Conveying belt cleaning device for belt conveyer

A belt conveyor and cleaning device technology, which is applied to cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of declining cleaning effect, affecting mud scraping effect, and affecting the working environment, so as to reduce flushing water consumption, Good mud scraping effect, guaranteed flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

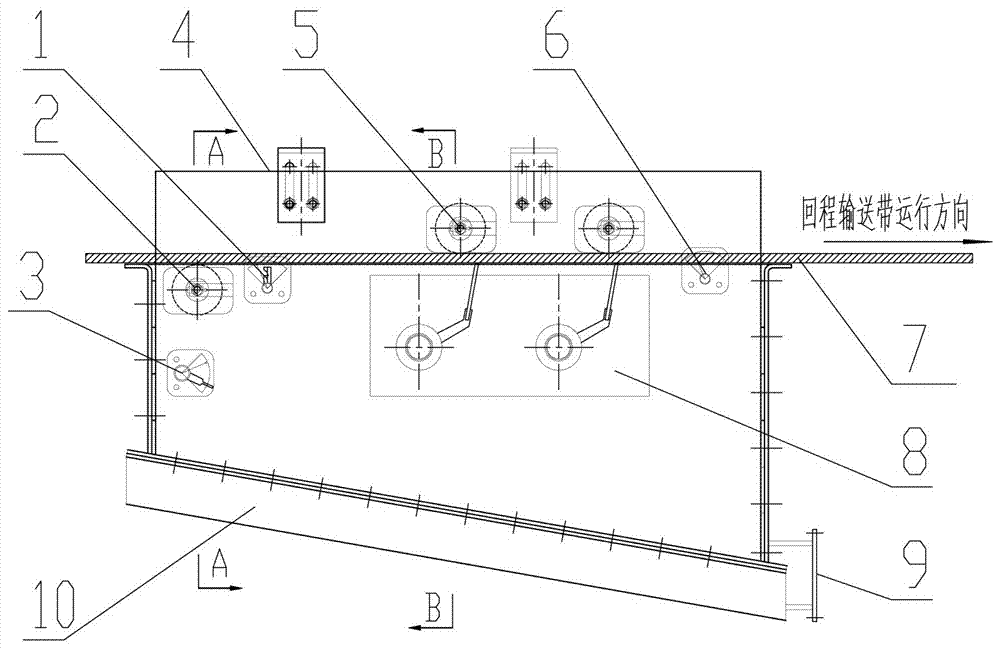

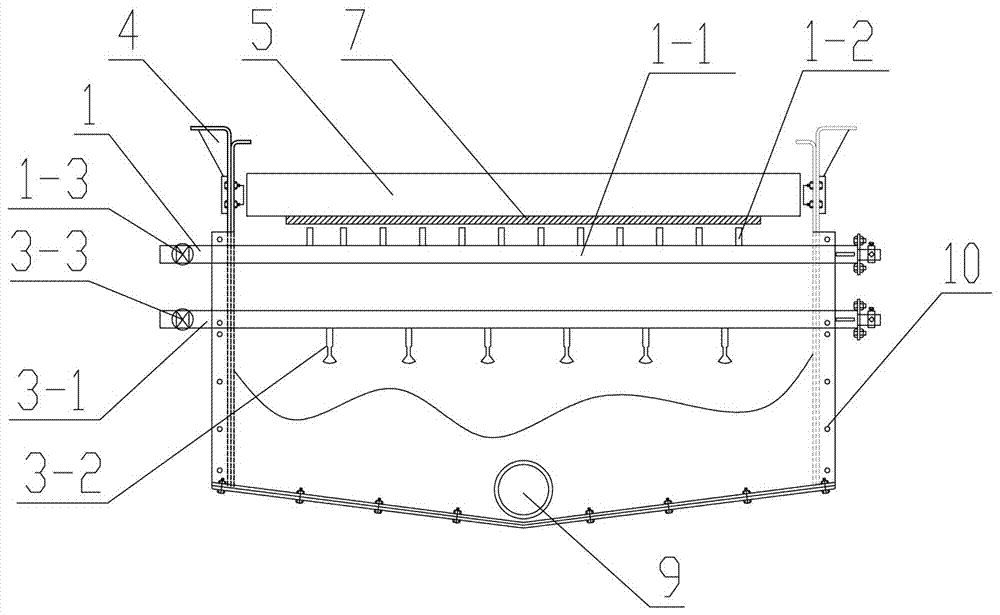

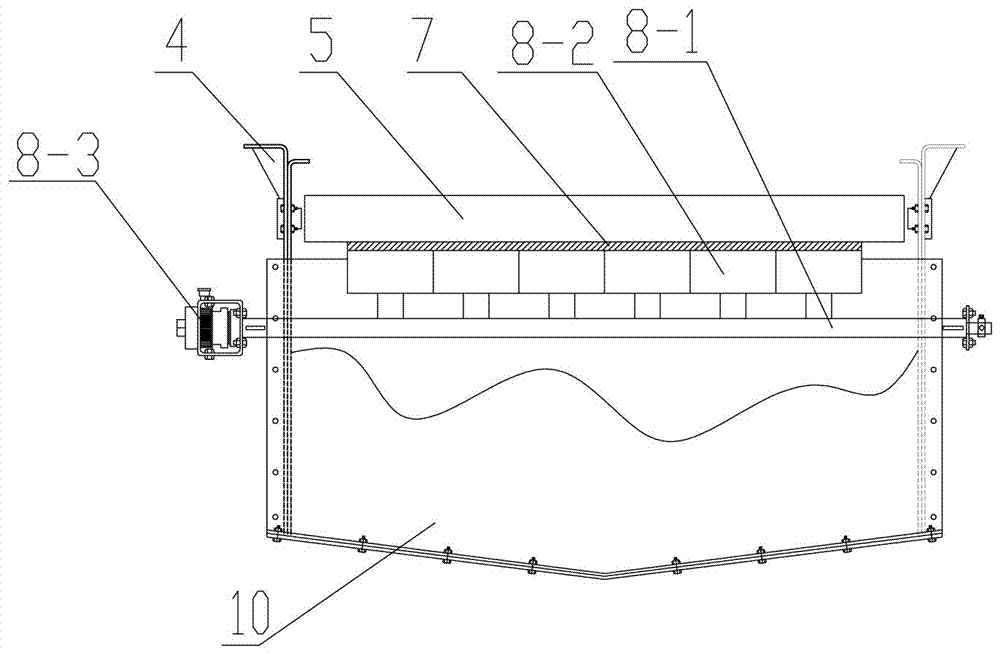

[0030] Such as Figure 1-Figure 4 Shown, a kind of belt conveyor conveyor belt cleaning device of the present invention, comprises the cleaning device that is arranged on the belt conveyor, electric automatic control system, is characterized in that described cleaning device includes and is installed on the belt conveyor by bolt The connection hanger 4 on the longitudinal beam has a long hole with adjustable up and down positions on the connection hanger 4, and is arranged on the mud collection box 10 at the bottom of the connection hanger 4, and is installed on the return conveyor belt 7. The pressure roller 5 and the lower idler roller 2 have upper pressure roller installation holes on the connecting hangers 4 on both sides of the upper pressure roller 5, and the two ends of the upper pressure roller shaft are respectively placed in the upper pressure roller installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com