Ecological pool and efficient coal chemical engineering waste water treatment combined process and system

A technology of coal chemical wastewater and ecological pool, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sewage treatment, etc., can solve the problems of difficult deep desalination treatment, inability to remove heavy metals at the same time, secondary pollution, etc., to achieve It is convenient for comprehensive utilization and prevents the effect of continuous accumulation of salt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

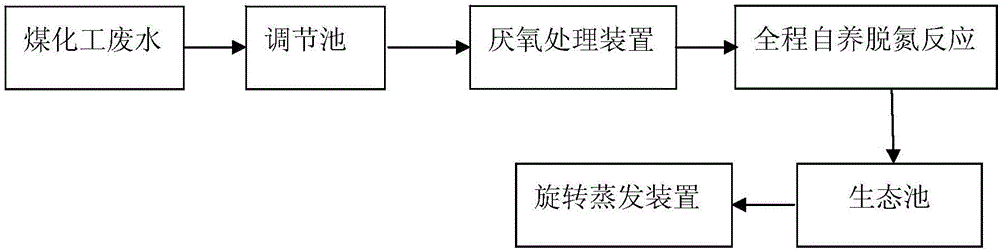

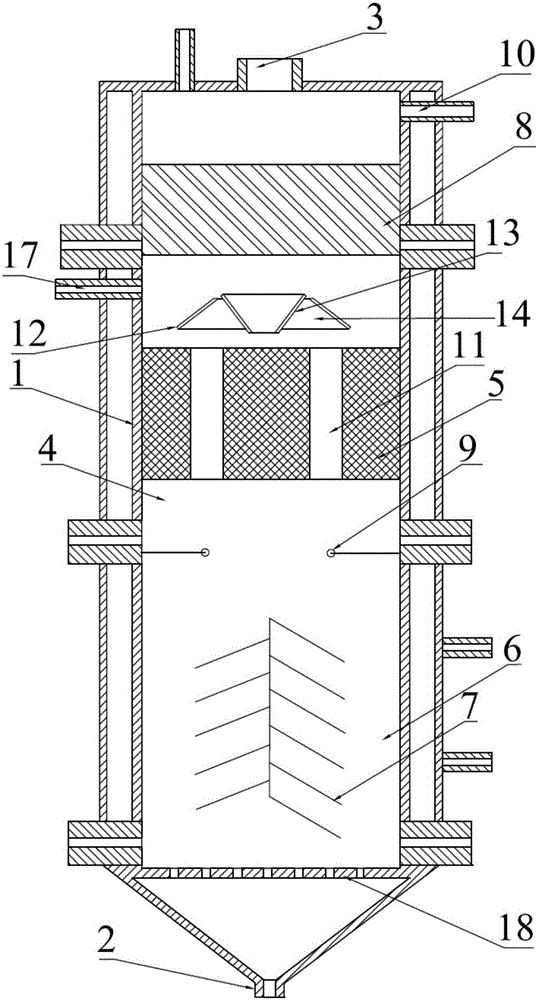

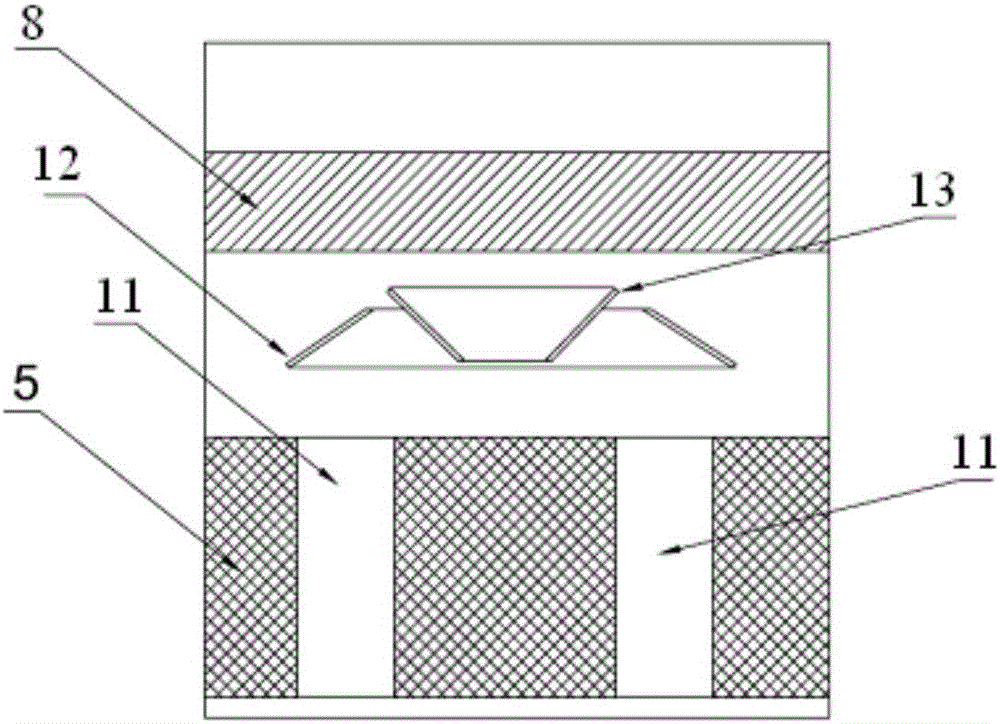

[0042] This embodiment provides a combined system for efficient treatment of coal chemical wastewater, the flow chart of which is as follows figure 1 As shown, it includes sequentially connected settings: an adjustment tank, the coal chemical industry wastewater enters the adjustment tank, and the pH value of the coal chemical industry wastewater is adjusted in the adjustment tank and treated by adding a flocculant; anaerobic treatment device, The effluent of the regulating pool enters the anaerobic treatment device; the whole process autotrophic denitrification reactor, and the wastewater treated by the anaerobic treatment device enters the full process autotrophic denitrification reactor for denitrification; the ecological pool, the The water inlet of the ecological pool is communicated with the outlet of the full autotrophic denitrification reactor, and an aeration device is arranged at the bottom of the ecological pool; a nanofiltration membrane device 25 is arranged in the...

Embodiment 2

[0055] This embodiment provides a combined system for efficient treatment of coal chemical industry wastewater, including: a regulating pool connected in sequence, the coal chemical industry wastewater enters the regulating pool, and the coal chemical industry wastewater is adjusted in the regulating pool pH value and adding flocculant for treatment; anaerobic treatment device, the effluent of the adjustment tank enters the anaerobic treatment device; the whole process autotrophic denitrification reactor, the wastewater treated by the anaerobic treatment device enters the whole process The autotrophic denitrification reactor carries out denitrification; the ecological pool, the water inlet of the ecological pool is connected with the outlet of the full autotrophic denitrification reactor, and an aeration device is arranged at the bottom of the ecological pool; The nanofiltration membrane device 25 is arranged in the ecological pool, and the nanofiltration membrane device 25 is ...

Embodiment 3

[0069] The combined system for efficient treatment of coal chemical wastewater in this embodiment is the same as that of Embodiment 1 and Embodiment 2, such as figure 1 As shown, including sequentially connected settings: regulating pond, anaerobic treatment device, full autotrophic denitrification reactor, ecological pond and rotary evaporation device. Wherein the bottom of described ecological pond is provided with aeration device; In described ecological pond, be provided with nanofiltration membrane device 25, described nanofiltration membrane device 25 is arranged near the air outlet of described aeration device; The membrane outlet side of device 25 is communicated with and is provided with water outlet; On the water surface of described ecological pool, ecological floating bed 19 is placed, and plant 20 is planted on described ecological floating bed 19; Water outlet connection setting.

[0070] The full autotrophic denitrification reactor described in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com