Hydraulic reversing mechanism

A reversing mechanism and hydraulic technology, which is used in cleaning methods using liquids, wellbore/well components, earth-moving drilling, etc., can solve the problems of fixed flushing direction, insufficient flushing operation, and weakened flushing ability, etc. To achieve convenient and quick disassembly and maintenance, to meet the cleaning operation, the effect of sufficient flushing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

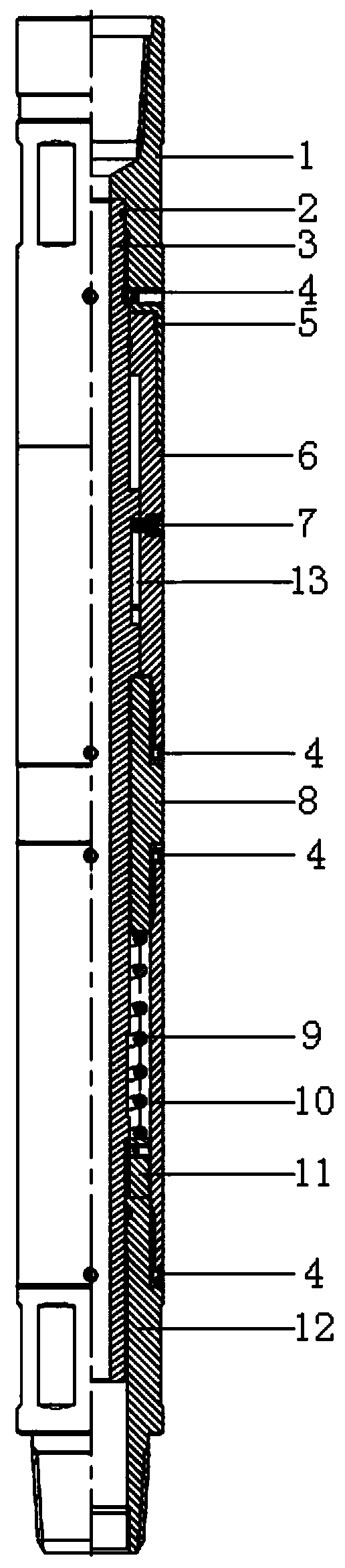

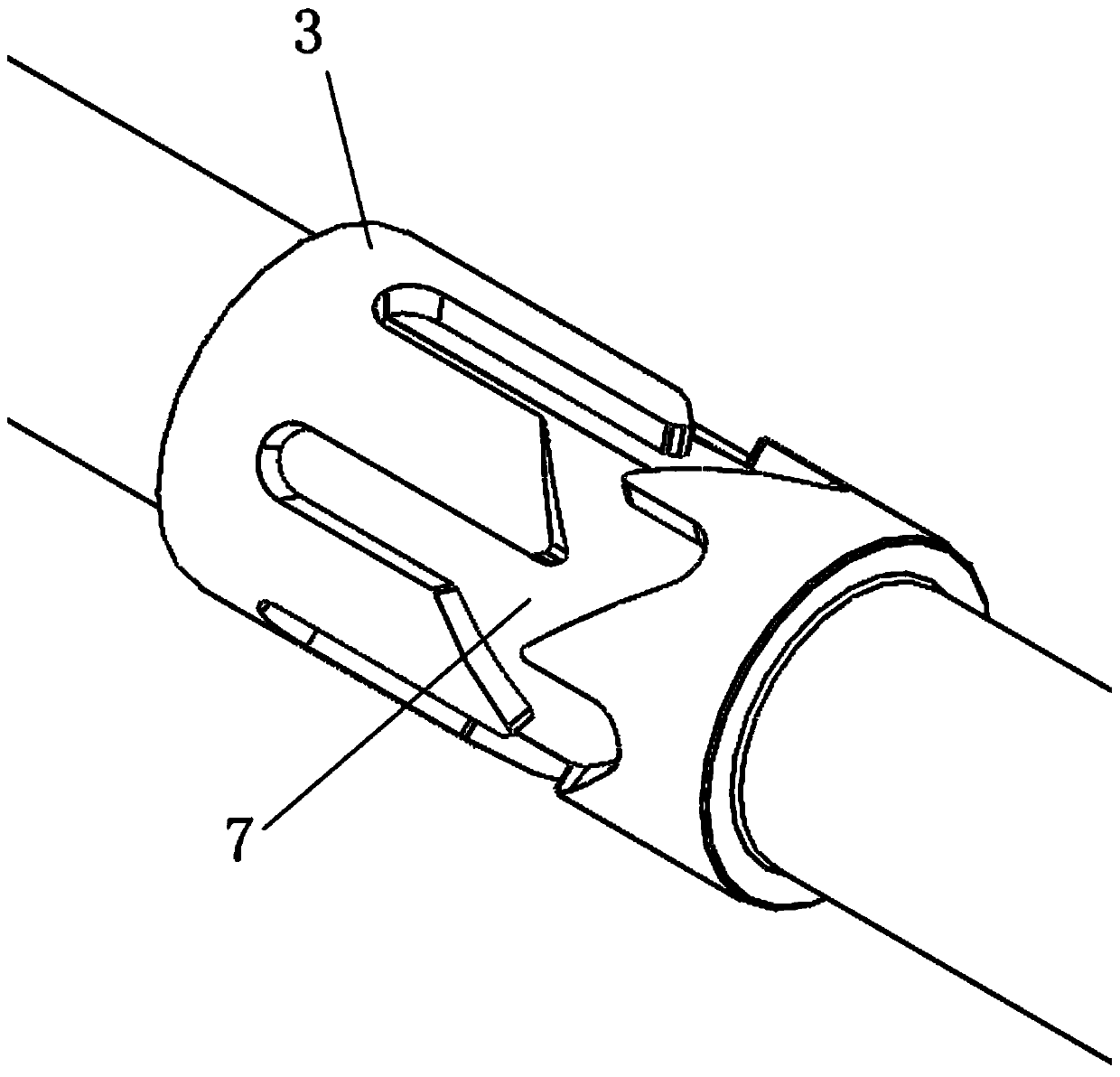

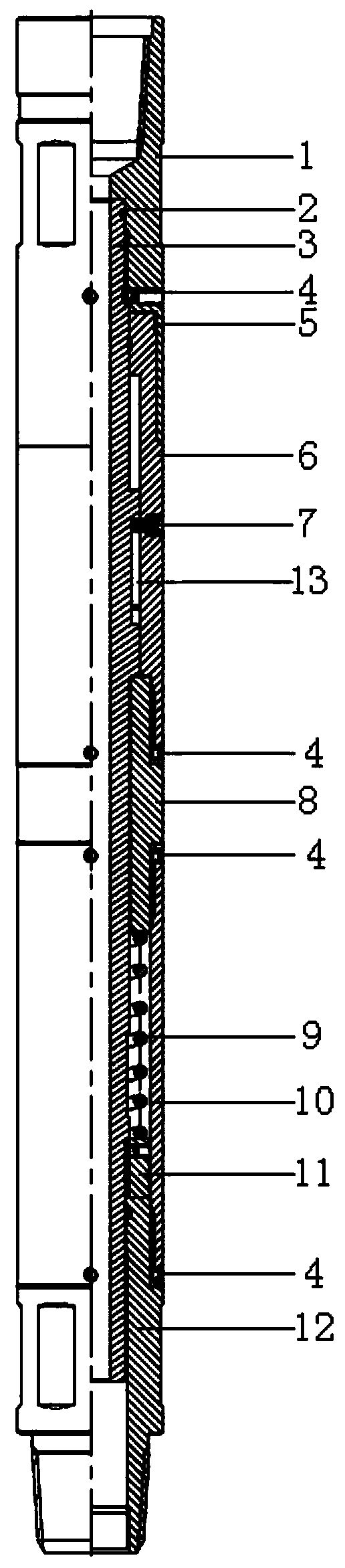

[0019] Such as Figures 1 to 2 As shown, a hydraulic reversing mechanism includes an upper joint 1, a central shaft 3, a guide ring 5, an upper housing 6, a guide pin 7, a connecting nipple 8, a compression spring 9, a lower housing 10, and a limit sleeve 11 and the lower joint 12, the upper joint 1 and the central shaft 3 are fixed and sealed connected, the guide ring 5 is arranged between the contact surface of the upper joint 1 and the upper shell 6, and the guide ring 5 is used for the rotation of the upper shell 6 in the guide. The upper casing 6 is connected to the short joint 8, the lower casing 10 and the lower joint 12 are slidably arranged on the outside of the central axis 3, and the upper casing 6 is provided with a guide pin 7 corresponding to the position of the guide pin 7. A guide groove 13 is set on the central axis 3 of the upper housing 6, and the guide pin 7 can rotate in the guide groove 13. One end of the upper housing 6 is connected to the upper joint 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com