Method for processing foods by ultrasonic waves and ultrasonic food processor

A food processing machine and food processing technology, which is applied in the field of ultrasonic applications, can solve the problems of high energy consumption and long processing cycle, and achieve the effects of short production cycle, less production process, and reduction of three wastes discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

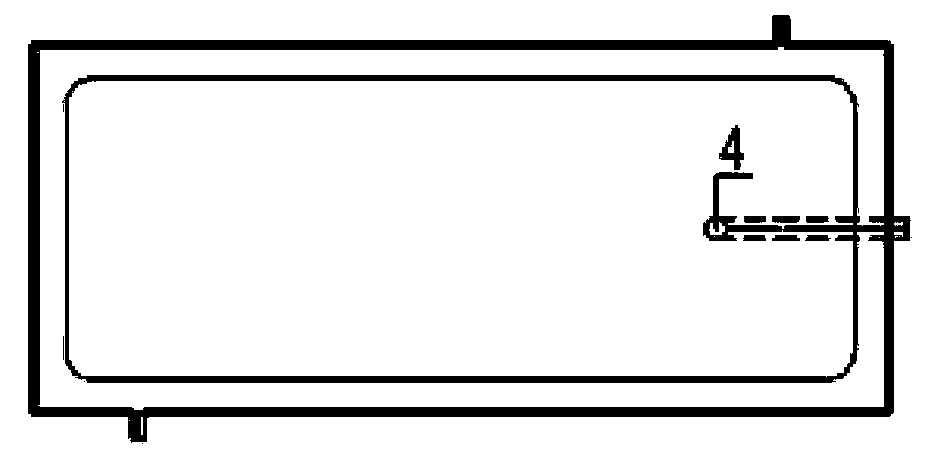

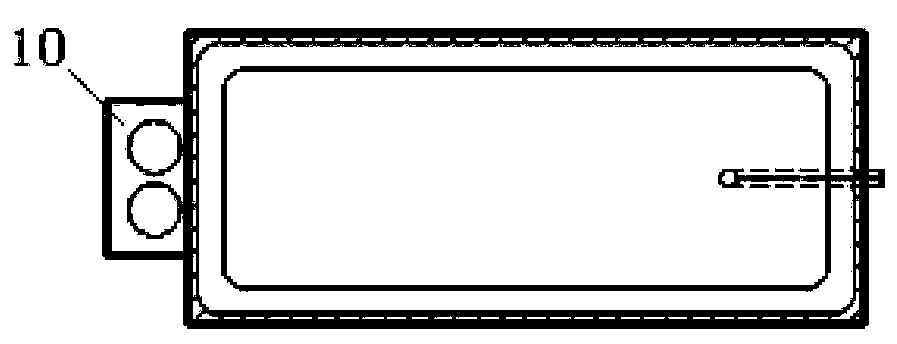

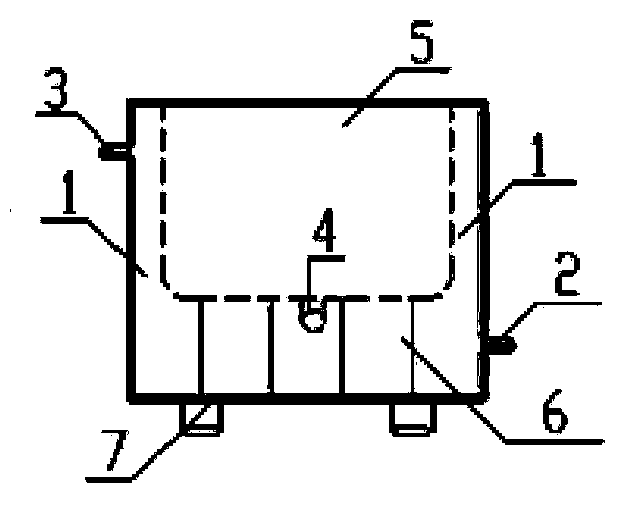

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Ultrasound is used in the production of cured meat products:

[0029] Pickled fish, livestock and poultry meat: first clean the raw materials, and then put them into the ultrasonic pool, add a certain amount of seasoning salt solution in the pool, use A-type ultrasonic equipment, the frequency is 50KHz, and adjust the temperature and frequency according to different raw materials The adjustment, 300W, the temperature reaches 15 ℃, and the ultrasonic wave is turned on for 1 hour, which can achieve the effect of sterilization, flavoring and marinating. The processing time is greatly shortened compared with the traditional fish and meat marinating time of 7 days (days), and marinated products No discoloration, good flavor, less nutritional loss. Commercial production needs to add biological preservatives to prolong the shelf life. The biological preservatives here refer to the nisin or natamycin specified in GB2760 obtained by microbial fermentation, as well as ...

Embodiment 2

[0030] Embodiment 2: Ultrasound is used for making braised meat products:

[0031]Livestock and poultry meat raw materials are pretreated with A-type equipment, frequency range 150KHz, power 300W, time 60min, and then put into cold brine to taste, still use A-type equipment at frequency 40KHz, power 600W for 60min, then use C-type equipment, hot brine for flavor, frequency 140KHz, temperature 85°C, time 180min, and finally use a high-efficiency air cooler to cool the food to room temperature for about 10 minutes, microwave drying and packaging is the finished product. Choose the appropriate temperature and frequency according to the size of the raw material, material characteristics such as whether it has bone, the amount of bone and the size of the bone, and choose the appropriate time according to the power. Compared with the traditional process, this process reduces the discharge of brine, because the brine can be reused many times; at the same time, it also reduces the fin...

Embodiment 3

[0032] Example 3: Ultrasound is used in the production of fruit and vegetable beverages:

[0033] Clean the raw materials of fruits and vegetables, slice them and dry them with microwaves to a certain amount of water, then put them into the ultrasonic pool to add ingredients and water, first use B-type equipment to process them at a frequency of 90KHz, power 700W, and temperature -5°C for 120 minutes, then Use type A equipment to process at a frequency of 80KHz and a power of 500W for 30 minutes, then boil the beverage at high temperature for 10 minutes and filter it, and finally cool it to room temperature with a high-efficiency cooler at a speed of ≧3°C / s and then aseptically fill it to obtain the corresponding beverage . If the cooling speed is not fast enough, natural preservatives can be added for antiseptic treatment. The natural preservatives here refer to the nisin used in GB2760 obtained by microbial fermentation, and the use of fruits, vegetables, and plant materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com