Device and method for flushing gravel using recirculated water at construction site

A technology for building construction and circulating water, applied in chemical instruments and methods, wet separation, multi-stage water/sewage treatment, etc., can solve problems such as unsatisfactory washing of stones, clogging of precipitated mud, and large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

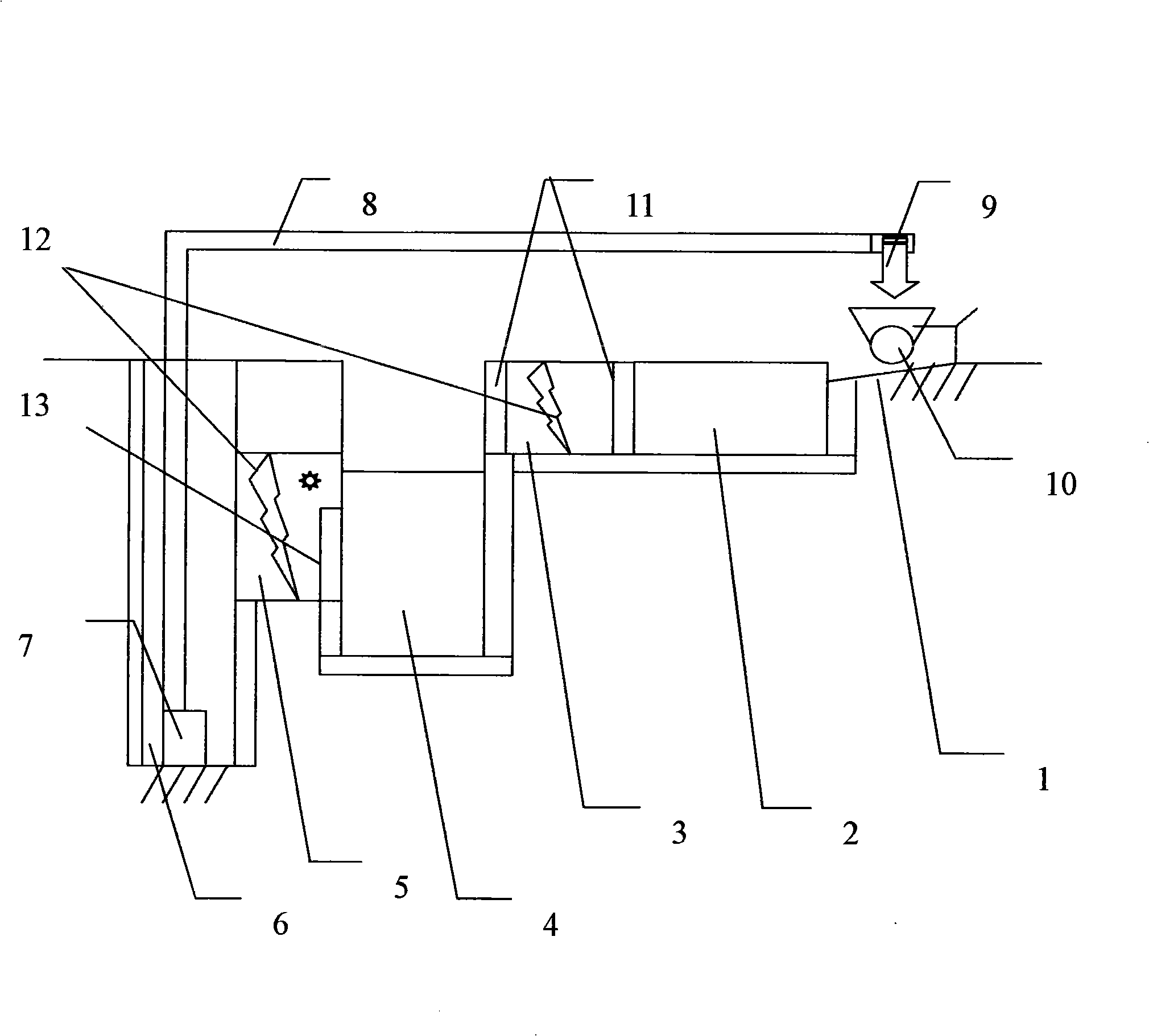

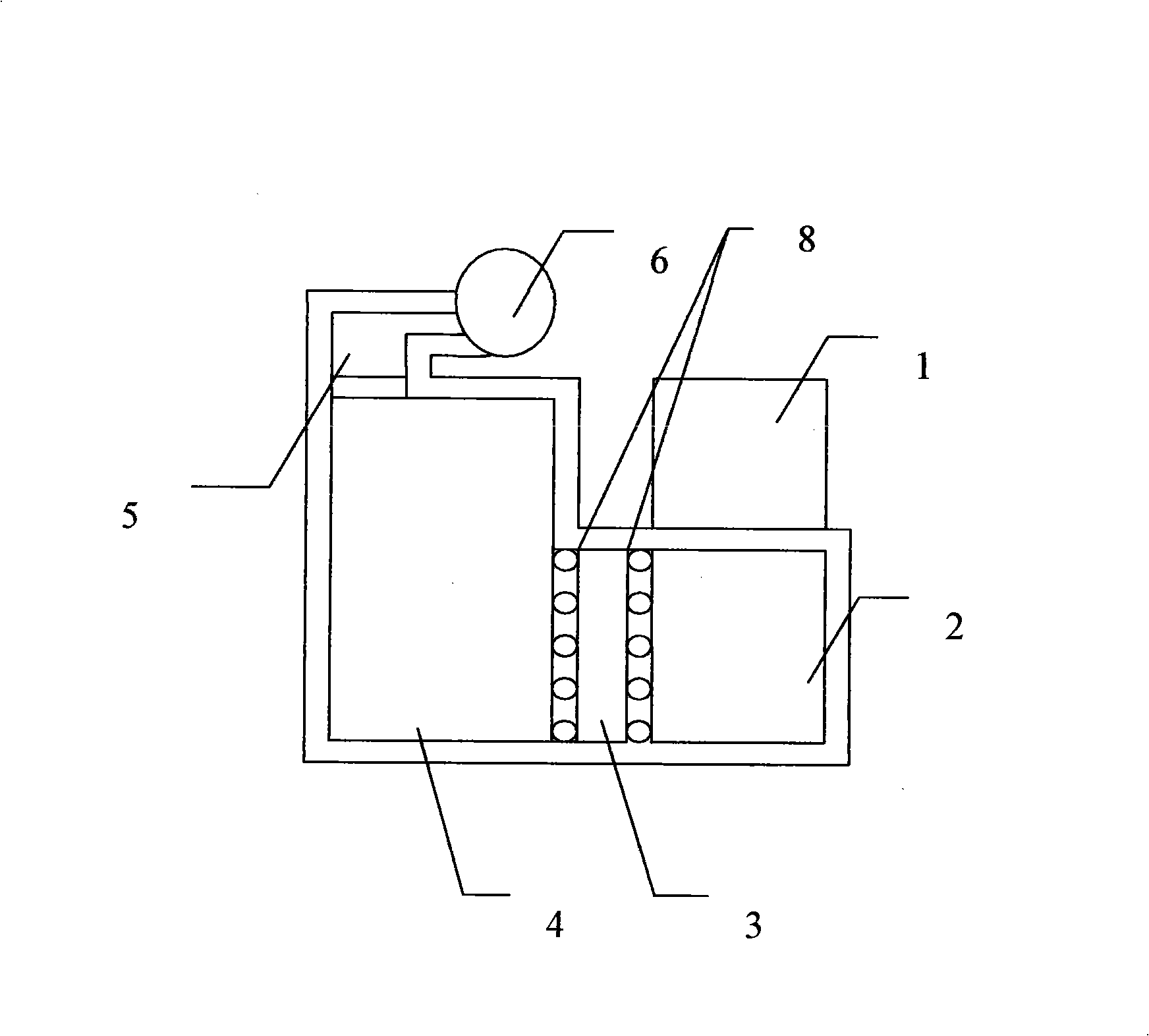

[0021] The device for washing stones with circulating water on construction site with purification function of the present invention is composed of three parts: a filtration system, a sedimentation system and a flushing system. The filter system is composed of a slope cleaning platform 1, a filter tank 2, a filter ditch 3, a fence 11 and a filler 12. Wherein the slope cleaning platform 1, the filter pool 2, and the filter ditch 3 are adjacent successively, the fence 11 is located at the two ends of the filter ditch 3, and the filler 12 is placed between the fence 11, which can be gravel or sacks. The slope of the slope cleaning platform 1 is about 5 to 10 degrees. The sedimentation system is composed of sedimentation tank 4, blind ditch 5, water collection well 6, filler 12, and drainage gate 13. The sedimentation tank 4 communicates with the water collection well 6 through the blind ditch 5, the filler 12 is filled in the blind ditch 5, and the drainage gate 13 is placed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com