Clothing washing facility with drying program and control method thereof

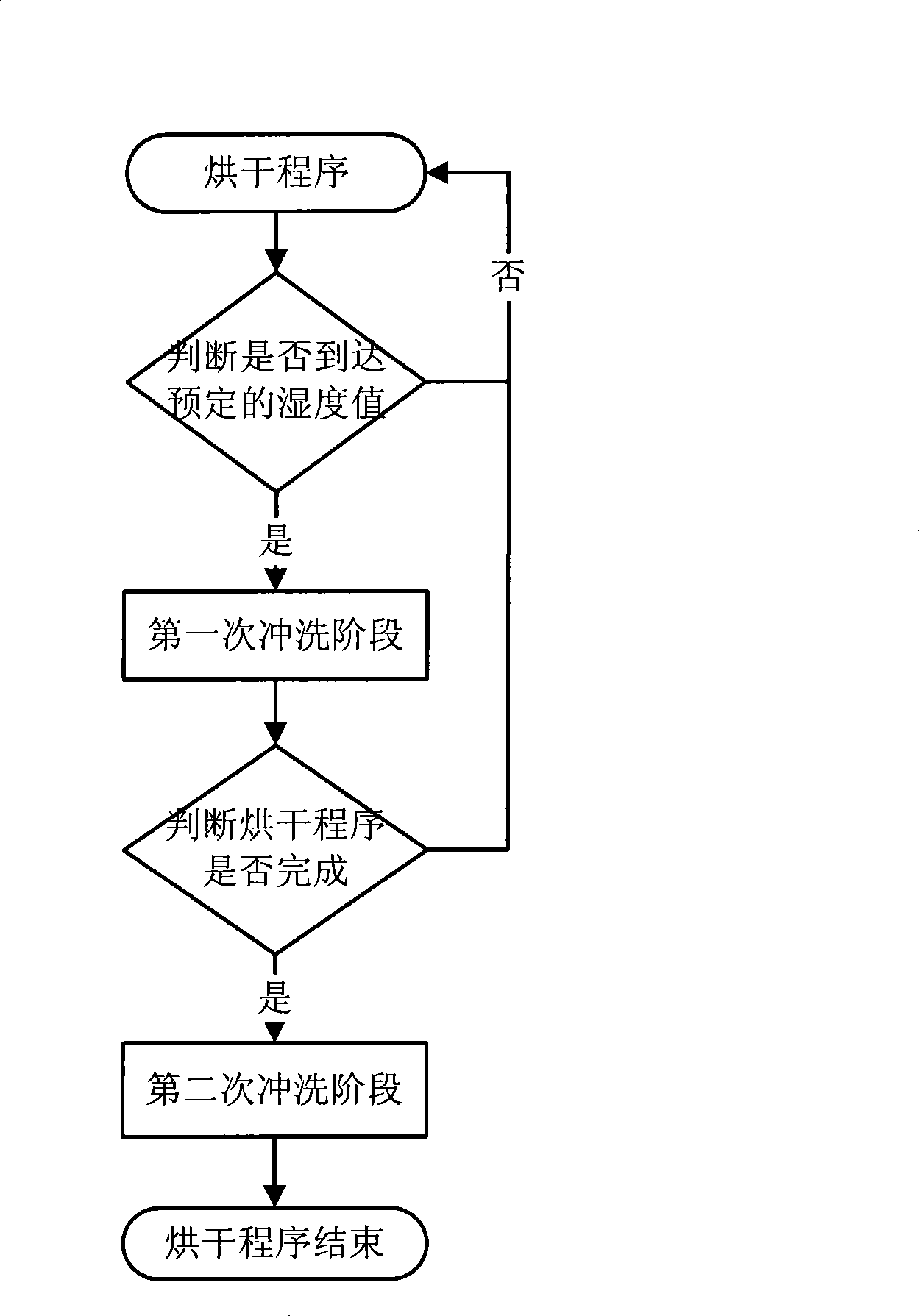

A drying procedure and laundry washing technology, applied in the control field of laundry washing equipment, can solve the problem that the ring flow adheres to the surface of the dehumidification device or even enters the blower fan and heating pipe, stains the laundry, and the flushing effect is not very ideal, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

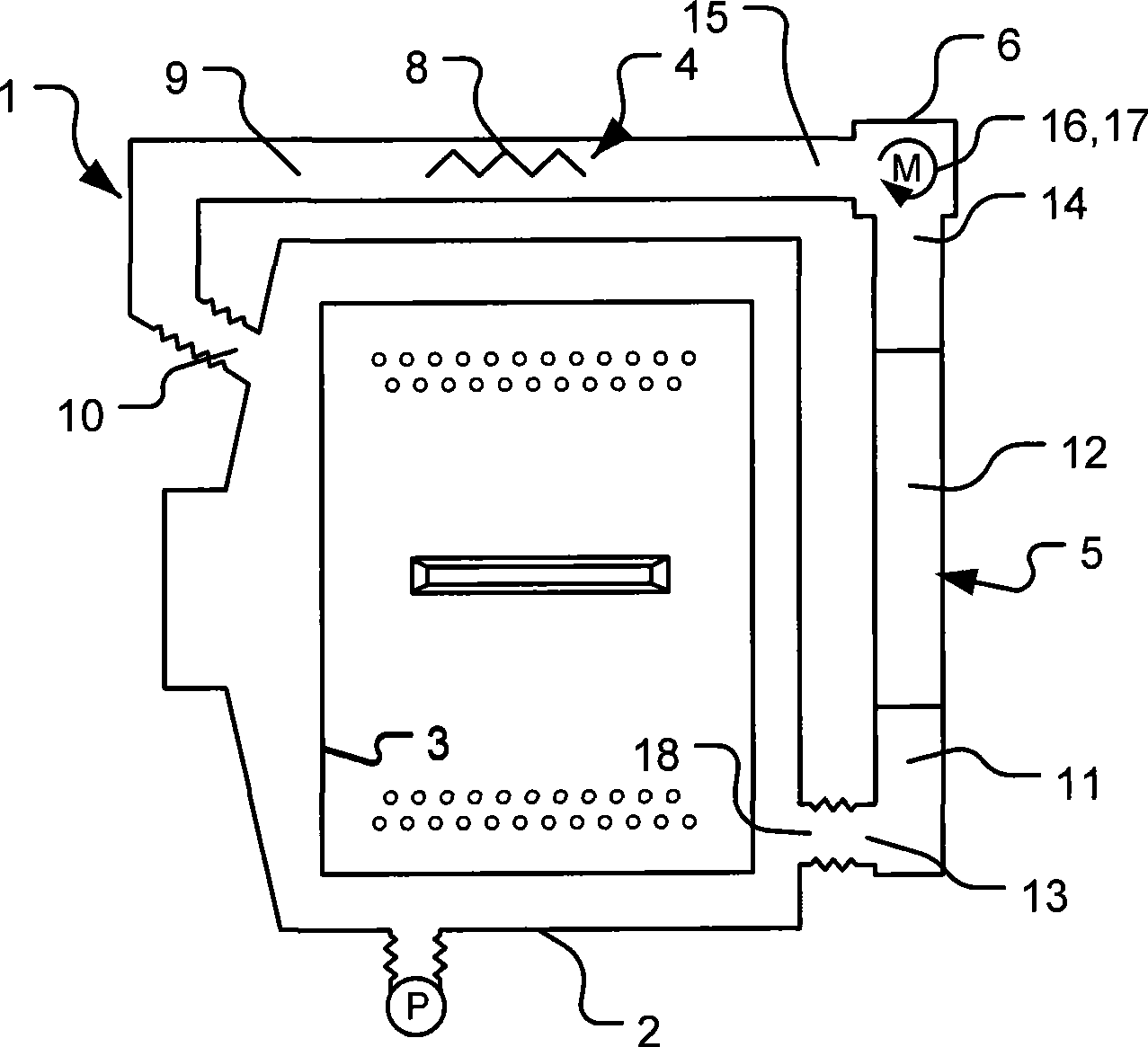

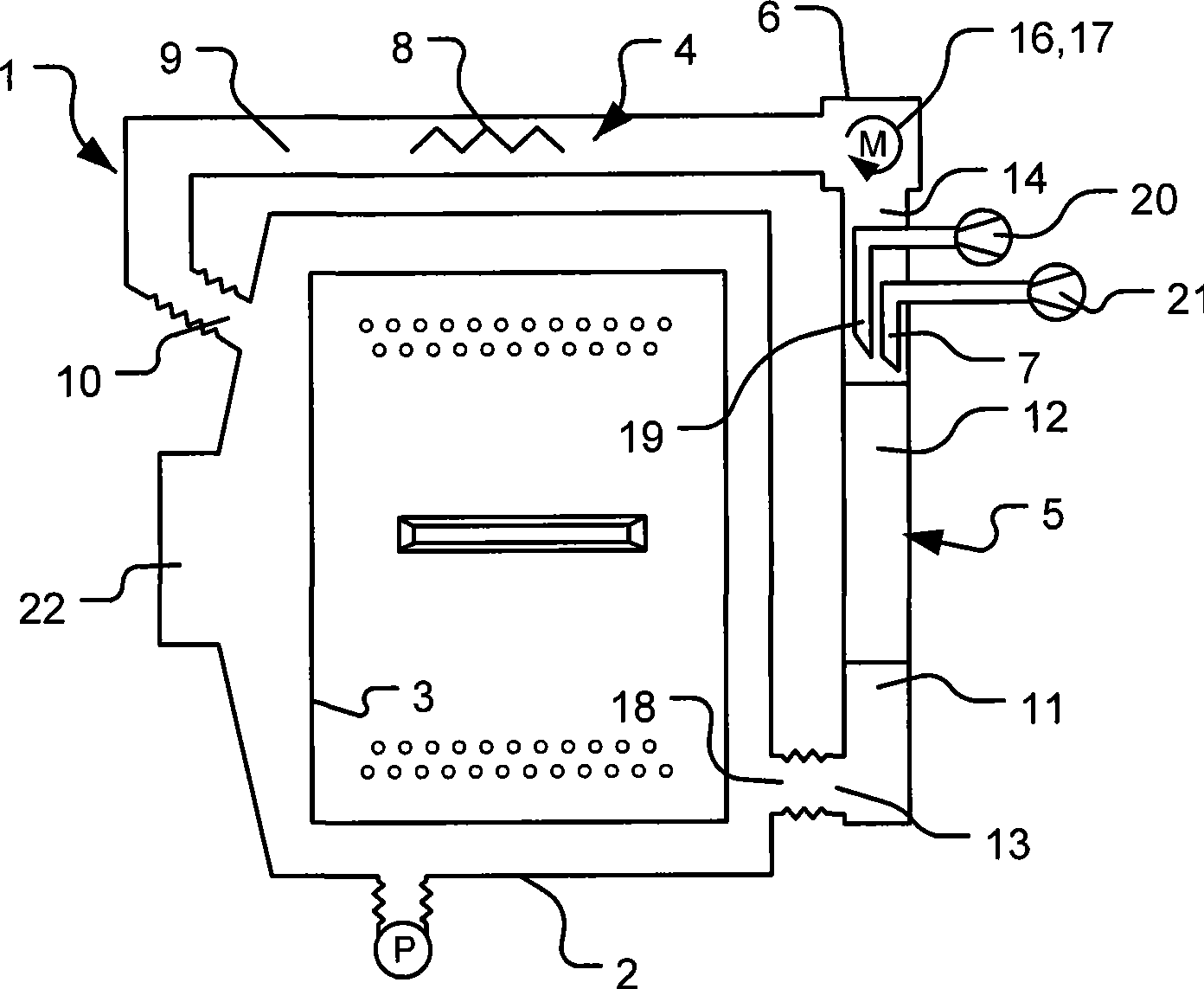

[0021] According to the specific embodiment of the present invention, there is a clothes washing device 1 with a drying program. Since the drum washer-dryer is roughly the same as the drum dryer in terms of drying function modules, the drum washer-dryer is taken as an example below, as figure 2As shown, the drum washer-dryer includes a tub 2 and a rotatable drum 3 disposed inside the tub 2 , and a heating assembly 4 is arranged on the upper side of the tub 2 , and the heating assembly 4 includes a heating device 8 And the drying pipeline 9, the bucket 2 and the drum 3 are provided with an opening 22 for the user to put in and take out clothes on the side facing the user, and the outlet 10 of the drying pipeline 9 is connected to the inside of the bucket 2 and is arranged in the The drum 3 inside the bucket 2 is connected through the opening 22 or another opening (not shown in the figure) above the opening 22. One side of the bucket 2 is provided with an air outlet 18 at a prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com