaning devices and other directions, can solve problems such as increasing boiler combustion time, increasing coal consumption, and deteriorating steam quality, and achieves the effect of ensuring flushing effect, simple operation mode, and good safety benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

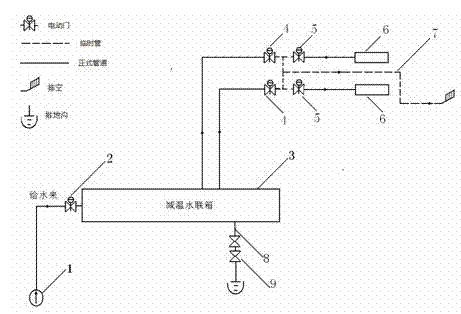

[0018] Embodiment of the present invention: the main components of the power station boiler desuperheating water system are: feed water pump 1, desuperheating water main pipe electric door 2, desuperheating water header 3, first electric door 4, second electric door 5, desuperheater 6, Cooling water header drain pipe 8 and drain manual door 9. The premise of the realization of the present invention is to first add a temporary connecting pipe on the desuperheating water system of the power station boiler. The temporary connecting pipe 7 is located between the first electric door 4 and the second electric door 5. The diameter of the warm water pipeline; the first electric door 4 and the second electric door 5 are located on the desuperheating water pipeline connecting the desuperheating water header 3 and the desuperheater 6; after the temporary connecting pipe 7 is installed, the power station boiler can be realized according to the following steps Flushing of the desuperheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com