Preparation method of shrimp meat

A technology for shelled shrimp and fresh shrimp, which is applied in shrimp/lobster processing, crustacean processing, slaughtering, etc. It can solve the problems of not being able to focus on peeling, low efficiency, and affecting operational efficiency, so as to stabilize color and nutritional content and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of shelled shrimp, comprises following concrete steps:

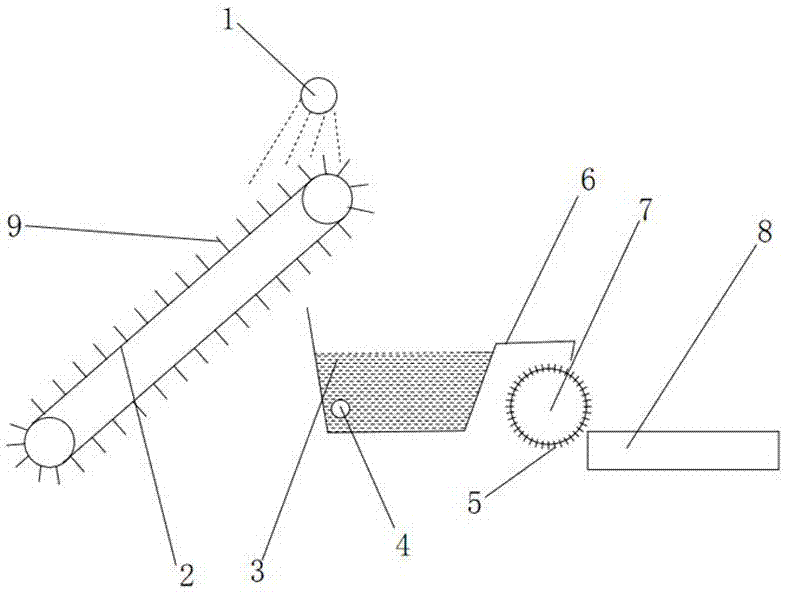

[0034] (1) Cleaning: Clean and screen fresh shrimp on the raw shrimp cleaning conveyor;

[0035] (2) Soaking preservation agent: Soak the cleaned fresh shrimp in the preservation agent for 0.2h; the main raw materials of the preservation agent include by weight: 2 parts of tapioca starch, 3 parts of chitosan, 5 parts of glycerin 1 part of trehalose, 1 part of lactitol, 0.2 part of calcium chloride, 70 parts of purified water.

[0036] (3) Cooking and cooling: take out the fresh shrimps treated in step (2) and cook them on a cooking machine, then cool them down to below 10°C;

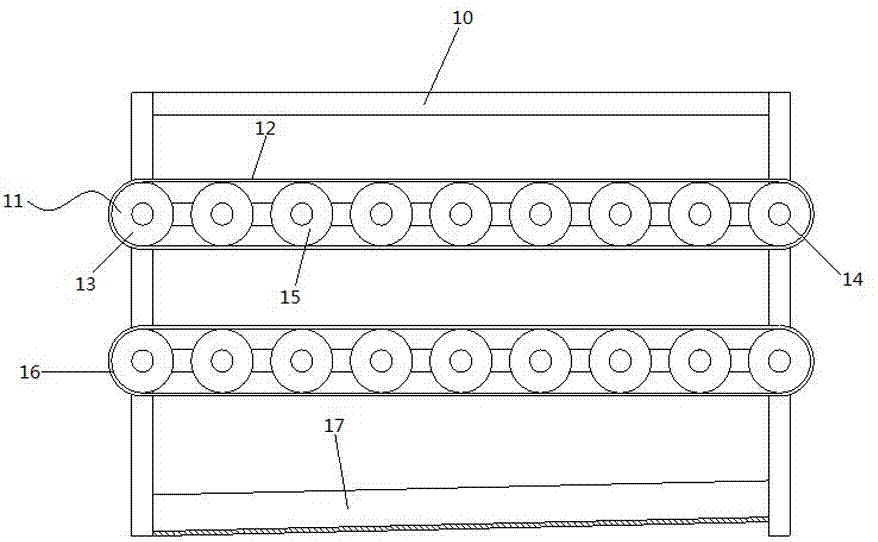

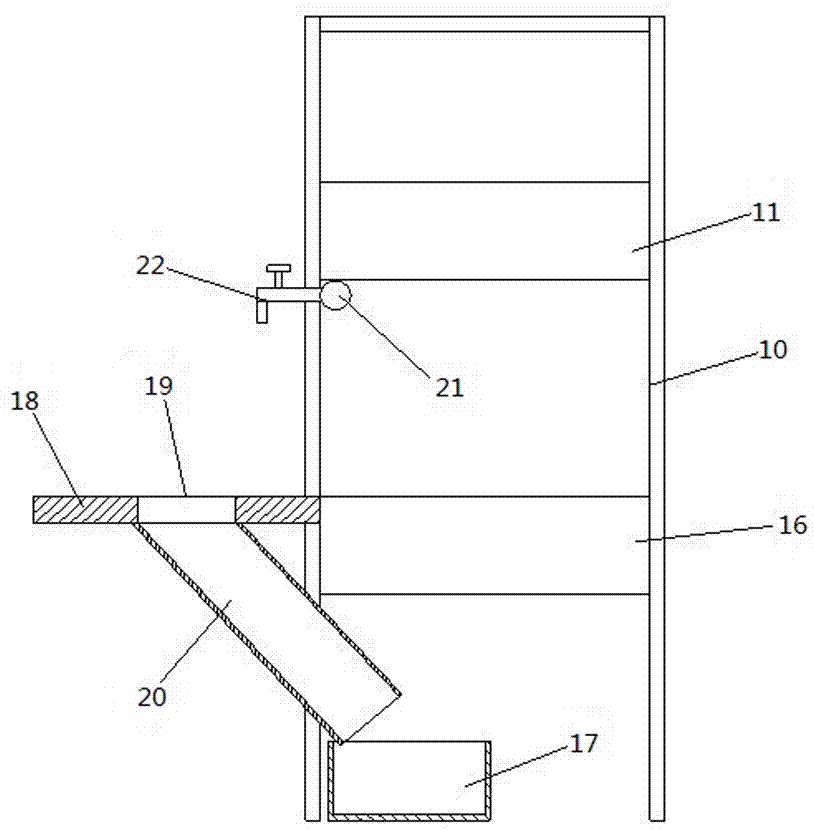

[0037] (4) Shelling: Shelling is carried out on the operating table for peeling shrimp shells;

[0038] (5) Cleaning: Wash the shelled shrimp with ice water mixture;

[0039] (6) Individual quick freezing: place the shrimps treated in step (5) at -21°C and freeze for 30 minutes;

[0040] (7) Packing and refri...

Embodiment 2

[0050] A kind of preparation method of shelled shrimp, comprises following concrete steps:

[0051] (1) Cleaning: Clean and screen fresh shrimp on the raw shrimp cleaning conveyor;

[0052] (2) Soaking preservation agent: Soak the cleaned fresh shrimp in the preservation agent for 1 hour; the main raw materials of the preservation agent include by weight: 4 parts of tapioca starch, 5 parts of chitosan, and 8 parts of glycerin , 2 parts of trehalose, 2 parts of lactitol, 0.3 parts of calcium chloride, 75 parts of purified water.

[0053] (3) Cooking and cooling: take out the fresh shrimps treated in step (2) and cook them on a cooking machine, then cool them down to below 10°C;

[0054] (4) Shelling: Shelling is carried out on the operating table for peeling shrimp shells;

[0055] (5) Cleaning: Wash the shelled shrimp with ice water mixture;

[0056] (6) Individual quick freezing: put the shrimps treated in step (5) at -20°C and freeze for 35 minutes;

[0057] (7) Packing ...

Embodiment 3

[0060] A kind of preparation method of shelled shrimp, comprises following concrete steps:

[0061] (1) Cleaning: Clean and screen fresh shrimp on the raw shrimp cleaning conveyor;

[0062] (2) Soaking preservation agent: Soak the cleaned fresh shrimp in the preservation agent for 2 hours; the main raw materials of the preservation agent include by weight: 5 parts of tapioca starch, 7 parts of chitosan, and 10 parts of glycerin , 2 parts of trehalose, 2 parts of lactitol, 0.5 parts of calcium chloride, 80 parts of purified water.

[0063] (3) Cooking and cooling: take out the fresh shrimps treated in step (2) and cook them on a cooking machine, then cool them down to below 10°C;

[0064] (4) Shelling: Shelling is carried out on the operating table for peeling shrimp shells;

[0065] (5) Cleaning: Wash the shelled shrimp with ice water mixture;

[0066] (6) Individual quick freezing: place the shrimps treated in step (5) at -18°C and freeze for 40 minutes;

[0067] (7) Pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com