Completely autotrophic nitrogen-removal reactor and nitrogen-removal process

A technology of fully autotrophic denitrification and reactor, which is applied in the field of fully autotrophic denitrification reactor and denitrification process, can solve the problems of increasing the height of the reactor and the inability to realize denitrification simultaneously, and achieve the goal of preventing pollution and clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

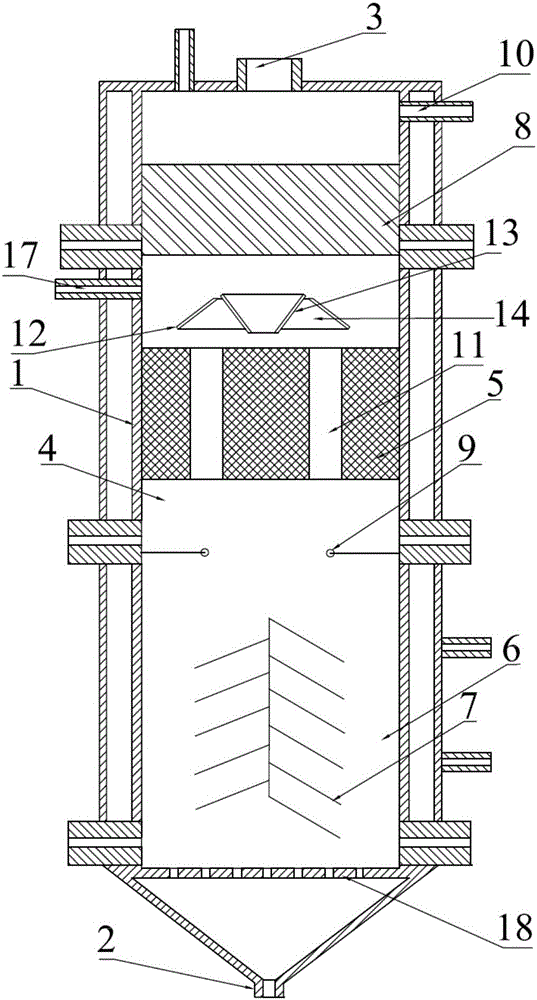

[0035] The full autotrophic denitrification reactor provided in this embodiment is as figure 1 As shown, it includes a reactor cylinder 1, a water inlet 2 is provided at the bottom of the reactor cylinder 1, and an exhaust port 3 is provided at the top; 1, above the water inlet 2 is provided with a water distributor 18.

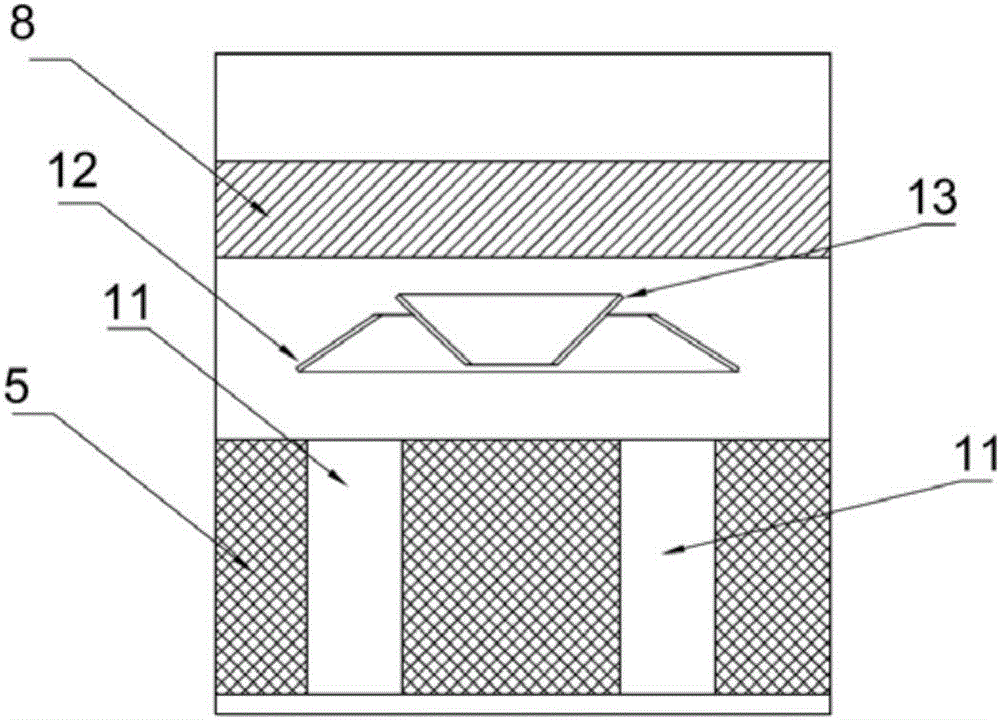

[0036] A nitrosation-ANAMMOX zone 4 is arranged on the upper part of the reactor cylinder 1, and a first packing assembly 5 is arranged in the nitrosation-ANAMMOX zone 4, and in the first packing assembly Anammox bacteria are attached to the inner layer of the surface of 5, and nitrosative bacteria are attached to the outer layer of the surface of the first packing assembly 5; in this embodiment, an aeration channel 11 is provided on the first packing assembly 5, The aeration channel 11 is arranged in a ring shape, such as figure 2 As shown, the first packing assembly 5 described in this embodiment is a non-woven packing, as an optional embodiment, the fir...

Embodiment 2

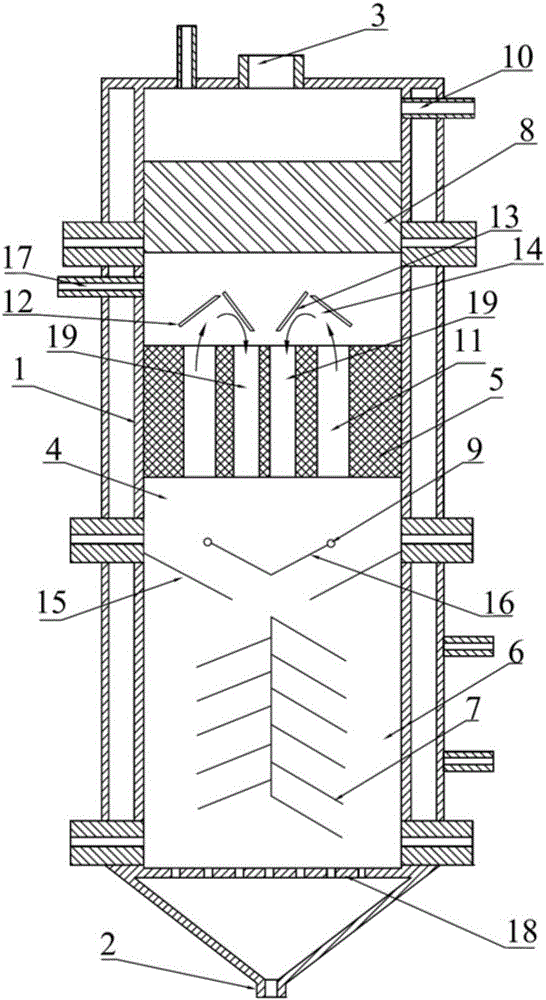

[0048] The full autotrophic denitrification reactor provided in this embodiment is as image 3 As shown, it includes a reactor cylinder 1, a water inlet 2 is provided at the bottom of the reactor cylinder 1, and an exhaust port 3 is provided at the top; 1, above the water inlet 2 is provided with a water distributor 18.

[0049] A nitrosation-ANAMMOX zone 4 is arranged on the upper part of the reactor cylinder 1, and a first packing assembly 5 is arranged in the nitrosation-ANAMMOX zone 4, and the first packing assembly is Non-woven packing; anammox bacteria are attached to the inner layer of the surface of the first packing assembly 5, and nitrosating bacteria are attached to the outer layer of the surface of the first packing assembly 5; A packing assembly 5 is provided with an aeration channel 11, and the aeration channel 11 is provided with two, and the two aeration channels are along the center of the reactor cylinder on the cross section of the reactor cylinder. Axisym...

Embodiment 3

[0055] The fully autotrophic denitrification reactor provided in this embodiment includes a reactor cylinder 1, a water inlet 2 is provided at the bottom of the reactor cylinder 1, and an exhaust port 3 is provided at the top; in order to make the water intake uniform, this Embodiment A water distributor 18 is provided in the reactor cylinder 1 above the water inlet 2 .

[0056] A nitrosation-ANAMMOX zone 4 is arranged on the upper part of the reactor cylinder 1, and a first packing assembly 5 is arranged in the nitrosation-ANAMMOX zone 4, and the first packing assembly 5 It is a non-woven filler; anammox bacteria are attached to the inner layer of the surface of the first filler component 5, and nitrosating bacteria are attached to the outer layer of the surface of the first filler component 5; the present embodiment is described in the The first packing assembly 5 is provided with an aeration channel 11, and the aeration channel 11 is arranged in a vertical direction. In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com