Patents

Literature

172results about How to "Guaranteed flushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

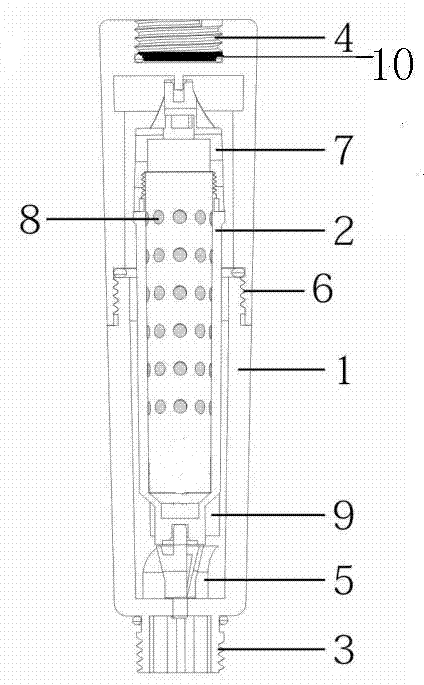

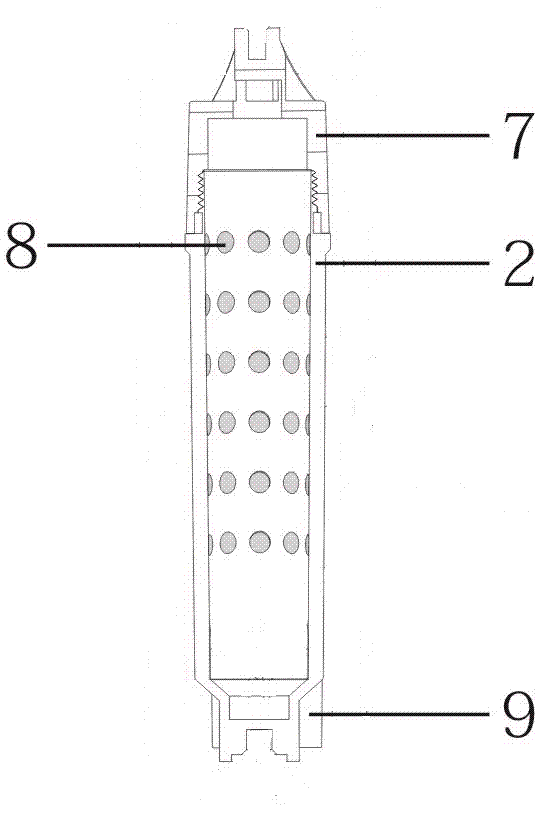

Hydraulic reversing mechanism

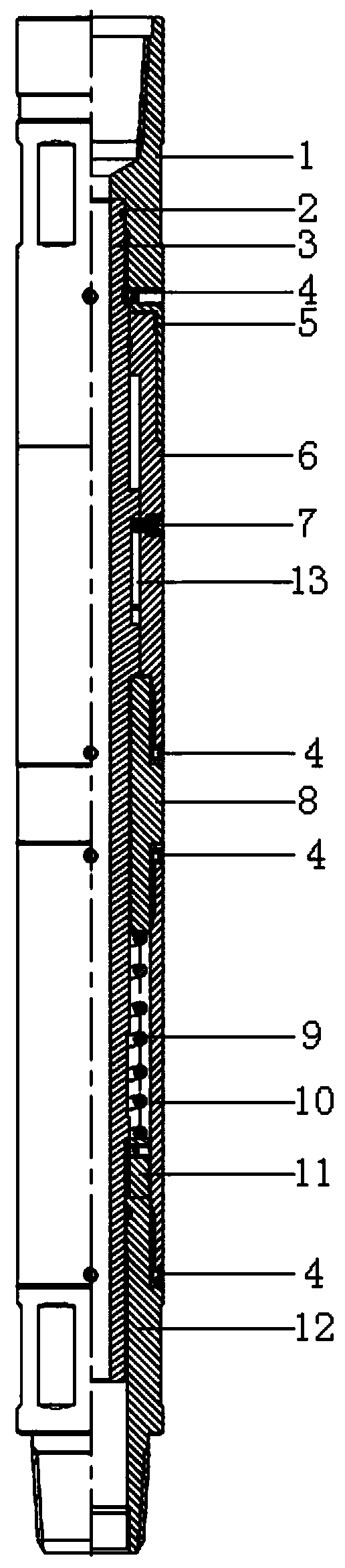

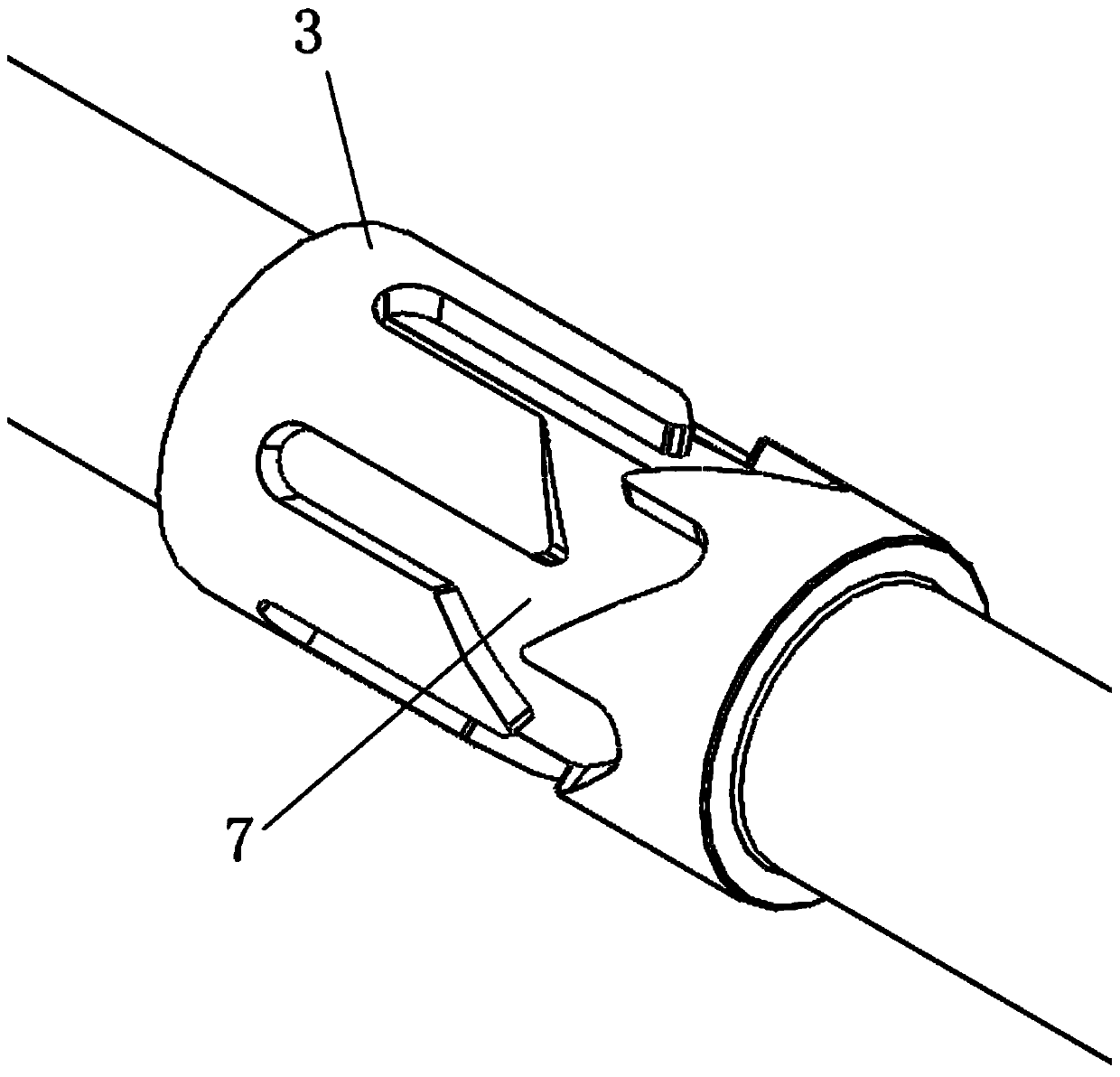

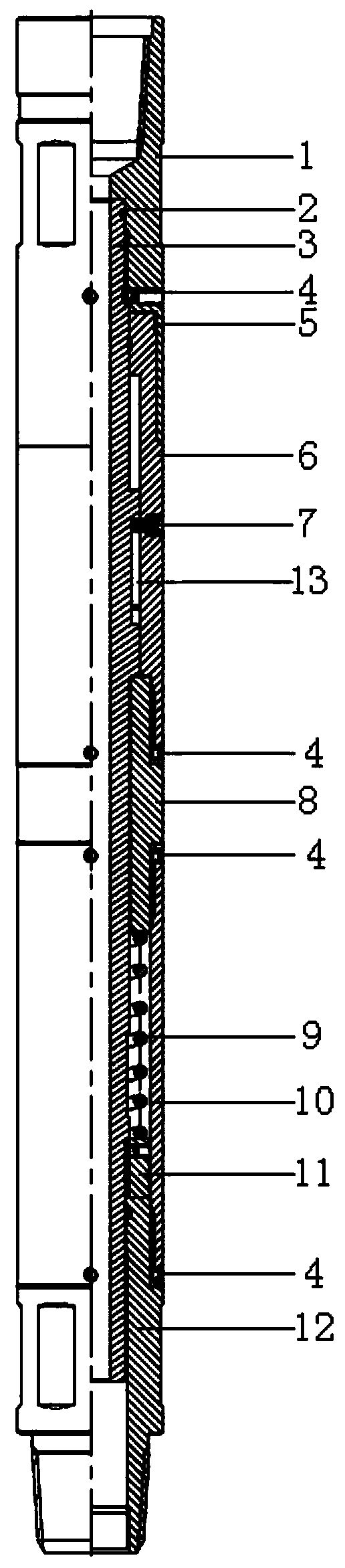

PendingCN111167769ASimple structureAchieve Rotary JettingFlushingCleaning using liquidsUpper jointEngineering

The invention discloses a hydraulic reversing mechanism. The hydraulic reversing mechanism comprises an upper joint, a center shaft, a guide ring, an upper shell, a guide pin, a connection nipple, a compression spring, a lower shell, a limiting sleeve and a lower joint, wherein the upper joint is connected with the center shaft, the guide ring is arranged between the upper joint and the upper shell, and the upper shell, the connection nipple, the lower shell and the lower joint can be slidably arranged on the outer side of the center shaft. The guide pin is arranged on the upper shell, a guidegroove is formed in the portion, corresponding to the guide pin, of the center shaft, the guide pin can rotate in the guide groove, a compression cavity is defined by the connection nipple, the lowershell, the lower joint and the center shaft, and the compression spring and the limiting sleeve are arranged in the compression cavity. The hydraulic reversing mechanism has the benefits that the hydraulic reversing mechanism can be used for rotational reversing of a sand washing tool, the washing operation is more sufficient, no atomization is generated, and the washing capacity is ensured. According to the hydraulic reversing mechanism, reversing is achieved under the hydraulic action, the structure is simple, and convenience is brought to installation, disassembly and maintenance. The large-discharge-capacity cleaning work can be met, and rotary jetting to the washing tool can be achieved.

Owner:JEREH ENERGY SERVICES

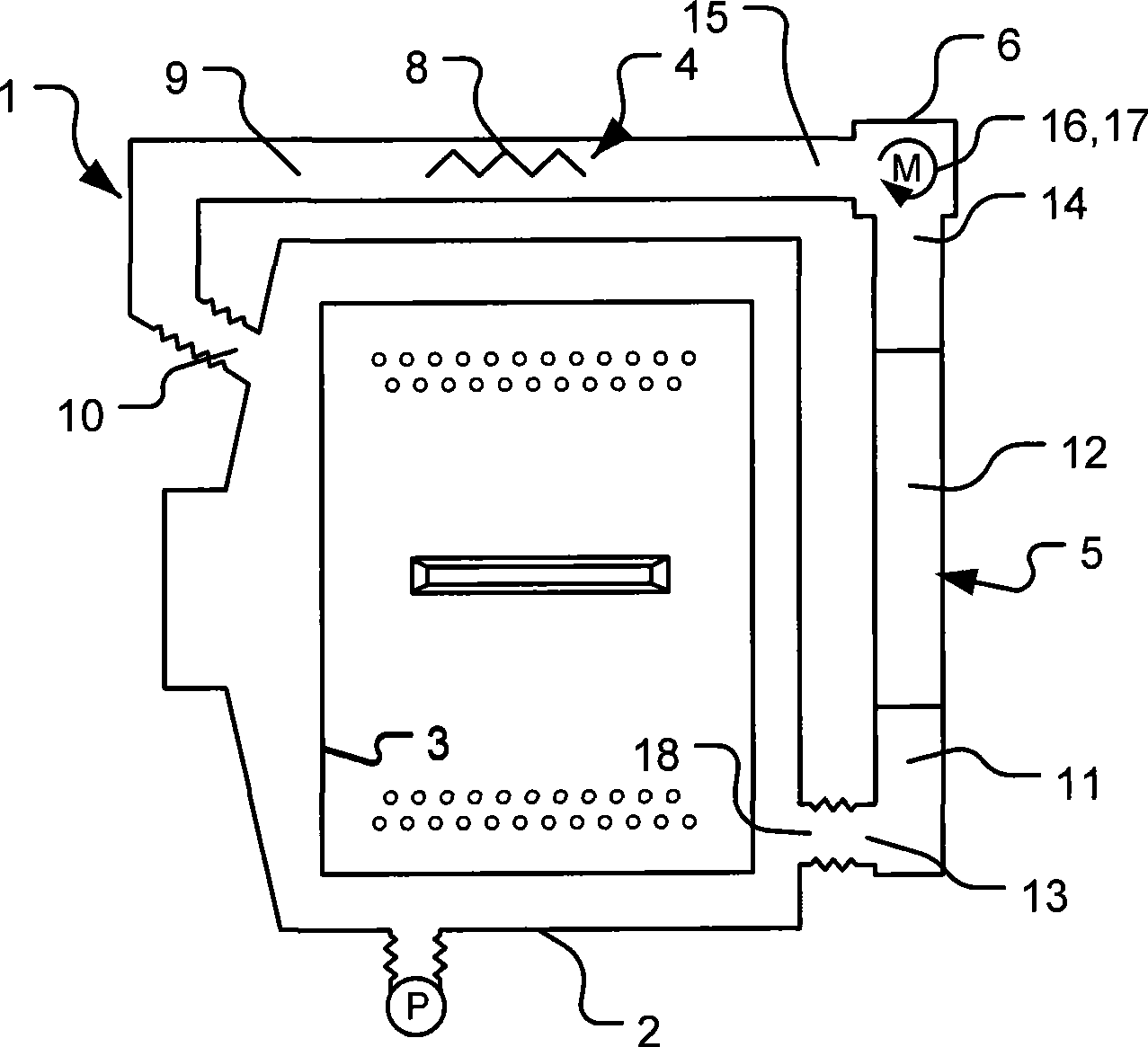

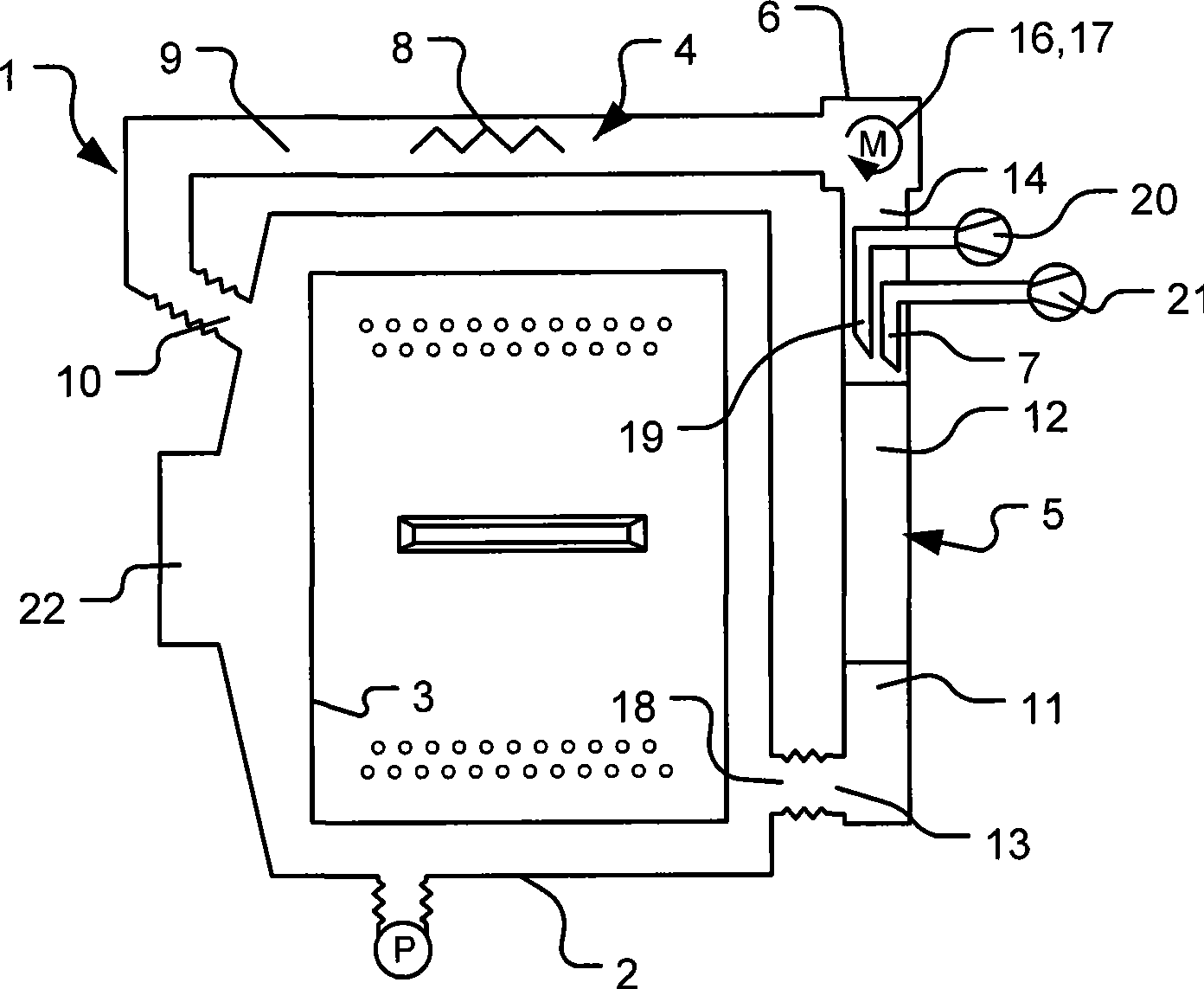

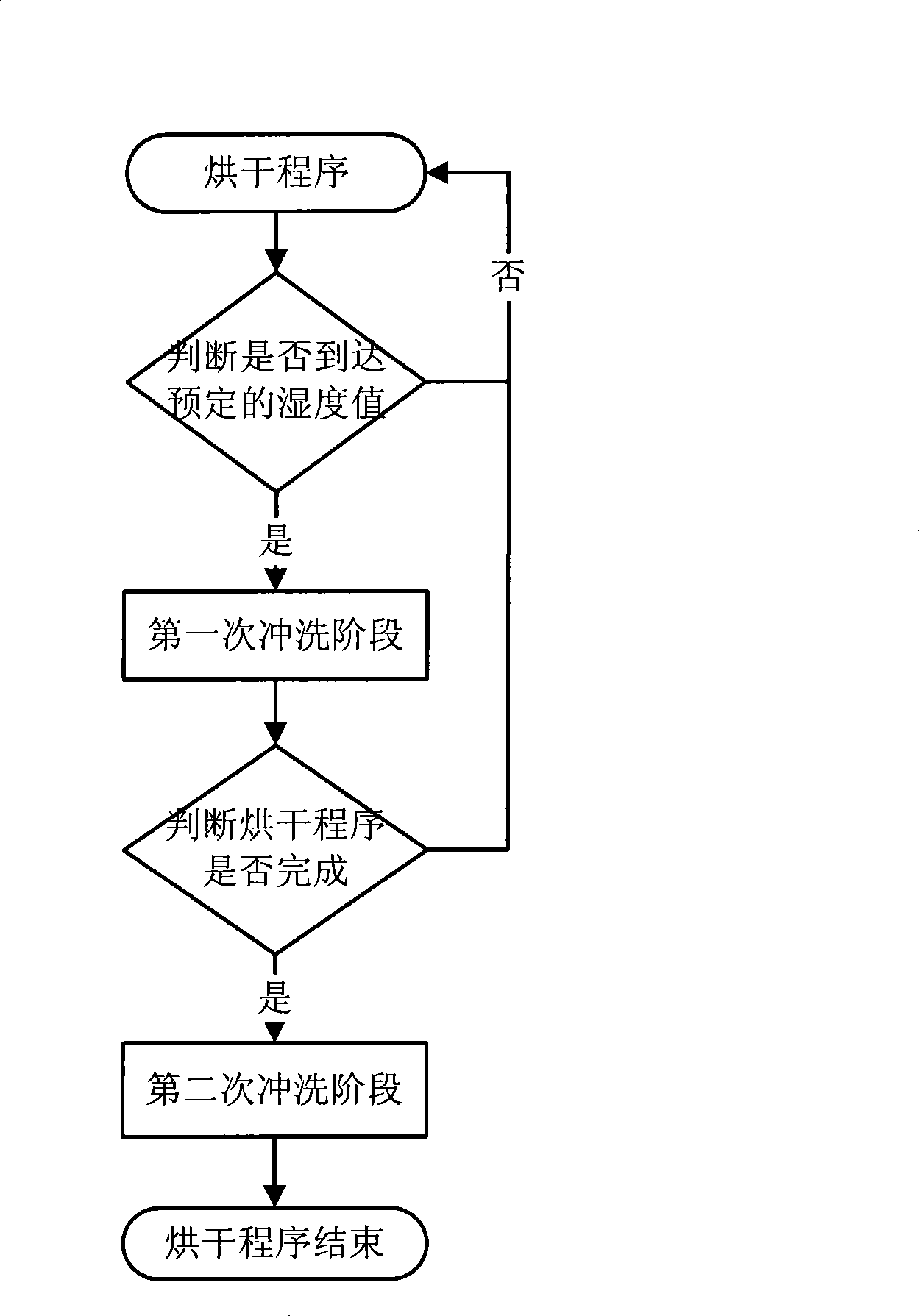

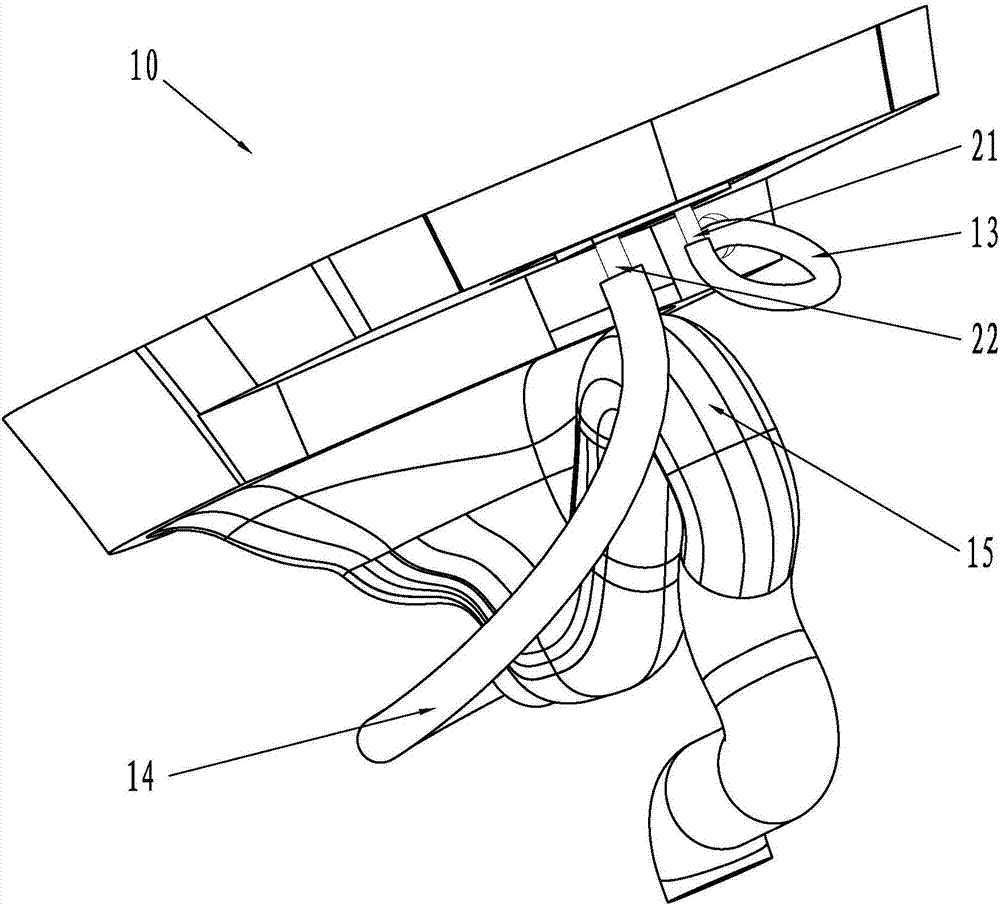

Clothing washing facility with drying program and control method thereof

ActiveCN101387059AGuaranteed flushing effectOther washing machinesControl devices for washing apparatusAir cycleWaste management

The invention provides clothes washing equipment with a drying program and a control method thereof. The clothes washing equipment comprises a water drum, a rotary drum arranged in the water drum and capable of rotating, a heating component capable of heating air into dry hot air, a condensation component capable of condensing water in the humid hot air and an air blowing device capable of driving the air circulation, wherein an air circulation loop is formed among the heating component, the water drum, the rotary drum, the condensation component and the air blowing device; and a spraying device used to wash out threads accumulated on the condensation component is arranged between the condensation component and the air blowing device. By the spraying device, water is sprayed on the condensation component from the top down, thereby washing out the threads accumulated on the condensation component.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

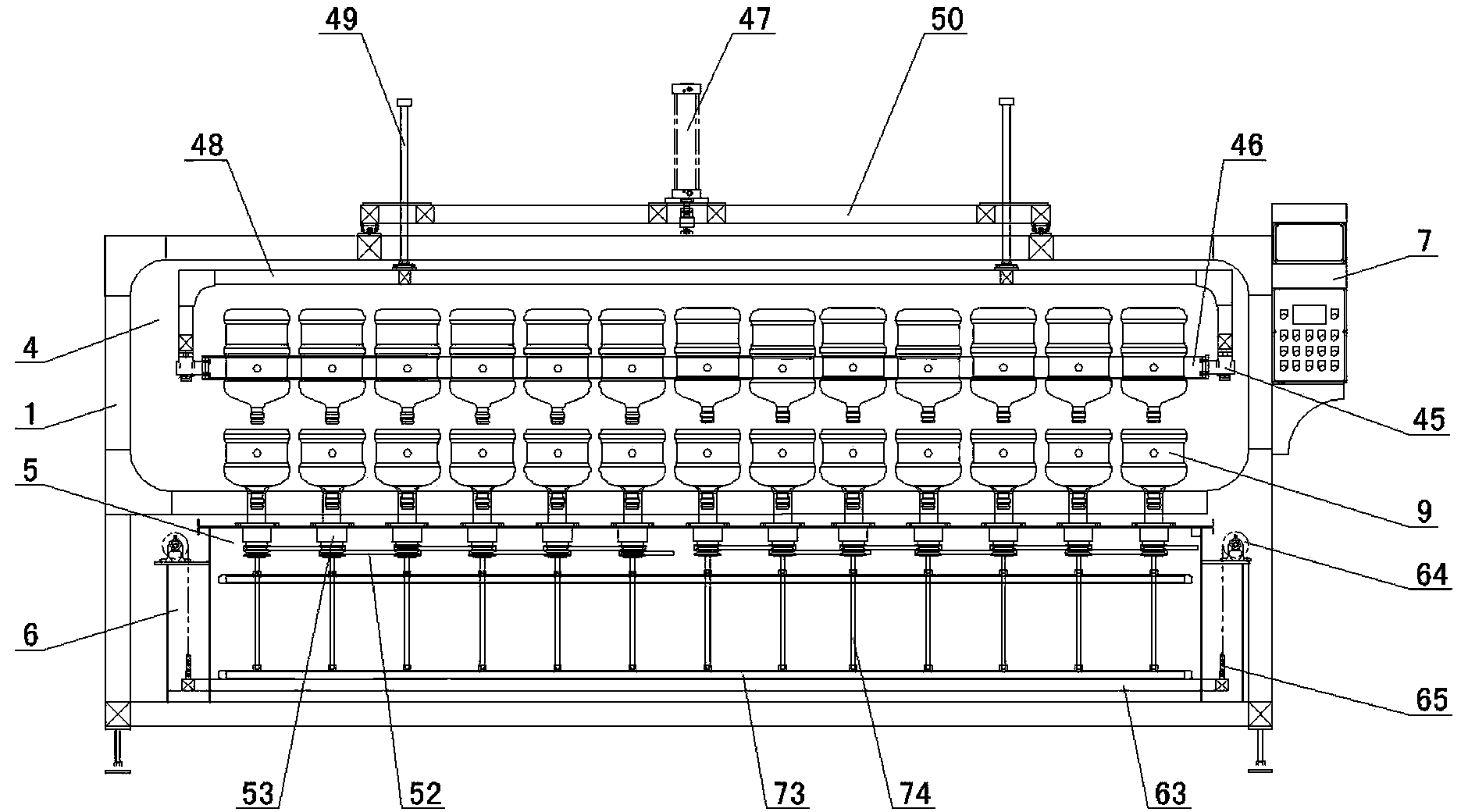

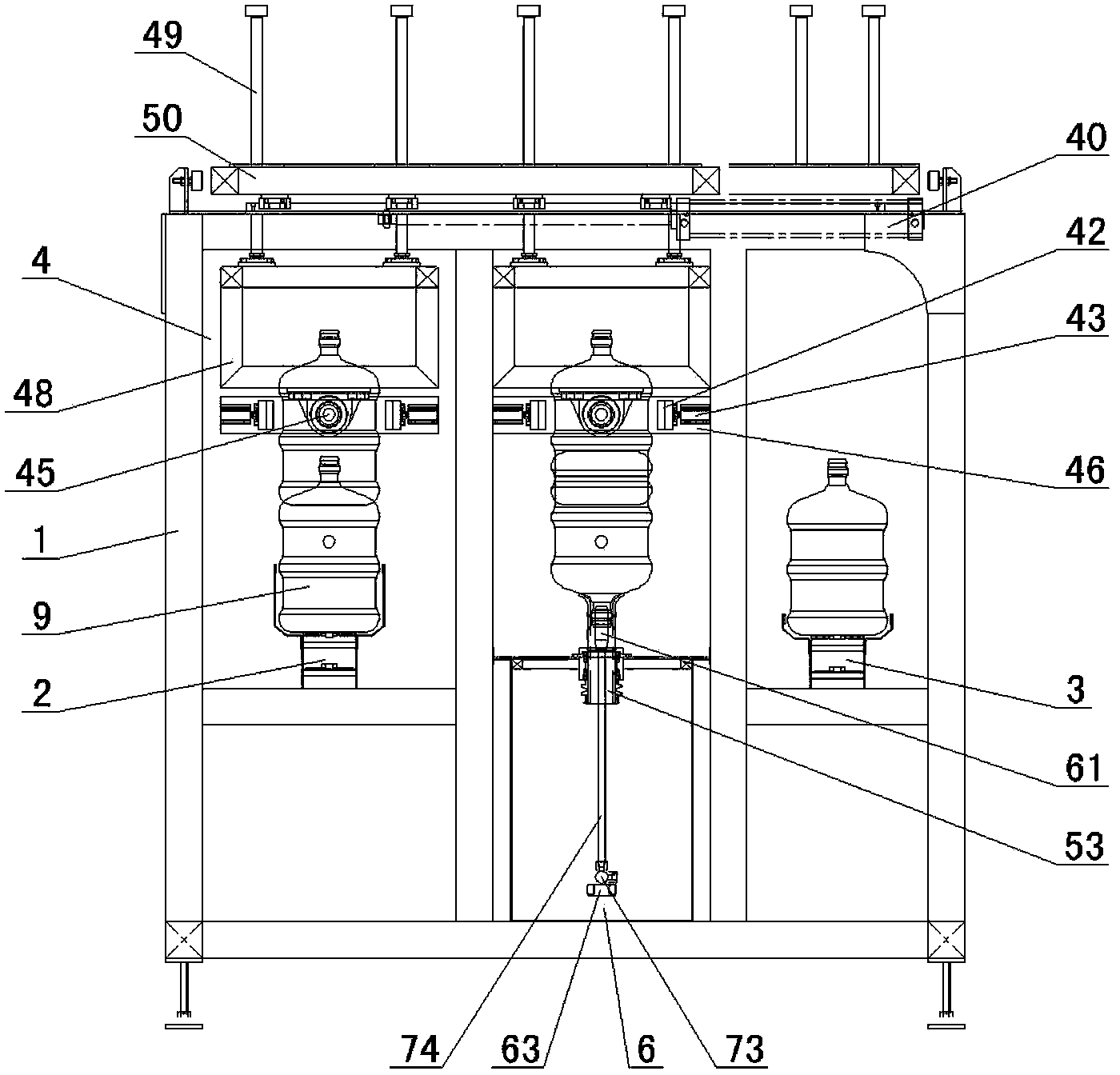

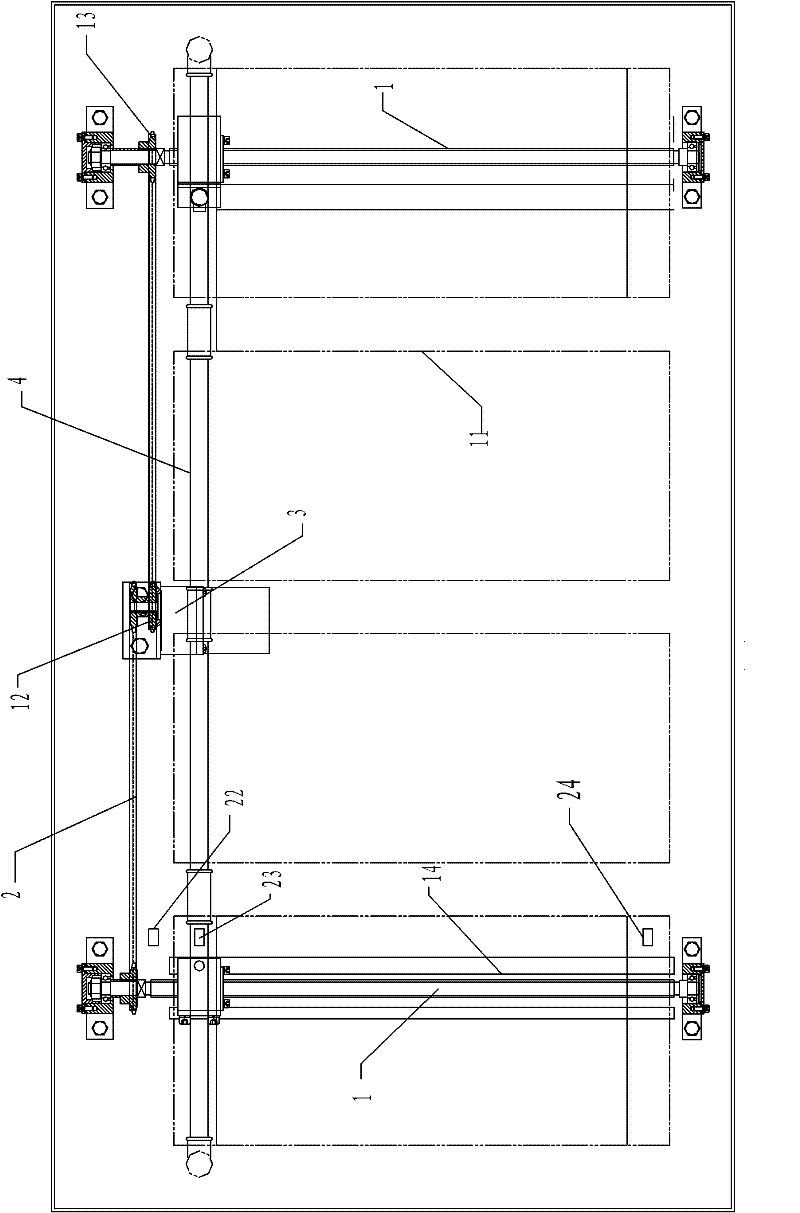

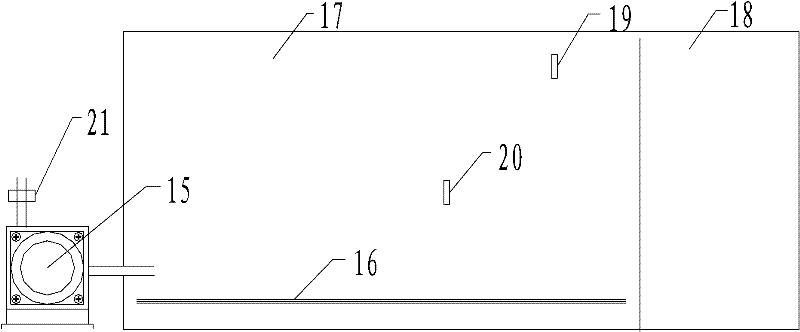

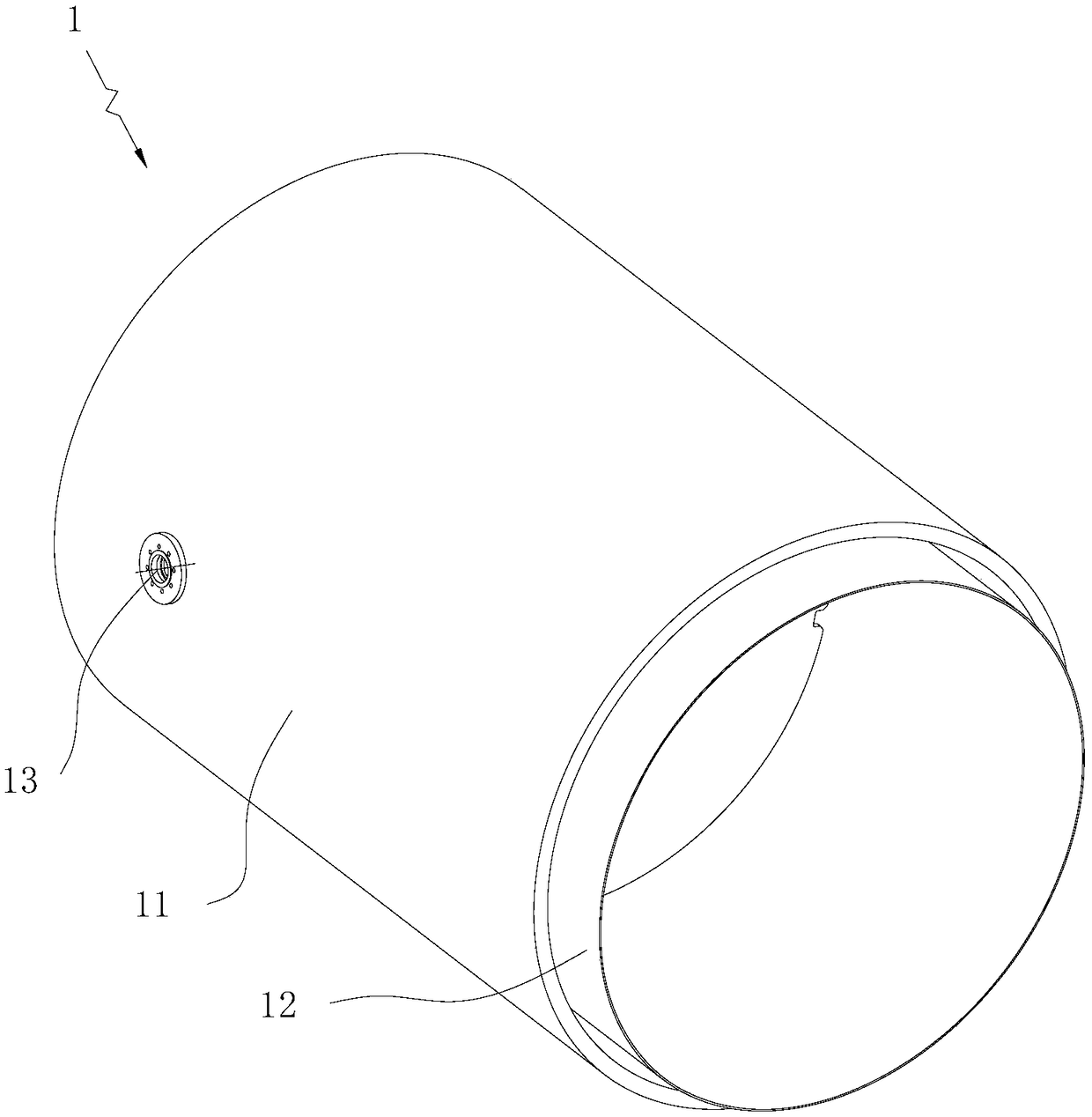

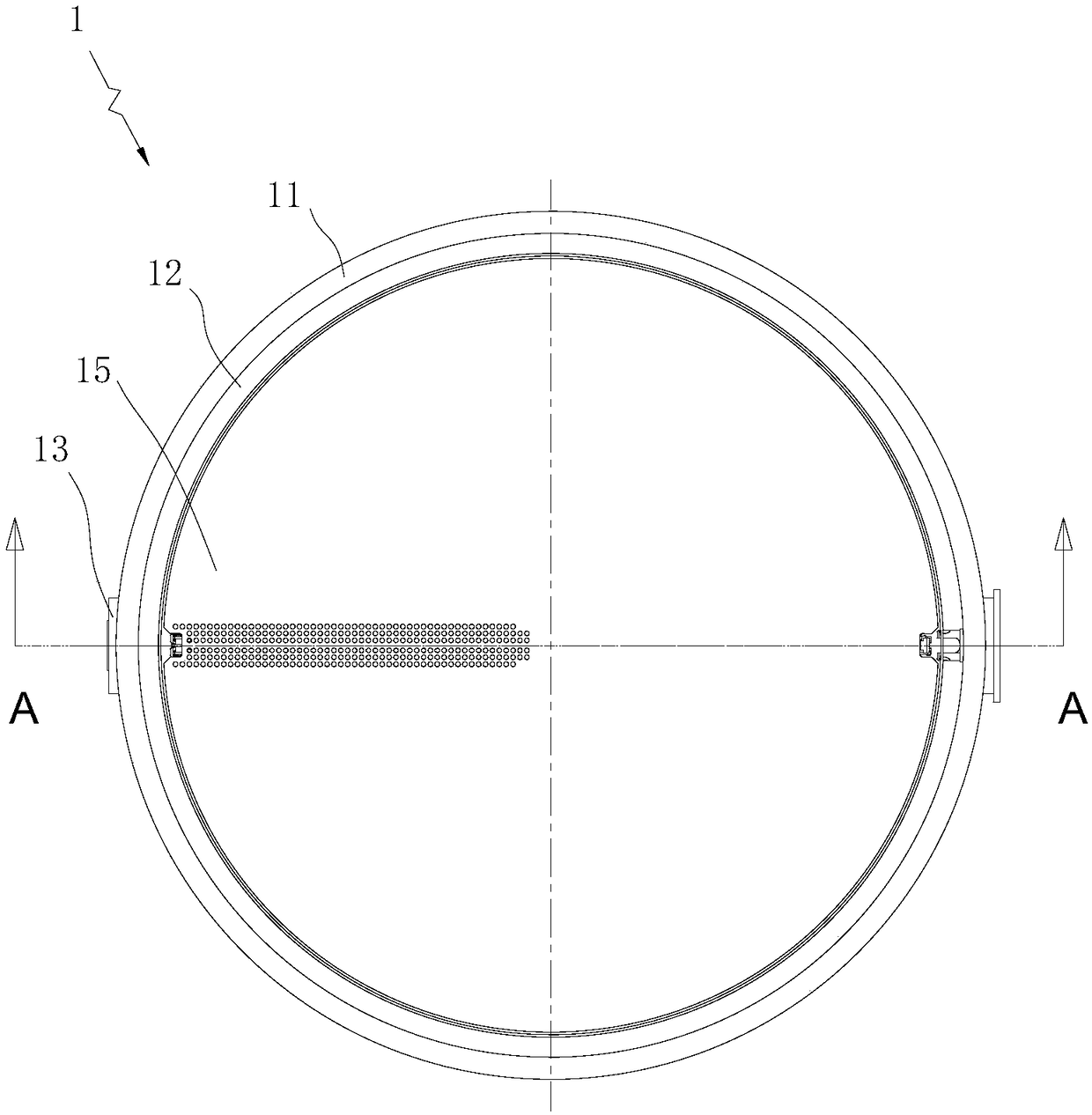

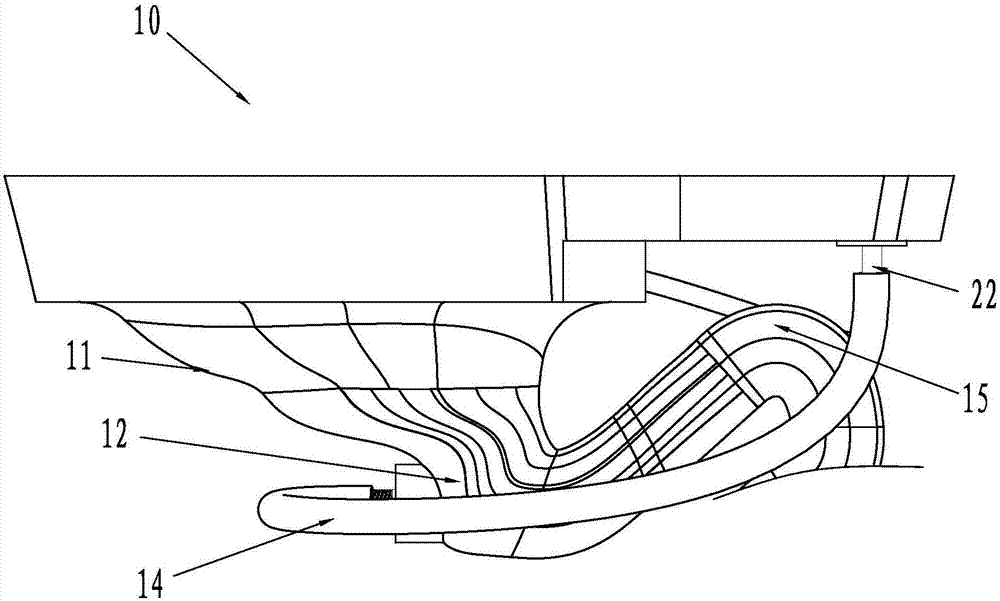

Machine for cleaning inner wall of barrel

ActiveCN103357629AGuaranteed cleaning qualityWork lessHollow article cleaningSpray nozzleEngineering

A machine for cleaning the inner wall of a barrel comprises a machine frame, a barrel inlet conveying chain, a barrel outlet conveying chain, a barrel clamping device, a barrel fixing rotary device, a high-pressure cleaning device and an operation control box, wherein the high-pressure cleaning device comprises a cleaning solution feeding device, a jet head and a pneumatic vertical lifting mechanism; the jet head is communicated with the cleaning solution feeding device through a liquid transport tube; the pneumatic vertical lifting mechanism is mounted on the machine frame and used for driving the jet head to move up and down vertically; at least three nozzles, which form different angles with the horizontal plane, are arranged on the jet head. According to the machine, the inner wall of the barrel of barreled water can be cleaned in an up-down 360 degrees' rotating isopiestic pressure cutting manner, so that each part of the inner wall of the barrel can be cleaned with high-pressure water proportionably, the effect of flushing the inner wall of the barrel completely is achieved effectively, the cleaning quality of the inner wall of the barrel is guaranteed, and the service life of the jet head is prolonged. The machine has the advantages that the structure is reliable; the running is stable; the cleaning efficiency is high; occupied production space is less; the labor cost, manufacture cost and running cost are low.

Owner:广东鼎湖山泉有限公司

Method for manufacturing spinel composite monoblock stopper for continuous casting of low-carbon free-cutting steel

The invention provides a method for manufacturing a spinel composite monoblock stopper for the continuous casting of low-carbon free-cutting steel, belonging to the field of a novel refractory material for continuous casting. The body of the monoblock stopper is made from an alumina-carbon material, the head of the monoblock stopper is made from spinel composite material, and the part between the body and head of the monoblock stopper is made from the mixed transitional material of the alumina-carbon material and the spinel composite material. The main raw material of the head of the monoblock stopper is fused spinel, and the auxiliary raw material comprises 2-6 percent of aluminum-silicon alloy powder, 2-5 percent of activated alumina micropowder and 5-9 percent of graphite. In the invention, the content of the graphite in the spinel composite material is reduced, and the aluminum-silicon alloy powder which can promote the resintering of the material in situ in the heat treatment process and the activated alumina micropowder which can form in-situ spinel in the heat treatment process are added to the spinel composite material to improve the compactness and strength of the material of the head of the monoblock stopper and ensure the hot molten steel erosion resistance of the material of the head of the monoblock stopper during use.

Owner:北京利尔高温材料股份有限公司 +2

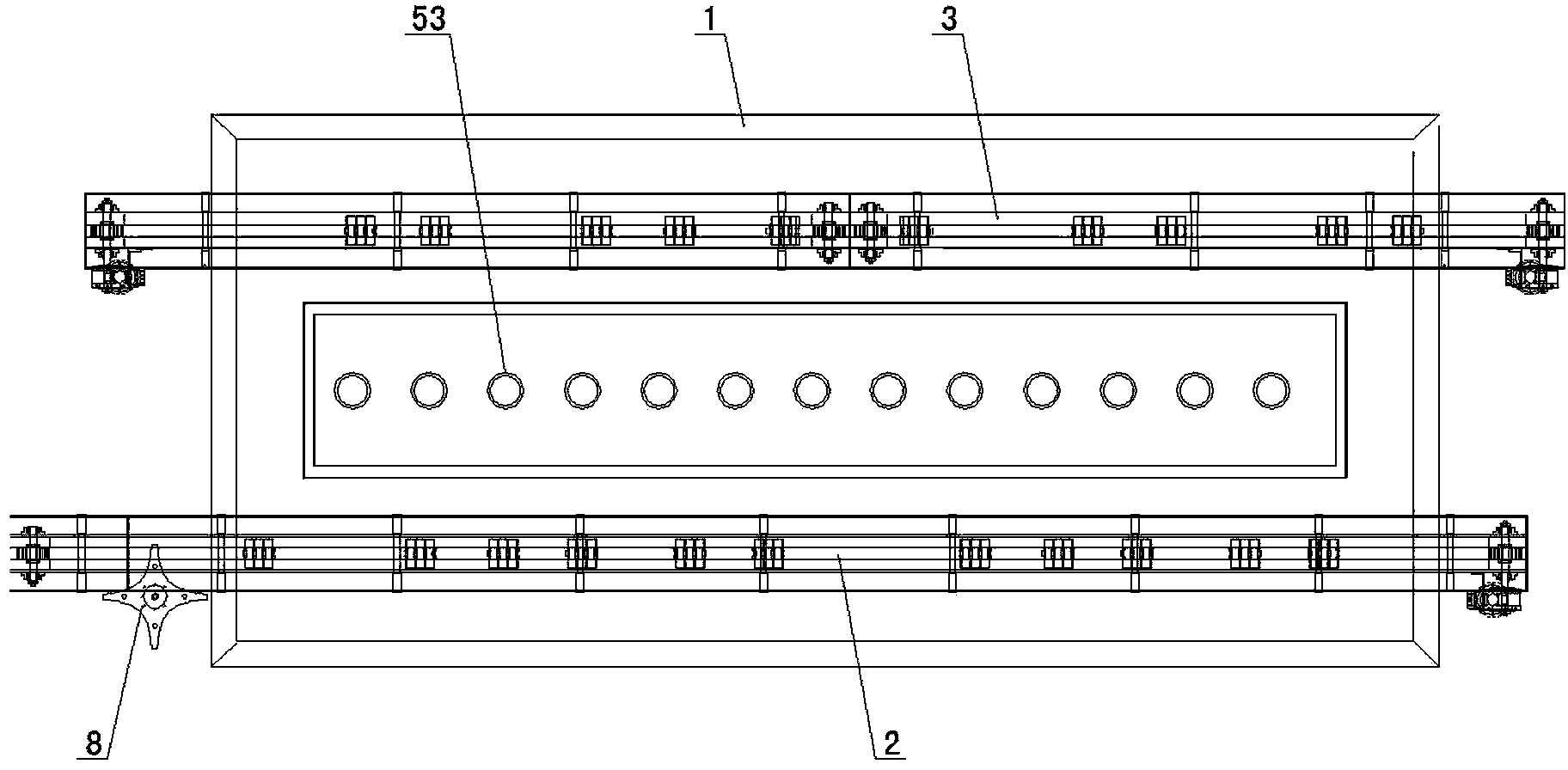

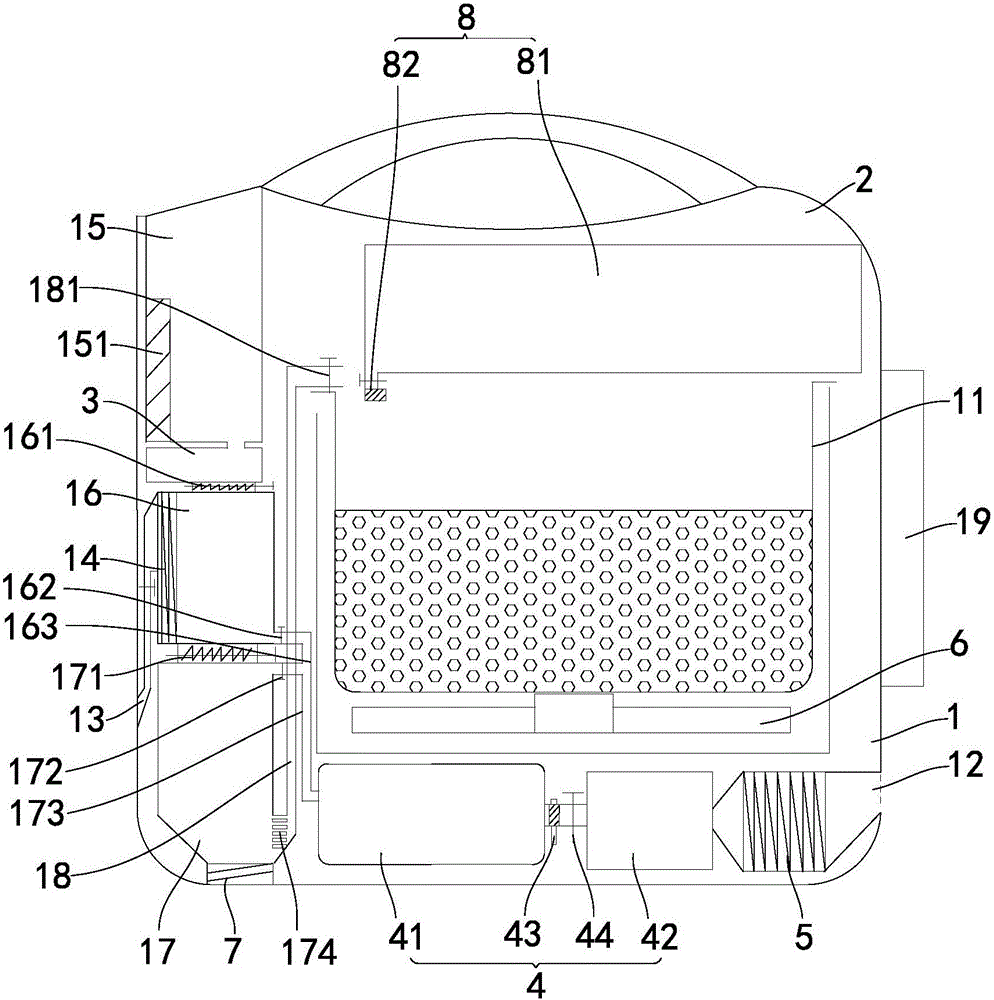

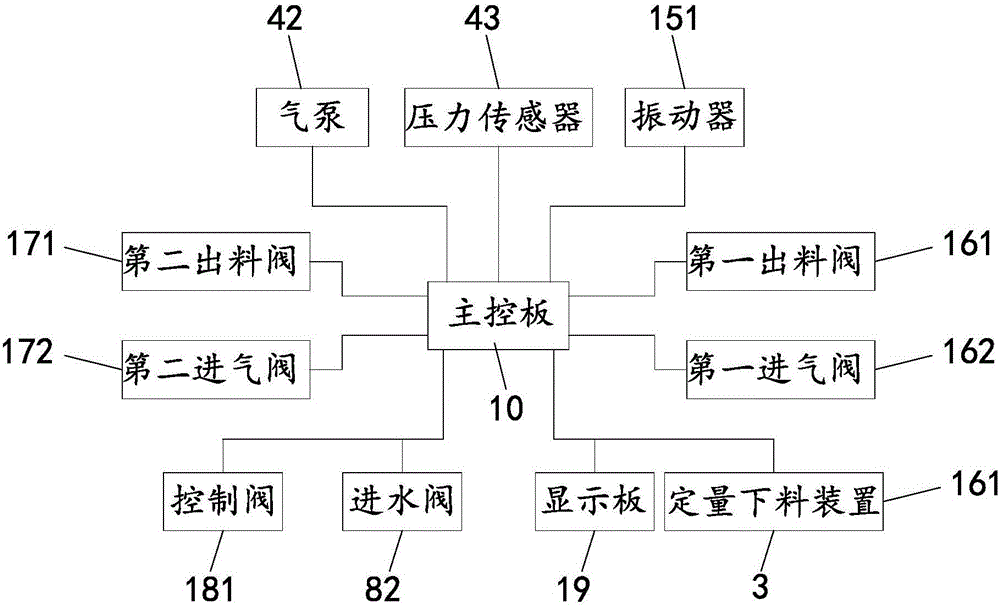

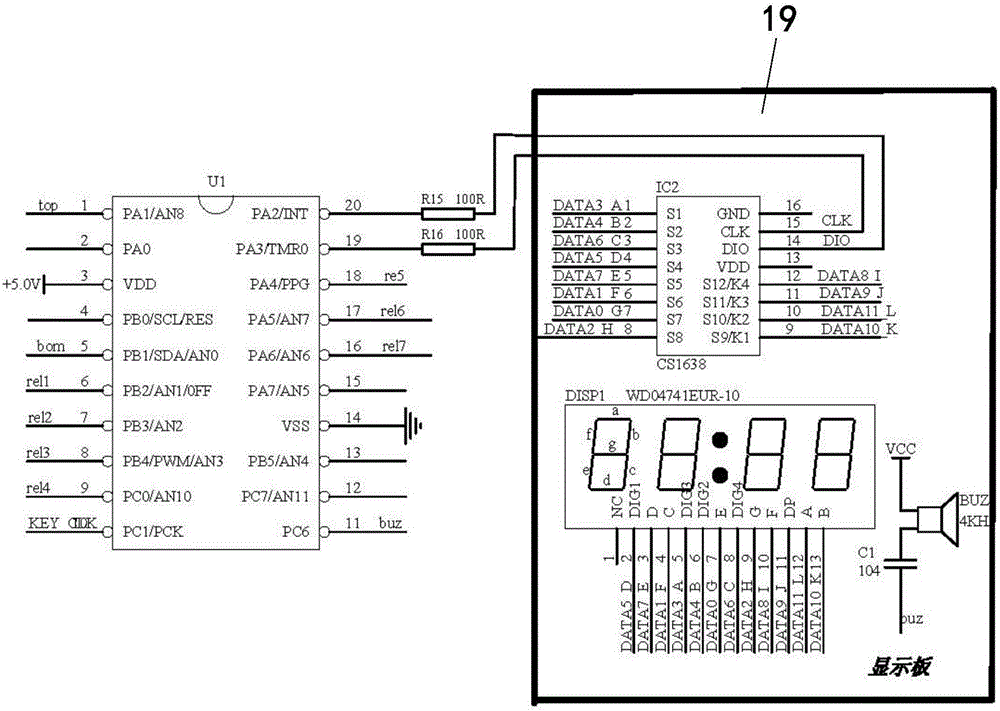

Control method of intelligent electric rice cooker

InactiveCN105768849ARetain nutritionAvoid churnVessels with intergral heatingEngineeringNutrient loss

The invention discloses a control method of an intelligent electric rice cooker, belongs to the field of kitchen cooking appliances, and solves the problems that an existing electric rice cooker causes cost loss and rice nutrient loss due to the use of water to wash rice. The intelligent electric rice cooker comprises a pot body, a cover, an inner pot and a control unit and also comprises a storage chamber, a washing chamber connected with the storage chamber and an air supply device connected with the washing chamber, and the control method at least comprises the steps: feeding: conveying material into the washing chamber from the storage chamber; washing: supplying air to the washing chamber from the air supply device so as to blow-wash the material in the washing chamber; discharging: conveying the material to the inner pot from the washing chamber. The embodiment of the invention is applicable to rice cooking, porridge making and cooking of other five cereals with electric rice cookers.

Owner:HONGYANG HOME APPLIANCES

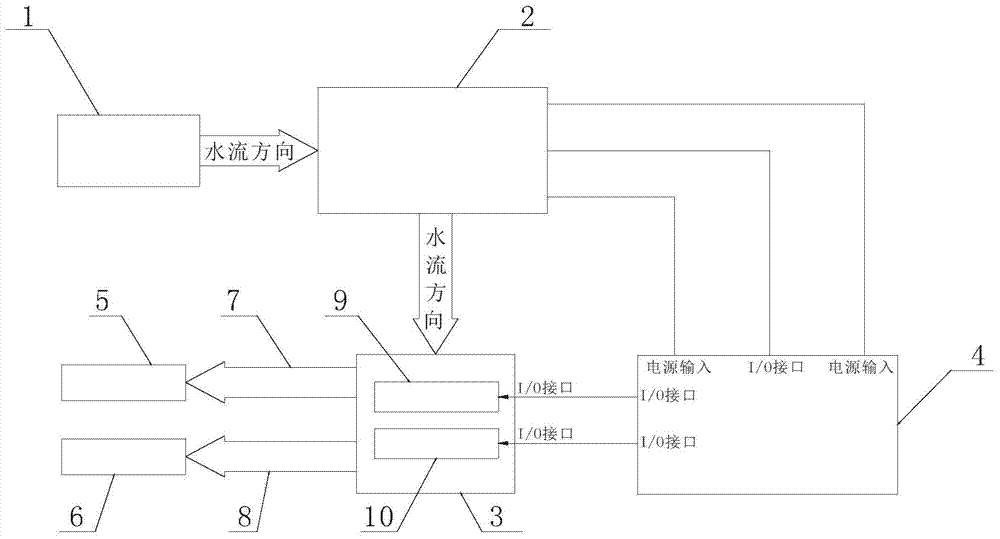

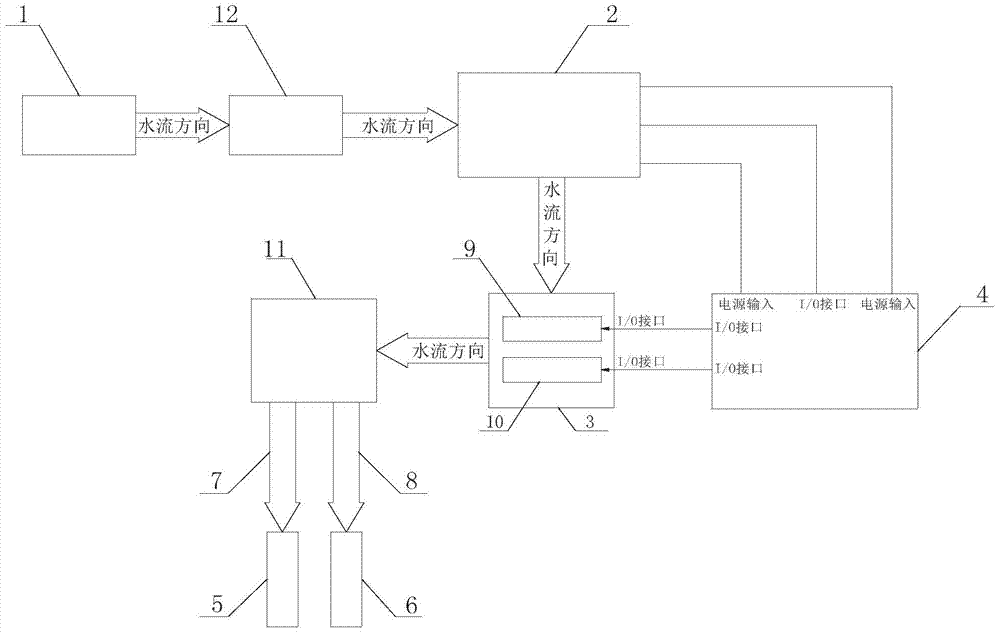

System and method for controlling water quantity of closestool

ActiveCN104264759AAccurately achieve water consumptionImprove washing effectFlushing devicesControl signalControl system

The invention relates to a system and method for controlling the water quantity of a closestool. The system comprises a sensor arranged at the water inlet end of the closestool and a control valve arranged at the water outlet end of the closestool, and the water inlet end of the closestool is communicated with the water outlet end of the closestool through the sensor and the control valve in sequence. The system for controlling the water quantity of the closestool further comprises a control circuit board connected with the sensor and the control valve. Compared with the prior art, the sensor can regularly detect water flow parameters of the water inlet end of the closestool, the control circuit board is responsible for collecting the water flow parameter values detected by the sensor and sending corresponding control signals to the control valve after analyzing relevant parameter values, and then the control valve is opened or closed according to the obtained control signals. When the quantity of water flowing out of the control valve reaches the preset water quality after the control valve is opened, the control valve is closed through the control circuit board, and therefore the rated water quantity of the closestool is achieved accurately, and the best flushing effect is achieved.

Owner:KOHLER CHINA INVESTMENT

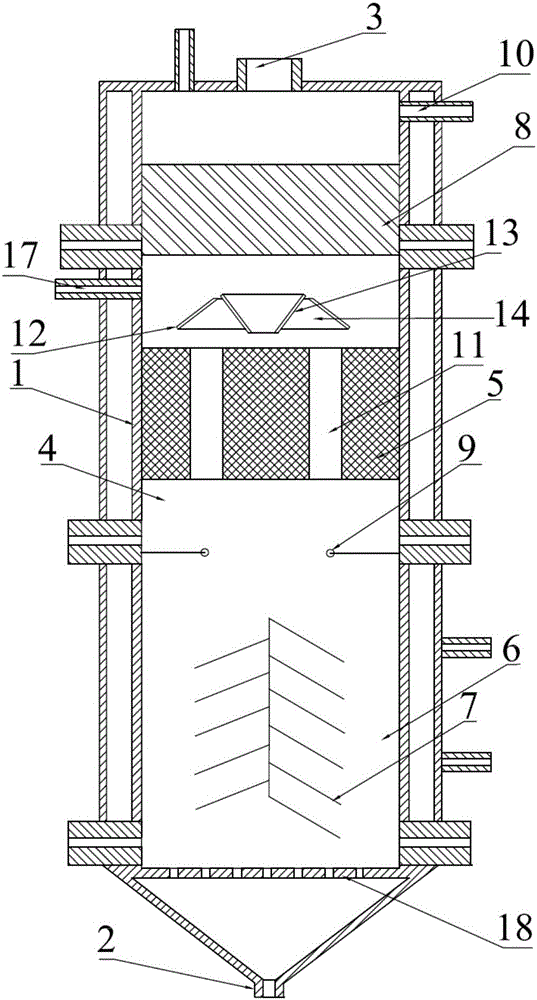

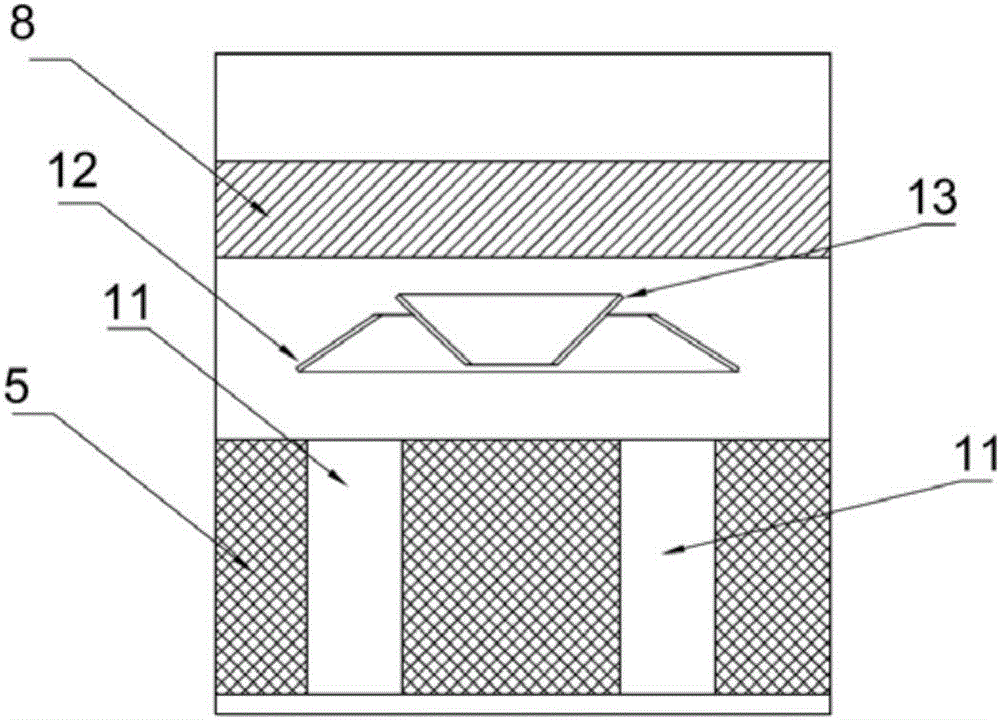

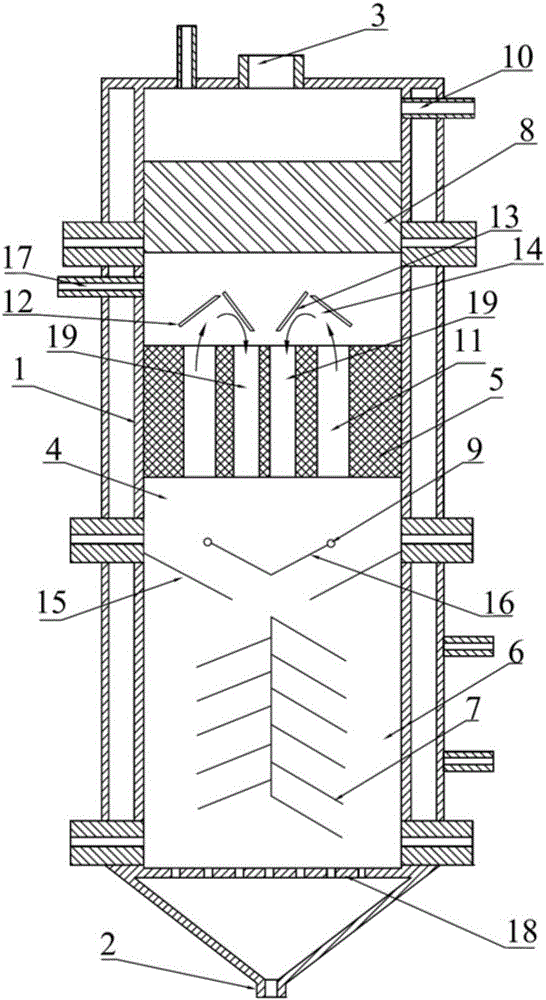

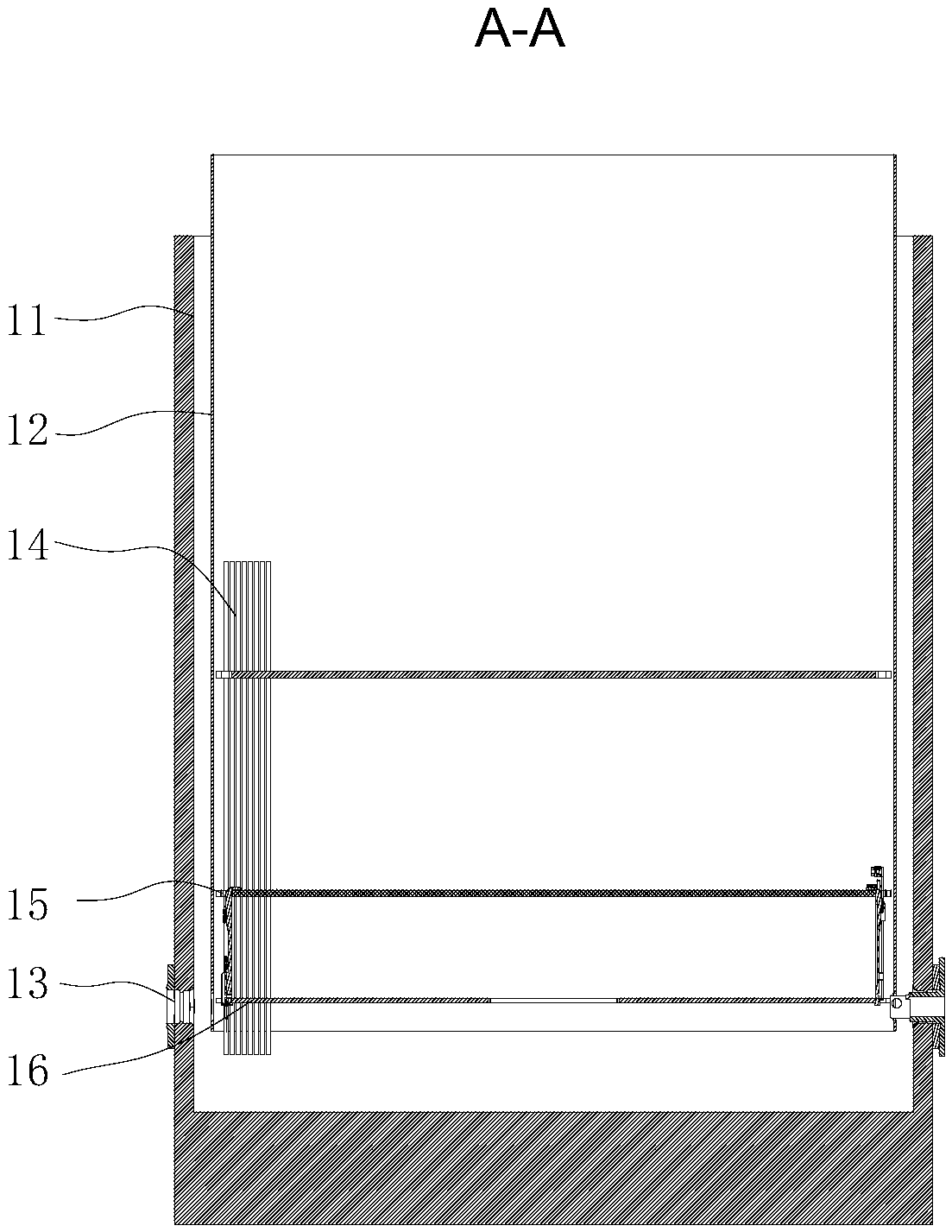

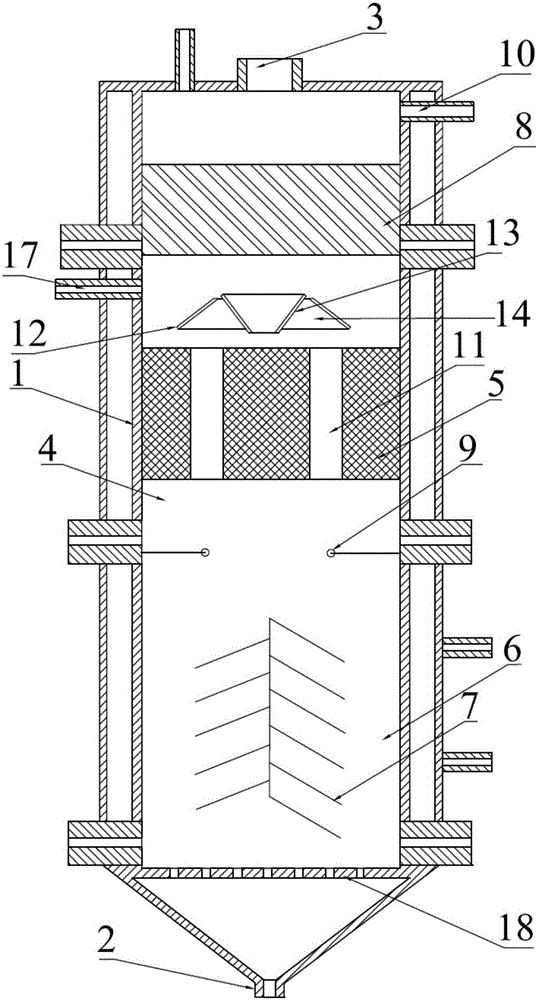

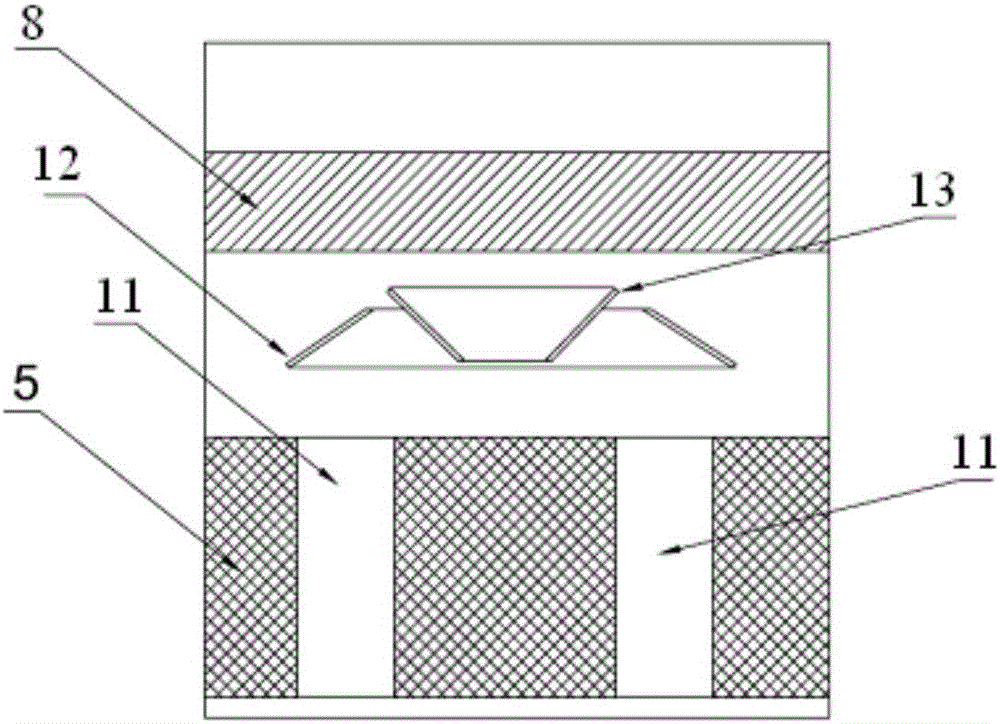

Completely autotrophic nitrogen-removal reactor and nitrogen-removal process

ActiveCN106277327AAvoid pollutionAvoid cloggingTreatment with aerobic and anaerobic processesDenitrifying bacteriaWastewater

The invention provides a completely autotrophic nitrogen-removal reactor. A nitrosation-anaerobic ammonia oxidation region is arranged on the upper part of a reactor barrel, a first packing assembly is arranged in the nitrosation-anaerobic ammonia oxidation region, anaerobic ammonium oxidation bacteria are attached to the inner layer of the surface of the first packing assembly, and nitrosobacteria are attached to the outer layer of the surface of the first packing assembly; a denitrification region is arranged on the lower part of the reactor barrel; a second packing assembly attached with denitrifying bacteria is arranged on the denitrification region; a film assembly is arranged at the top end of the nitrosation-anaerobic ammonia oxidation region; a water outlet communicates with a water outlet side of the film assembly; an aeration device is arranged in the nitrosation-anaerobic ammonia oxidation region and is positioned below the first packing assembly; and a first three-phase separator is arranged between the first packing assembly and the film assembly. By the reactor, pollution and blocking of the film assembly are prevented effectively, the effect of treating waste water is enhanced, and whole completely autotrophic nitrogen-removal reaction can be carried out efficiently and stably.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

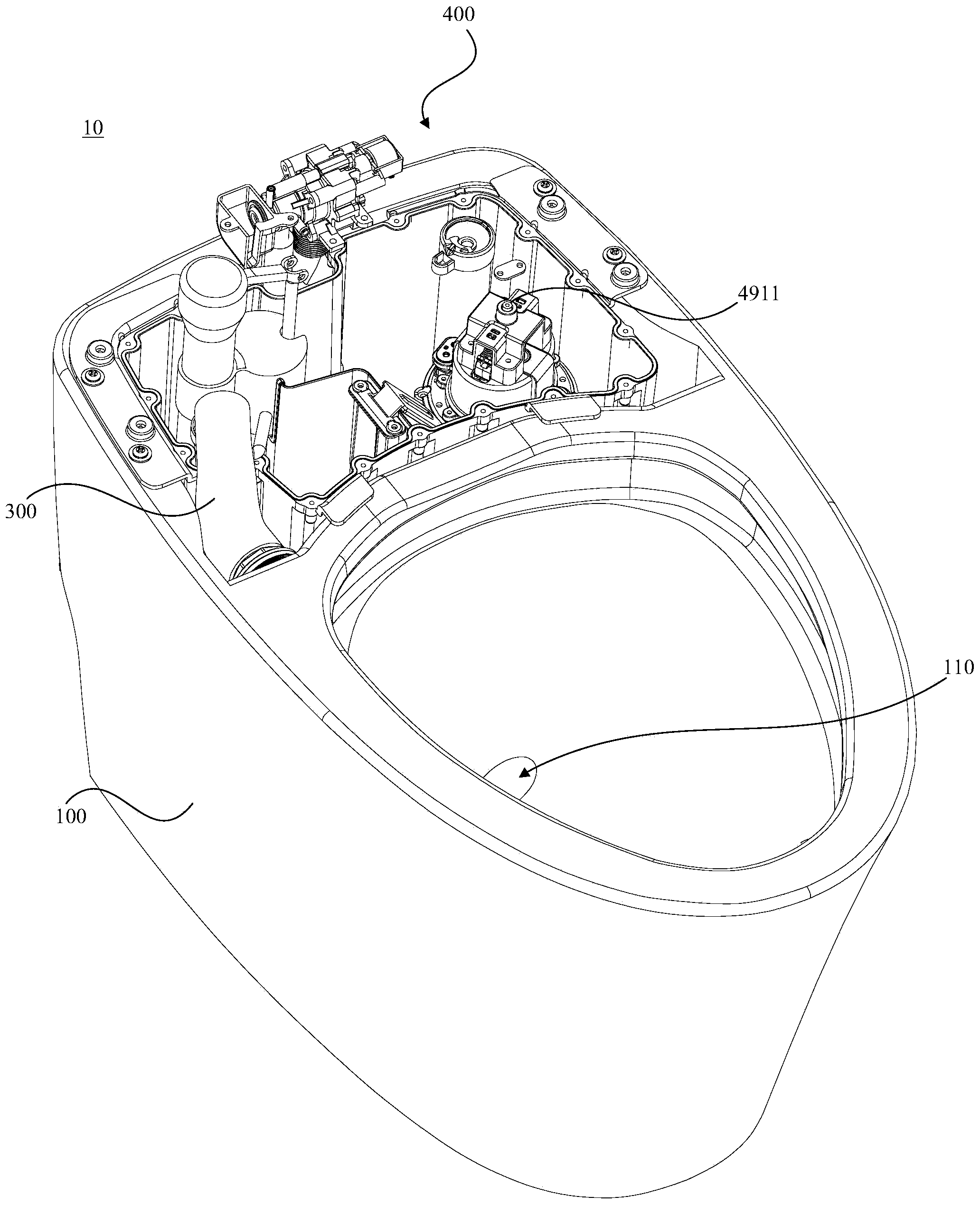

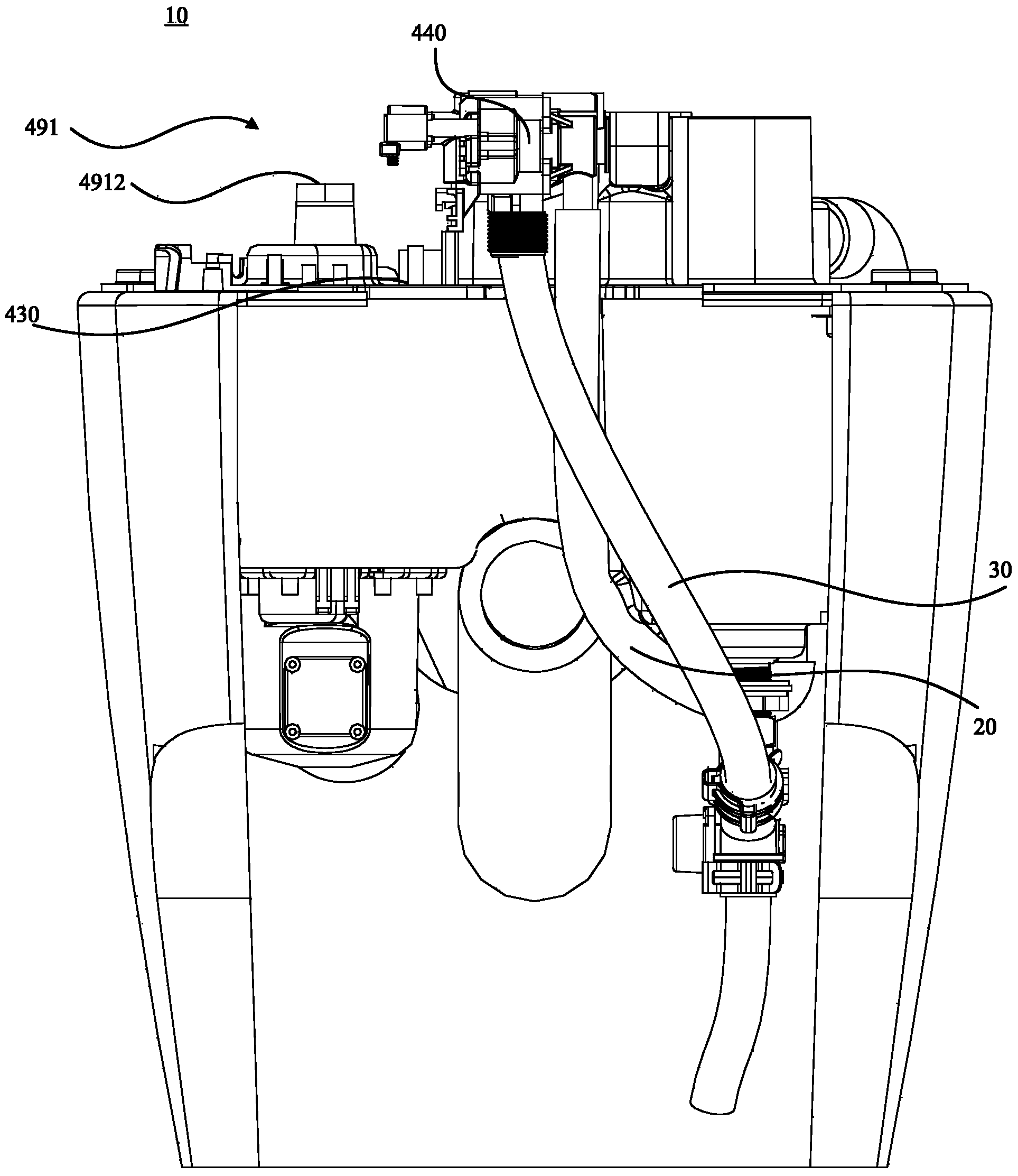

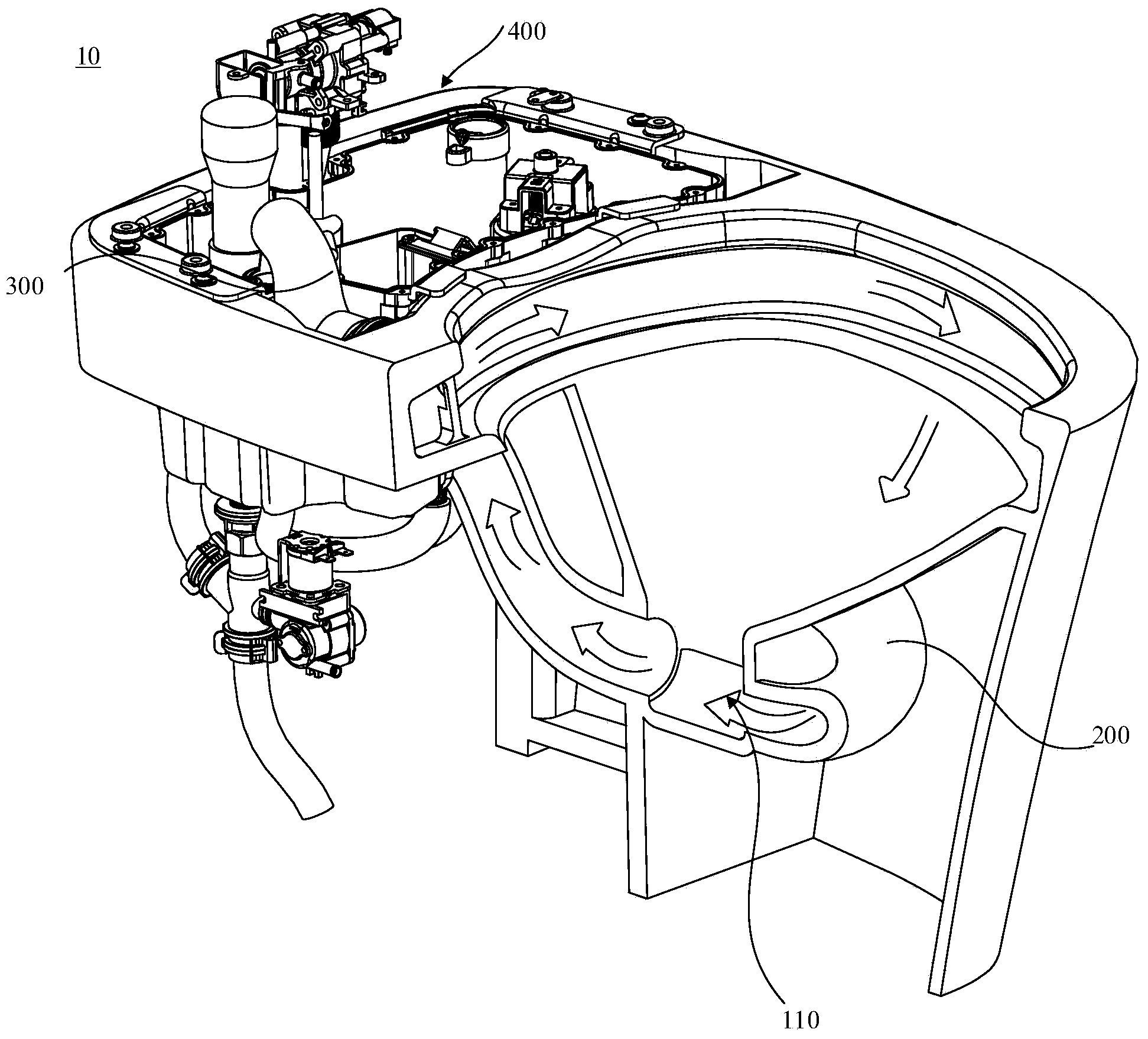

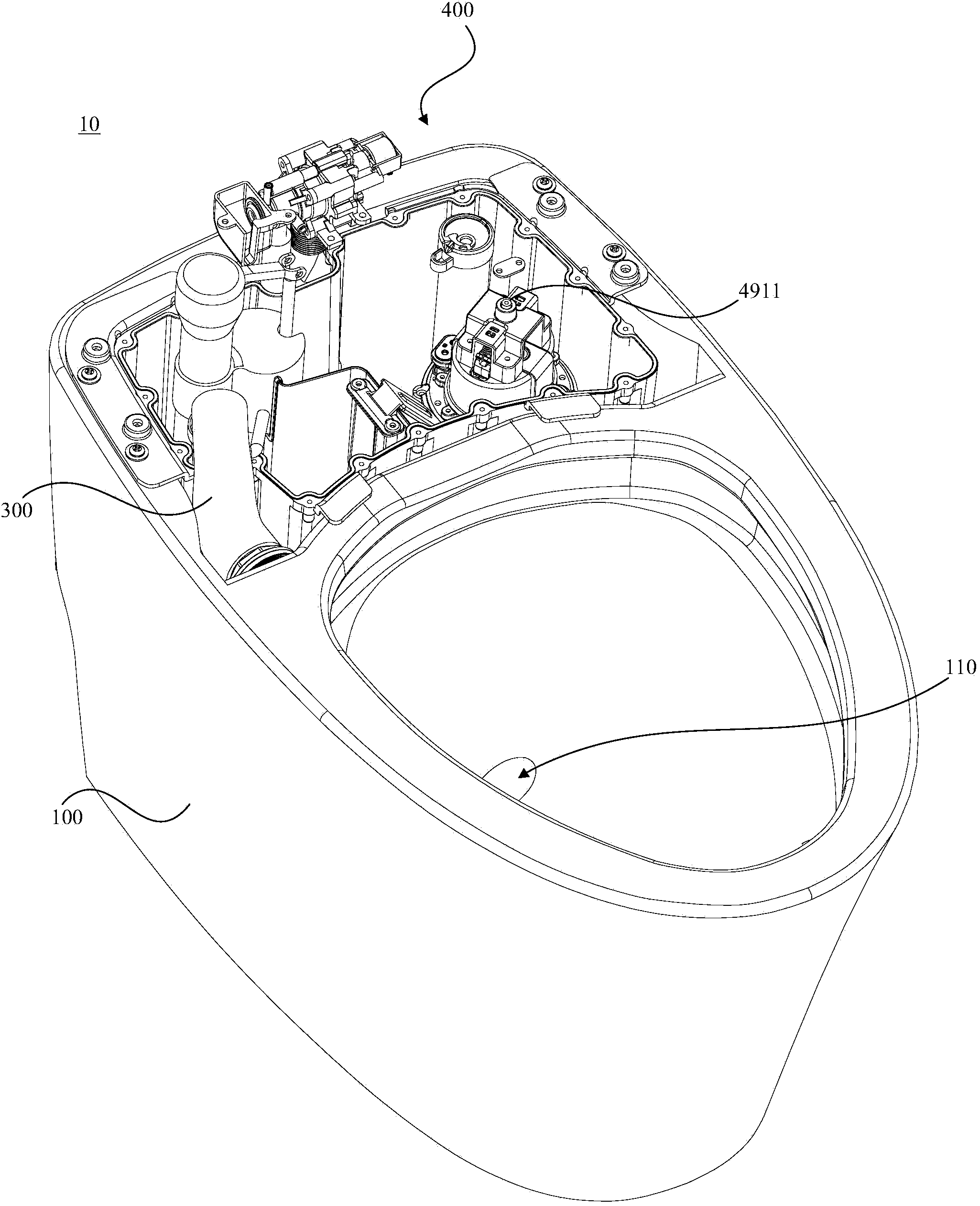

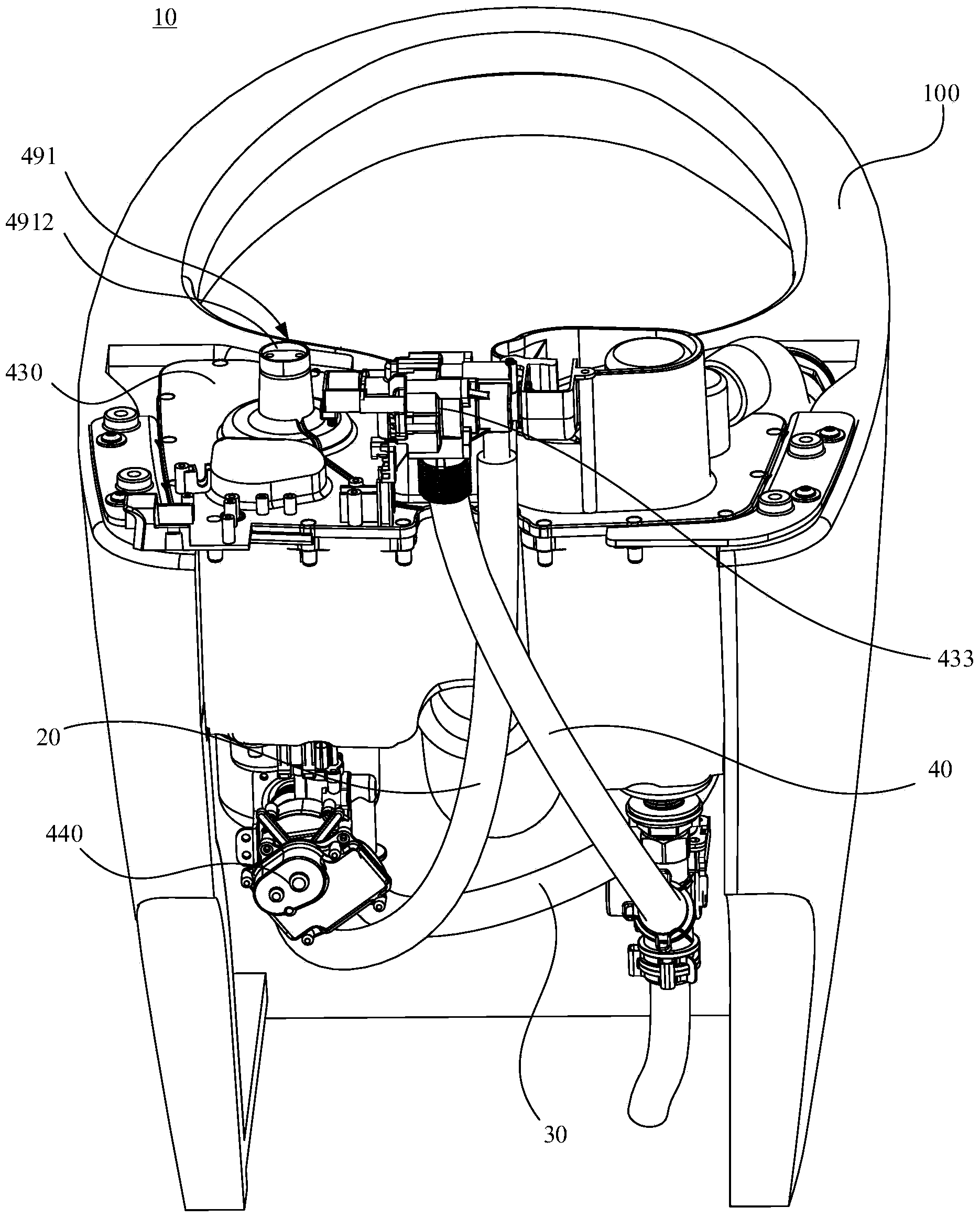

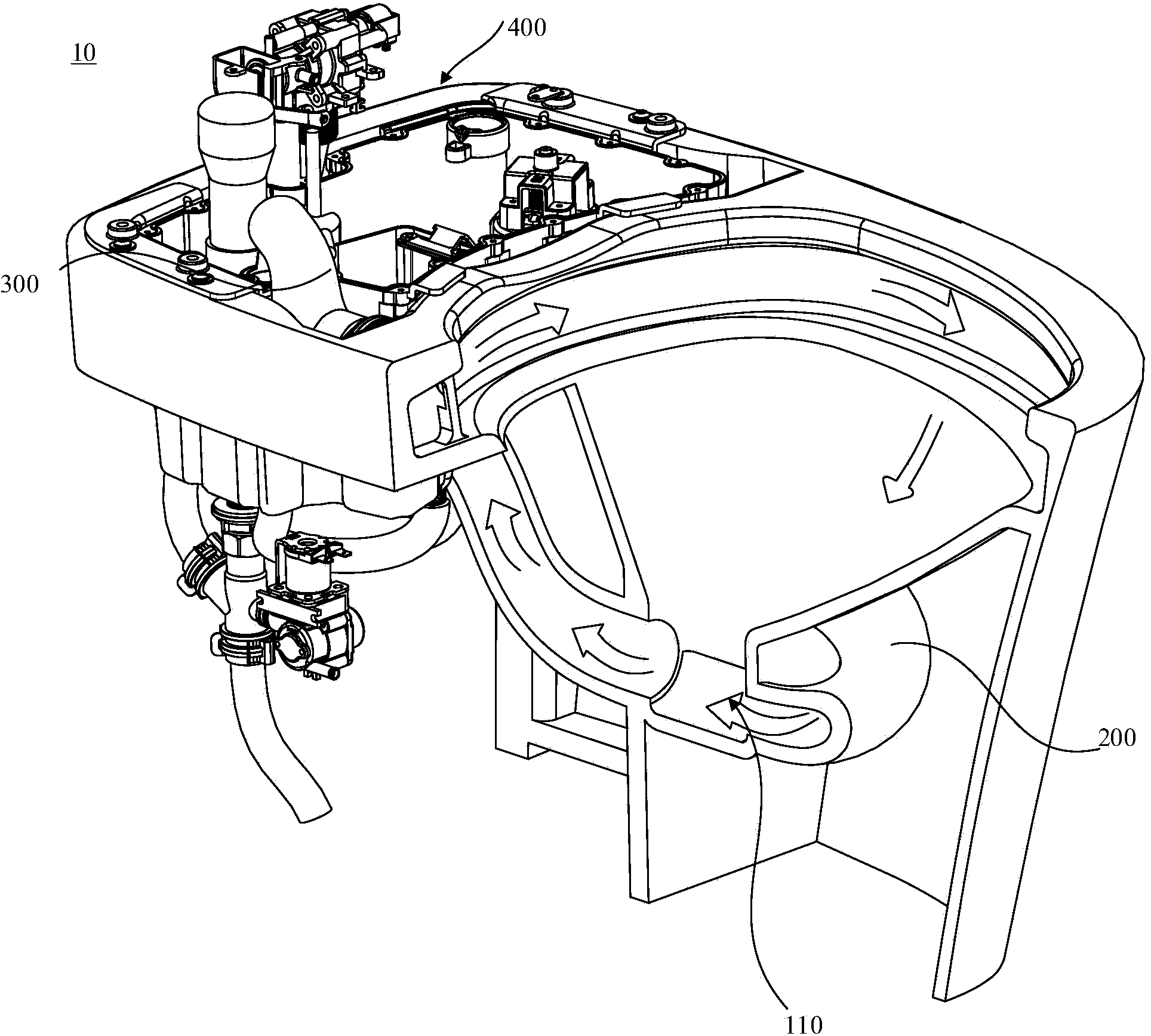

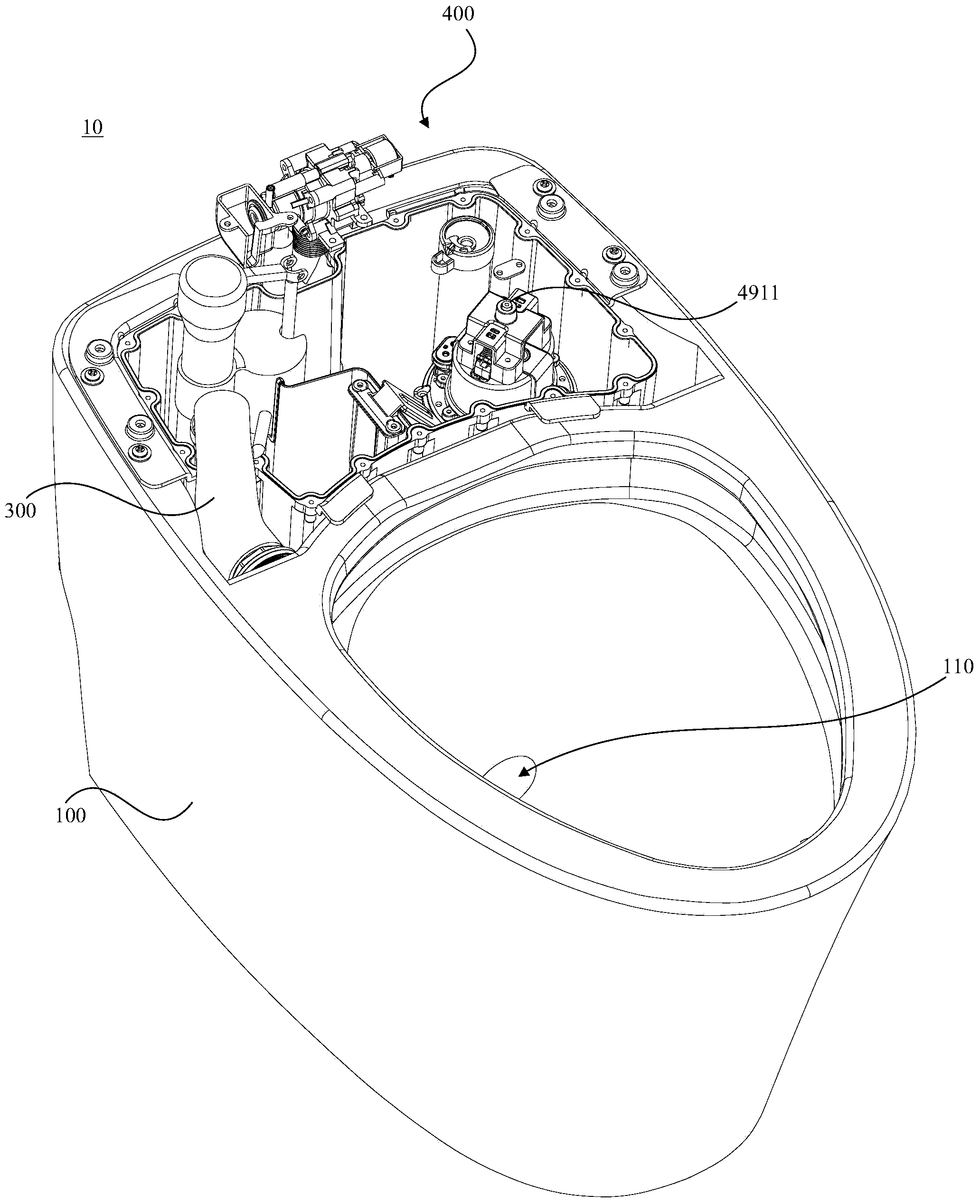

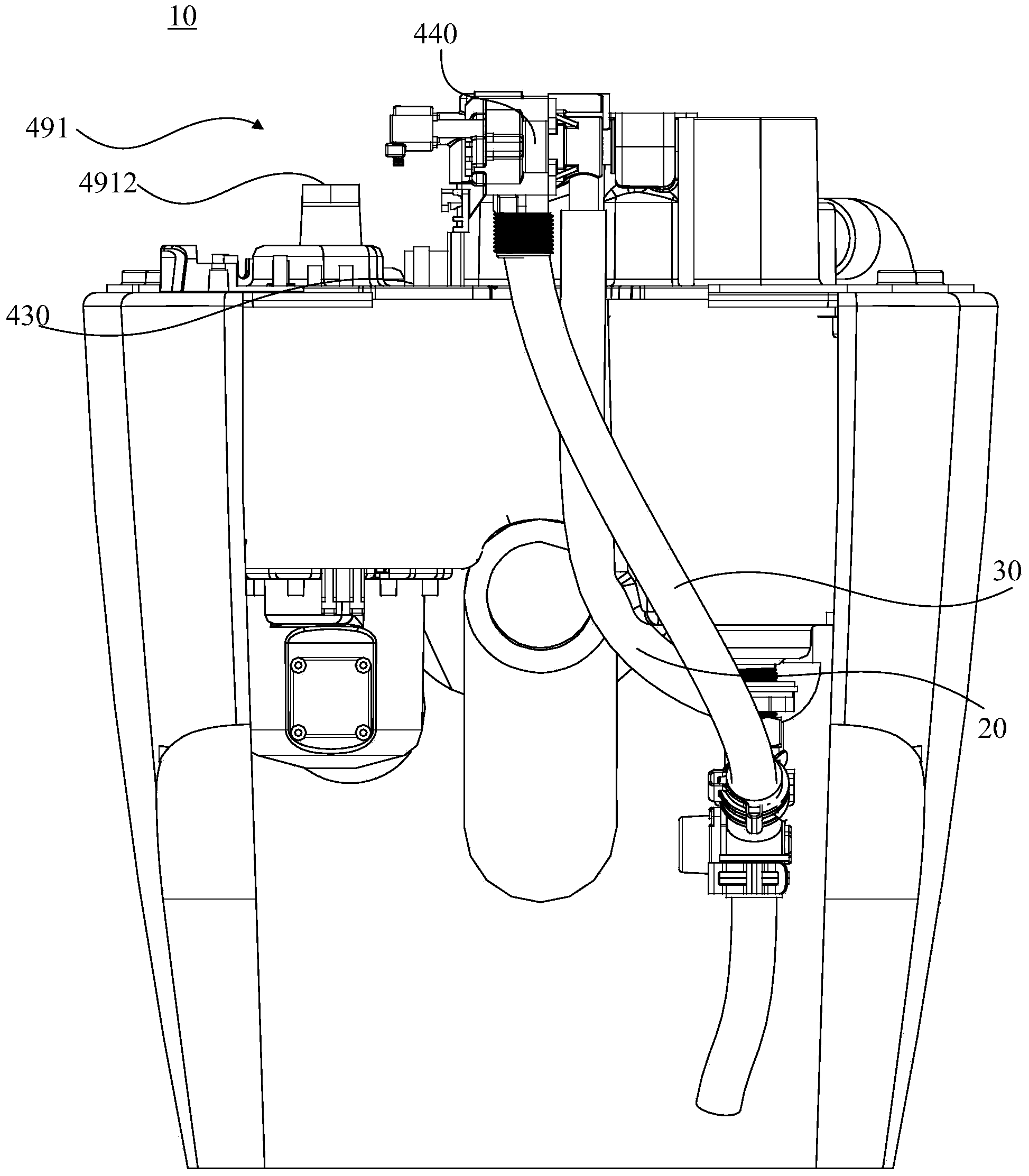

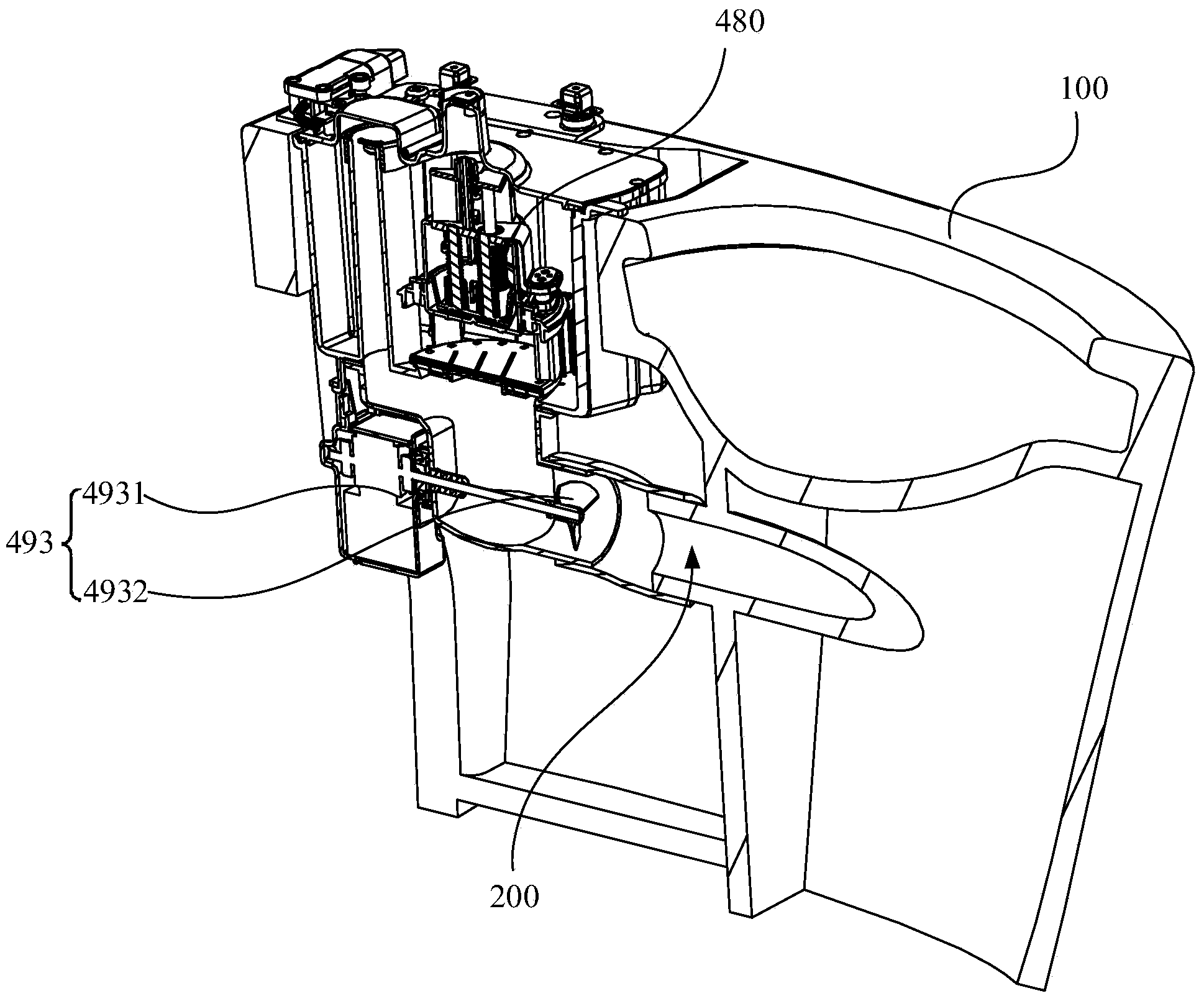

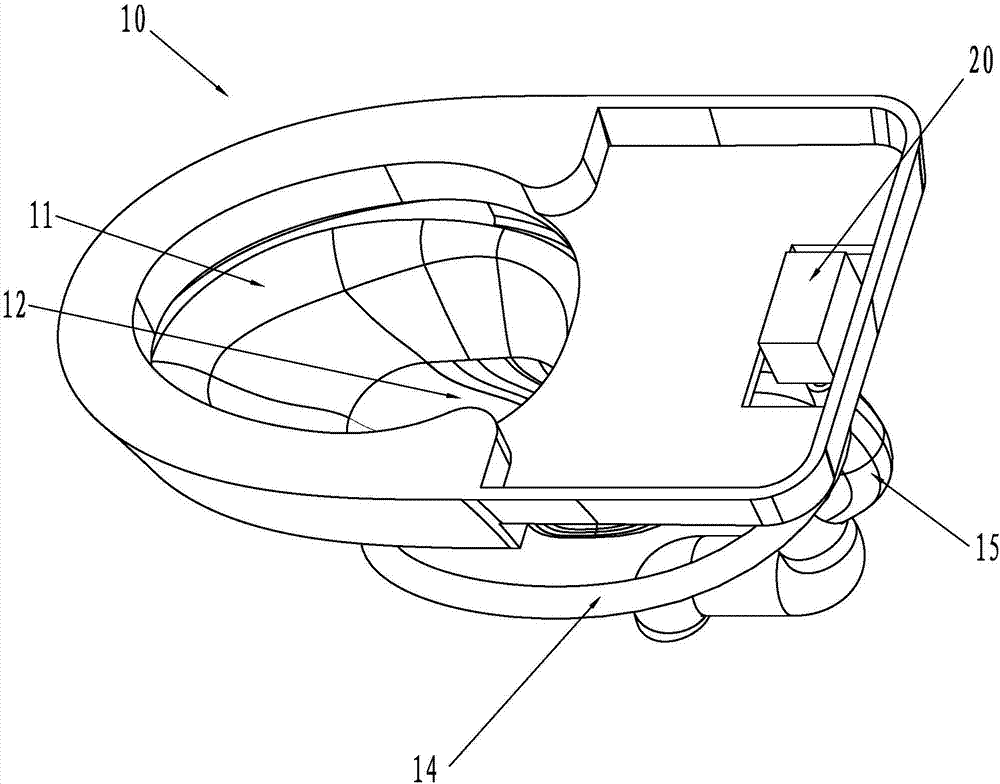

Toilet bowl and flushing system thereof

ActiveCN104164913AReduce volumeImprove scrubbing effectWater closetsFlushing devicesEngineeringElectromagnetic valve

The invention provides a flushing system of a toilet bowl. The flushing system comprises a water tank, a one-way device, a water tank cover, a pilot-operated type electromagnetic valve, a water yield doubler, a water yield doubler pipe, a water inlet piece, a float bowl and an explosion drain valve. Due to the fact that a ceramic water tank arranged on a toilet bowl body is removed, a containing cavity is formed in the toilet bowl body, the water tank is divided by a partition plate into a brushing water tank and a flushing water tank, the water tank is contained in the containing cavity, and the size is small. Due to the fact that the one-way device is arranged, the accumulated water in the flushing water tank cannot flow back to the brushing water tank in a short time, and the flushing effect is guaranteed. The yield of water flushing into a brushing pipeline in the brushing water tank is doubled through the water yield doubler and the water yield doubler pipe, and the brushing effect is good. Due to the delay effect of the explosion drain valve and a detecting device, the flushing action is slower than the brushing action after the brushing action is finished, it can be guaranteed that the flushing effect is better when flushing is carried out after brushing is finished. The invention further provides the toilet bowl with the flushing system.

Owner:TAKA TECH CO LTD

Toilet bowl and flushing system thereof

ActiveCN104164907AReduce volumeGood scrubbing effectFlushing devicesEngineeringElectromagnetic valve

The invention provides a flushing system of a toilet bowl. The flushing system comprises a water tank, a one-way device, a water tank cover, a pilot-operated type electromagnetic valve, a water yield doubler, a water yield doubler pipe, a water inlet piece, a float bowl, an explosion drain valve and a water yield distributor. Due to the fact that a ceramic water tank arranged on a toilet bowl body is removed, a containing cavity is formed in the toilet bowl body, the water tank is divided by a partition plate into a brushing water tank and a flushing water tank, the water tank is contained in the containing cavity, and the size is small. Due to the fact that the one-way device is arranged, the accumulated water in the flushing water tank cannot flow back to the brushing water tank in a short time, and the flushing effect is guaranteed. The yield of water flushing into a brushing pipeline in the brushing water tank is doubled through the water yield doubler and the water yield doubler pipe, and the brushing effect is good. Due to the delay effect of the explosion drain valve and a detecting device, the flushing action is slower than the brushing action after the brushing action is finished, it can be guaranteed that the flushing effect is better when flushing is carried out after brushing is finished. The invention further provides the toilet bowl with the flushing system.

Owner:TAKA TECH CO LTD

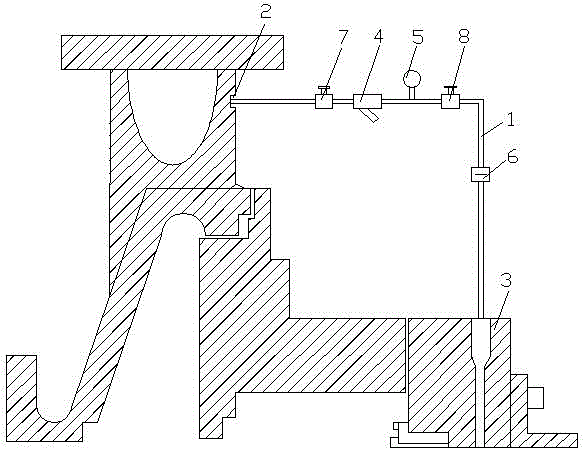

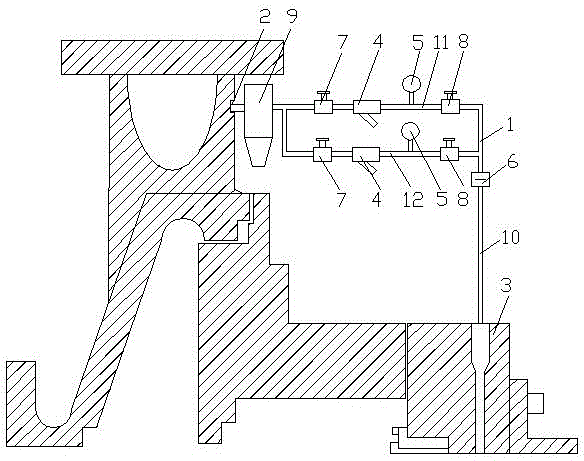

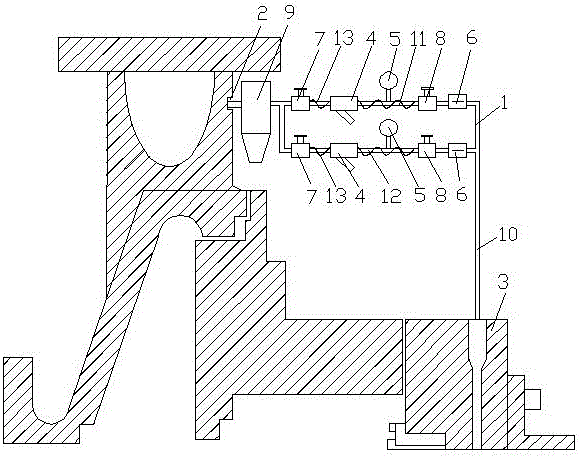

Flushing device for mechanical seal of centrifugal pump

ActiveCN106122108AFlow is stable and cleanPrevents deposition of particulate impuritiesPump componentsPumpsCentrifugal pumpOrifice plate

The invention discloses a flushing device for a mechanical seal of a centrifugal pump, and belongs to the technical field of centrifugal pumps. The flushing device comprises a flushing pipe connected to the centrifugal pump; the liquid feeding end of the flushing pipe is connected with the outlet end of the centrifugal pump; the liquid discharging end of the flushing pipe is connected with the mechanical seal of the centrifugal pump; the flushing device is characterized in that the flushing pipe is connected with a tubular filter, a pressure gauge and a throttling orifice plate; the tubular filter is close to the outlet end of the centrifugal pump; the throttling orifice plate is close to the mechanical seal of the centrifugal pump; a first stop valve and a second stop valve are arranged on the flushing pipe; the first stop valve is positioned between the outlet end of the centrifugal pump and the tubular filter; and the second stop valve is positioned between the pressure gauge and the throttling orifice plate. The flushing device can both achieve a good cooling effect on the mechanical seal and prevent particle impurities from being deposited on the sealing surfaces of movable and fixed rings, thus effectively protecting the sealing surfaces of the movable and fixed rings, relieving wear and enhancing the sealing effect; and therefore, normal and stable operation of the centrifugal pump is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

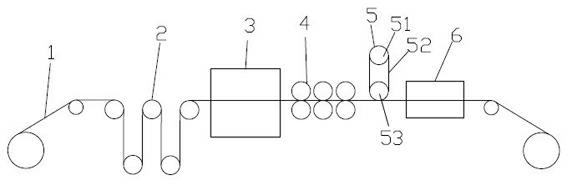

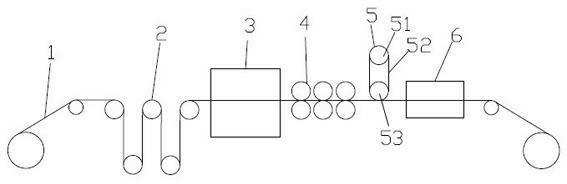

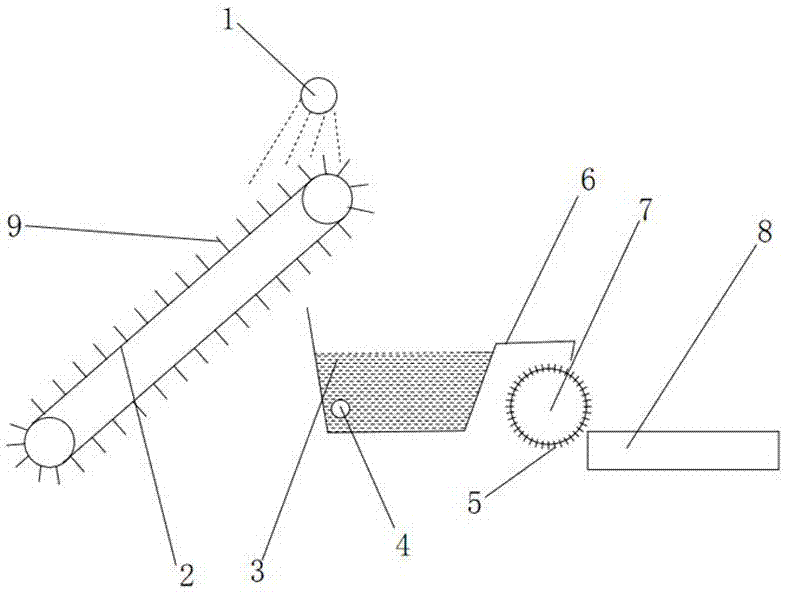

Steel strip descaling method

InactiveCN102601742AWashing surface is largeGood cleaning and descaling effectBlast gunsAbrasive machine appurtenancesHigh pressure waterBrush device

The invention belongs to the field of steel strip production, and particularly relates to an environment-friendly thorough method for removing oxide, namely scale, on the surface of a steel strip with a fine condition. The method includes the steps: A, feeding the steel strip into a scale breaking device to break the scale on the surface of the steel strip; B, feeding the steel strip treated in the step A into a sand blaster, blasting steel shots, high-pressure water and high-pressure air to the surface of the steel strip, and further breaking and washing the scale on the surface of the steel strip; C, feeding the steel strip treated in the step B into a brush roll device, polishing and brushing the surface of the steel strip and further removing residual scale and smoothening the surface of the steel strip; D, feeding the steel strip treated in the step C into a strip brush device and brushing off cuttings and remaining scale on the upper surface of the steel strip after polishing and brushing; E, feeding the steel strip treated in the step D into a cleaning device and washing the surface of the steel strip with clear water; and F, rolling the cleaned steel strip by the aid of a gripping roll.

Owner:HUZHOU JINYE ELECTRONICS MATERIAL +1

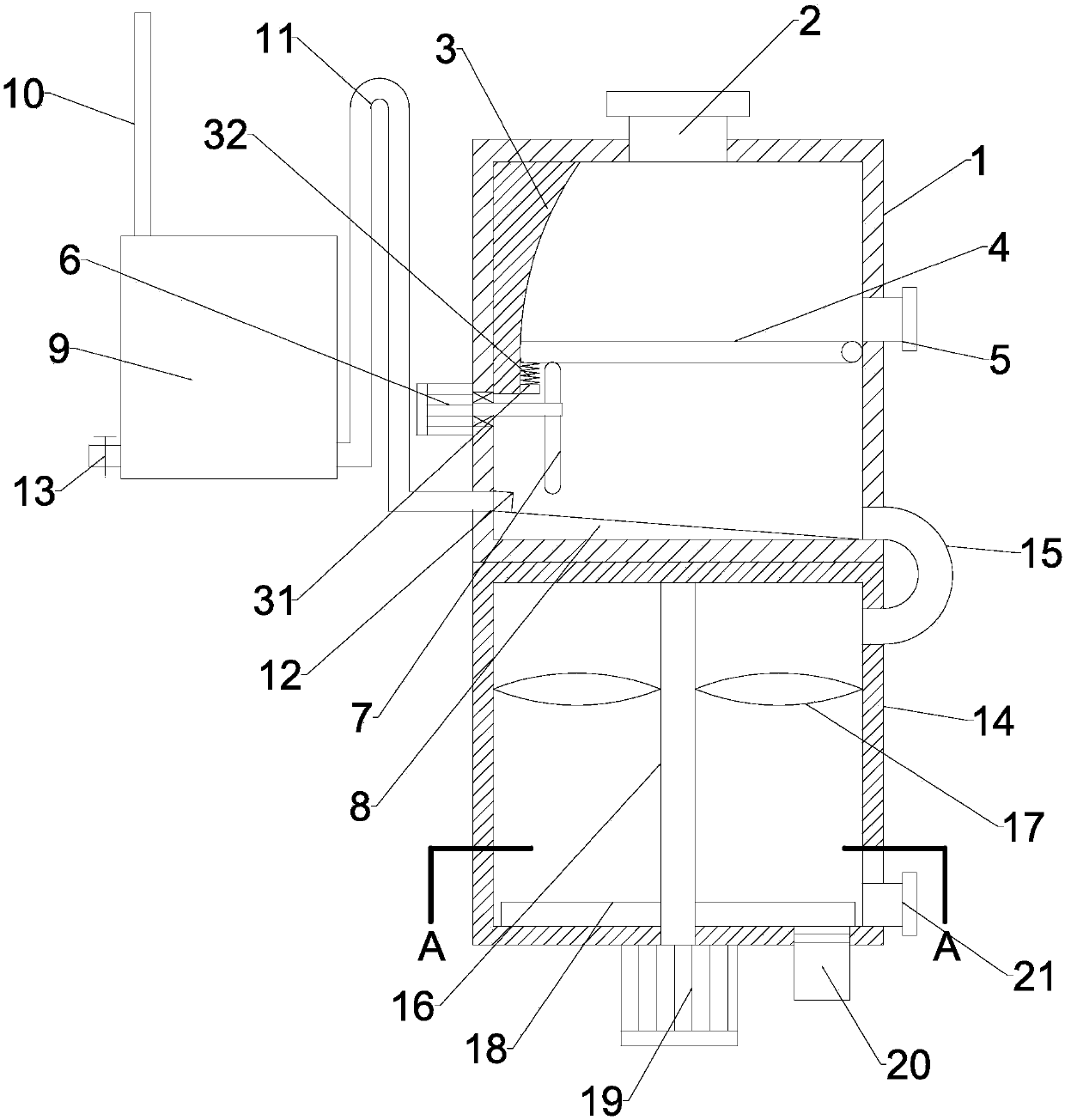

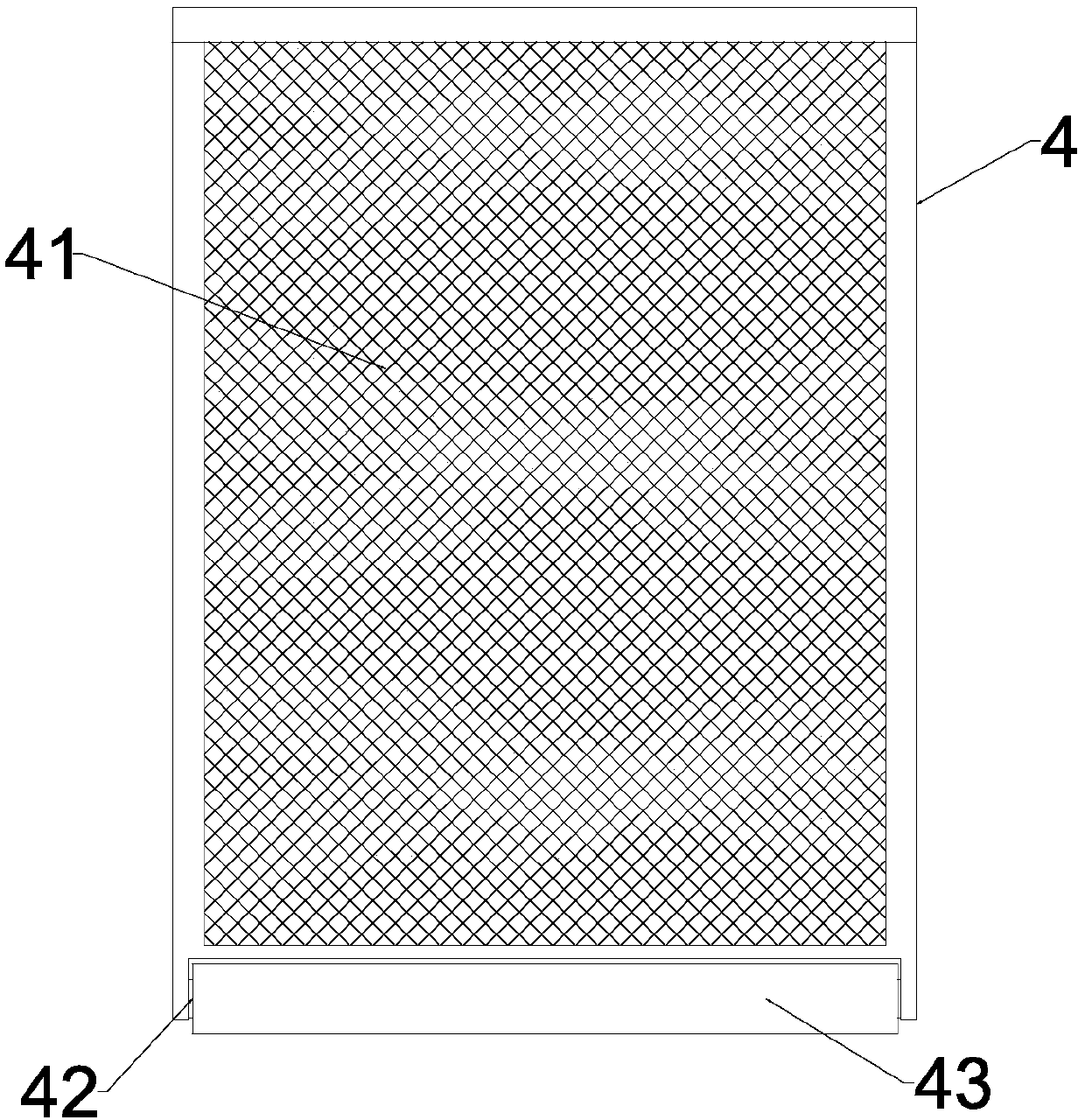

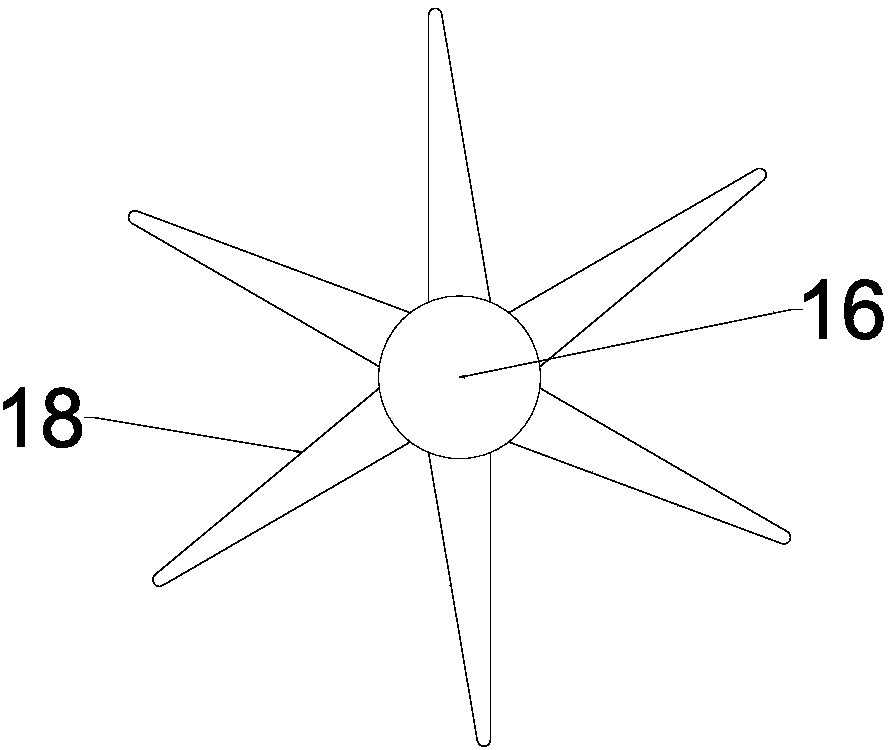

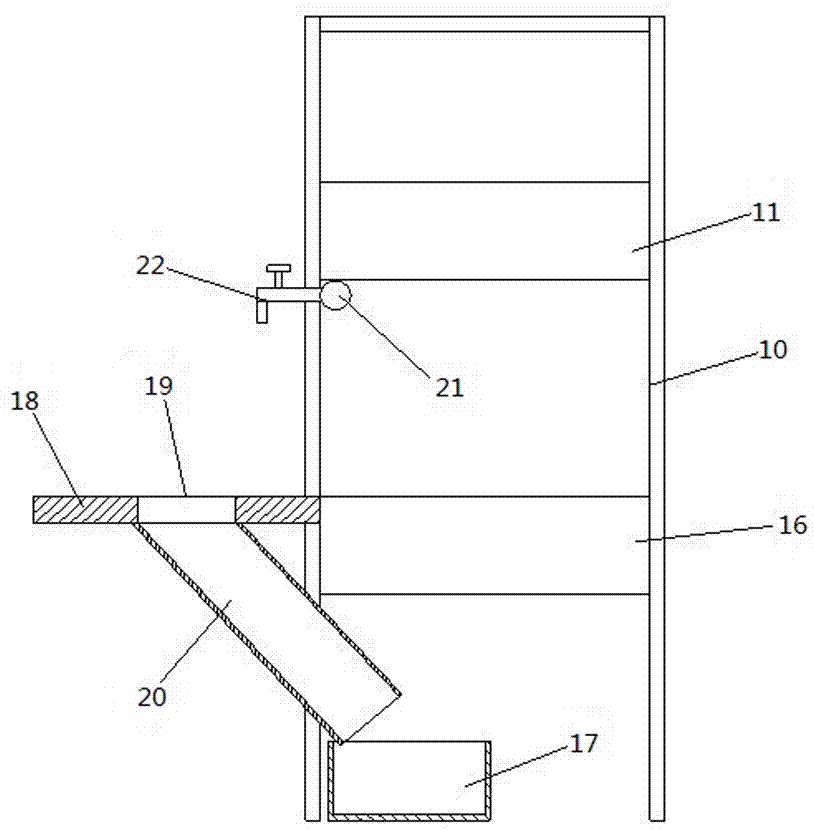

Vibration separation and collection system of grain impurities

InactiveCN108043704AImprove screening efficiencyPrevent leakageSievingScreeningSiphonCollection system

The invention discloses a vibration separation and collection system of grain impurities. The vibration separation and collection system comprises a filtering cavity, a water tank and an impurity processing cavity, wherein the filtering cavity is provided with a feeding pipe, an arc-shaped plate, a rotating frame, a discharging pipeline, a vibration motor, a cam and a material guide bottom plate;the arc-shaped plate is provided with a lining plate and a spring, and a filter screen, a containing groove and a rotating shaft are arranged on the rotating frame; the water tank is arranged above the left side of the filtering cavity, and a control water pipe, a siphon, a water outlet pipe opening and a water inlet pipe are arranged in the water tank; and the impurity processing cavity is formedin the lower end of the filtering cavity and is provided with a connecting pipeline, a stirring shaft, crushing blades, discharge fan blades, a stirring motor, a drainage pipe and an impurity discharging pipeline. According to the vibration separation and collection system of the grain impurities, grain screening and impurity collecting treatment can be carried out continuously; the filter screenis driven to rotate and screen materials through the rotating frame so as to improve screening efficiency; and the siphon is designed on the water tank so as to carry out intermittent quantitative flushing, and under cooperation with impurity processing, processing continuity and processing efficiency can be improved.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

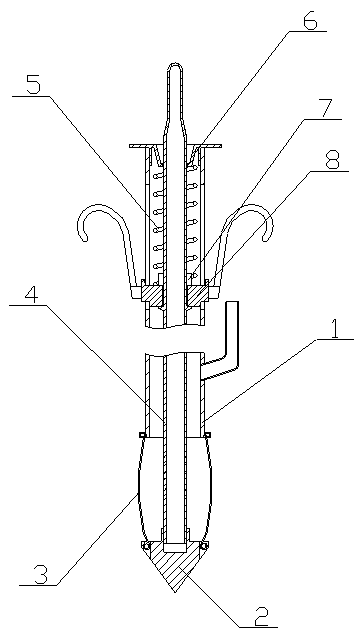

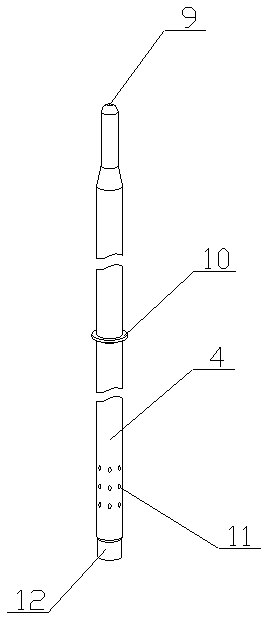

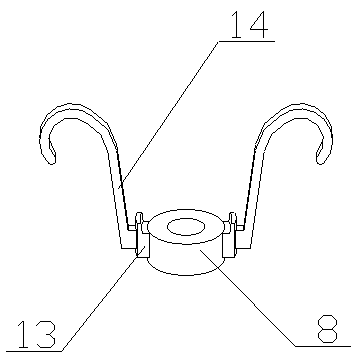

Pipeline inner wall dredging device

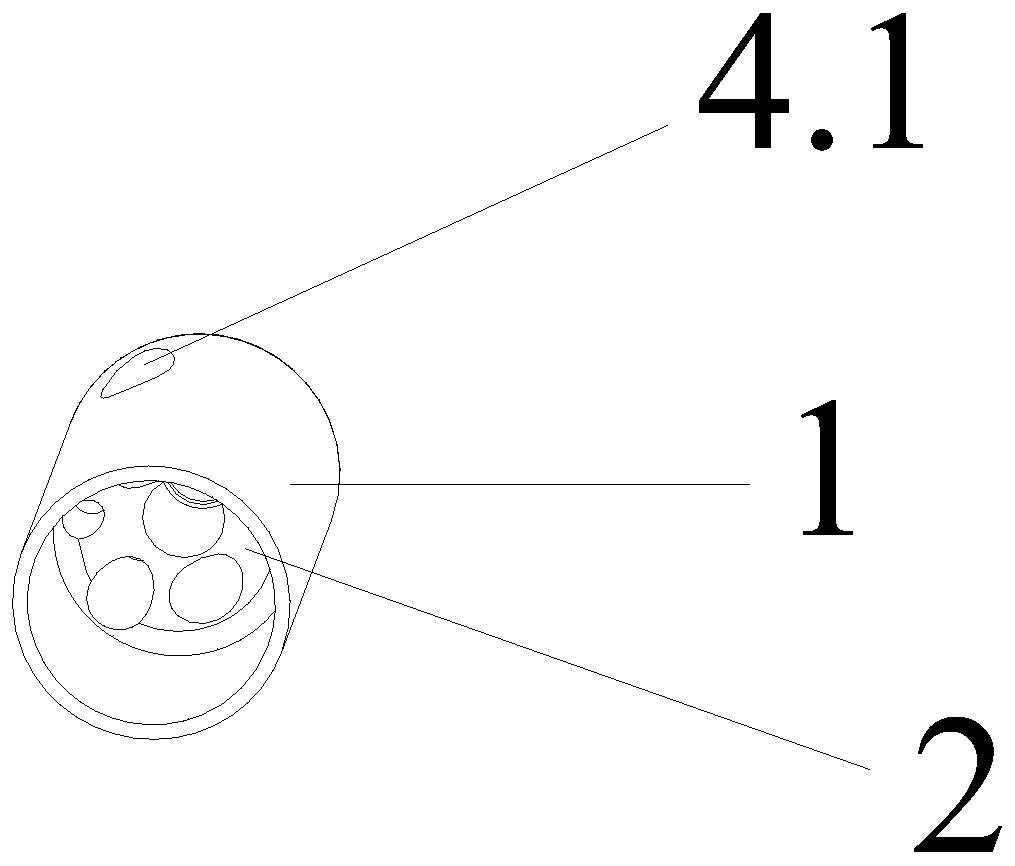

ActiveCN110681655AGuaranteed flushing effectClean thoroughlyHollow article cleaningMarine engineeringThreaded pipe

The invention discloses a pipeline inner wall dredging device, and discloses a dredging device which is suitable for small-caliber pipelines, can be used for scraping and cleaning pipe walls by makingexpansion elastic pieces attached to the pipe walls and rotate and cooperates with high-pressure gas and cleaning liquid to conduct high-pressure flushing on the pipelines. The dredging device is characterized in that an inner gas pipe is arranged in a main body pipe, the two ends of the inner gas pipe penetrate out from the inside of the main body pipe respectively, a threaded pipe is connectedwith the bottom end of the inner gas pipe, a lead-in head is placed on the threaded pipe, a mounting sleeve is arranged in the middle of the top of the lead-in head, the mounting sleeve is in threadedconnection with the threaded pipe, the lead-in head is of a conical structure, the tip of the lead-in head is downward, a plurality of mounting tables are arranged on the outer side face of the bottom end of the main body pipe at equal angles, a plurality of mounting grooves are formed in the outer side face of the lead-in head at equal angles, one ends of the expansion elastic pieces are correspondingly arranged on the mounting tables one to one through connecting shafts, and the other ends of the expansion elastic pieces are correspondingly arranged in the mounting grooves one to one and connected with the lead-in head through connecting shafts.

Owner:徐州华显凯星信息科技有限公司

Toilet bowl and flushing system thereof

ActiveCN104164914AReduce volumeTo achieve the purpose of supercharging and increasing flowWater closetsFlushing devicesEngineeringElectromagnetic valve

The invention provides a flushing system of a toilet bowl. The flushing system comprises a water tank, a one-way device, a water tank cover, a pilot-operated type electromagnetic valve, a water yield doubler, a water yield doubler pipe, a water inlet piece, a float bowl, an explosion drain valve and a pressurizing axial pump. Due to the fact that a ceramic water tank arranged on a toilet bowl body is removed, a containing cavity is formed in the toilet bowl body, the water tank is divided by a partition plate into a brushing water tank and a flushing water tank, the water tank is contained in the containing cavity, and the size is small. Due to the fact that the one-way device is arranged, the accumulated water in the flushing water tank cannot flow back to the brushing water tank in a short time, and the flushing effect is guaranteed. The yield of water flushing into a brushing pipeline in the brushing water tank is doubled through the water yield doubler and the water yield doubler pipe, and the brushing effect is good. Due to the delay effect of the explosion drain valve and a detecting device, the flushing action is slower than the brushing action after the brushing action is finished, and it can be guaranteed that the flushing effect is better when flushing is carried out after brushing is finished. The invention further provides the toilet bowl with the flushing system.

Owner:TAKA TECH CO LTD

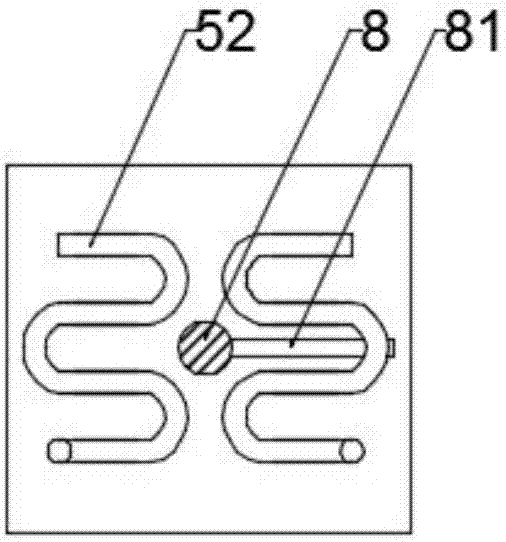

Laboratory sand-stone cleaning device

InactiveCN107309204AThe serpentine outlet pipes above the cleaning frame expand the flushing evenlyAvoid flushing effectsCleaning using liquidsImpellerCircular disc

The invention discloses a sandstone cleaning device for laboratory, which comprises a frame body, a cleaning frame and a water pump; The two sides of the cleaning frame are symmetrically provided with a vertical plate with a return port, and a filter screen is fixed between the inner cavity side wall of the frame and the vertical plate; two water pumps are symmetrically installed on the left and right side walls of the inner cavity of the frame. , the water pump is connected to the suction pipe and the outlet pipe, the suction pipe extends downward to the top of the filter screen, and the outlet pipe extends to the top of the cleaning frame; the upper part of the inner cavity of the frame is symmetrically equipped with impellers, and the position corresponding to the impeller on the outlet pipe is connected to a diagonal The nozzle and the inclined nozzle are facing the blades of the impeller; a disk is arranged above the vertical plate, the impeller drives the disk to rotate, and the disk is connected to the side plate through a connecting rod. The sand and gravel cleaning device of the present invention can recycle water resources, save energy and protect the environment, and has good washing effect at the same time, and is worthy of popularization and use.

Owner:苏锦忠

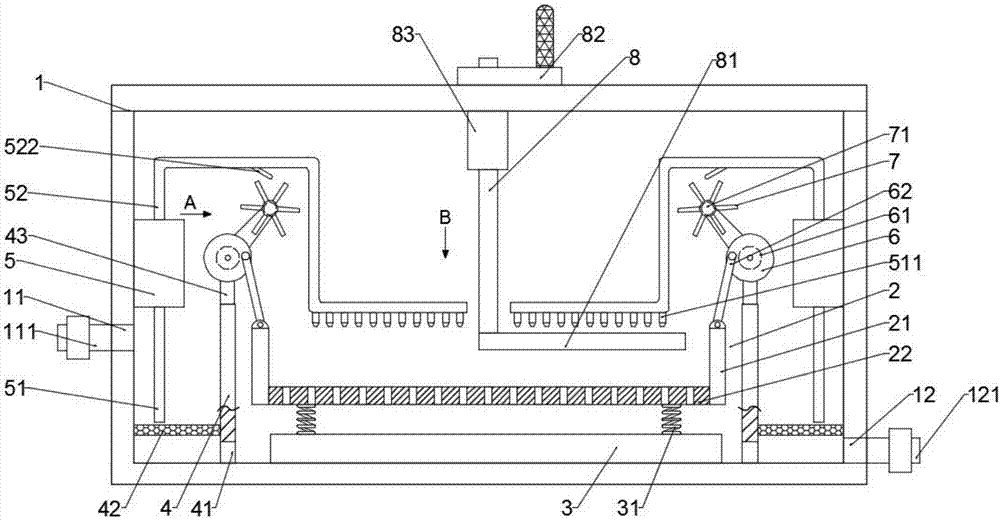

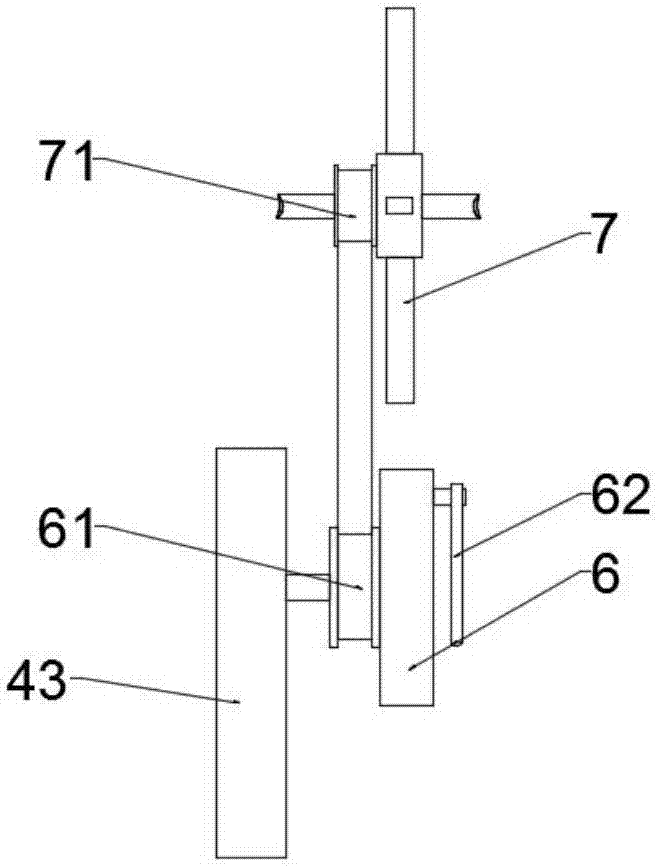

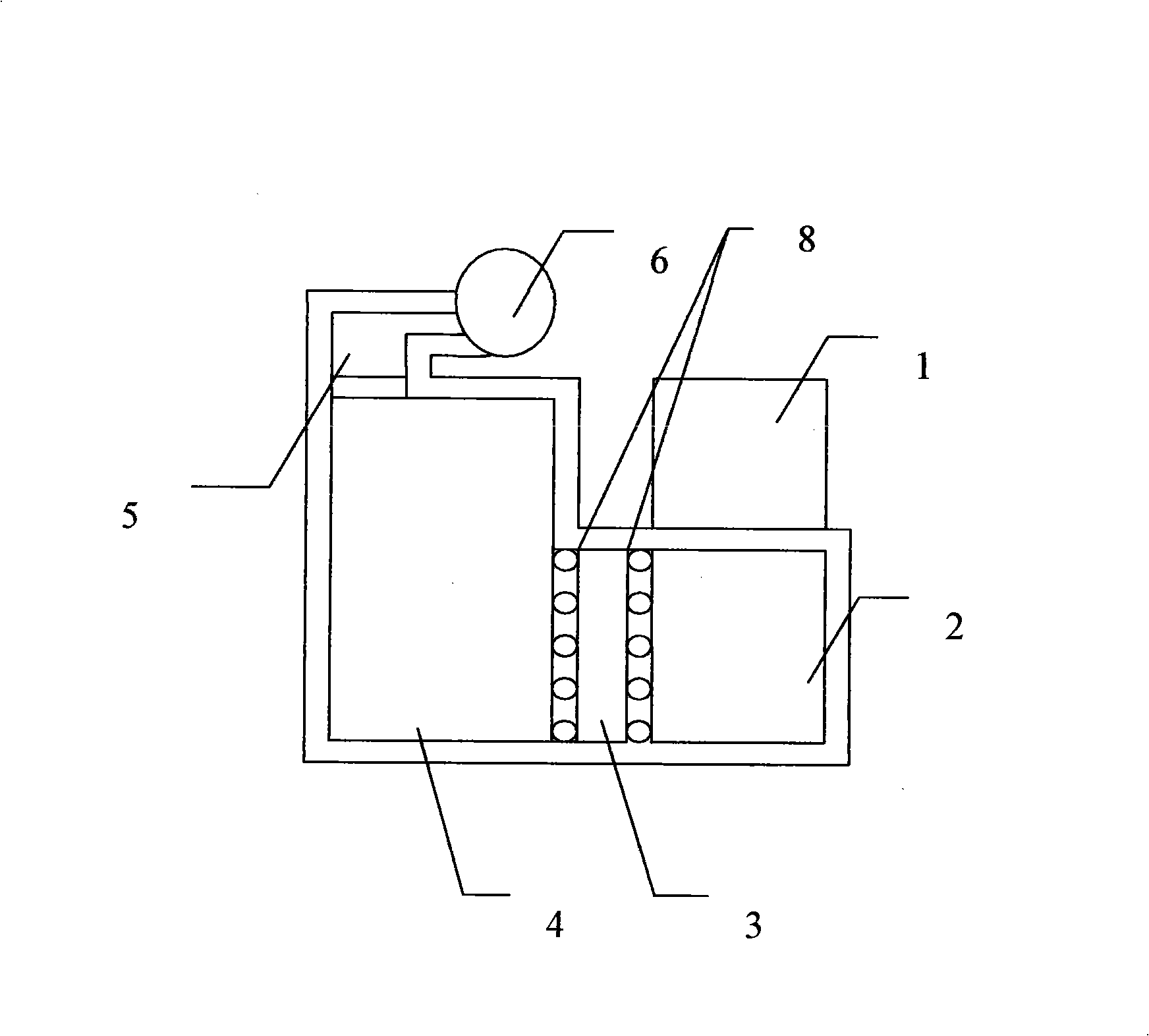

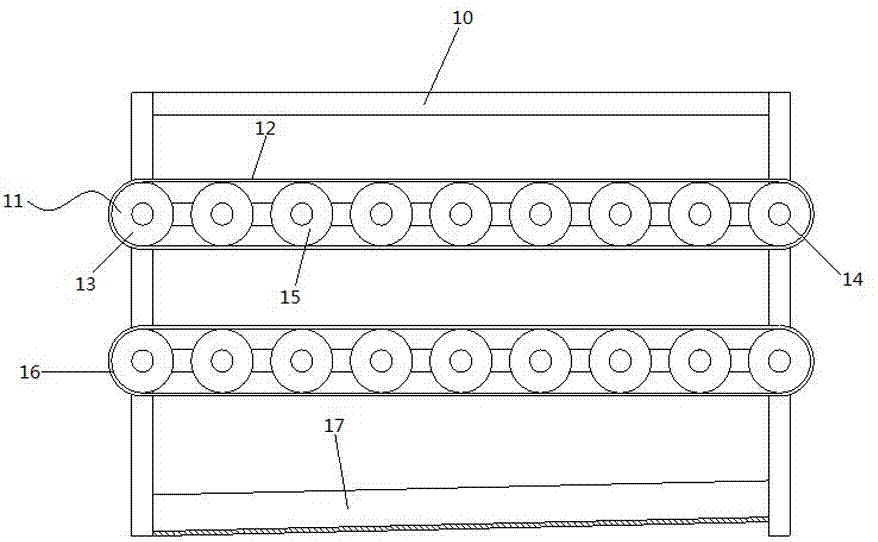

Washing machine and control method for washing machine

ActiveCN106381646AGuaranteed flushing effectEnsure normal flowOther washing machinesControl devices for washing apparatusWater flowEngineering

The invention discloses a washing machine and a control method for the washing machine. The washing machine comprises a filtering draining device and a control device, wherein the filtering draining device comprises a water inlet, a filtering component, a draining component and a circulating component; the filtering component is arranged between the water inlet and the circulating component and is used for supplying the washing water after being filtered to the circulating component; the draining component is arranged along a tangential direction of a filtering surface of the filtering component; the control device is respectively connected with the draining component and the circulating component; the control device is used for controlling the running of the washing machine, acquiring the running stage of the washing machine and controlling the draining component and the circulating component according to the running stage of the washing machine. Thus, when the circulating component works, the washing water flows by the filtering component from top to bottom, so that the circulating water free from impurities like soft flocks can be guaranteed and the washing effect in the washing machine can be guaranteed. When the draining component works, the draining water can flow along the tangential direction of the filtering component and can take away the impurities like soft flocks accumulated on the surface, so that the self-cleaning effect can be achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

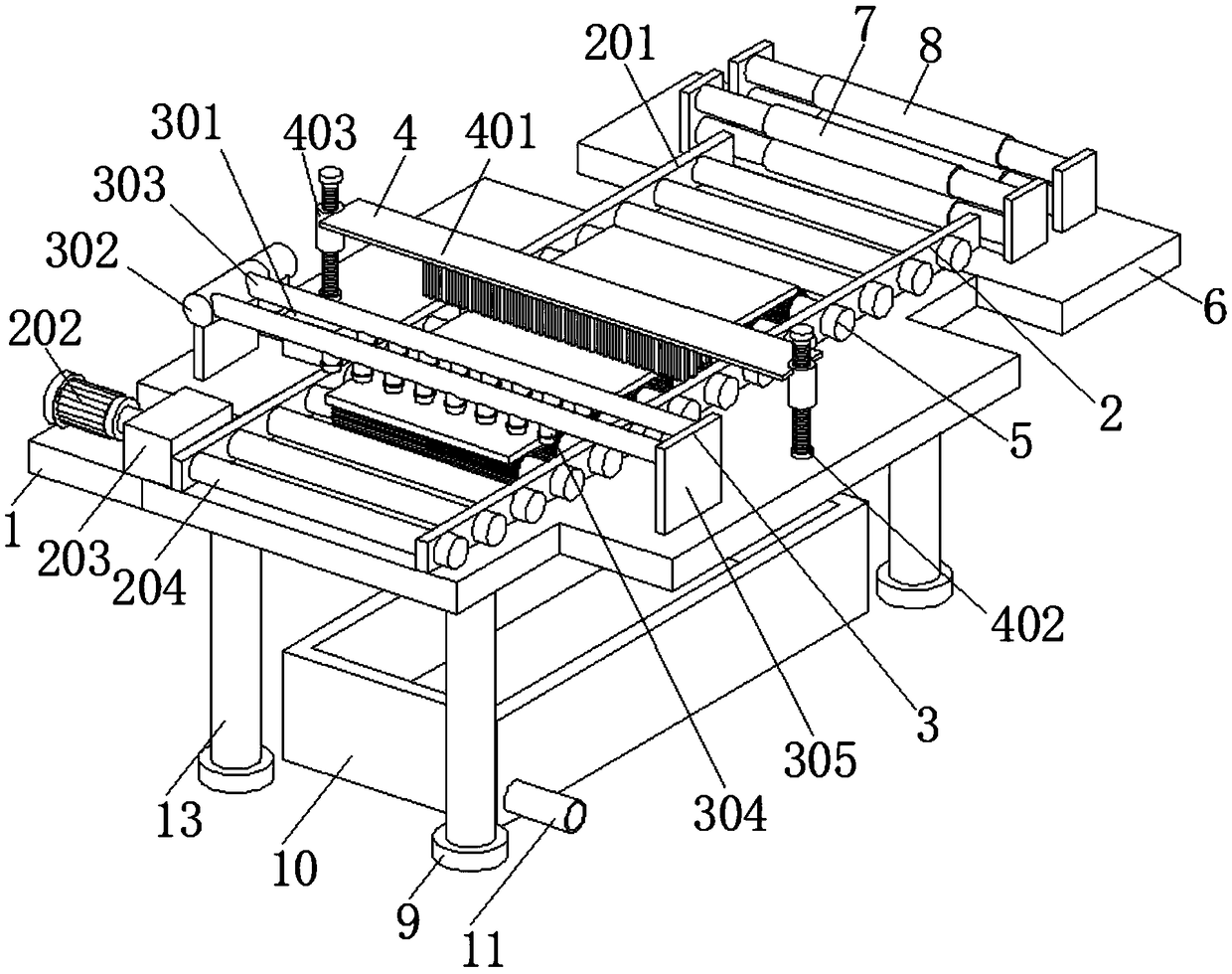

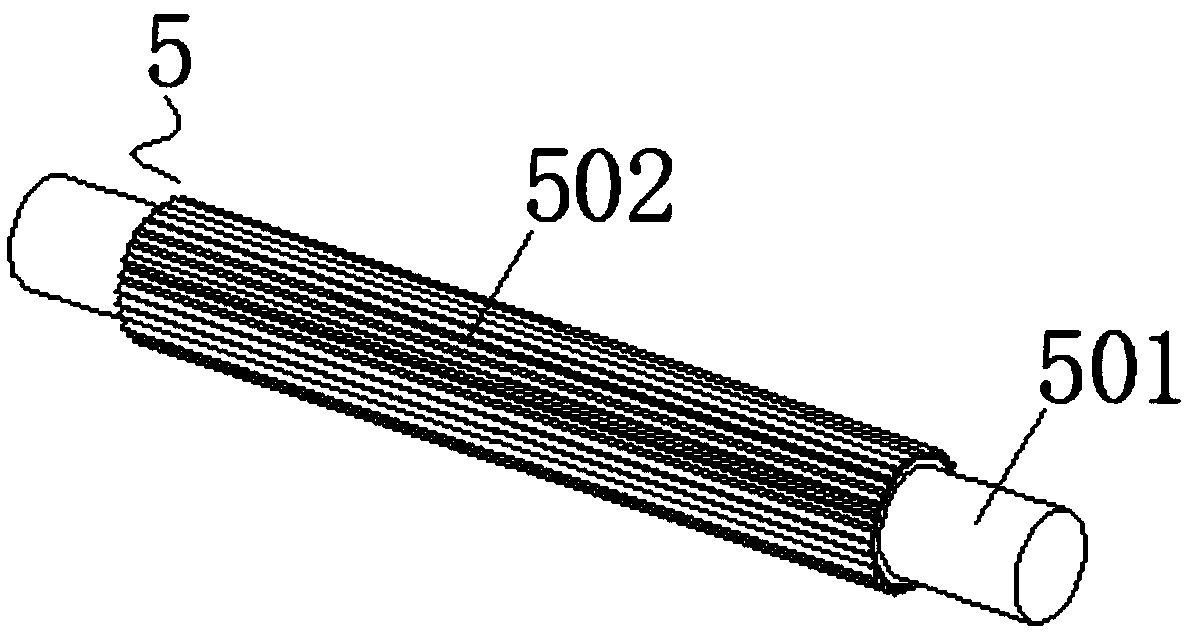

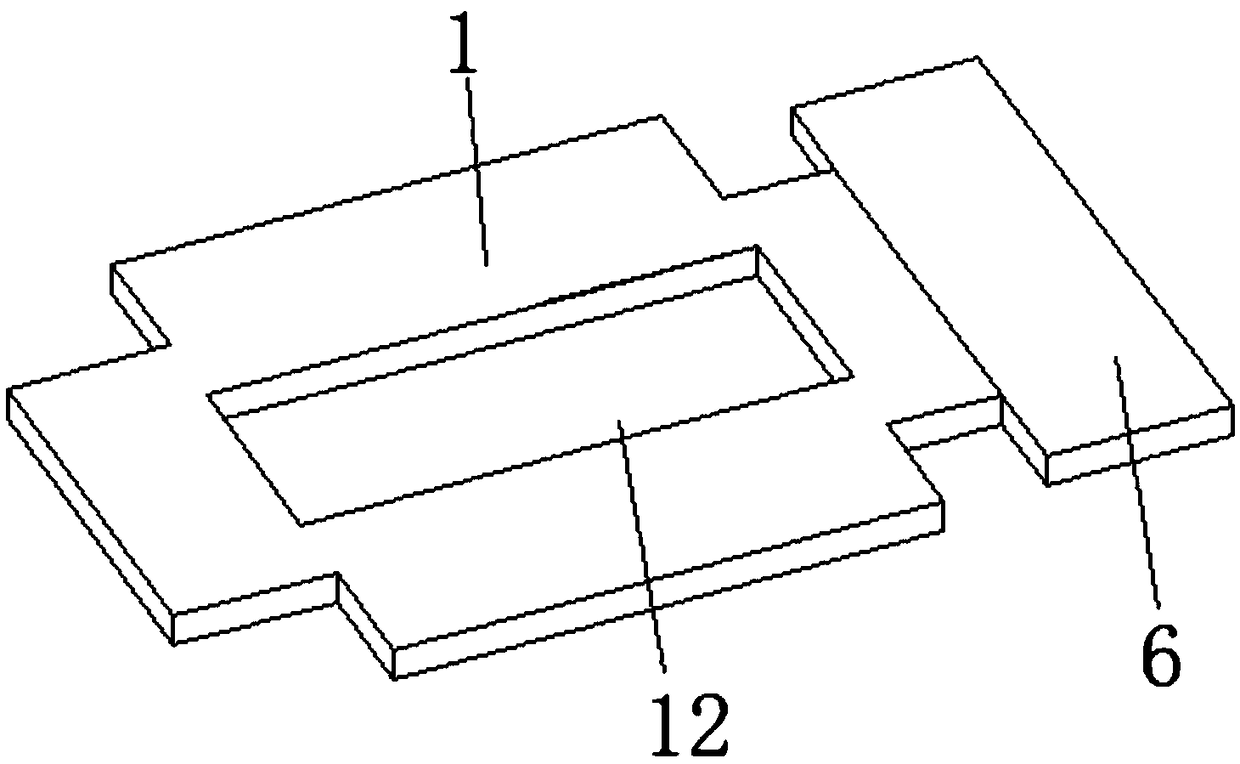

Feeding mechanism for knurling machine

PendingCN109454399AGood effectReduce yieldMetal working apparatusMaintainance and safety accessoriesKnurlingEngineering

The invention discloses a feeding mechanism for a knurling machine. The feeding mechanism comprises a working platform, the top of the working platform is provided with a transmission mechanism, a flushing mechanism is arranged at the top of the working platform, the flushing mechanism is located at the top of the transmission mechanism, the top of the working platform is fixedly connected with abrushing mechanism, the brushing mechanism is located at the top of the transmission mechanism, and a bottom brushing roller is arranged at the top of the working platform. The feeding mechanism solves the problems that an existing knurling machine cannot pre-treat materials, dirt such as residual dust is prone to being left on the materials, the condition of the poor knurling effect in the feeding knurling process is caused, and the yield rate of the product is greatly reduced; and the feeding mechanism of the knurling machine has the advantages of pretreating the materials and improving theyield rate, the structure is simple, operation is convenient, the use cost is low, the knurling effect can be further improved, and the defective percentage of the knurling machine is greatly reduced.

Owner:浙江中诺智能机械有限公司

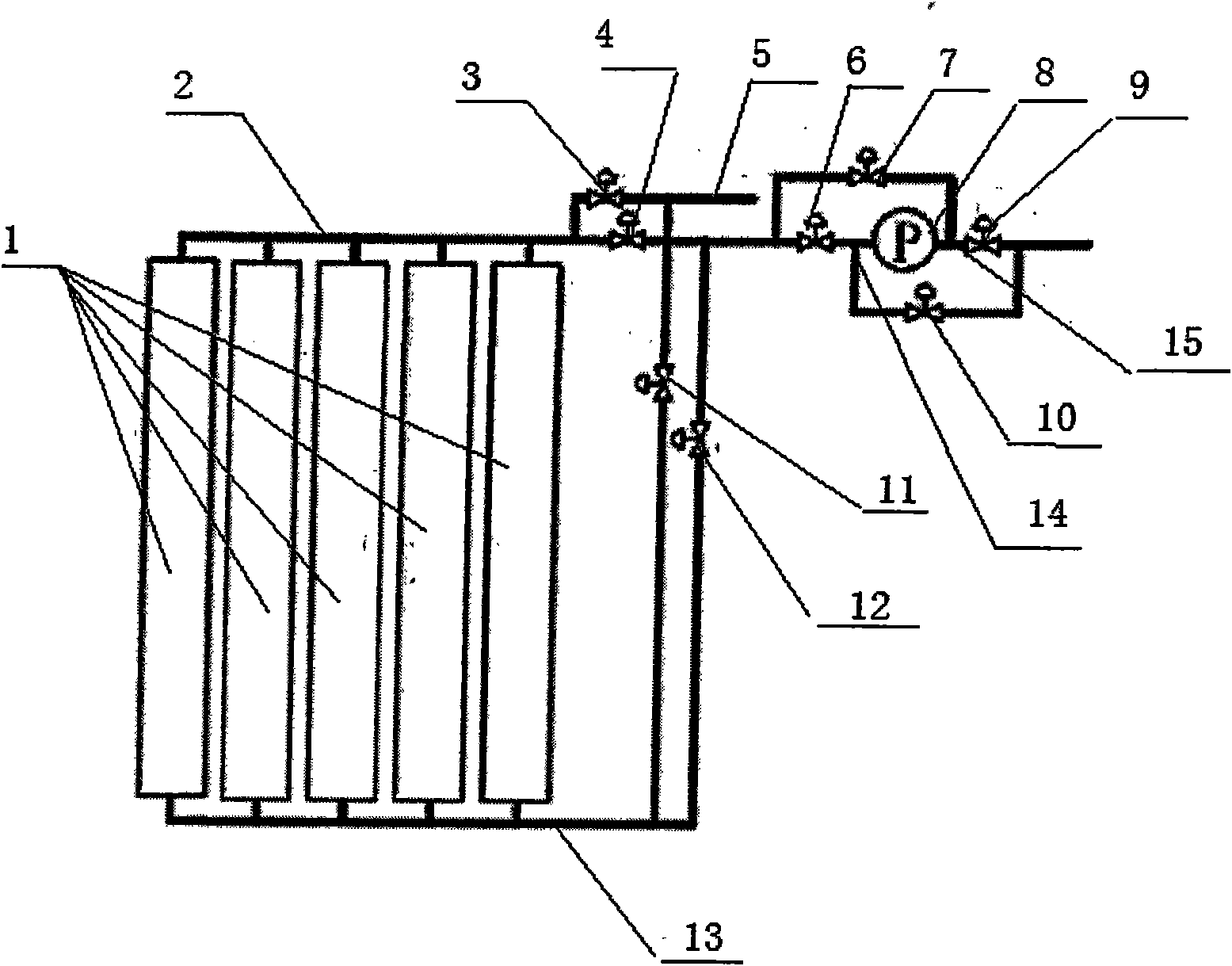

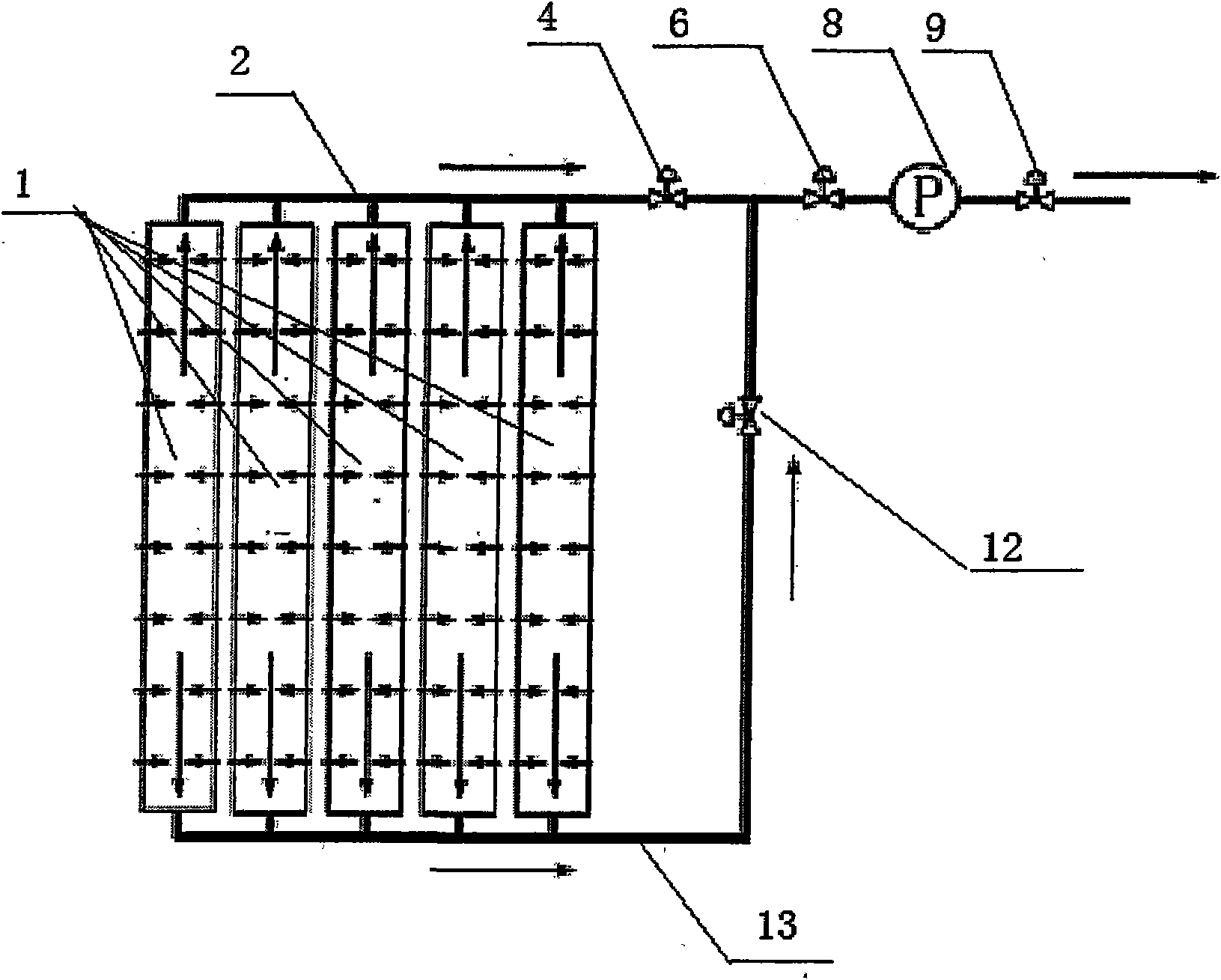

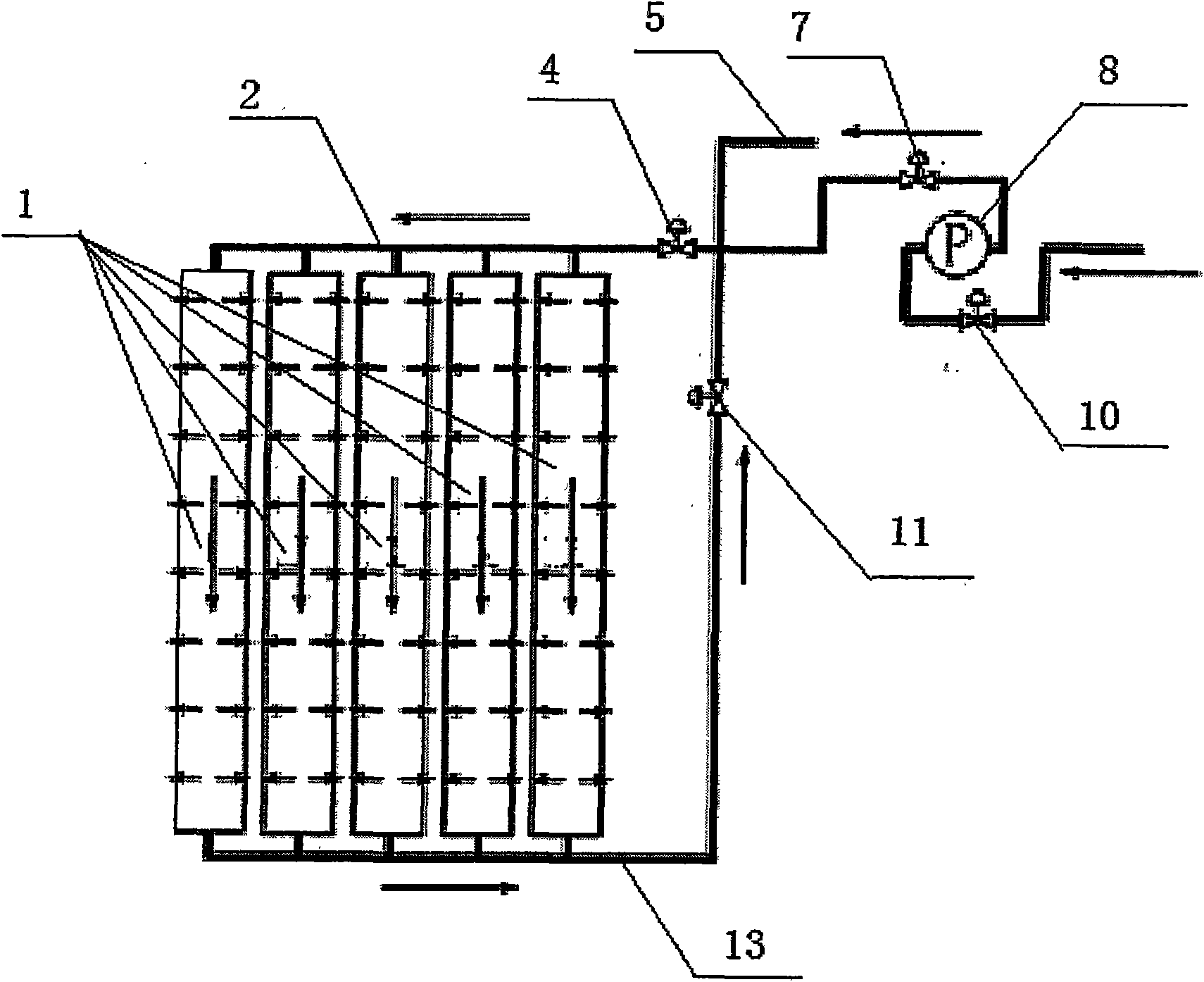

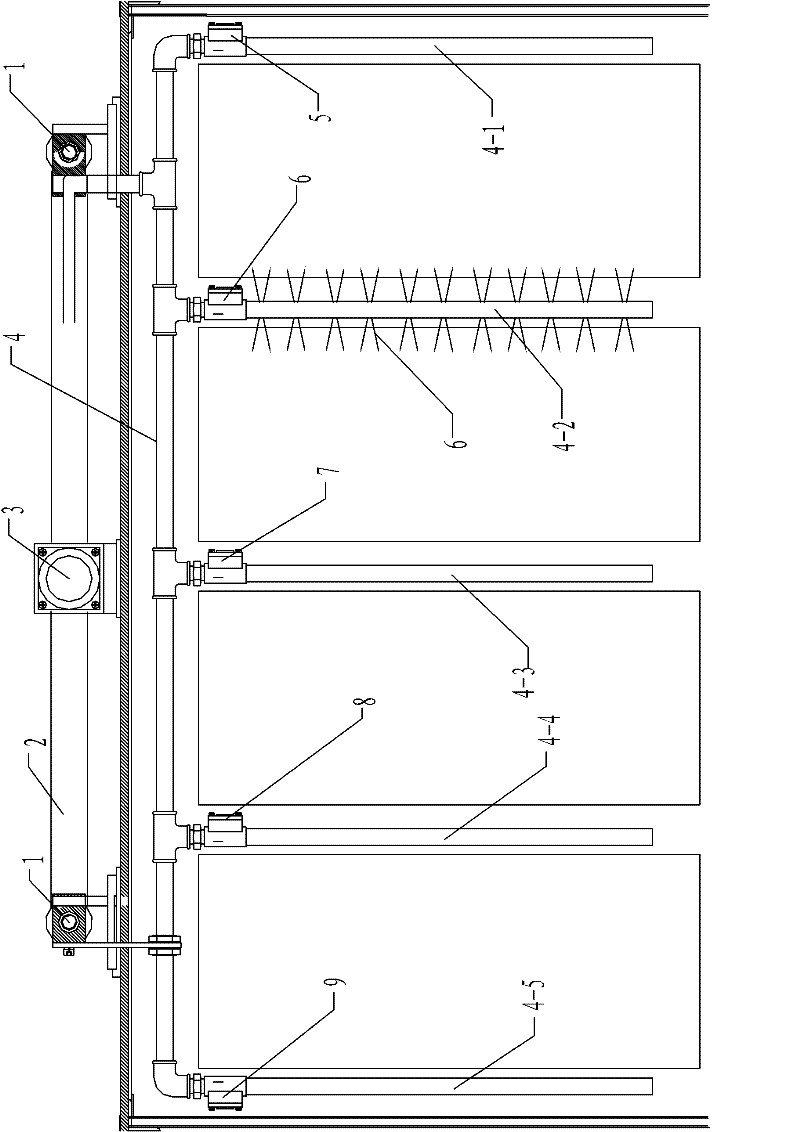

Water treatment system with bidirectional cleaning function

ActiveCN101785972AOvercome blockageOvercome cleaningSemi-permeable membranesWater treatment systemEngineering

The invention discloses a water treatment system with bidirectional cleaning function, and aims to provide a water treatment system capable of realizing bidirectional alternate cleaning. The upper water outlet of a double-end water outlet external-pressing membrane assembly is connected with an upper filtrate collecting conduit, while the lower water outlet is connected with a lower filtrate collecting conduit; the upper filtrate collecting conduit is connected with a first control valve and a second control valve; the lower filtrate collecting conduit is connected with a third control valve and a fourth control valve; the first control valve is connected in parallel with the third control valve and then is connected with a fifth control valve, a water pump and a seventh control valve in turn; one end of an eighth control valve is connected with a second connector of the water pump, while the other end is connected in parallel with the fifth control valve; one end of a sixth control valve is connected with a first connector of the water pump, while the other end is connected in parallel with the seventh control valve; and the second control valve is connected in parallel with the fourth control valve and then is connected with a residual cleaning solution outlet. The system can realize bidirectional alternate cleaning, improve the flushing effect on pollutants in a membrane cavity, and ensure the membrane cleaning efficiency and reflux recovery rate.

Owner:TIANJIN MOTIMO MEMBRANE TECH

Full-automatic high-voltage electrostatic oil fume purifier utilizing segmented cleaning

InactiveCN102476005AGuaranteed flushing effectReduce pump powerCombination devicesCleaning using liquidsControl valvesHigh pressure

A full-automatic high-voltage electrostatic oil fume purifier utilizing segmented cleaning is characterized by being provided with a full-automatic cleaning device which comprises a reduction motor, a lead screw, a transmission device, a movable cleaning main water pipe, a plurality of position sensors and a single-chip controller. The movable cleaning main water pipe is provided with a plurality of cleaning water pipes with water nozzles, and control valves are arranged at upper ends of the cleaning water pipes respectively. An output shaft of the reduction motor is connected with the lead screw through a driven gear of the transmission device, a lead screw bush of the movable cleaning main water pipe is connected with a thread of the lead screw movably, and the movable cleaning main water pipe is communicated with a water outlet of a water pump. The position sensors are arranged at two ends of the lead screw respectively, the reduction motor and the control valves are connected with an output end of the single-chip controller respectively, and signal output ends of the position sensors are connected with an input end of the single-chip controller respectively. The common problem that existing oil fume purifiers are incapable of running normally due to accumulated oil is solved thoroughly and purifying efficiency is constant all year round.

Owner:刘海龙 +1

Cleaning method of steam generator

ActiveCN109482583AAvoid the problem of susceptibility to more radiationGuaranteed flushing effectHollow article cleaningElectricityEngineering

The invention provides a cleaning method of a steam generator. The cleaning method of the steam generator is used for cleaning the outer wall of a pipeline of the interior of the steam generator, a chain assembly, a flushing trolley and other parts are placed on the inner side of the steam generator through a hand hole in one side of the steam generator, and the flushing trolley, a forward traction assembly and a reverse tensioning assembly are sequentially arranged; the position of the flushing trolley is adjusted, it is guaranteed that the flushing trolley can flush the middle position of the outer wall of the pipeline, the flushing effect is guaranteed, the flushing trolley is controlled by a control mechanism in the exterior, the problem of electricity generating efficiency parameter affected by dirt accumulated on the surface of the pipeline wall and the decline of thermal transmission efficiency is solved, and in addition, the problem that personnel is prone to more radiation directly entering the steam generator for cleaning can be effectively solved.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

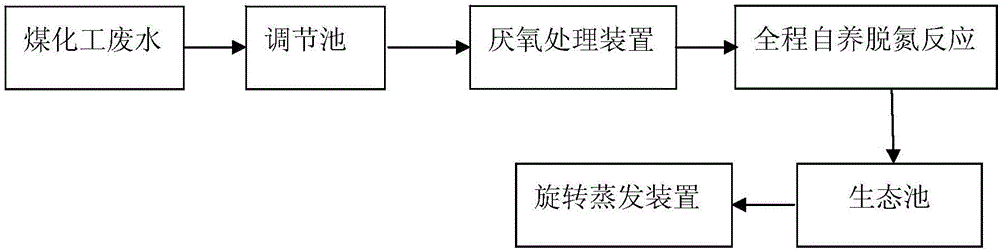

Ecological pool and efficient coal chemical engineering waste water treatment combined process and system

ActiveCN106495328AEffective absorptionAchieve absorptionMultistage water/sewage treatmentNature of treatment waterNitrogen removalWater treatment system

The invention provides an ecological pool and an efficient coal chemical engineering waste water treatment system and process based on the ecological pool. The system comprises an adjusting pool, an anaerobic treatment device, a whole-process autotrophic nitrogen removal reactor, the ecological pool and a rotary evaporation device which are sequentially connected and arranged. The adjusting pool is used for adjusting the pH value of coal chemical engineering waste water and adding a flocculant for treatment; the waste water treated by the anaerobic treatment device enters the whole-process autotrophic nitrogen removal reactor for nitrogen removal; the ecological pool is provided with a nanofiltration membrane device, an ecological floating bed is arranged on the water level of the ecological pool, and an aeration device is arranged on the bottom layer of the ecological pool. Filtrate obtained after filtering of the nanofiltration membrane device enters the rotary evaporation device. Clean effluent quality is obtained through the adjusting pool, the anaerobic treatment device, the whole-process autotrophic nitrogen removal reactor, the ecological floating bed and the aeration device in the ecological pool, blocking of a nanofiltration membrane can be effectively reduced, and the service life of the nanofiltration membrane can be prolonged. The whole process has the advantages of being low in energy consumption and free of secondary environmental pollution.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Medical hybrid flushing device

InactiveCN103690354AEasy to carryConserve waterEnemata/irrigatorsBathing devicesAdditive ingredientWhole body

The invention discloses a medical hybrid flushing device which comprises a hollow water pipe and a built-in rotary cylindrical bottle arranged in the hollow water pipe, water outlet holes are distributed in the wall of the rotary cylindrical bottle so that active ingredient for treatment in a traditional Chinese medicine bag or tablet in the rotary cylindrical bottle is mixed with a flushing liquid in the hollow water pipe via the water outlet holes, meanwhile, the active ingredient for treatment in the traditional Chinese medicine bag or tablet in the rotary cylindrical bottle flows out of the water outlet holes and is gradually mixed with the flushing liquid flowing through the hollow water pipe by rotation of the rotary cylindrical bottle during flushing so as to form a uniform flushing liquid containing treatment ingredients. The flushing liquid obtained through the device can have effects of treatment, sterilization, inflammation diminishing, prevention, cleaning and health protection on whole body and disease parts such as nasal cavity, vagina and oral cavity.

Owner:张雷 +1

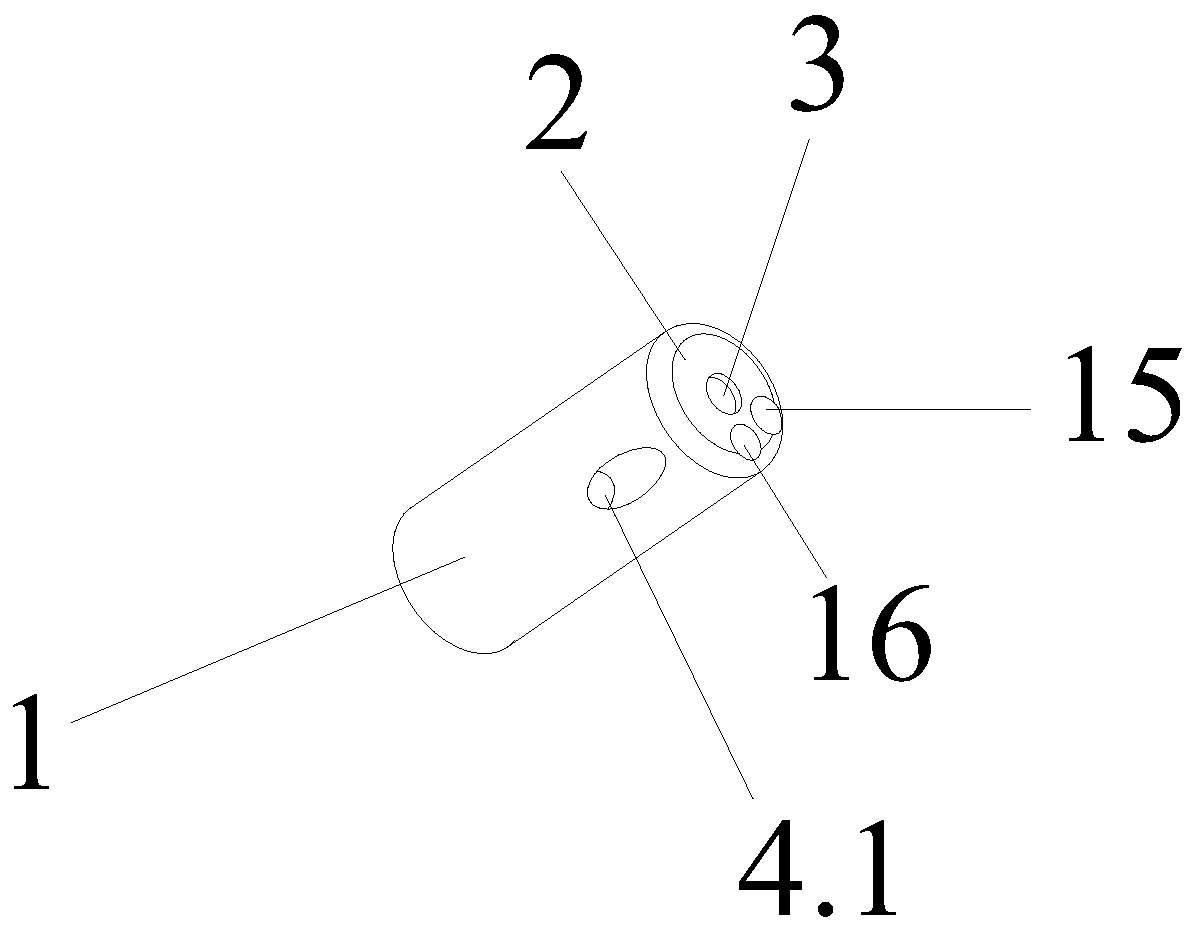

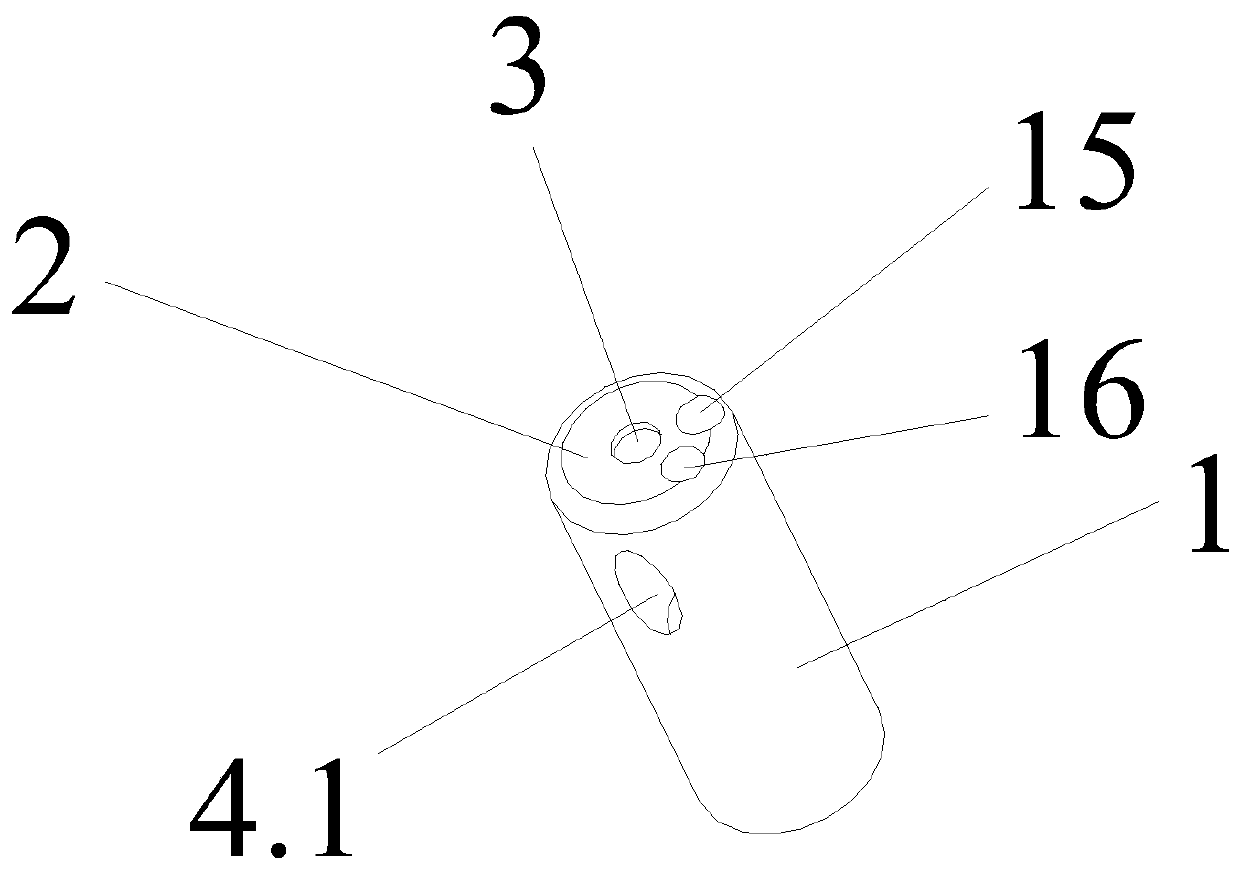

Sheath pipe cap and endoscope guide sheath with same

PendingCN109998672AIncrease the probability of getting out of the stone pointGuaranteed flushing effectEndoscopesSurgical instruments for irrigation of substancesWater flowEngineering

The invention discloses a combination set for calculus breaking and removing treatment for calculi in the human body cavity. The set comprises a shell lantern ring and a cylinder coaxially fixed to the inner surface of one end of the shell lantern ring, the cylinder is internally provided with a mechanical channel straight hole and a water spray channel straight hole which are parallel to the axial direction of the cylinder, and a sheath pipe cap is provided with a water spray channel oblique hole which is communicated with the water spray channel straight hole and can spray water to the lateral front of the sheath pipe cap. By designing the combined hole structure mode of the water spray channel straight hole and the water spray channel oblique hole on the sheath pipe cap, water flow entering from an endoscope guide sheath can be sprayed to the front face and the side face of calculus point in front of the sheath pipe cap simultaneously, while broken calculi at the calculus point aresubjected to multi-angle washing to increase the probability that the broken calculi get away from the calculus point, water flow in the front direction and water flow in the side direction of the sheath pipe cap interact with each other to form a vortex, the broken calculi are further separated from the calculus point under the action of the vortex, the separation probability of the broken calculi and the calculus point is greatly increased, and the washing effect of the water flow to the broken calculi is guaranteed.

Owner:YOUCARE TECH CO LTD

Cementing material, and concrete suitable for plant growth

InactiveCN111302750AGuaranteed bond strength performanceDoes not produce strong basesCeramicwareSlagMining engineering

The invention discloses a cementing material, and concrete suitable for plant growth. The concrete comprises the following components in parts by mass: 50-80 parts of clay, 10-20 parts of fly ash, 5-10 parts of the cementing material as described in claim 1, 2-10 parts of sawdust, 2-8 parts of a fermented organic fertilizer, 0.1-1 part of calcium superphosphate and 0.1-2 parts of water-retaining resin, wherein the cementing material comprises 70% of gypsum, 20% of blast furnace slag and 10% of low-alkali sulphoaluminate cement. According to the concrete in the invention, a combination of the gypsum, the blast furnace slag and a small amount of the low-alkali sulphoaluminate cement is adopted to replace common Portland cement as the cementing material, so generation of strong alkali and useof rubber powder can be avoided, and the anti-scouring strength of the concrete is improved; a part of generated alkalinity can be consumed through a reaction of the fly ash, the blast furnace slag and a small amount of the low-alkali sulphoaluminate cement, so a neutral environment suitable for plant growth is created; and the strength of the vegetation concrete is improved through the synergistic effect of gypsum.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

High-efficiency ultrafiltration membrane cleaning solution and cleaning method

The invention discloses a high-efficiency ultrafiltration membrane cleaning solution which comprises a main cleaning solution and a biochemical additive solution, wherein the main cleaning solution comprises 2-5 parts of EDTA sodium salt, 1.5-3.2 parts of sodium dodecyl benzene sulfonate, 1.3-2.8 parts of lauryl sodium sulfate, 0.5-2.5 parts of fatty alcohol-polyoxyethylene ether, 0.4-2 parts of ethoxylated lauryl alcohol sulfates, 0.1-0.3 part of sodium hexametaphosphate, 0.5-3 parts of sodium citrate, 0.1-0.7 part of sodium silicate and 80-100 parts of product water; the biochemical additive solution comprises 0.6-2 parts of a bactericide, 0.2-1.5 parts of cellulase, 0.3-1.5 parts of pectinase, 0.2-1 part of protease, 0.5-1 part of a pH buffer solution and 80-100 parts of product water. The high-efficiency ultrafiltration membrane cleaning solution disclosed by the invention is excellent in effect, has an excellent effect for removing inorganic and organic pollutants and biological pollutants and also has a flexible processing property.

Owner:太仓市金鹿电镀有限公司

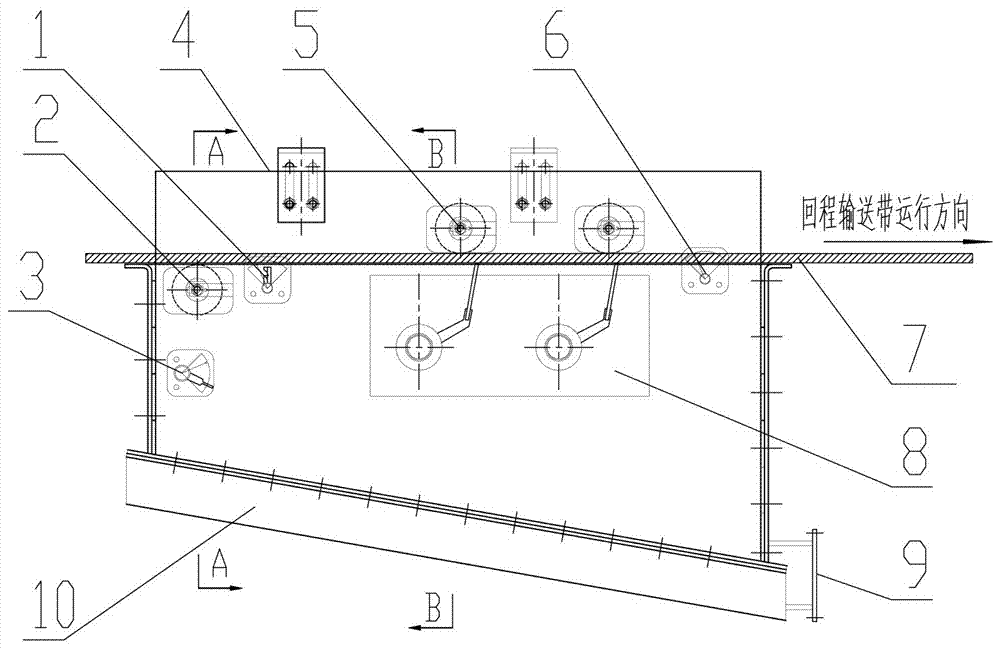

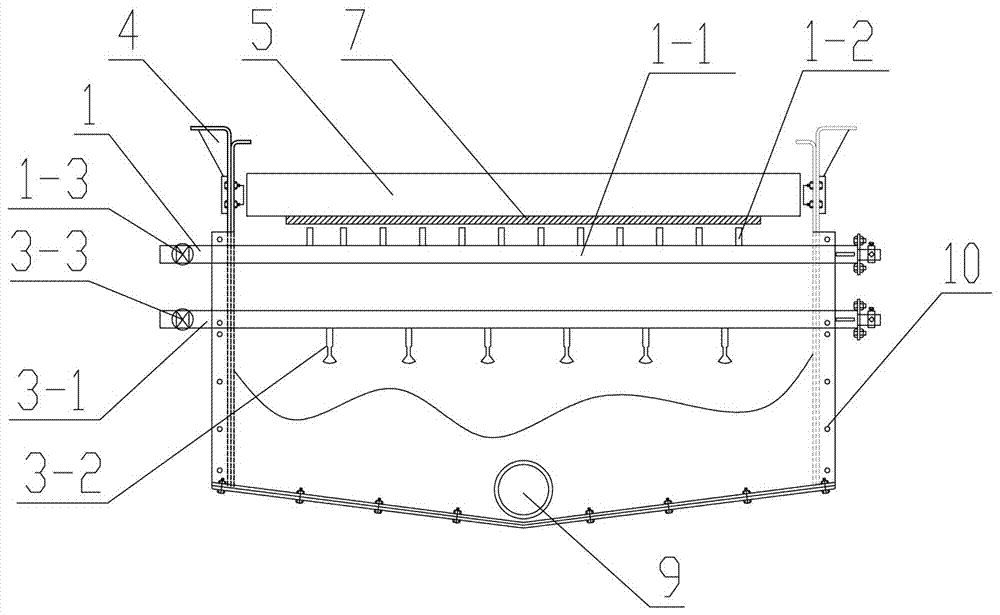

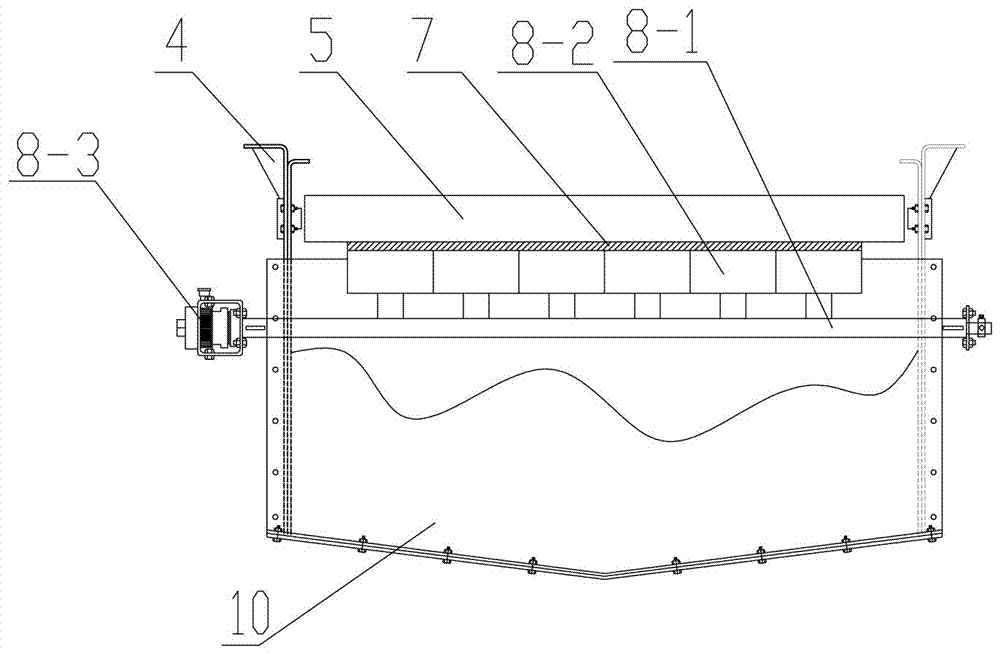

Conveying belt cleaning device for belt conveyer

The invention discloses a conveying belt cleaning device for a belt conveyer. The conveying belt cleaning device comprises a connection hanging bracket, a top water spraying system, an end part water spraying system, a compressed gas blowing-drying system, a carrier roller, a carrier roller rack, scraping knife systems, a mud collection box and the like. The conveying belt cleaning device disclosed by the invention is applicable to cleaning for a conveying belt of the belt conveyer, and in particular to an occasion with a high requirement on the cleanliness degree of the conveying belt of the belt conveyer and a high requirement on environmental protection. The device is installed on a return-stroke conveying belt of the belt conveyer, and on an inclined section or a horizontal section. A material adhesion force is reduced through the water spraying systems of the device, and materials adhered onto the conveying belt are effectively cleaned through the two scraping knife systems, so that material scattering of the belt conveyer on the way is reduced and even avoided, the environment of a plant is improved, and the workload of cleaners in the plant is reduced. The device has the advantages of being easy to install, low in member cost, easy to adjust, not provided with a drive component, convenient to maintain, long in service life, capable of prolonging the service life of the conveying belt, and the like.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

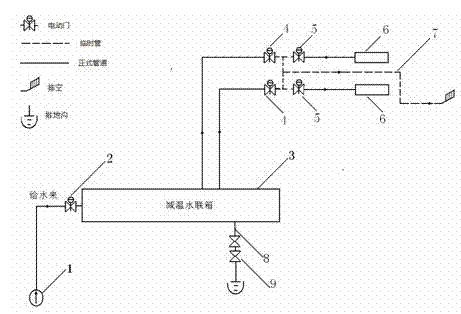

Washing method of power station boiler temperature reducing water system and washing pipeline connection structure

InactiveCN102777884AEffective flushingSignificant safety benefitsBoiler cleaning apparatusPower stationMotor drive

The invention discloses a washing method of a power station boiler temperature reducing water system and a washing pipeline connection structure. The washing method and the structure comprise a power station boiler temperature reducing water system. The method includes first increasing a temporary communication pipe on the power station boiler temperature reducing water system. The temporary communication pipe is located between two motor-driven doors connecting a temperature reducing water connection tank and a temperature reducing water pipeline of a temperature reducer. After the temporary communication pipe is connected, the washing steps comprise first way water washing, second way water washing and third way steam back washing. The washing method and the structure ensure that all temperature reducing water systems can be washed by a simple temporary system and the operation mode and ensure washing flow quantity and washing effect due to the fact that the inner diameter of a temporary pipe is larger than the inner diameter of the temperature reducing water pipeline.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

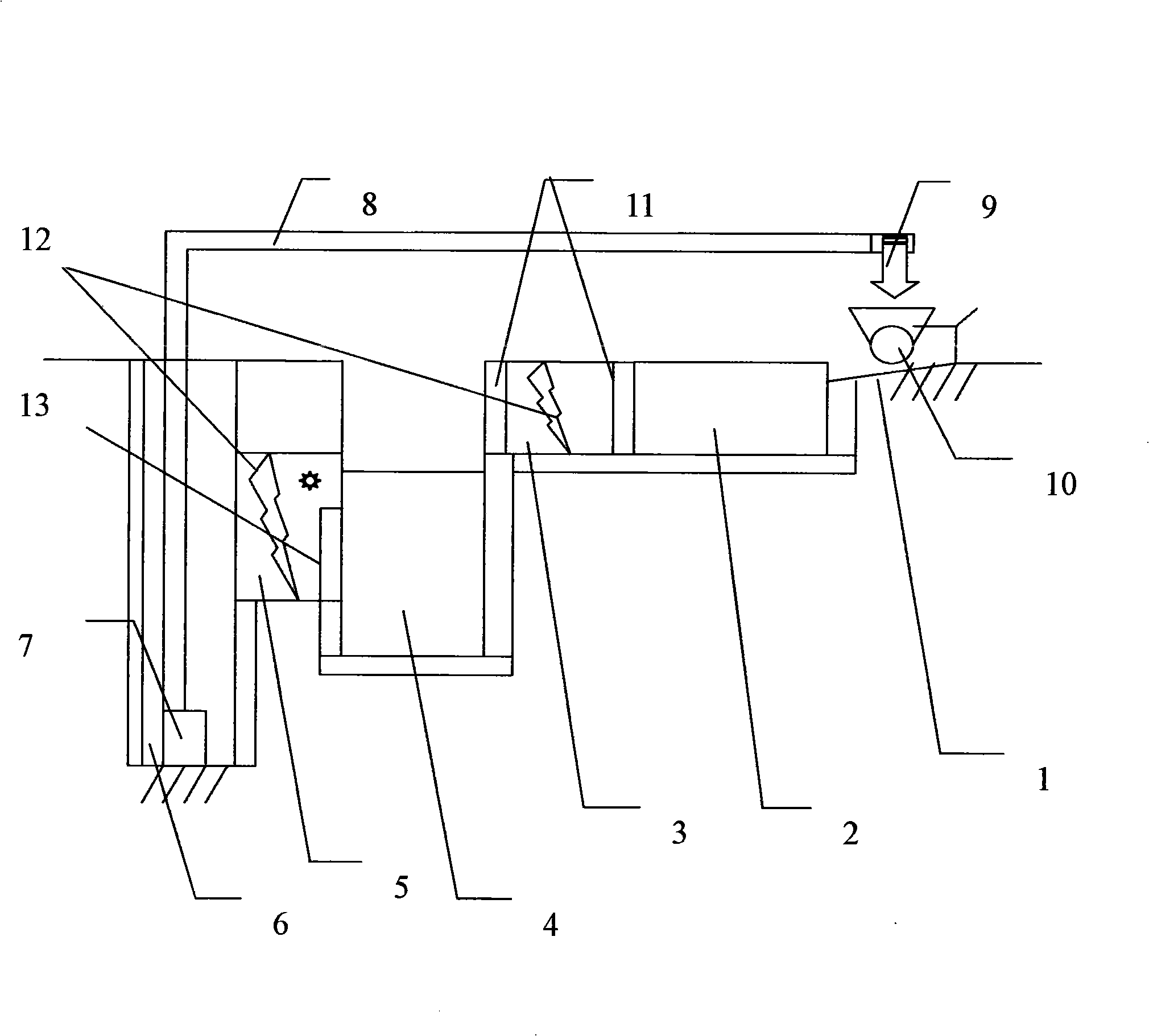

Device and method for flushing gravel using recirculated water at construction site

InactiveCN101332446AReduce lossGuaranteed flushing effectMultistage water/sewage treatmentWet separationTap waterWater flow

The invention relates to a device for flushing stones with circulating water at a construction site and a method thereof. The device comprises a filtering system, a settling system and a flushing system, wherein, the filtering system consists of a gradient rising table and a filter basin which forms a filter channel by a fence and is provided with a filler; a settling basin and a collecting well of the settling system are communicated with each other by a blind ditch; and the flushing system is provided with a water pump and a rotatable water gun. The flushing steps are as follows: the stones are flushed with a common tapping pipe, when the settling basin and the collecting well are filled with water, the tapping pipe is closed, the water pump is turned on, then the flushing is carried out when the rotatable water gun aims at a car hopper; the muddy water from flushing the stones flows into the filtering basin, most silt settles at the bottom of the filtering basin when the muddy water flows through the filtering basin, then the muddy water flows into the settling basin by the filtering channel for settling, after settling, the water at the upper section of the settling basin is relatively clear and runs into the collecting well by the blind ditch, and then the water is pumped by a water pump for recycling. The device has low cost, and the method is easily achieved and has good effect, which are favorable for settling and silt discharging.

Owner:湖北全洲扬子江建设工程有限公司

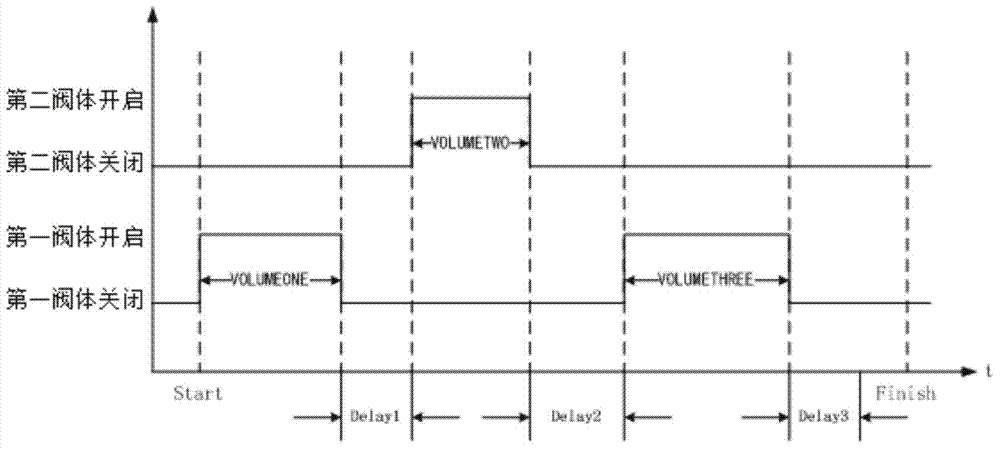

Toilet bowl flushing method

The invention relates to a toilet bowl flushing method. The method includes the steps of S1, allowing a control valve to open a jetting water path to allow the jetting water path to jet the bottom in a toilet bowl urinal so as to discharge dirt in the toilet bowl urinal out of a discharge pipe, and allowing the control valve to close the jetting water path after the jetting path is opened for a preset time period T1; S2, allowing the control valve to open a washing water path to allow the washing water path to wash the surface of the toilet bowl urinal so as to wash the dirt on the surface of the toilet bowl urinal to the bottom of the toilet bowl urinal, and allowing the control valve to close the washing water path after the washing water path is opened for a preset time period T2; S3, allowing the control valve to open the jetting water path again to allow the jetting water path to jet the bottom of the toilet bowl urinal to discharge the dirt in the toilet bowl urinal out of the discharge pipe again, and allowing the control valve to close the jetting water path after the jetting water path is opened again for a preset time period T3. The toilet bowl flushing method has the advantages that the hardware structure of an existing toilet bowl does not need to be changed, a toilet bowl can be effectively flushed by controlling the flushing steps of the toilet bowl, and an evident effect is achieved.

Owner:XIAMEN R&T PLUMBING TECH

Preparation method of shrimp meat

PendingCN106923246AColor stableStable NutrientsFood ingredientsShrimp/lobster processingPreservativeCool storage

The invention provides a preparation method of shrimp meat. A formula of a preservative, a raw shrimp cleaning and conveying device and a shrimp shelling operating table are included. The preparation method comprises the specific steps as follows: cleaning, soaking with the preservative, cooking and cooling, shelling, cleaning, individual quick freezing, packaging, cold storage and the like. The shrimp meat which is stable in color, elastic in meat quality and delicious can be obtained quickly and efficiently with the preparation method of the shrimp meat.

Owner:福清朝辉水产食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com