Aerogel thermal insulation coating for aluminum alloy material, fireproof thermal insulation coating layer for aluminum alloy battery pack and aluminum alloy upper cover of battery pack

A technology of aluminum alloy material and thermal insulation coating, applied in coatings, fire retardant coatings, epoxy resin coatings, etc., can solve the problem of unexplained heat insulation and flame retardant effect, and achieve good water resistance, acid resistance, alkali resistance, good resistance The effect of improving fire resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

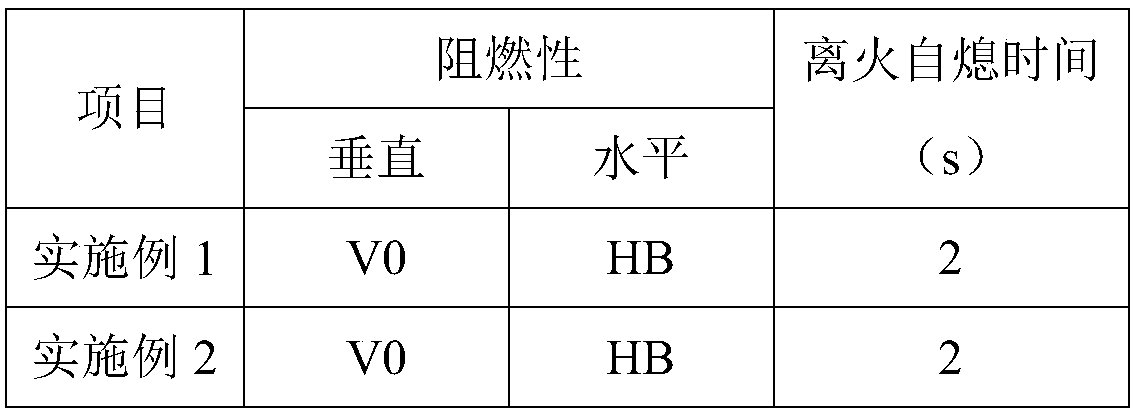

Embodiment 1

[0035] The airgel heat-insulating coating for aluminum alloy materials of the present embodiment includes the following components by weight: 50 parts of water-based epoxy resin emulsion, 20 parts of nano-silica airgel powder, 5 parts of dispersant, 2 parts of Thickener, 2 parts defoamer, 5 parts flame retardant, 1 part preservative.

[0036] The dispersant is sodium polyacrylate, the thickener is sodium carboxymethyl cellulose, the defoamer is silicone defoamer, the flame retardant is expanded graphite, and the preservative is sodium sorbate.

Embodiment 2

[0038] The airgel heat-insulating coating for aluminum alloy materials of the present embodiment includes the following components by weight: 45 parts of water-based epoxy resin emulsion, 20 parts of nano-silica airgel powder, 5 parts of dispersant, 5 parts of Thickener, 5 parts of defoamer, 5 parts of flame retardant, 2 parts of preservative.

[0039] The dispersant is sodium metaphosphate, the thickener is sodium carboxymethyl cellulose, the defoamer is silicone defoamer, the flame retardant is aluminum hydroxide, and the preservative is sodium sorbate.

Embodiment 3

[0041] The airgel thermal insulation coating for aluminum alloy material of the present embodiment comprises the following components by weight: 30 parts of water-based epoxy resin emulsion, 5 parts of film-forming aids, 15 parts of nano-silica airgel powder, 0.5 1 part dispersant, 4 parts thickener, 1 part defoamer, 1 part flame retardant, 5 parts preservative.

[0042] The film-forming aid is ethylene glycol, the dispersant is polyethylene glycol, the thickener is hydroxyethyl cellulose, the defoamer is silicone defoamer, the flame retardant is tributyl phosphate, and the preservative is benzene sodium formate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com