Subsection rotating multi-head spring type self-cleaning reinforced heat exchanger

A heat-enhancing, spring-type technology, used in cleaning heat transfer devices, rotating equipment cleaning, heat transfer modification, etc., can solve problems such as large flow resistance, poor cleaning and descaling effects, and limited heat transfer enhancement effects. , to achieve the effect of strengthening convection heat transfer in the tube, good cleaning and descaling effect, and good cleaning and descaling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

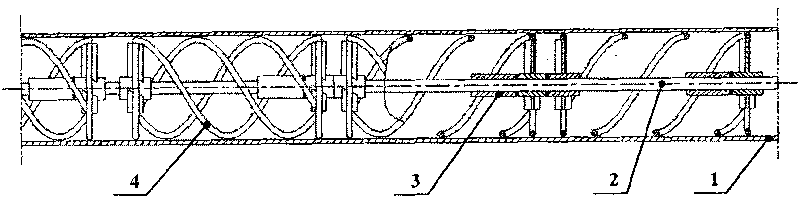

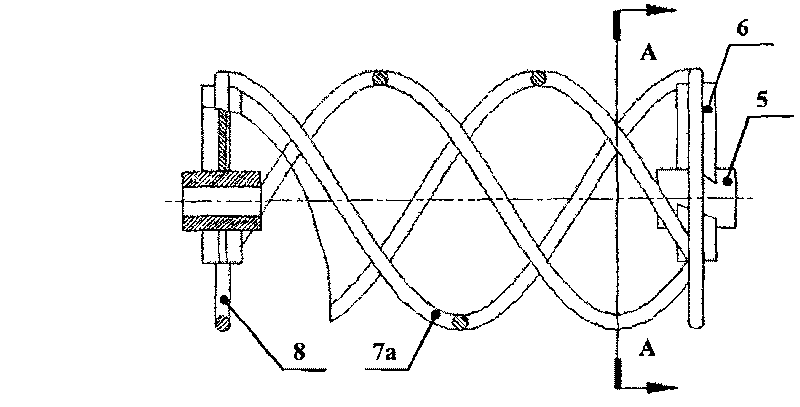

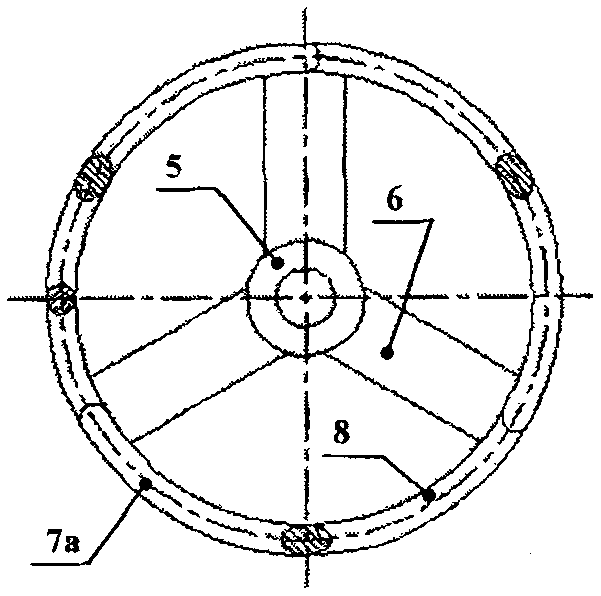

[0040] Such as figure 1As shown, the segmented rotating multi-head spring type self-cleaning enhanced heat exchange device of the present invention includes: a support frame installed at both ends of the heat exchange tube 1 (the heat exchange tube shown in the figure is a partial diagram after sectioning, and the support frame is used as a conventional technology not shown), two ends of the flexible shaft 2 fixed on the support frame, a plurality of axial positioning sleeves 3 sleeved and fixed on the flexible shaft 2, and a plurality of sleeves on the flexible shaft and can rotate around the flexible shaft 2 The self-rotating rotor 4 and other components. exist figure 1 There are four self-rotating rotors 4 in the cut-away partial heat exchange tube shown in , and the self-rotating rotors can be adjacent to each other or have gaps.

[0041] The axial positioning sleeve 3 is fixed on the flexible shaft 2, usually next to the self-rotating rotor, and the axial positioning sl...

Embodiment 2

[0055] Figure 9 It is a structural schematic diagram of Embodiment 2 of the present invention. exist Figure 9 Among them, 1 is a heat exchange tube (the heat exchange tube shown in the figure is a cutaway view), 2 is a flexible shaft with both ends fixed, 3 is an axial positioning sleeve, and 10 is a self-rotating rotor. The difference between this embodiment and the above-mentioned embodiments is that the self-rotating rotor of this embodiment has a double-rotation network multi-head spring structure, while the first embodiment has a single-rotation multi-head spring structure.

[0056] Figure 10 It is a structural schematic diagram of the self-rotating rotor in Embodiment 2 of the present invention, Figure 11 yes Figure 10 C-C section view. exist Figure 10 with Figure 11 Among them, 6 is a rotating blade, 8 is a connecting ring, 9 is a rotating sleeve, and 11 is a multi-head spring group with a bidirectional mesh structure. The rotating shaft sleeve 9 and the ...

Embodiment 3

[0061] Figure 13 It is a structural schematic diagram of Embodiment 3 of the present invention. exist Figure 13 Among them, 1 is a heat exchange tube (the heat exchange tube shown in the figure is a cutaway view), 2 is a flexible shaft with both ends fixed, 3 is an axial positioning sleeve, and 12 is a self-rotating rotor. The difference between this embodiment and the above-mentioned embodiments is: the self-rotating rotor of this embodiment is that one end of the multi-headed spring is connected to the rotating shaft sleeve, and the other end is in a free state, while the multi-headed spring of the first and second embodiments Both ends are connected to each other as a whole. Compared with Embodiment 1 and Embodiment 2, the flow resistance of this embodiment is smaller.

[0062] Figure 14 It is a structural schematic diagram of the self-rotating rotor in Embodiment 3 of the present invention, Figure 15 yes Figure 14 The D-D section view. exist Figure 14 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com