Pair rubber ball for cleaning and descaling in heat-exchange tubes

A technology for heat exchange tubes and rubber balls, which can be used in cleaning methods and utensils, cleaning heat transfer devices, cleaning hollow objects, etc., and can solve the problems of low ball collection rate, easy pipe blocking, difficult wet diameter and specific gravity of rubber balls, etc. , to achieve the effect of good effect, long life and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

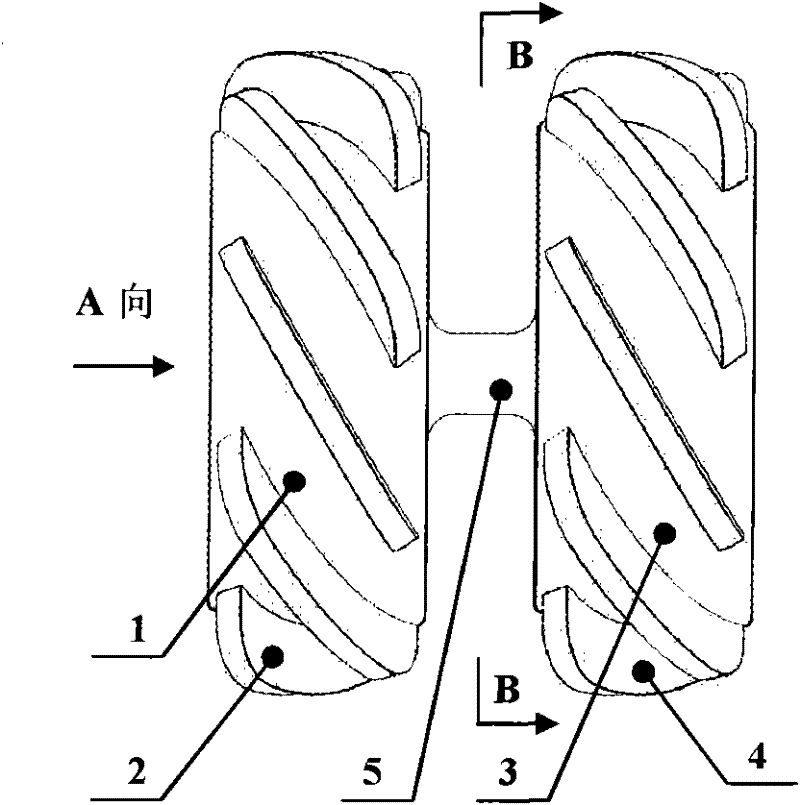

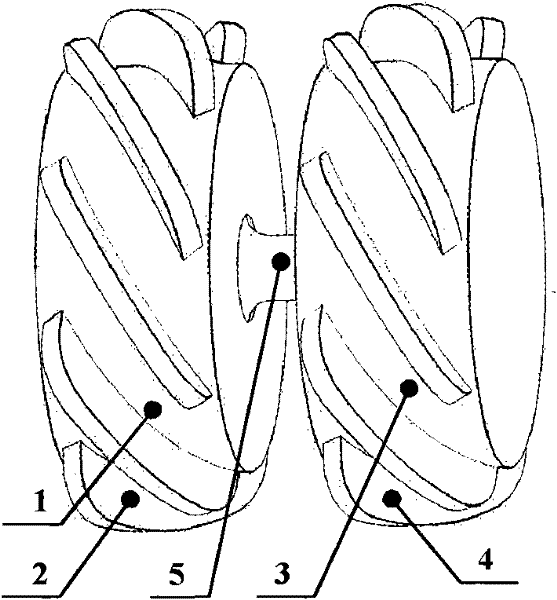

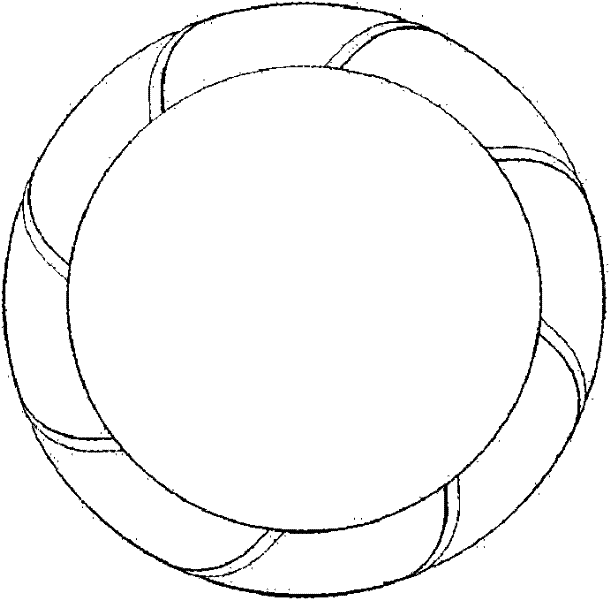

[0032] figure 1 Is a schematic diagram of the two-dimensional structure of the first embodiment of the present invention, figure 2 Is a schematic diagram of the three-dimensional structure of the first embodiment of the present invention, image 3 Is the first embodiment of the present invention figure 1 Schematic diagram of the A-direction structure in Figure 4 Is the first embodiment of the present invention figure 1 Schematic diagram of the B-B cross-sectional structure in.

[0033] Such as figure 1 with figure 2 As shown, this embodiment includes a solid columnar body 1, 8 inclined fins 2 on the columnar body 1, a solid columnar body 3, and 8 inclined fins 4 on the columnar body 3, and the columnar body 5 is elastically connected in the middle. In this embodiment, the solid cylindrical body 1 and 8 inclined fins 2 constitute one cleaning and descaling rubber ball, the solid cylindrical body 3 and 8 inclined fins 4 constitute another cleaning and descaling rubber ball, and th...

Embodiment 2

[0037] Such as Figure 5 As shown, this embodiment includes a solid columnar body 6, 8 inclined fins 7 on the columnar body 6, a solid columnar body 8, and 8 inclined fins 9 on the columnar body 8, elastically connecting the columnar and sheet-like composites in the middle. 体10。 Body 10. In this embodiment, the cylindrical body 6 and the 8 inclined fins 7 constitute a cleaning and descaling rubber ball, the cylindrical body 8 and the 8 inclined fins 9 constitute another cleaning and descaling rubber ball, and the two cleaning and descaling rubber balls The middle elastic connecting columnar and the sheet-shaped composite body 10 are connected as a whole to form a double-connected rubber ball for cleaning and descaling in the heat exchange tube. The middle elastic connecting columnar and sheet-like composite body 10 is composed of a columnar body and three sheet-like bodies, wherein the sheet-like bodies are arranged in a T shape. Image 6 Is for this embodiment Figure 5 Schemat...

Embodiment 3

[0042] Such as Figure 7 As shown, this embodiment includes a solid columnar body 11, 8 inclined fins 12 on the columnar body 11, a solid columnar body 13, and 8 inclined fins 14 on the columnar body 13, and a twisted sheet body 15 is elastically connected in the middle. . In this embodiment, the cylindrical body 11 and the 8 inclined fins 12 constitute a cleaning and descaling rubber ball, the cylindrical body 13 and the 8 inclined fins 14 constitute another cleaning and descaling rubber ball, and the two cleaning and descaling rubber balls The twisted sheet-shaped body 15 is connected by the elastic connection in the middle to form a double-connected rubber ball for cleaning and descaling in the heat exchange tube. Figure 8 Is for this embodiment Figure 7 Schematic diagram of the mid-section structure in. The outer envelope surface of the inclined fin is a cylindrical surface.

[0043] The difference between this embodiment and Embodiment 1 is that the middle elastic connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com