A kind of black talc-polyvinyl formal gel composite adsorption material

A polyvinyl formal, composite adsorption material technology, applied in the direction of adsorption water/sewage treatment, alkali metal compounds, other chemical processes, etc., can solve the problems of poor chemical and mechanical properties, brittleness, poor recycling effect, etc. Achieve the effects of good adsorption, easy control of reaction conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

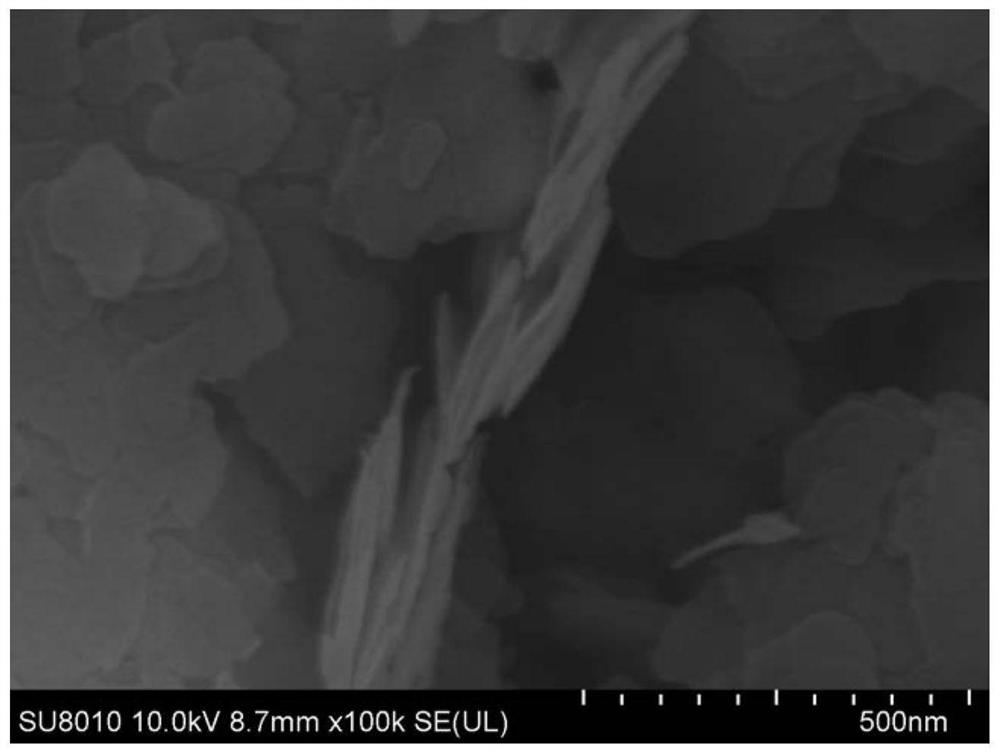

Image

Examples

Embodiment 1

[0028] (1) Add 2.0g PVA to a 100ml three-neck flask, then add 18g of water, stir at 95 °C in an oil bath pot to dissolve completely, and mix into a 10wt% aqueous PVA solution. Then add 0.5g of black talc powder and stir for 1h to form a black talc / PVA homogeneous emulsion. Cool down to 72°C.

[0029] (2) Weigh 0.1 g of hexane and 1.0 g of sodium bicarbonate in a 10 ml centrifuge tube, add 3 ml of water and shake to evenly blister. The foaming solution was added to the black talc / PVA homogeneous emulsion cooled to 72 °C and stirred until the sodium bicarbonate was dissolved in the mixed solution, and the emulsion volume expanded from the original 18 ml foam to 36 ml. Continue stirring for 5 min and cool down to 40 °C.

[0030] (3) When the temperature drops to 40 °C, 2 ml of formaldehyde is added, and the crosslinking reaction is 20 min. Pour the hydrogel into a mold at 60 °C and cure for 12 h, remove, repeatedly soak in water, squeeze, remove the unreacted monomers, wash to neutra...

Embodiment 2

[0032] (1) Add 2.0g PVA to a 100ml three-neck flask, then add 18g of water, stir at 95 °C in an oil bath pot to dissolve completely, and mix into a 10wt% aqueous PVA solution. Then add 1.0g of black talc powder and stir for 1.5h to form a black talc / PVA homogeneous emulsion. Cool down to 72°C.

[0033] (2) Weigh 0.15g hexane and 1.2g sodium bicarbonate in a 10ml centrifuge tube, add 3ml of water and shake to evenly foam. The foaming solution was added to the black talc / PVA homogeneous emulsion cooled to 72 °C and stirred until the sodium bicarbonate was dissolved in the mixed solution, and the emulsion volume expanded from the original 22 ml foam to 40 ml. Continue stirring for 5 min and cool down to room temperature.

[0034] (3) When the temperature drops to room temperature, 2 ml of formaldehyde is added to react for 20 min. Pour the hydrogel into a mold at 60 °C and cure for 12 h, remove, repeatedly soak in water, squeeze, remove the unreacted monomers, wash to neutral. Drying a...

Embodiment 3

[0036] (1) Add 2.0g PVA to the three-neck flask, then add 18g of water, stir at 95 °C in an oil bath pot to dissolve completely, and mix into a 10wt% aqueous PVA solution. Then add 1.5g of black talc powder and stir for 2h to form a black talc / PVA homogeneous emulsion. Cool down to 72°C.

[0037] (2) Weigh 0.15g hexane and 1.5g sodium bicarbonate in a 10ml centrifuge tube, add 3ml of water and shake to evenly blister. The foaming solution is added to the black talc / PVA homogeneous emulsion cooled to 72 °C and stirred until the sodium bicarbonate is dissolved in the mixed solution, and the emulsion is expanded from the original 25 ml foam to 55 ml. Continue stirring for 5 min and cool down to room temperature

[0038] (3) When the temperature drops to room temperature, 2 ml of formaldehyde is added to react for 30 min. Pour the hydrogel into a mold at 60 °C and cure for 12 h, remove, repeatedly soak in water, squeeze, remove the unreacted monomers, wash to neutral. Dry at room temp...

PUM

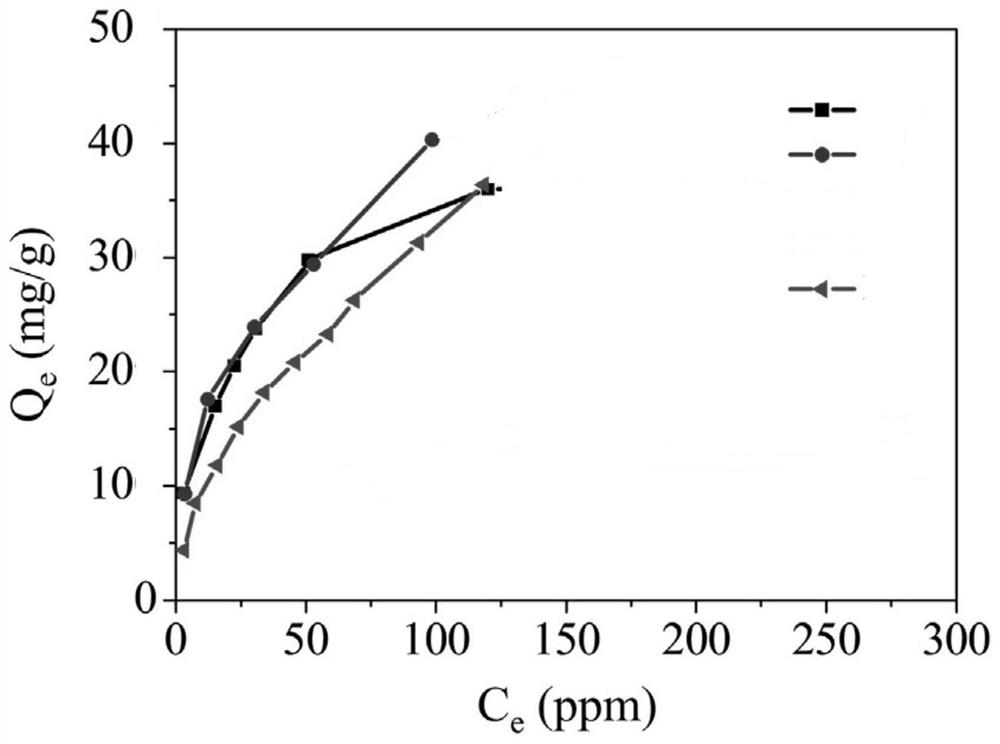

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com