Patents

Literature

48results about How to "Bubble stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macromolecule conductive master batches

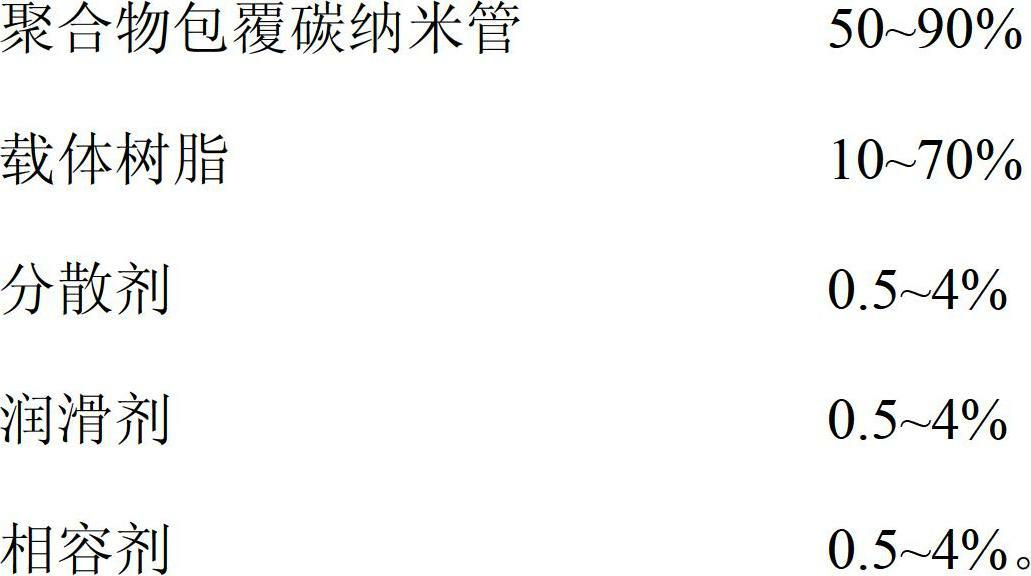

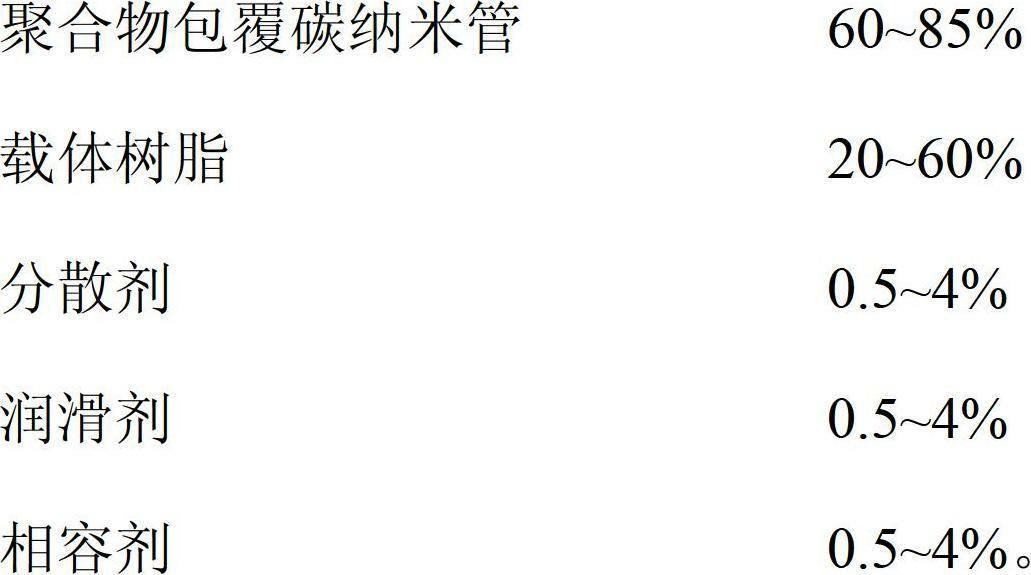

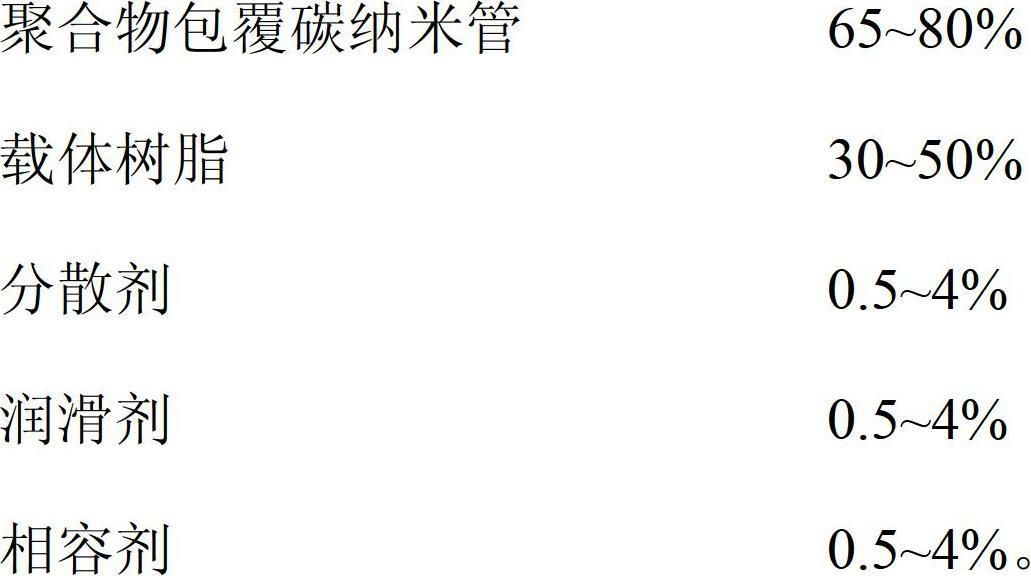

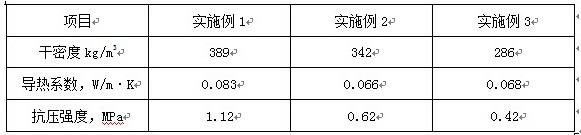

The invention relates to macromolecule conductive master batches which comprise, by mass ratio, 50% to 90% of polymer coated carbon nanometer tubes and 10% to 70% of carrier resin. Plastic finished products obtained through the conductive master batches are low in production utilization cost, the pipe surface is smooth, dispersity is good, no air bubble is inside products, and the quality is stable; the conductivity property (surface and internal resistance) achieves 5000 omegas on the premise of not increasing the cost, so that products have excellent antistatic properties.

Owner:DONGGUAN DECHENG PLASTIC TECH

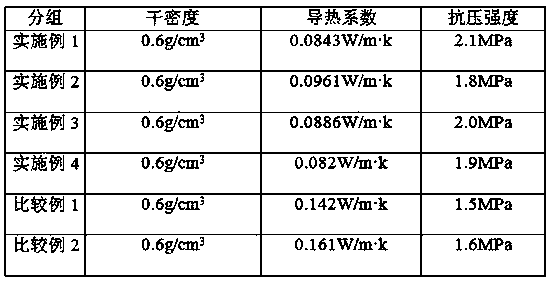

Foaming agent used in ultra-low density anti-seepage foamed concrete, and preparation method thereof

The invention relates to a foaming agent used in ultra-low density anti-seepage foamed concrete, and a preparation method thereof. The foaming agent comprises components of, by mass: 8 to 18 parts of sodium polyoxyethylene fatty alcohol sulfate, 0.1 to 7 parts of sodium dodecylsulfate, 0.5 to 7 parts of sodium dodecylbenzene sulfonate, 4 to 15 parts of pure acrylic emulsion or styrene-acrylate emulsion, 3 to 6 parts of fatty alcohol polyoxyethylene ether, 0.5 to 2 parts of hydroxyethyl cellulose or hydroxy propyl methylcellulose, 0.1 to 5 parts of modified silicon resin or modified nano-gradebentonite, 0.1 to 0.5 parts of a thickener, and balance of water. The anti-seepage foamed concrete foaming agent provided by the invention has stable property, high foaming multiple, and good workability with a substrate. The agent can be used in a foamed concrete product with a density of 100 to 600kg / m<3>. The raw materials are easy to obtain, and the cost is low. The foaming agent can be stored for a long term with out deteriorating. With the agent, foamed concrete properties such as strength and softening coefficient can be improved.

Owner:梁材

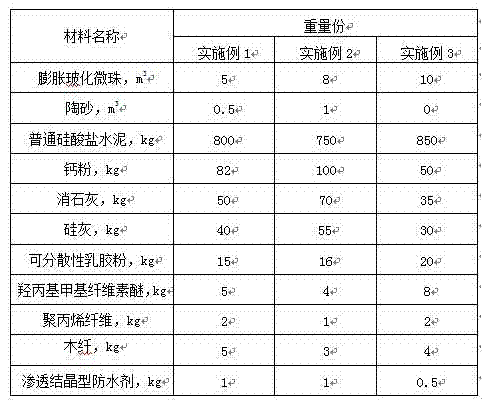

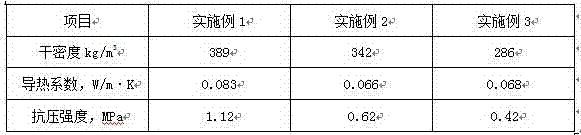

Waterproof crack-resistant inorganic heat-insulating mortar and preparation method thereof

The invention relates to waterproof crack-resistant inorganic heat-insulating mortar and a preparation method thereof. The mortar comprises 5-10 m<3> of small expended and vitrified balls, 0-1 m<3> of pottery sand, 750-850 kg of ordinary portland cement, 50-100 kg of calcium powder, 35-70 kg of hydrated lime, 30-55 kg of siliceous dust, 15-20 kg of dispersible polymer powder, 4-8 kg of hydroxypropyl methyl cellulose ether, 1-2 kg of mekralon, 0.5-1 kg of capillary crystalline waterfroof agent, and 3-5 kg of wood fiber. The preparation method comprises the following steps: loading ordinary portland cement, siliceous dust, hydrated lime, hydroxypropyl methyl cellulose ether, dispersible polymer powder, calcium powder, mekralon, capillary crystalline waterfroof agent and wood fiber at one time, and stirring for 3 min; adding small expended and vitrified balls and pottery sand in the stirred powder blend, and continuously stirring for 2 min; and packaging and storing the finished productsin warehouse. Compared with the prior art, by using the pottery sand and capillary crystalline waterfroof agent, the problems of large water absorption, easy cracking when water seepage occurs and the like of traditional inorganic small expended and vitrified ball heat-insulating mortar are solved.

Owner:上海英硕聚合材料股份有限公司

High liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use

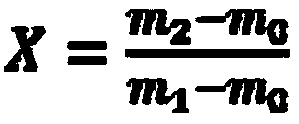

ActiveCN106279494AHigh specific surface areaStrong foaming abilityCoatingsAbsorption rateStorage material

The invention provides high liquid absorption rate acrylic acid water-absorbent resin and its preparation method and use. The high liquid absorption rate acrylic acid water-absorbent resin is prepared from acrylic acid, an alkali, water, a cross-linking agent, a high temperature-resistant foaming agent, a copolymerization monomer, a reducer and an initiator. A mass ratio of the acrylic acid, alkali to water is (25-45): (7-22): (33-68) and based on the acrylic acid mass, a use ratio of the cross-linking agent is in a range of 0.001-1wt%, a use ratio of the high temperature-resistant foaming agent is in a range of 0.01-2wt%, a use ratio of the copolymerization monomer is in a range of 0-10wt%, a use ratio of the reducer is in a range of 30-500ppm and a use ratio of the initiator is in a range of 0.001-1wt%. A high liquid absorption rate of the acrylic acid water-absorbent resin is 15-40s. The acrylic acid water-absorbent resin can be used as a liquid absorption material in fields of paper diapers, baby diapers and sanitary napkins in the health care industry and can also be used as a water absorption and storage material in industries of desert treatment, water blockage in an oil field and agricultural and forestall water retention.

Owner:WANHUA CHEM GRP CO LTD

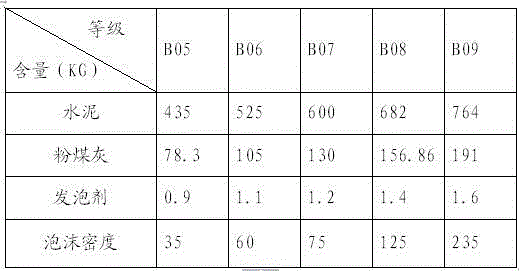

Cast-in-place light-weight foamed concrete construction technique

The invention discloses a cast-in-place light-weight foamed concrete construction technique. The technique comprises the following steps: earlier stage preparation; cement mortar solution preparation: mixing cement and fly ash in a mixing hopper; foaming agent water solution preparation: weighing a foaming agent, adding the foaming agent and water into a mixing hopper of a hydraulic foaming machine, uniformly mixing to form the foaming agent water solution; foamed concrete preparation: gradually adding the foaming agent water solution prepared in the step 2 into the cement mortar solution by a conveyer belt, mixing for 1-3 minutes to form the foamed concrete; discharging the mortar and delivering the foamed concrete; casting the foamed concrete; and curing. The foamed concrete can not easily collapse in the in-place casting process, and has the advantages of high construction speed and low construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Gypsum-based light plastering material and preparation method thereof

The invention relates to the technical field of buildings, and particularly provides a gypsum-based light plastering material and a preparation method thereof. The first aspect of the invention provides a gypsum-based light plastering material which at least comprises the preparation raw materials in parts by weight: 80-95 parts of gypsum powder, 0.5-2 parts of an alkaline agent, 0.1-0.2 part of awater-retaining agent, 0.1-0.3 part of a mixture, 0.05-0.2 part of a retarder and 0-20 parts of glass microbeads.

Owner:JASON PLASTERBOARD JIAXING

Foam aerated concrete building block prepared from iron tailings at normal temperature and under normal pressure and preparation method of foam aerated concrete building block

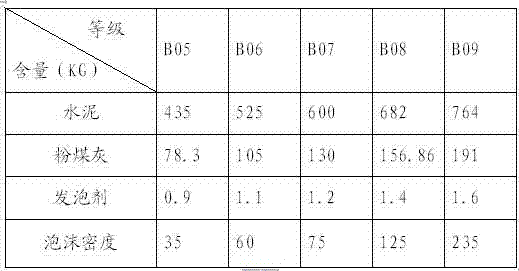

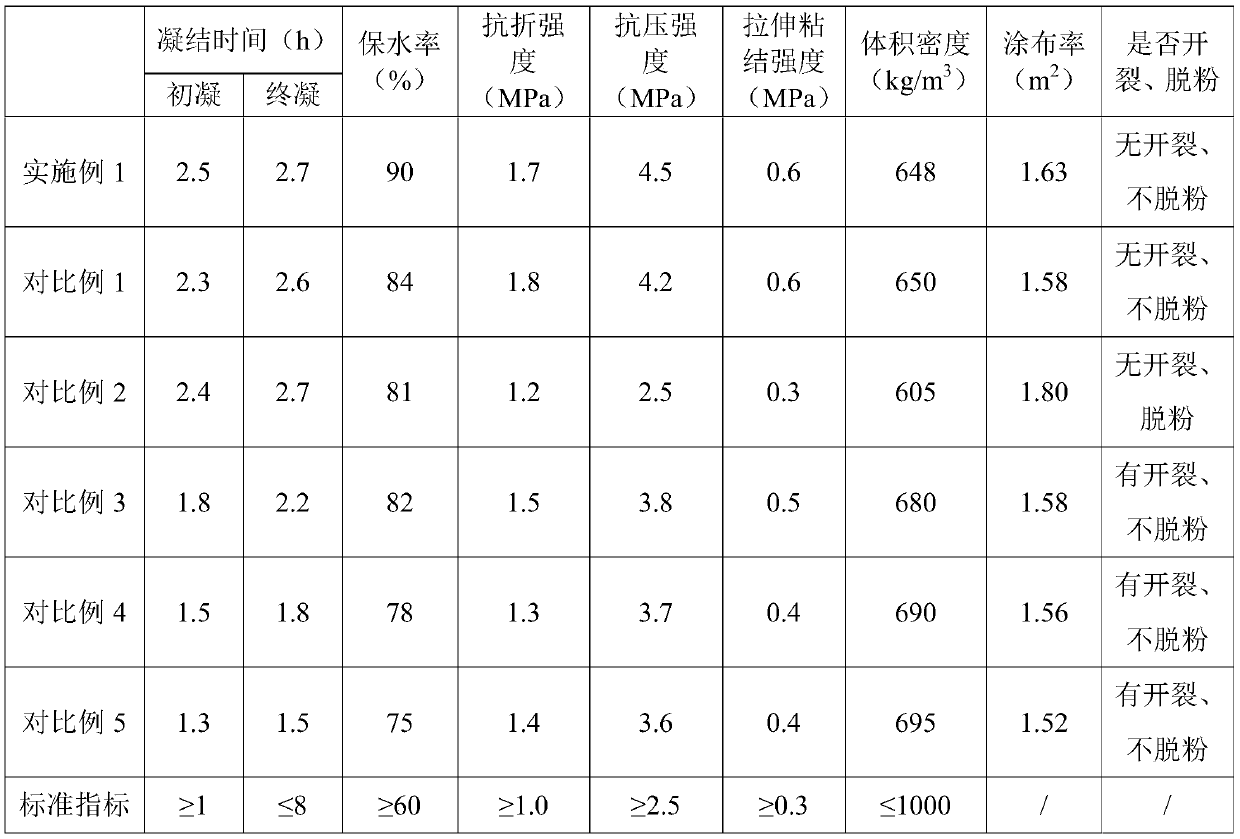

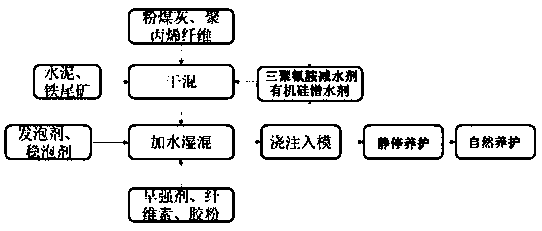

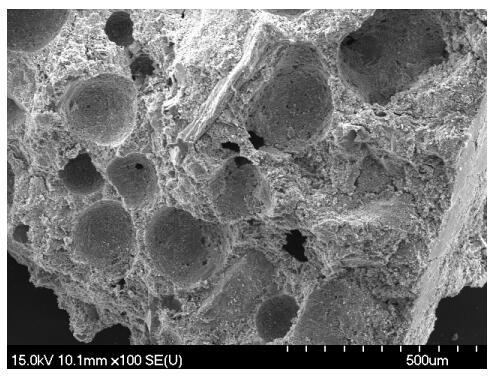

The invention discloses a foam aerated concrete block prepared from iron tailings at normal temperature and under normal pressure and a preparation method of the foam aerated concrete building block.The foamed aerated concrete block comprises the following components in percentage by weight: 20-50% of the iron tailings, 30-60% of cement, 2-4% of an early strength agent, 3-10% of fly ash, 1-3% ofcellulose, 1-3% of glue powder, 2-4% of polypropylene fibers, 1-2% of a foaming agent, 1-2% of a melamine water reducer, 1-2% of an organic silicon hydrophobic agent and 0.5-1.5% of a foam stabilizer.The foam concrete building block prepared by the invention has lower density, higher porosity, higher sound insulation property and stronger heat insulation property after being tested; the foam concrete building block prepared by the invention has excellent performance, and in a process of preparing the foam aerated concrete building block, process steps are simple, the reaction treatment time is extremely fast, the curing method is simple, and the production efficiency of enterprises can be greatly improved.

Owner:ZHEJIANG UNIV OF TECH

Calcium fortified soymilk based frozen dessert

InactiveUS20070014913A1Provide strengthProvide structureFrozen sweetsFood ingredientsChemistryFood science

Owner:SPECIALITY MINERALS (MICHIGAN) INC

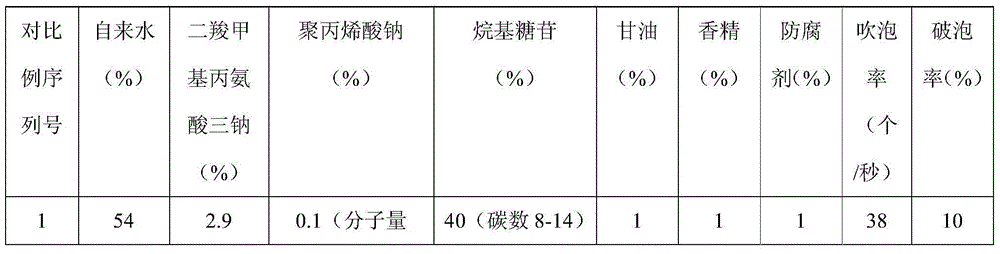

Concentrated solution of bubble liquid

The invention discloses a concentrated solution of bubble liquid, and belongs to the field of daily chemicals. The concentrated solution comprises the following components in percentage by mass: 50%-80% of running water, 1%-6% of trisodium N-iminodiacetate, 1%-10% of sodium polyacrylate, 10%-40% of alkyl glycoside, 1%-10% of glycerin, 0.1%-1% of essence, and 0.1%-1% of preservative. When the concentrated solution is used, the concentrated solution is diluted into 5-10 times, so as to prepare a bubble liquid solution. The concentrated solution has the advantages that the components of the bubble liquid are food level green and nonpoisonous raw materials, the degradability is good, and the cost is low; a formula of the concentrated liquid is adopted, the packaging and transportation cost is reduced, the convenience is realized, the use is easy, and the bubbling effect is good.

Owner:SHANGHAI FINE CHEM CO LTD

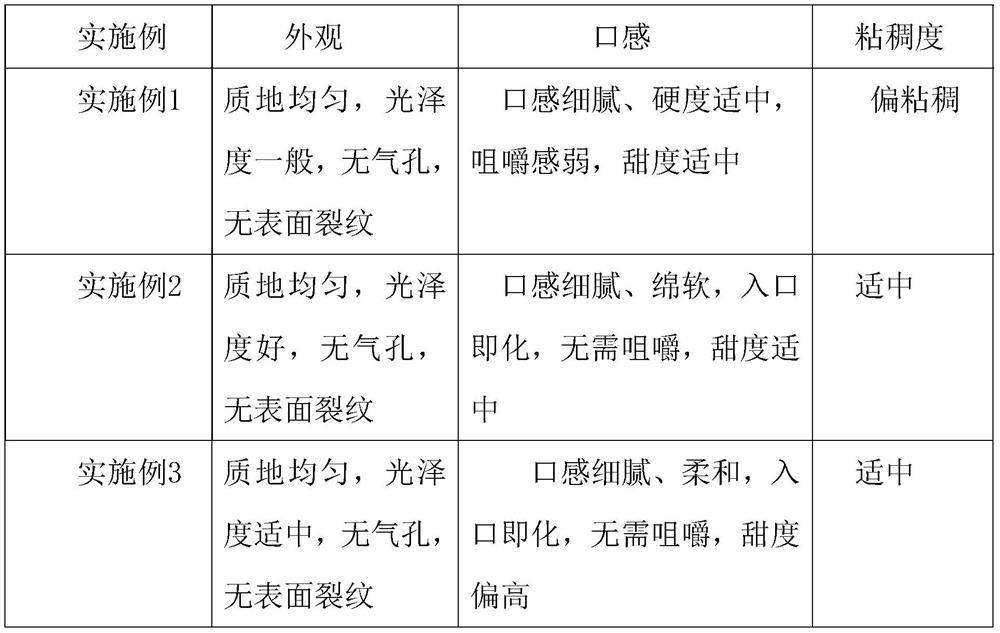

Citrus fiber mousse yogurt and preparation method thereof

InactiveCN109938100AImprove water holding capacityBubble stabilizationMilk preparationFiberProduct system

The invention discloses citrus fiber mousse yogurt and a preparation method thereof, and belongs to the technology field of dairy product processing. The yogurt is prepared from, by weight, 500-900 parts of raw milk, 0-100 parts of sugar, 10-300 parts of single cream or anhydrous milk fat, 2-50 parts of citrus fiber, 0-30 parts of dried skim milk, 0-30 parts of milk protein concentrate, 5-20 partsof whey protein, 5-30 parts of a compound emulsifying stabilizer, 0-10 parts of a compound sweetener and 0.02-0.08 part of a starter; after fermentation demulsification, direct agitating beating or sterile nitrogen filling is conducted, and the volume expansion rate is 20-100%. The obtained mousse yogurt still has the capacity of supporting the yogurt structure and keeping bubbles stable at the low pH value (pH=4.0-4.6), and the product system is made to be stable and superior to the existing products. The texture is dense, the taste is smooth, and meanwhile the dietary fiber function is achieved.

Owner:山东乐檬生物科技有限公司

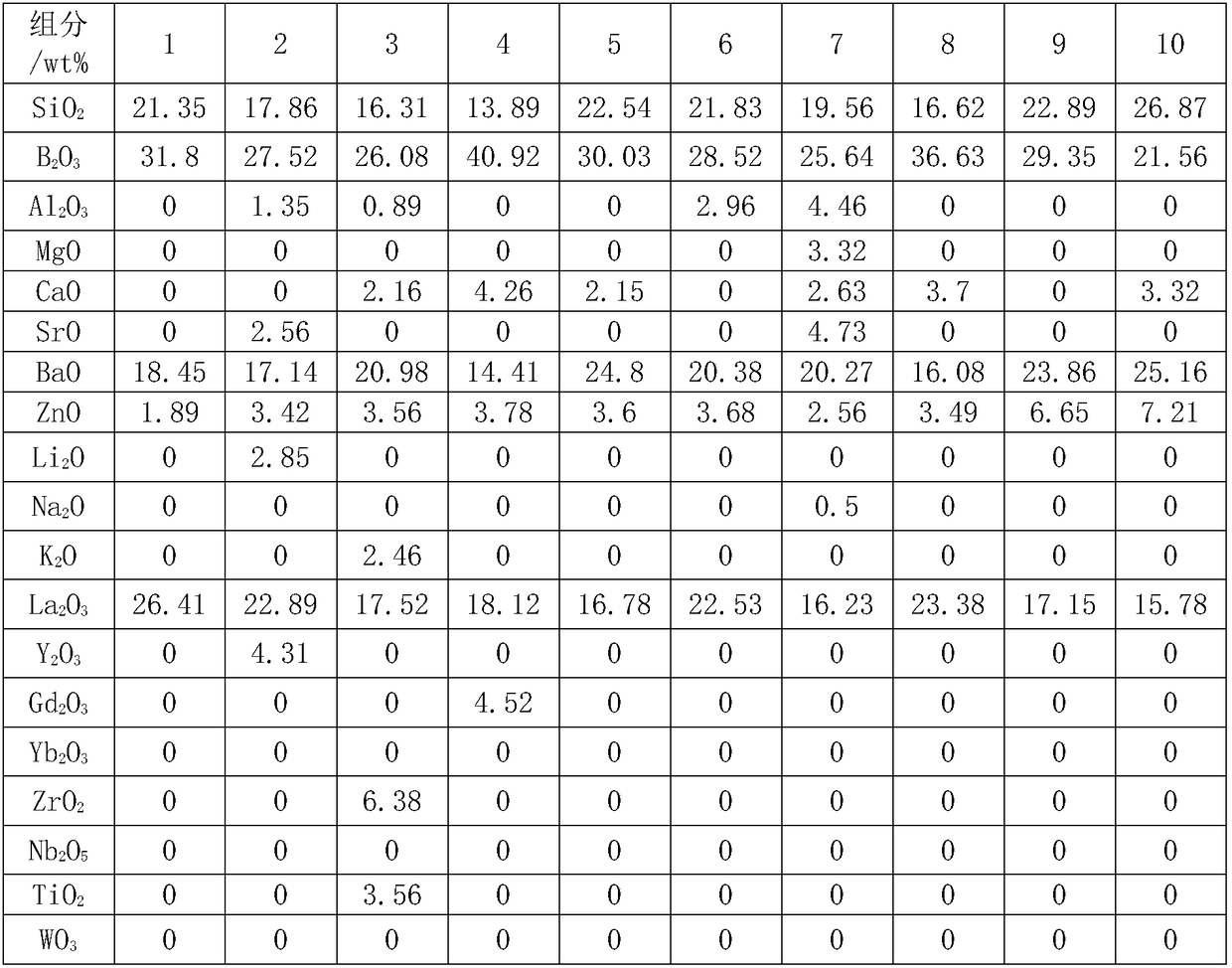

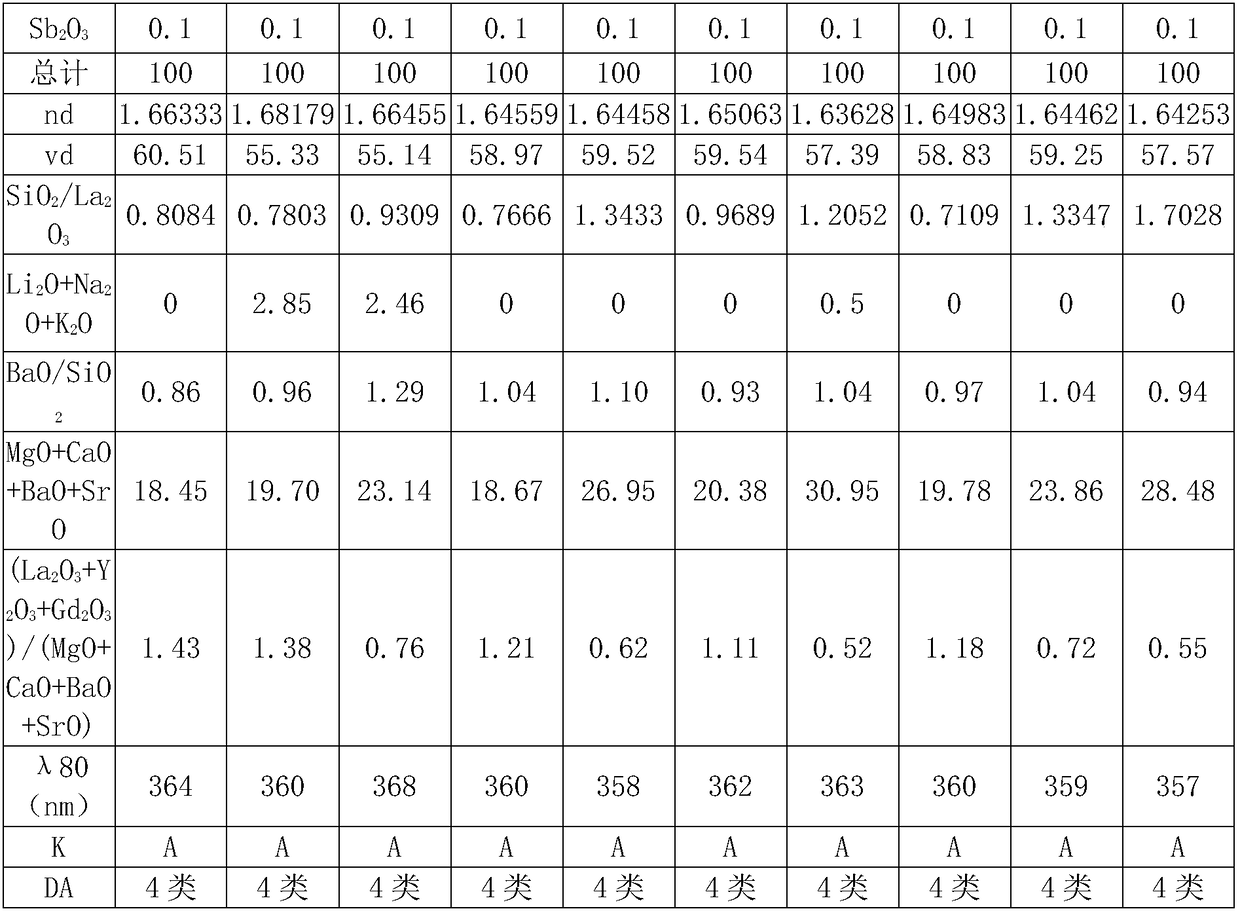

Optical glass

The invention provides optical glass which has reduced or no tantalum, low cost and good bubbles and stripes and is easy to be stably produced. The optical glass comprises 10-30% by weight of SiO2, 20-45% by weight of B2O3, 10-35% by weight of La2O3, 12-30% by weight of BaO, 0-10% by weight of ZrO2, and 0-10% by weight of ZnO. Through reasonable refractive index design, the refractive index of theoptical glass is 1.62-1.70, and the Abbe number is 55-62. The optical glass has low cost, good chemical stability, excellent anti-crystallization property and good transmittance. At the same time, the bubbles and stripes of the glass are good, and the optical glass is easy to be stably produced, and can be widely applied to digital cameras, digital video cameras, camera cell phones and the like.

Owner:CDGM OPTICAL GLASS

Modified polyurethane expanded plastic and preparation method thereof

The invention belongs to the plastic field and discloses modified polyurethane expanded plastic and a preparation method thereof. The modified polyurethane expanded plastic is prepared from 120 to 150 parts by weight of isocyanate, 100 to 120 parts by weight of polyester polyol, 20 to 30 parts by weight of a glass fiber cloth, 0.6 to 1 part by weight of a silane coupling agent, 0.4 to 0.8 parts by weight of a titanate coupling agent, 0.6 to 1 part by weight of monoglyceride, 3 to 5 parts by weight of triethanolamine, 10 to 20 parts by weight of carbon nanotubes, 20 to 30 parts by weight of low-density polyethylene, 20 to 30 parts by weight of aramid pulp, 10 to 20 parts by weight of ceramic fibers, 1 to 2 parts by weight of azodicarbonamide, 0.3 to 0.5 parts by weight of a foam stabilizer, 1 to 2 parts by weight of sodium dodecyl sulfate and 0.6 to 1 part by weight of an antioxidant. The modified polyurethane expanded plastic has the advantages of uniform bubbles, light weight, good toughness, wear resistance, anisotropy and excellent thermal insulation performances.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

Concrete air entraining agent

The invention belongs to the technical field of concrete admixture, and in particular relates to a concrete air entraining agent which is prepared from the following raw materials in parts by weight: 40-60 parts of rosin powder, 10-18 parts of sodium hydroxide, 6-16 parts of sulfuric acid, 8-18 parts of glycol, 5-13 parts of bisphenol A, 7-15 parts of pentaerythritol and 90-130 parts of water. When being used in concrete, the concrete air entraining agent is stable in bubble, appropriate in size, uniform in distribution, capable of increasing strength of concrete, and capable of improving peaceability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

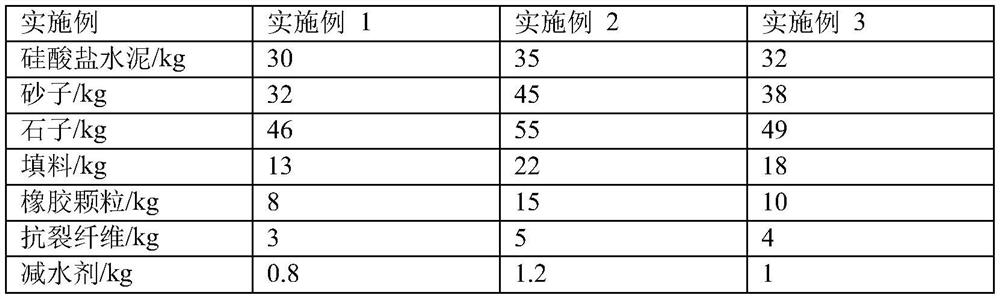

Anti-freezing concrete and preparation method thereof

ActiveCN113292289AIncrease elasticityImprove crack resistanceSolid waste managementFiberFreeze thawing

The invention relates to the field of concrete, and particularly discloses anti-freezing concrete and a preparation method thereof. The anti-freezing concrete is composed of the following components in parts by weight: 30 to 35 parts of Portland cement, 15 to 20 parts of water, 32 to 45 parts of sand, 46 to 55 parts of pebbles, 13 to 22 parts of filler, 0.8 to 1.2 parts of a water reducing agent, 3 to 5 parts of anti-crack fibers, 8 to 15 parts of rubber particles, 0.5 to 1 part of a waterproof agent, 0.1 to 0.3 part of an anti-freezing agent and 0.3 to 0.6 part of an air entraining agent, wherein the surface of the concrete is coated with a surface reinforcing agent. The anti-crack fibers in the concrete can improve the crack resistance of the concrete and reduce cracks, so that water permeation is reduced; the rubber particles and the anti-crack fibers can improve the elastic modulus of the concrete, the air entraining agent introduces air holes in the concrete, frost heaving pressure can be buffered, and freeze-thaw damage can be reduced; and the waterproof agent has a waterproof effect, and the anti-permeability is improved, so moisture infiltration is reduced, and the freeze-thaw resistance is improved.

Owner:海阳市利安建材有限公司

Bubble stability

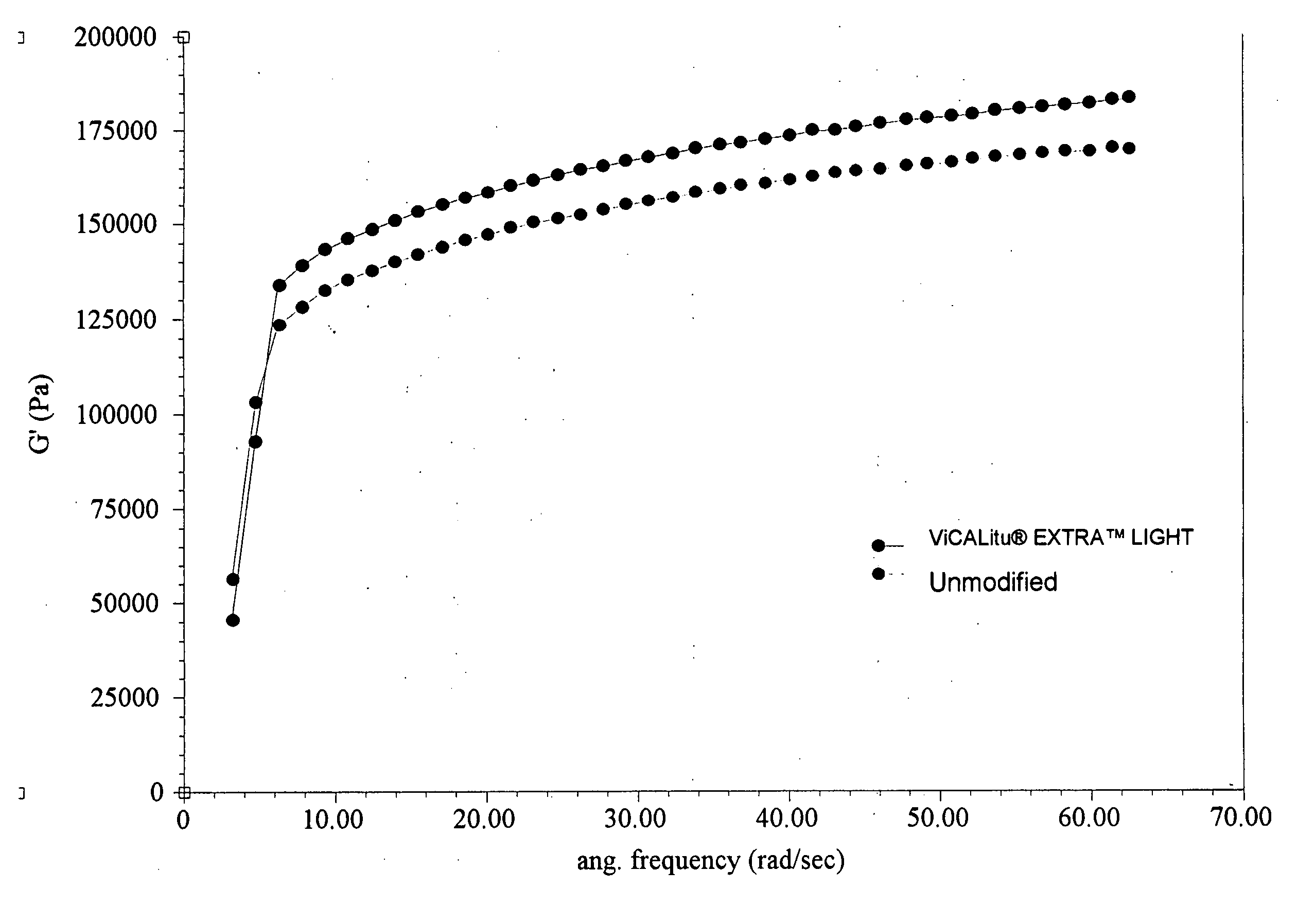

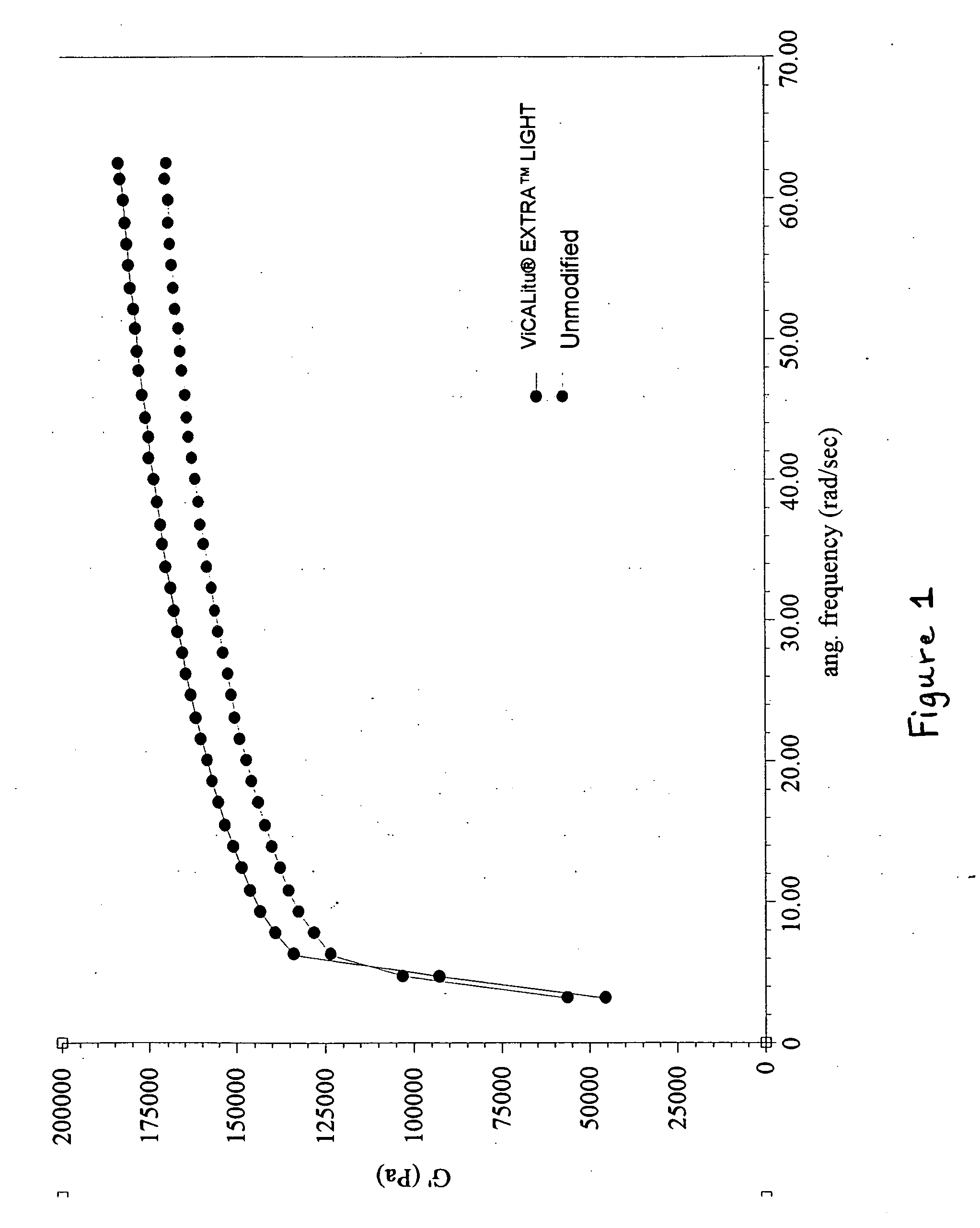

ActiveUS20100015375A1Bubble stabilizationImprove bubble stabilityClosuresClosure using stoppersBlow moldingSolubility

The invention includes a copolymer of vinylidene chloride with at least one monounsaturated comonomer and at least one branching monomer in an amount sufficient to increase molecular weight over that of a polymer prepared using the same process and same monomers in the same relative amounts except without the branching monomer, but preferably the branching monomer is present in a quantity not sufficient to result in measurable crosslinking as determined by solubility in tetrahydrofuran at up to 83° C. The invention includes a process for making the polymer and processes for forming the copolymer or compositions thereof as well as articles comprising the copolymer and compositions thereof. The copolymer exhibits improved bubble stability and is particularly useful for processes in which the copolymer is at least partially oriented in formation such as blow molding, formation of monofilament fiber and film blowing.

Owner:SK GEO CENTRIC CO LTD

Construction technology of cast-in-place lightweight foam concrete

The invention discloses a cast-in-place light-weight foamed concrete construction technique. The technique comprises the following steps: earlier stage preparation; cement mortar solution preparation: mixing cement and fly ash in a mixing hopper; foaming agent water solution preparation: weighing a foaming agent, adding the foaming agent and water into a mixing hopper of a hydraulic foaming machine, uniformly mixing to form the foaming agent water solution; foamed concrete preparation: gradually adding the foaming agent water solution prepared in the step 2 into the cement mortar solution by a conveyer belt, mixing for 1-3 minutes to form the foamed concrete; discharging the mortar and delivering the foamed concrete; casting the foamed concrete; and curing. The foamed concrete can not easily collapse in the in-place casting process, and has the advantages of high construction speed and low construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Heat-insulating and fire-proofing material

InactiveCN1422933ANo crackingGood heat insulation and fire performanceFireproof paintsPolymer scienceFoaming agent

The invention refers to an adiabatic fireproof material prepared by high-aluminium cement and foaming agent and the preparing method. Its components: cement base 350-600 kg / m, foaming agent, 0.1-20 kg / m to the power 3, additive 50-250 kg / m to the power 3, the cement base being high-aluminium cement, the foaming agent composed of foam initiating agent and foam stabilizing agent. The method: before or after stirring the mixture of high-aluminium cement and additive by water, inject the foamed solution into the water, mix evenly, and make hardening reaction to prepare the material.

Owner:韩玉春

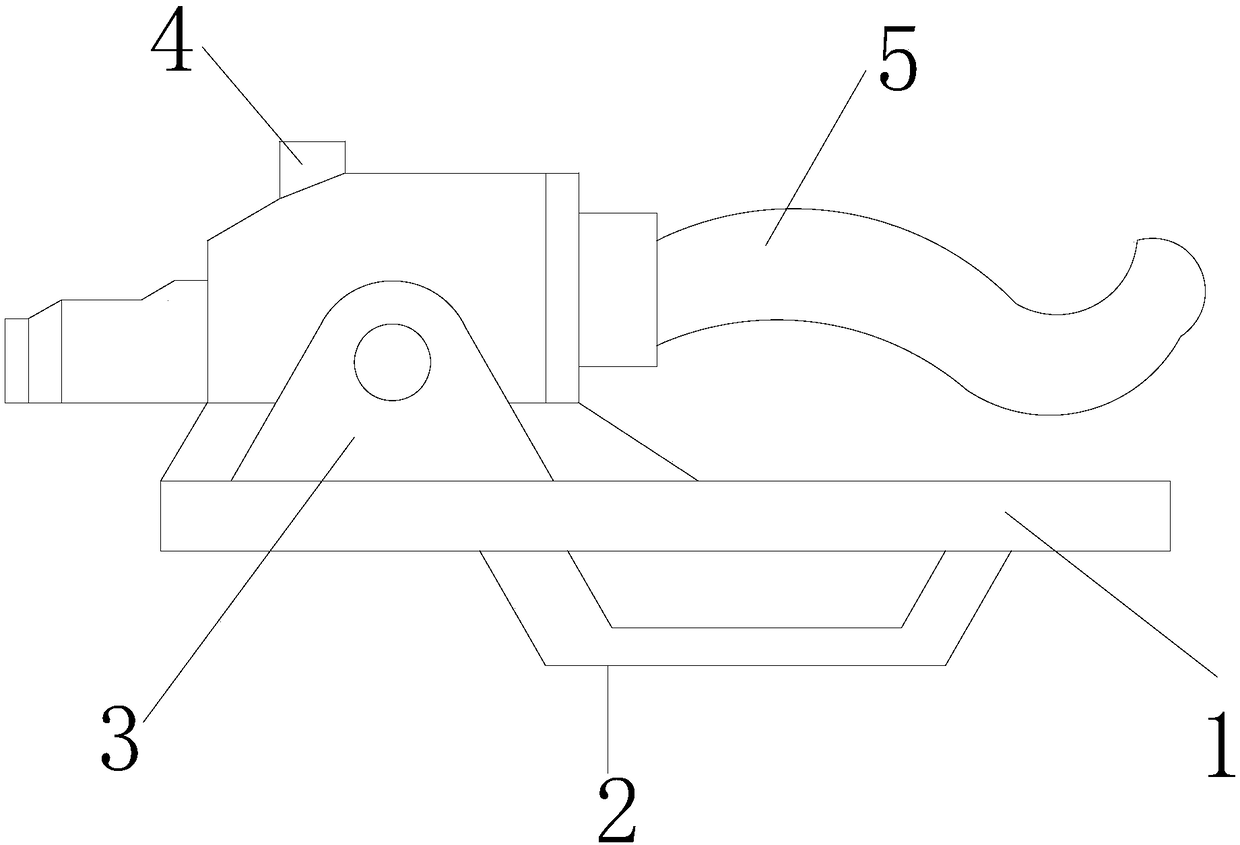

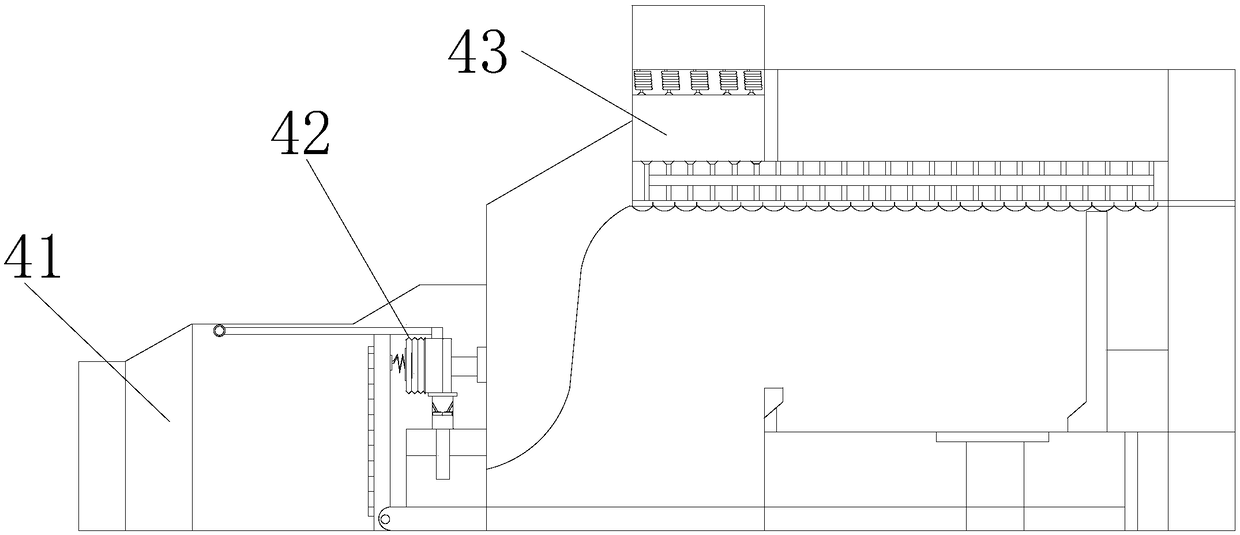

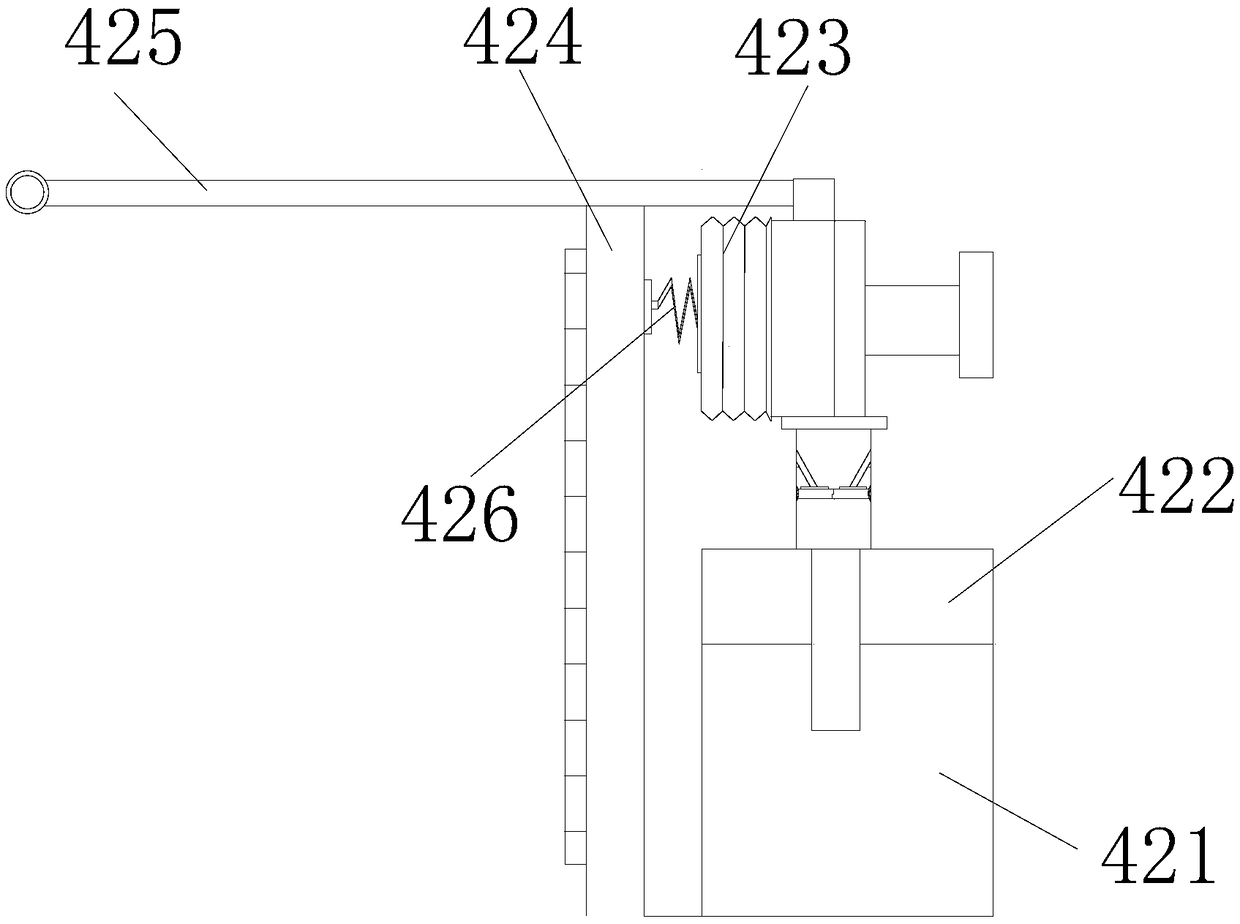

Metallurgy heating furnace rapid fettling equipment adopting structural pressurized crushing for exhausting and bubble preventing

The invention discloses metallurgy heating furnace rapid fettling equipment adopting structural pressurized crushing for exhausting and bubble preventing. The metallurgy heating furnace rapid fettlingequipment structurally comprises a mounting plate, a handle frame, a hinged seat, an intelligent supplementing device and a conveying pipe, the conveying pipe is located on the right side end face ofthe intelligent supplementing device and embedded into the intelligent supplementing device, the hinged seat is arranged on the outer side end face of the intelligent supplementing device, and the hinged seat and the intelligent supplementing device are in clearance fit. Water glass is output from the interior of the equipment through an internal input pipe, meanwhile, through force applying of apush rod on the rear side, a jacking plate on the front part moves forwards, then by extruding the water glass and through clamping of a pressing bent frame on the upper part, gas extrusion discharging of the internal water glass is conducted, and thus the explosion phenomenon during water glass outputting is prevented; and meanwhile, integration is conducted through a water storage barrel on thelower part, then through unified force applying of the push rod, a press fit frame is pulled out, meanwhile, suck-out work of the internal water glass is conducted, and the backflow phenomenon of thewater glass can be well prevented.

Owner:黄崇生

Building thermal insulation mortar material taking gold tailings and oil sand tailings as raw materials as well as preparation method and application thereof

PendingCN112500115AAchieve recyclingTo achieve the purpose of resource reuseSolid waste managementCrack resistanceLithium hydroxide

The invention discloses a building thermal insulation mortar material taking gold tailings and oil sand tailings as raw materials as well as a preparation method and application of the building thermal insulation mortar material. The building thermal insulation mortar material is prepared from the following raw materials in parts by weight: 40-50 parts of gold tailings, 100-130 parts of cement, 20-30 parts of oil sand tailings, 20-30 parts of expanded perlite, 20-25 parts of gypsum, 2-5 parts of octenyl succinic acid aluminum starch, 6-10 parts of 2, 4-pentanediol, 3-6 parts of tridecyl trimellitate, 2-4 parts of lithium hydroxide, 7-9 parts of sodium hydroxide, 6-10 parts of kanuma soil, 1-2 parts of water glass and 10-15 parts of an air entraining agent. According to the invention, through reasonable design of the raw materials and the ratio thereof and synergistic effect of the raw materials, the thermal insulation mortar can be ensured to have good thermal insulation performance, waterproof performance and fireproof performance, and the workability and crack resistance of the thermal insulation mortar can be improved, so that the use effect of the thermal insulation mortar is improved; therefore, the thermal insulation mortar is more suitable for internal and external wall thermal insulation systems of buildings and has good social and economic benefits.

Owner:任海良

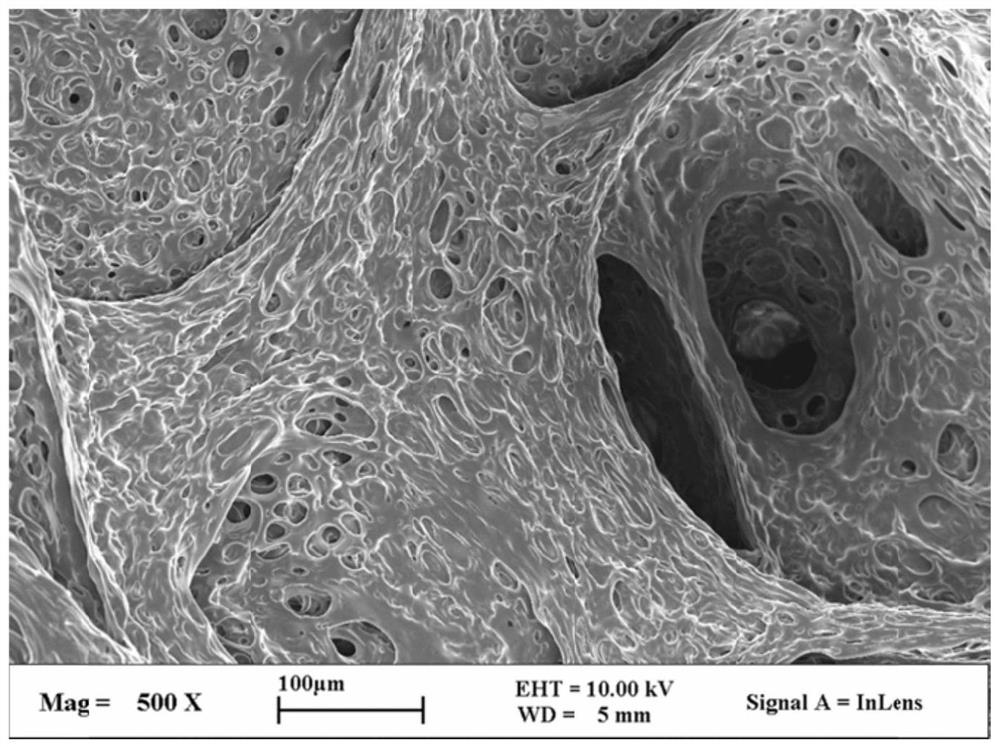

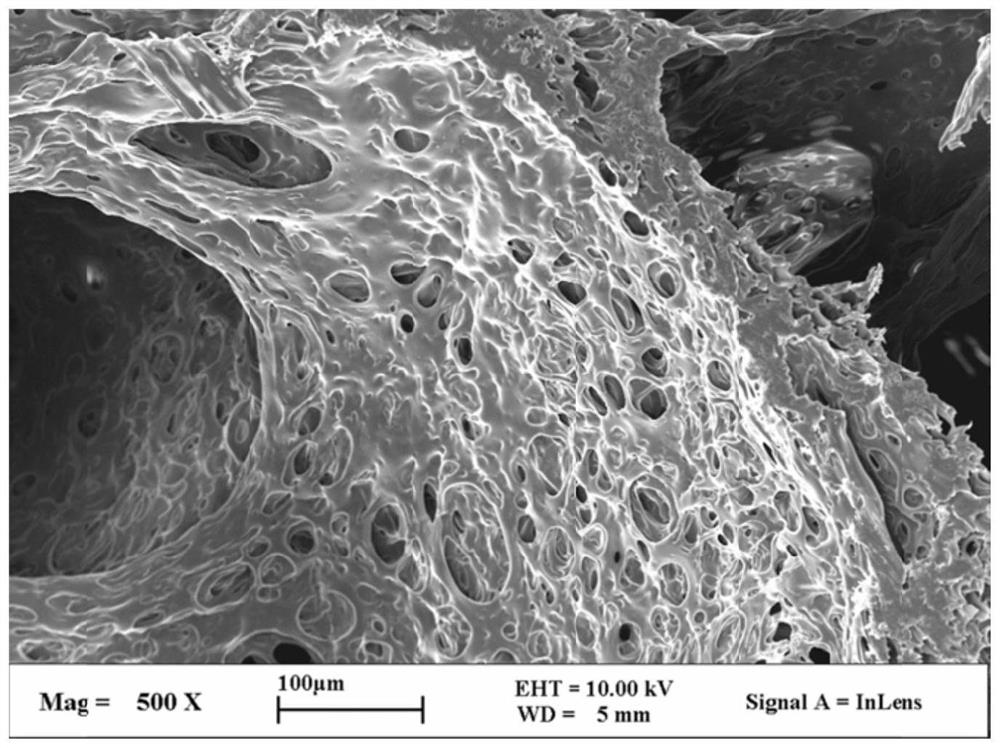

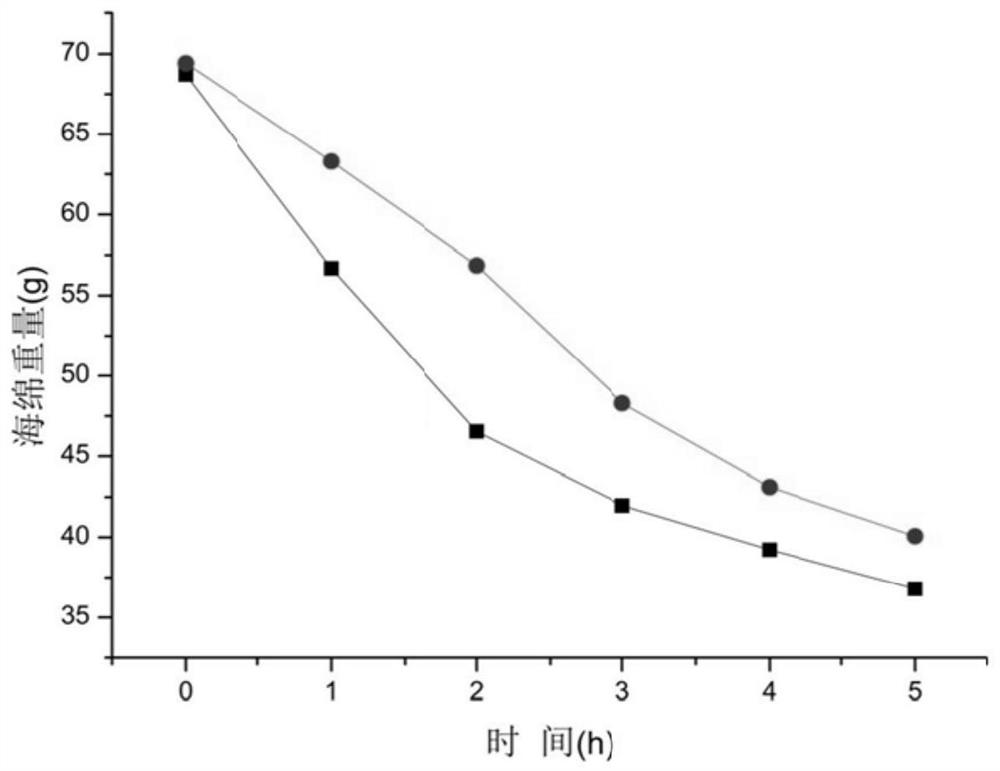

Composite sponge, preparation method thereof, negative pressure drainage dressing, device and medical equipment

ActiveCN109646705BKeep hydrophilicReduce moisture evaporationNon-adhesive dressingsAbsorbent padsMedical equipmentFoaming agent

The invention discloses a composite sponge with better water retention, a preparation method thereof, a negative pressure drainage dressing, a device and medical equipment. The composite sponge comprises the following components: alginate, polyvinyl alcohol, foaming agent, surfactant, cross-linking agent, acid catalyst, and deionized water. The preparation method of the composite sponge comprises the following steps: stirring alginate, polyvinyl alcohol and deionized water; sequentially adding foaming agent, surfactant, crosslinking agent, acid catalyst, mixing, cooling, stirring and pouring into a mold , carry out the cross-linking reaction, cool and remove the mold and clean it. The alginate used in the present invention will not produce precipitation in the acidic solution, which can promote the water retention performance of the sponge to the greatest extent, reduce the moisture volatilization of the composite sponge during use, change the hardness of the dry composite sponge, and reduce the impact of the dry sponge on The compressive force of the wound can reduce the pain of the patient and speed up the healing process of the patient's wound.

Owner:SHENZHEN QIKANG MEDICAL DEVICES

Prolamin composition and preparation method thereof

PendingCN109984246AQuick passBubble stabilizationCream preparationProtein foodstuffs working-upProlaminDextrin

The invention provides a prolamin composition. The prolamin composition comprises, by weight, 50-95 parts of prolamin, 3-14 parts of water, optionally 0-150 parts of dextrin, and optionally 0-56 partsof polyhydroxy compounds. The invention also provides a preparation method of the prolamin composition. The prolamin composition can be used as a cream texturing agent. Cream products prepared from the prolamin composition have higher foaming and stability than cream products prepared by the prior art.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Cream composition and preparation method thereof

The invention provides a cream composition which is characterized by comprising, by weight, 1-10 parts of alcohol soluble protein compositions, 10-50 parts of animal fat, 0.05-5 parts of oil soluble emulsifiers, 10-120 parts of water and / or skimmed milk, 0-1 part of optionally selected stabilizers, 0-1 part of optionally selected second emulsifiers and 0-8 parts of optionally selected non-animal fat. The invention further discloses a preparation method of the cream composition. The cream composition is uniform and stable and has better whipability, higher whipped rate, hardness (plasticity) and wider pH (potential of hydrogen) application ranges, and use of the animal fat can be reduced.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Bubble stability

ActiveUS8298638B2Avoid discontinuitiesTest sensitiveClosuresClosure using stoppersBlow moldingPolymer science

The invention includes a copolymer of vinylidene chloride with at least one monounsaturated comonomer and at least one branching monomer in an amount sufficient to increase molecular weight over that of a polymer prepared using the same process and same monomers in the same relative amounts except without the branching monomer, but preferably the branching monomer is present in a quantity not sufficient to result in measurable crosslinking as determined by solubility in tetrahydrofuran at up to 83° C. The invention includes a process for making the polymer and processes for forming the copolymer or compositions thereof as well as articles comprising the copolymer and compositions thereof. The copolymer exhibits improved bubble stability and is particularly useful for processes in which the copolymer is at least partially oriented in formation such as blow molding, formation of monofilament fiber and film blowing.

Owner:WEIFANG YAXING CHEM CO LTD

Preparation method of comfortable seersucker

ActiveCN111334917AStable twist performanceEffect of heat shrinkageFilament/thread formingHeating/cooling textile fabricsPolymer scienceCotton fibre

The invention relates to a preparation method of comfortable seersucker. The preparation method comprises the steps of weaving 28-32s warp yarns (cotton fibers) and 50-60s weft yarns (polyamide yarns)to obtain gray fabric, and carrying out relaxation heat treatment to obtain the comfortable seersucker; preparation of polyamide yarns: in the process of preparing the round sheath-core composite fiber from two kinds of polyamide 6 with different viscosities according to the FDY technology, changing spinneret holes in a spinneret plate into trefoil shapes from round shapes, adopting circular airblowing cooling, and controlling the arrangement of the trefoil spinneret holes in the spinneret plate to meet certain conditions so as to prepare the polyamide yarn; the gram weight of the prepared comfortable seersucker ranges from 100 g / m<2> to 130 g / m<2>, the seersucker width ranges from 1.30 cm to 1.50 cm, the seersucker density ranges from 38 pieces / 10 cm to 42 pieces / 10 cm, and the fullnessranges from 6.6 to 7.5; hygroscopicity: the water absorption rate is greater than or equal to 280%, the drip diffusion time is less than or equal to 2.0 seconds, and the wicking height is greater than or equal to 138 mm; and quick dryness: the evaporation rate is more than or equal to 0.32 g / h.

Owner:JIANGSU HENGLI CHEM FIBER

concrete air entraining agent

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

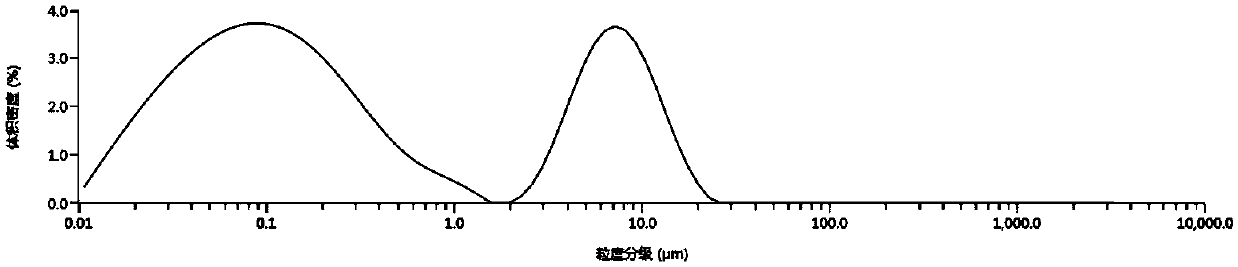

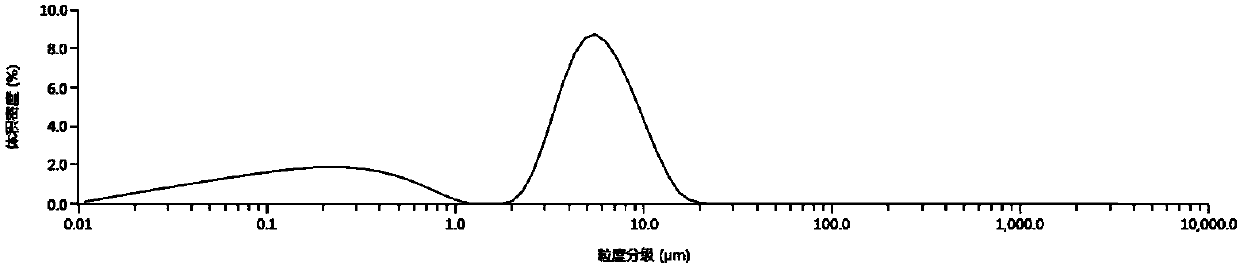

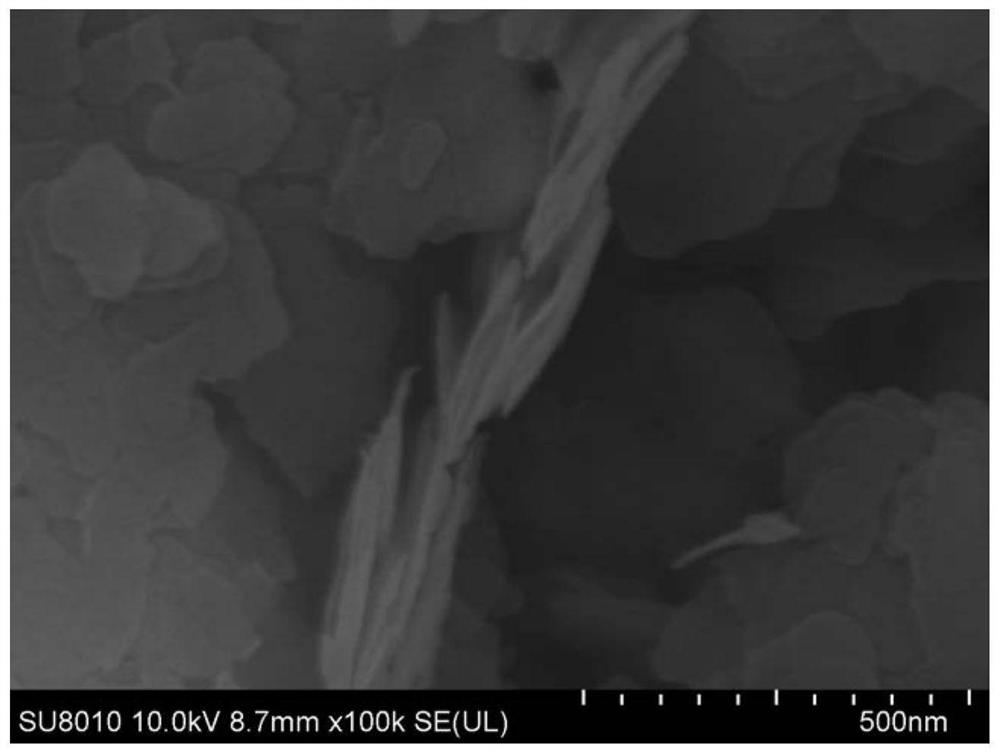

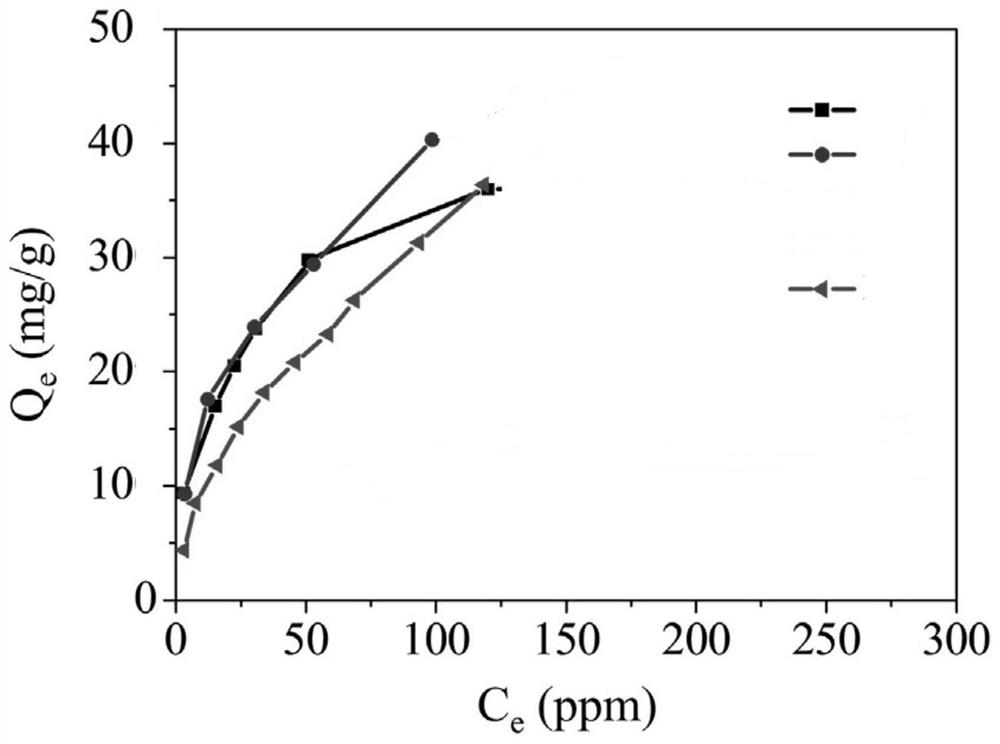

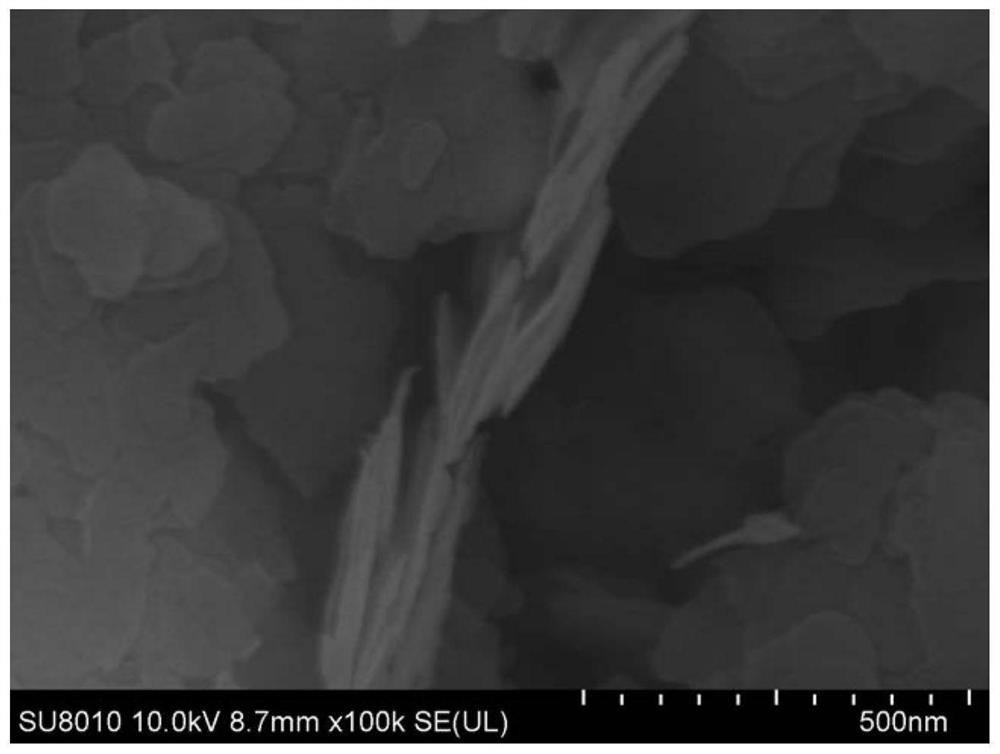

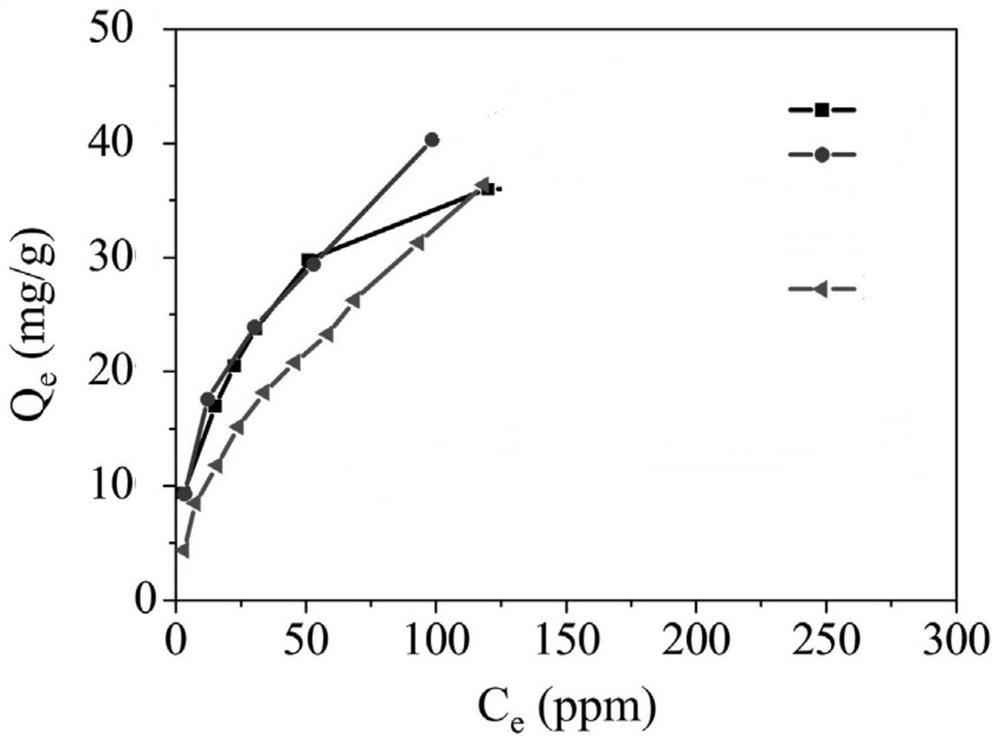

A kind of black talc-polyvinyl formal gel composite adsorption material

ActiveCN112844338BLow viscosityBubble stabilizationOther chemical processesWater contaminantsSodium bicarbonatePolyvinyl alcohol

The invention discloses a black talc-polyvinyl formal gel composite adsorption material and a preparation method thereof, belonging to the technical field of dye adsorption preparation. The specific method is: dissolve polyvinyl alcohol, then add hexane / sodium bicarbonate mixture, stir and foam, then add black talc powder with a particle size of about 300nm, stir and mix well, then add formaldehyde to react and cross-link to prepare a hydrogel glue composite material, and finally cured and shaped in an oven to obtain a black talc-polyvinyl formal gel composite adsorption material. The black talc-polyvinyl formal composite gel of the present invention can not only fix / adsorb the dye, but also has excellent water absorption, swelling and compression properties, and overcomes the technical problem that the adsorbent is difficult to recycle in the prior art; the method is simple , easy to operate and has broad application prospects.

Owner:ZHEJIANG UNIV OF TECH

Cream composition and preparation method thereof

The invention discloses a cream composition and a preparation method thereof. The cream composition is prepared from the following raw materials in parts by weight: 25 to 35 parts of vegetable oil, 30 to 50 parts of anhydrous cream, 8 to 12 parts of trehalose, 8 to 12 parts of glucose powder, 5 to 8 parts of yolk liquid, 3 to 8 parts of whey calcium, 2 to 5 parts of compound vitamin, 2 to 5 parts of probiotics, 1 to 3 parts of an emulsifier, 0.5 to 2 parts of a thickener, 1 to 2 parts of table salt and the balance drinking water. According to the cream composition disclosed by the invention, a specific ratio is adopted and the yolk liquid is added into the cream; the added yolk liquid not only provides microelements including fat-soluble vitamin, monounsaturated fatty acid, phosphorus, iron and the like for the cream, but also can be used for enhancing bubbles in the cream when the cream is whipped; framework support is provided for the cream in a whipping process and the cream bubbles can be effectively stabilized, so that the cream composition with moderate rigidity and stable properties is obtained; meanwhile, the probiotics, the whey calcium and the compound vitamin are added so that nutrients of the cream can be enriched and the cream is easily absorbed by human bodies; and meanwhile, the flavor of the cream composition is increased and the cream composition is convenient to eat.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

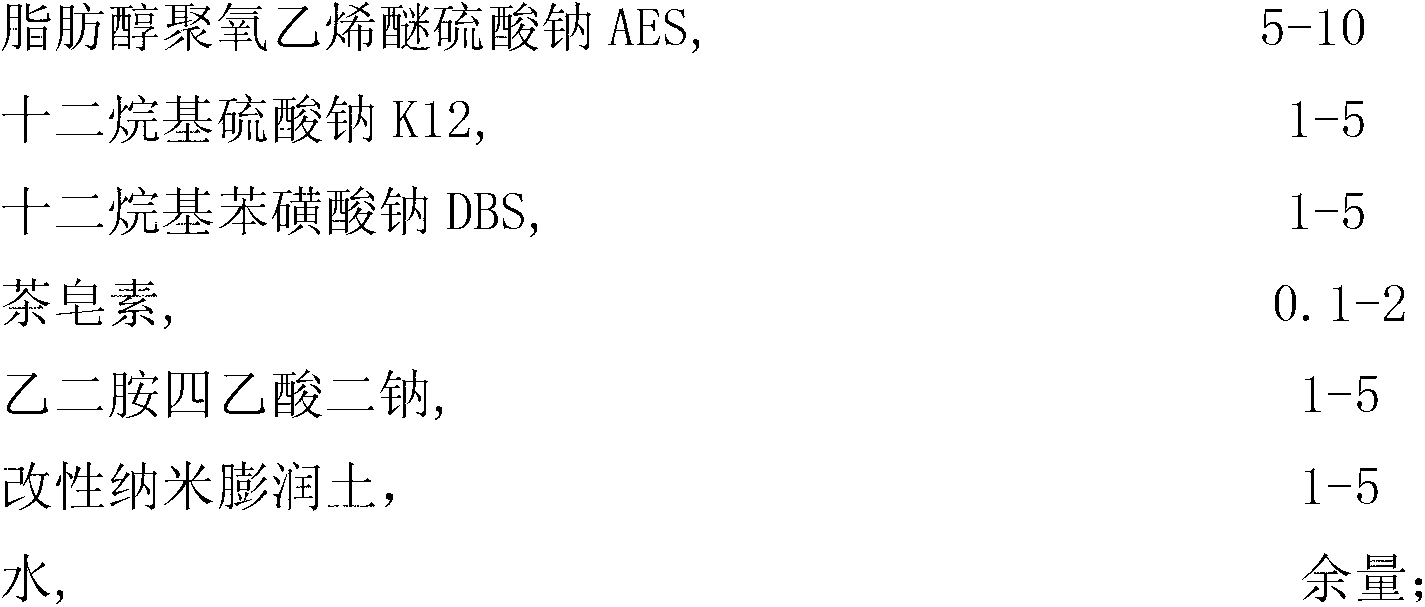

Foaming agent for sound absorption foam concrete product and preparation method for foaming agent

InactiveCN102329149BUniform bubble diameterBubble stabilizationCeramicwareFoam concreteSodium Bentonite

The invention relates to a foaming agent for a sound absorption foam concrete product and a preparation method for the foaming agent. The foaming agent comprises the following components in percentage by mass: 5 to 10 percent of fatty alcohol-polyoxyethylene ether sodium sulfate, 1 to 5 percent of lauryl sodium sulfate, 1 to 5 percent of sodium dodecyl benzene sulfonate, 0.1 to 2 percent of tea saponin, 1 to 5 percent of disodium ethylene diamine tetraacetate, 1 to 5 percent of modified nanometer bentonite and the balance of water. The foaming agent special for sound absorption foam concrete is stable in performance, high in foaming times and high in workability with concrete base materials, and has an adjustable pore structure.

Owner:梁材

Black talc-polyvinyl formal gel composite adsorption material

ActiveCN112844338ALow viscosityBubble stabilizationOther chemical processesWater contaminantsSodium bicarbonatePolyvinyl alcohol

The invention discloses a black talc-polyvinyl formal gel composite adsorption material and a preparation method thereof, belonging to the technical field of dye adsorption and preparation. The preparation method specifically comprises the following steps: dissolving polyvinyl alcohol, then adding a hexane / sodium bicarbonate mixed solution, conducting stirring and foaming, then adding black talcum powder with a particle size of about 300 nm, conducting full stirring and uniform mixing, then adding formaldehyde for a reaction and crosslinking to prepare a hydrogel composite material, and finally, conducting curing and forming in a drying oven to obtain the black talc-polyvinyl formal gel composite adsorption material. The black talc-polyvinyl formal composite gel provided by the invention not only can fix / adsorb dyes, but also has excellent water absorption, swelling and compression properties, and overcomes the technical problem that an adsorbent is difficult to recover in the prior art; and the method is simple and easy to operate, and has wide application prospects.

Owner:ZHEJIANG UNIV OF TECH

Waterproof crack-resistant inorganic heat-insulating mortar and preparation method thereof

The invention relates to waterproof crack-resistant inorganic heat-insulating mortar and a preparation method thereof. The mortar comprises 5-10 m<3> of small expended and vitrified balls, 0-1 m<3> of pottery sand, 750-850 kg of ordinary portland cement, 50-100 kg of calcium powder, 35-70 kg of hydrated lime, 30-55 kg of siliceous dust, 15-20 kg of dispersible polymer powder, 4-8 kg of hydroxypropyl methyl cellulose ether, 1-2 kg of mekralon, 0.5-1 kg of capillary crystalline waterfroof agent, and 3-5 kg of wood fiber. The preparation method comprises the following steps: loading ordinary portland cement, siliceous dust, hydrated lime, hydroxypropyl methyl cellulose ether, dispersible polymer powder, calcium powder, mekralon, capillary crystalline waterfroof agent and wood fiber at one time, and stirring for 3 min; adding small expended and vitrified balls and pottery sand in the stirred powder blend, and continuously stirring for 2 min; and packaging and storing the finished products in warehouse. Compared with the prior art, by using the pottery sand and capillary crystalline waterfroof agent, the problems of large water absorption, easy cracking when water seepage occurs and the like of traditional inorganic small expended and vitrified ball heat-insulating mortar are solved.

Owner:上海英硕聚合材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com