Full-automatic high-voltage electrostatic oil fume purifier utilizing segmented cleaning

A fume purifier and segmental cleaning technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of high water consumption, difficulty in cleaning, and user acceptance, so as to ensure the flushing effect and reduce the cost of pumps. The effect of water power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

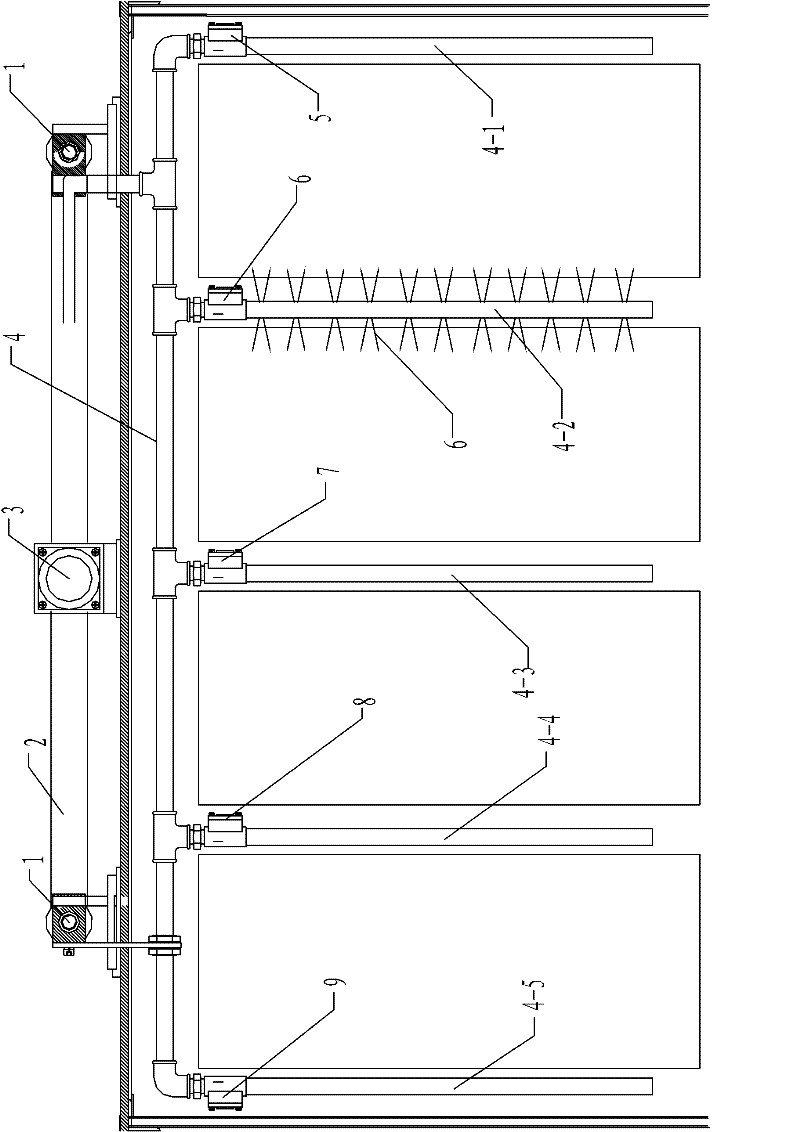

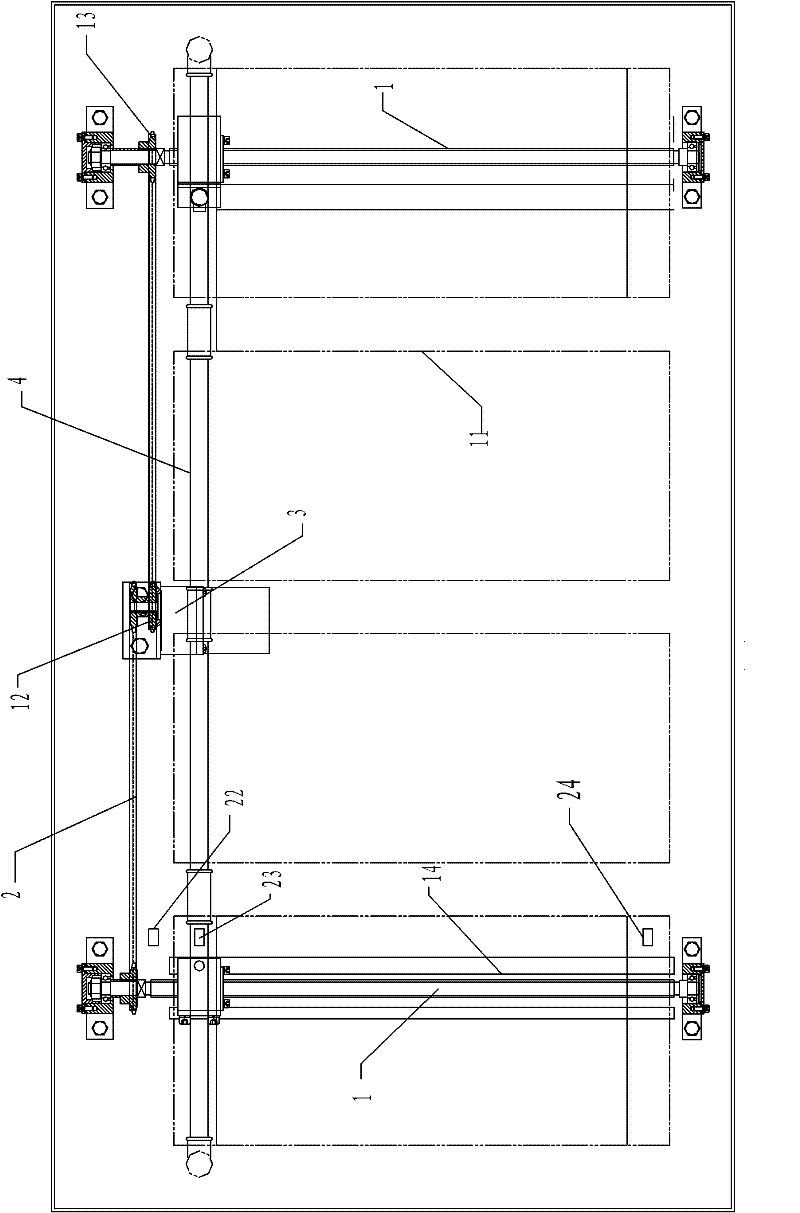

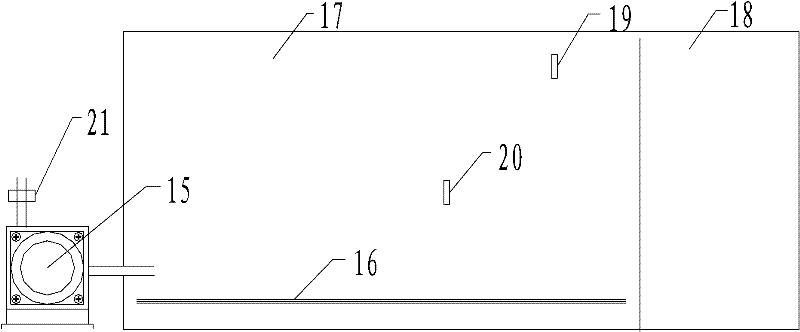

[0023] Below in conjunction with accompanying drawing, the present invention will be further described, figure 1 , 2 Among them, the above-mentioned fully automatic segmental cleaning high-voltage electrostatic oil fume purifier includes multiple purification units, water storage tanks, water pumps, and oil-water separators. The automatic segmental cleaning device includes: gear motor 3, screw rod 1, transmission device, movable cleaning water main pipe 4, position sensor, single-chip controller 25, and the movable cleaning water main pipe is provided with multiple cleaning water pipes with nozzle nozzles, The upper end of the cleaning water pipe is provided with a control valve. The output shaft of the reduction motor 3 is connected to the screw rod 1 through the passive gear 13 of the transmission device. The main water pipe is connected to the water outlet of the water pump, and the cleaning water pipe is set correspondingly to the purification unit. Multiple position sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com