Brewing method of fermented blueberry wine

A blueberry wine, fermentation-type technology, applied in the field of fruit wine brewing technology, can solve the problems of impure and full flavor, low extraction utilization rate of active ingredients, poor color, etc., to ensure color, avoid sugar content from falling too low, and preserve The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

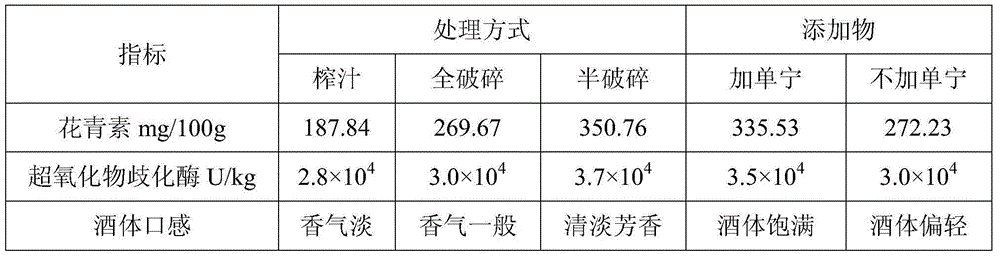

Image

Examples

Embodiment 1

[0050] (1) Select the blueberry fruit of Lanfeng variety.

[0051](2) Properly crush the blueberries, and the blueberries are in a half-whole state after crushing.

[0052] (3) Add 100 mg / kg of potassium metabisulfite and 100 mg / kg of tannin, and mix well to prevent oxidation of blueberry anthocyanins.

[0053] (4) Adjust the temperature to 20°C-30°C, and add 60mg / kg of pectinase.

[0054] (5) Yeast inoculation: Saccharomyces cerevisiae was selected for inoculation, and the inoculation amount was 0.5‰.

[0055] (6) Control of the fermentation process: the fermentation temperature does not exceed 30°C, and the mixture is stirred every 2 hours until the residual sugar is ≤4g / L.

[0056] (7) Squeeze: After the fermentation is finished, the skin dregs and wine liquid are separated by mechanical extrusion.

[0057] (8) The precipitate is clarified, the supernatant is taken and the lees is filtered.

[0058] (9) Gum clarification: use 2.0kg / t bentonite for clarification and prec...

Embodiment 2

[0063] (1) Select the blueberry fruit of the duke variety.

[0064] (2) Properly crush the blueberries, and the blueberries are in a half-whole state after crushing.

[0065] (3) Add 200 mg / kg of potassium metabisulfite and 300 mg / kg of tannin, and mix well to prevent oxidation of blueberry anthocyanins.

[0066] (4) Adjust the temperature to 20°C-30°C, and add 20 mg / kg of pectinase.

[0067] (5) Yeast inoculation: Saccharomyces cerevisiae was selected for inoculation, and the inoculation amount was 0.2‰.

[0068] (6) Control of the fermentation process: the fermentation temperature does not exceed 30°C, and the mixture is stirred every 2 hours until the residual sugar is ≤4g / L.

[0069] (7) Squeeze: After the fermentation is finished, the skin dregs and wine liquid are separated by mechanical extrusion.

[0070] (8) The precipitate is clarified, the supernatant is taken and the lees is filtered.

[0071] (9) Glue clarification: Use 1.5kg / t bentonite for clarification and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com