Patents

Literature

196results about How to "Save water and electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

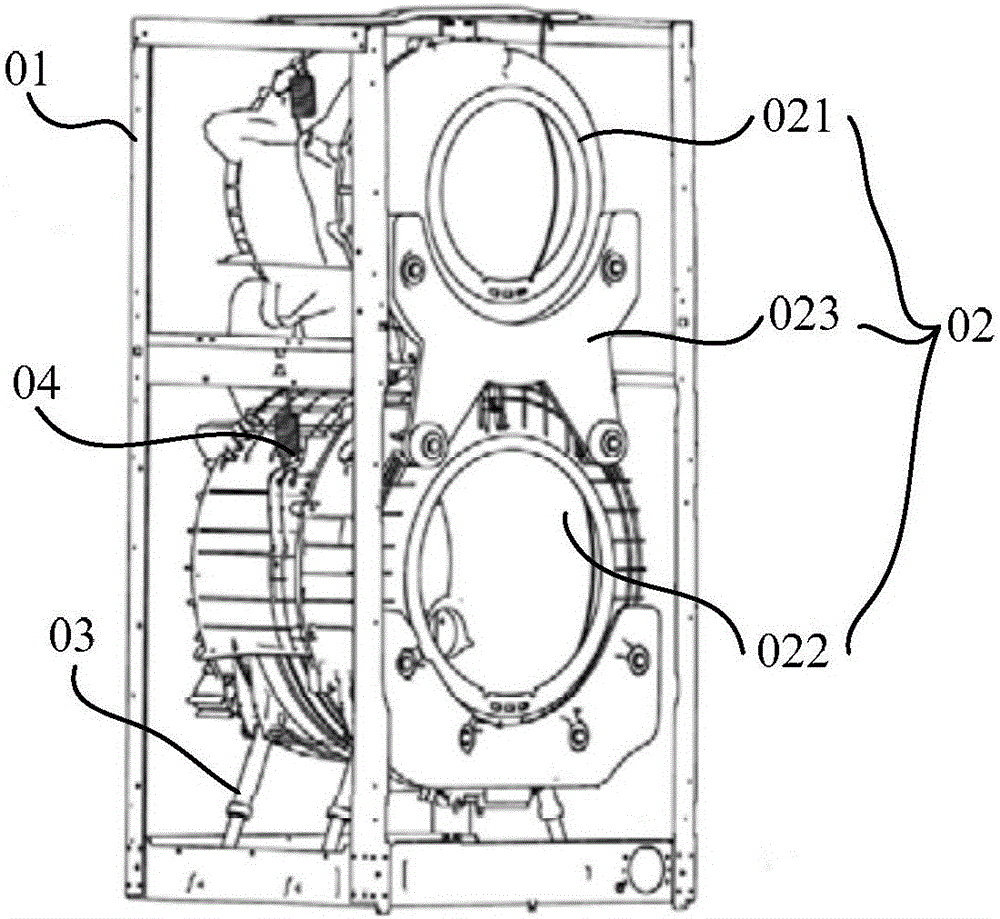

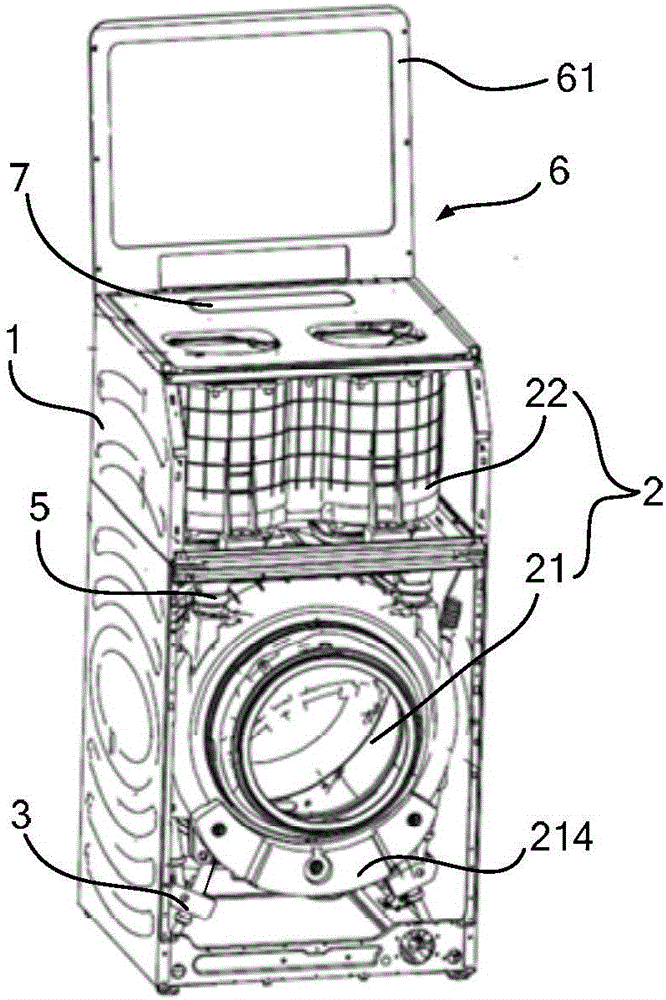

Category washing single barrel drum washing machine

InactiveCN102268800AAvoid cross infectionAvoid stainsOther washing machinesControl devices for washing apparatusLaundry washing machineEngineering

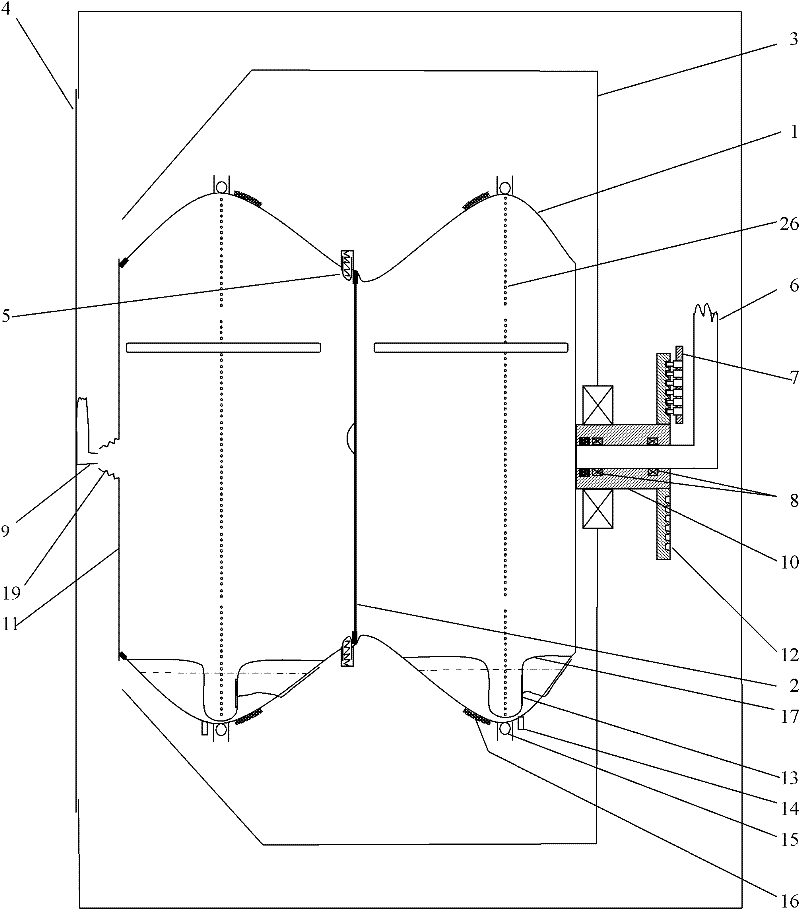

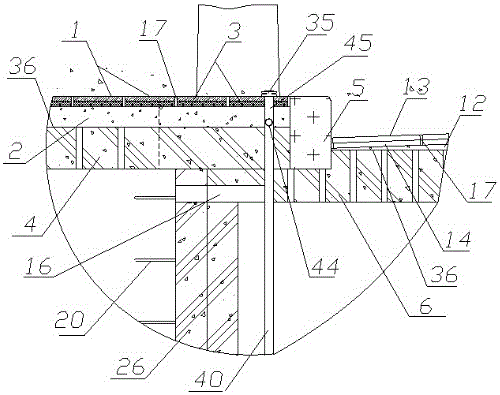

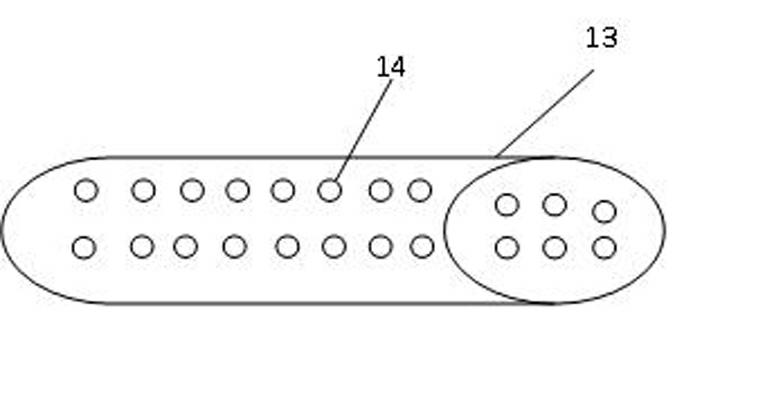

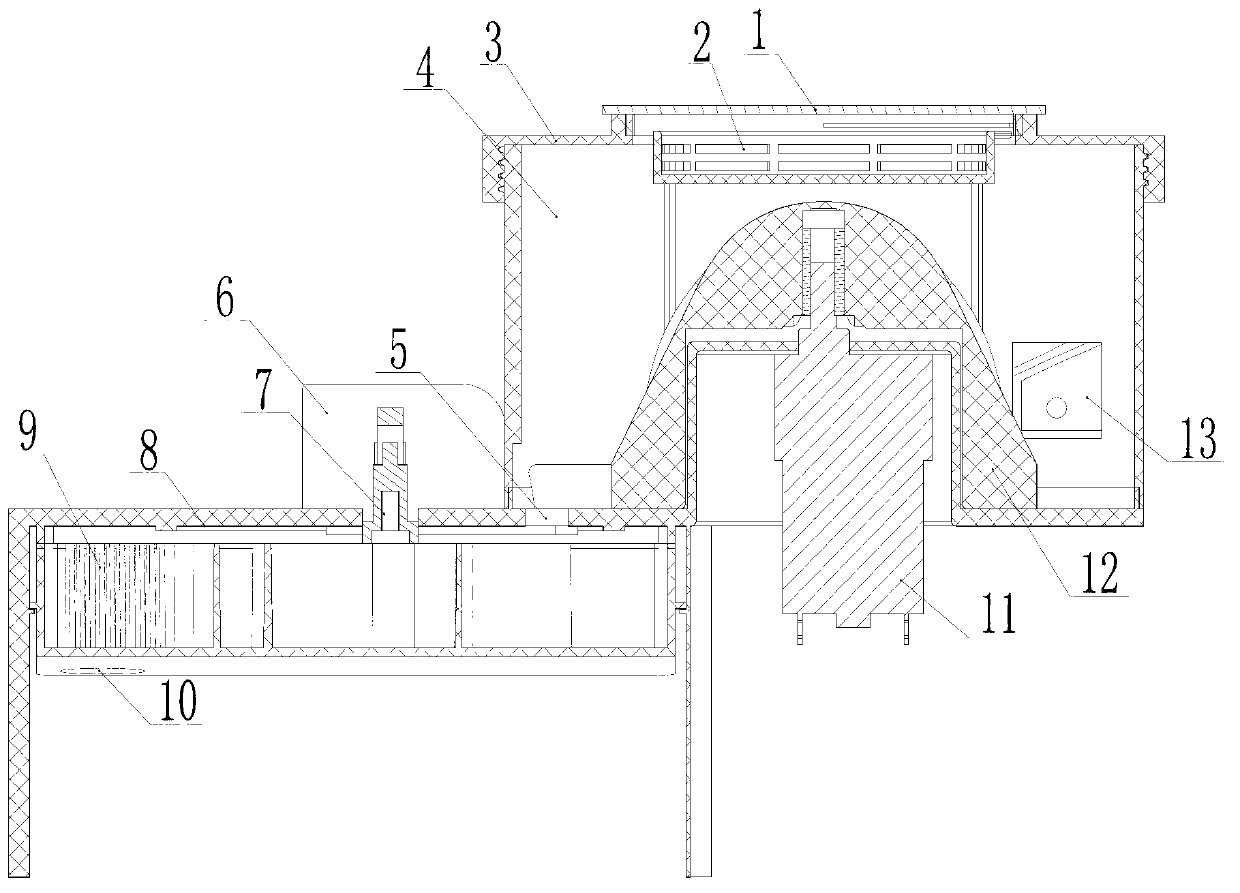

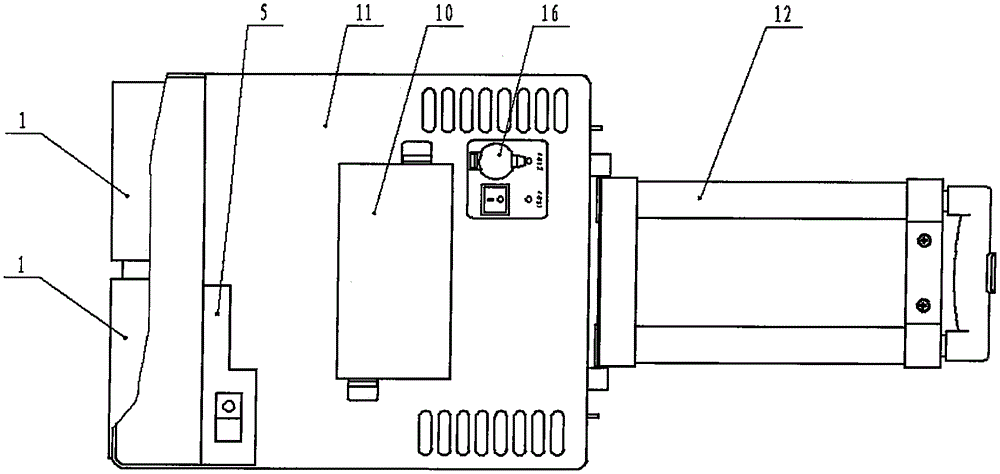

The invention relates to an improvement of a drum of a classification washing single-tub drum washing machine. When people wash clothes, they always hope that underwear and outerwear, decolorized clothes, and clothes for adults and children can be washed separately, so as to avoid cross-contamination and dyeing between clothes. However, the current single-tub drum washing machine washes one type of clothing first and then washes another type of clothing, which not only wastes water, electricity and time, but also requires manual intervention in the middle, which brings inconvenience to users. In the present invention, a detachable partition 22 is added in the single-tub drum 21, and the inner space of the single-tub drum 21 is divided into two independent washing spaces with different sizes on the left and right (the front and rear can also be separated), and different kinds of clothes can be placed at the same time Wash in 2 independent washing spaces, and take off the partition 22 when you need to wash bulky clothes. Among the figure, two of 25 are the washing ribs that the top is provided with grooves and are sealingly connected with the cylinder inwall, 23 and 24 are washing ribs, and 27 is a water level sensor.

Owner:任文涛

Foaming agent used in ultra-low density anti-seepage foamed concrete, and preparation method thereof

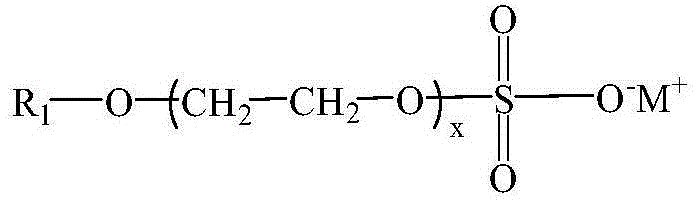

The invention relates to a foaming agent used in ultra-low density anti-seepage foamed concrete, and a preparation method thereof. The foaming agent comprises components of, by mass: 8 to 18 parts of sodium polyoxyethylene fatty alcohol sulfate, 0.1 to 7 parts of sodium dodecylsulfate, 0.5 to 7 parts of sodium dodecylbenzene sulfonate, 4 to 15 parts of pure acrylic emulsion or styrene-acrylate emulsion, 3 to 6 parts of fatty alcohol polyoxyethylene ether, 0.5 to 2 parts of hydroxyethyl cellulose or hydroxy propyl methylcellulose, 0.1 to 5 parts of modified silicon resin or modified nano-gradebentonite, 0.1 to 0.5 parts of a thickener, and balance of water. The anti-seepage foamed concrete foaming agent provided by the invention has stable property, high foaming multiple, and good workability with a substrate. The agent can be used in a foamed concrete product with a density of 100 to 600kg / m<3>. The raw materials are easy to obtain, and the cost is low. The foaming agent can be stored for a long term with out deteriorating. With the agent, foamed concrete properties such as strength and softening coefficient can be improved.

Owner:梁材

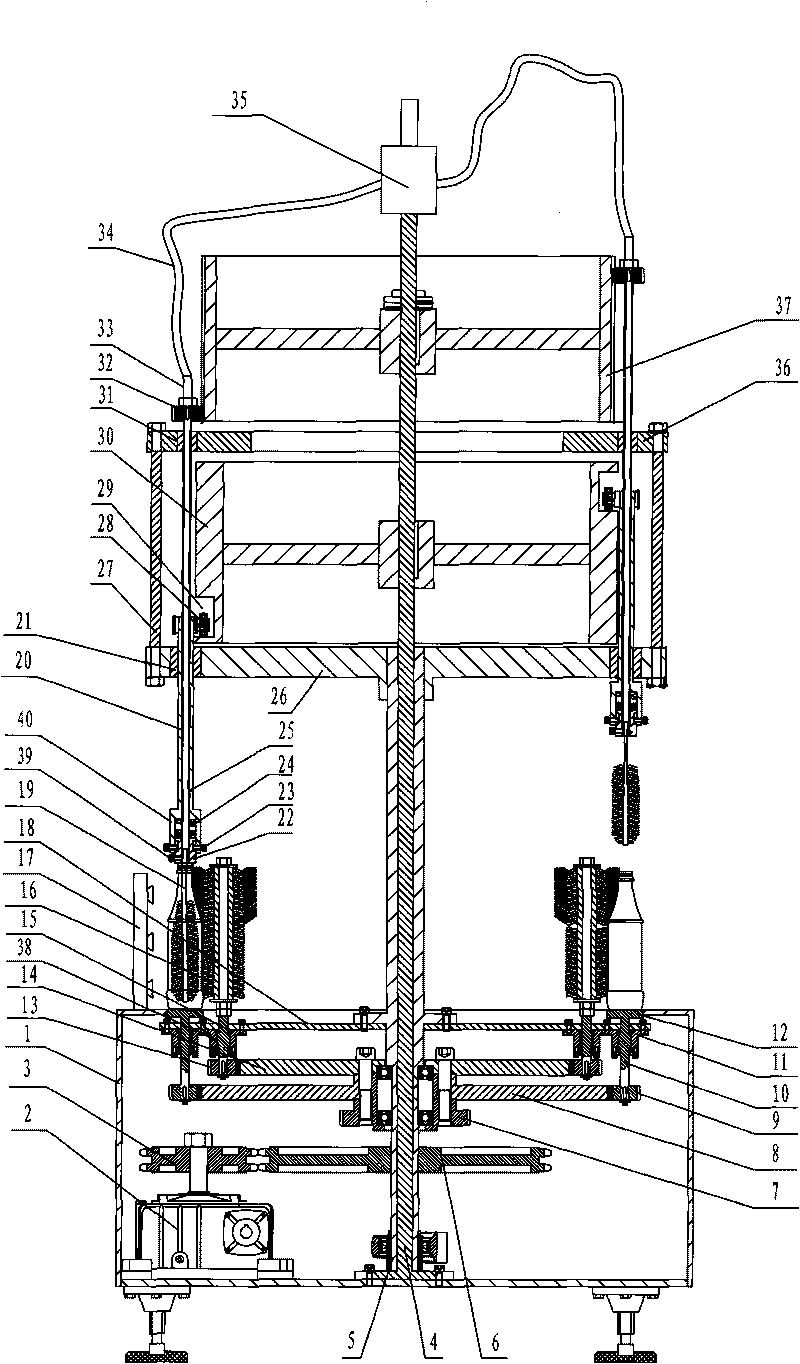

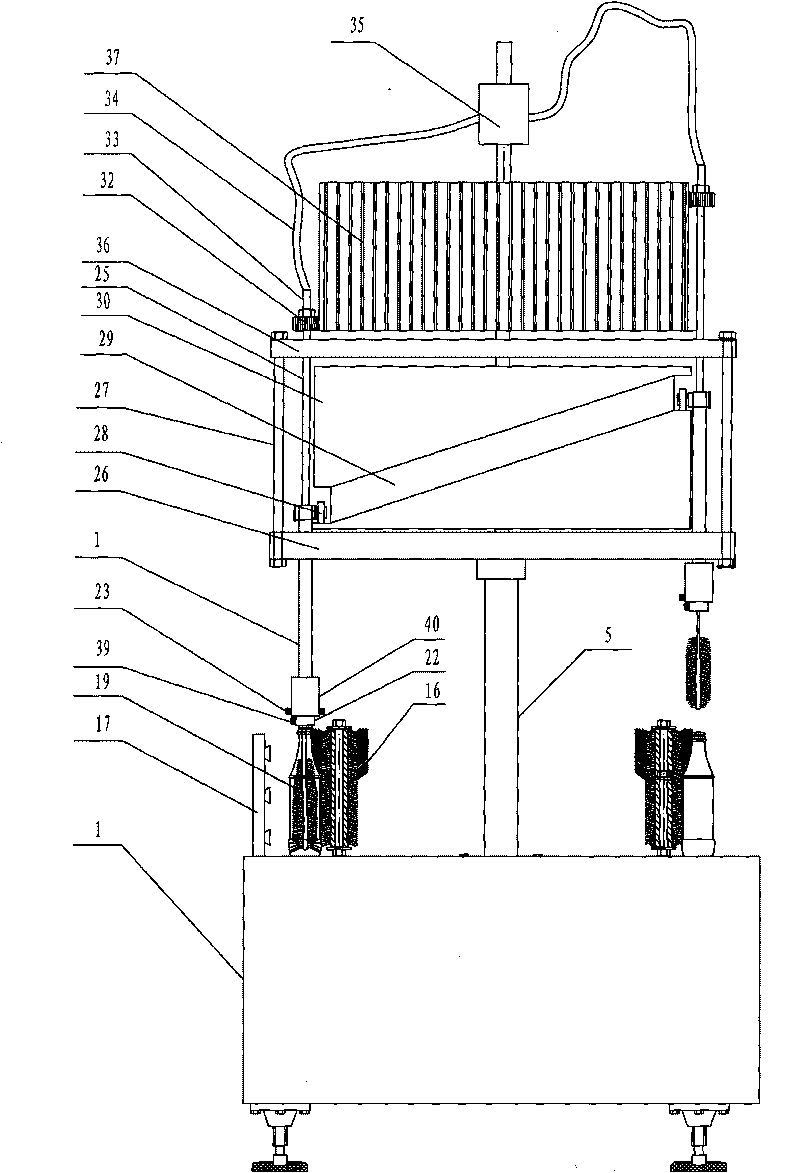

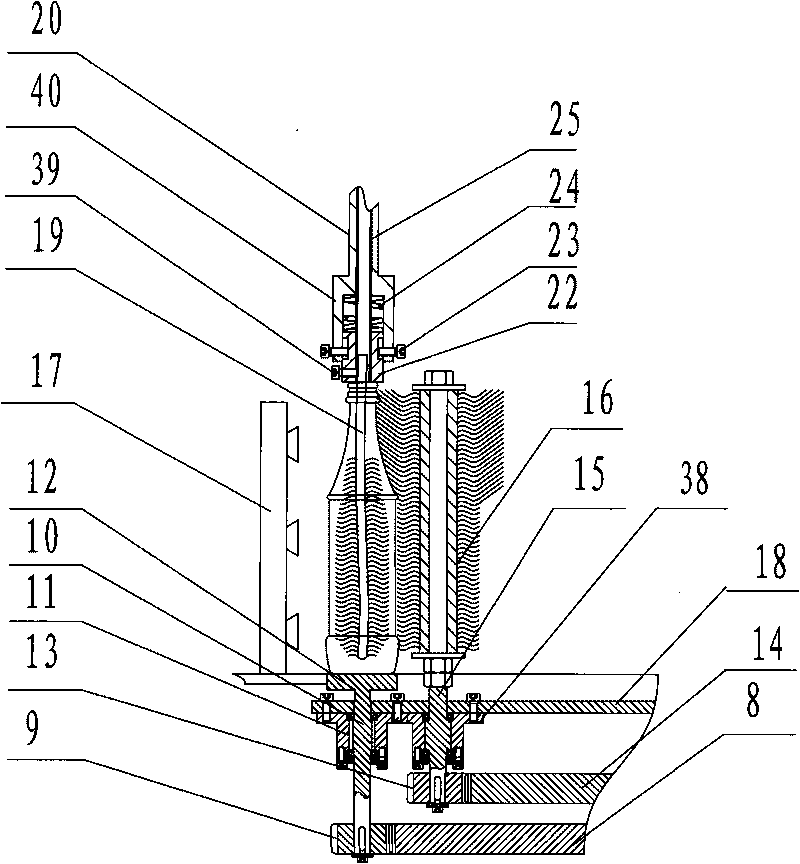

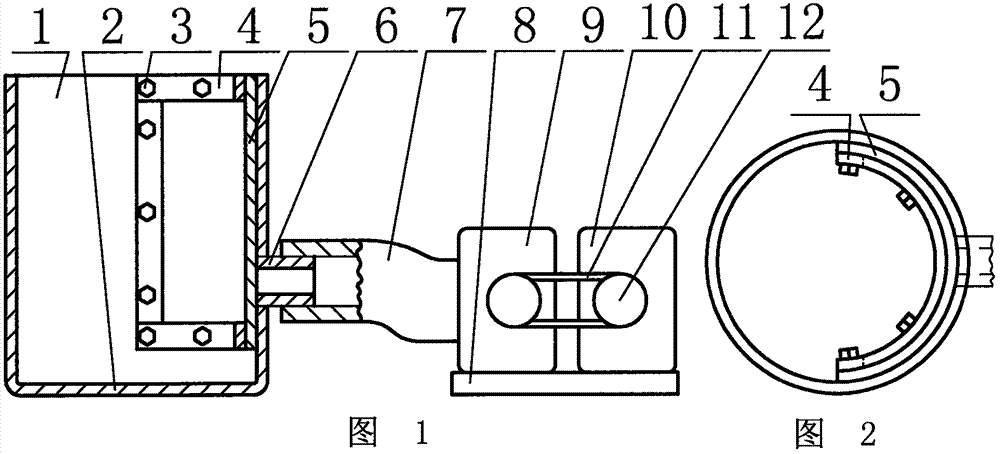

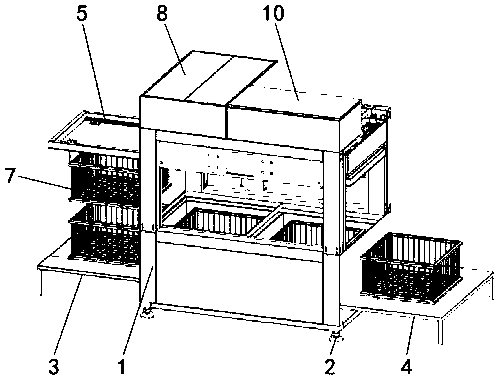

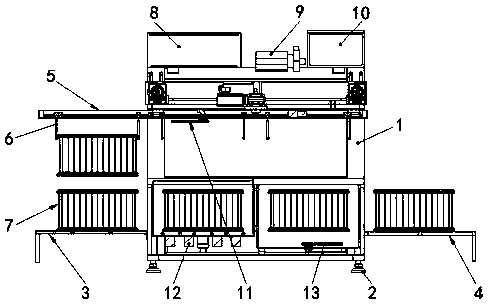

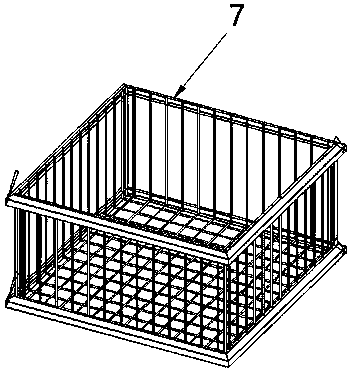

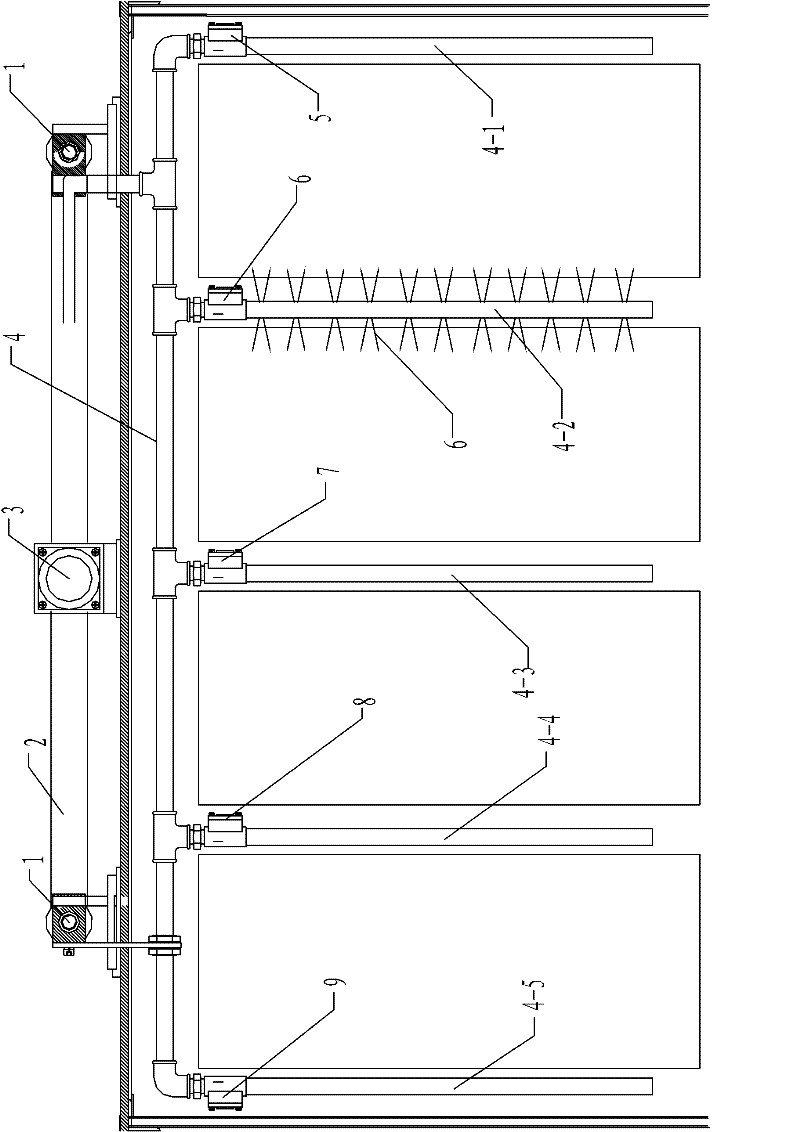

Full-automatic inner-outer bottle cleaning machine

The invention discloses a full-automatic inner-outer bottle cleaning machine which aims at overcoming the disadvantages of complicated structure, large volume, high price, separate inner-outer wall cleaning of bottles, excessive working procedures and high consumption of water and electricity of the present bottle cleaning machine. The full-automatic inner-outer bottle cleaning machine comprises a power mechanism, an inner brush and an outer brush. The bottle cleaning machine has the benefits of simple structure, small occupied area and low price; moreover, the bottle cleaning machine not only can clean the inner and outer walls of the bottles at the same time, but also can finish the cleaning in one step and save water as well as electricity.

Owner:湘潭林海机械制造有限公司

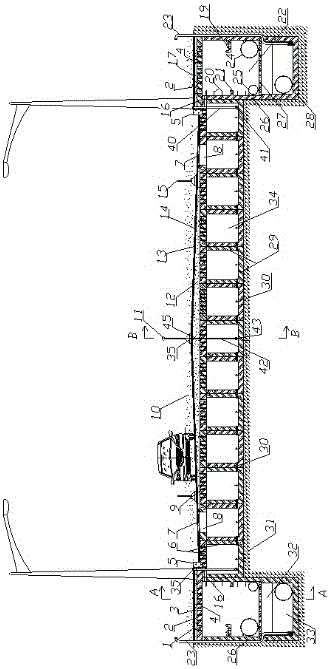

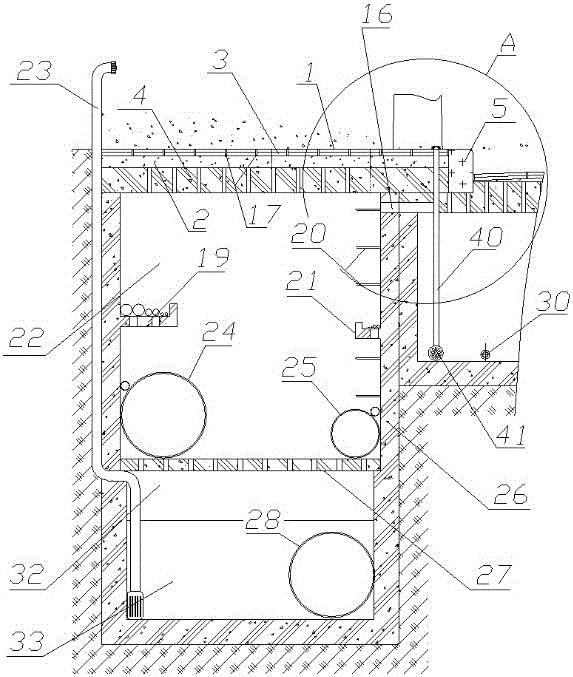

Urban road structure with rainwater collecting and solar power generation functions

ActiveCN106522052AReduce urban waterlogging and river floodingSave water and electricityBatteries circuit arrangementsRoadwaysSprinkler systemCushion

The invention relates to an urban road structure with rainwater collecting and solar power generation functions. The urban road structure with rainwater collecting and solar power generation functions includes a motor way, a non-motor way and a sidewalk, also includes a green belt rainwater spraying irrigation system, a rainwater road surface cooling dedusting sprinkler system and a road surface photovoltaic power station storage power supply system, the motor way and the non-motor way respectively comprise a photovoltaic battery road surface layer, a water permeable cushion layer and a water reservoir cell layer, the photovoltaic battery road surface layer comprises many pieces of photovoltaic battery unit boards, water permeable slits are between the photovoltaic battery unit boards, the photovoltaic battery road surface layer is closely stuck on the water permeable cushion layer, the water reservoir cell layer is under the water permeable cushion layer, and the water reservoir cell layer comprises a plurality of water reservoir cells in splicing. The urban road structure can fully collect and use rainwater and makes full use of road surface resources, collected rainwater can irrigate green belts, also can cool and dedust road surface, and a road surface photovoltaic power station can light roads, and provides electric power resources to electrical public transportation.

Owner:日照市政设计研究院有限公司

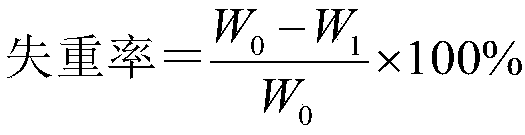

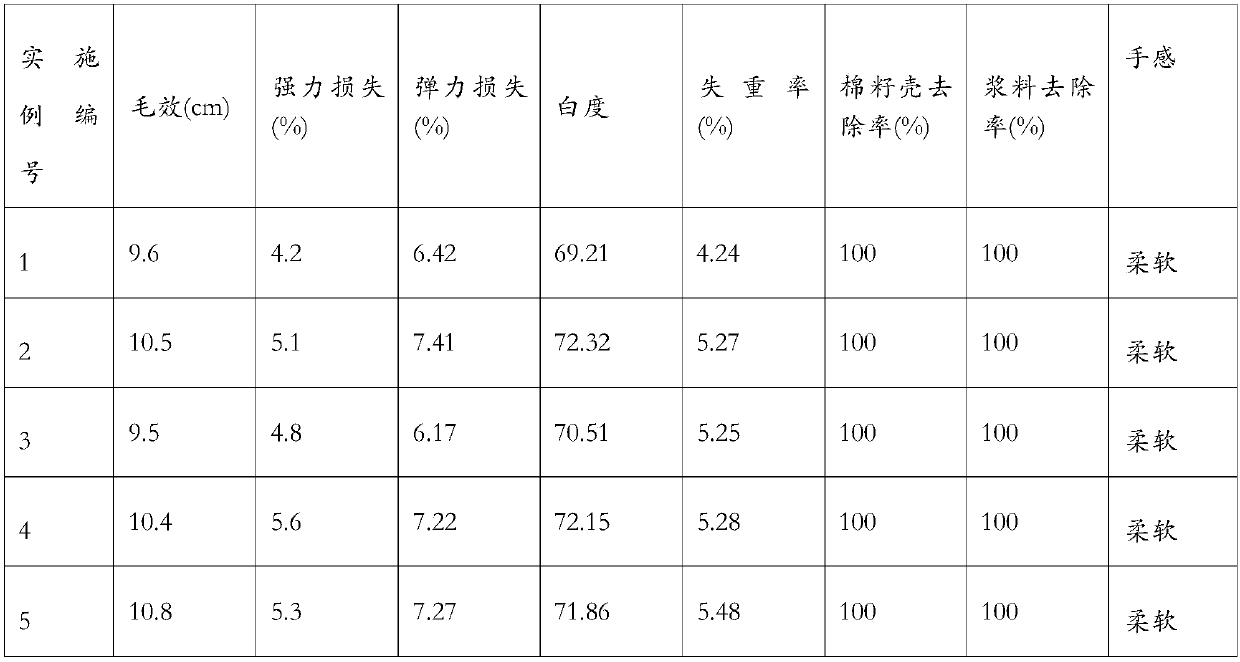

Heavy pure cotton fabric cold padding and stacking pretreatment method

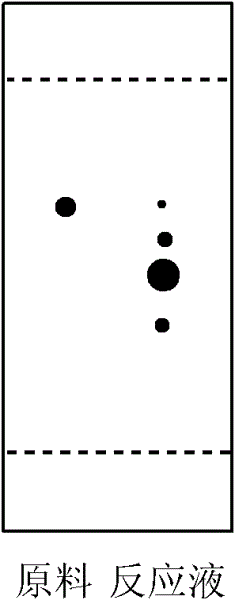

ActiveCN103088645AExcellent desizingExcellent and refinedPhysical treatmentBiochemical fibre treatmentPretreatment methodTherapeutic effect

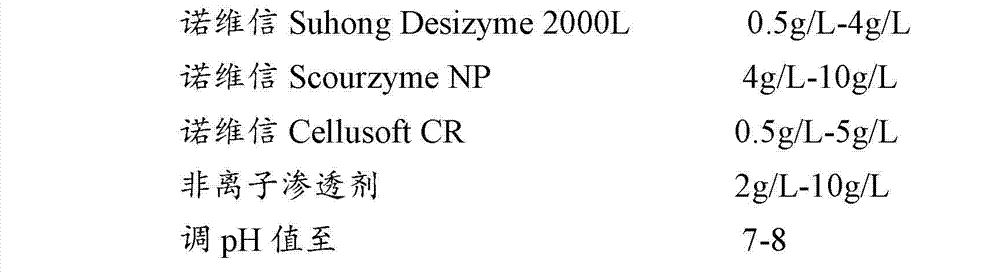

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after normal pressure plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the normal pressure plasma treatment on the singed heavy pure cotton grey fabric; carrying out refining enzyme liquid padding on the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process; and the process is a clean production process meeting the environmental protection requirement, so that the sewage treatment burdens of enterprises are greatly reduced, the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:浙江肯特科技股份有限公司

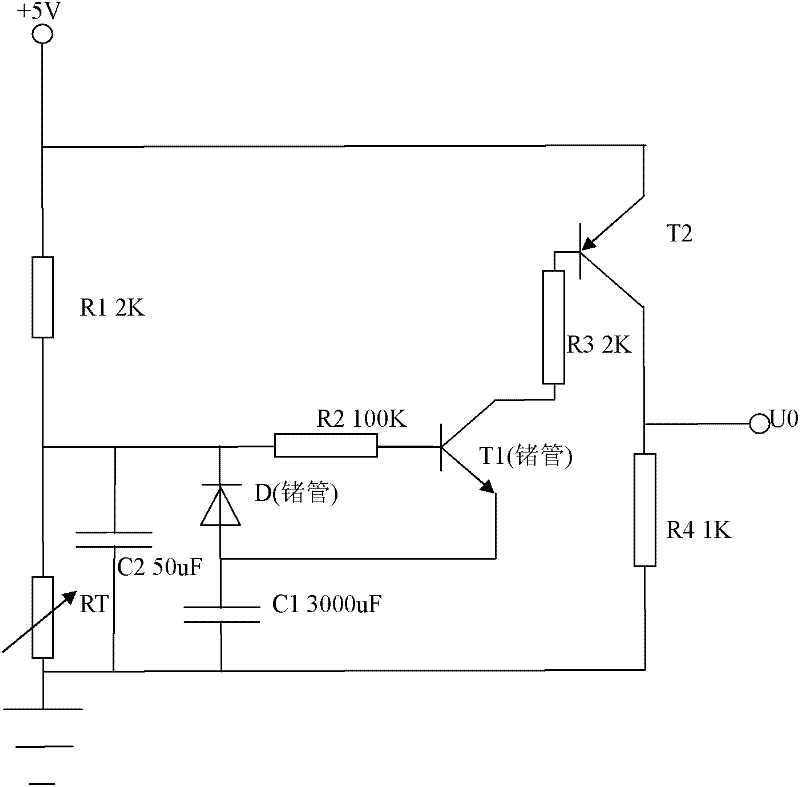

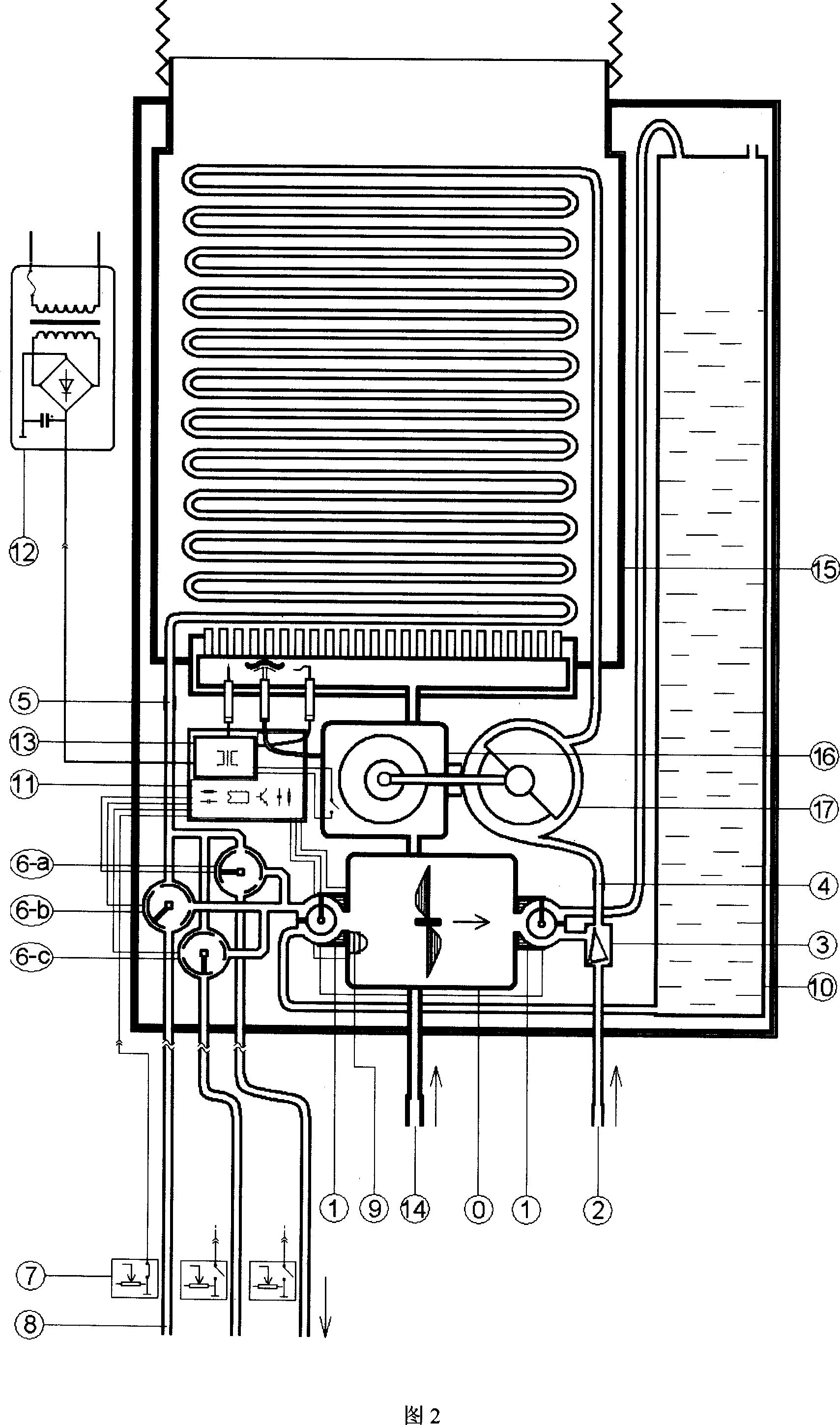

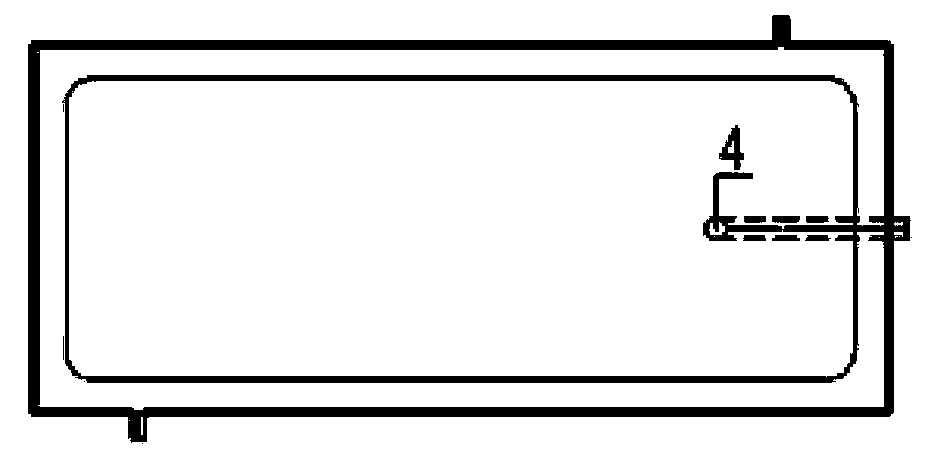

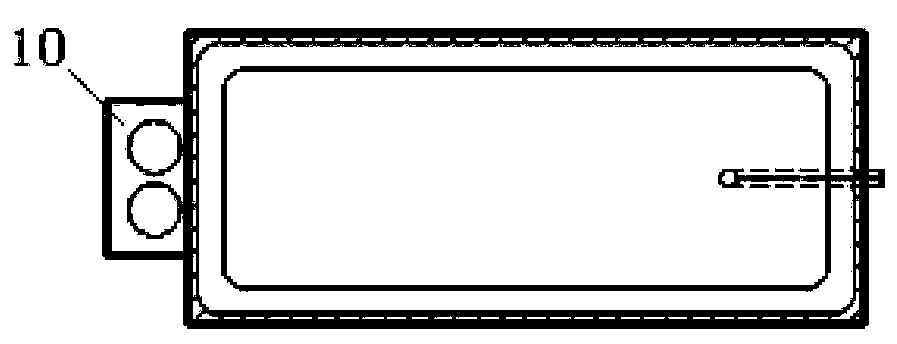

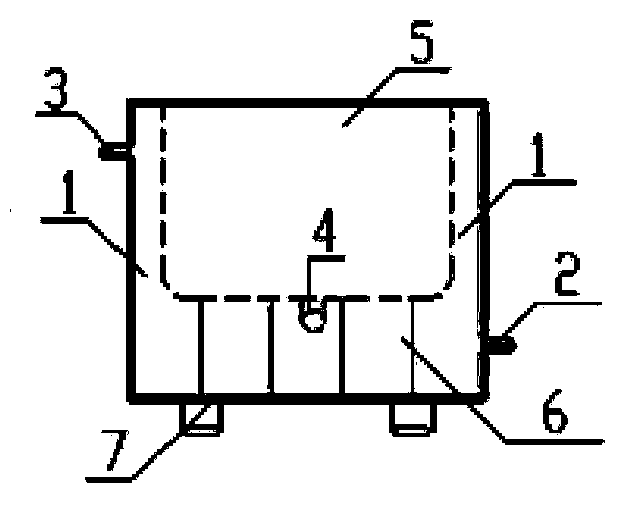

Water saver with waste-water backflow reutilizing function for water heater

InactiveCN101029773AReduce power consumptionSave water and electricityFluid heatersPipeline systemsWater savingEngineering

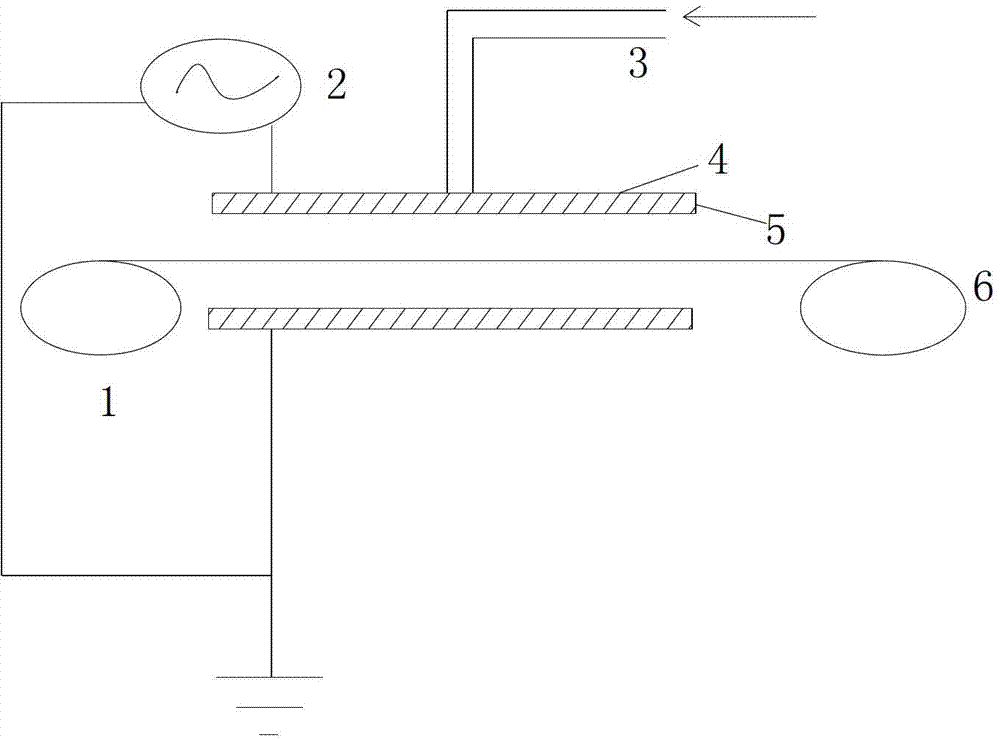

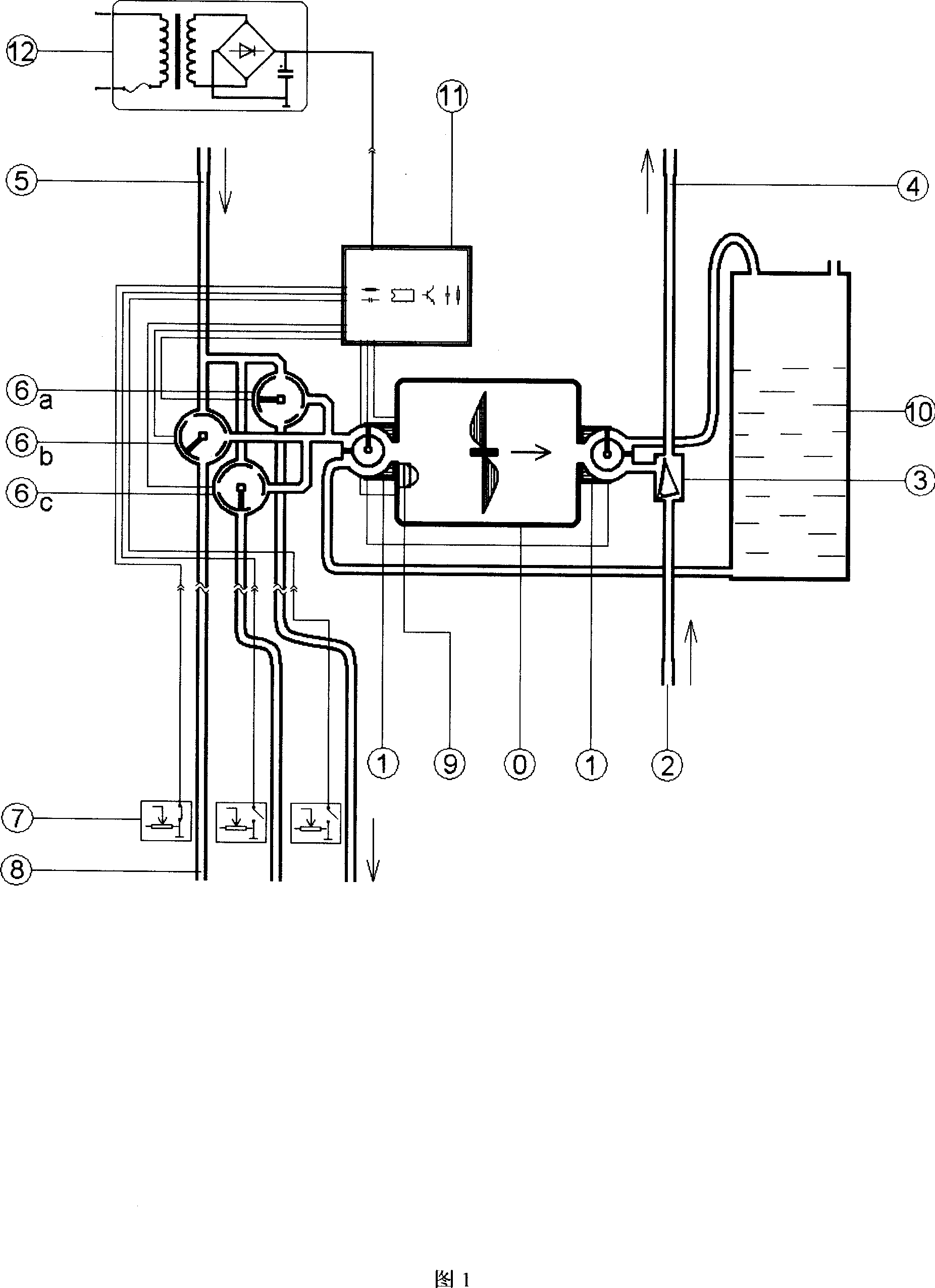

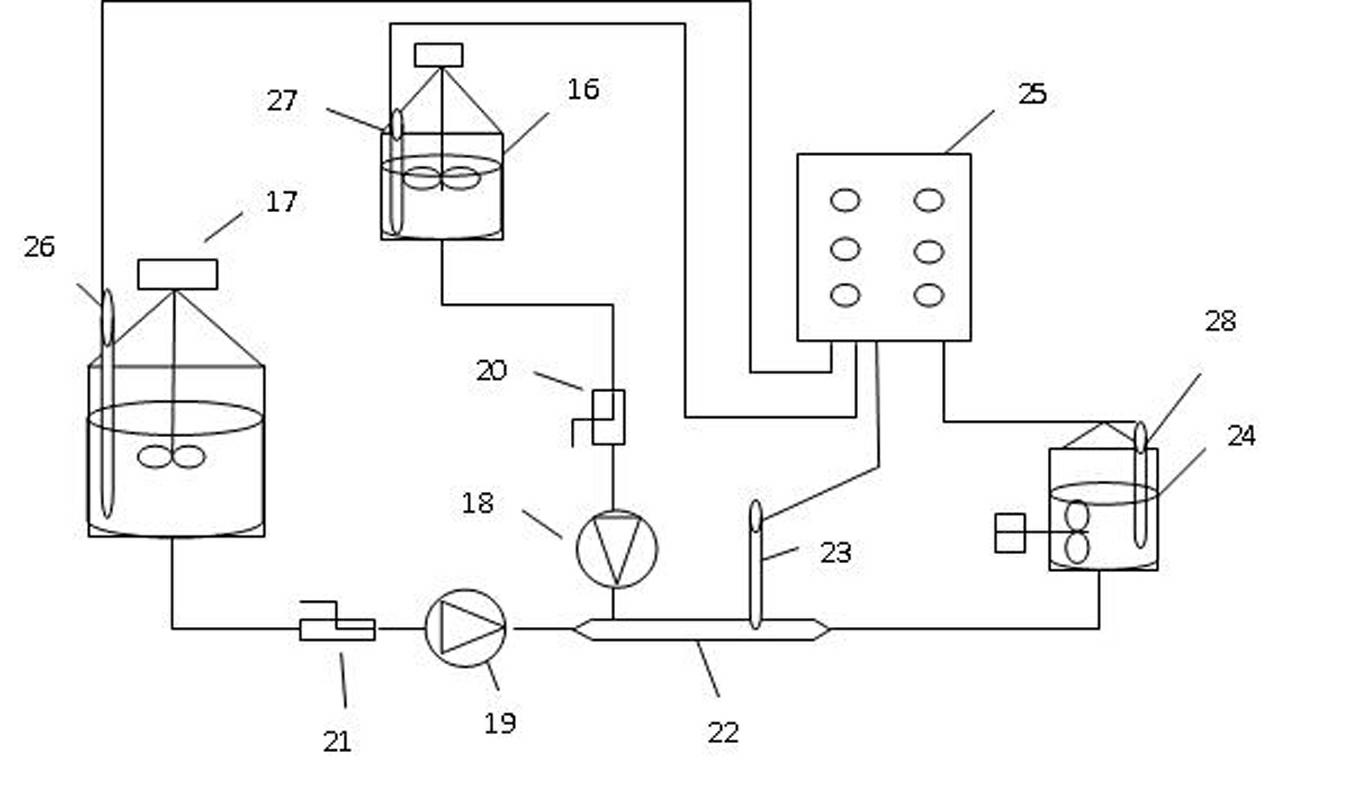

The invention is a water-saving device, it is mainly used to pave with longer water pipe of hot water. Using the device, the water not used in the water pipe will refluence into water tank and can be recycled next time when the user's terminal close the equipment, and when the users start the equipment, cold water will not flow, reversely, the hot water will flow after excluding the air in the water pipe. Water pump and water tank connecting with three terminal adjustable electric control hydrovalve, two shelves electric control selector valve and one-way automatic pressure valve are set up between fill hose and let-off pipe of user terminals. When it works, water tank, two shelves electric control selector valve, water pump, one-way automatic pressure valve and connecting end of water heater's fill hose link together to form a water access, water in the water tank is pressed into connecting end of water heater's fill hose by water pump with a proper pressure; When it is closed, let-off pipe of user terminals, three terminal adjustable electric control hydrovalve, two shelves electric control selector valve, water pump and water tank link together to form a water access, the water of the whole user terminal not used is drew into the water tank by water pump to be recycled.

Owner:周长清

Method for processing foods by ultrasonic waves and ultrasonic food processor

ActiveCN103918954AGuaranteed nutritionKeep the flavorFood shapingCleaning using liquidsHazardous substanceUltrasonic machining

The invention discloses a method for making foods by ultrasonic waves. According to the technical scheme, in the food processing process, the temperature is between -5 DEG C and 95 DEG C, and the adopted ultrasonic frequency is 20-200 KHz. The novel method has the beneficial effects of no production of harmful substances during processing, short production period, few production procedures, saving of places and workers as well as water and power and reduction of three-waste emission, and is capable of keeping the nutrition, flavor and safety of foods.

Owner:重庆鸿紫圆光生物科技有限公司

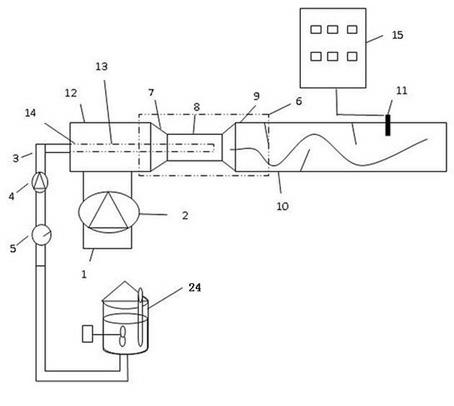

Automatic acid mixing apparatus and method thereof, and automatic pipeline iodic acid apparatus and method thereof

ActiveCN102351945AUniform precipitationRapid precipitationPeptide preparation methodsOther dairy technologyHigh concentrationAutomatic control

An objective of the invention is to provide an automatic acid mixing apparatus and a method thereof, and an automatic pipeline iodic acid apparatus and a method thereof. Therefore, problems of nonuniform mixing and over high local acidity are solved, wherein the problems exist in a current on-line souring system. The automatic pipeline iodic acid apparatus comprises a material pipeline, a material variable frequency pump, an acid pipeline, a diluted acid variable frequency pump, a Venturi tube and a mixer; an entrance section of the Venturi tube is connected with a premixer; an acid jetting pipeline is arranged in the premixer; and a tail portion of the mixer is connected with an iodic acid pH monitor, which is connected with an automatic control module. according to the invention, the automatic pipeline iodic acid apparatus is utilized to enable automatic iodic acid to be realized; a diluted acid that is configured by the automatic iodic acid apparatus enters the automatic acid mixing apparatus to carry out automatic acid mixing. Besides, materials can be mixed fully, rapidly and high efficiently; occurrences of unstable acid concentration and a local peracid phenomenon during the iodic acid processing can be effectively avoided; and denaturation of active materials with acid nonresistant performance on the condition of acid with high concentration can be reduced.

Owner:甘肃华羚乳品股份有限公司

Secondary design construction method for low-pressure boiler small pipeline on the basis of BIM (Building Information Modeling) technology

InactiveCN106951637AIntuitive visualization of project progressDo a good job of progress controlGeometric CADSpecial data processing applicationsSocial benefitsField conditions

The invention discloses a secondary design construction method for a low-pressure boiler small pipeline on the basis of a BIM (Building Information Modeling) technology. The method comprises the following steps that: establishing the three-dimensional stereo models of all pipeline and equipment, and importing pipeline and equipment model and position data to carry out the collision detection of a three-dimensional stereo model graph; designing the starting point and the end point of the small pipeline, establishing the position data, and carrying out the collision detection of the three-dimensional stereo model graph on electric and thermal control equipment; according to a material bill provided by the BIM software technology, carrying out statistics on the type, the amount and the length information of each component of the boiler small pipeline; installing a small pipeline hanging bracket, and baiting and bending the small pipeline on the ground; and carrying out collision detection on an important position and a field condition, and guaranteeing a construction plan. According to the construction plan, construction simulation and progress simulation are carried out, each professional collision problem is coordinated to generate coordinated data to determine a reasonable construction scheme and construction period, a construction period is reduced in general, a great quantity of artificial, material, mechanical and equipment costs can be saved, and economic benefit and social benefit are obvious.

Owner:POWER CHINA HENAN ENG CO LTD

Neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics

ActiveCN102154230AReduce pollutionImprove water absorptionBiochemical fibre treatmentEnzymesPectinaseCellulose

The invention relates to a neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics. The neutral low-temperature refining enzyme comprises 15 to 50 weight parts of neutral cellulose, 30 to 70 weight parts of pectinase, 10 to 30 weight parts of xylanase, 5 to 30 weight parts of lipase and 10 to 15 parts of laccase. When the neutral low-temperature refining enzyme is used, cotton seed hulls, pectic substances, waxiness and the like can be removed effectively, the water absorptivity, fiber strength and dyeing property of cotton fabrics can be improved, dye can be saved, process time can be reduced and the production efficiency can be improved. A green processing method which is low in carbon content, environment-friendly and energy-efficient can be realized actually in the fabric dyeing industry.

Owner:沧州夏盛酶生物技术有限公司

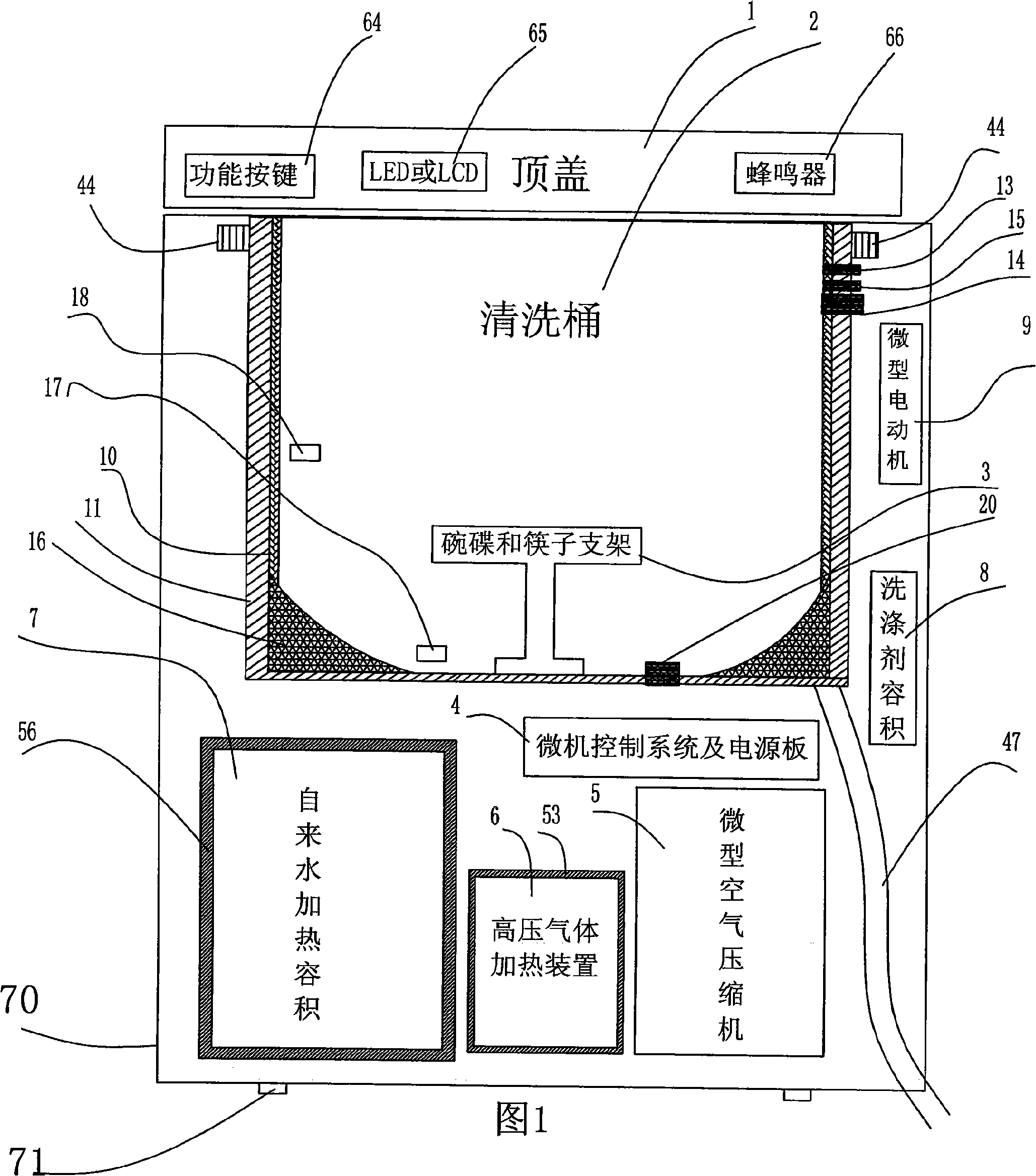

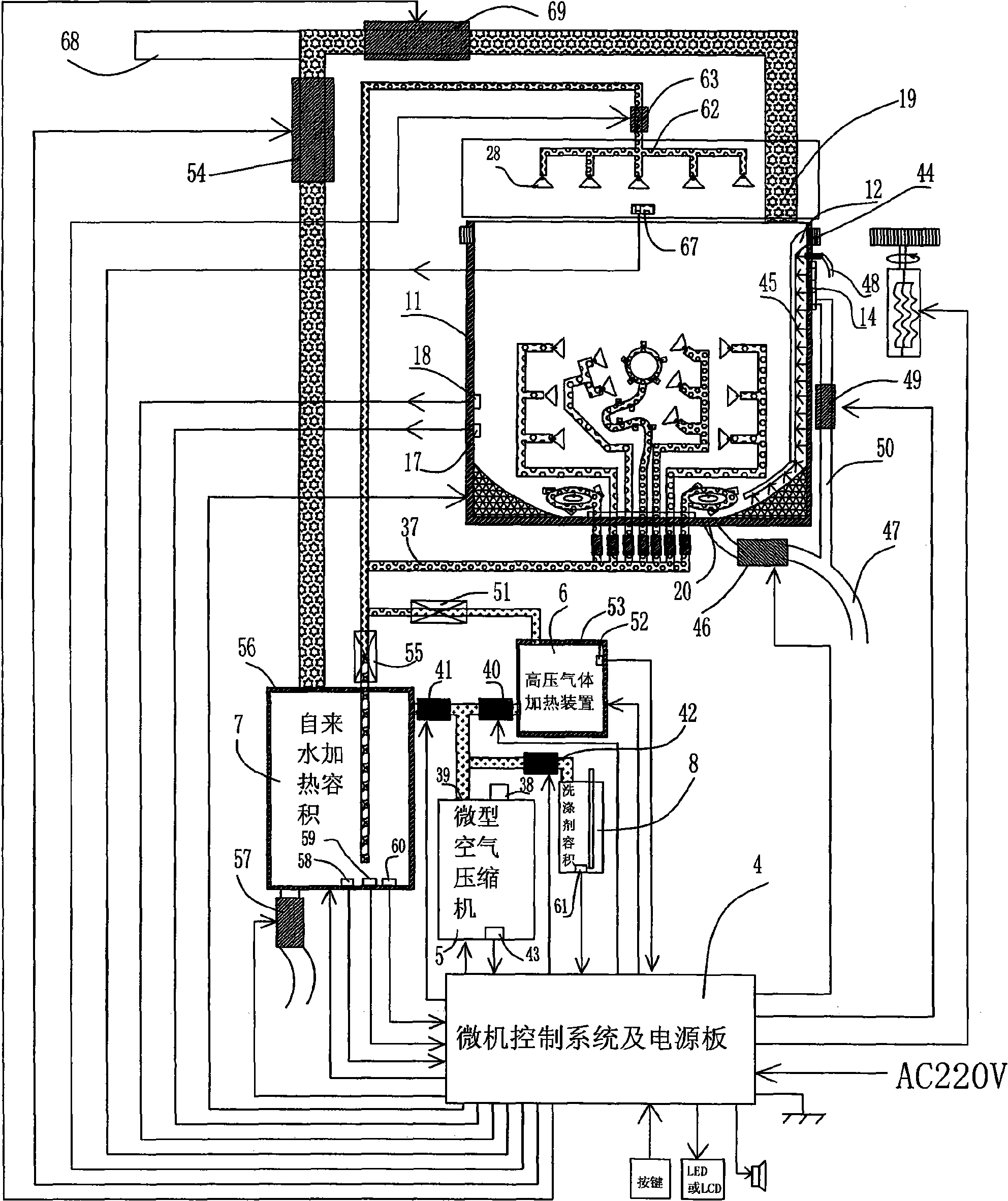

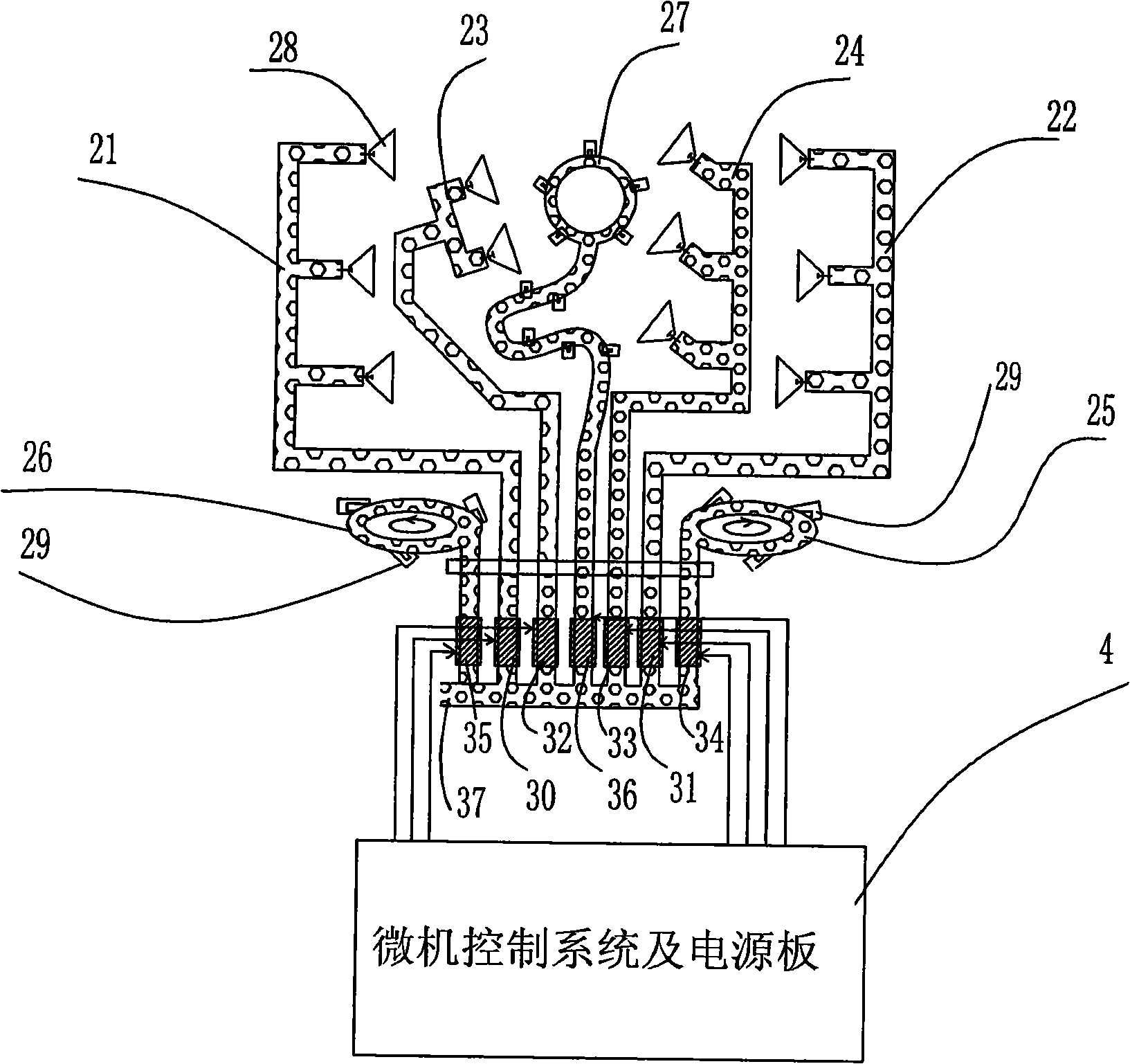

Chinese style domestic bowl-washing machine with micro air-compressor

InactiveCN101327113AIncrease the areaClean upTableware washing/rinsing machinesHome appliance efficiency improvementAir compressorHigh pressure

The present invention discloses a Chinese style household dishwasher with a micro air compressor, which comprises a top cover, a washing barrel, a dish and chopstick bracket, a micro control system, a power plate, a tap water heating volume, a micro motor, a micro air compressor, a high-pressure air heating device and a detergent chamber. The washing barrel consists of a liner body and a heat insulating layer; the liner body is assembled with the top cover and a liner washing device; the top part of the liner body is sequentially provided with a water level height limit hole, a detergent liquid inlet and an oil dirt effluent trough; the bottom center of the liner body is provided with the dish and chopstick bracket; the liner body is provided with an annular electronic heater, a first water-level sensor and a first temperature transducer; the liner body is provided with a tap water inlet pipe and a drainage outlet. The micro air compressor supplies power for the transportation of hot water and air; the dish and chopstick bracket as well as the matched use of a high-temperature and high-pressure liquid gasified nozzle ensures clean dish washing, water and energy saving, dish drying and effective disinfection.

Owner:王辉武

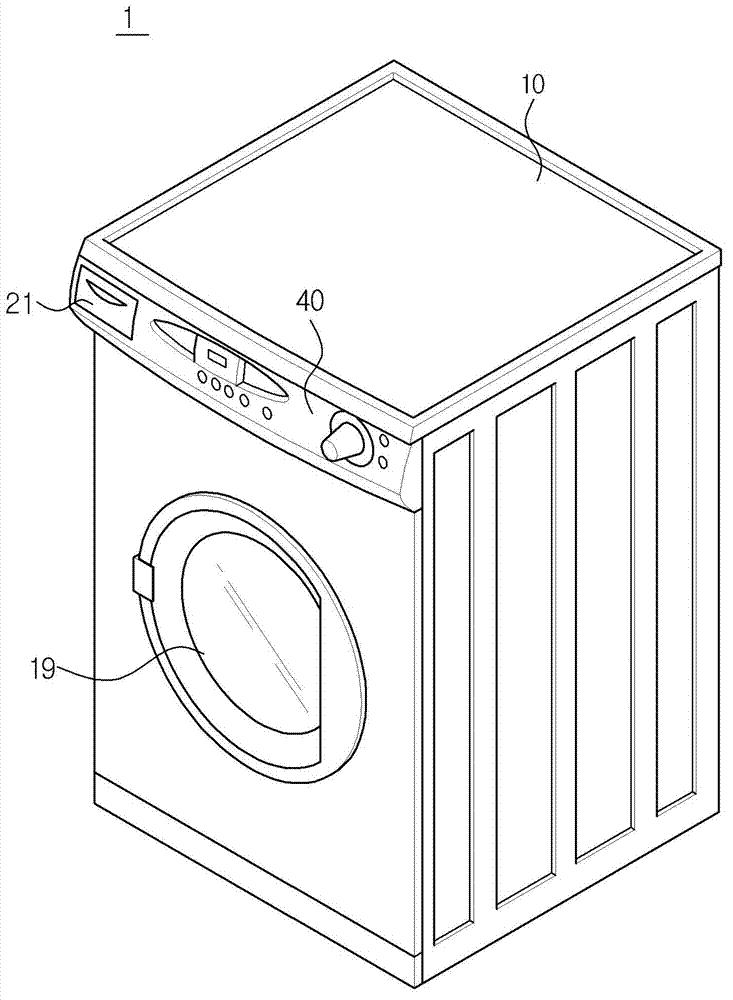

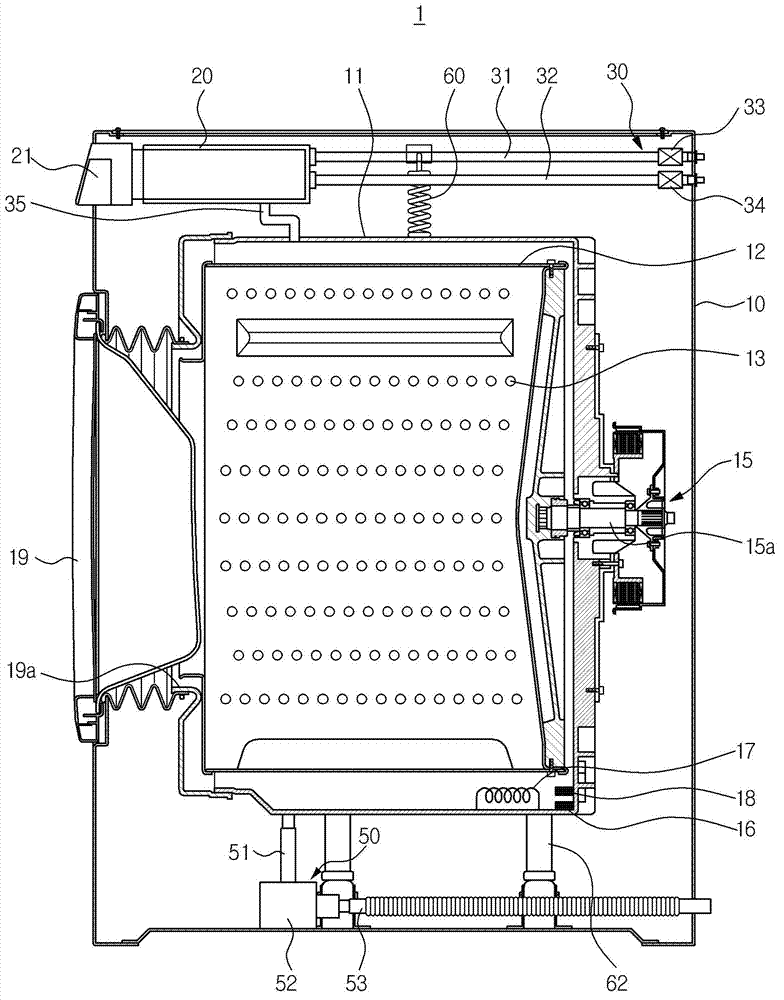

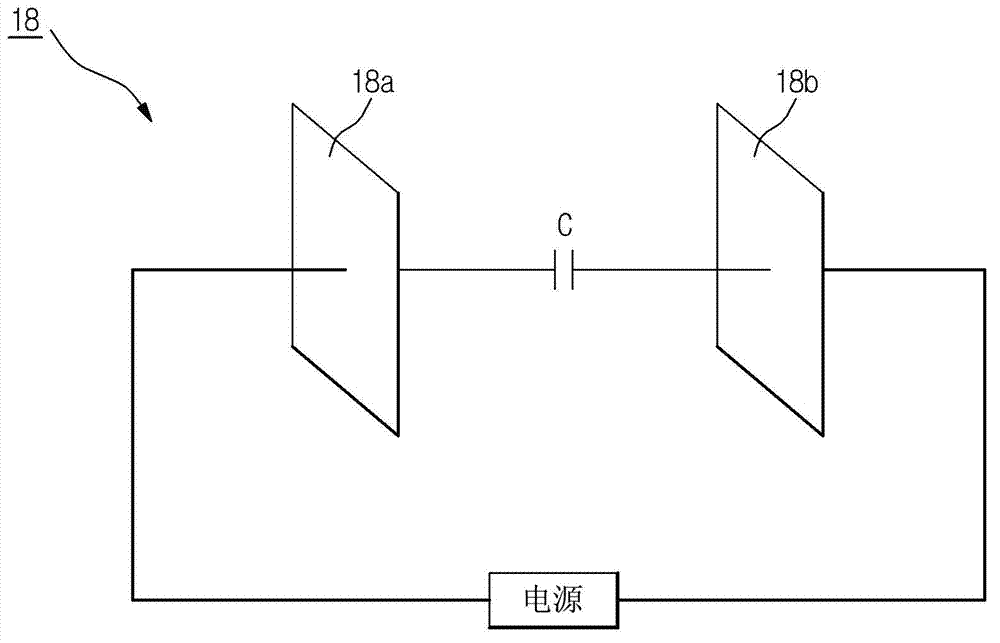

Washing machine with conductivity sensor and method of controlling rinsing cycle

InactiveCN103161051AExtension of timeMinimize timeRinsing apparatusOther washing machinesRinse waterEnvironmental engineering

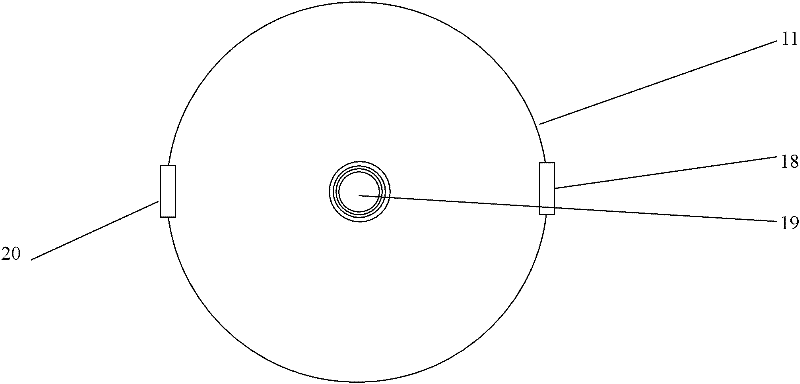

A washing machine capable of optimizing the rinsing time and the amount of rinsing water by using a conductivity sensor (18), and a method of controlling a rinsing cycle thereof. When the amount of detergent remaining in the rinsing water is determined to be small according to the measured conductivity, the amount of rinsing water and the rinsing time are minimized, that is, the rinsing water is alternately supplied in stages of times, the conductivity of the rinsing water is measured at the stop of the supply of rinsing water, and if the measured conductivity is below a reference value, the rinsing cycle is stopped and enters to a final-spin dry cycle, so that the water and energy is saved and the rinsing is achieved with the optimum algorithm when laundry having a little contamination and a small amount of detergent is input.

Owner:SAMSUNG ELECTRONICS CO LTD

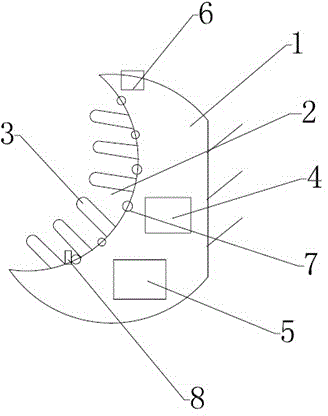

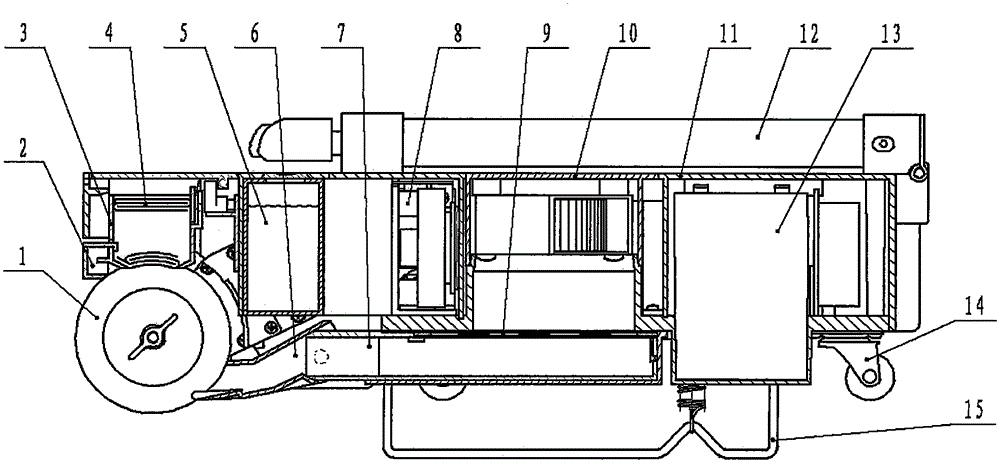

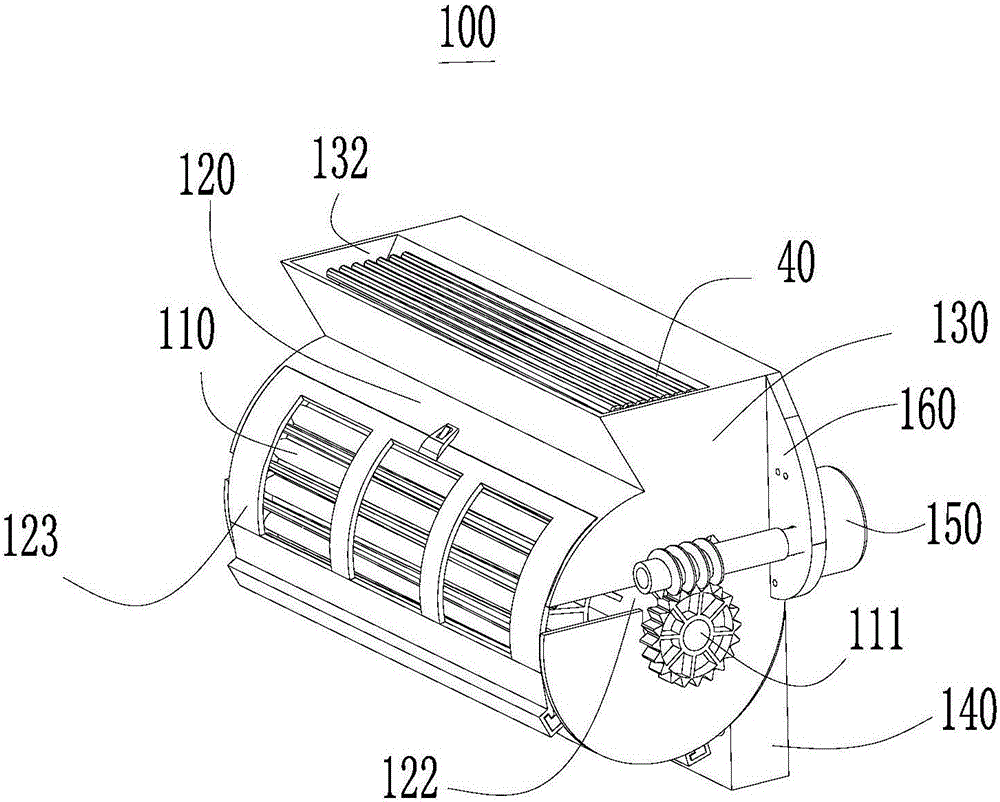

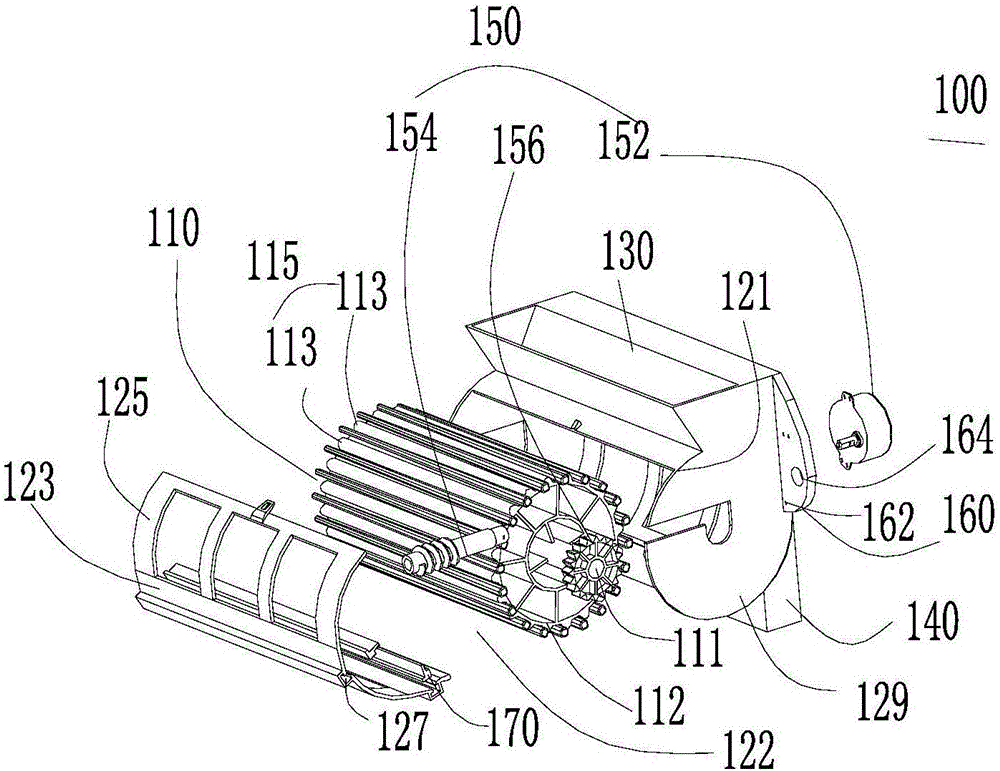

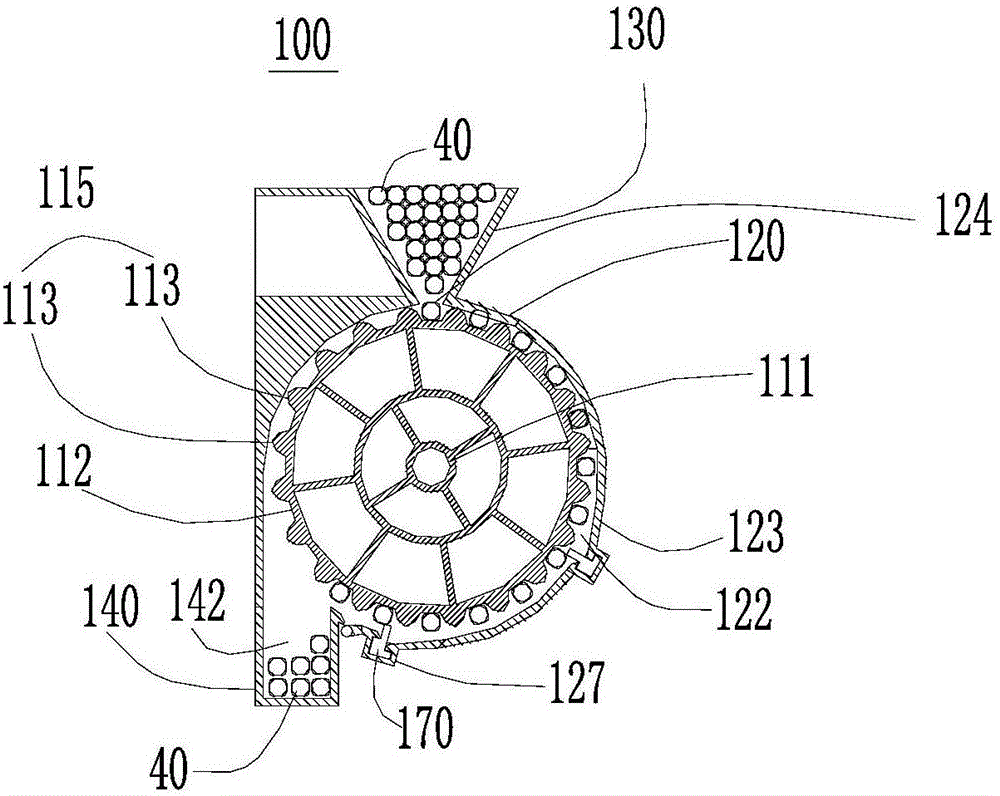

Automatic hair washing machine

InactiveCN104687701AIncrease labor intensityPromote blood circulationTravelling articlesHair cleaningElectricityDual effect

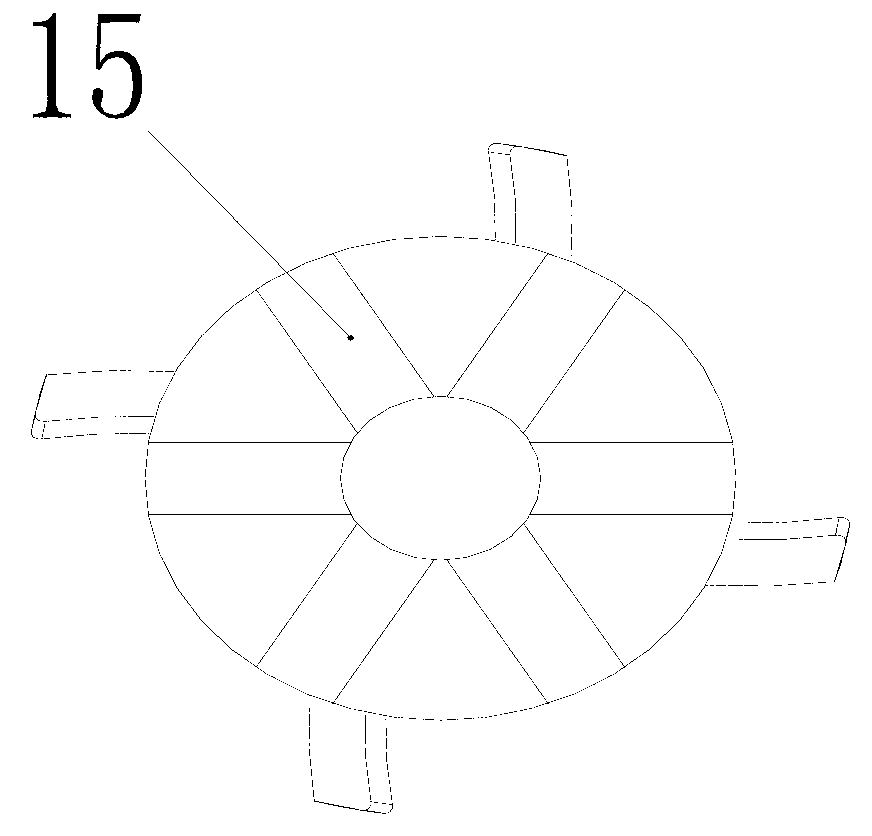

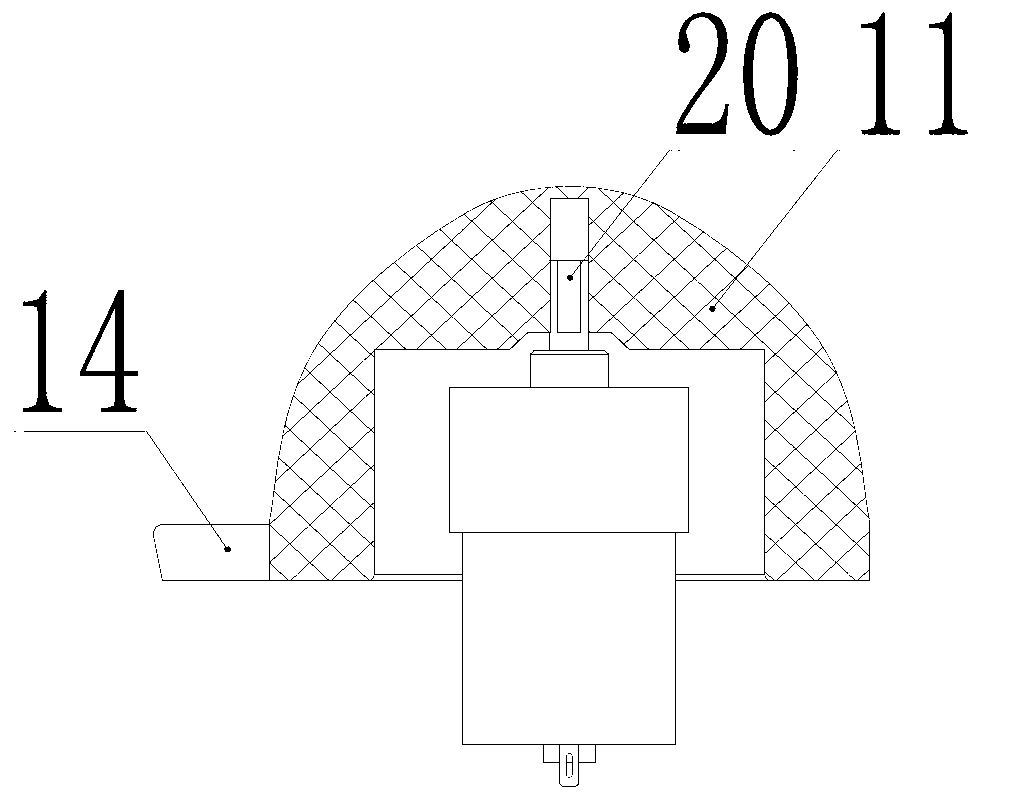

The invention discloses an automatic hair washing machine. The automatic hair washing machine comprises an outer shell, an inner barrel, rubbing rods, a mechanical program controller, a motor, a hair lotion box, a water inlet and an induction device; the mechanical program controller is arranged between the outer shell and the inner barrel; the multiple rubbing rods similar to fingers are arranged on the wall of the inner barrel; fine water inlet holes are formed in the all of the inner barrel; the hair lotion box is arranged at the top of the outer shell; the induction device is arranged at the bottom of the wall of the inner barrel; and the motor mechanically works to drive the inner barrel to rotate. The automatic hair washing machine has the beneficial effects that the structure is simple; the head is massaged and rubbed through the rubbing rods on the wall of the inner barrel, so that the function of automatically cleaning the head is achieved, the labor intensity caused by manual hair washing is improved, time, water and electricity are saved, and the work efficiency is improved. Meanwhile, important acupuncture points of the head can be massaged, the scalp blood circulation is simulated, the mind is relaxed, fatigues are eliminated, and the dual effects of cleaning hairs and relieving the mental stress can be achieved.

Owner:QINGDAO JIENENG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

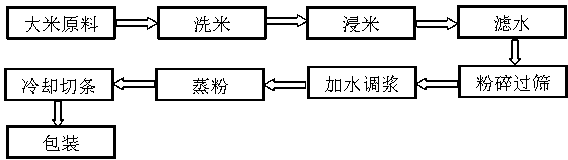

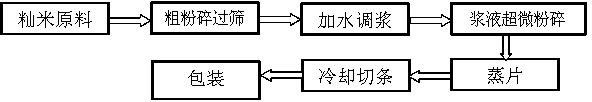

Method for processing fresh fried rice noodles

ActiveCN103504213AIncrease profitIncrease productionFood homogenisationFood shapingMicrometerWastewater

The invention discloses a method for processing fresh fried rice noodles, and belongs to the technical field of food processing. The method comprises the following process steps: taking long-shaped rice as a raw material, roughly crushing and screening, adding water and mixing slurry, crushing the slurry in a superfine grinding manner, steaming slices, cooling, cutting, forming, packaging and the like, wherein a superfine grinding machine is a wet type superfine grinding machine, that is, a colloid mill; and the key point of the process is that the rice slurry after slurry mixing is repeatedly grinded for 1.5-2 minutes inside the colloid mill, so that the diameter of the rice slurry is less than 20 micrometers. The fresh fried rice noodles manufactured by using the method are glittering and translucent in color and tender and smooth in taste. Due to adoption of the method disclosed by the invention, the defects that a great amount of water is used, a great amount of wastewater is generated and the machining time is long because of the rice soaking procedure when the rice is machined in conventional fresh fried rice noodle machining, are overcome, and the method has the characteristics that the production efficiency is high, the production period is short, the raw material utilization rate is high, no wastewater is generated, and the cost is low, and therefore, the method is applicable to industrial production of large scale.

Owner:JIANGNAN UNIV

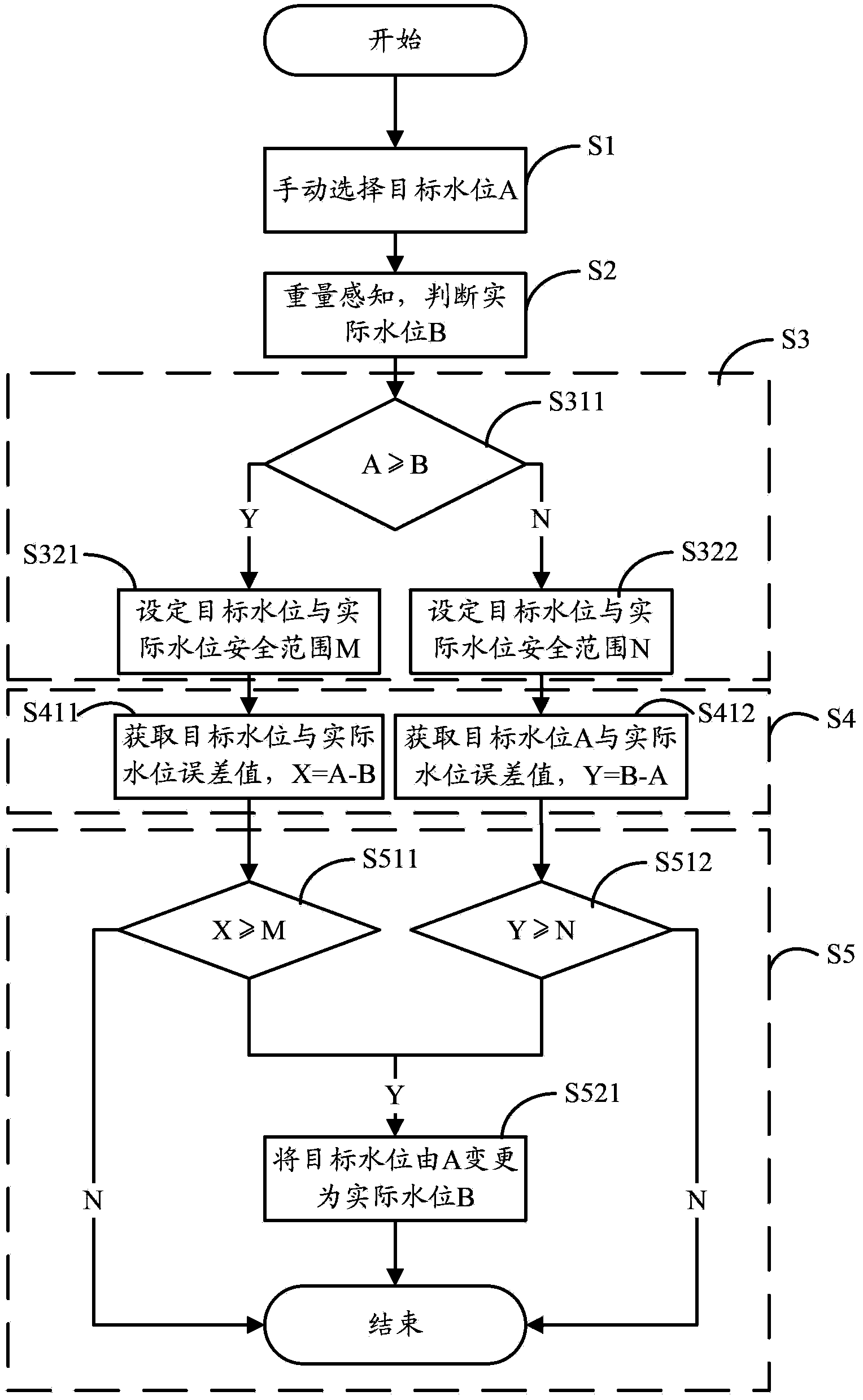

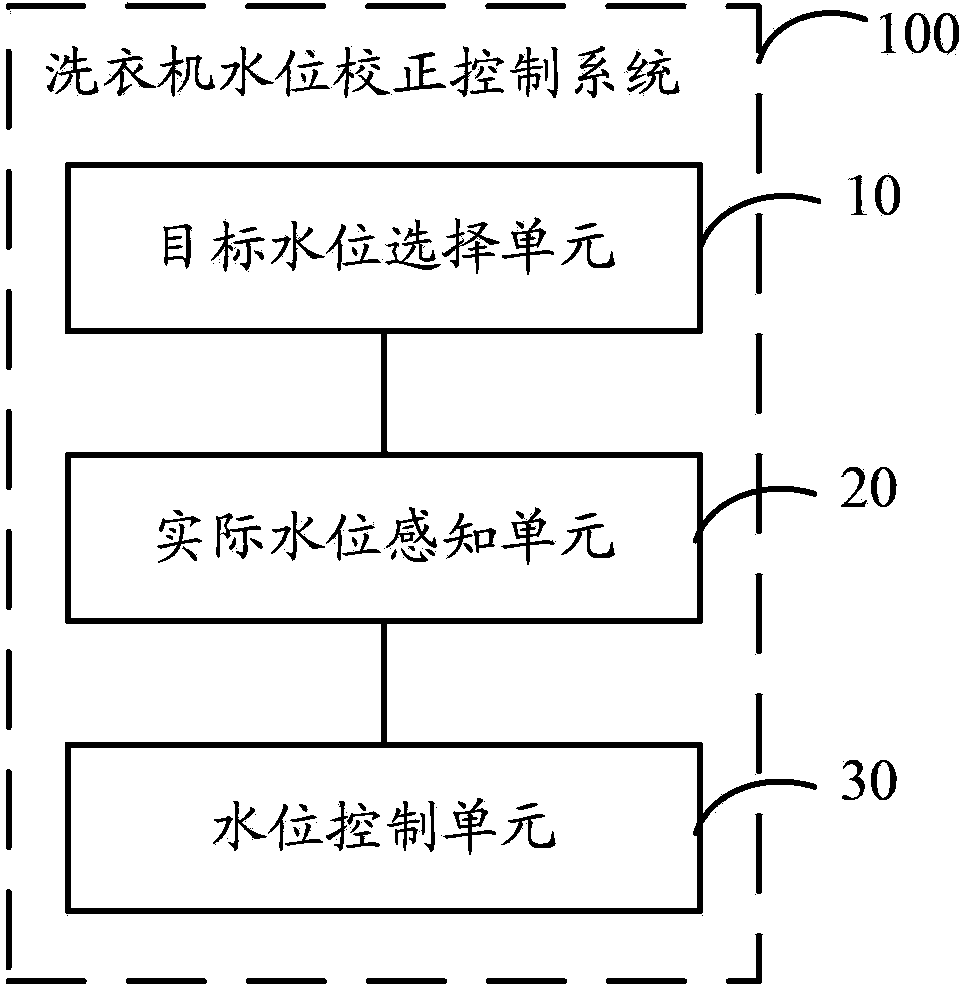

Washing machine water level correction control method and system

ActiveCN103850086ASmall differenceSave water and electricityOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a washing machine water level correction control method and system. The method comprises S1, selecting a target water level after clothes to be washed are put in the washing machine; S2, performing weight sensing automatically to determine the actual water level; S3, setting the target water level and actual level safety range; S4, calculating the error of the target water level and the actual water level; S5, determining whether the error is larger than or equal to the safety range, setting the actual water level as the target water level if the error is larger than or equal to the safety range, otherwise, keeping the target water level unchanged. By means of the method and the system, the situation of the large difference between the load actually needed water level and the current selected water level can be prevented effectively, clothes and the washing machine are protected, resources of water and electricity are saved, and the cleanness ratio is guaranteed.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

Automatic washing powder putting device

InactiveCN102995359APrecise deliveryStable deliveryOther washing machinesTextiles and paperImpellerElectricity

The invention relates to an automatic washing powder putting device. The device comprises a solvent box, an upper cover of the solvent box, and a powder leakage hole in a bottom disc. The device is characterized in that an impeller is arranged in the solvent box; a motor supplies kinetic energy to the impeller so as to drive the impeller to rotate; and a dissolving box is arranged on the other side of the powder leakage hole and is provided with a water inlet and a liquid leakage hole. According to the invention, the dissolving box can be used for fully dissolving washing powder, thus improving the purifying capacity of the washing powder, and avoiding waste caused by the inaccuracy of the quantity of the washing power manually put by a user; and the time for dissolving the washing power in a washing machine before is shortened since the washing powder is fully dissolved, so that the washing time of the washing powder is prolonged, and within the same set time, the frequency of rinsing is reduced and water and electricity are saved to achieve the aim of energy conservation. The automatic washing powder putting device conforms to green design and is energy-saving and man-machine.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

Method for printing PCB solder resist layer with heat-set ink

InactiveCN106982517AMeet quality requirementsSave materialNon-metallic protective coating applicationCooking & bakingResist

The invention provides a method for printing a PCB solder resist layer with heat-set ink. The method comprises the following steps of: a, polishing a PCB to remove foreign matters such as oxide and garbage on the surface of the PCB; b, making a silk screen plate, coating the silk screen plate with a layer of photosensitive resist, putting a film on the silk screen plate to be exposed, and transferring a pattern to the silk screen plate and performing development; c, installing the silk screen plate; d, deploying the heat-set ink, adding a curing agent and a diluents to the heat-set ink and uniformly stirring; e, printing: enabling a semi-automatic printing press to print the deployed heat-set ink on the surface of the PCB by using a scraper; f, baking: placing the printed PCB into an oven to be baked in order that the heat-set ink is cured to form the solder resist layer; and g, checking the PCB. The heat-set ink is printed on the PCB surface by the silk screen plate, and is directly heated and cured to form the solder resist layer. The method can achieve an effect that completely satisfies the quality requirement of a solder resist layer obtained by a traditional process, and can reduce production cost and can improve the production efficiency.

Owner:东莞翔国光电科技有限公司

Extrusion type washing machine

ActiveCN107217441AReduce wearRelative velocity maximizationOther washing machinesWashing machine with receptaclesDrive shaftTransmitted power

Disclosed is an extrusion type washing machine. The extrusion type washing machine is characterized in that an extrusion fabric is arranged inside a washing barrel, and the edge of the extrusion cloth is connected to the washing barrel; the upper portion and the middle portion of a hollow shaft is mounted inside the axle hole of a washing bottom plate as well as the axle hole of a water containing bottom plate and provided with a through hole penetrating the top surface and the bottom surface of the hollow shaft; a positioning device is connected with the water containing bottom plate and a transmission shaft; a water pump and a washing motor are arranged; the water outlet pipe of the water pump is connected with the bottom of the hollow shaft through a connecting device; the water inlet pipe of the water pump is connected with the water pipe joint of a water containing barrel through a water pipe; the washing motor transmits power to the water pump through a transmission device, the water pump can drive water to enter the through hole of the hollow shaft and further drive the extrusion cloth to extrude clothes in the washing barrel; a targeting spray pipe is arranged to rinse extremely dirty parts of the clothes in a targeted mode; washing water flows back to the water containing barrel and enters the washing barrel through water holes in the washing barrel to rinse the clothes. The extrusion type washing machine achieves washing through extrusion and rinsing, thereby being high in efficiency and effects.

Owner:柴文龙

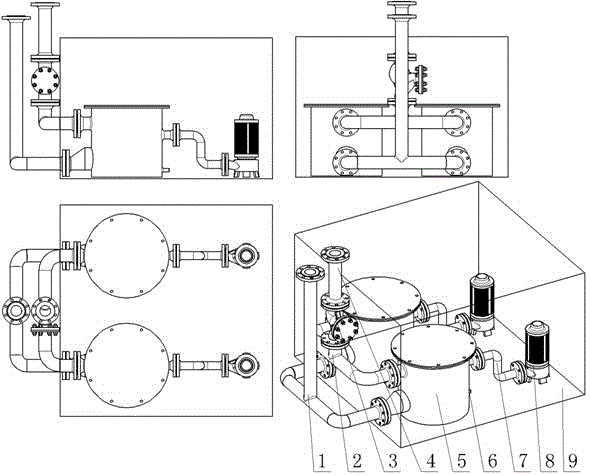

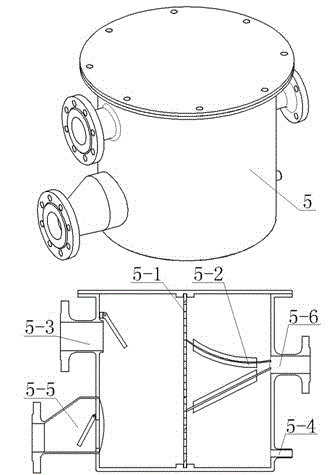

Lift pump station for sewage treatment

InactiveCN103938706AAvoid easy cloggingPass smoothlyFatty/oily/floating substances removal devicesSewerage structuresSpray nozzleSewage

The invention discloses a lift pump station for sewage treatment. The lift pump station is mainly used for lifting sewage. In the device, a filtering and flow guiding device firstly filters the domestic sewage for solid-liquid separation, and it is avoided that because the domestic sewage directly flows through a pump, solid impurities in the sewage block the pump, and the pump can not operate normally. Solids and the impurities after filtering are precipitated at the bottom of the filtering and flow guiding device, the filtered sewage enters a water tank, and when the sewage in the water tank reaches a certain height, submerged type sewage pumps are started. At the moment, the sewage enters the filtering and flow guiding device again to clean a filter net in an all-around mode. The solids and impurities which are filtered and precipitated before are discharged from the pump station together with the sewage. Flow-guiding plates enable the sewage to clean the filter net in the more all-around mode, the filter net can not be blocked, and resistance of pipelines is reduced. The discharged sewage is prevented from flowing back to the water inlet pipeline to the maximum degree due to two non-return devices, and therefore the lift pump station can be safer. An even-mixing nozzle in a water outlet is used for flushing precipitates in the water tank, and then the precipitates are discharged through the pump.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

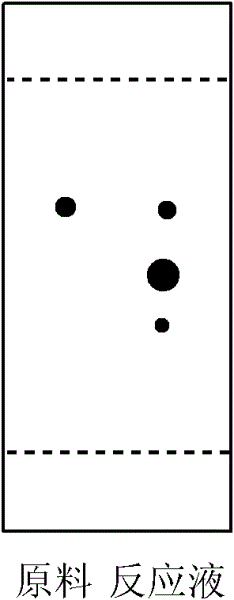

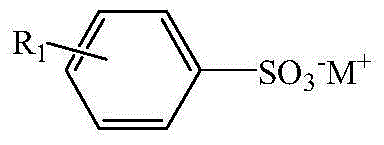

Preparation method and use of 3,3'-methylenebis(1H-Indole)

ActiveCN102617442ALow priceReduce pollutionOrganic active ingredientsOrganic chemistryP-Toluenesulfonic acidSolvent

The invention provides a preparation method of 3,3'-methylenebis(1H-Indole). The preparation method comprises the following steps that 1, indole and p-toluenesulfonic acid are dissolved in a solvent comprising water and 95wt% of ethanol and a formaldehyde aqueous solution is added into the mixed solution in a nitrogen protective atmosphere; 2, the mixture obtained by the step 1 undergoes a reaction at a room temperature in dark for 20 to 30 hours, preferably, for 24 hours; 3, reaction products are filtered so that solids precipitated by the step 2 are obtained; and 4, the solids obtained by the step 3 are subjected to recrystallization purification. In addition, the invention also provides a use of the prepared 3,3'-methylenebis(1H-Indole) which is a high purity compound in preparation of drugs.

Owner:SOURCING BIZ GUILIN INC

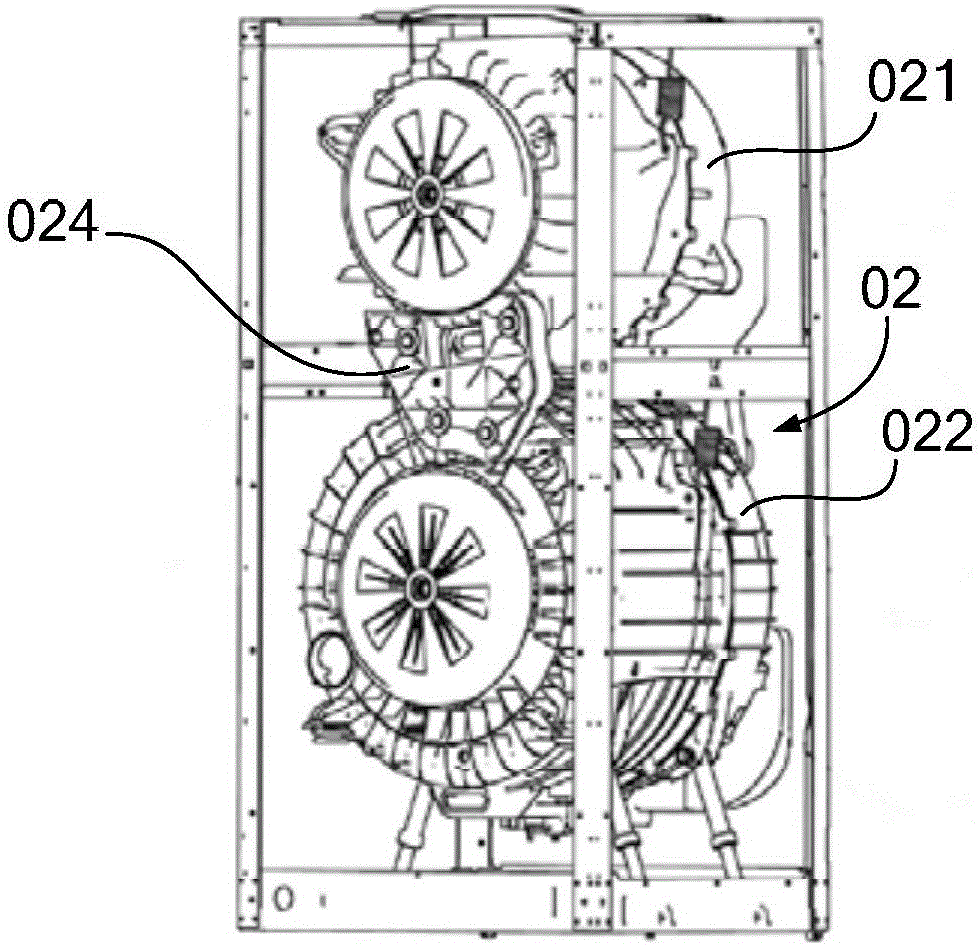

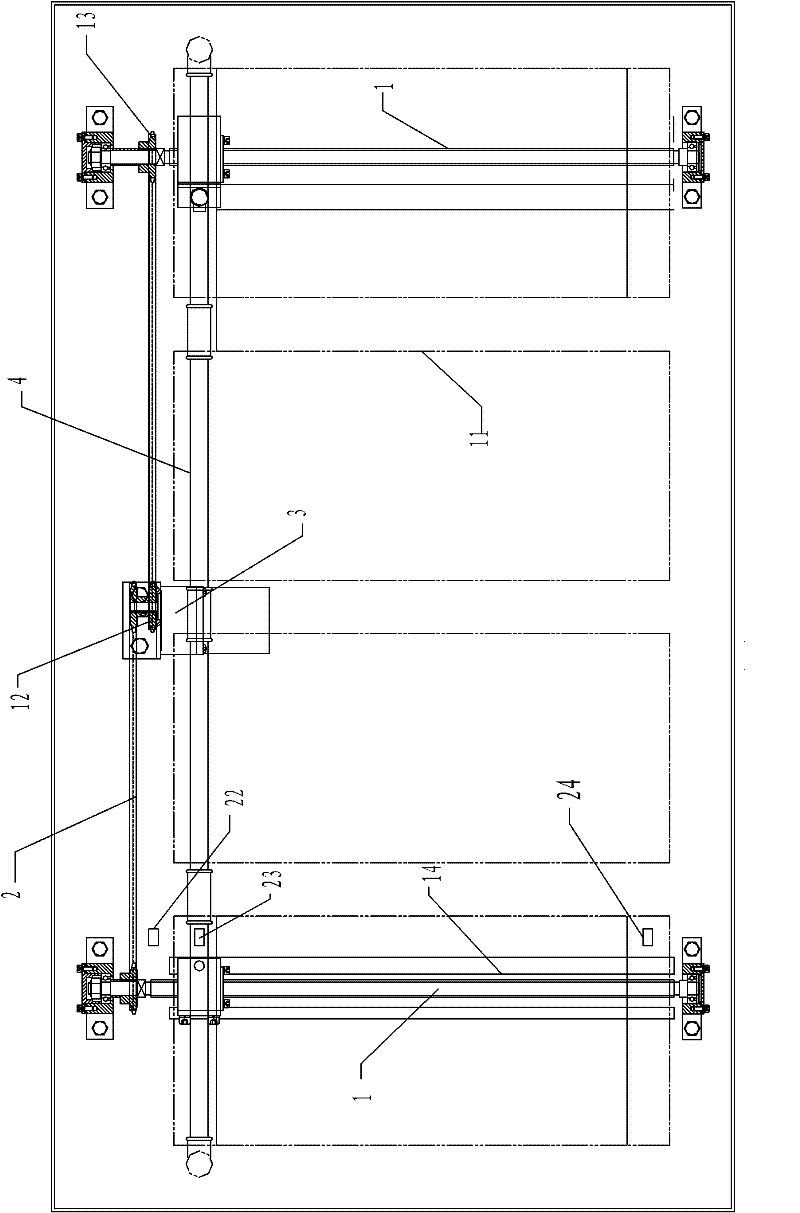

Three-drum washing machine

ActiveCN106637802AMeticulous laundry sorting and cleaningSave water and electricityOther washing machinesTextiles and paperElectricityPulp and paper industry

The invention discloses a three-drum washing machine, and relates to the technical field of washing machines. The three-drum washing machine is designed in order to solve the problems in the prior art that the washing machine cannot provide more careful classified clothes washing, and when small-lot clothes with high washing frequency and small washing amount in a single time is washed, water waste and electricity waste are easily caused. The three-drum washing machine comprises a machine housing, a washing drum assembly is arranged in the machine housing, the washing drum assembly comprises a lower part washing drum and two upper part washing drums side-by-side arranged at the upper part of the lower part washing drum, and the lower part washing drum is a drum type washing machine. The three-drum washing machine can be used for classified washing of clothes.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

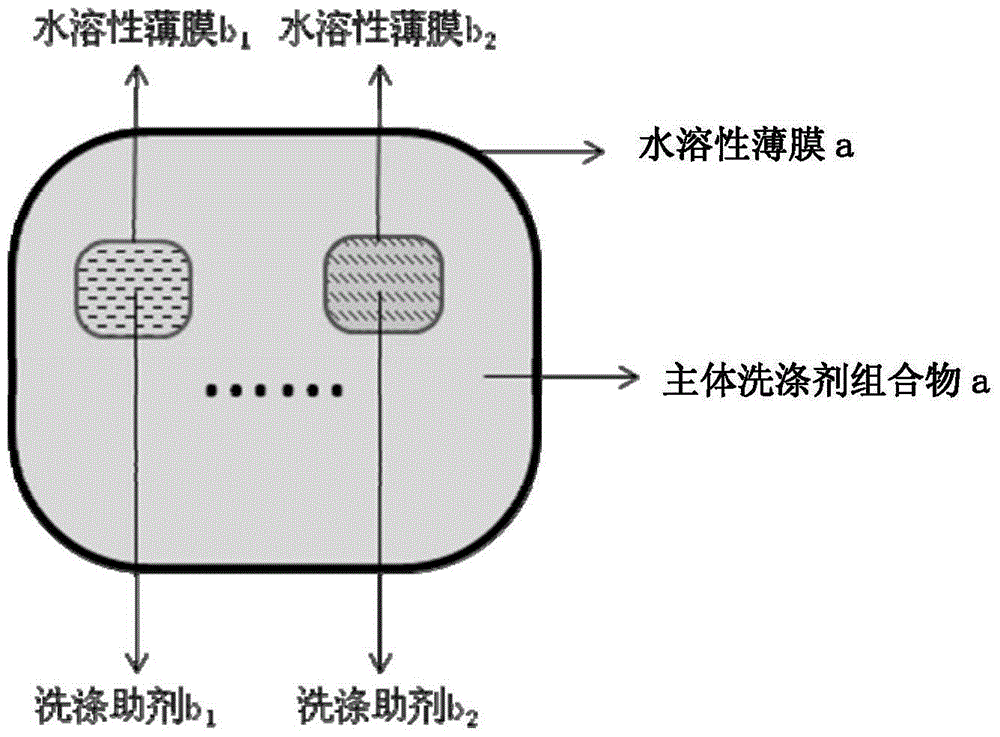

Water soluble unit dose product applicable to fabric washing

ActiveCN105199863AReduce wasteReduce resource requirementsNon-ionic surface-active compoundsDetergent dyesMicrometerComposition B

The invention discloses a water soluble unit dose product applicable to fabric washing. The water soluble unit dose product comprises a first closed portion a and a second closed portion b, wherein the first closed portion is at least made of a water soluble film a, the content of the first closed portion is a main detergent composition a, the weight-average molecular weight of the water soluble film a ranges from 5000 to 120000, and the thickness ranges from 25 micrometers to 100 micrometers; the second closed portion is at least made of a water soluble film b, the content of the second closed portion is a washing assistant composition b, the weight-average molecular weight of the water soluble film b ranges from 40000 to 250000, and the thickness ranges from 25 micrometers to 120 micrometers. According to the water soluble unit dose product, the purpose that a main detergent composition packet and a washing assistant packet are broken at different moments is achieved, so that washing components are released at different time points, and the advantage that the washing or nursing effect of the washing components is brought into play to the maximum extent is achieved.

Owner:GUANGZHOU LIBY

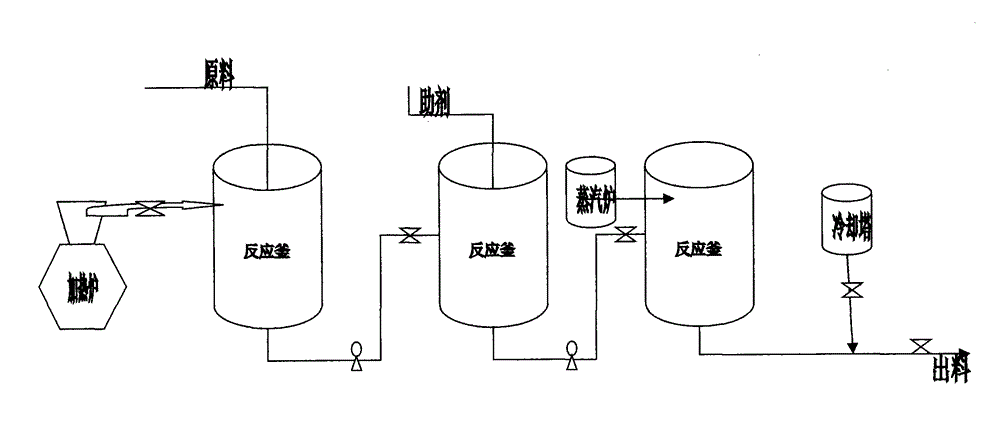

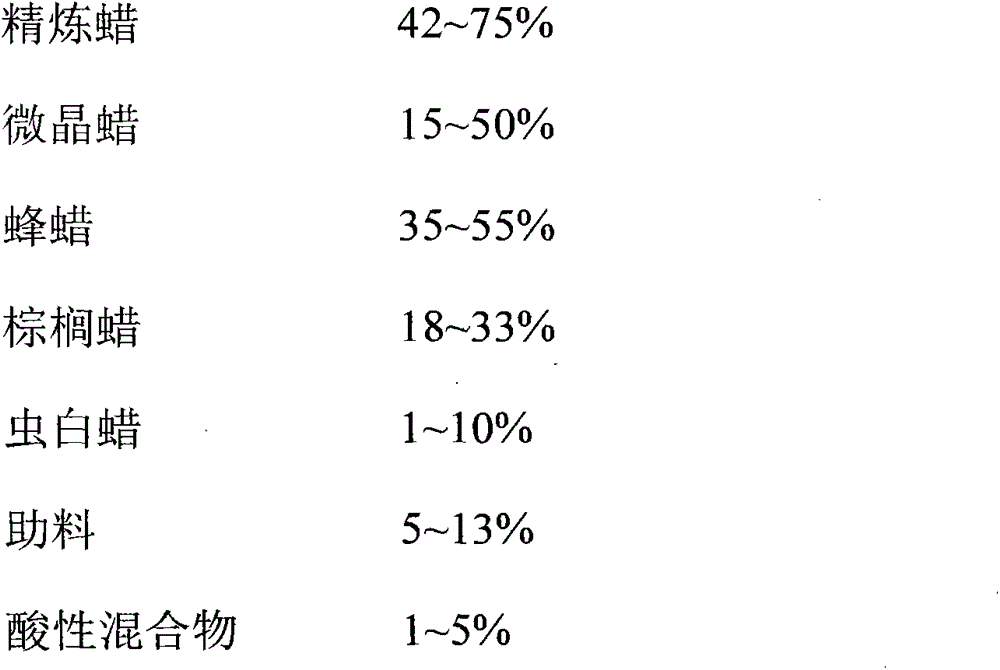

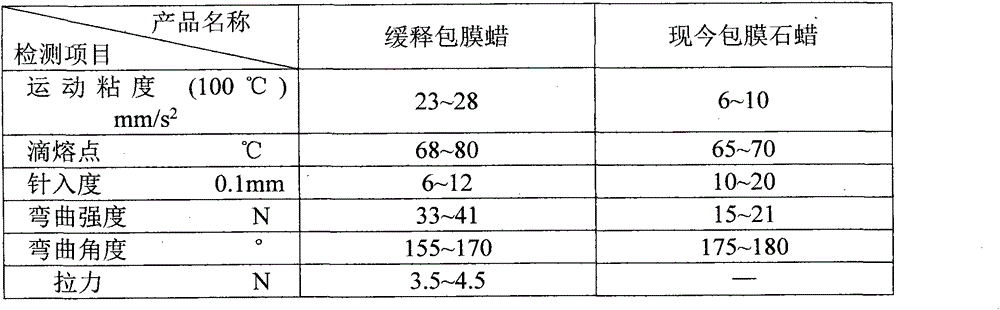

Slow release coated wax of efficient slow release composite fertilizer

InactiveCN104003784AAdjustable and controllable drop melting pointNo damage to technical indicatorsFertilizer mixturesMicrocrystalline waxUltimate tensile strength

The invention relates to a slow release coated wax of an efficient slow release composite fertilizer. The slow release coated wax of an efficient slow release composite fertilizer is glistened particles, and is prepared through a reaction of main raw materials comprising 42-75wt% of refined wax, 15-50wt% of microcrystalline wax, 35-55wt% of beeswax, 18-33wt% of palm wax and 1-10wt% of Chinese insect wax, and substances comprising an additive, an assistant, a biodegradation promotion substance, an acidic mixture and an organic material at 95-105DEG C for 20-40min. The slow release coated wax of an efficient slow release composite fertilizer has the advantages of simple preparation, wide raw material sources, good toughness and strength, good slow release effect in soil, neutralization of alkaline soil, and no pollution to the environment.

Owner:DALIAN NINGHUA MICROCRYSTALLINE WAX CHEM

Full-automatic intelligent dish washing machine

PendingCN110801190ALarge storage capacitySave spaceTableware washing/rinsing machine detailsCleaning equipmentRobot handControl engineering

The invention relates to the technical field of dish washing machines, and discloses a full-automatic intelligent dish washing machine. The full-automatic intelligent dish washing machine comprises amain body frame, wherein supporting legs are fixedly mounted at four corners of the bottom of the main body frame; a feeding table is fixedly installed on the left side of the main body frame; a discharging table is fixedly installed on the right side of the main body frame; and an extraction moving mechanism is fixedly installed on the left side of the main body frame and located above the feeding table. According to the full-automatic intelligent dish washing machine, the main body frame, the supporting legs, a spraying pump, a first spraying pipe, an ultrasonic vibration head and a second spraying pipe are arranged, so that when a user uses the equipment, a bowl frame adopts a standard frame type bowl frame, various bowl types can be stored, and the storage capacity is large; a servo manipulator can also meet the standard action of grabbing, the storage can be overlapped when the bowl frame is stored, and the space is saved; and the extraction moving mechanism can meet the requirement of the precise grabbing function of the bowl frame in various functional areas, alarming can be performed in time in case of overload, and the action can be timely stopped, so that the safety of the equipment is guaranteed.

Owner:重庆樽禄科技有限公司

Xylose production process

InactiveCN105219892ASolve the problem of longevitySolve efficiency problemsSaccharides productionFiberHydrolysate

The invention discloses a xylose production process. The xylose production process comprises the following steps: adding pretreated pentosan-enriched plant fiber into a 1.0%-1.5% sulfuric acid solution to generate hydrolysis reaction, and filtering liquid to obtain hydrolysate; decoloring the hydrolysate by virtue of activated carbon or decoloring resin until the transparency of the hydrolysate is 20%-80%, and filtering to remove impurities by virtue of membrane filter equipment; concentrating the filtered hydrolysate by virtue of membrane concentration equipment, and decoloring the hydrolysate until the transparency of the hydrolysate is 60%-90% to obtain feed liquid, wherein leachate of the membrane concentration equipment is used as inflow water of an electroosmosis concentrated water chamber; desalting the feed liquid by virtue of electroosmosis and ion exchange resin, wherein electroosmosis concentrated water is circularly applied to a hydrolysis step; concentrating the feed liquid until the refractive index is 80%, crystallizing in a crystallization tank, and centrifuging to separate mother liquid, so as to obtain xylose crystals. According to the xylose production process, the problem that the costs for sewage treatments including neutralization and ion exchange in the prior art are high is solved, and the problems of short service life, low desalting efficiency, poor stability and high power consumption of an electroosmosis manner in the production of xylose are solved.

Owner:FUTASTE PHARM CO LTD

Full-automatic high-voltage electrostatic oil fume purifier utilizing segmented cleaning

InactiveCN102476005AGuaranteed flushing effectReduce pump powerCombination devicesCleaning using liquidsControl valvesHigh pressure

A full-automatic high-voltage electrostatic oil fume purifier utilizing segmented cleaning is characterized by being provided with a full-automatic cleaning device which comprises a reduction motor, a lead screw, a transmission device, a movable cleaning main water pipe, a plurality of position sensors and a single-chip controller. The movable cleaning main water pipe is provided with a plurality of cleaning water pipes with water nozzles, and control valves are arranged at upper ends of the cleaning water pipes respectively. An output shaft of the reduction motor is connected with the lead screw through a driven gear of the transmission device, a lead screw bush of the movable cleaning main water pipe is connected with a thread of the lead screw movably, and the movable cleaning main water pipe is communicated with a water outlet of a water pump. The position sensors are arranged at two ends of the lead screw respectively, the reduction motor and the control valves are connected with an output end of the single-chip controller respectively, and signal output ends of the position sensors are connected with an input end of the single-chip controller respectively. The common problem that existing oil fume purifiers are incapable of running normally due to accumulated oil is solved thoroughly and purifying efficiency is constant all year round.

Owner:刘海龙 +1

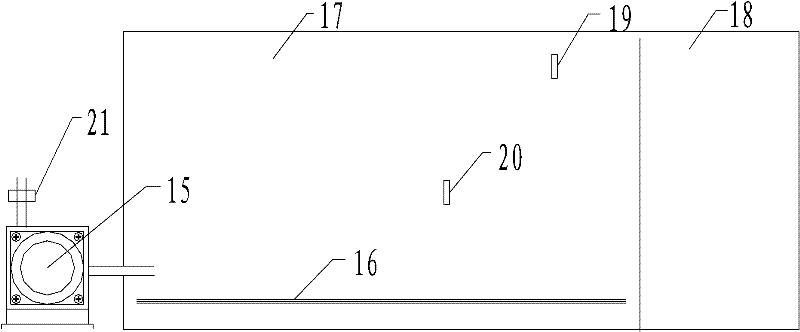

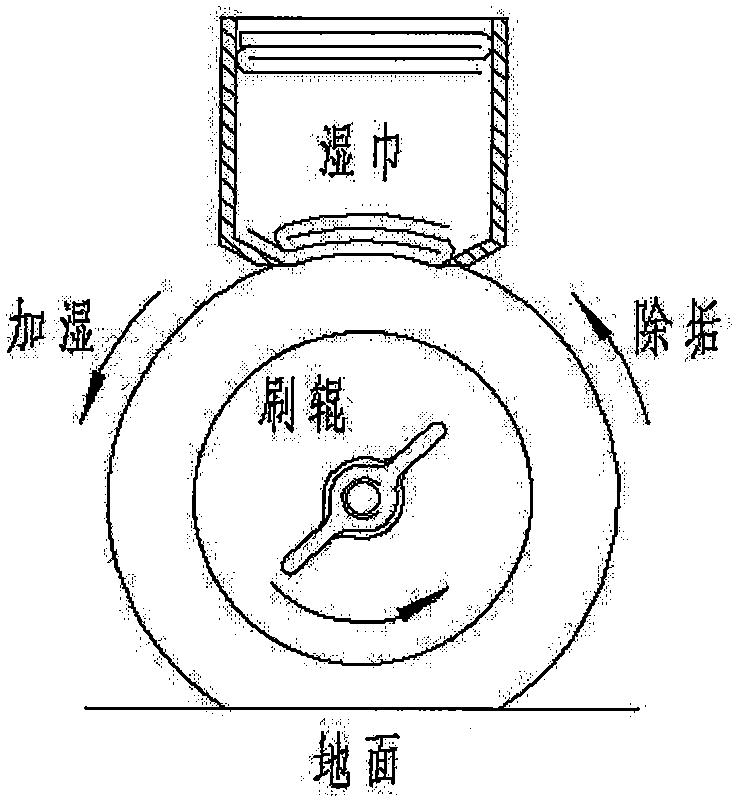

Floor-wiping and shoe-wiping dual-purpose machine

InactiveCN105534421AReduce labor intensityImprove operating postureCarpet cleanersFloor cleanersYarnElectricity

The invention discloses a floor-wiping and shoe-wiping dual-purpose machine, namely an electric floor wiping machine which can serve as a shoe wiping machine at the same time and has functions of sweeping, wiping and sucking. A storage battery supply is adopted, and cotton yarn brush rollers are used for wiping the floor, so that the machine integrates the functions of sweeping, wiping and sucking and achieves dry and wet double purposes. When the machine is used for wiping the floor, the brush rolls rotate back and forth in a rolling mode, swing left and right in a reciprocating mode and act in a mode that the height floats with topography; and wet tissues are used for wiping the floor indirectly, so that the machine is simple to operate and convenient for maintenance. When the machine is used for wiping shoes, the effect of induced air dust removal is promoted, so as to bring about benefits for air cleaning. The machine has the characteristics of reducing labor intensity, guaranteeing cleaning quality, improving working efficiency and reducing water and electricity consumption.

Owner:杨金泉

Chopstick cleaning assembly and bowl washing machine

ActiveCN106562748AImprove cleaning efficiencyCleaning time is shortTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention relates to a chopstick cleaning assembly and a bowl washing machine. The chopstick cleaning assembly comprises a tubular cleaning structure and a tubular accommodating structure, wherein the tubular cleaning structure comprises a rotating shaft and a tubular carrying part; the tubular carrying part is fixedly connected with the rotating shaft, and comprises a plurality of chopstick accommodating elements arranged at intervals; the tubular accommodating structure forms a tubular accommodating space so as to accommodate the tubular cleaning structure; the tubular cleaning structure is rotatablely arranged in the tubular accommodating space and is coaxial with the tubular accommodating structure; a chopstick inlet extending in a direction being parallel to the rotating shaft is arranged on the top of the tubular accommodating structure; and the chopstick accommodating elements and the tubular accommodating structure form a space for accommodating chopsticks. The chopstick cleaning assembly and the bowl washing machine provided by the invention have the advantages that the cleaning efficiency is high; and the cleaning time is short, so that the water and the electric energy can be saved.

Owner:GREE ELECTRIC APPLIANCES INC

Short-flow pre-treatment method for pure cotton heavy fabrics

PendingCN109576975ASimple processWater saving and energy saving production costVegetal fibresChemistryDyeing

The invention discloses a short-flow pre-treatment method for pure cotton heavy fabrics and belongs to the technical field of dyeing and finishing pre-treatment. The short-process pre-treatment methodfor pure cotton heavy fabrics comprises the steps of padding a singed pure cotton heavy gray fabric with scouring and bleaching liquid, then piling up the fabric at room temperature, executing steaming and washing, executing slight rinsing with a dilute aqueous solution of hydrogen peroxide, finally executing low-alkali mercerizing, and then executing full washing to complete the pure cotton heavy fabric pre-treatment process. The process is good in treatment effect, has the advantages of small fabric strength damage, high quality, soft handfeel, high hair effect and good glossiness, also creates the high color yield condition for subsequent dyeing and printing processing and is simple in technological operation and strong in controllability. In addition, the treatment wastewater, chemical agent use amount and energy consumption of the process are far lower than those of a traditional strong alkali scouring process, and the burden of sewage treatment of enterprises is greatly reduced.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

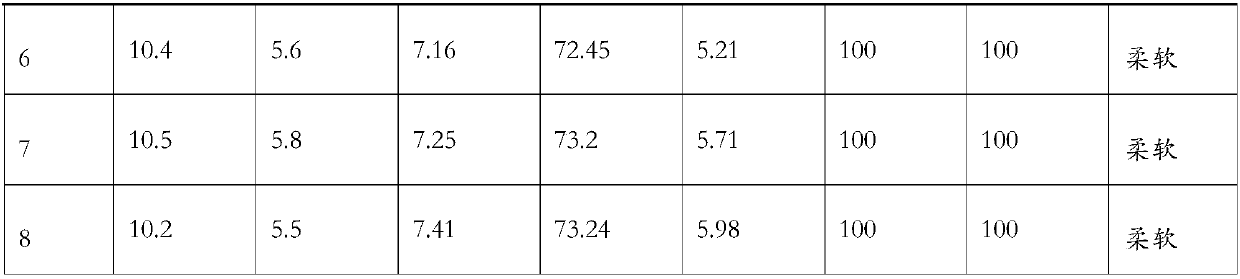

Method for producing casein through dry sterilization

InactiveCN105315358AEfficient killingLess investmentPeptide preparation methodsAnimals/human peptidesMilk SerumSodium metabisulfite

The invention discloses a method for producing casein through dry sterilization. The method comprises the following steps: putting Qula into a dissolving vat, adding an auxiliary material, dissolving while the pH value is kept to be 9.5-10.0, filtering, performing centrifugal degreasing, regulating the feed liquid temperature to be 40 DEG C after degreasing, adding sodium hydrosulfite, sodium sulfite and sodium pyrosulfite, performing precipitation on casein through the diluted hydrochloric acid with the Baume density of 4.5, regulating the feed liquid pH to be 4.4-4.6 to enable the casein to be fully precipitated, and removing milk serum to obtain a precipitate; washing the precipitate with lukewarm water, dehydrating through plate frame pressure filtration and extrusion, performing material pelletization through a screen mesh, drying, pulverizing the pelletized and dried material, conveying the pulverized material to a material mixing bin, and fully sterilizing the material in the material mixing bin through ozone. According to the method, sterilization is realized by introducing ozone during the packaging link of casein production, so that microbes can be effectively killed; the operation is run in a dry environment and equipment is simple, so that equipment investment can be reduced, the product quality is stabilized, the automatic control level is improved, water and electricity consumption is reduced, and human resources are saved.

Owner:GANSU PULUO BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com