Cream composition and preparation method thereof

A composition and cream technology, applied in cream preparations, dairy products, applications, etc., can solve the problem of low cream hardness and achieve the effects of reduced intake, good whipping performance, and high whipping hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Next, the present invention will be described in further detail through examples, but the present invention is not limited to these examples.

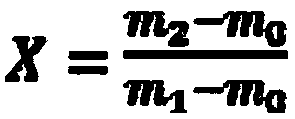

[0124] In an embodiment of the present invention, the physical and chemical properties of the gliadin composition and its use performance are determined by the following methods:

[0125] Determination of wetting angle: Use an infrared tablet press to compress 1g of the sample to be tested (30MPa) to obtain a sheet-like sample with a diameter of 13mm and a thickness of 2mm, and then put it into a fully automatic contact angle measuring instrument (Zhongchen Digital Technology Equipment Co., Ltd. , JC2000D4M) on the stage, use 2μL pure water droplet and take pictures to measure the wetting angle.

[0126] Determination of instant solubility: Disperse 10 grams of protein powder with a dry content of D% in 180 grams of deionized water at 24 °C ± 1 °C, and stir with a bench mixer at a speed of 400 rpm. After stirring for 10 minutes...

preparation example 1

[0141] (1) Raw material dissolution: 50 parts by weight of zein (α-gliadin, β-gliadin and γ-gliadin account for 97wt%, 2wt% and 0% of gliadin respectively) are completely dissolved in In 375 parts by weight of 70v / v% ethanol solution at 50°C, the pH was adjusted to 6 to obtain the first feed solution.

[0142] (2) 25 parts by weight of dextrin were completely dissolved in 987 parts by weight of water to obtain a second feed liquid.

[0143] (3) Primary reverse phase precipitation: 250 parts by weight of 40v / v% ethanol (50°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and stirred and kept at 50°C for 30min, A reversed-phase precipitate was obtained.

[0144] (4) Secondary reverse-phase precipitation: Add the primary reverse-phase precipitation in step (3) to the second material liquid obtained in step (2) and stir for rapid dispersion. The reaction temperature is controlled at 15°C, and the pore size is 100 μm. After the filter cloth removes...

preparation example 2

[0148] (1) Dissolving raw materials: 60 parts by weight of zein (alpha-gliadin, beta-gliadin and gamma-gliadin respectively account for 90wt%, 5wt% and 1wt% of the prolamin), 7 wt% Parts of glycerol and 3 parts by weight of polyethylene glycol were completely dissolved in 450 parts by weight of 70v / v% ethanol solution at 45°C, and the pH was adjusted to 2.8 to obtain the first feed solution.

[0149] (2) 18 parts by weight of chitosan were completely dissolved in 1184 parts by weight of water to obtain a second feed liquid.

[0150] (3) One-time reverse phase precipitation: 300 parts by weight of 40v / v% ethanol (45°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and kept at 45°C for 30min to obtain A reverse phase eluate.

[0151] (4) Secondary reverse phase precipitation: Add the primary reverse phase precipitation solution in step (3) to the second material liquid obtained in step (2) and stir to make rapid dispersion. The reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com