Method for processing fresh fried rice noodles

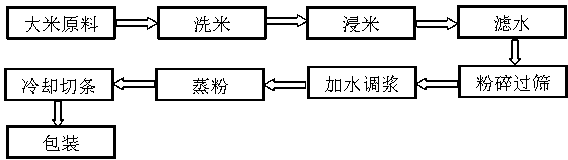

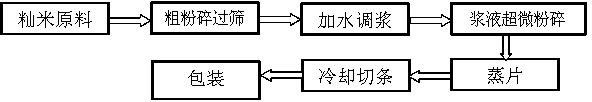

A processing method and technology for rice noodles, applied in the processing field of fresh rice noodles, can solve the problems such as hindering the expansion of the international market of rice noodles, requiring more workers due to the large workload, and a long soaking period of 4 hours for rice, and saving water, electricity and labor. , The particle fineness is uniform, and the product taste is smooth and delicate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Select 100 parts of first-grade indica rice, remove yellow-grained rice, and crush through a 60-mesh sieve. Add 200 parts of water to the sieved dry powder and stir evenly. After flowing out of the colloid mill, it directly enters the steamer-type continuous steaming machine to steam the flour. Steam the flour for 100s under the conditions of 100°C and 0.30MPa. After the steamed flour flakes are fully cooled, they are cut into 30cm lengths with an automatic strip cutter. The vermicelli is packaged according to 300g / package.

Embodiment 2

[0021] Select 100 parts of high-grade indica rice, remove yellow-grained rice, and crush through a 40-mesh sieve. Add 220 parts of water to the sieved dry powder and stir evenly. After flowing out of the colloid mill, it directly enters the steamer-type continuous steaming machine to steam the flour. Steam the flour for 120s under the conditions of 105°C and 0.25MPa. After the steamed flour flakes are fully cooled, cut them into 30cm lengths with an automatic strip cutter. The vermicelli is packaged according to 300g / package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com