Steel strip descaling method

A technology for steel strip and scale skin, which is applied in the field of removing oxide scale or scale on the surface of steel strip, can solve the problems of different steel products, incomplete descaling, large equipment loss, etc., and achieves small loss of steel strip and good washing and descaling effect. , the effect of small equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

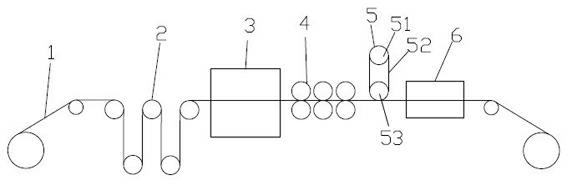

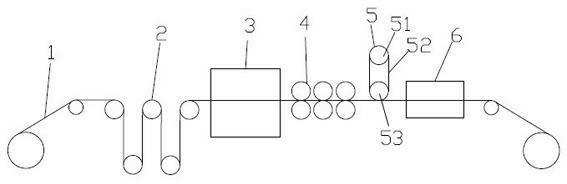

[0040] As shown in accompanying drawing, a kind of strip descaling method, it comprises the following steps:

[0041] A, the steel strip 1 is sent into the scale breaking device 2 through the pulling roller, and the scales on the surface of the steel strip 1 are broken;

[0042] B, sending the steel strip 1 processed through step A into the sandblasting device 3, spraying steel grit, high-pressure water and high-pressure air to the steel strip 1 surface, further crushing and scouring the scales on the steel strip 1 surface;

[0043] C, the steel strip 1 processed through step B is sent to the brush roller device 4, and the surface of the steel strip 1 is brushed, further removing residual scales and making the surface of the steel strip smooth;

[0044] D, the steel strip 1 processed through step C is sent into the band brushing device 5, and the powder crumbs and the remaining scales left after the brushing on the steel strip 1 upper surface are removed by brushing;

[0045]...

Embodiment 2

[0049] As shown in the drawings, the difference from the first embodiment is that the axial direction of the water outlet nozzle forms an included angle of 45 degrees with the steel strip surface. The water supply pressure of high pressure water is 9Mpa. The axial direction of the nozzle forms an included angle of 45 degrees with the surface of the steel strip 1 .

Embodiment 3

[0051]As shown in the drawings, the difference from the above-mentioned embodiments is that the axial direction of the water outlet nozzle and the steel strip surface form an included angle of 40 degrees. The water supply pressure of high pressure water is 10Mpa. The axial direction of the nozzle forms an included angle of 40 degrees with the surface of the steel strip 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com