Cotton covered wire with flame-retardant protective outer layer and flame-retardant protective outer layer manufacturing device

A technology for making devices and wiring wires, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., and can solve problems such as poor flame retardancy and fire resistance, insulation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

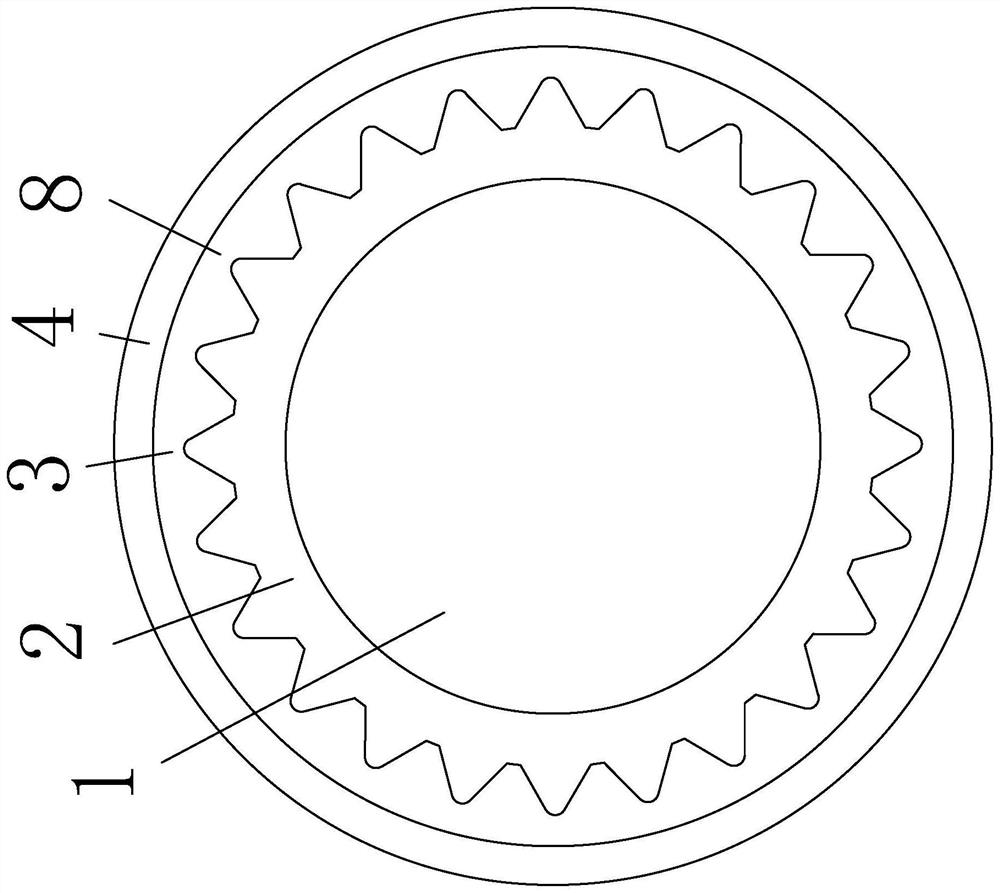

[0020] Such as figure 1 Shown: a kind of electrical wiring with a flame-retardant protective outer layer, including: a conductor 1, an insulating layer 2 wrapped around the outer conductor 1 and provided with a plurality of protruding teeth 8 evenly distributed along the circumference, and a flame-retardant protective outer layer layer; the flame-retardant protective outer layer includes: a fire-resistant coating 3 coated on the outside of the insulating layer 2, and an outer protective layer 4 coated on the outside of the fire-resistant coating 3.

[0021] The insulating layer 2 is a 105°C radiation cross-linked halogen-free low-smoke flame-retardant polyolefin insulating layer 2; the material of the fireproof coating 3 is cable fireproof coating, and the outer sheath 4 is a halogen-free flame-retardant nylon sheath layer.

[0022] The conductor 1 is a single wire or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com