Patents

Literature

35results about How to "Good heat insulation and fire performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

ActiveCN106189066ANo sheddingNo separabilityBulk chemical productionThermal insulationNanoscopic scale

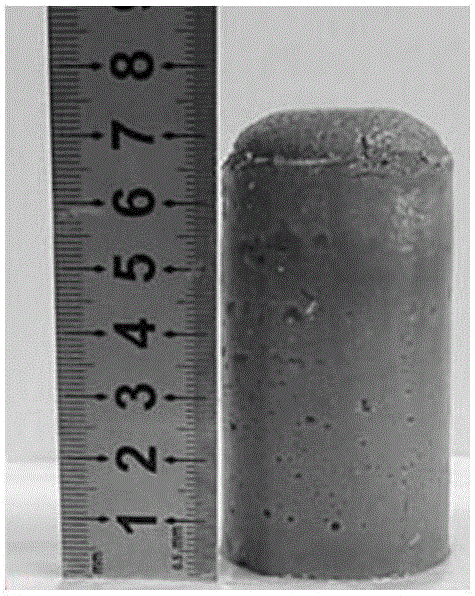

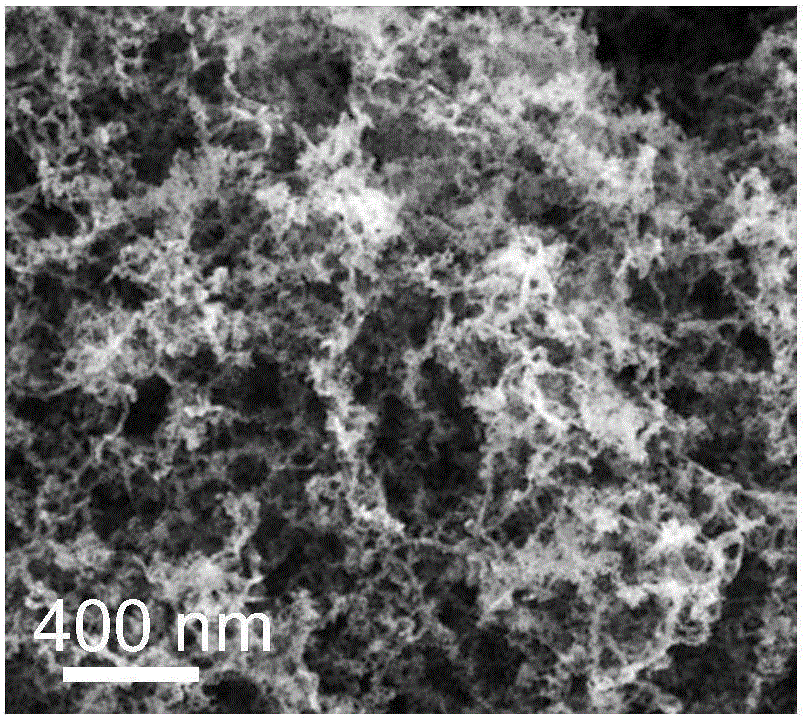

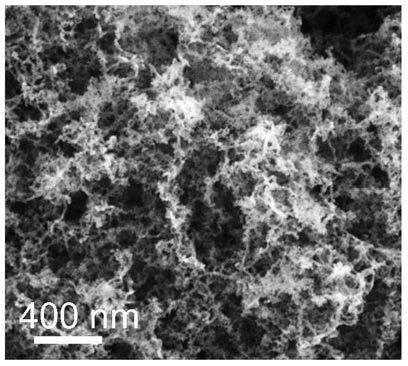

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

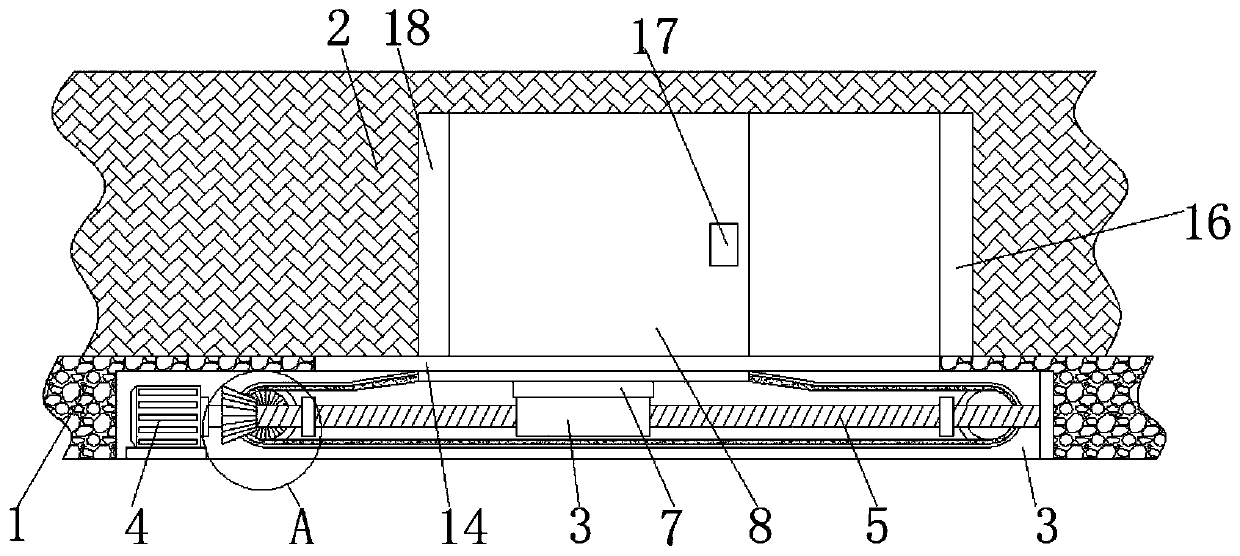

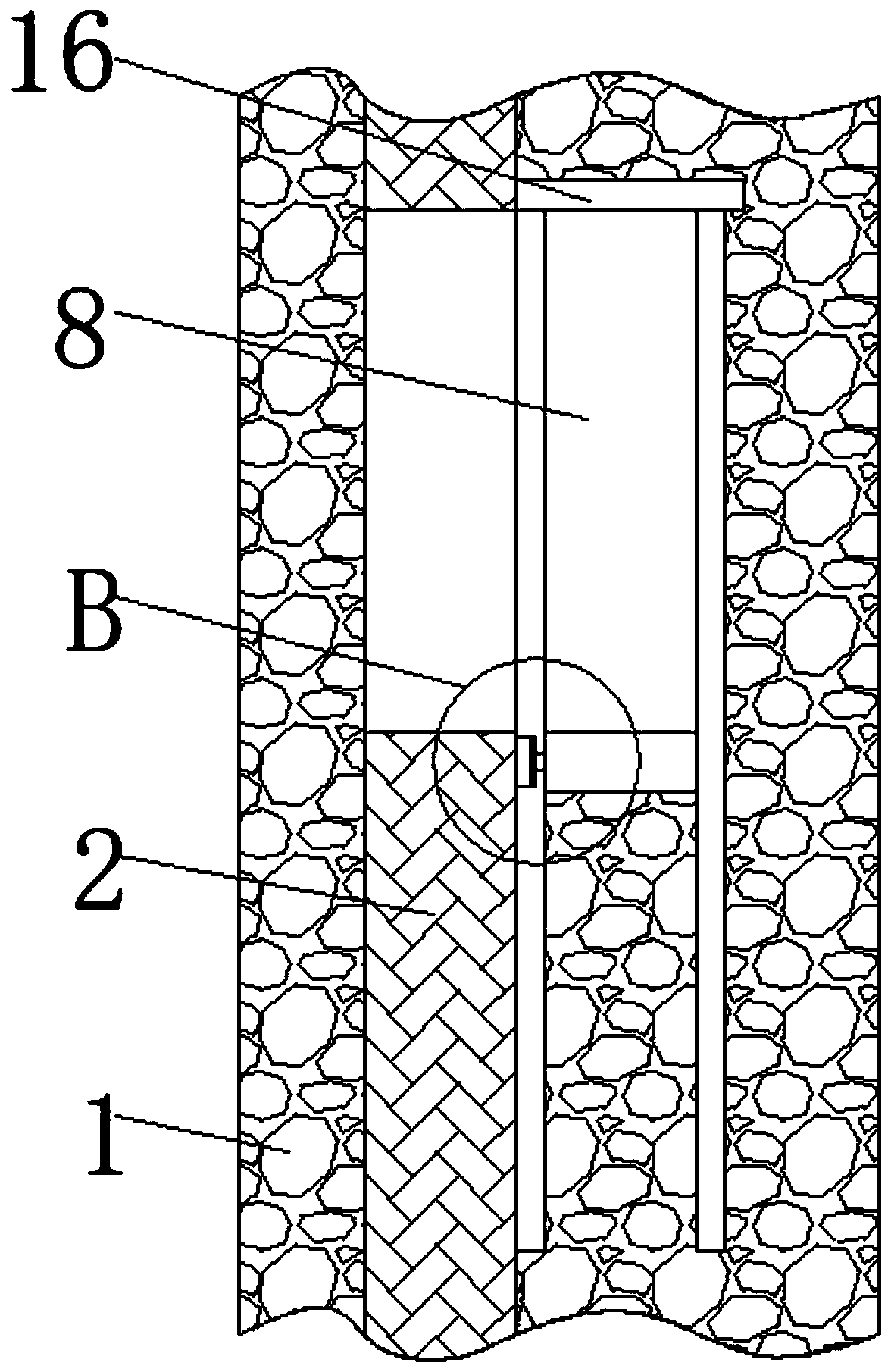

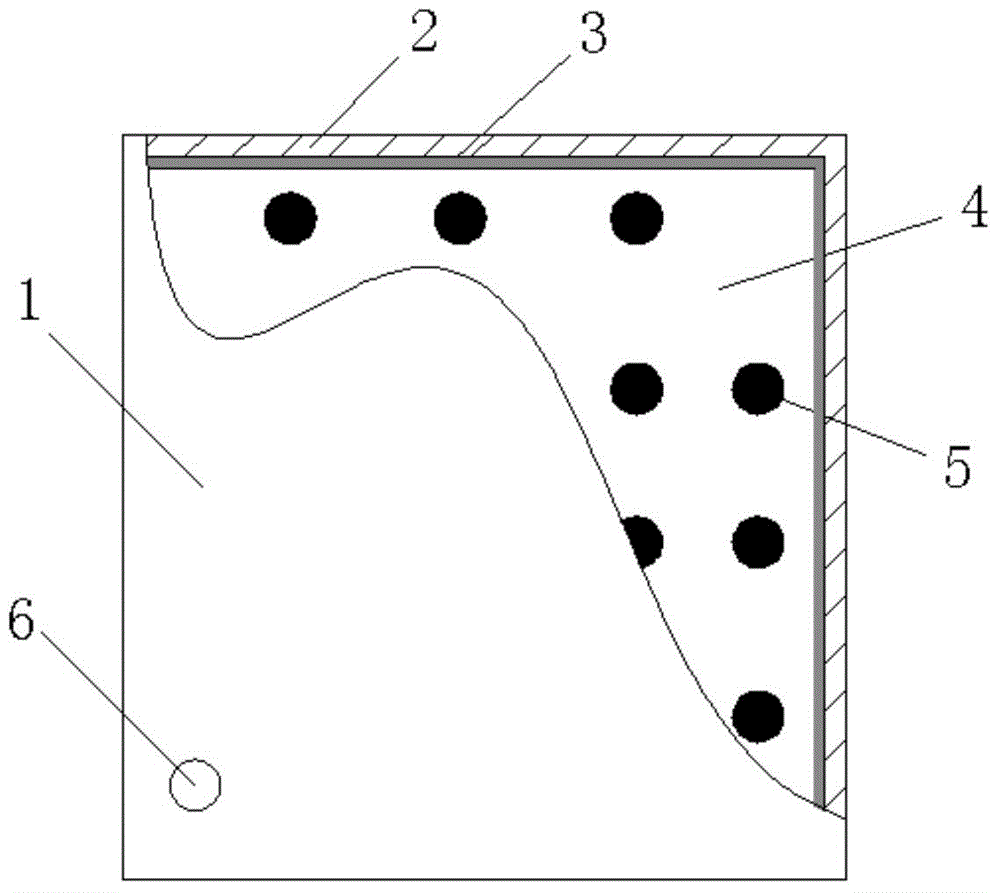

Deep high-ground-temperature roadway heat-insulation lining structure and construction method thereof

ActiveCN106988769ARealization of thermal insulation liningHigh strengthUnderground chambersTunnel liningInsulation layerArchitectural engineering

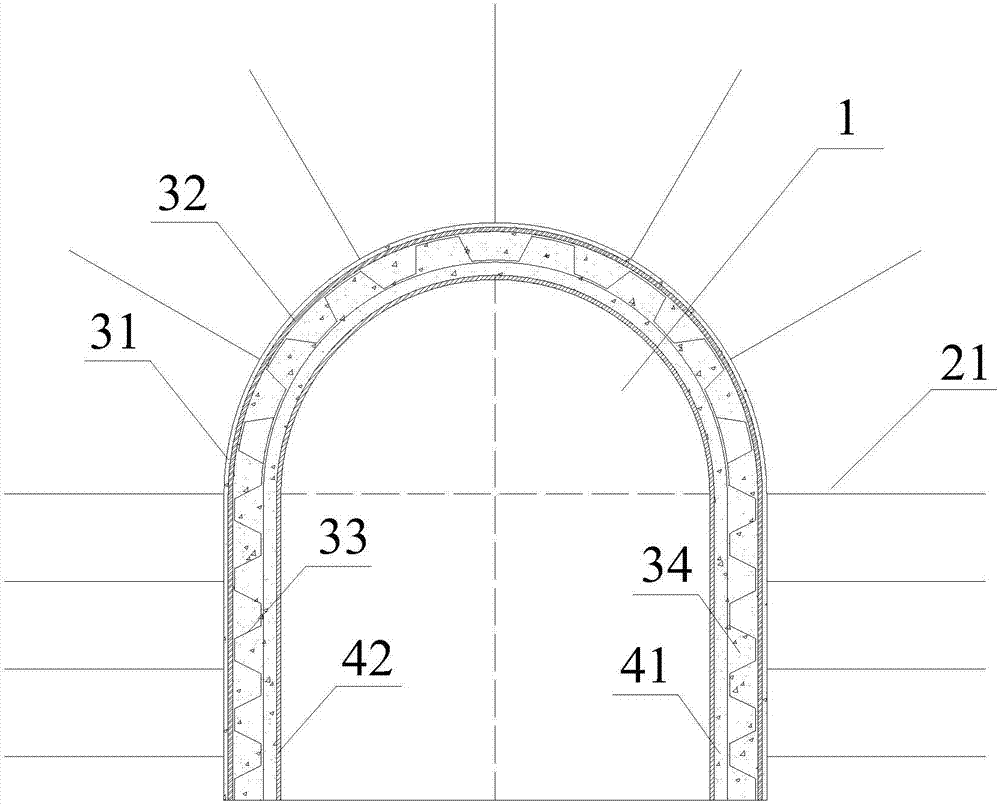

The invention discloses a deep high-ground-temperature roadway heat-insulation lining structure and a construction method thereof. The lining structure comprises a grouting heat-insulation ring, a primary lining heat-insulation layer and a secondary lining heat-insulation layer. Firstly, a heat-insulation grout material is injected through a hollow grouting anchor rod to form a grouting heat-insulation ring; the primary lining heat-insulation layer is distributed to form a primary support, wherein the primary lining heat-insulation layer comprises a first jet ceramsite concrete layer, a reinforcing mesh layer, a metal support and a second jet ceramsite concrete layer; after roadway deformation is stabilized, the secondary lining heat-insulation layer is constructed, and construction of the structure is completed, wherein the secondary lining heat-insulation layer comprises a third jet ceramsite concrete layer and a heat-insulation plate. By means of the structure and existing common support means and according to the current situation that deep mining high-temperature damage is severe, the stability of a roadway support structure is ensured by reasonably improving supporting materials and increasing the heat-insulation plates; by means of multiple heat-insulation measures, heat is effectively prevented from spreading into a roadway, and the application and popularization value is good.

Owner:ANHUI UNIV OF SCI & TECH

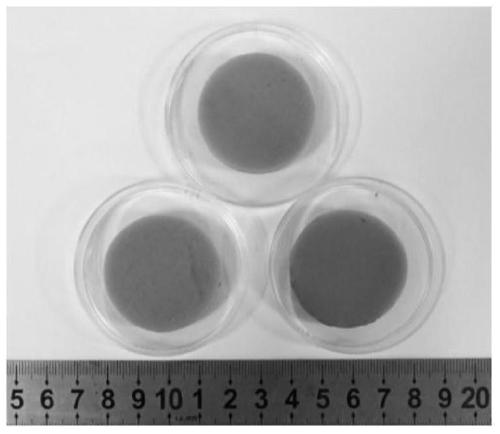

Aerogel composite material and preparation method thereof

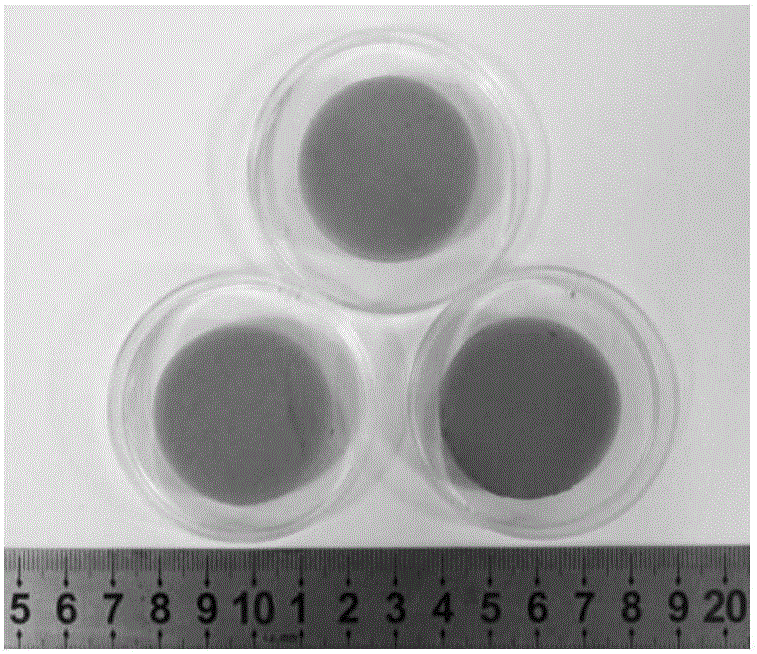

InactiveCN109987963AGood heat insulation and fire performanceIdeal flexural compressive strengthAerogel preparationCeramicwareThermal insulationAdhesive

The invention discloses an aerogel composite material and a preparation method thereof. The aerogel composite material is characterized in that the aerogel composite material is composed of aerogel particles and a heat insulation inorganic adhesive, the aerogel particles are hydrophobic aerogel particles or aerogel particles with internal hydrophobic and surface hydrophilic structure characteristics, and the heat insulation inorganic adhesive is composed of an inorganic adhesive and a heat insulation filler. The invention provides the preparation method of the aerogel composite material. The preparation method comprises the following steps: (1) coating the surfaces of aerogel particles with a heat-insulating inorganic adhesive; and (2) before the heat-insulating inorganic adhesive is cured, stacking the aerogel particles of which the surfaces are coated with the heat-insulating inorganic adhesive in the step (1), conducting pouring molding and curing, so as to obtain the aerogel composite material. The aerogel composite material provided by the invention has excellent thermal insulation and fireproof performance and ideal flexural and compressive strength, and also has sound insulation, damping and energy absorption characteristics; and the aerogel still retains an original nano-porous structure, so that the material can be applied to the fields of energy-saving buildings suchas building outer walls, inner walls and partition walls and the fields of aerospace, national defense military industry, transportation and the like, and has a huge market prospect.

Owner:卢锋

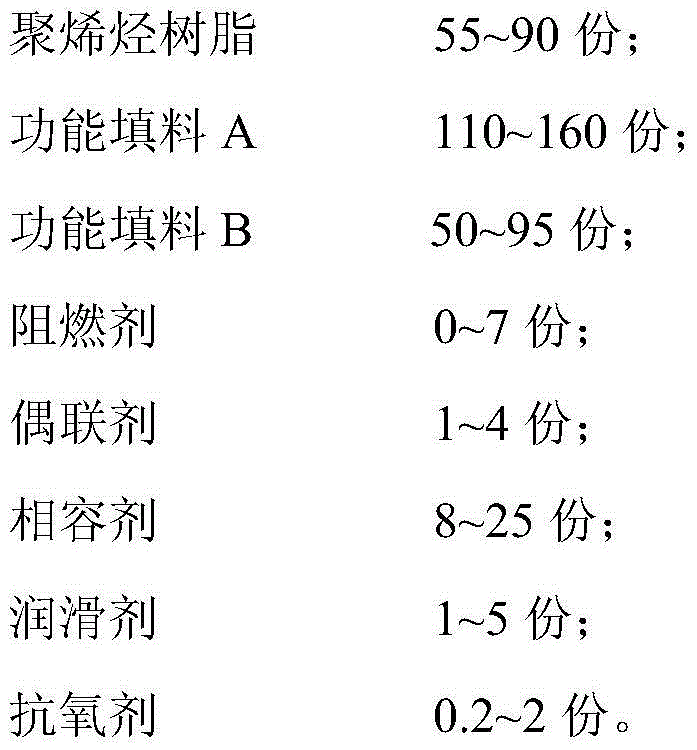

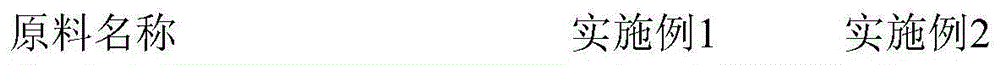

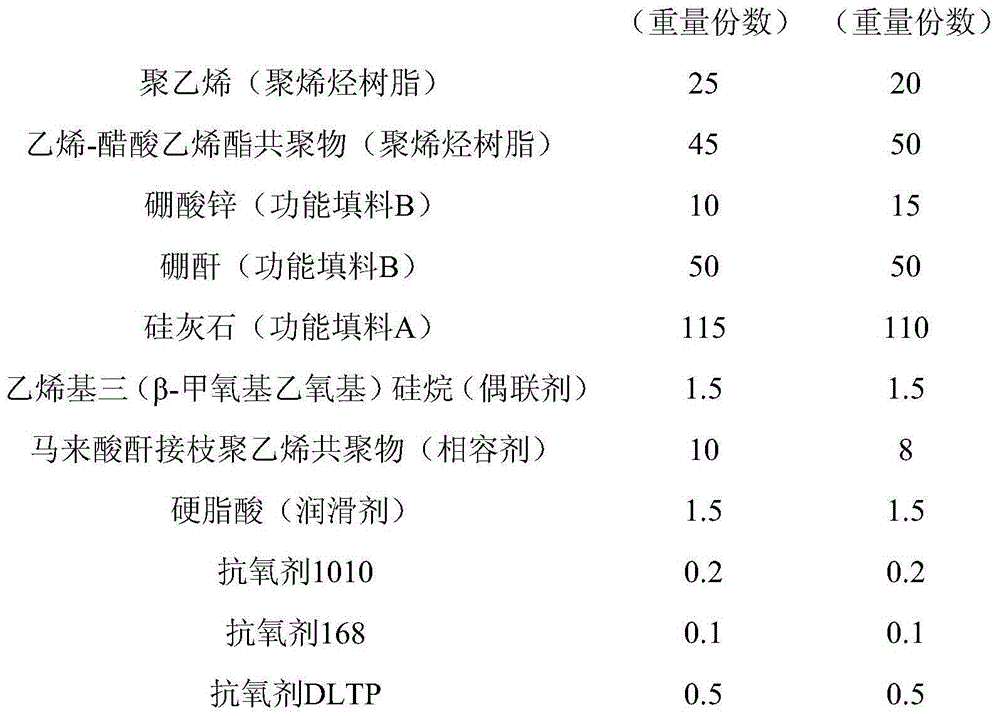

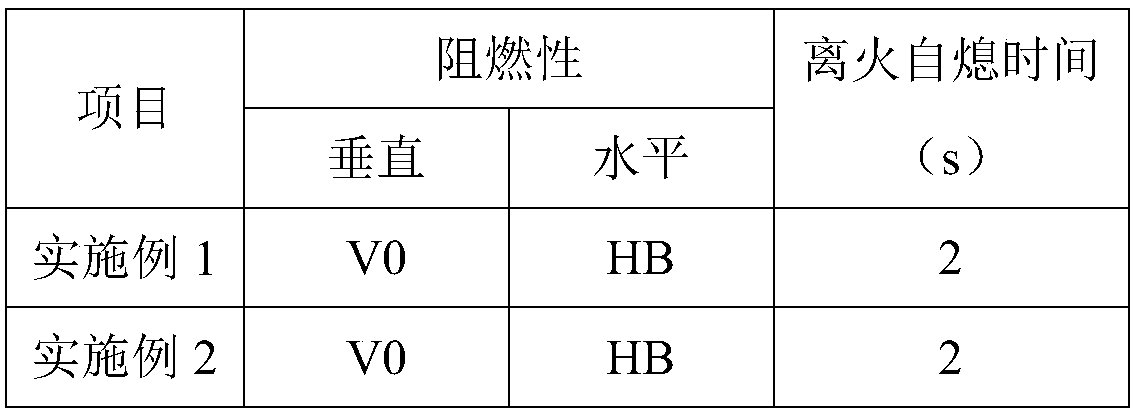

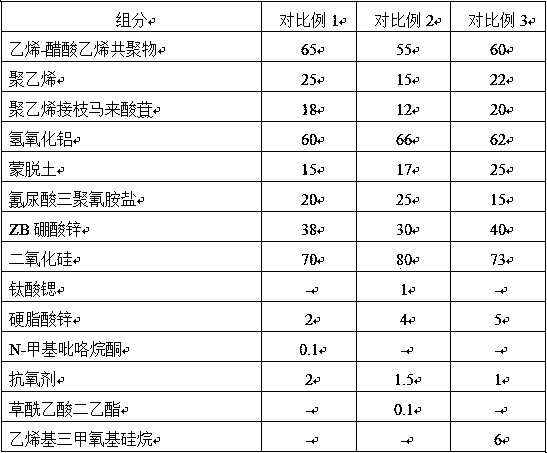

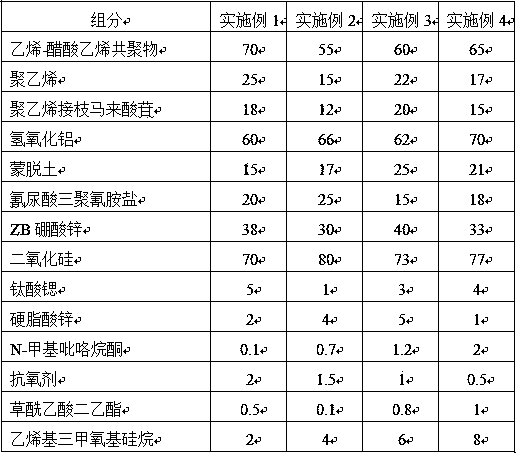

Low-smoke halogen-free heat-insulating fireproof cable material used for fire-resistant cable, and preparation method and application thereof

ActiveCN105801992AGood flexibilityGuaranteed uptimePlastic/resin/waxes insulatorsPolyolefinCombustion

The invention relates to the field of refractory materials, specifically to a low-smoke halogen-free heat-insulating fireproof cable material used for a fire-resistant cable, and a preparation method and application thereof. The low-smoke halogen-free heat-insulating fireproof cable material provided by the invention comprises the following raw materials by weight: 55 to 90 parts of polyolefin resin, 110 to 160 parts of a functional filling material A, 50 to 95 parts of a functional filling material B, 0 to 7 parts of a flame retardant, 1 to 4 parts of a coupling agent, 8 to 25 parts of a compatibilizing agent, 1 to 5 parts of a lubricant and 0.2 to 2 parts of an antioxidant. The fireproof cable material provided by the invention has good processing performance; the whole preparation process comprises basic steps like batching, material mixing, extrusion granulation, drying and packaging; and the process is simple. The cable material has good flexibility and is convenient to install; during combustion under the flame with a temperature of 500 to 1000 DEG C, the cable material does not drip and can generate a hard shell; meanwhile, the cable material has small shrinkage ratio before and after combustion, so normal operation of internal circuit can be protected; and the cable material can be applied in a fire-resistant filling layer and a heat-insulating fireproof layer of the fire-resistant cable, and has good heat-insulating and fireproof effects.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Aerogel thermal insulation coating for aluminum alloy material, fireproof thermal insulation coating layer for aluminum alloy battery pack and aluminum alloy upper cover of battery pack

InactiveCN111100526AHigh viscosityRestricted free movementFireproof paintsEpoxy resin coatingsEpoxyThermal insulation

The invention belongs to the technical field of coatings, and particularly relates to an aerogel thermal insulation coating for an aluminum alloy material, a fireproof thermal insulation coating layerfor an aluminum alloy battery pack and an aluminum alloy upper cover of the battery pack. The aerogel thermal insulation coating for the aluminum alloy material comprises the following components (byweight): 30-50 parts of a film-forming agent, 10-20 parts of silicon dioxide aerogel, 0.5-5 parts of a dispersing agent, 0.5-5 parts of a thickening agent, 0.5-5 parts of a defoaming agent, 0.5-5 parts of a flame retardant and 0.5-5 parts of a preservative, wherein the film-forming agent is a water-borne epoxy resin emulsion. The aerogel thermal insulation coating is used as an inner layer, the fireproof coating is used as an outer layer, and the inner layer and the outer layer form the fireproof thermal insulation coating layer for the aluminum alloy battery pack. The coating layer acts on the upper cover of the aluminum alloy battery pack, so that the upper cover of the aluminum alloy battery pack has better fireproof heat-insulating property and can pass an external fire test in GB / T 31467.3.

Owner:郑州深澜动力科技有限公司

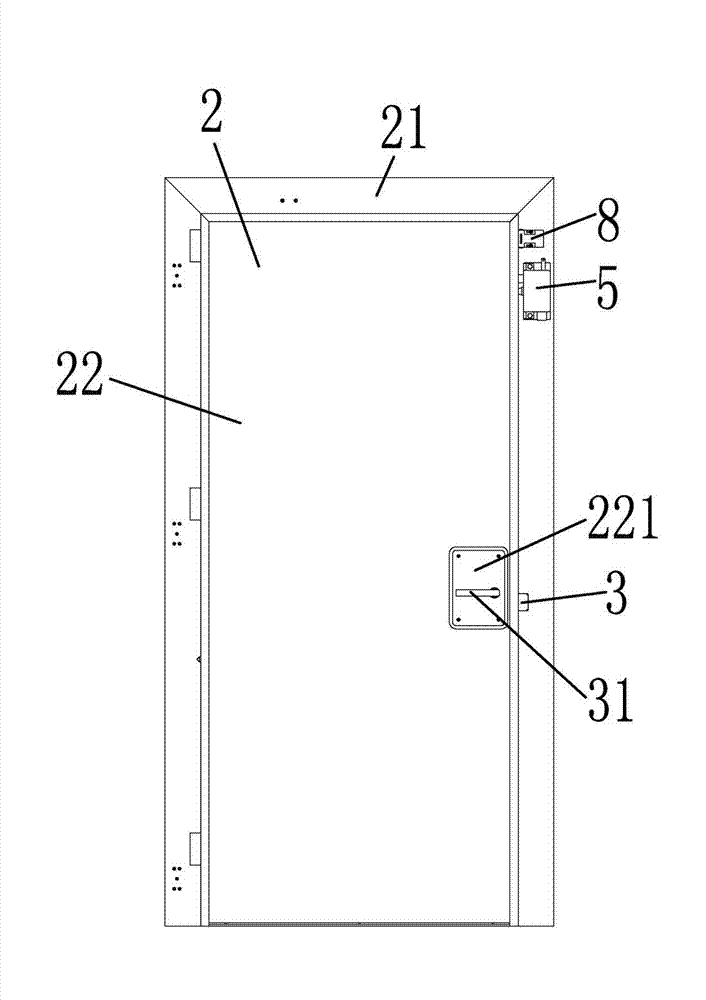

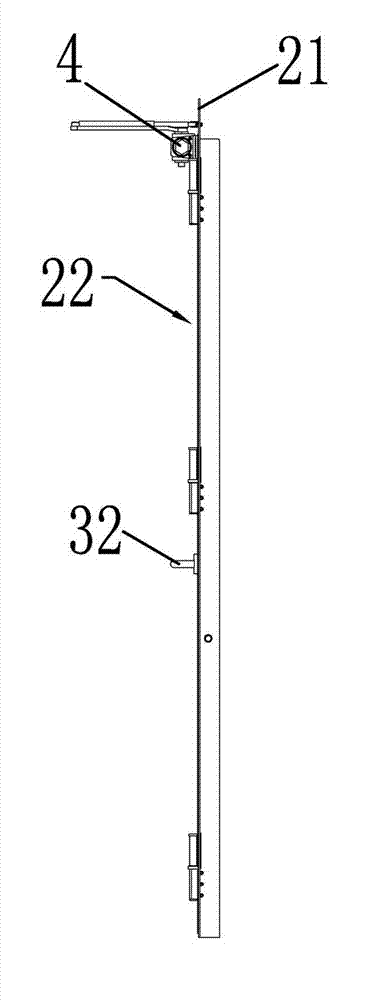

Fireproof hinged door of ship elevator

InactiveCN102785986AImprove sealingOpen efficientlyElevatorsBuilding liftsSash windowMachine control

The invention discloses a fireproof hinged door of a ship elevator, belonging to the field of window sashes, door leafs or similar members capable of being closed and opened. The fireproof hinged door comprises an elevator car door and an elevator shaft door, wherein the elevator shaft door comprises a door frame, a door plate and a door machine control system; the door plate is hinged with the door frame; an opening and closing mechanism is arranged on the door plate; a sealing part is arranged between the door plate and the door frame; the sealing part adopts a fireproof expansion strip; the fireproof expansion strip can be heated for expansion after the fire to seal up a gap between the door plate and the door frame, so that smoke is prevented from entering into a shaft; the door plate is connected with the door frame through an automatic closing device; the elevator shaft door and the elevator car door are provided with a locking mechanism, wherein the locking mechanism comprises a guide mechanism arranged on the elevator car door and is connected with the door machine control system through a transmission line. The hinged door of the ship elevator is fireproof and good in sealing property.

Owner:浙江巨人集团有限公司

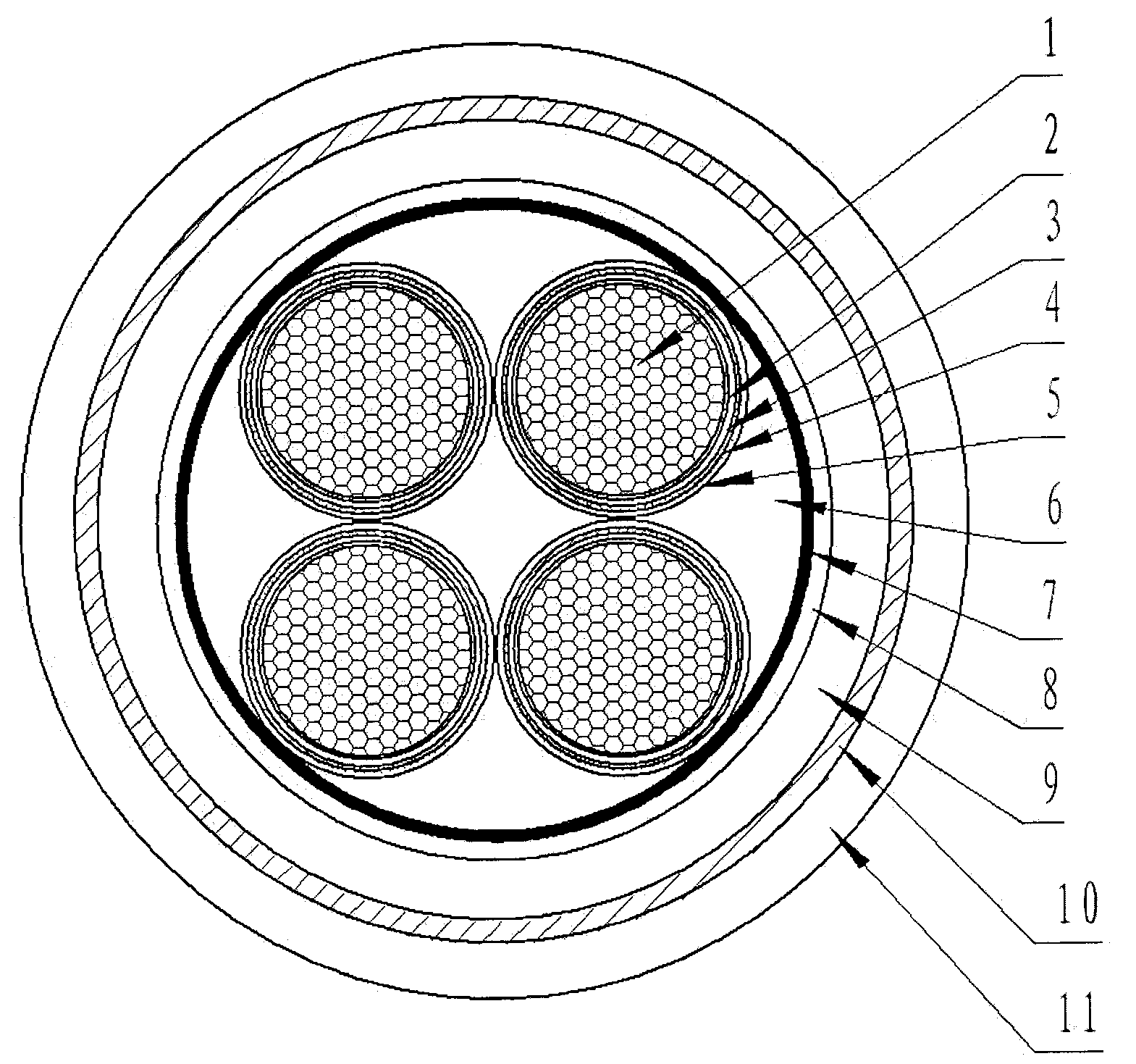

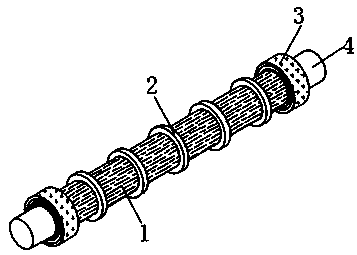

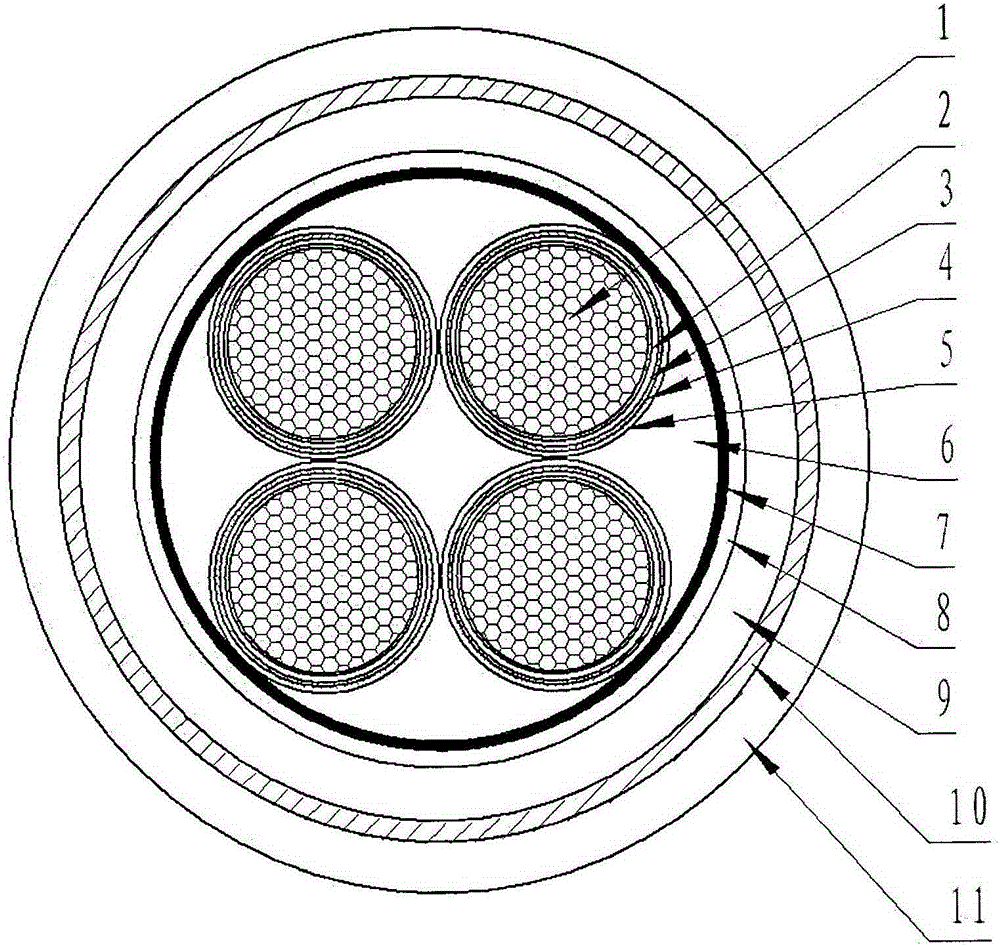

Flame-retardant composite fireproof cable

ActiveCN103646712AImprove fire performanceSmall bending radiusClimate change adaptationInsulated cablesElectrical conductorCopper wire

A flame-retardant composite fireproof cable is characterized by comprising at least two cable cores, wherein each cable core is composed of twisted copper wire conductors each coated with a mica fireproof layer, an insulating damp-proof layer, an aluminum alloy interlocked armor barrier layer and a flame-retardant layer sequentially from inside to outside; the flame-retardant composite fireproof cable is composed of a cabling wrapping belt, an oxygen isolating layer, a ceramic fireproof layer, an interlocked armoring layer and a flame-retardant outer protective layer all of which are sequentially coated outside each cable core from the inside to the outside, and a flame-retardant filling material filled between the cable cores and the cabling wrapping belt.

Owner:JINSHUI CABLE GRP

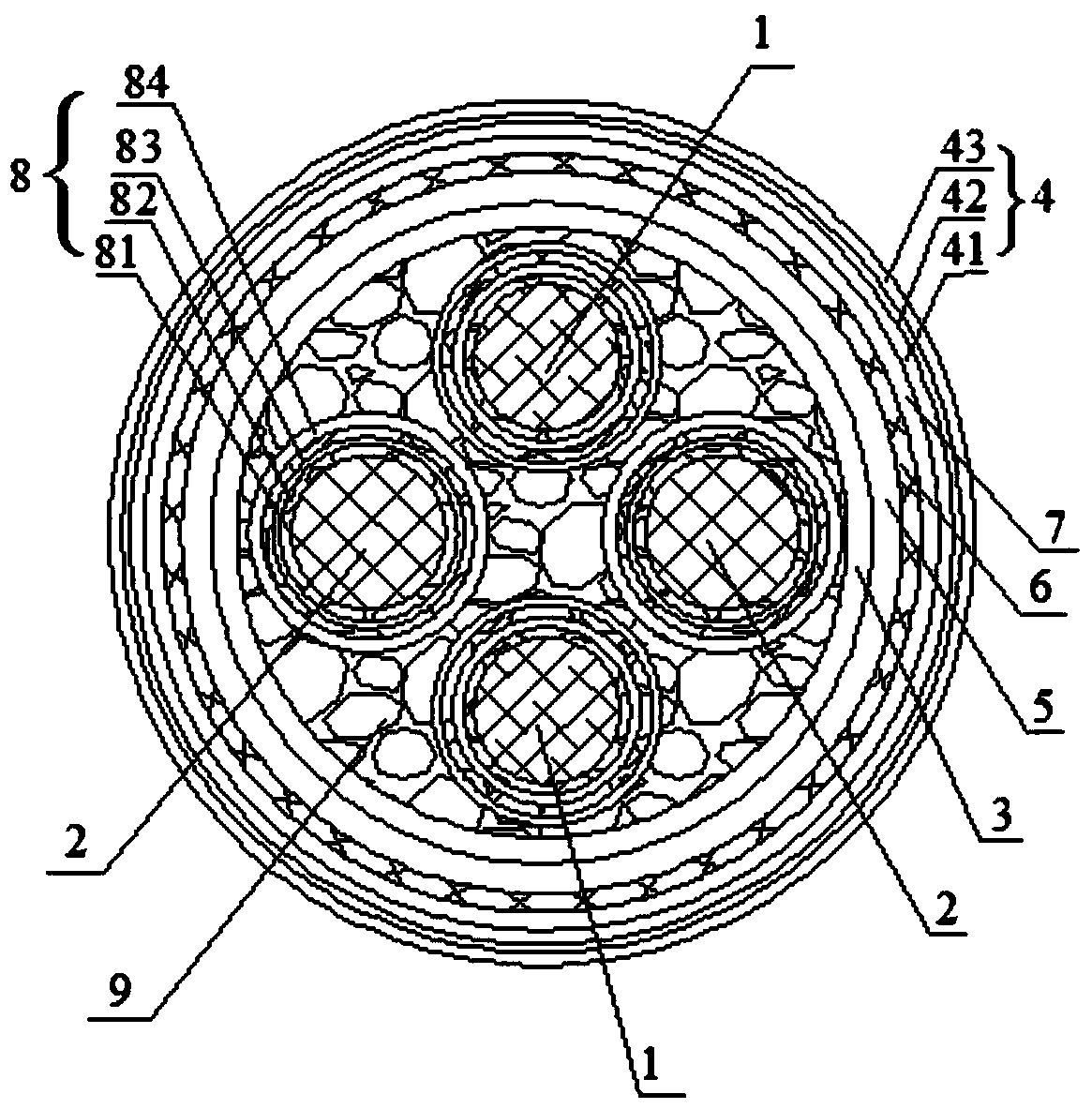

Fireproof ultraviolet-ray-resistant multi-core optical cable

InactiveCN108732701AStable structureImprove fire performanceFibre mechanical structuresFiberUltraviolet

The invention discloses a fireproof ultraviolet-ray-resistant multi-core optical cable which relates to the technical field of fibers and optical cables. The multi-core optical cable comprises two optical cable cores and two carbon fiber composite core rods at the inner part, an outer shielding layer and an outer insulating layer arranged outside. A metal pipe, a fiber sleeve and a metal woven netare arranged between the outer insulating layer and the outer shielding layer. The outer insulating layer comprises a first polytetrafluoroethylene layer, a ceramic silicon rubber layer and high-flame-retardance halogen-free polyethylene layer which are successively arranged from inside to outside. An inner protecting layer is arranged outside the optical fiber cores and the carbon fiber composite core rods. The inner protecting layer comprises a second polytetrafluoroethylene layer, a silicon nitride ceramic layer, an inner shielding layer and a low-flame-retardance halogen-free polyethylenelayer which are successively arranged from inside to outside. An optical cable filler is arranged between the low-flame-retardance halogen-free polyethylene layer and the outer shielding layer. The fireproof ultraviolet-ray-resistant multi-core optical cable has advantages of excellent fireproof performance, excellent flame retardance, excellent ultraviolet ray resistance, stable integral structure and effective service life prolonging.

Owner:安徽唯诗杨信息科技有限公司

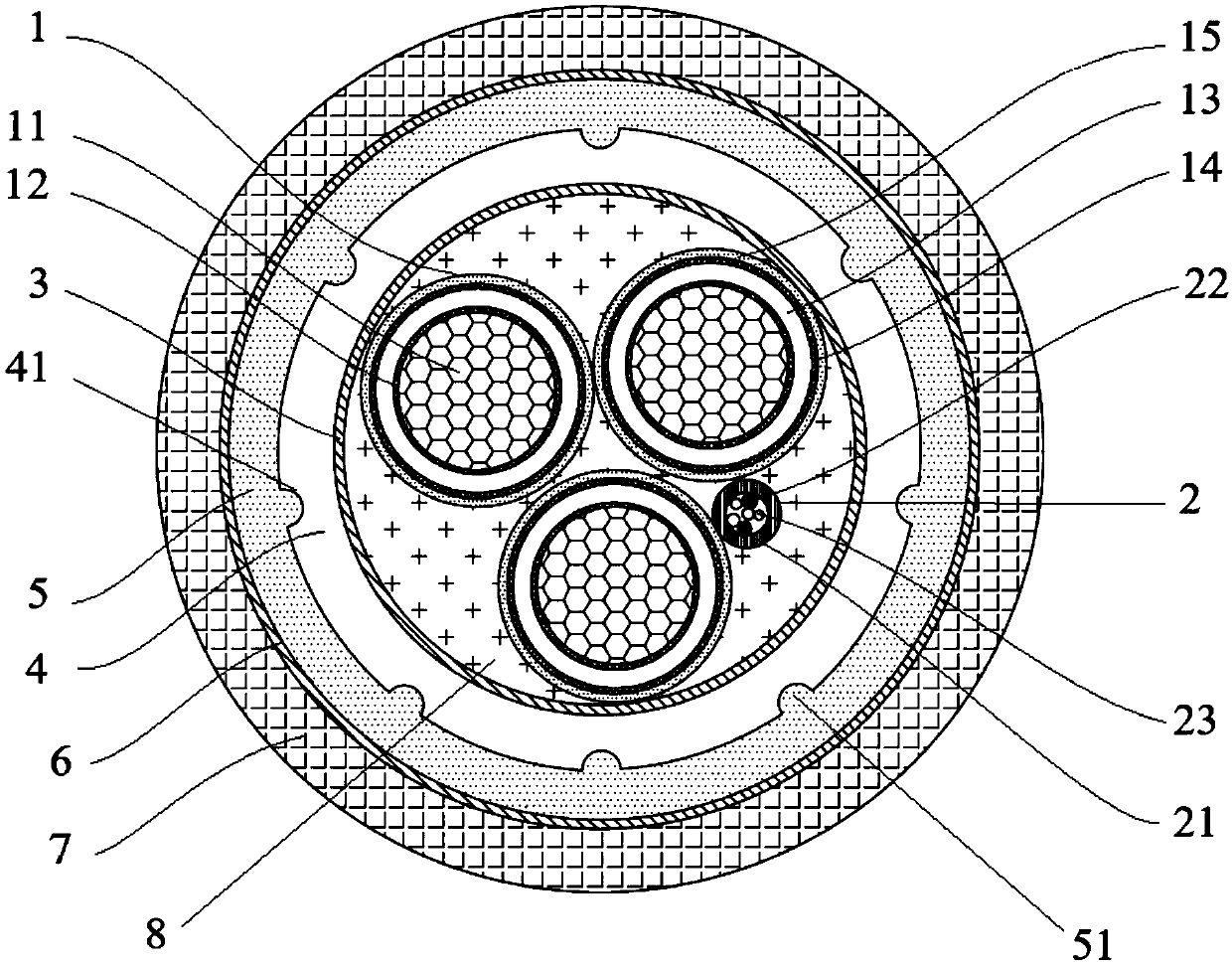

Manufacturing process of medium-voltage fireproof cable for intelligent early warning communication

InactiveCN109524172APlay a role in communicationEnsure normal communicationInsulating conductors/cablesCopper conductorElectric power transmission

The invention discloses a manufacturing process of a medium-voltage fireproof cable for intelligent early warning communication. The medium-voltage fireproof cable for intelligent early warning communication comprises a power transmission unit and an optical transmission unit, and the power transmission unit is formed by a copper conductor, a conductor shielding layer, an insulating layer and an insulating shielding layer which coats the outer surface of the copper conductor from inside to outside, and a metal shielding layer coating the outer surface of the insulating shielding layer. The power transmission unit and the optical transmission unit are wrapped by a wrapping tape to form a first winding layer, the outer surface of the first winding layer is coated with an oxygen barrier layer, and the outer surface of the oxygen barrier layer is coated with a refractory layer. The outer surface of the refractory layer is coated with a second winding layer, and an outer sheath is extrudedon the outer surface of the second winding layer. The prepared cable has good heat insulation and flame retardant performance and is used for a distributed optical fiber temperature measuring system to achieve the purpose of timely detecting a disaster and emitting an early warning in the early stage of fire, and a time guarantee is provided for escape and disaster relief.

Owner:JIANGSU HENGTONG POWER CABLE

Fireproof and flame-retardant material

InactiveCN105368110AGood heat insulation and fire performanceNo cracking and no falling offFireproof paintsEpoxyMethacrylate

The invention discloses a fireproof and flame-retardant material. The fireproof and flame-retardant material is prepared from raw materials in parts by mass as follows: 12-18 parts of polybutylene terephthalate, 55-65 parts of epoxy resin, 11-18 parts of hydroxyethyl cellulose, 15-17 parts of asbestos powder, 8-14 parts of calcium carbonate, 6-10 parts of perlite, 12-18 parts of dimethylacetamide, 6-9 parts of ethyl acetate, 5-7 parts of aluminium hydroxide, 9-13 parts of an acrylic emulsion and 8-10 parts of stearic methacrylate. The fireproof and flame-retardant material is good in heat insulating and fireproof performance, capable of avoiding cracking and falling off, high-temperature-resistant, economical and environment-friendly.

Owner:QINGDAO MAIKE 3D HI TECH CO LTD

Heat-insulating and fire-proofing material

InactiveCN1422933ANo crackingGood heat insulation and fire performanceFireproof paintsPolymer scienceFoaming agent

The invention refers to an adiabatic fireproof material prepared by high-aluminium cement and foaming agent and the preparing method. Its components: cement base 350-600 kg / m, foaming agent, 0.1-20 kg / m to the power 3, additive 50-250 kg / m to the power 3, the cement base being high-aluminium cement, the foaming agent composed of foam initiating agent and foam stabilizing agent. The method: before or after stirring the mixture of high-aluminium cement and additive by water, inject the foamed solution into the water, mix evenly, and make hardening reaction to prepare the material.

Owner:韩玉春

Fire-proof composite board core material and preparation method

InactiveCN108395200ALow solid state heat transferReduce fireCeramic shaping apparatusFiberFire protection

The invention discloses a fire-proof composite board core material. Powder of the fire-proof composite board core material comprises a base material and mixing liquid. The base material is prepared from aluminium silicate fibers, magnesium hydrate, mineral cotton, silicon dioxide, expanded vermiculite, silicon carbide and nano-reinforced fibers. The mixing liquid is ZRY fiber flame-retardant liquid. The nano-reinforced fibers comprise nano aluminium oxide powder and flame-retardant fibers or fire-proof fibers covered by the nano aluminium oxide powder. A core board is rational in formula design, the synergistic effect is achieved between components, the core board prepared by the formula of the preparation method has low solid heat conduction, and fire protection and flame retarding effects, and the effect is apparently superior to the prior art.

Owner:JIANGSU ALUMEIGE NEW MATERIALS

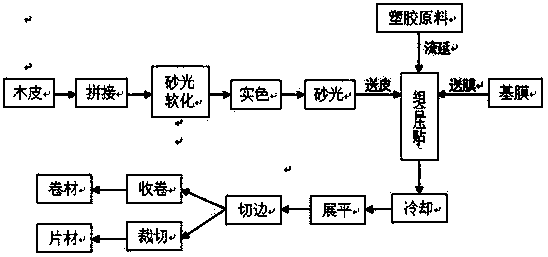

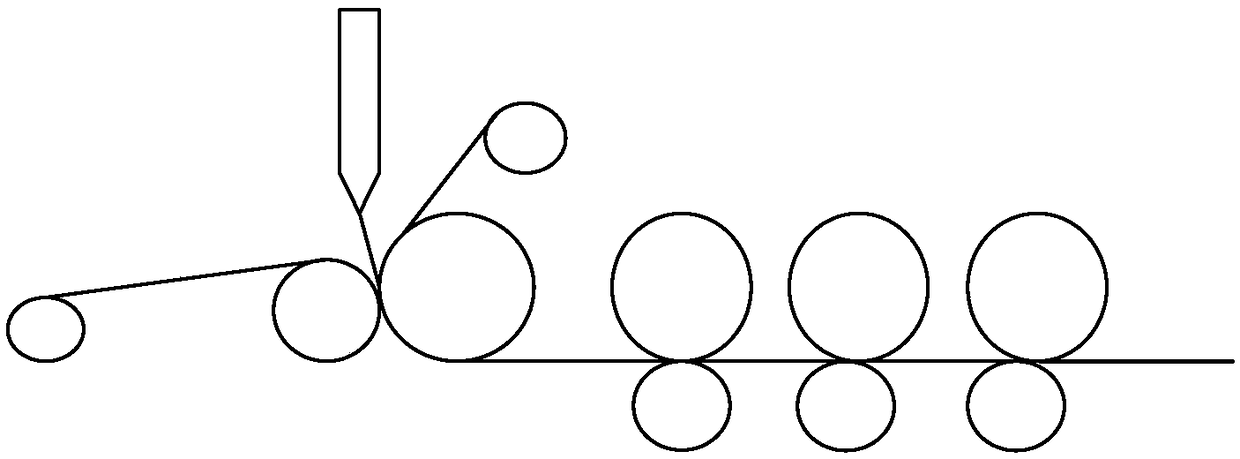

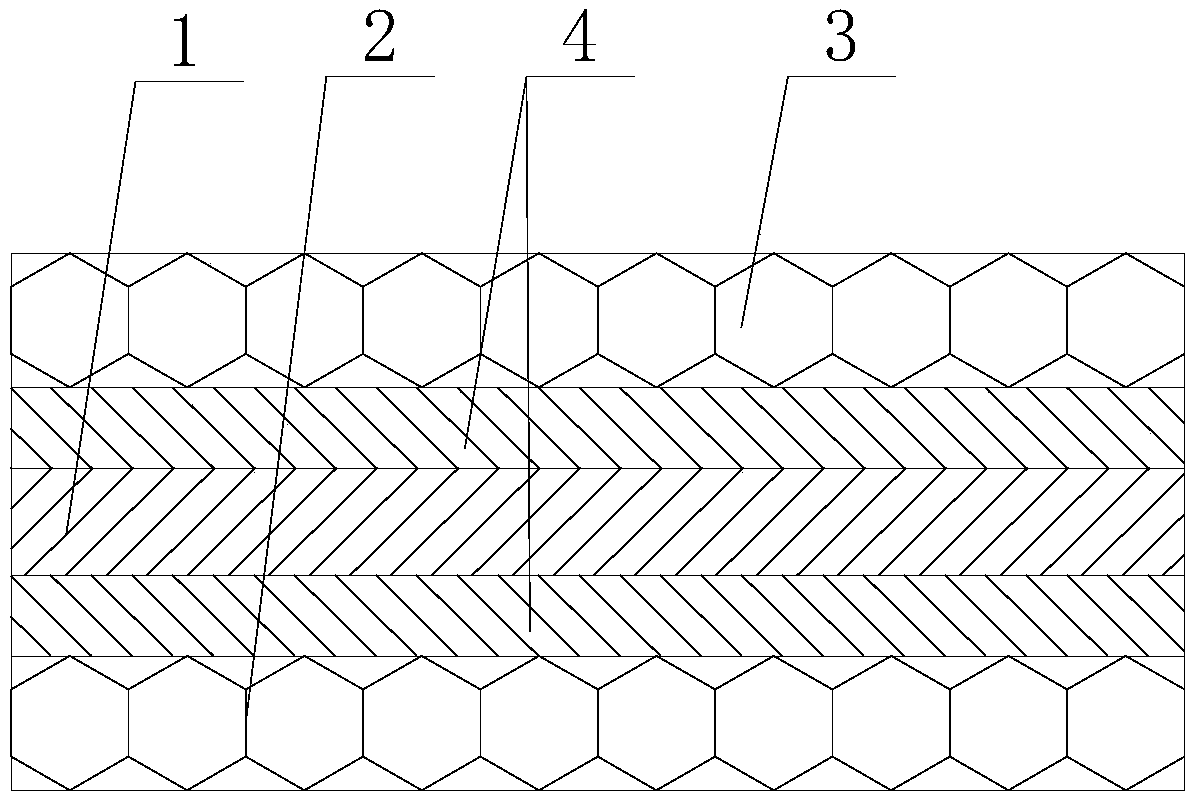

Integral forming processing technology for pressing and laminating veneers through film spraying and calendering process

ActiveCN109130442AIncrease profitImprove work efficiencyLaminationLamination apparatusWinding machineEngineering

The invention discloses an integral forming processing technology for pressing and laminating veneers through a film spraying and calendering process. According to the technical scheme, the technologyis characterized by including the following steps of a, splicing skin, wherein the veneers are longitudinally or transversely seamlessly spliced into a sheet, the maximum width of the veneers is ensured, the surfaces of the veneers are decorated with transparent patterns, filling is conducted through the color the same as that of the wood patterns, and it is ensured that the thin veneers are unified in overall appearance, free of solid color abnormity, transparent and the like; b, conducting extruding and curtain coating, wherein one or more of plastic raw materials with different performanceare mixed and put into a material hopper of an extruder, extruding and curtain coating are conducted on a film spraying machine through heating, mixing, plasticizing and extruding to form a film, andthe thin film is adjusted to have the required thickness and bias; c, conducting film spraying and laminating, the spliced veneers and the high-temperature-resistant base film are introduced into a laminating roller group on the adjusted curtain coating film for multi-roller-group pressing; d, conducting cooling forming, wherein the laminated veneers are cooled, trimmed and then wound into a coiled material through a winding machine.

Owner:上海诚简环保科技有限公司

Fireproof flame-retardant material

InactiveCN109423007AGood heat insulation and fire performanceNo cracking and no falling offEpoxyEthyl acetate

The invention discloses a fireproof flame-retardant material. The fireproof flame-retardant material is prepared from the following raw materials: in parts by mass, 40-50 parts of polybutylene terephthalate, 110-130 parts of epoxy resin, 30-40 of hydroxyethyl cellulose, 12-20 parts of asbestos powder, 30-40 parts of calcium carbonate, 6-8 parts of perlite, 5-10 parts of dimethylacetamide, 4-6 parts of ethyl acetate, 6-8 parts of magnesium hydroxide, 25-35 parts of acrylic acid emulsion and 20-30 parts of stearyl methacrylate. The fireproof flame-retardant material has good heat insulation andfire resistance, no cracking, no falling off and high temperature resistance, and is economical and environmentally friendly.

Owner:张云

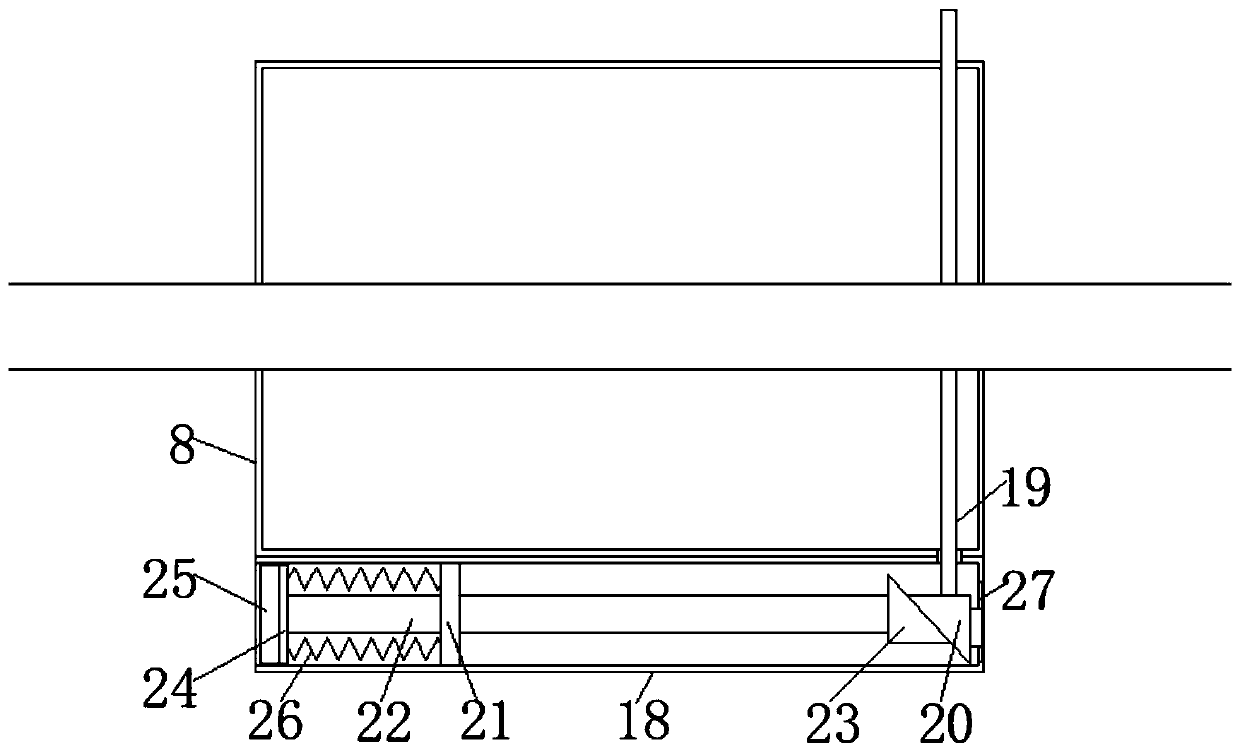

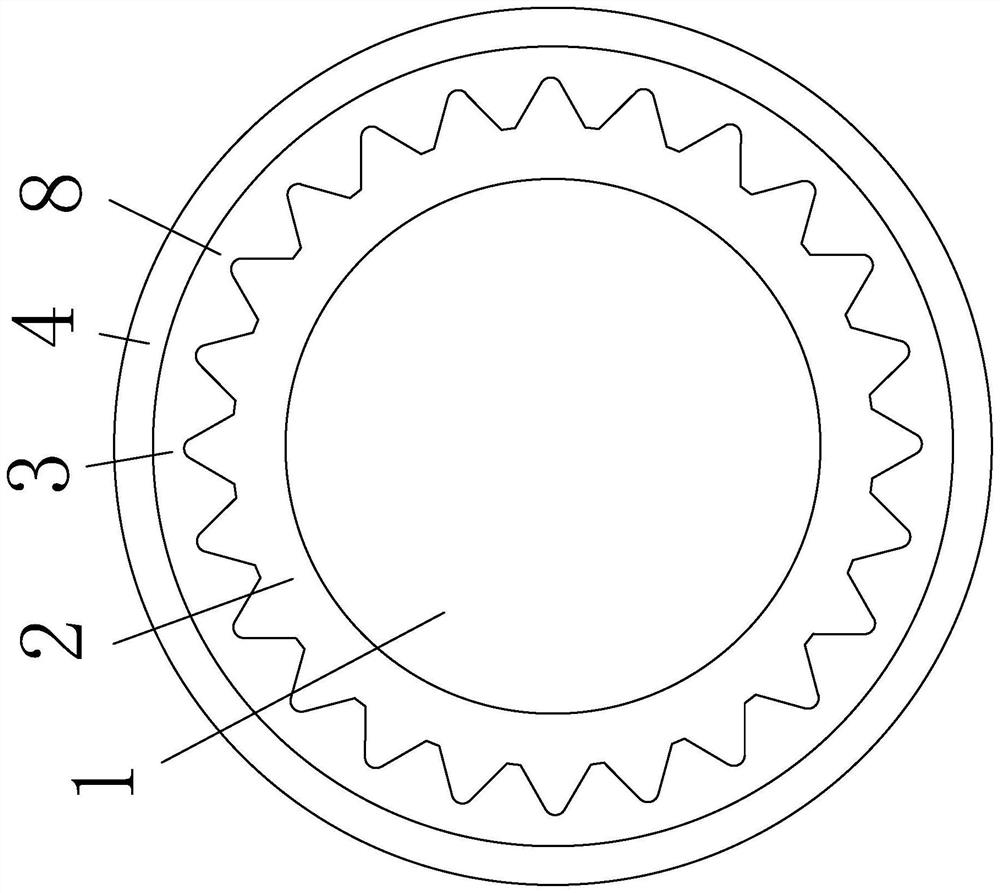

Steel heat isolation seal fireproof door

InactiveCN110894771AEasy to open and closeAvoid the problem of being stuck and unable to moveFireproof doorsPower-operated mechanismGear wheelTransmission belt

The invention relates to the technical field of building materials, and discloses a steel heat isolation seal fireproof door. A ground and a wall are included. The wall is fixedly connected to the upper surface of the ground. An installing groove is formed in the upper surface of the ground. The bottom wall in the installing groove is fixedly connected with a drive motor. The output end of the drive motor is fixedly connected with a threaded rotation shaft. When a user uses the device and the steel heat isolation seal fireproof door moves left and right, the rotation shaft drives a rotation rod to rotate through a driving bevel gear and a driven bevel gear, the rotation rod drives a transmission belt to move through a transmission wheel, the transmission belt drives a leather sheath to move, the leather sheath synchronously moves along with the steel heat isolation fireproof door, and the situation that when the steel heat isolation fireproof door moves left and right, the leather sheath is torn damaged is avoided; and through the arranged leather sheath, the problem that dust or sundries in air fall into the installing groove, and consequently the steel heat isolation fireproof door is stuck and cannot move is solved, and accordingly the service life of the device is prolonged.

Owner:JIANGSU YAYA ANTITHEFT DOORS

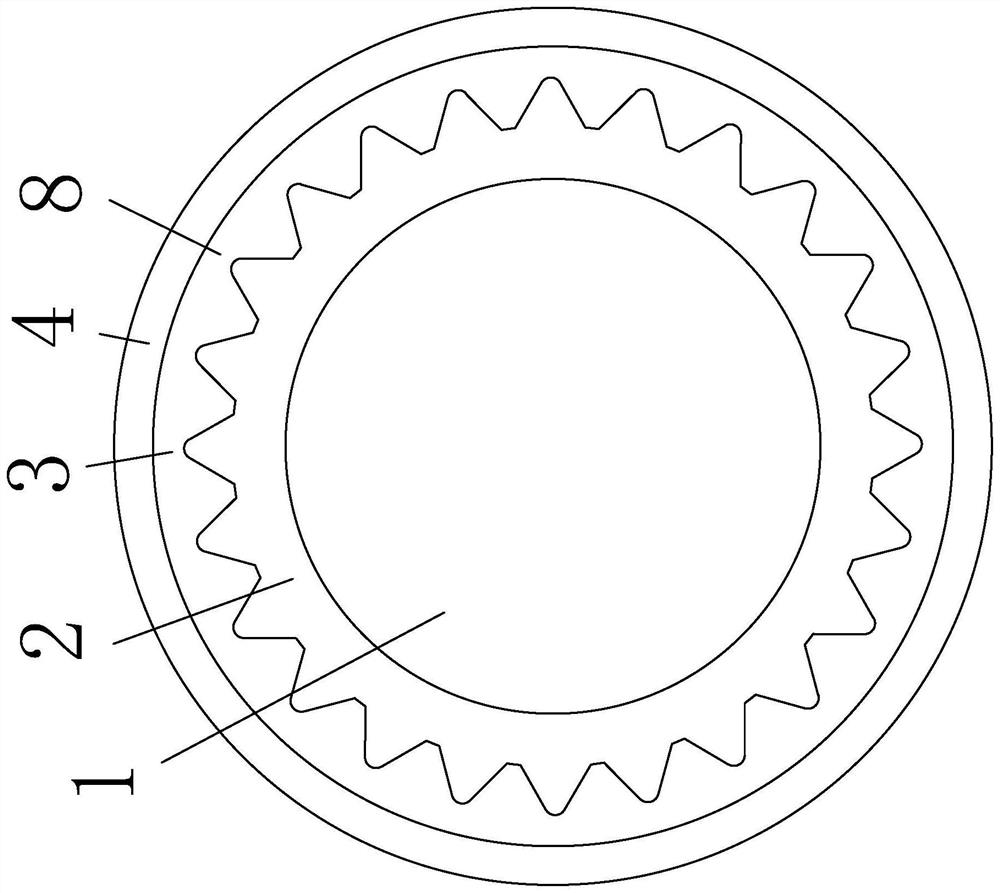

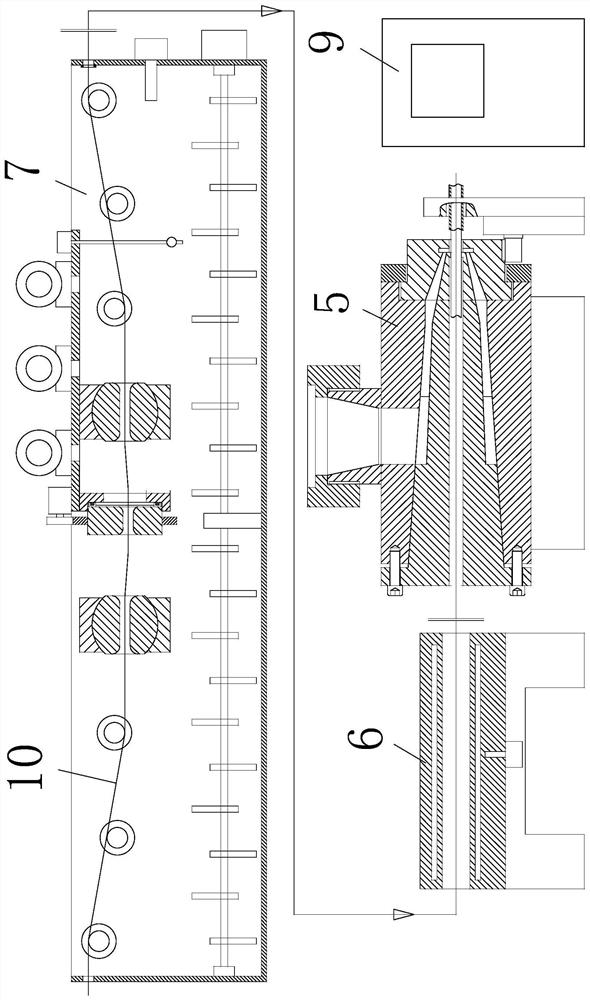

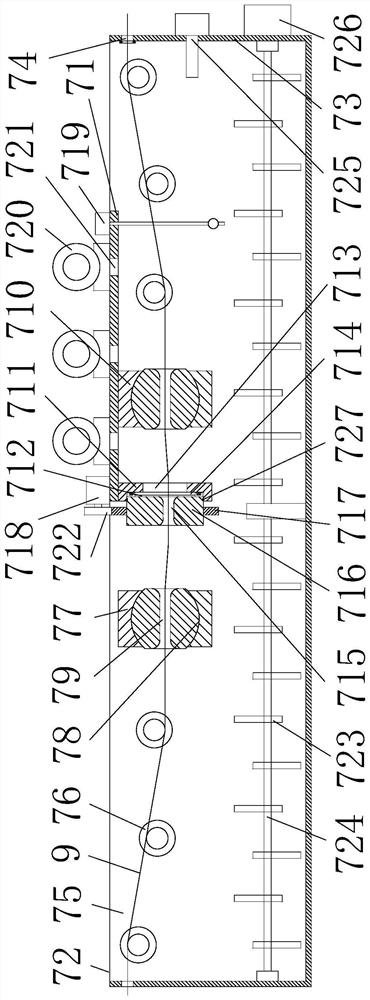

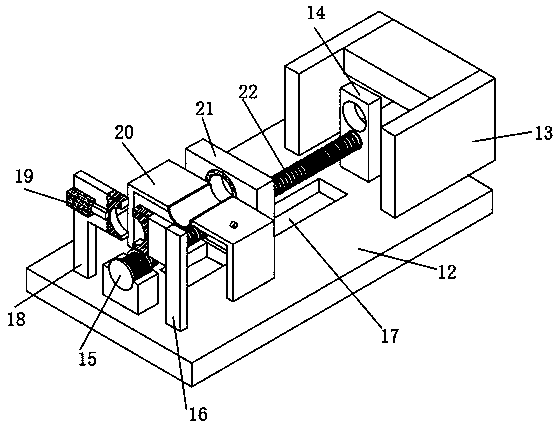

Cotton covered wire with flame-retardant protective outer layer and flame-retardant protective outer layer manufacturing device

ActiveCN113362993ALess likely to cause damageGood weather resistanceClimate change adaptationInsulated cablesElectrical conductorElectric wire

The invention relates to a cotton covered wire with a flame-retardant protective outer layer. The cotton covered wire comprises a conductor, an insulating layer and the flame-retardant protective outer layer, wherein the insulating layer wraps the conductor, and twenty to thirty convex teeth distributed along the circumference are arranged in the outer side of the insulating layer in a surrounding manner; and the flame-retardant protective outer layer comprises a fireproof coating coated outside the insulating layer and an outer protective layer coated outside the fireproof coating. A related flame-retardant protective outer layer manufacturing device for the cotton covered wire with the flame-retardant protective outer layer comprises a controller, and an outer protective layer coating device, a heating and drying device and a fireproof coating dip-coating device which are sequentially arranged from front to back. The cotton covered wire with the flame-retardant protective outer layer is high in flame-retardant and fireproof performance, and insulation damage is not prone to being caused in the installation and construction process.

Owner:浙江万马股份有限公司

A kind of phenolic resin/silica composite aerogel material and preparation method thereof

ActiveCN106189066BGood heat insulation and fire performanceEasy to operateBulk chemical productionThermal insulationPhenol Compound

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

Fireproof flame-retardant material

InactiveCN109423080AGood heat insulation and fire performanceNo cracking and no falling offFireproof paintsEmulsionPerlite

The invention discloses a fireproof flame-retardant material. The material is prepared from, by mass, the following raw materials: 20-30 parts of polybutylene terephthalate, 80-100 parts of epoxy resin, 20-24 parts of hydroxyethyl cellulose, 6-10 parts of asbestos powder, 16-20 parts of calcium carbonate, 1-5 parts of perlite, 5-10 parts of dimethylacetamide, 1-5 parts of ethyl acetate, 2-4 partsof magnesium hydroxide, 15-20 parts of an acrylic emulsion, and 12-16 parts of octadecyl methacrylate. The material has the characteristics of good heat insulation and fire resistance, no cracking andno falling off, high temperature resistance, economy and environmental protection.

Owner:姜泓

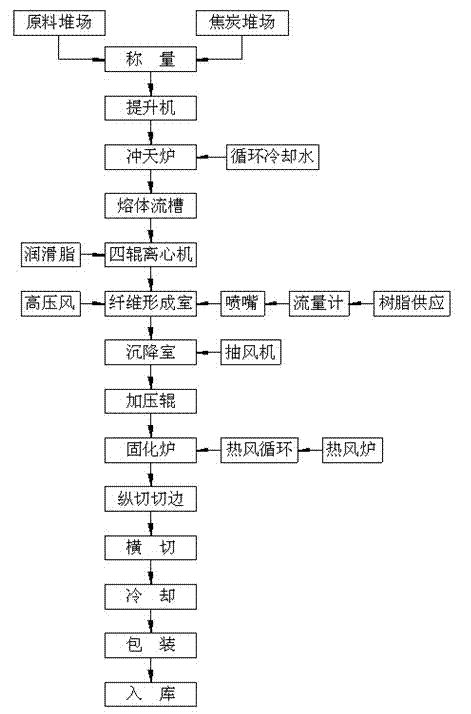

Production method for basalt fiber materials

ActiveCN102329080BImprove mechanical propertiesGood heat insulation and fire performanceGlass making apparatusNatural resourceBasalt fiber

The invention discloses a production method for basalt fiber materials, which comprises the following steps of: 1) mixing raw materials: mixing raw basalt ores, limestone and coke to obtain mixed raw materials; 2) heating for melting: heating for melting the mixed raw materials obtained in the step 1) to obtain melted liquid; and 3) drawing and producing fibers: introducing the melted liquid obtained in the step 2) into a centrifugal machine, drawing and producing cotton-like fibers. By using the basalt ores as main raw materials and in combination with other fillers, the natural resources are reasonably utilized, the production process is pollution-free, the produced fiber materials have excellent mechanical properties and good heat insulating and fireproof performances; and moreover, the compression strength of the produced fiber boards which are physically and deeply processed and are chemically modified is high, the fire rating is A1, the coefficient of heat conductivity is small,the melting temperature is high, the hydrophobic nature is great, the acidity coefficient is large, and the produced fiber boards can be used as energy-saving, heat-preserving and heat-insulating fireproof materials for buildings and sound-insulating shielding materials for high-speed railways, expressways, airports and the like.

Owner:CHONGQING ZAISHENG TECH CORP

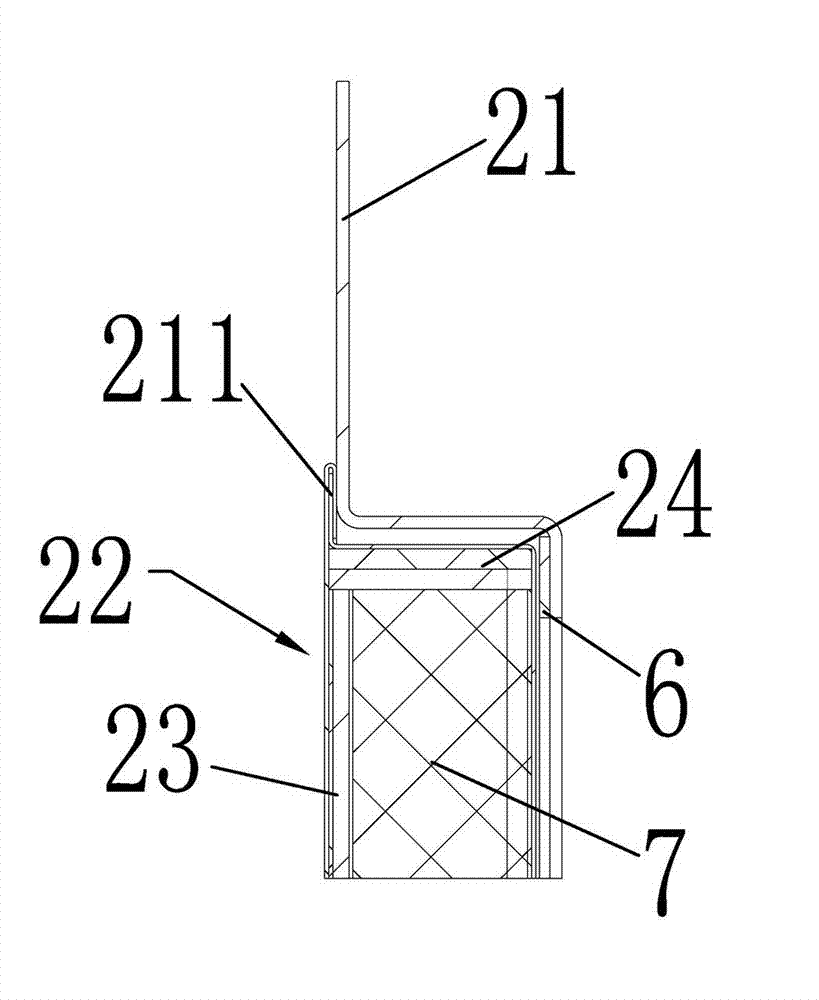

Composite Metal Insulation Vacuum Panel

PendingCN106065672AGood pressure resistanceExcellent airtight performanceHeat proofingFire proofingEngineeringRefrigerated temperature

The invention provides a composite metal thermal insulation vacuum panel, the vacuum panel includes a face plate, a connecting plate, a sealing layer and a vacuum cavity; the connecting plate connects two panels together, and the sealing layer is arranged in the connecting plate, A vacuum chamber is formed inside the two panels, and a support is also arranged in the vacuum chamber. The vacuum panel proposed by the present invention not only has good compression resistance and impact resistance, but also has superior airtight performance, good heat insulation and fire prevention effect, can be used as external wall insulation material, and can also be used for refrigerators, freezers, refrigerated carriages and heat preservation Production of boxes, etc.

Owner:贾飞涛

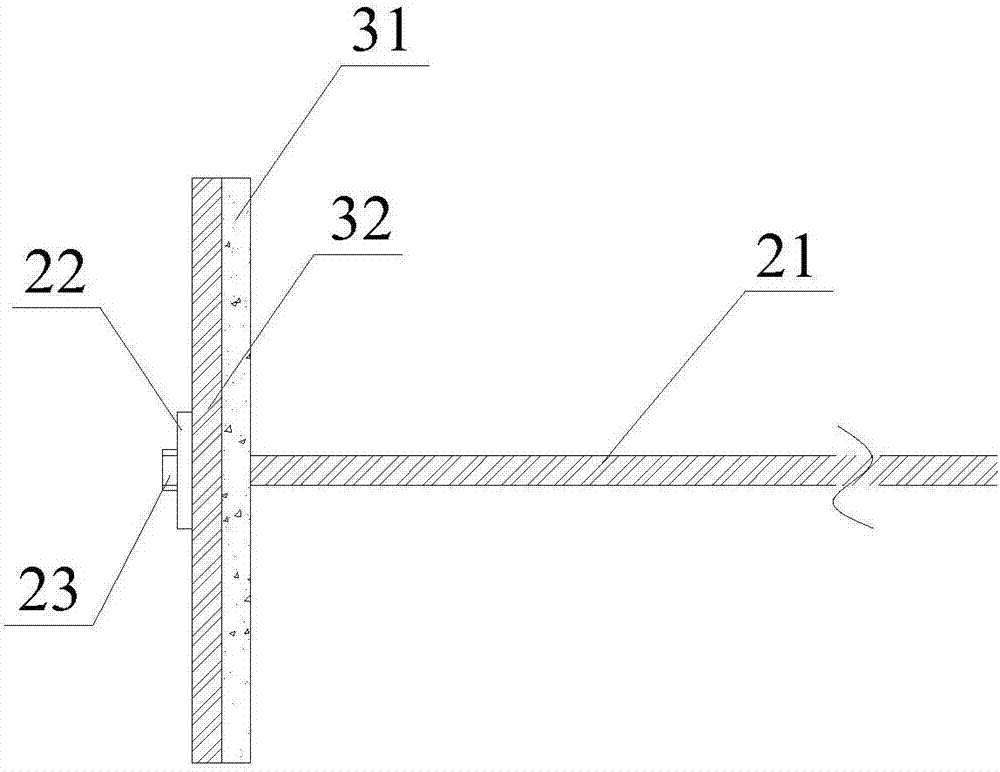

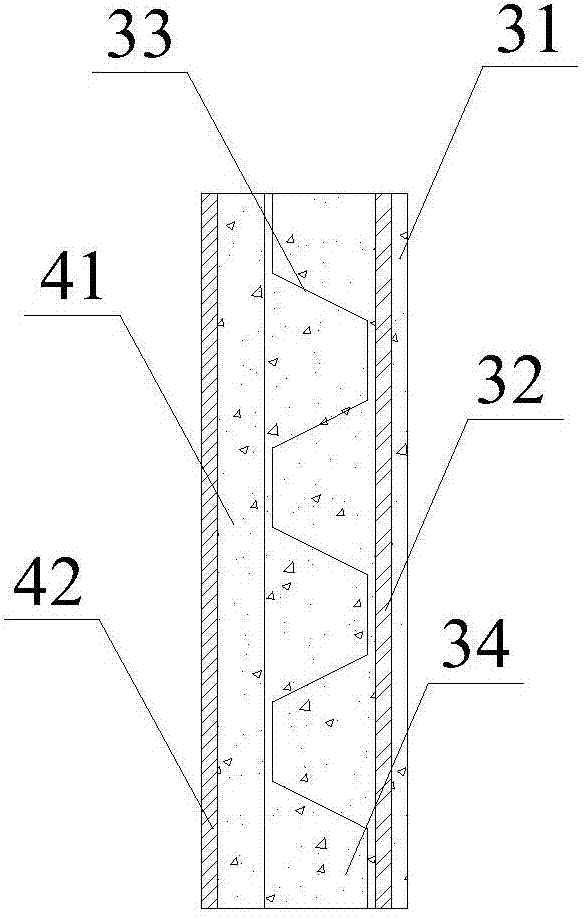

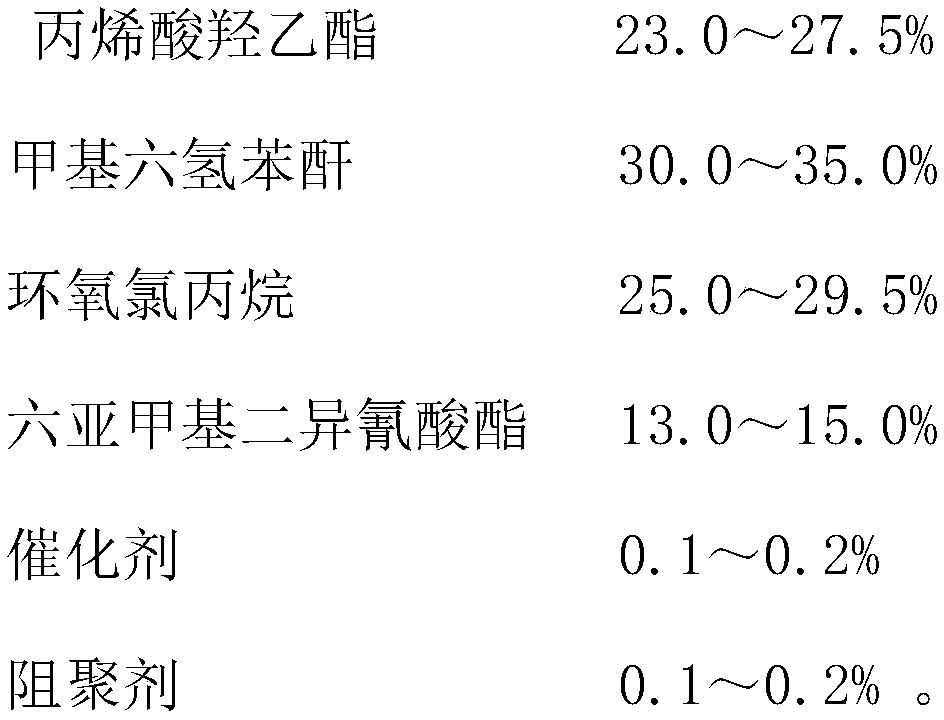

Polymer-filled light material, and method for manufacturing partition wall by using same

The invention discloses a polymer filled light material, and a method for manufacturing a partition wall by using the same. The polymer filled light material is formed by mixing a polyphenyl polymethylene polyisocyanate mixture and polyether polyurethane, the whole wall can be completely filled with the polymer filled light material, and the polymer filled light material has better functional effects of heat insulation, fire prevention, heat preservation, noise prevention, moisture prevention, water prevention and the like; and the manufacturing method of the polymer filled light partition wall is achieved through the steps of basal plane cleaning, positioning, light plate mounting, pre-buried hole pipeline mounting, grouting nozzle mounting, burdening, grouting, filling material reactionfoaming and nozzle dismounting, a complete dry operation mode is adopted, assembly type construction is adopted, and wallboards can be cut at will to adjust the width and the length.

Owner:四川童燊防水工程有限公司

Manufacturing process of novel imitation wood heat insulation broken bridge wall body

InactiveCN102108745BGood heat insulation and fire performanceGood sound insulation and shockproof effectWallsHeat proofingPolyesterFoaming agent

The invention relates to a manufacturing process of a common wall body construction member for a building and discloses a manufacturing process of a novel imitation wood heat insulation broken bridge wall body construction member, which comprises the following steps: taking a metal rod, extruding into a metal profile with a dovetail groove, using a strip penetrating machine to respectively penetrate two heat insulation strips into the dovetail groove for being pressed into a metal housing with an inner mold cavity, further arranging load-bearing supports with metal pipelines into the inner mold cavity of the metal housing, enabling the two load-bearing supports with through holes to be just hermetically arranged at two side ends of the inner mold cavity, enabling the load-bearing support with a drainage hole and the through hole to be arranged at the middle of the inner mold cavity, opening an injection hole on the metal housing, injecting a flame retardant polyester foaming agent into the injection hole, and further sealing the injection hole after the inner mold cavity of the metal housing is filled with the flame retardant polyester foaming agent which is filled through a diversion hole of the load-bearing support. According to the technical scheme of the invention, the fireproof performance is good, the effects of sound insulation and shock resistance are good, and the combined strength is high, thereby having great advantages.

Owner:黄尚进

Fireproof isolation bandage

InactiveCN110978677AEasy constructionNo site requirementsSynthetic resin layered productsGlass/slag layered productsFiberGlass fiber

The invention discloses a fireproof isolation bandage, and belongs to the technical field of power construction safety. The fireproof isolation bandage comprises a bandage body. The bondage body is wound around the surface of a cable. Two ends of the bondage body are fixedly connected to a three-layer reinforcing patch. Five self-lock stainless steel ribbons are fixedly connected to the surface ofthe bondage body at equal intervals. The bondage body is a flexible fireproof bandage. The reinforcing patch is a 75 DEG C irreversible temperature measuring patch. The external side of the flexiblefireproof bandage is fixedly connected to MM Kevlar bulletproof fiber cloth. The flexible fireproof bandage comprises following components from inner to outer: glass fiber decorative cloth (A), aluminum silicate fireproof cloth (A), an aluminum silicate fiber blanket, aluminum silicate fireproof cloth (B), glass fiber decorative cloth (B), and high-viscosity high temperature resistant acrylic glue, which is fixedly connected to the Kevlar bulletproof fiber cloth. The problems that in the prior art, a cable bandage does not have a fireproof function, and the winding mode of a bandage can influence the protection efficiency of the bandage are solved.

Owner:王耀东

Fireproof and heat-insulation building material

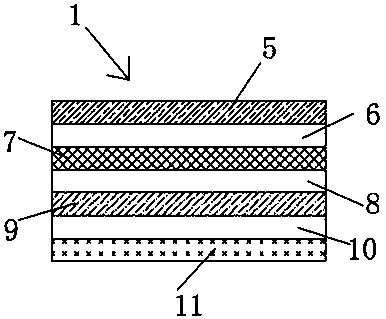

InactiveCN110512756ASimple structureGood heat insulation and fire performanceLayered productsFire proofingInsulation layerHoneycomb structure

The invention relates to a fireproof and heat-insulation building material, which comprises a base layer, a first fireproof layer, a second fireproof layer and heat-insulation layers. The first fireproof layer and the second fireproof layer are both honeycomb structure layers, and fireproof glue is coated on each surface of the honeycomb structure layers; the heat-insulation layers are arranged onthe upper surface and the lower surface of the base layer correspondingly; the first fireproof layer and the second fireproof layer are arranged on the outer sides of the heat-insulation layers correspondingly; and the base layer, the first fireproof layer, the second fireproof layer and the heat-insulation layers are bonded in a solidified mode through bonding agents. The fireproof and heat-insulation building material is simple in structure, and has good heat-insulation and fireproof performance, fire potential safety hazards can be completely eradicated effectively, and the safety performance of a building is guaranteed.

Owner:成都德优装饰工程有限公司

Distributed wire with flame retardant protective outer layer and production device for flame retardant protective outer layer

ActiveCN113362993BLess likely to cause damageGood weather resistanceClimate change adaptationInsulated cablesElectrical conductorDip-coating

The invention relates to a wiring wire with a flame-retardant protective outer layer. The flame retardant protective outer layer includes: a fire retardant coating coated on the insulating layer, and an outer sheath coated on the outside of the fire retardant coating. It relates to a flame retardant and protective outer layer manufacturing device for the above-mentioned cloth wire with a flame retardant protective outer layer, comprising: a controller, an outer sheath coating device arranged in sequence from front to back, a heating and drying device, a fireproof coating Layer dip coating device. The cloth wire with the flame-retardant protective outer layer has good flame-retardant and fire-proof performance, and is not easy to cause insulation damage during installation and construction.

Owner:浙江万马股份有限公司

An electromechanical heat insulation and fire protection device

ActiveCN107270042BPrevent incomingFully absorbedMachine framesThermal insulationThermal breakThermal insulation

Disclosed is a novel electromechanical thermal insulation and fire prevention protective device. The novel electromechanical thermal insulation and fire prevention protective device comprises a protective shell, a mounting frame, buffering frames and a protective device. The protective shell is fixedly installed on the surface of the mounting frame. The protective device comprises a thermal insulation device and a fire prevention device, wherein the thermal insulation device is arranged inside the protective shell, and the fire prevention device is arranged outside the protective shell. The fire prevention device comprises a fire prevention layer and a thermal insulation layer. The fire prevention layer comprises a fire prevention plate and an aluminum alloy plate, wherein the fire prevention plate and the aluminum alloy plate are connected together through flame retardance strips in the mode that the flame retardance strips penetrate through the fire prevention plate and the aluminum alloy plate. The thermal insulation layer is uniformly arranged on the surface of the fire prevention layer. The thermal insulation device comprises radiating pipes and cooling fins. Each buffering frame comprises a spring rod and a soft gasket, wherein each spring rod and the corresponding soft gasket are connected together through a connecting plate. The mounting frame is arranged at the bottom end of the protective shell. The novel electromechanical thermal insulation and fire prevention protective device can achieve the good thermal insulation and fire prevention capacity, can also conduct sufficient thermal dissipation and buffering protection on an electromechanical machine, prolongs the service life, is convenient to install and deserves promotion.

Owner:ANHUI SHENGMEI METAL TECH CO LTD

Nano-composite photovoltaic material and preparation process thereof

InactiveCN107868368AImprove wear resistanceImprove flame retardant performanceGlass fiberNano silicon

The invention discloses a nano-composite photovoltaic material and a preparation process thereof. The photovoltaic material is prepared from the components in parts by weight: 10 to 20 parts of PVC (Polyvinyl Chloride) resin, 8 to 20 parts of modified phenolic resin, 4 to 12 parts of nanometer silica, 3 to 9 parts of nano-silicon micro powder, 8 to 20 parts of silane coupling agent, 4 to 12 partsof fire retardant, 5 to 10 parts of glass fiber, and 2 to 8 parts of nano-zinc oxide. The preparation process provided by the invention is simple in process, the prepared photovoltaic material has excellent shock resistance, wear resistance and fire retardance, and the service life of the photovoltaic material is effectively prolonged.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

A flame retardant composite fireproof cable

ActiveCN103646712BImprove fire performanceSmall bending radiusClimate change adaptationInsulated cablesElectrical conductorCopper wire

A flame-retardant composite fireproof cable is characterized by comprising at least two cable cores, wherein each cable core is composed of twisted copper wire conductors each coated with a mica fireproof layer, an insulating damp-proof layer, an aluminum alloy interlocked armor barrier layer and a flame-retardant layer sequentially from inside to outside; the flame-retardant composite fireproof cable is composed of a cabling wrapping belt, an oxygen isolating layer, a ceramic fireproof layer, an interlocked armoring layer and a flame-retardant outer protective layer all of which are sequentially coated outside each cable core from the inside to the outside, and a flame-retardant filling material filled between the cable cores and the cabling wrapping belt.

Owner:JINSHUI CABLE GRP

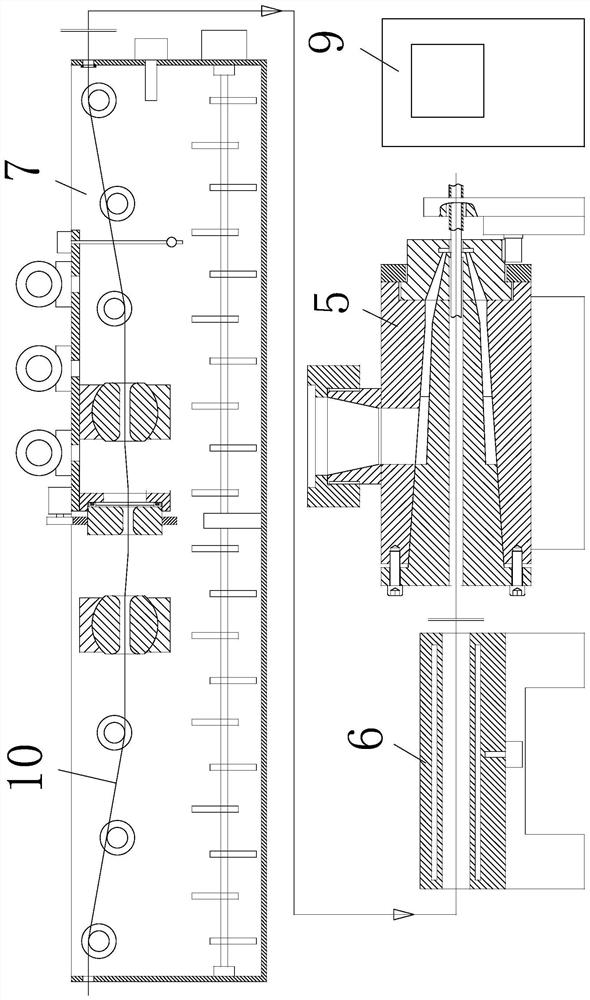

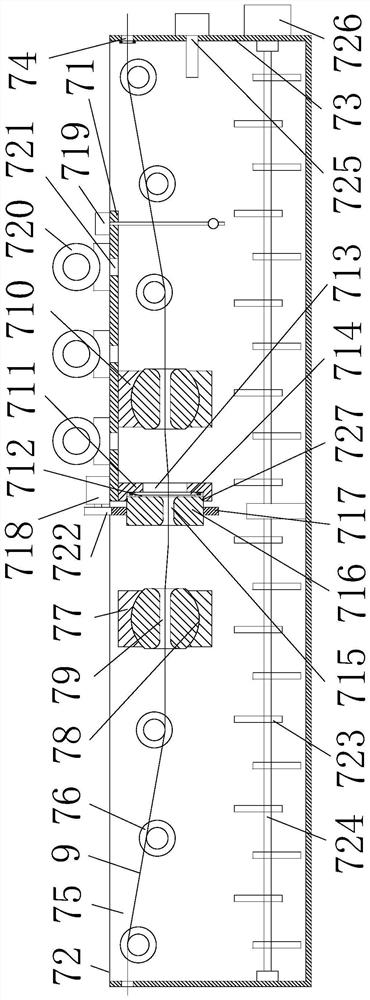

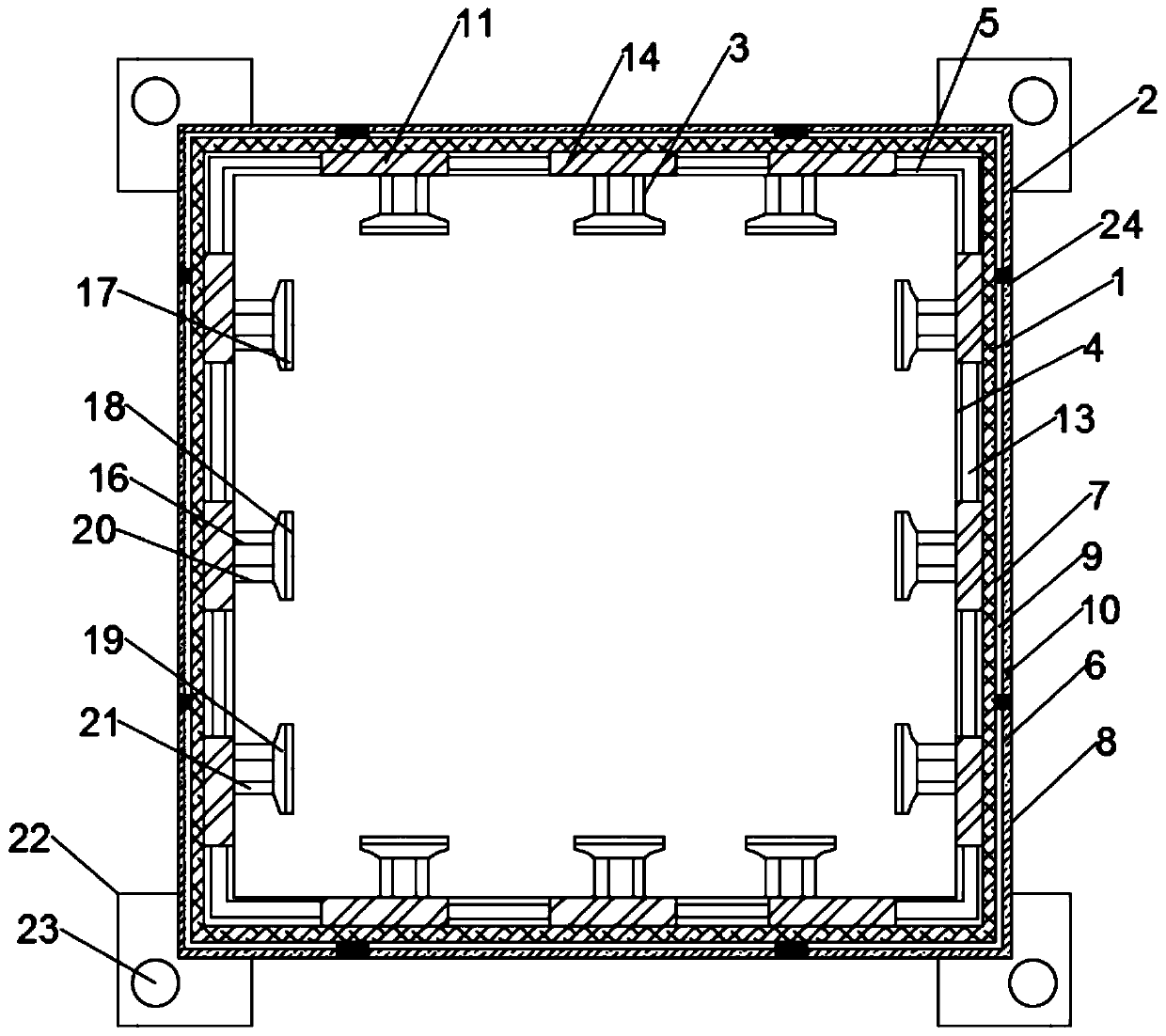

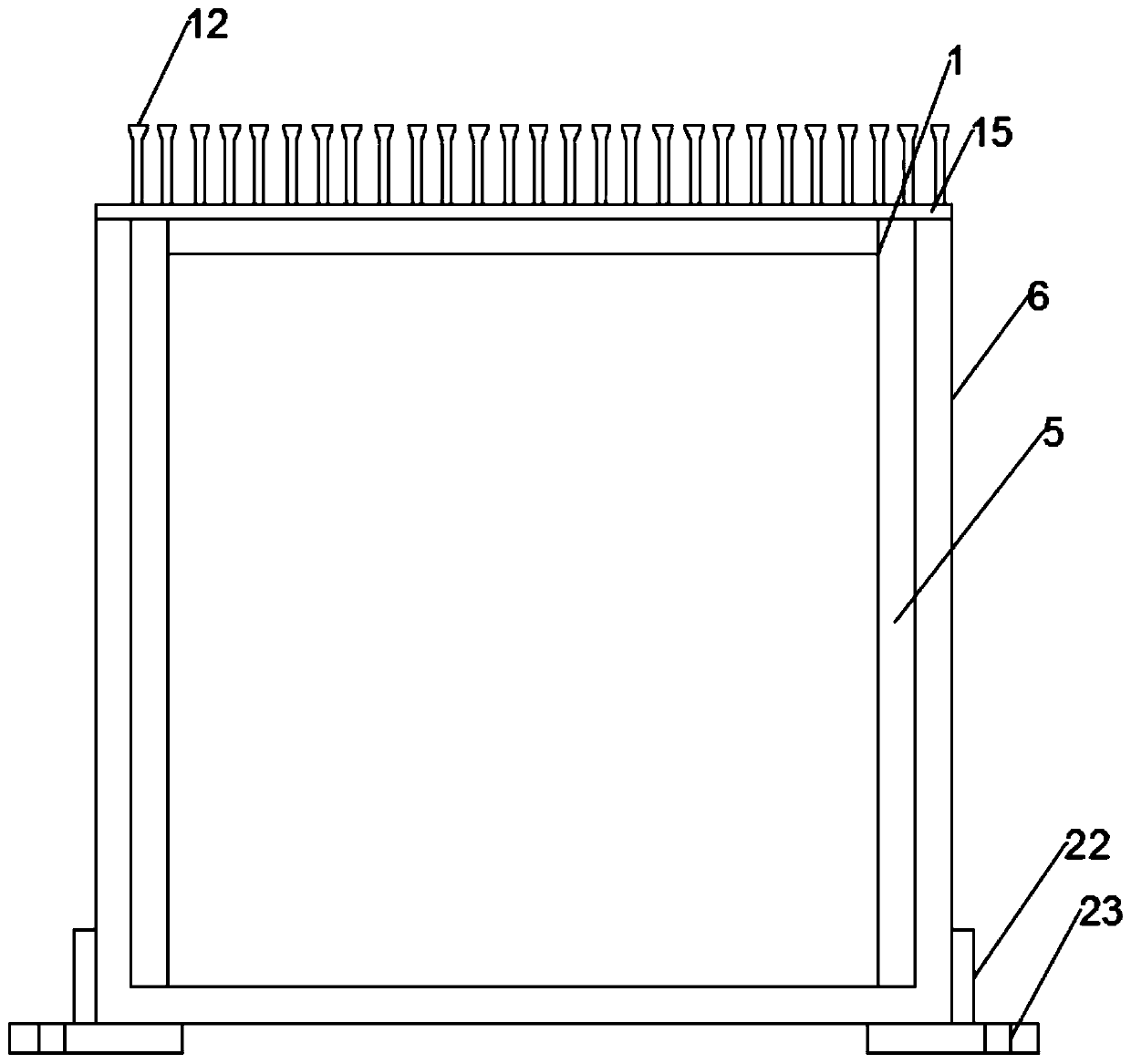

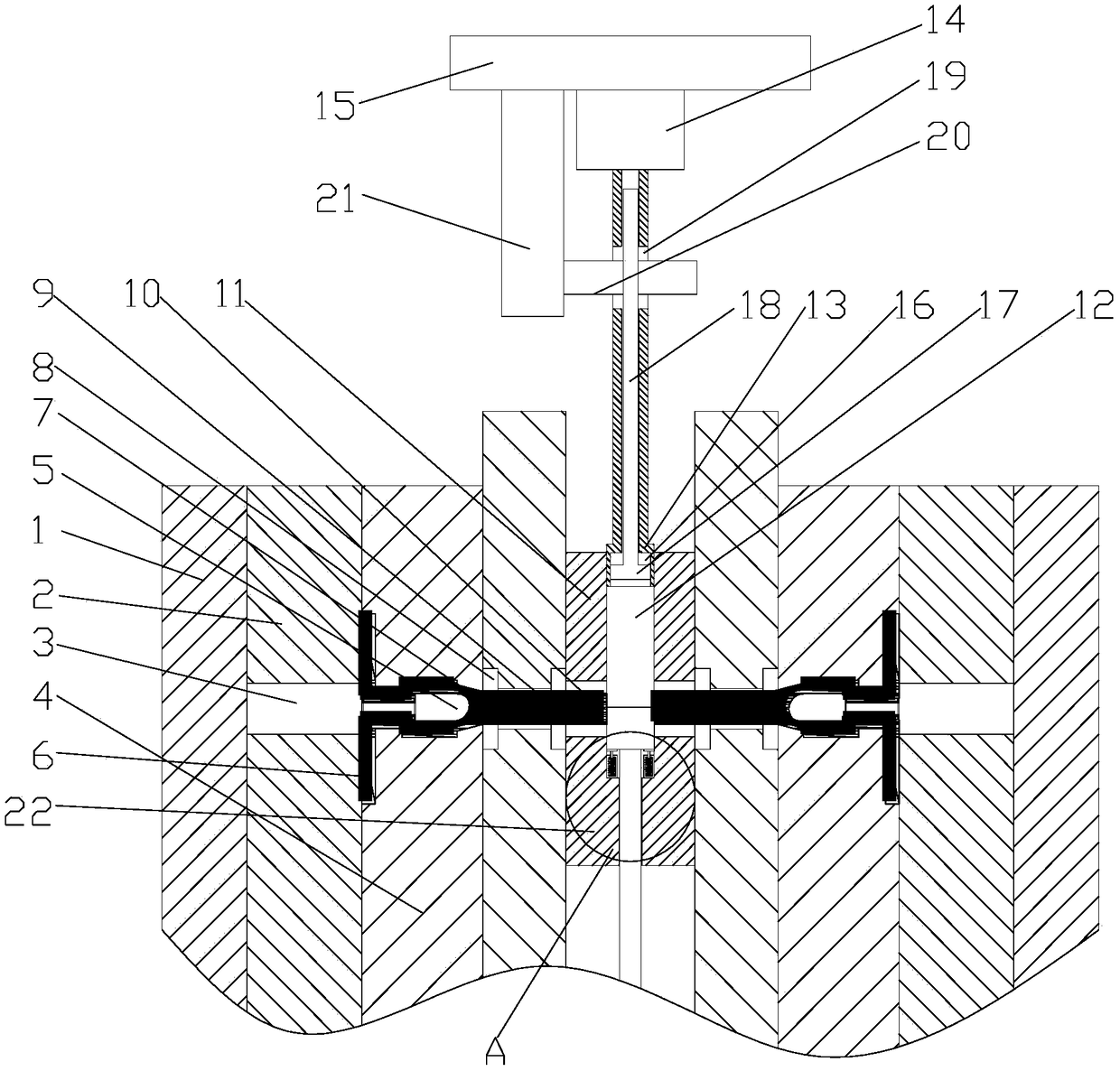

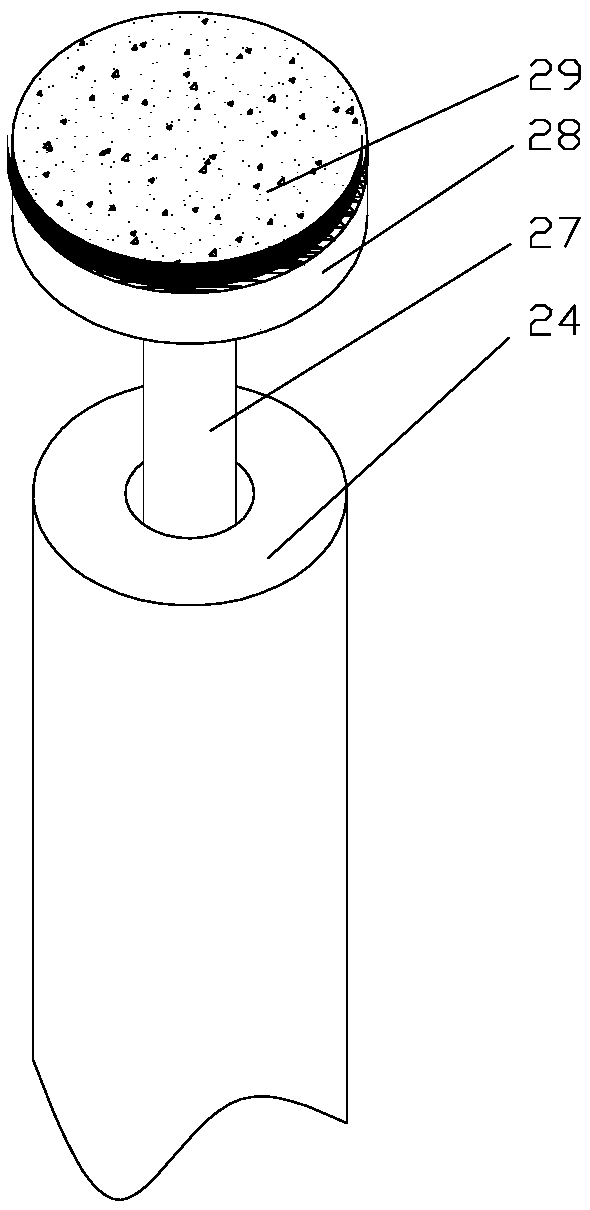

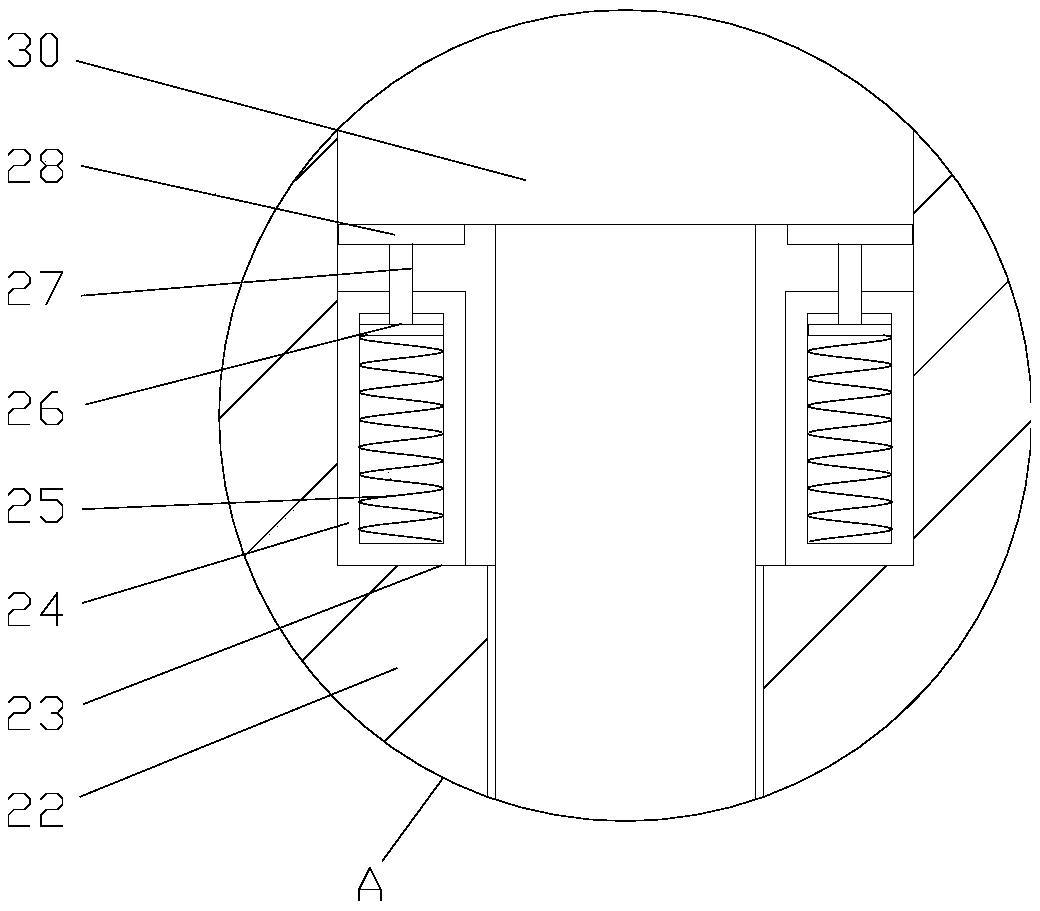

High-efficiency vertical die casting machine

The invention discloses a high-efficiency vertical die casting machine, comprising a pressure chamber, an upper punch and a lower punch. The pressure chamber is composed of upper pressing blocks whichare symmetrically arranged on the left and right sides, the lower part of the left and right upper pressing blocks are processed with sprues, nozzles are disposed on the left and right sprues away from the pressure chamber side, sprue sleeves are disposed on the left and right nozzles away from the pressure chamber side, the sprue sleeves on the left and right sides are fixed and clamped by the fixed mold, a flow gate is formed between sprue sleeve and the fixed molds, a flow divider is disposed on the left and right side of the sprue sleeve away from the pressure chamber side, and the flow divider away from the pressure chamber side is connected with a movable mold. The high-efficiency vertical die casting machine greatly prolongs the service life of the lower punch and the lower pressing block, doubles the working efficiency of the traditional die casting machine by completing the processing of the left and right two castings by one die casting, and greatly improves the enterprise'sproductivity.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

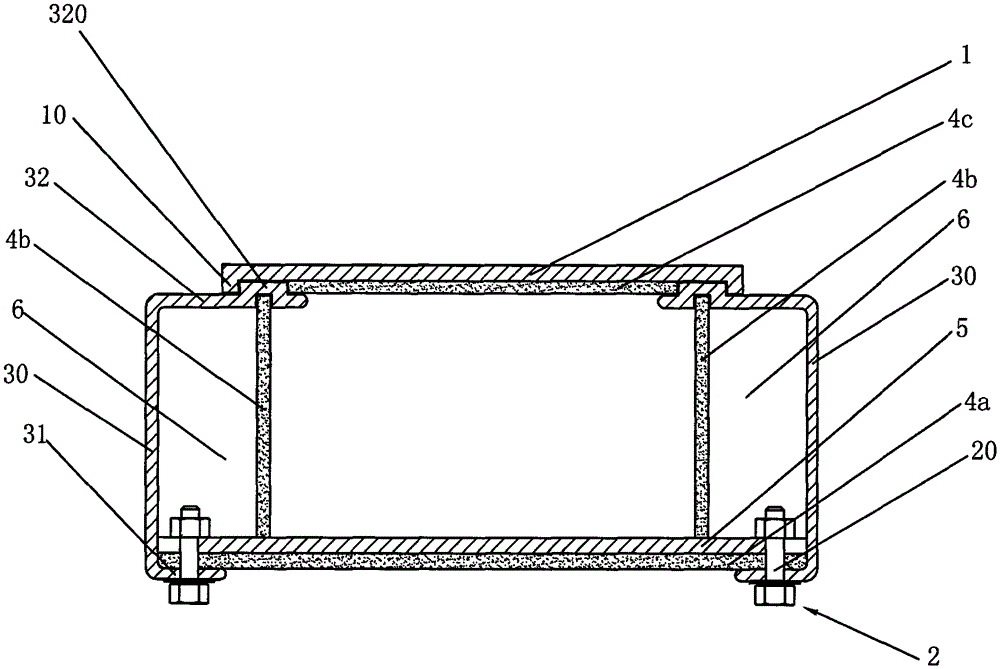

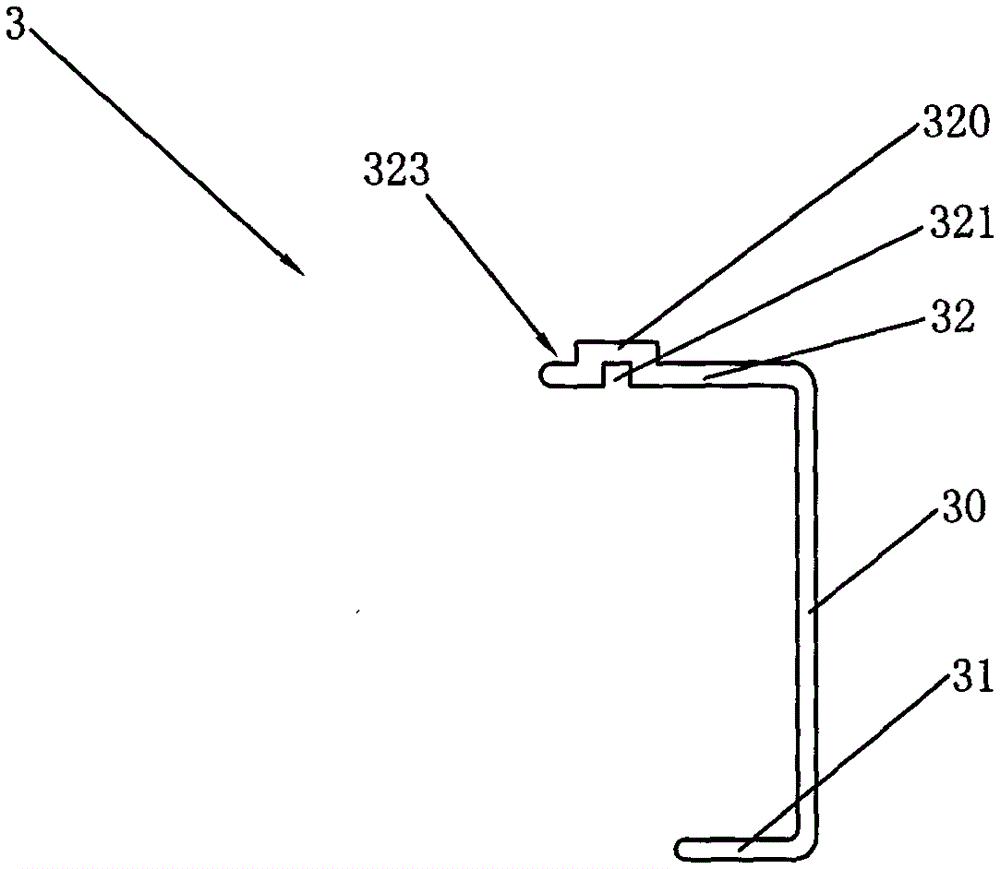

A fireproof cable bridge

ActiveCN103375643BGood heat insulation and fire performanceConvenient one-time stamping and formingPipe supportsThermal insulationCable trayEngineering

Owner:江苏众汇电气工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com