Patents

Literature

278results about How to "Improve bundling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crab binding equipment

ActiveCN105857683ASimple and reasonable structureEasy to process and manufactureBundling machine detailsEngineeringBinding efficiency

The invention provides crab binding equipment. The crab binding equipment comprises a drive assembly, an installing plate, a fixed table, a crab fixing assembly and a binding assembly. The fixed table is installed on the upper plate face of the installing plate, a groove for containing a crab is formed in the top face of the fixed table, the fixed table is provided with four containing grooves, two containing grooves form a set and are coaxially formed, the two sets of containing grooves are vertically formed, and the two containing grooves in the same set are both communicated with the groove. The crab fixing assembly is installed on the installing plate, and the drive assembly is in drive connection with the crab fixing assembly to drive the crab fixing assembly to move towards the groove and abut against the crab. The crab binding equipment is simple and reasonable in structure, convenient to machine and manufacture, low in manufacturing cost and convenient to install and use; meanwhile, the crab can be rapidly fixed through the crab binding equipment, a worker is not easily hurt in the fixing process, crab claws of the crab are not easily damaged, the crab binding efficiency is improved, and meanwhile the crab binding equipment is safe, reliable and convenient to use.

Owner:YANCHENG INST OF TECH

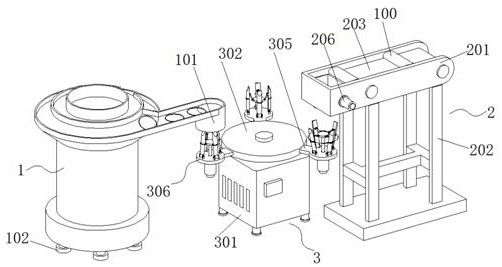

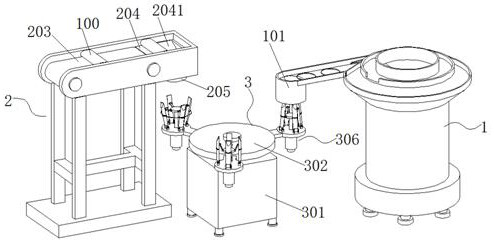

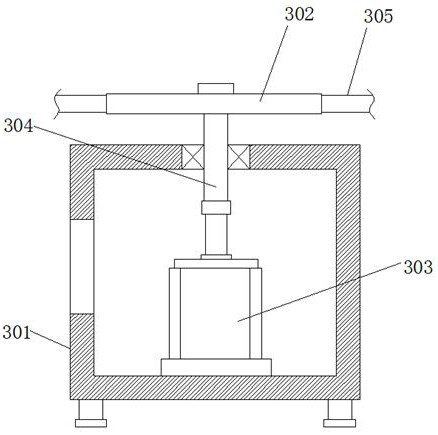

Automatic bundling equipment for plastic bag production

InactiveCN111605776AReduce laborRealize the effect of reducing staff and increasing efficiencyPaper article packagingBinding material applicationRubber ringElectric machinery

The invention relates to the technical field of plastic bag packaging equipment, and particularly discloses automatic bundling equipment for plastic bag production. The equipment comprises a rubber ring vibrating plate, a plastic bag discharging mechanism and a bundling device, wherein the bundling device is arranged between the rubber ring vibrating plate and the plastic bag discharging mechanism, the bundling device comprises a machine box, a turntable and a stepping motor, a PLC is arranged on the outer side surface of the machine box, the stepping motor is arranged inside the machine box,the upper end of an output shaft of the stepping motor is connected with a rotating rod through a coupler, the top end of the rotating rod penetrates through the top wall of the machine box and is connected with the circle center of the turntable, a plurality of connecting strips are uniformly connected to the circumferential surface of the turntable, and the outer end of each connecting strip isconnected with a rubber band bundling mechanism. According to the plastic bag bundling equipment, compared with the prior art, manual assistance is not needed to make rubber bands slip off in the process of bundling the folded plastic bags or the coiled plastic bags with the rubber bands, the labor amount of operators is reduced, and the effect of downsizing and increasing efficiency is achieved.

Owner:BENGBU WEIGUANG PLASTIC PRODS

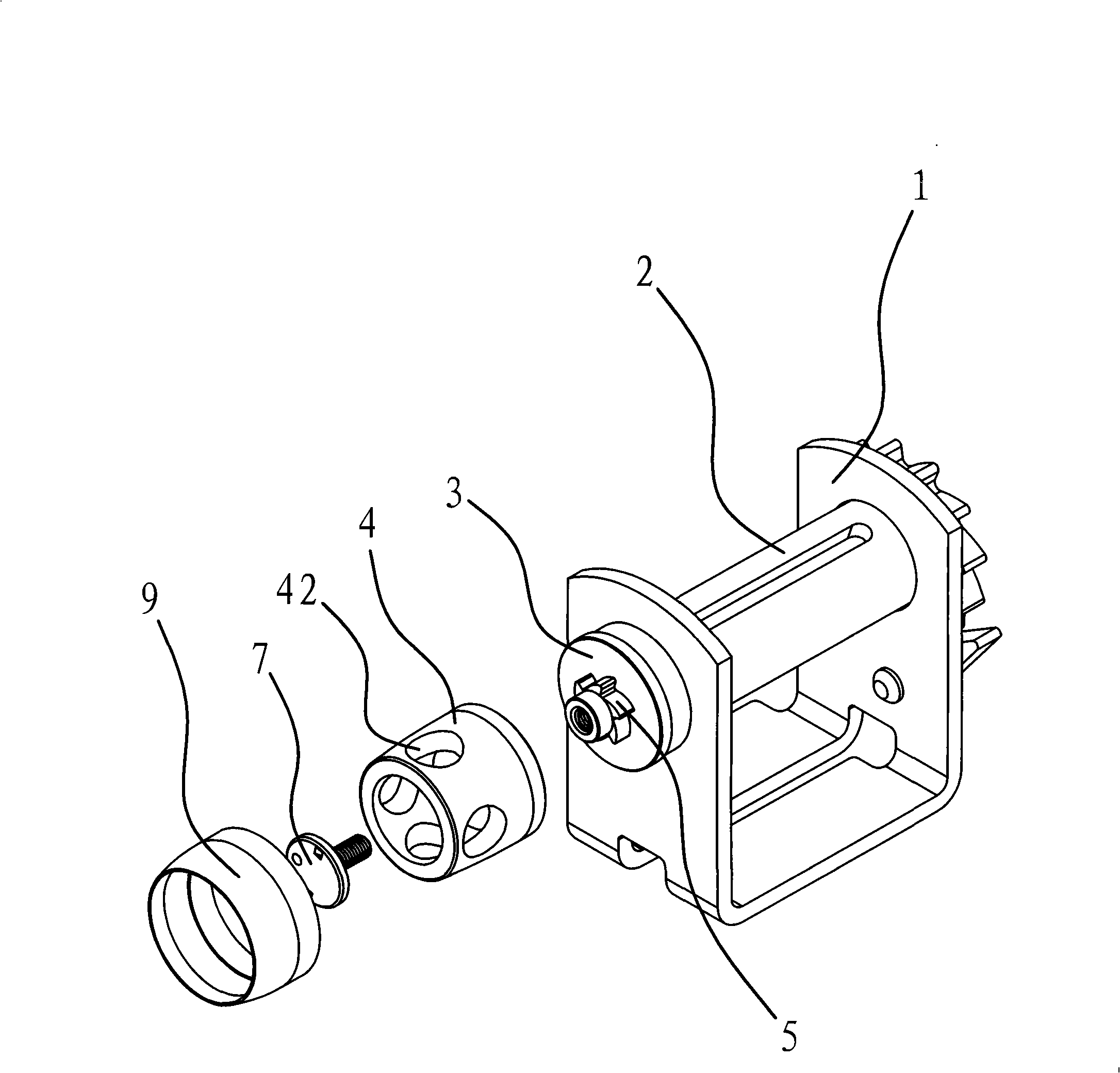

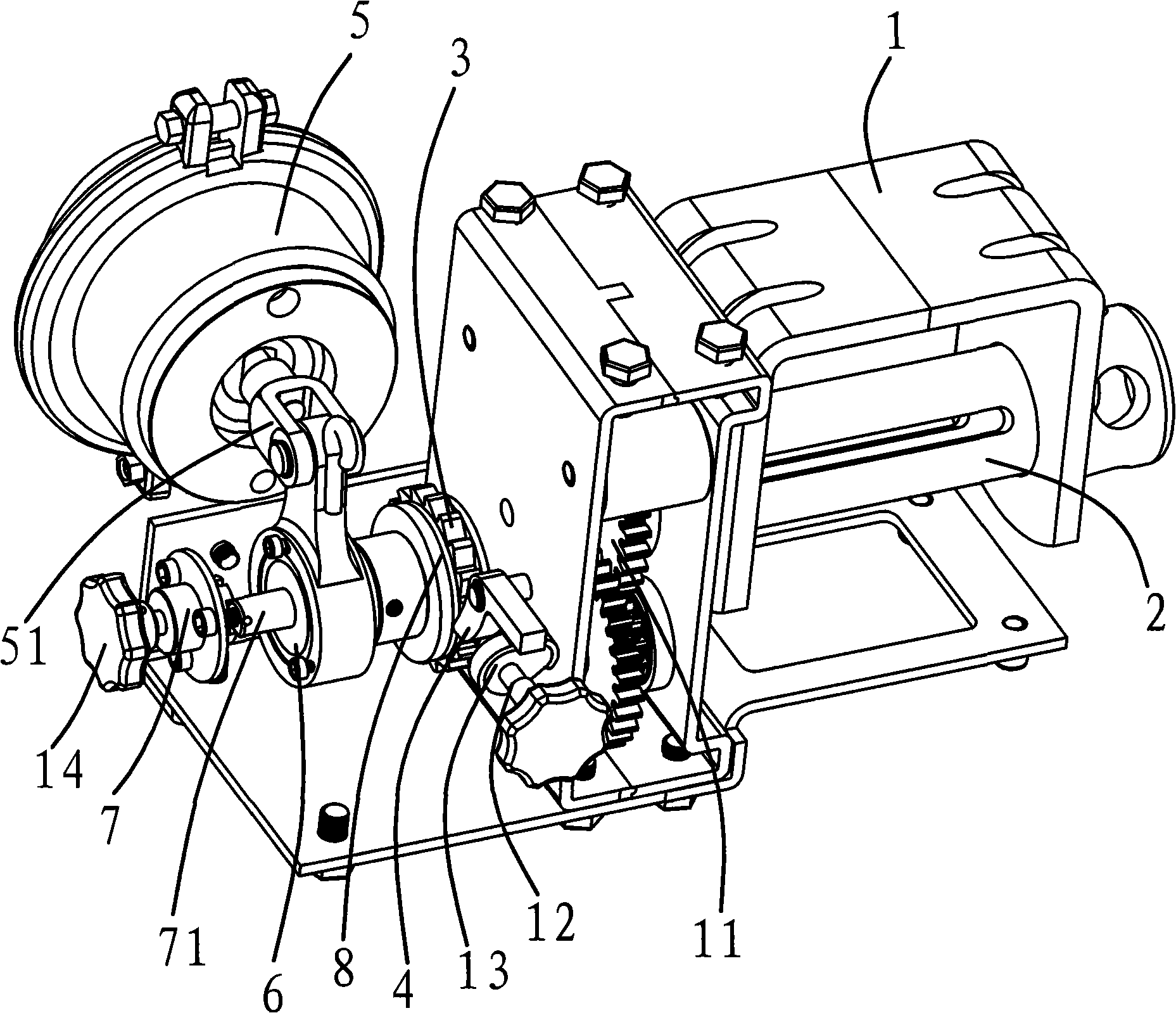

Fast rotation device for winch band axis

InactiveCN101264743AEasy to useImprove bundling efficiencyBinding material applicationLoad securingWinchTime-Consuming

The invention relates to a hoist zone axis fast rotating device, belonging to machinery technology field, which solves the problem of laboursome operation, time consuming and low seizing efficiency of prior hoist zone axis. The fast rotating device of the gin zone axis is arranged on the zone axis extension end at the lateral part of a gin support, which comprises a permanent seat and a rotating body, wherein the permanent seat is fixedly connected with the zone axis; the lateral part of the permanent seat is sleeve-jointed with the internal end of the rotating body; at least one crowbar hole is positioned at the outer end of the rotating body; the rotating device also comprises a ratchet wheel and a pawl, wherein the ratchet wheel is fixedly connected with the terminal of the permanent seat; a slot is arranged at the inner side of the rotating body, which is clipped on the internal end of the pawl; an elastic member is arranged between the pawl and the inner side of the rotating body; the outer end of the pawl is embedded on the ratchet wheel on the elasticity effect of the elastic member. The hoist zone axis fast rotating device has the advantages of convenient use and high using stability.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

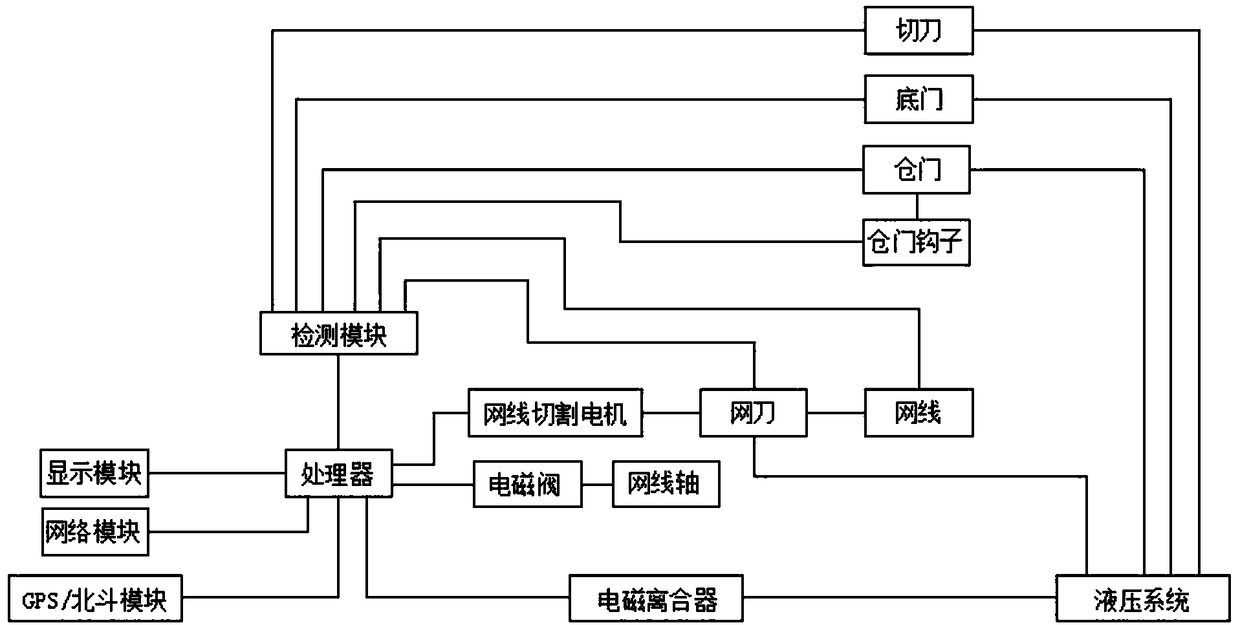

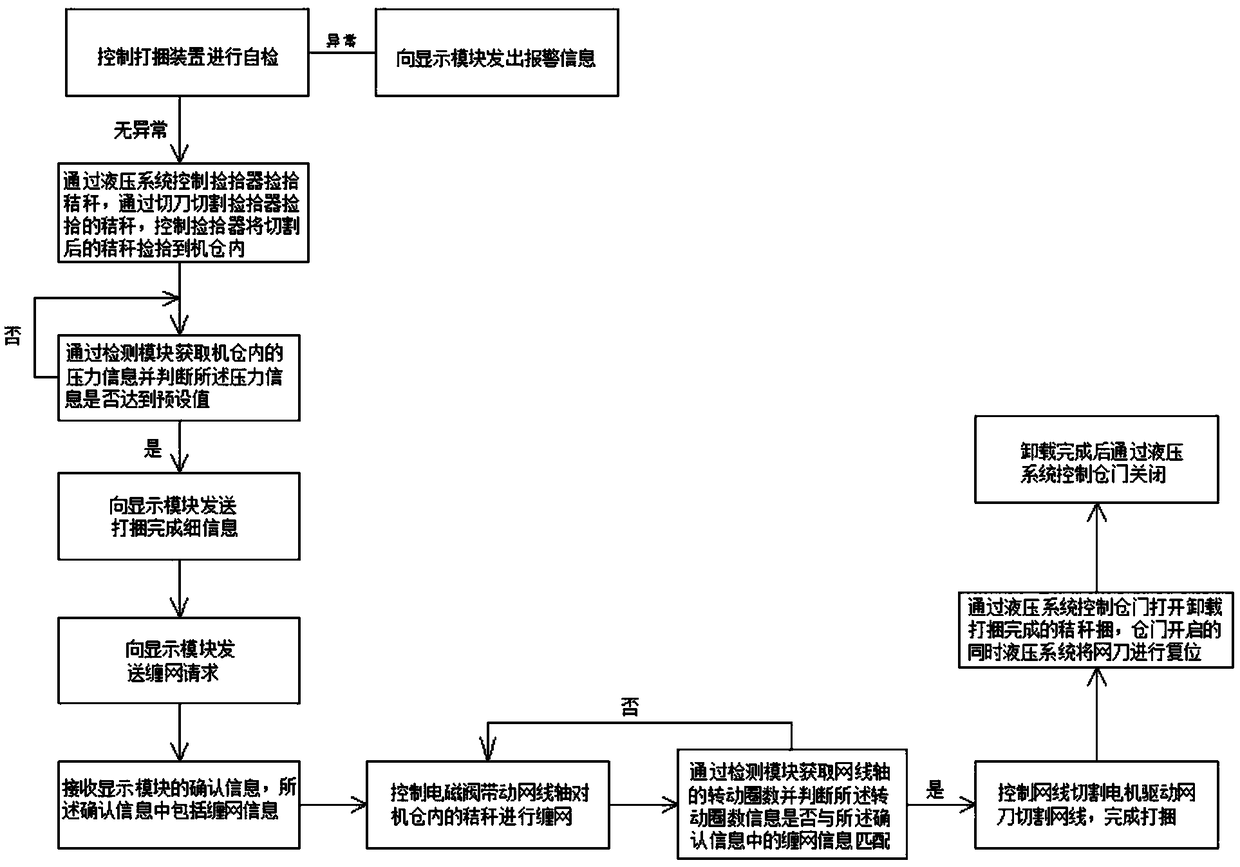

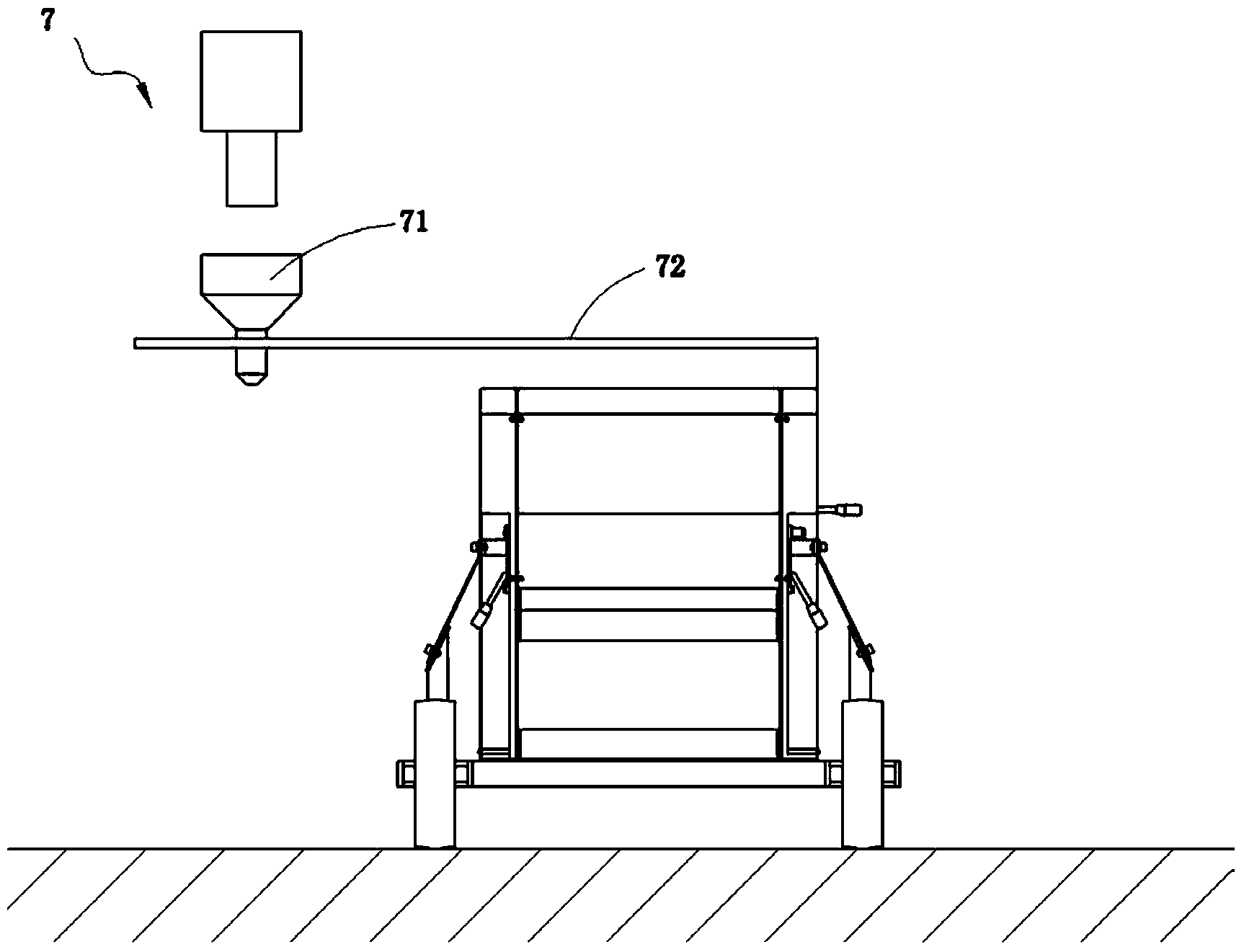

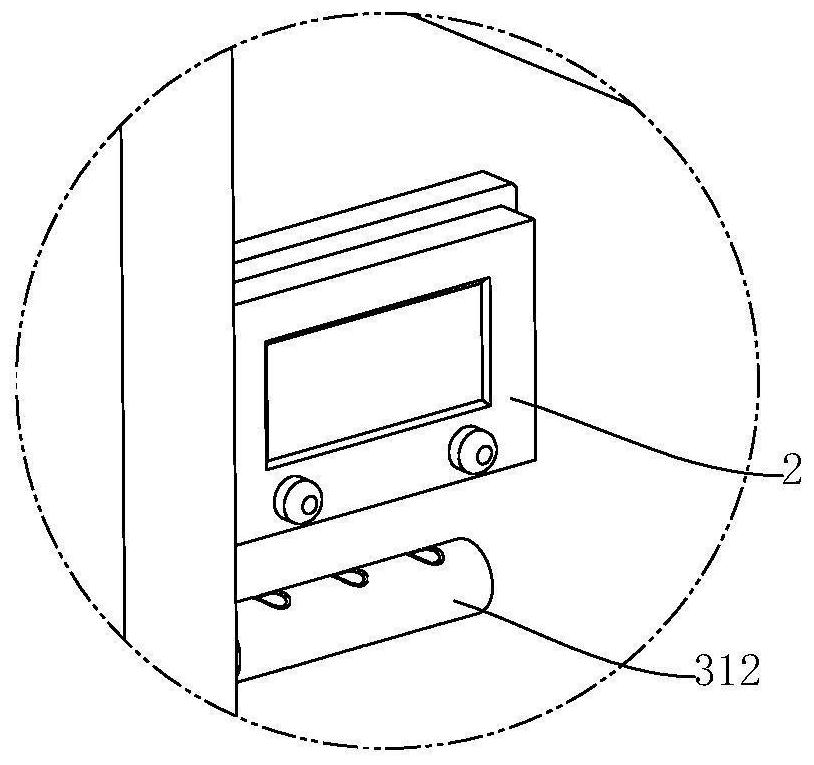

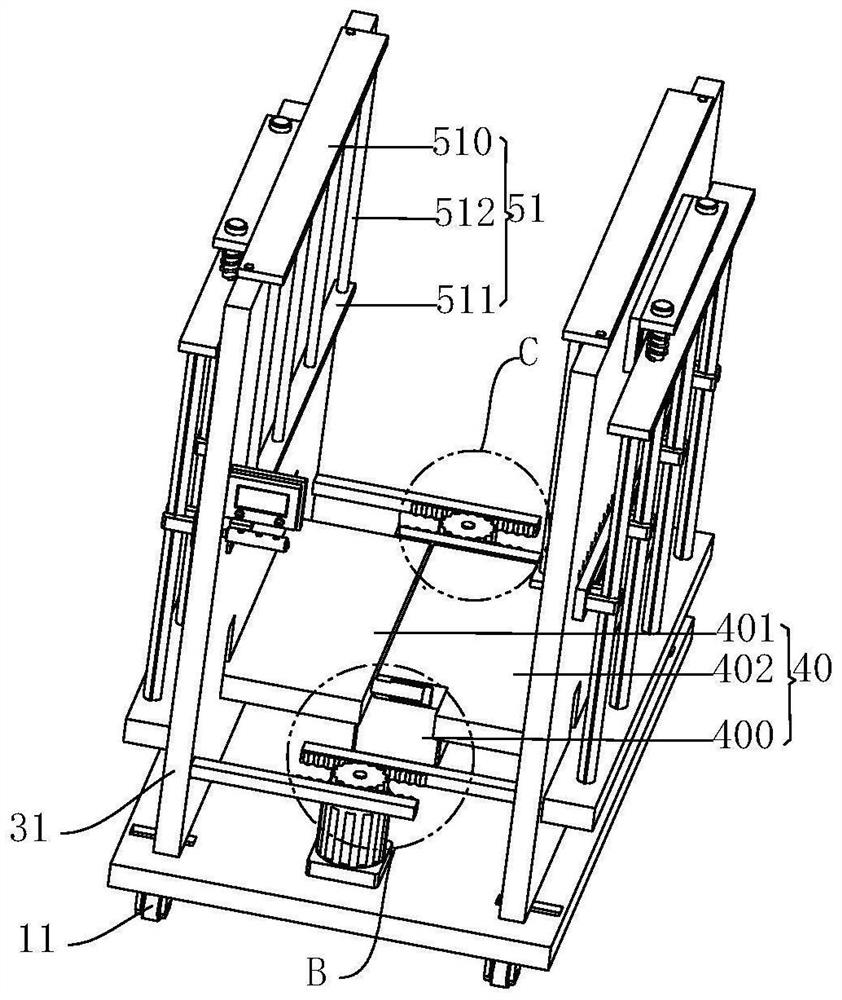

Intelligent straw bundling device and bundling method

ActiveCN109041813AHigh working reliabilityImprove baling efficiency while increasing work reliabilityLoadersBalingControl systemWire cutting

The invention discloses an intelligent straw bundling device. The bundling device comprises a bundling machine and a control system which is used for controlling the bundling machine, the bundling machine comprises a chamber used for loading straw, a cutter used for cutting the straw, a net wire used for winding the straw, a net knife used for cutting the net wire, a net winding electromagnetic valve which is used for driving the net wire to wind the net and a net wire cutting motor which is used for cutting the net wire; the control system comprises a detecting module, a processing unit and adisplay module, wherein the display module and the detecting module are connected with the processing unit. By arranging the detecting module which can set parameters and display on-site detecting information, the device is more intelligence, straw can be well bundled more reasonably, and the working reliability of the bundling device is increased while the bundling efficiency is improved.

Owner:浙江致靖超云科技有限公司

Binding device for tobacco leaf-covering bag

ActiveCN107347477ASimple and reliable mechanical structureLightweight and flexible mechanical structureHorticulture methodsWinding machineBaseboard

The invention discloses a binding device for a tobacco leaf-covering bag. The device comprises a supporting baseboard, a leaf-covering bag necking system, a wire feeding system, a wire shearing system and a wire stranding system, and the leaf-covering bag necking system, the wire feeding system, the wire shearing system and the wire stranding system are installed on the supporting baseboard; the leaf-covering bag necking system comprises a necking mechanism which is used for necking a sealing mouth of the leaf-covering bag, and a wire winding mechanism which is used for winding a binding wire at the sealing mouth of the necked leaf-covering bag; the wire feeding system is used for delivering the binding wire to the winding position of the winding mechanism; the wire shearing system is used for shearing the part, entering a winder, of the binding wire; the wire stranding system is used for stranding the binding wire in the winder to achieve binding of the tobacco leaf-covering bag.

Owner:SOUTHWEST UNIV

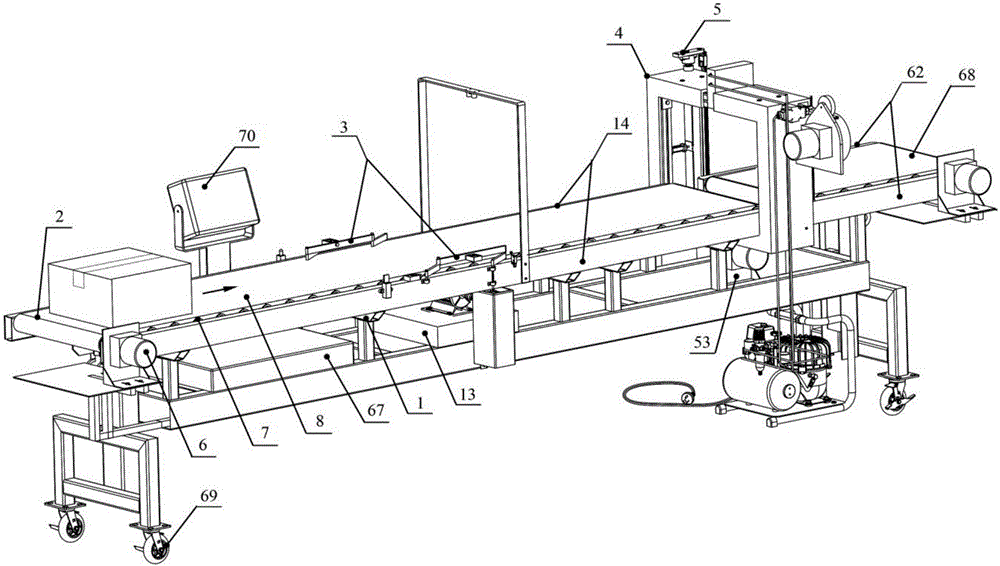

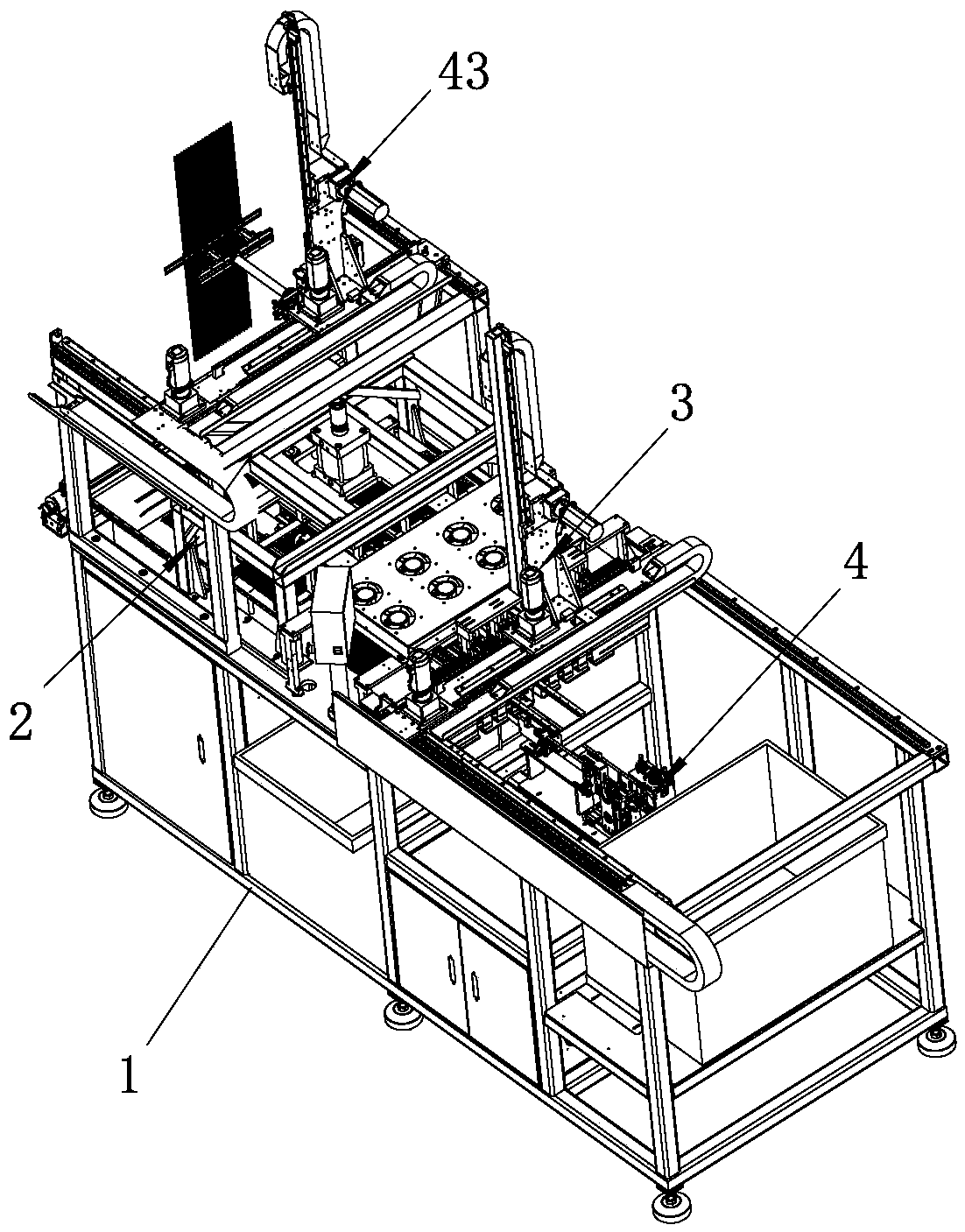

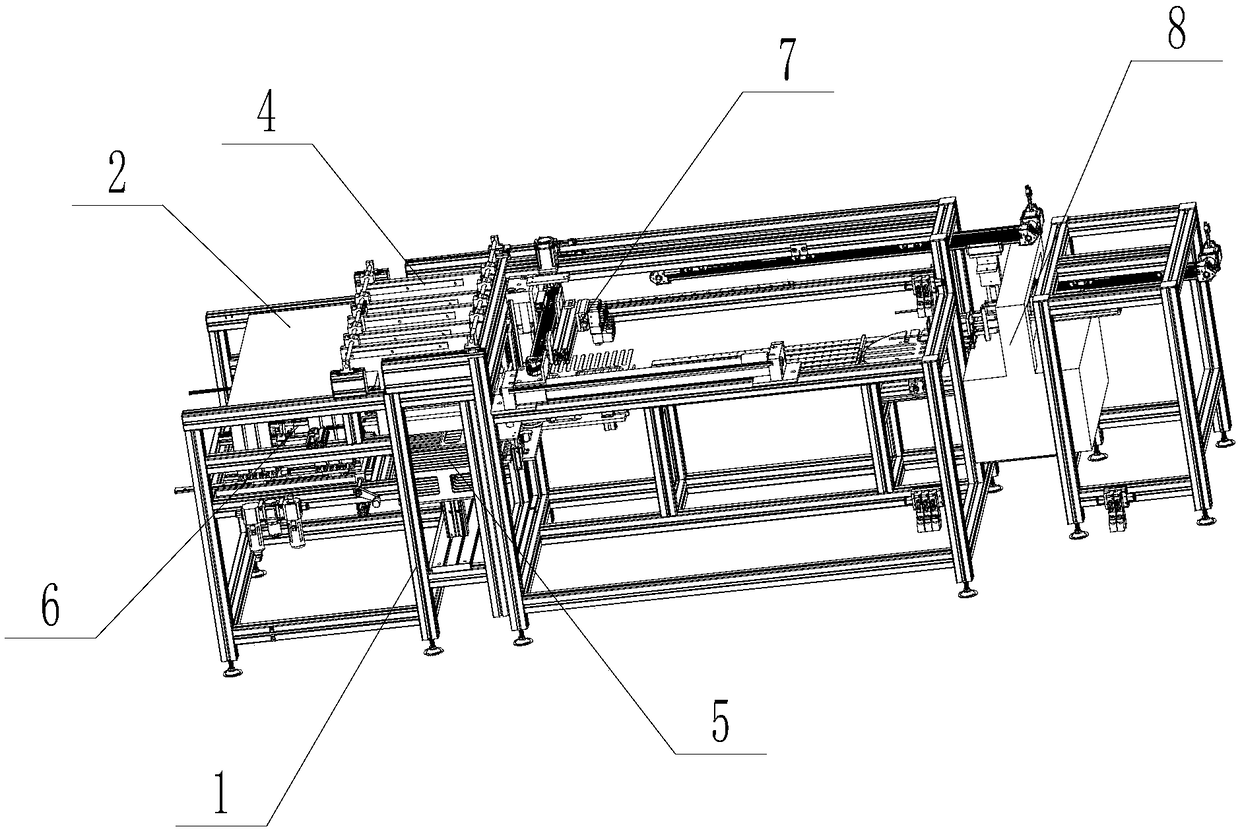

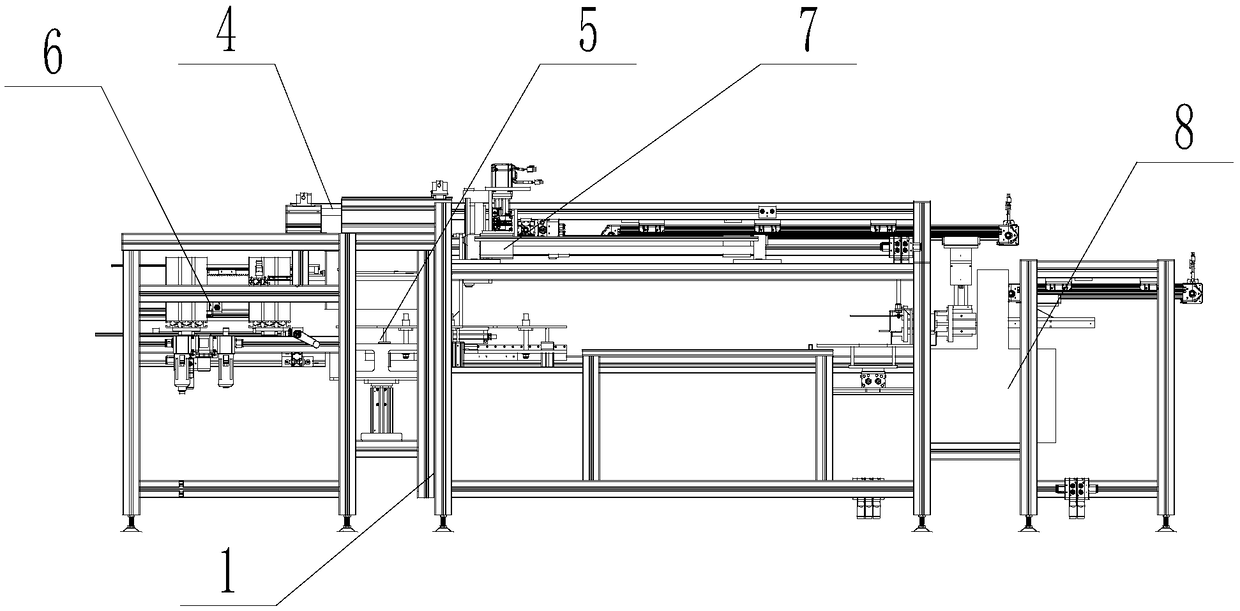

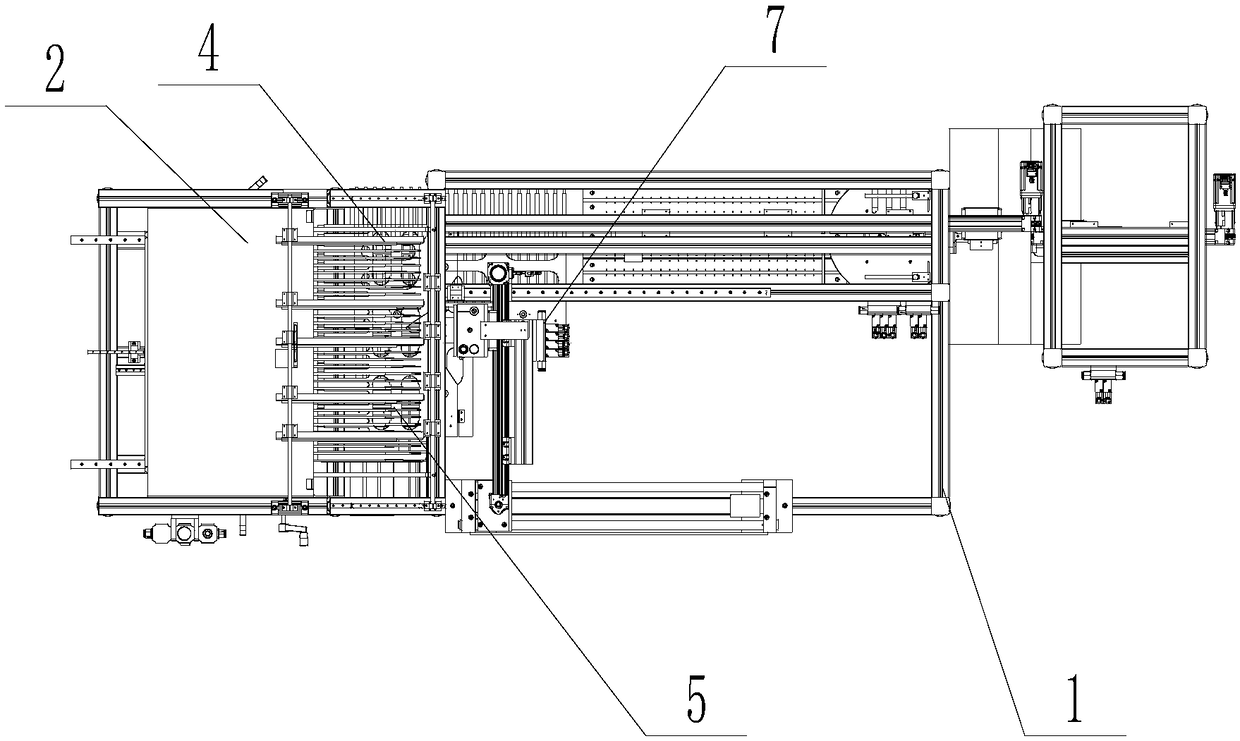

High-speed intelligent identification bag sorting machine

ActiveCN108773535AHigh-speed automatic strappingImprove bundling efficiencyPackaging automatic controlBundling machine detailsAgricultural engineeringPlastic bag

The invention discloses a high-speed intelligent identification bag sorting machine. The high-speed intelligent identification bag sorting machine comprises an integral machine frame, a feeding transmission module, a pressing wheel module, a separation baffle module, a discharging groove module, a reciprocating material pushing block rod module, a transfer module and a bundling module. The feedingtransmission module, the pressing wheel module, the separation baffle module, the discharging groove module, the reciprocating material pushing block rod module, the transfer module and the bundlingmodule are all arranged on the integral machine frame. The high-speed intelligent identification bag sorting machine can realize automatic bundling of plastic bags with high bundling efficiency and low labor cost, can be adjusted to adapt to the automatic bundling of plastic bags with different widths, lengths and thicknesses, and has a wide application range. The unqualified products can be detected and rejected with high rejection efficiency.

Owner:浙江创派智能科技有限公司

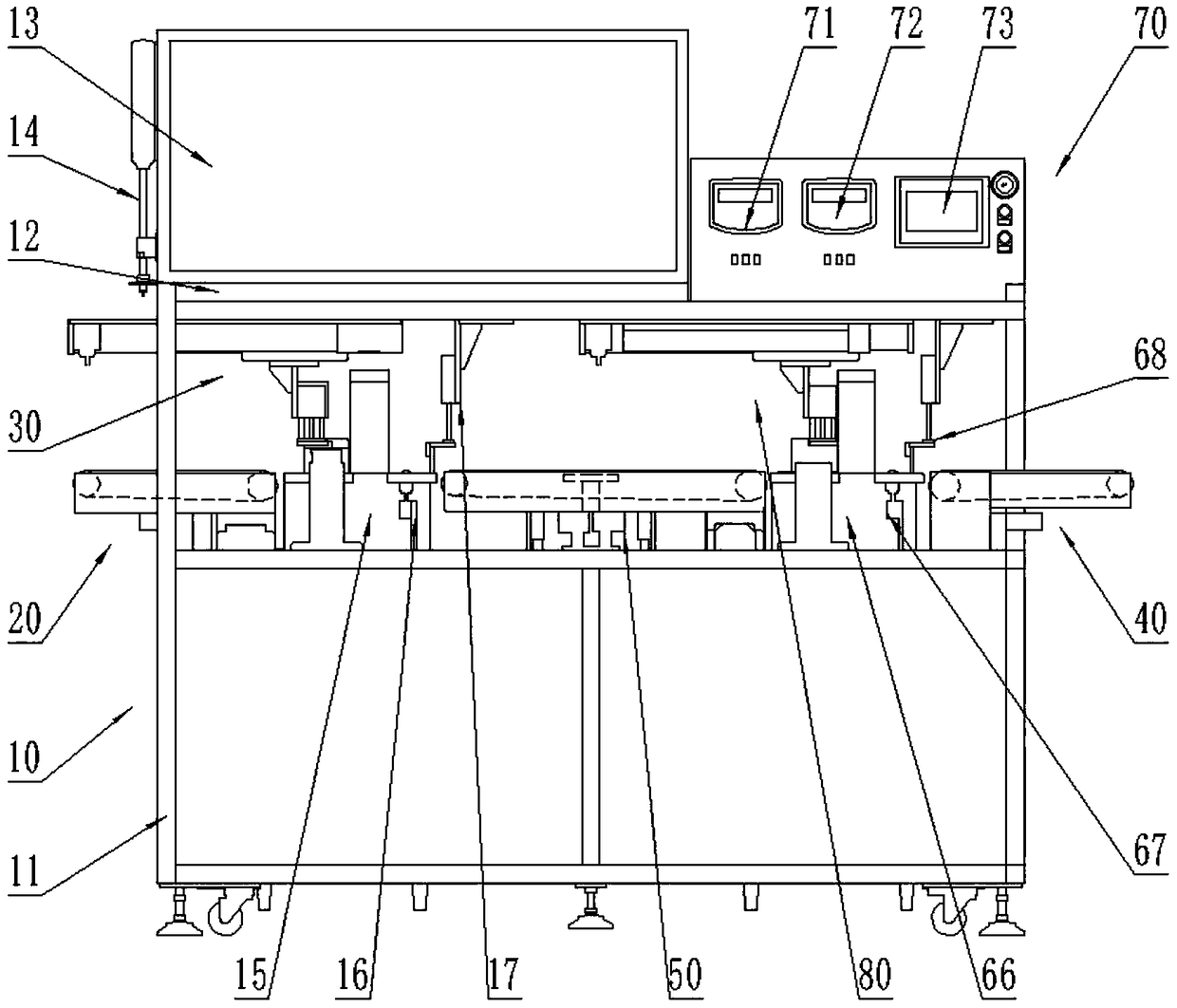

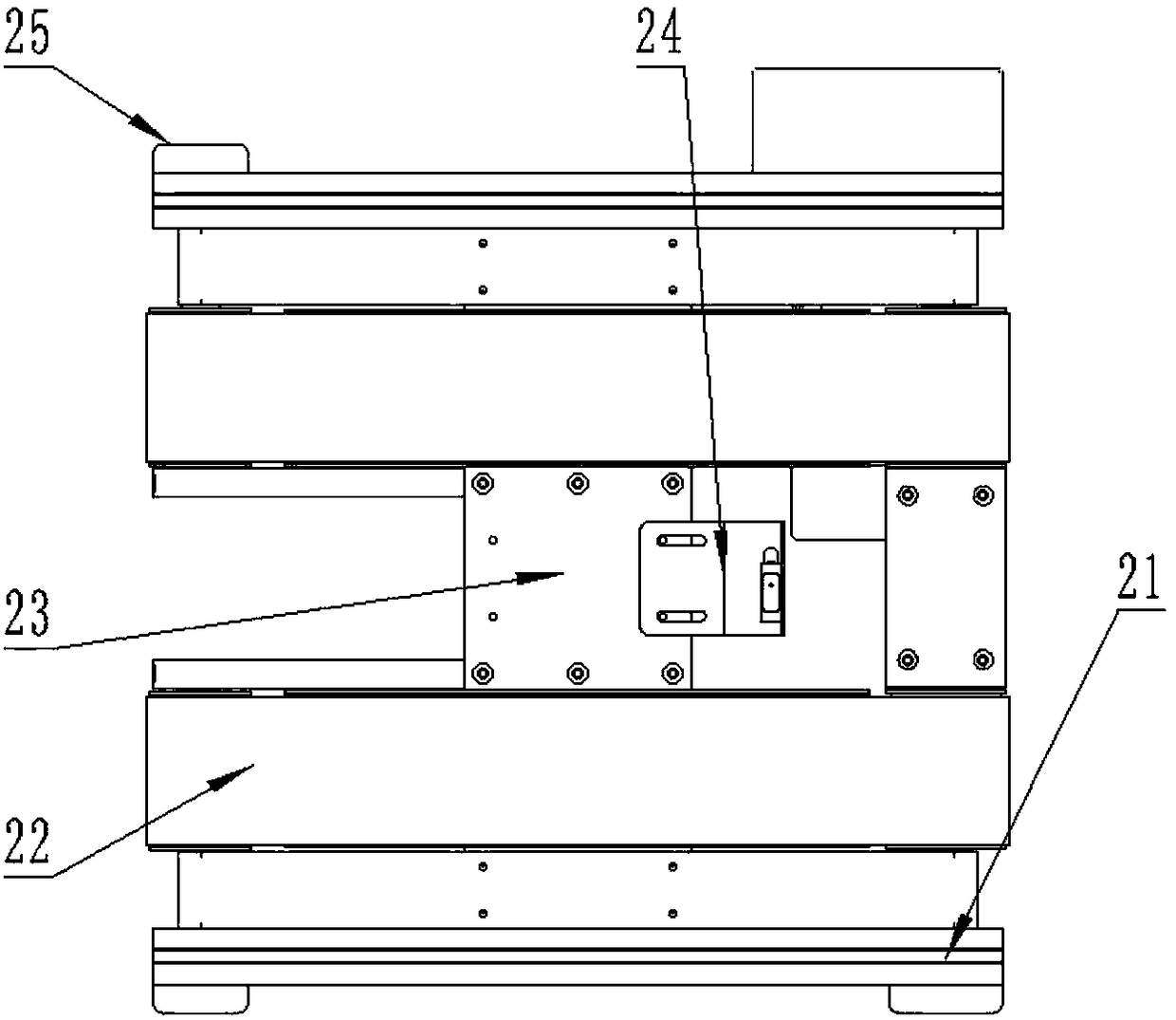

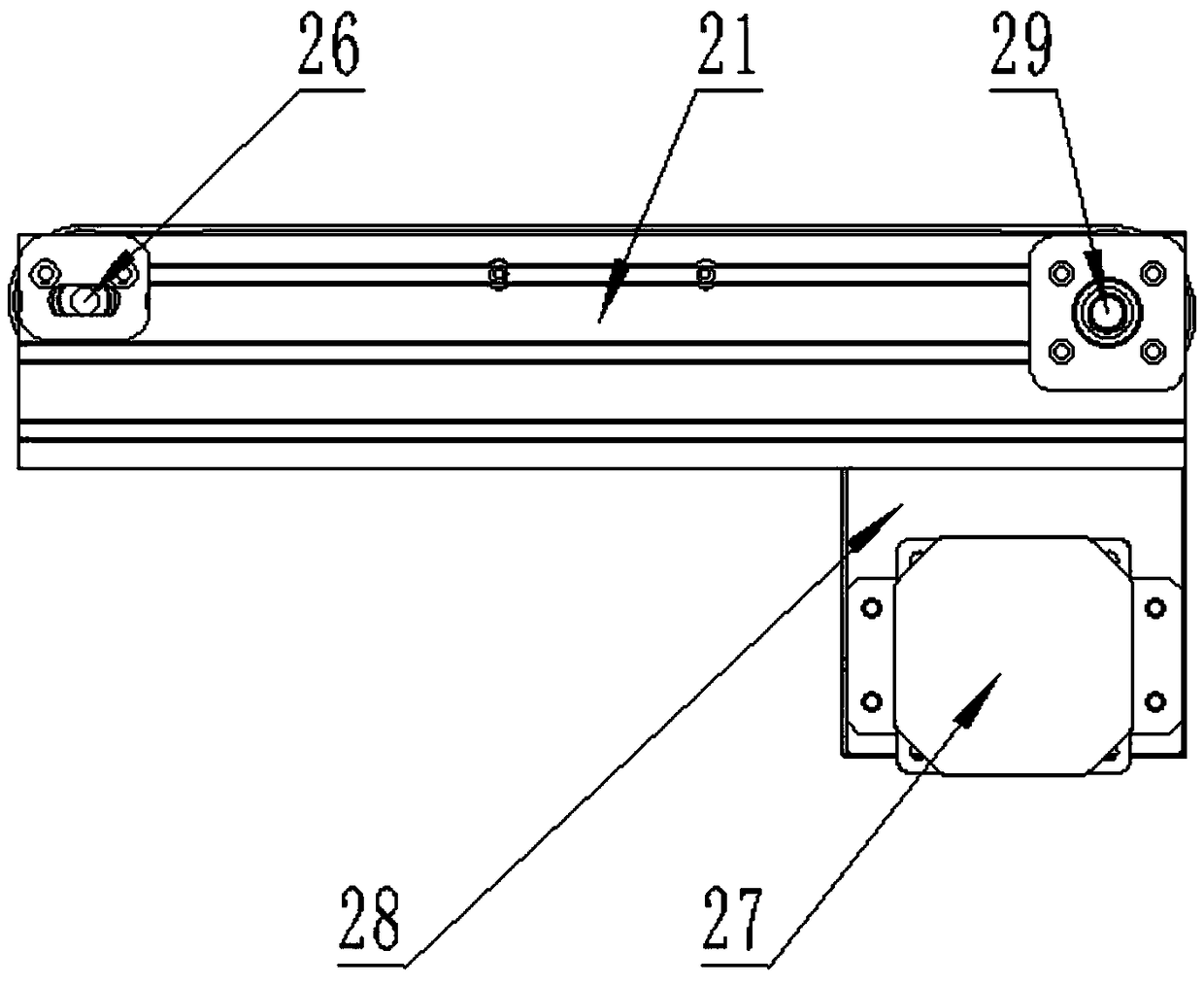

Full-automatic strapping machine used for multi-specification express box and work method

ActiveCN106184903AImprove bundling efficiencyFully automatic strappingBinding material applicationPackaging automatic controlStrappingEconomic benefits

The invention discloses a full-automatic strapping machine used for a multi-specification express box. The full-automatic strapping machine comprises a rack, the rack comprises two left cross beams and two right cross beams which are mounted in a parallel isolation manner, a left conveying device is arranged on the left cross beams, a right conveying device the same with the left conveying device in structure is arranged on the right cross beams, an automatic strapping device and an automatic lifting device are arranged between the left cross beams and the right cross beams, and an automatic straightening device and a controller used for controlling the left conveying device, the right conveying device, the automatic straightening device, the automatic strapping device and the automatic lifting device are further arranged in the middle of the left conveying device. According to the machine, express boxes of different specifications can be continuously strapped in a full-automatic manner, the strapping efficiency is improved, the manpower cost is reduced, and economic benefits of Taobao sellers are improved. The invention further discloses a work method of the full-automatic strapping machine used for the multi-specification express box.

Owner:江苏新美星物流科技有限公司

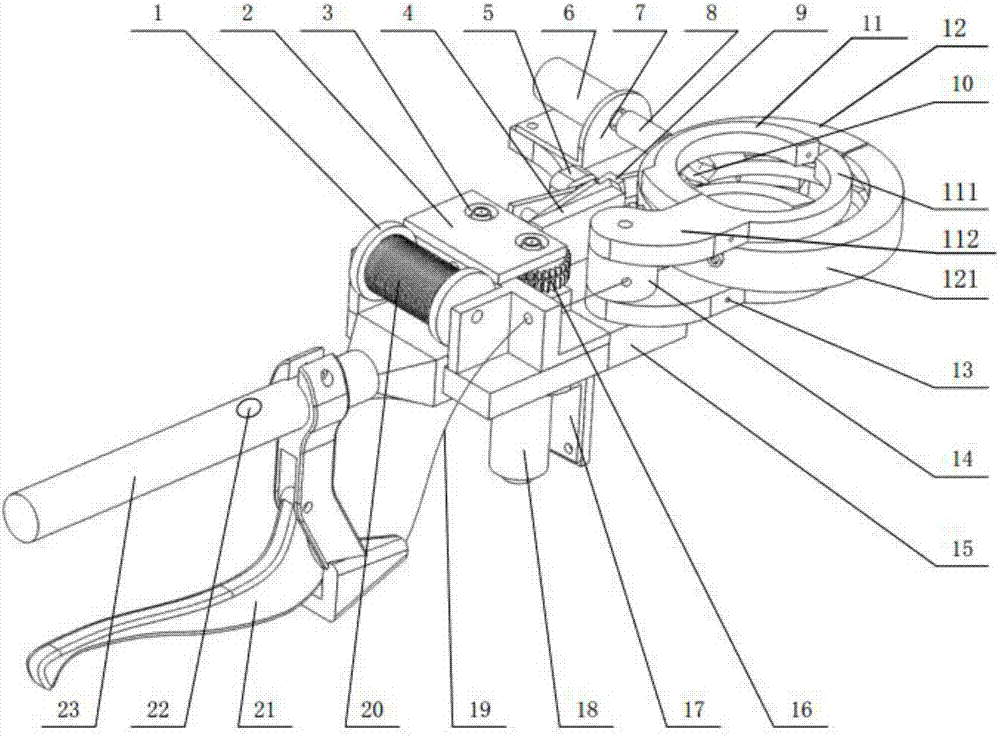

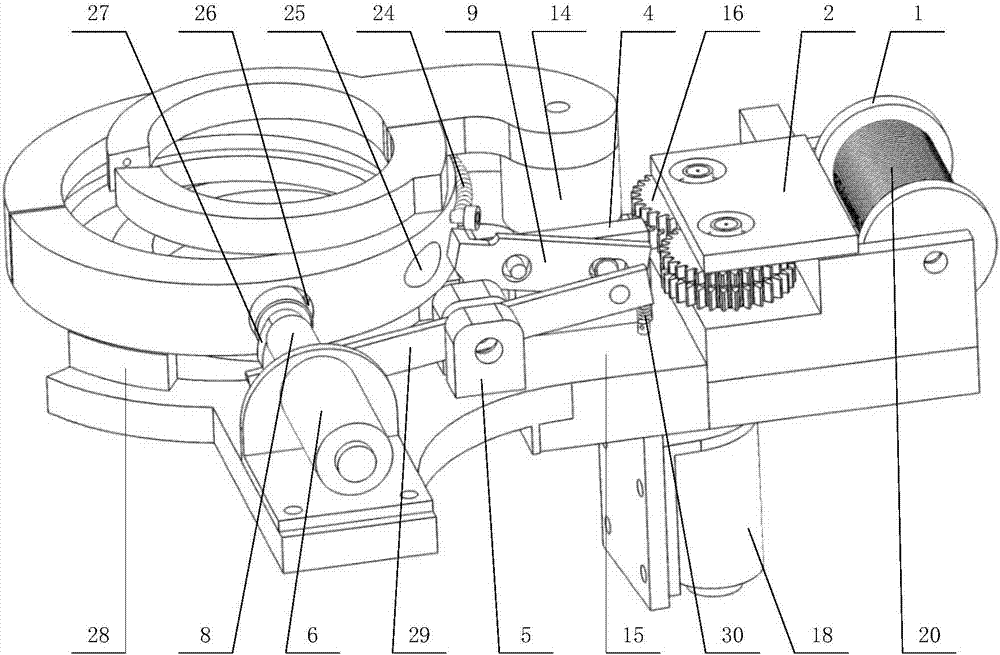

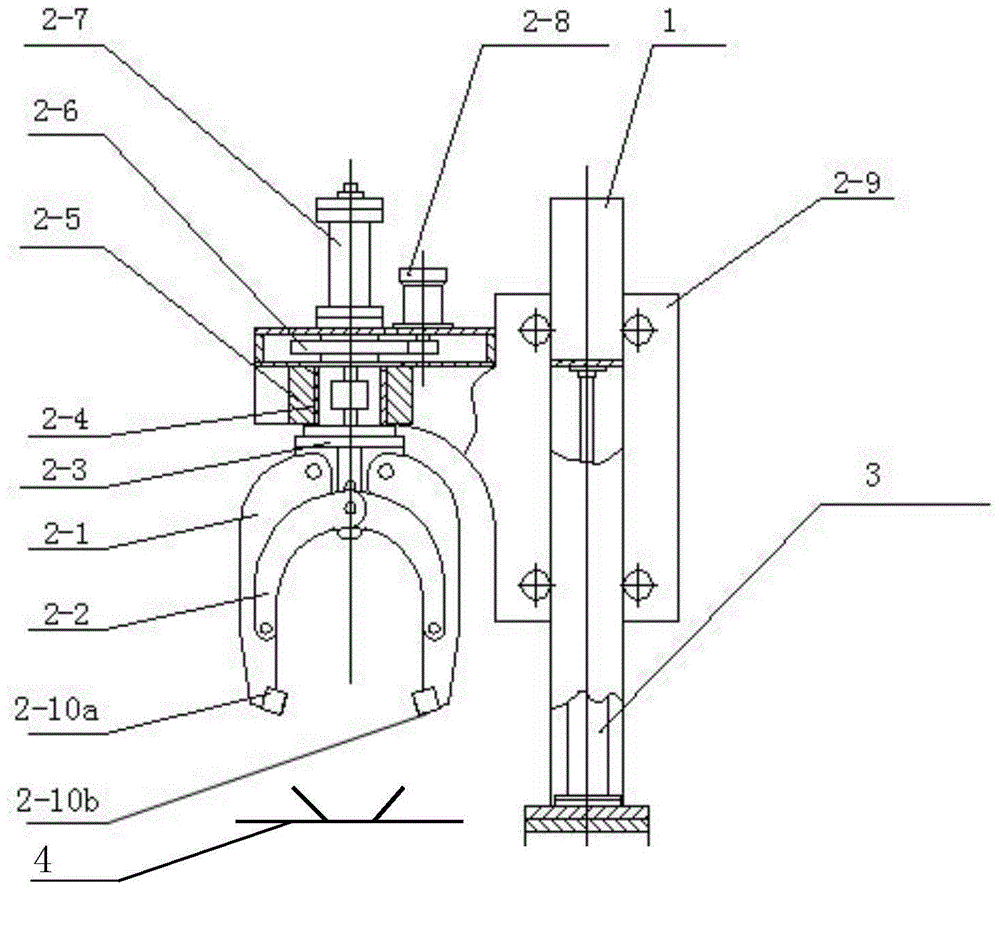

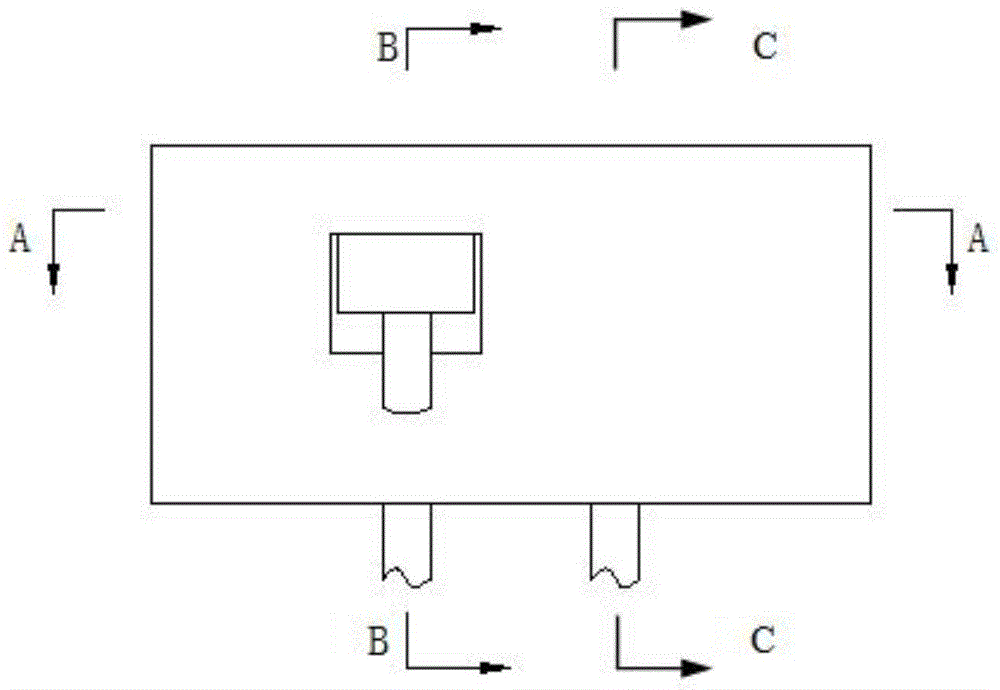

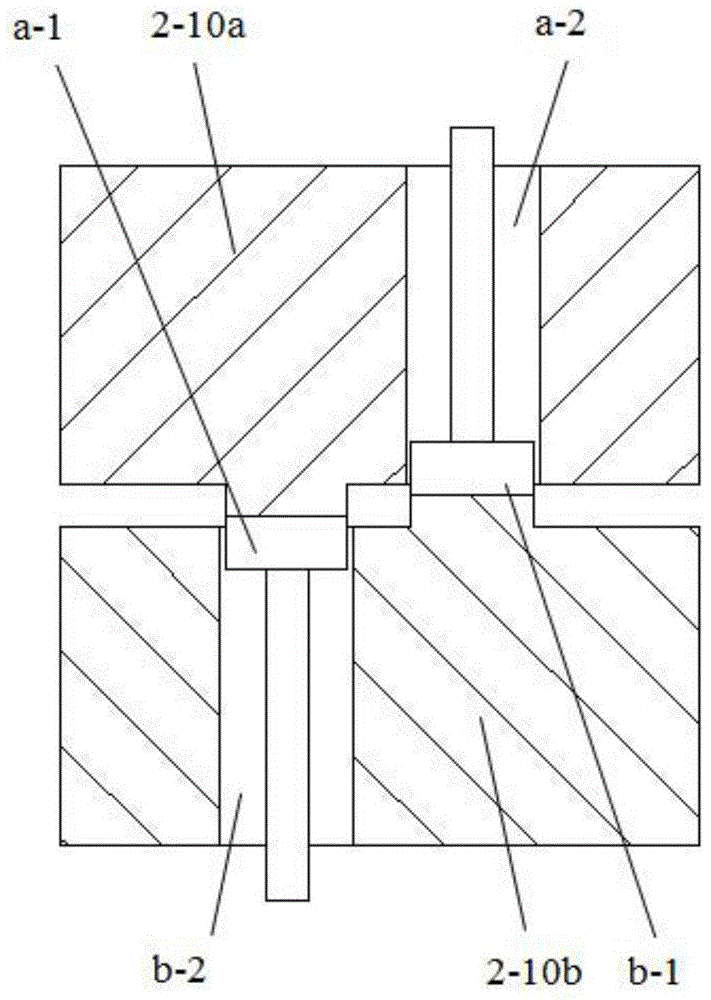

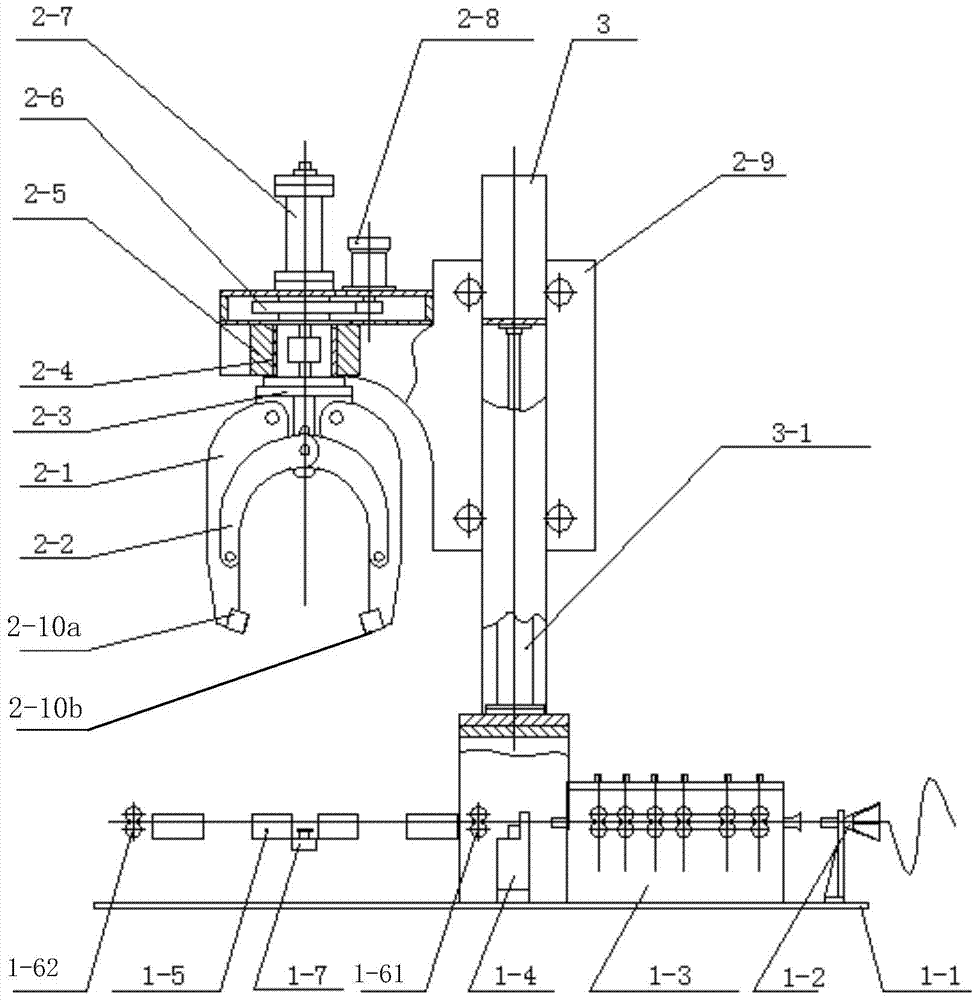

Mechanical hand for screwing and bundling

ActiveCN104925294ARealize the tightening functionSimple structureProgramme-controlled manipulatorBundling machine detailsManipulatorIndustrial engineering

Owner:天津市福鼎机电设备有限公司

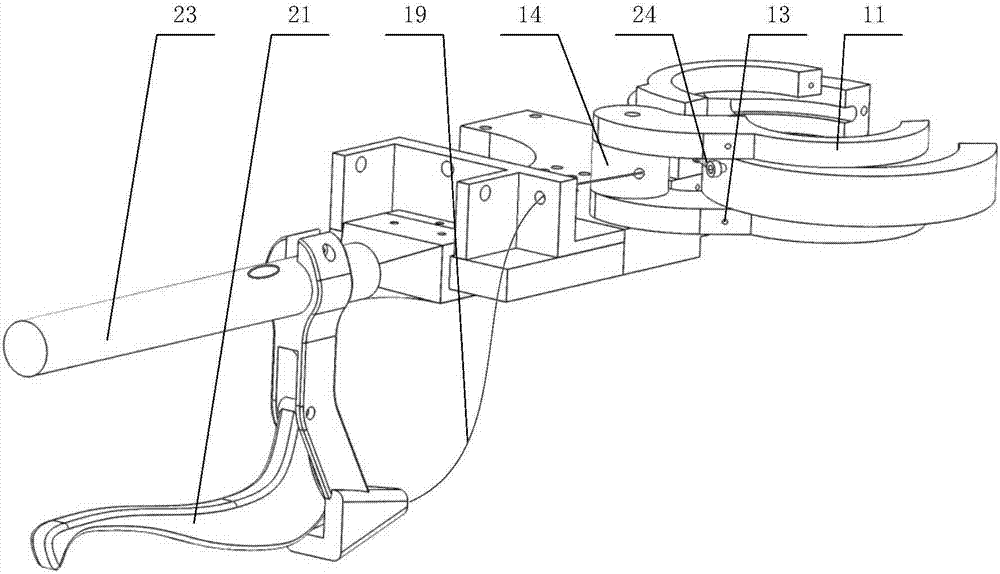

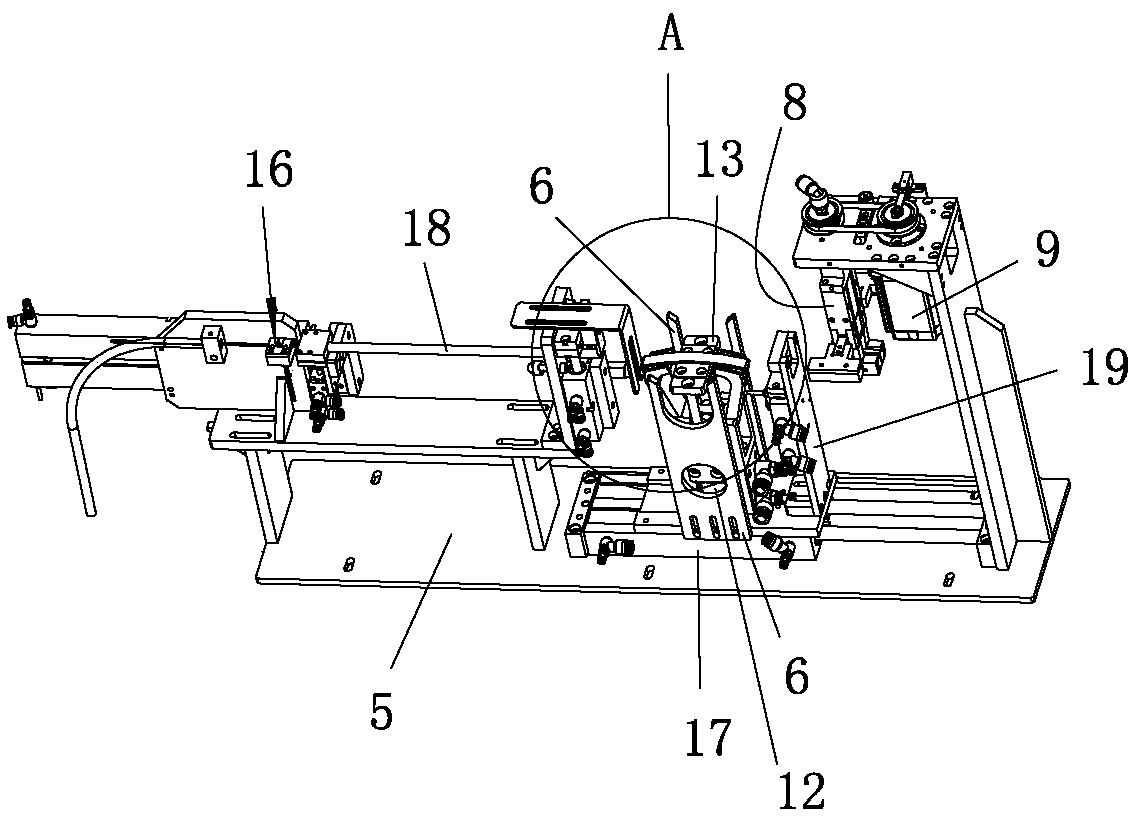

Fully automatic manipulator steel bar baler

ActiveCN104925293BRealize the tightening functionSimple structureBinding material applicationBundling machine detailsEngineeringRebar

The invention discloses a fully automatic manipulator rebar baling machine which comprises a lower threading straightening working table and a rotary clamping mechanical claw, wherein the lower threading straightening working table comprises a base, a mess wire frame, a roll type straightening machine, a hydraulic shear and an opening and closing guide pipe; the rotary clamping mechanical claw is composed of a rotating mechanism and a clamping mechanism. Bailing of rebar bundles can be realized by the aid of matching of the lower threading straightening working table and the rotary clamping mechanical claw. The lower threading straightening working table can perform automatic straightening threading to a steel wire used for packaging and cuts the steel wire at fixed length simultaneously, and the steel wire can be straightened through the mess wire frame simultaneously and is prevented from coiling. By the aid of the design of through holes and clamping structures on a left clamping working surface and a right clamping working surface, the rotary clamping mechanical claw can well solve the problem that the clamping force for the packaging steel wire is not enough, so that bailing tightening strength is improved, and bailing claw falling and loosening are avoided.

Owner:天津市福鼎机电设备有限公司

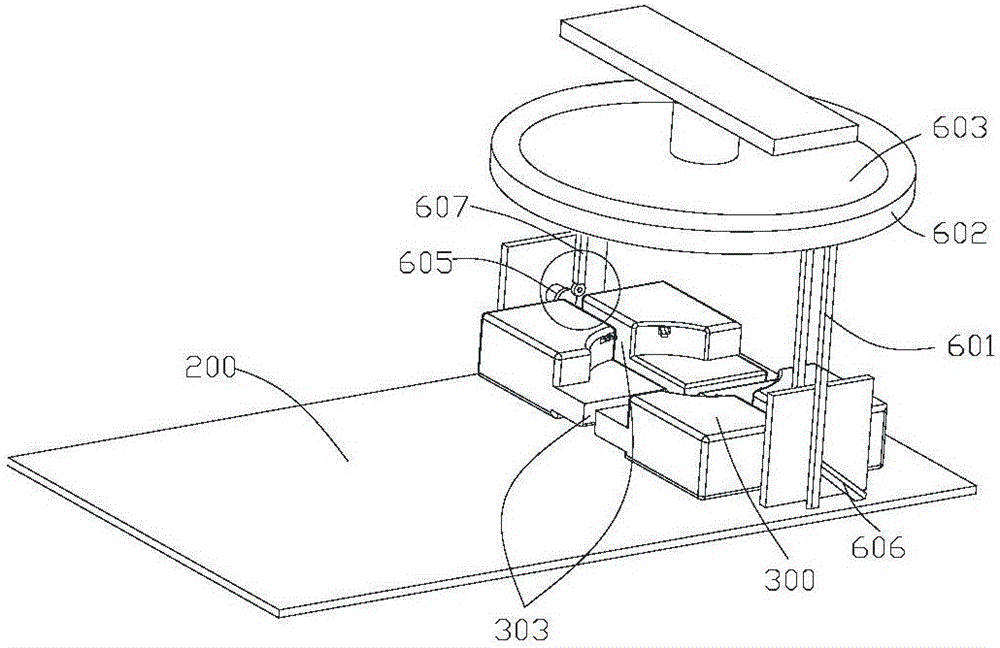

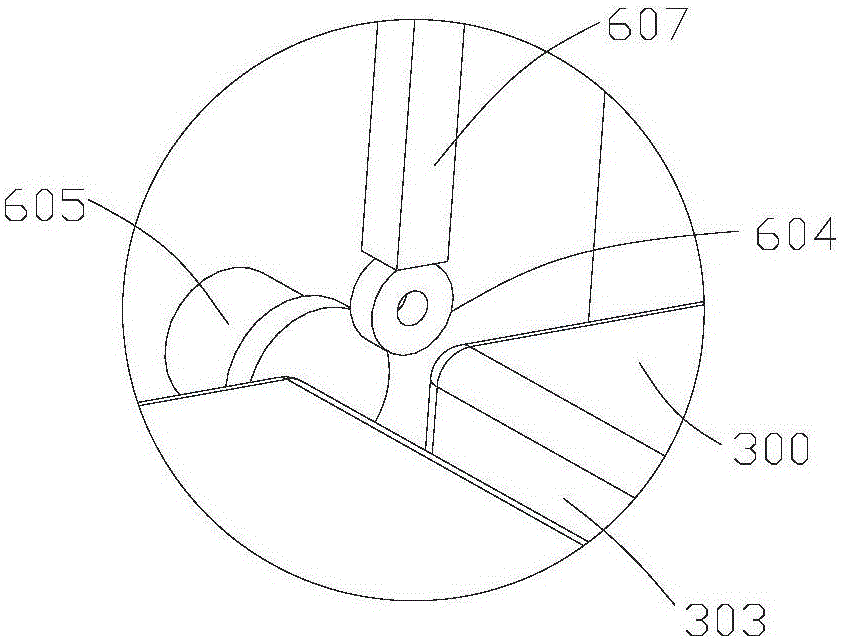

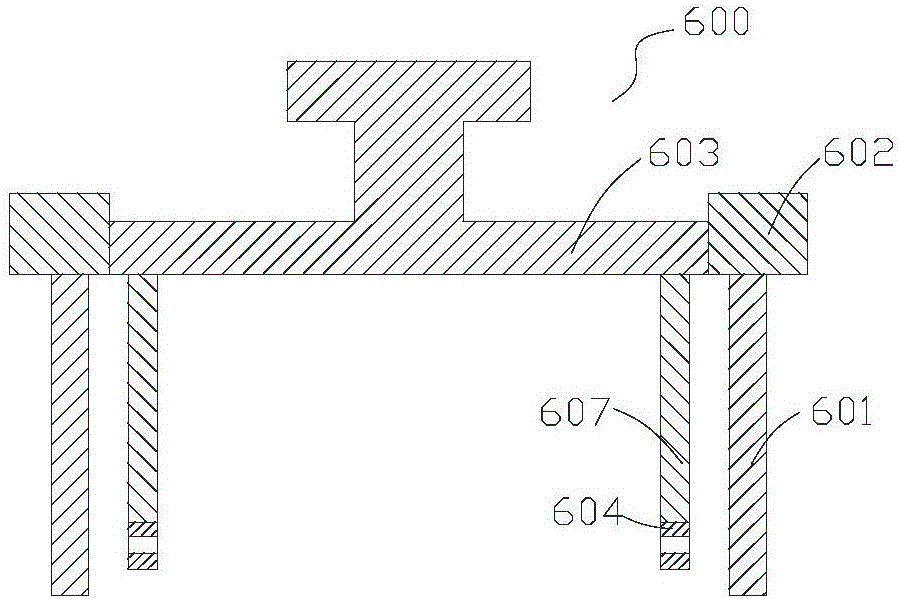

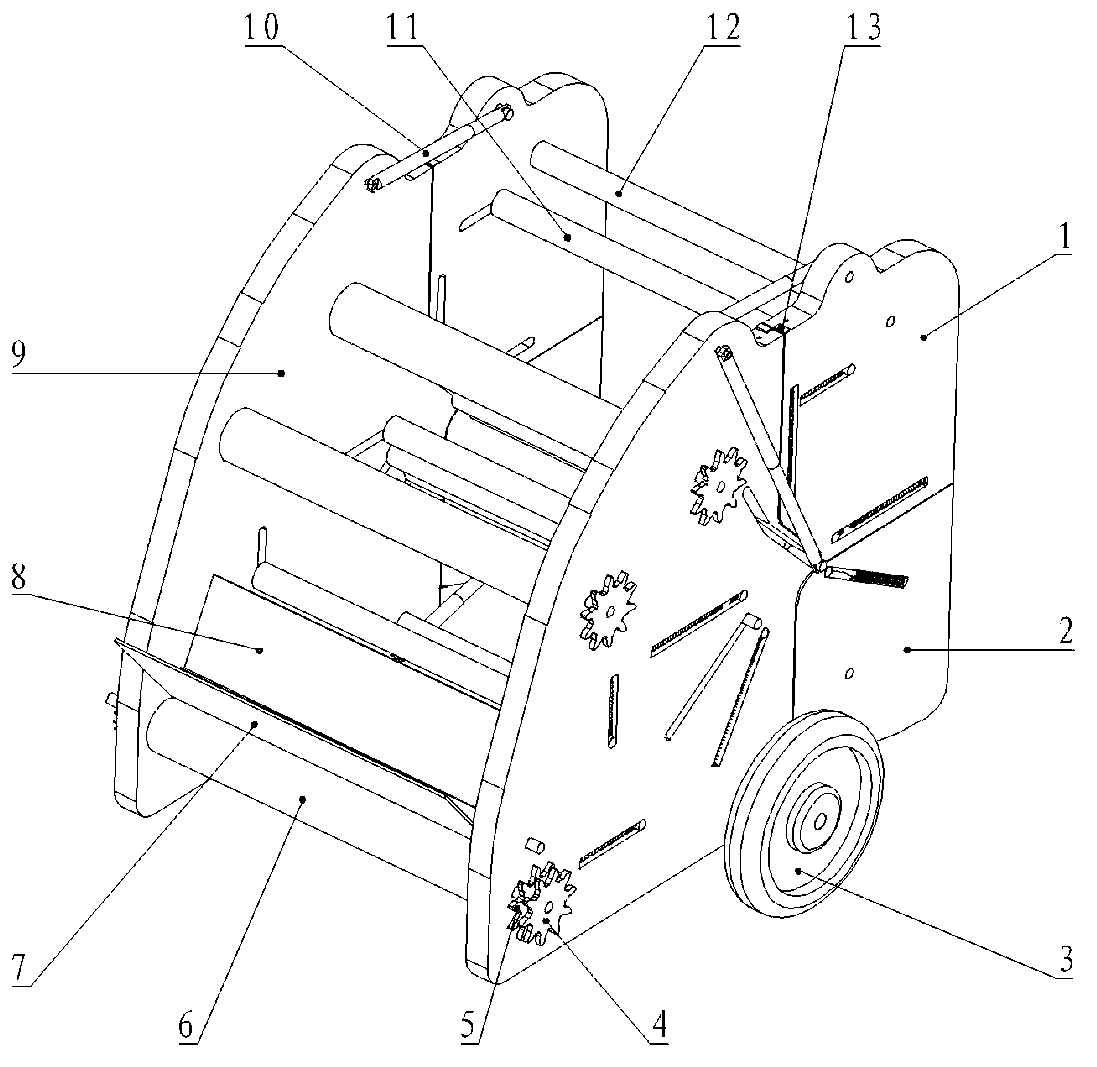

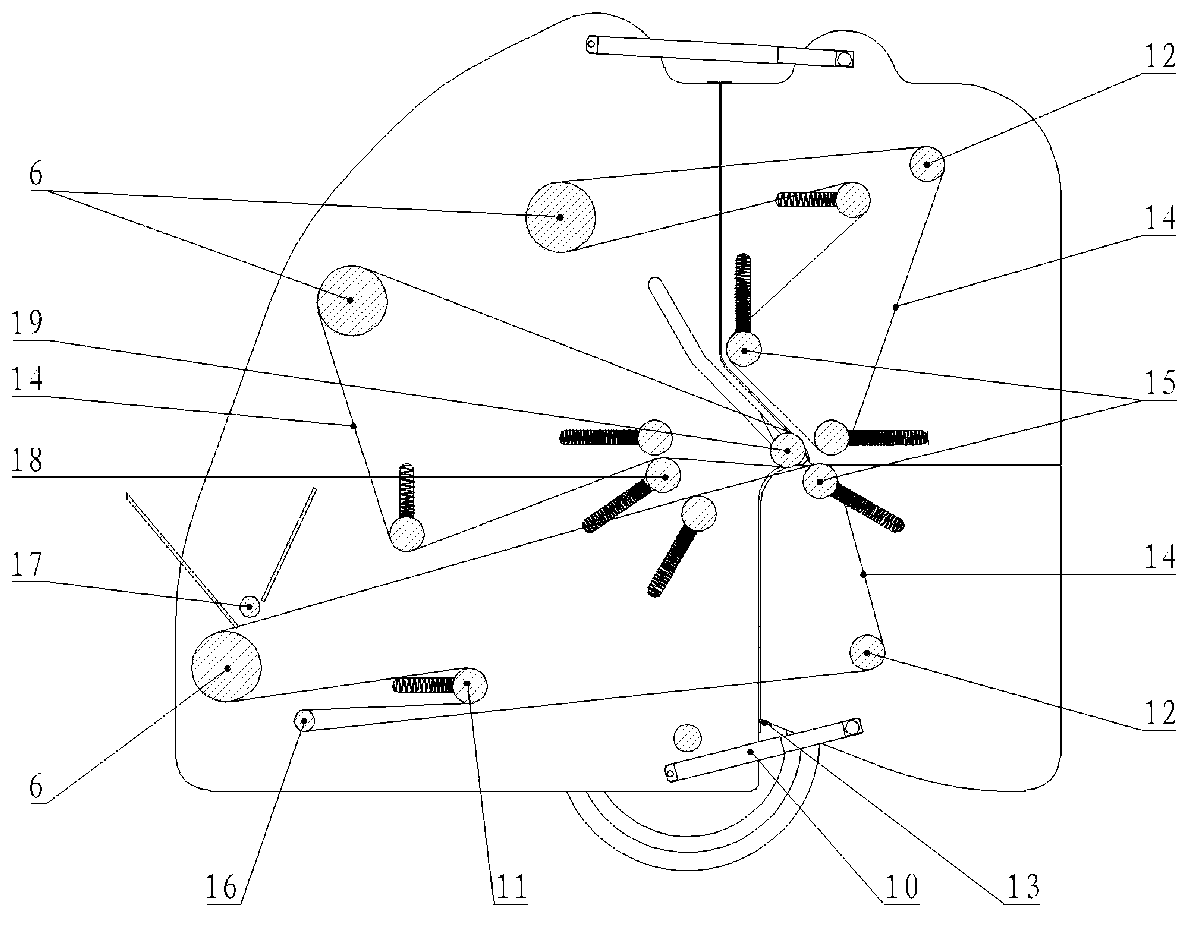

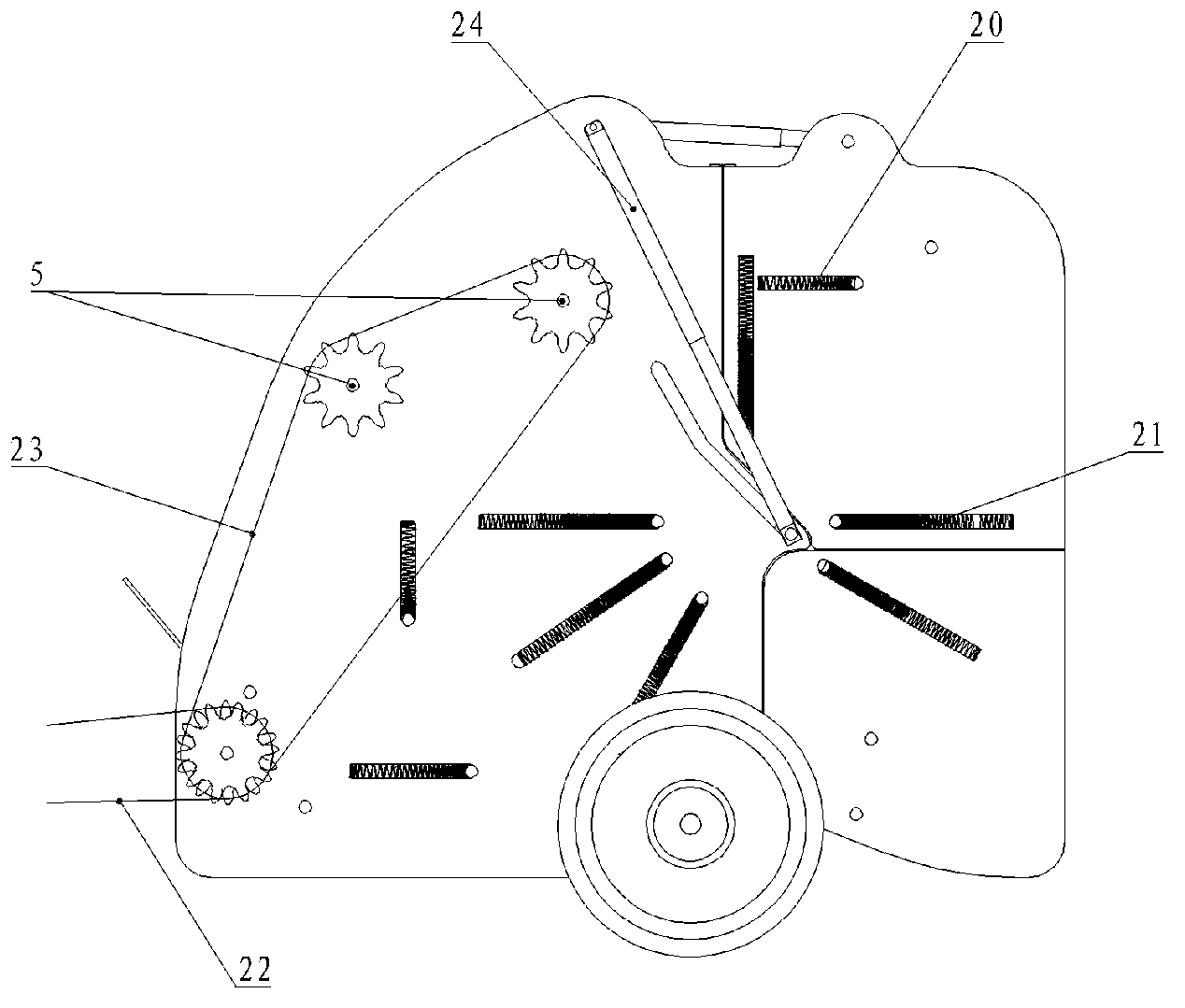

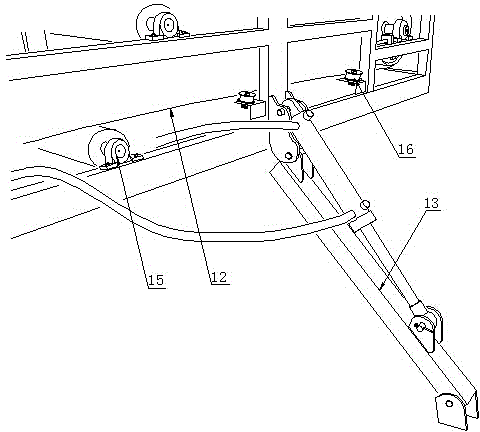

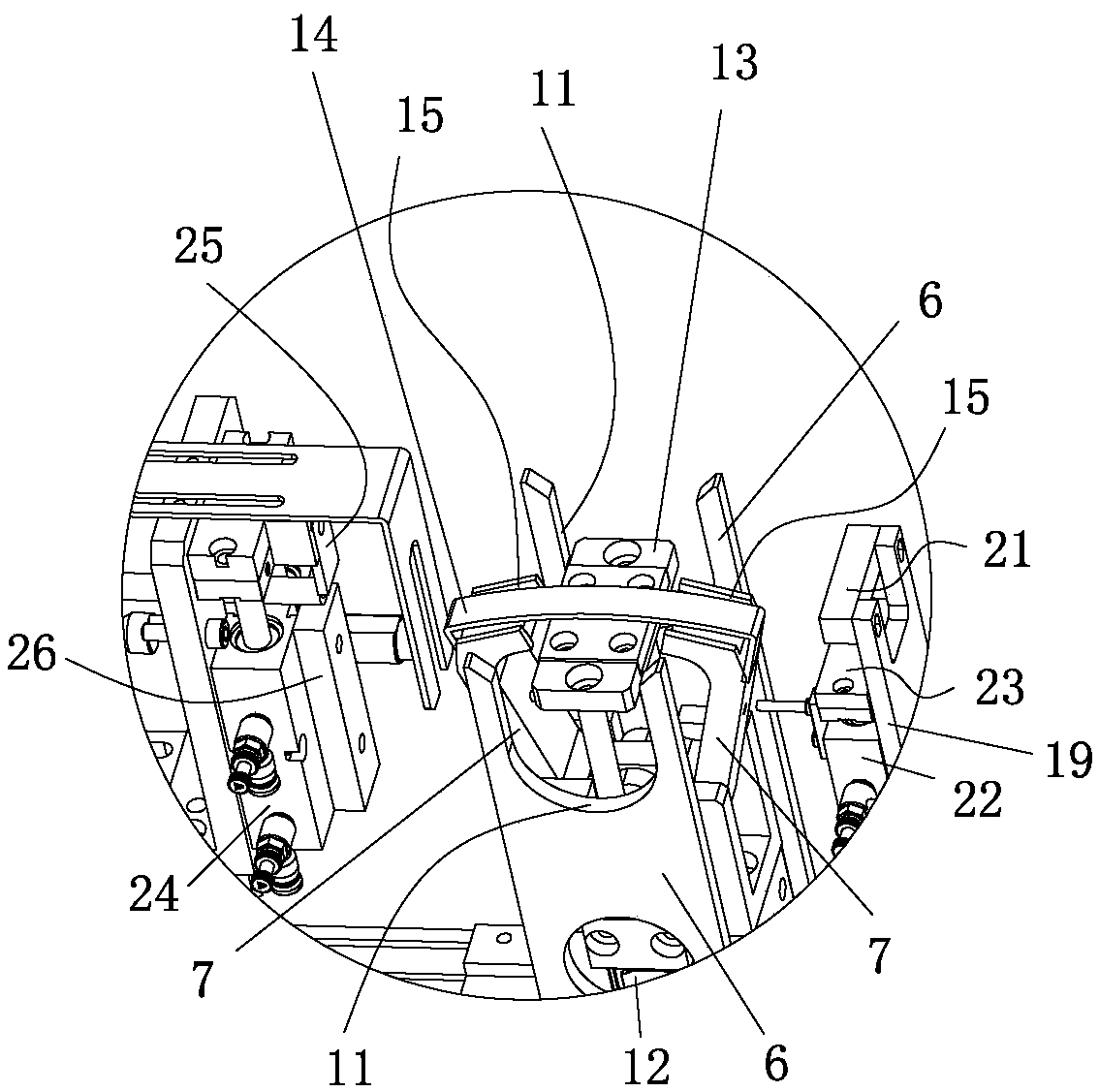

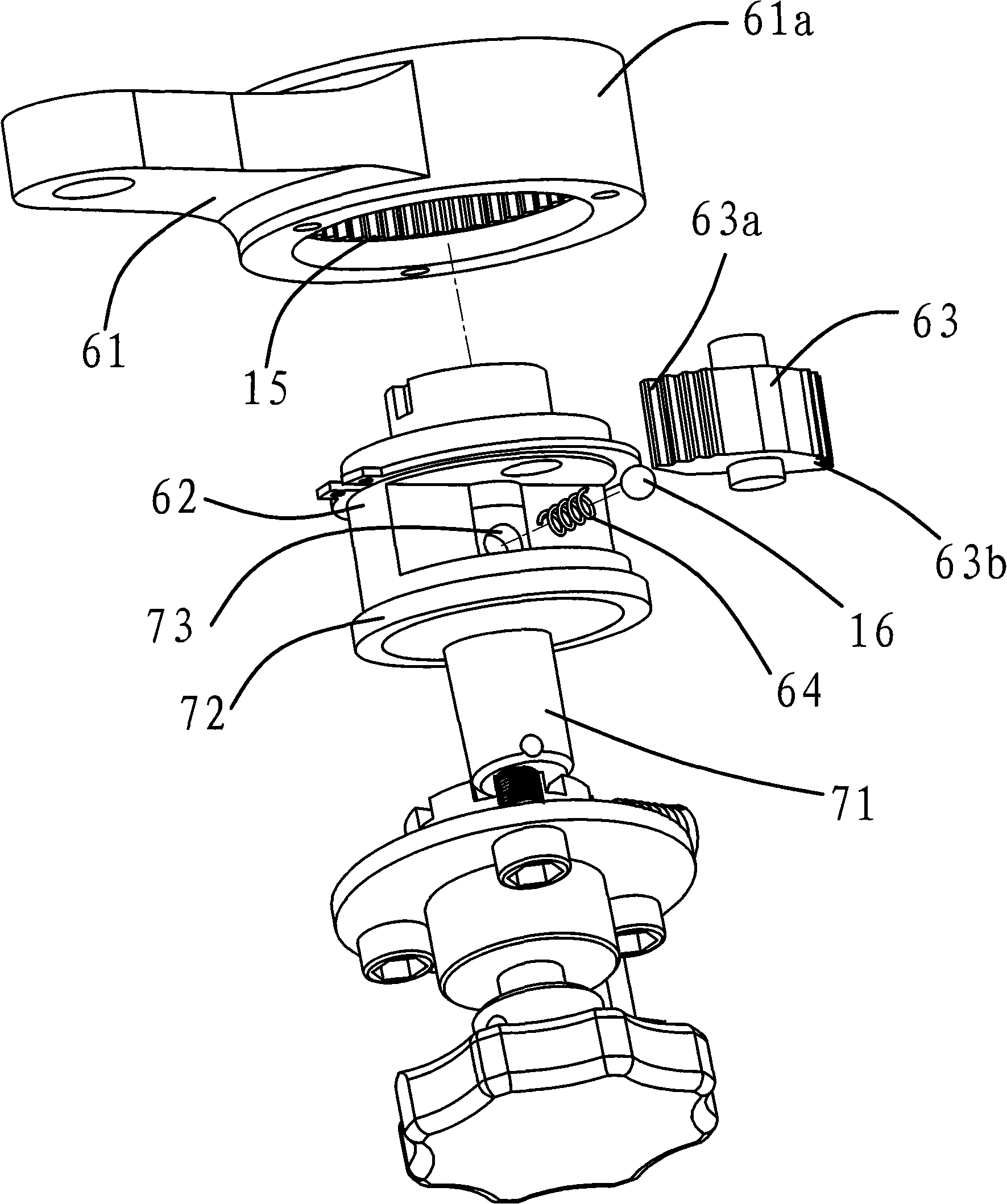

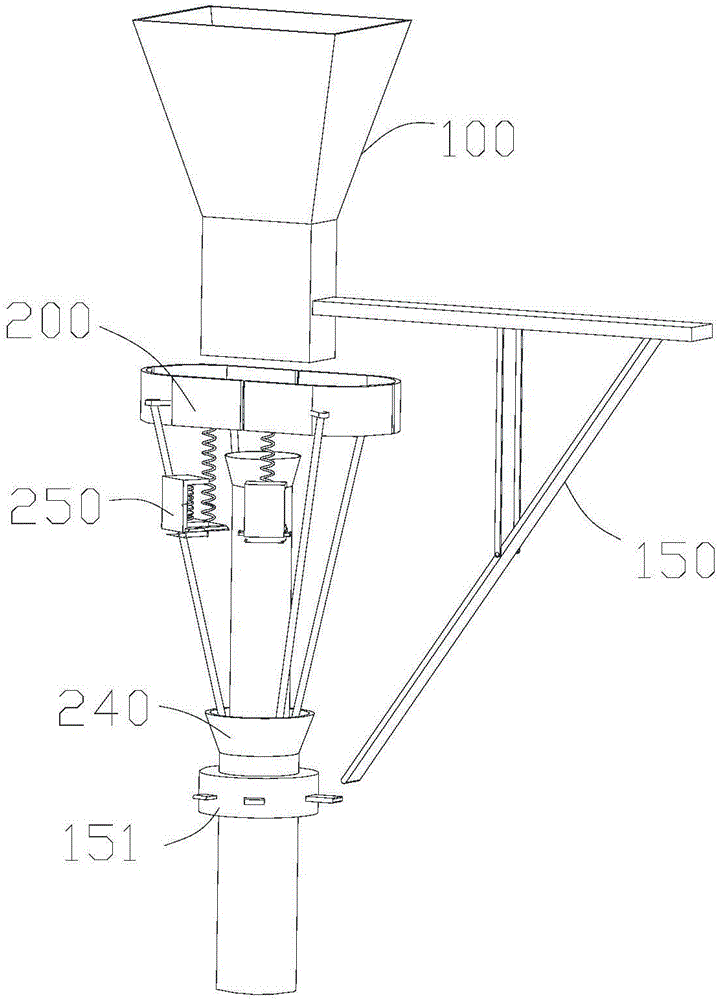

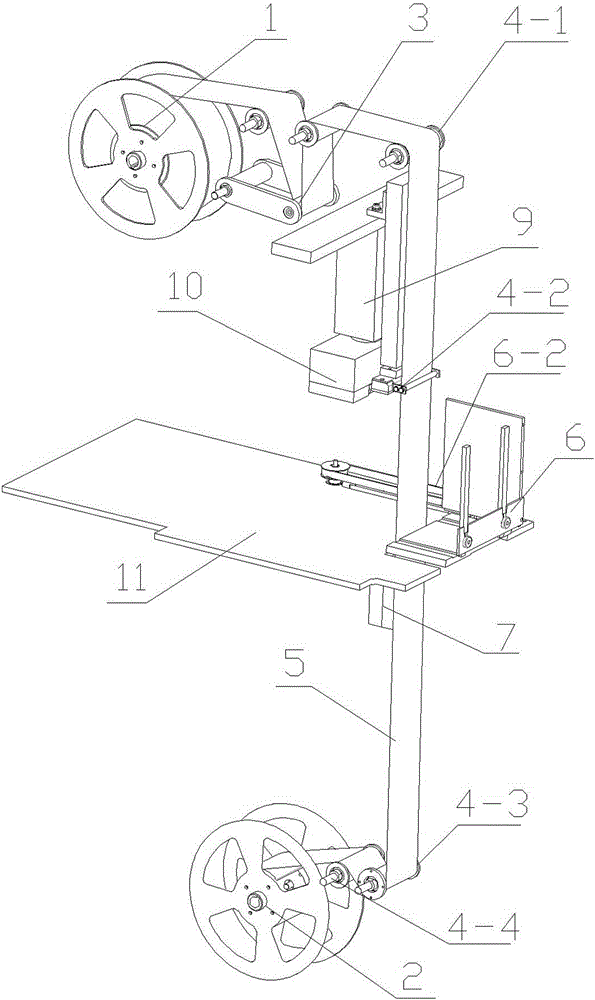

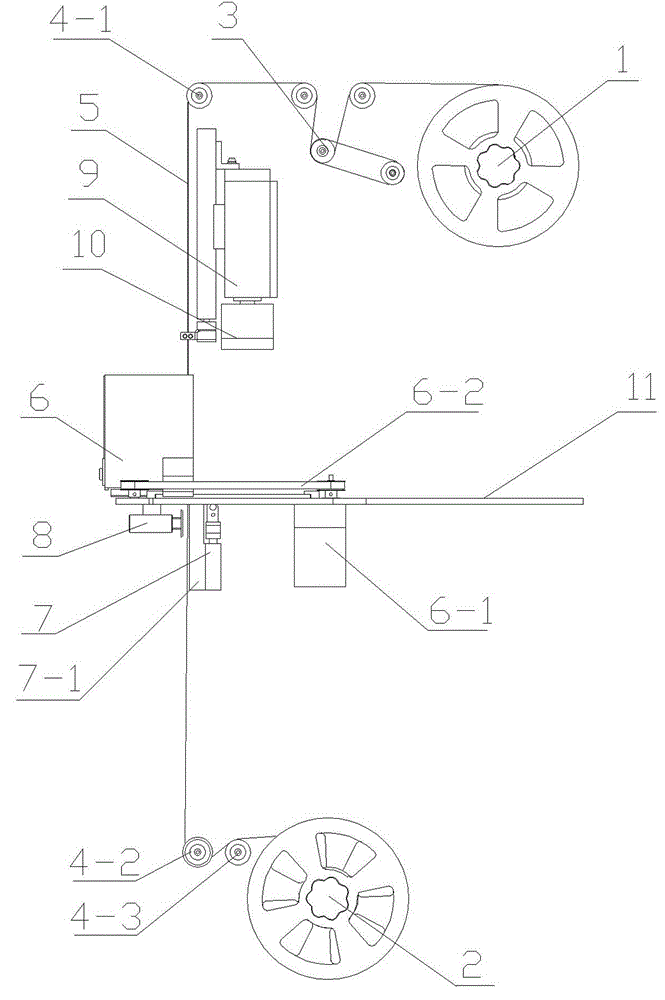

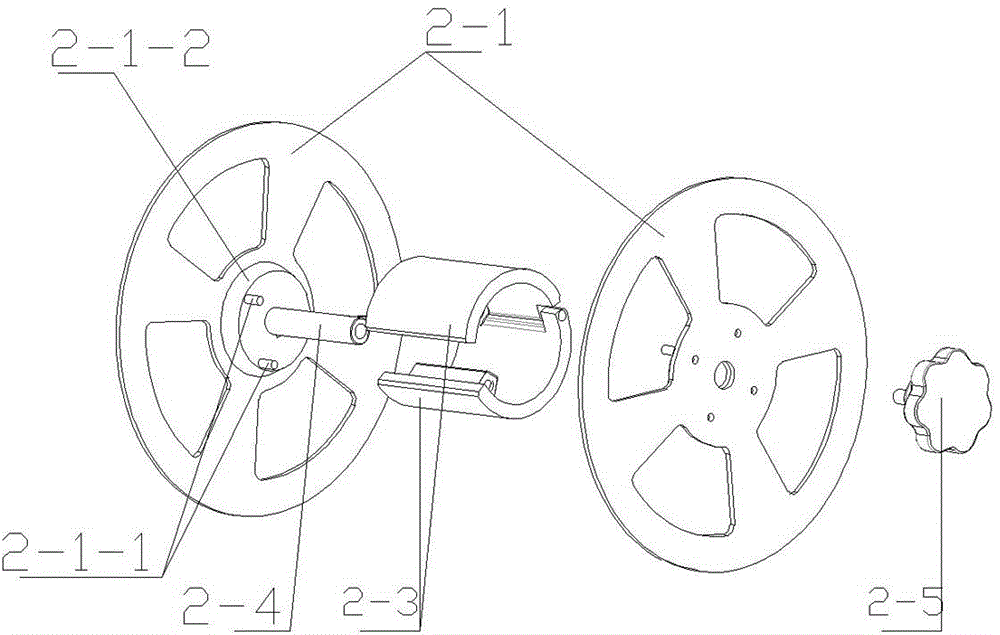

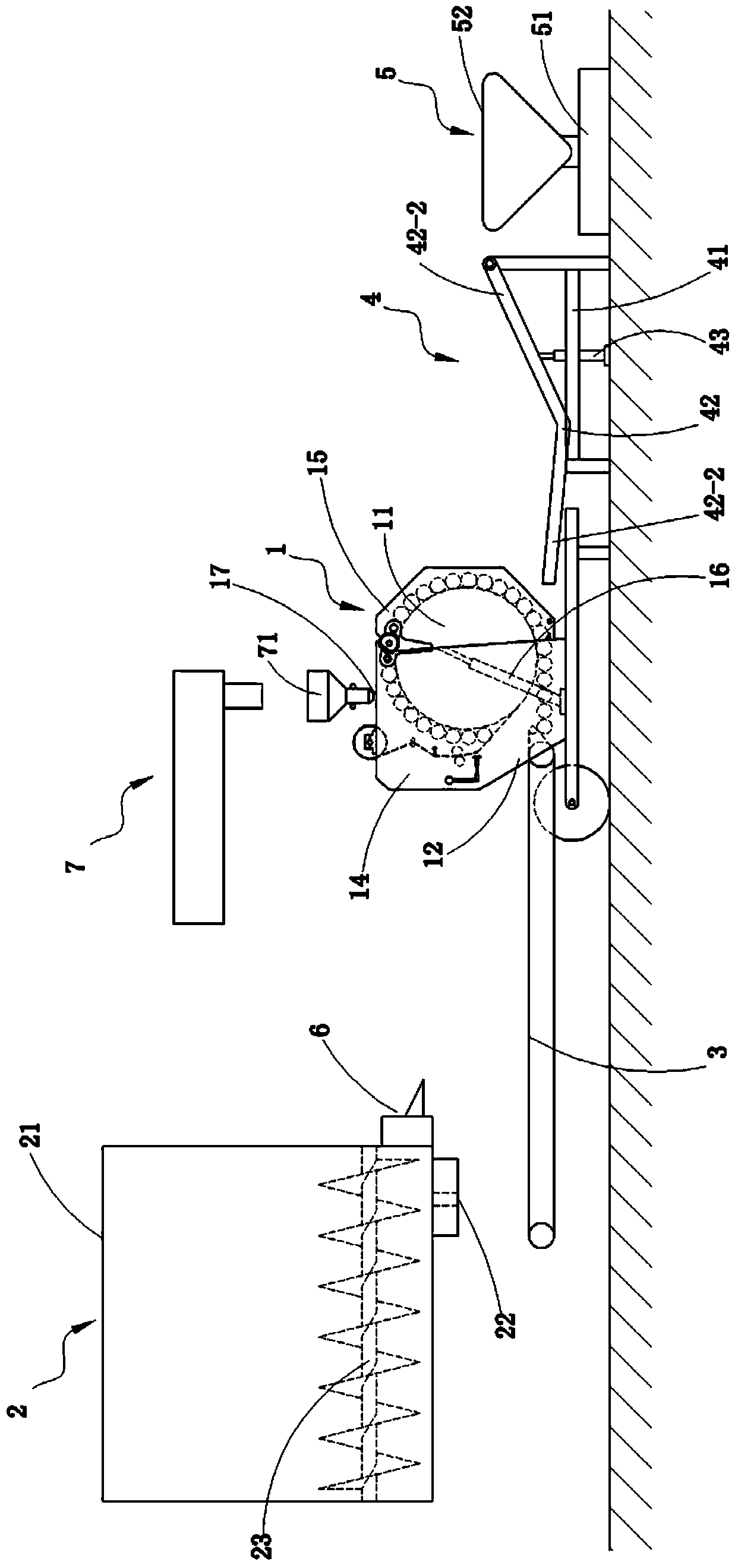

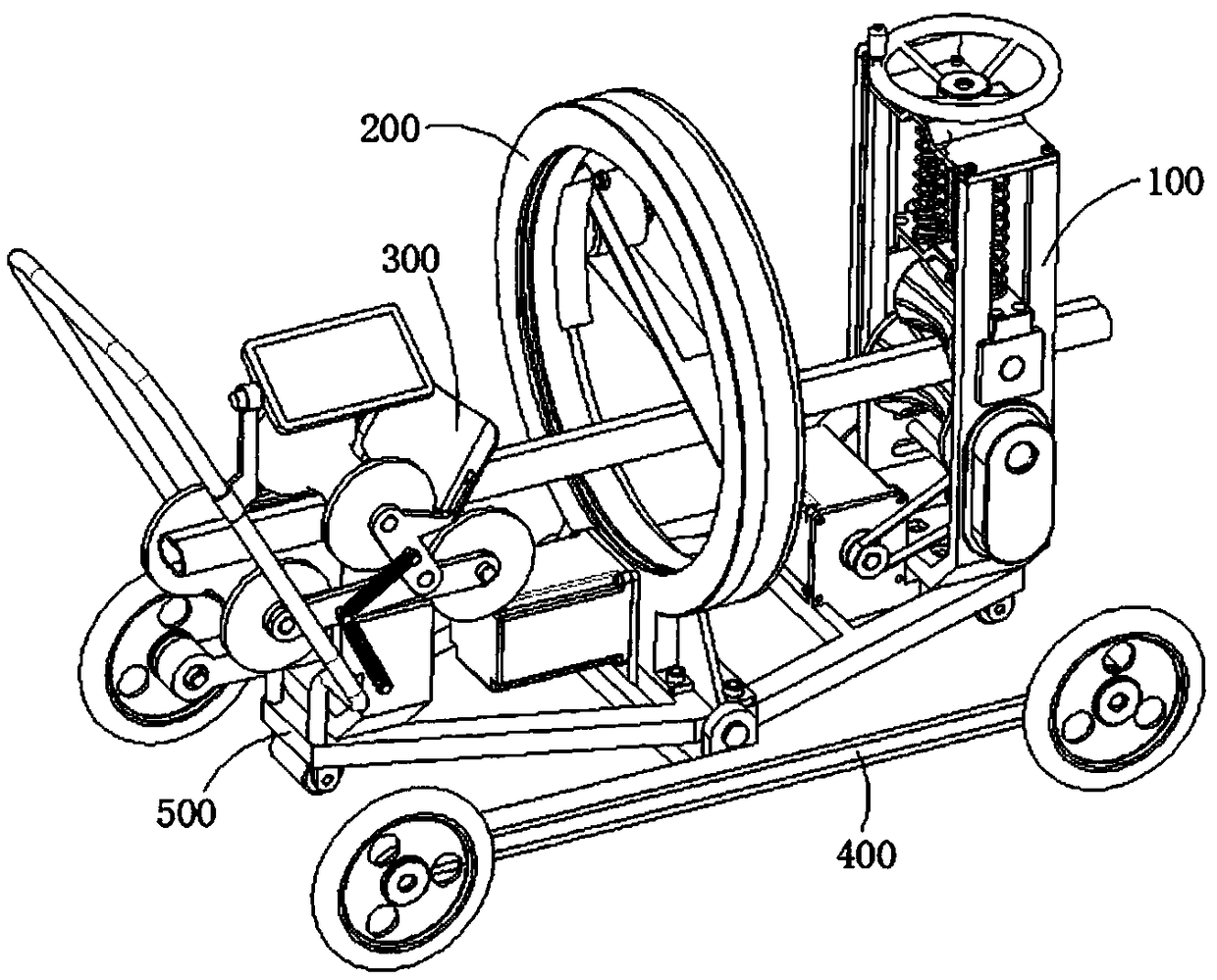

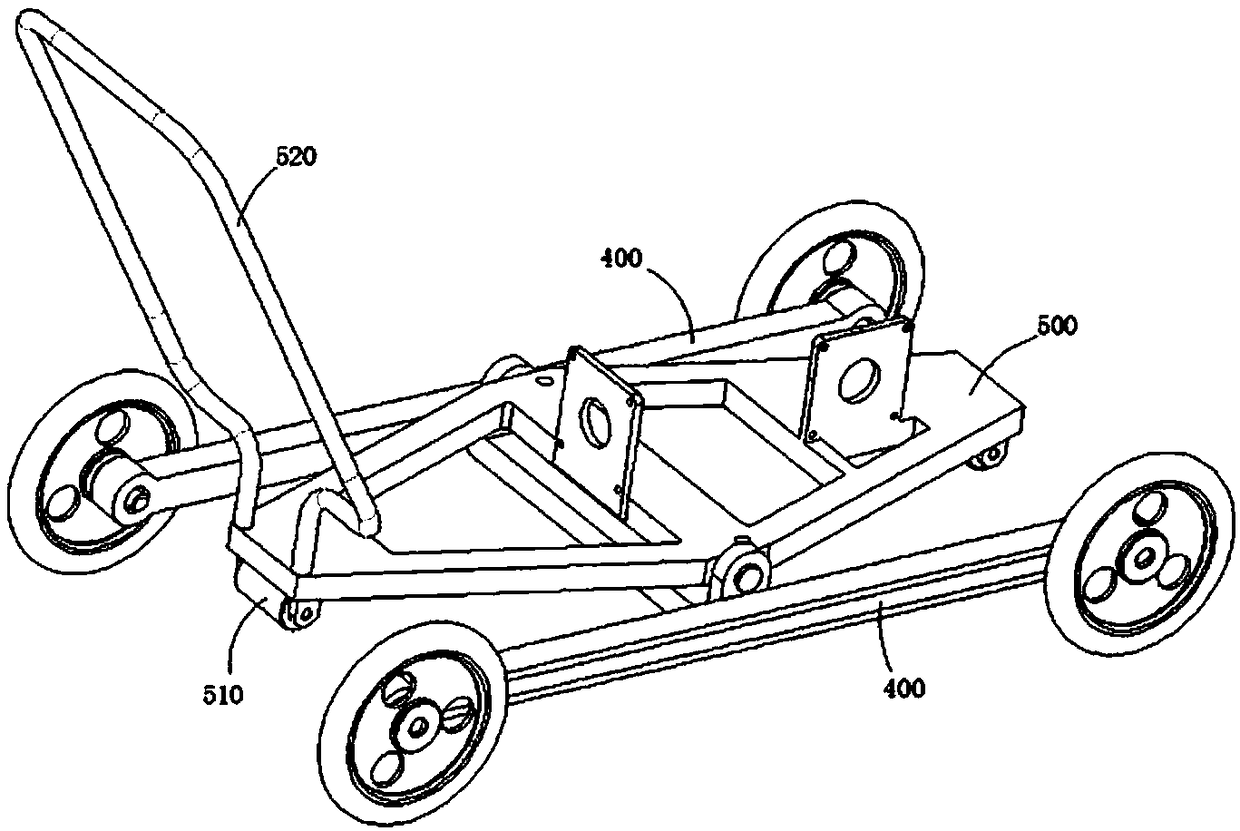

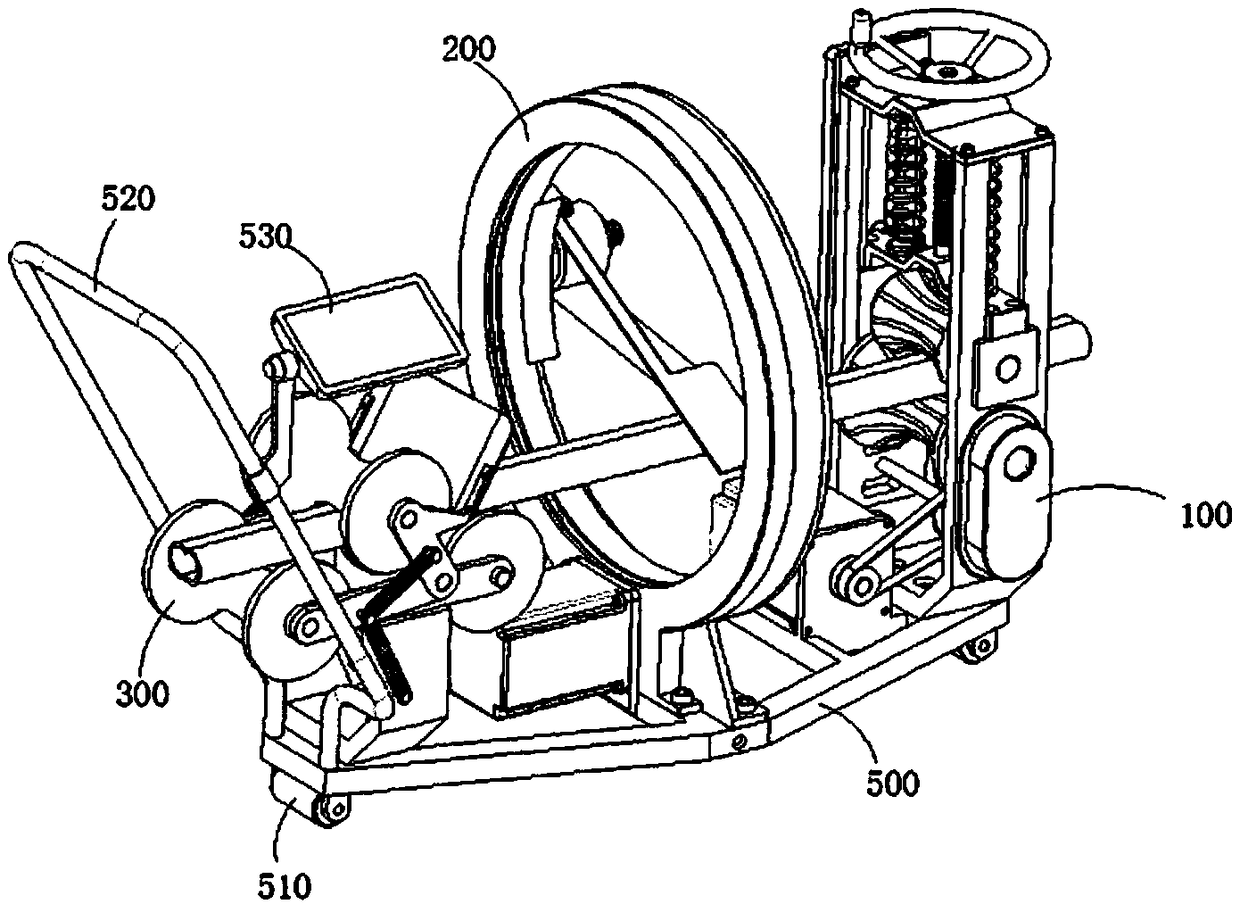

Portable automatic bunching device for crabs

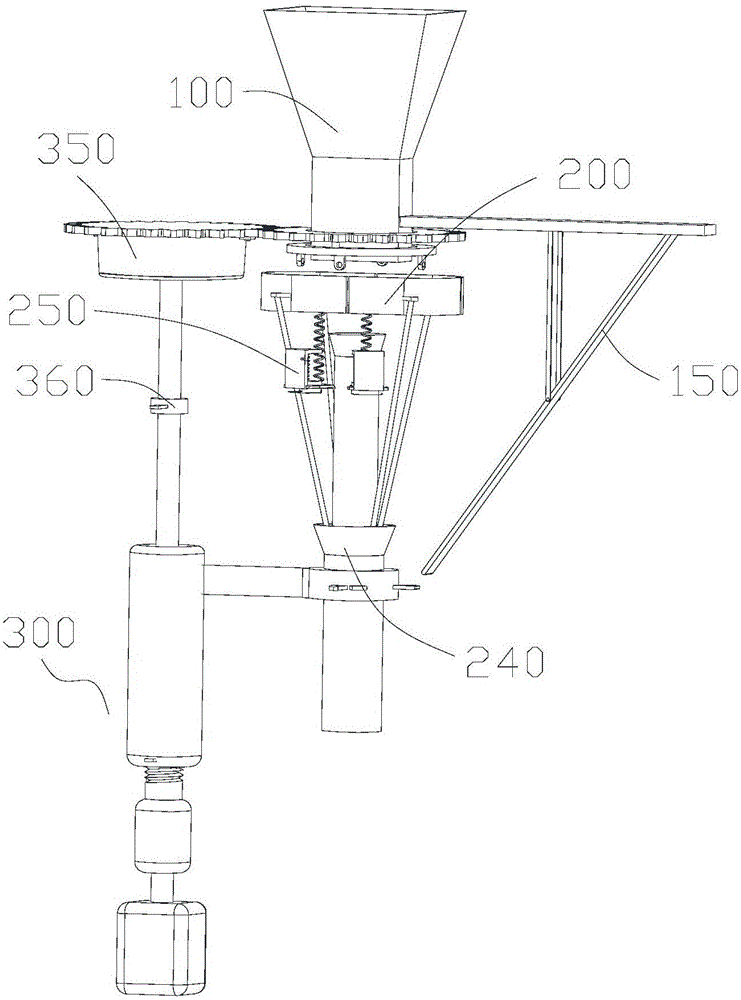

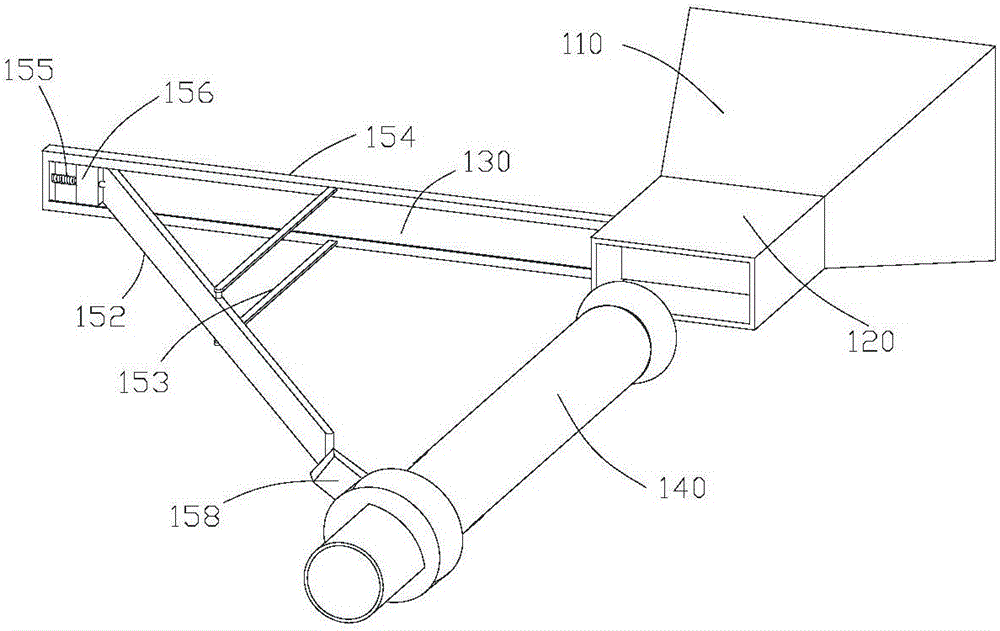

ActiveCN106043777AQuick fixImprove bundling efficiencyBinding material applicationEngineeringAssistive equipment

The invention provides a portable automatic bunching device for crabs, and belongs to the field of crab processing devices. The portable automatic bunching device comprises a feeding mechanism, a bunching mechanism and a positioning mechanism. The positioning mechanism is used for fixing crab legs. The feeding mechanism comprises a hopper, a channel and a baffle. The hopper is mounted at the top of the channel. The channel is vertically arranged. The baffle is mounted in the channel, and is used for controlling the channel to be opened or closed. The positioning mechanism is positioned at the lower part of a discharge opening of the channel, and is used for bearing crabs falling from the discharge opening and fixing the crab legs. The bunching mechanism is located between the positioning mechanism and the feeding mechanism, and is used for bunching crabs. An auxiliary device, that is, the portable automatic bunching device, is simple and reasonable in structure, convenient to process and manufacture, low in manufacturing cost, and convenient to mount and use; and besides, crabs can be quickly fixed through the auxiliary device, workers are not easily injured during the fixing process, and crab claws are not prone to be damaged, so that the crab bunching efficiency is improved, and the auxiliary device is safe, reliable, and convenient to use.

Owner:YANCHENG INST OF TECH

Room-changing belt-type binding machine

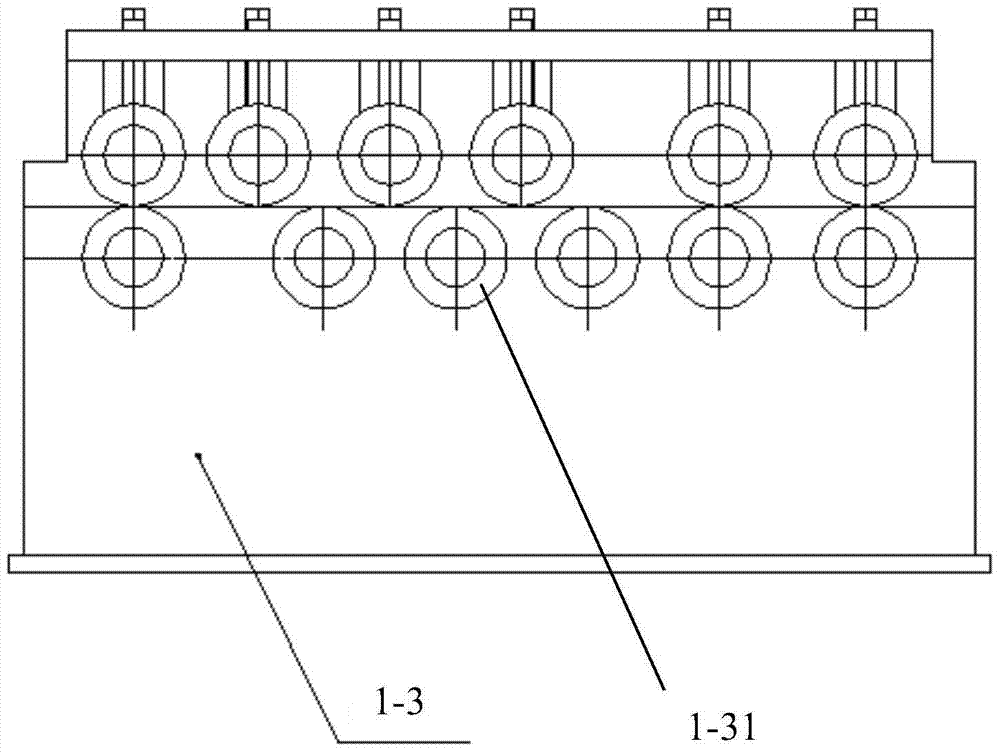

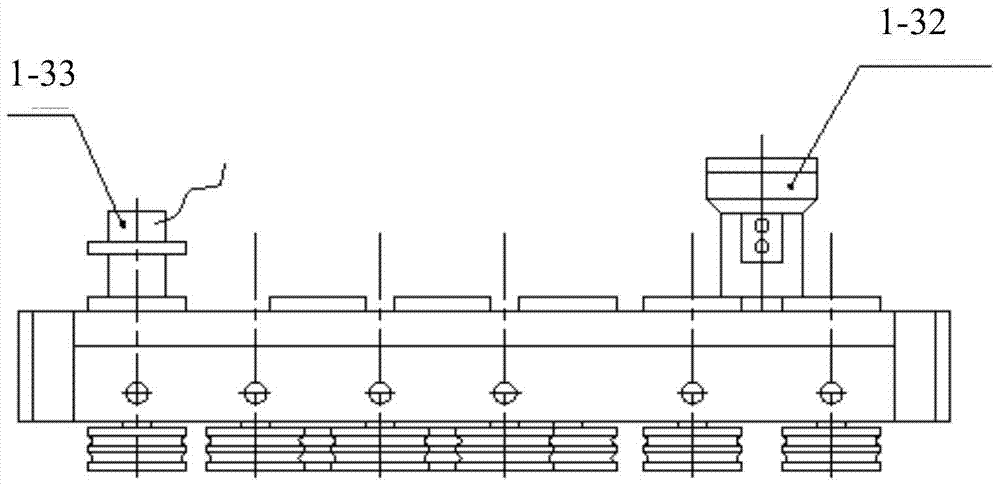

The invention discloses a room-changing belt-type binding machine. The binding machine consists of installation plates, a feed channel, a chain mechanism, a compressor and wheels, wherein the feed channel is arranged on the lower part in front of a space between the two installation plates and is connected with a discharge hole of a harvester; the compressor is arranged in middle of the space between the installation plates; and the chain mechanism is arranged on the front parts of the outer side surfaces of the installation plates. When the room-changing belt-type binding machine works, straws are primarily compressed, so that gaps among the stalks are fully reduced, part of gas is exhausted, the surfaces of fibers can be sufficiently contacted with one another, and the compression rate of the stalks can be improved since the fibers are staggered with one another in the compression process; and the stalks are secondarily compressed by a rubbing and pressing forming manner with a high core forming rate, thereby guaranteeing the forming rate of bales. When the compressor is used for forming roll cores, a hydraulic control mechanism implements force application in a rubbing and pressing process, so that compressing force is large, the bales are stressed uniformly in the compression process, and the shapes of hay cores and the formed bales are regular. The room-changing belt-type binding machine is simple in structure and low in cost, can achieve a high binding efficiency, and can be widely applied to agricultural production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

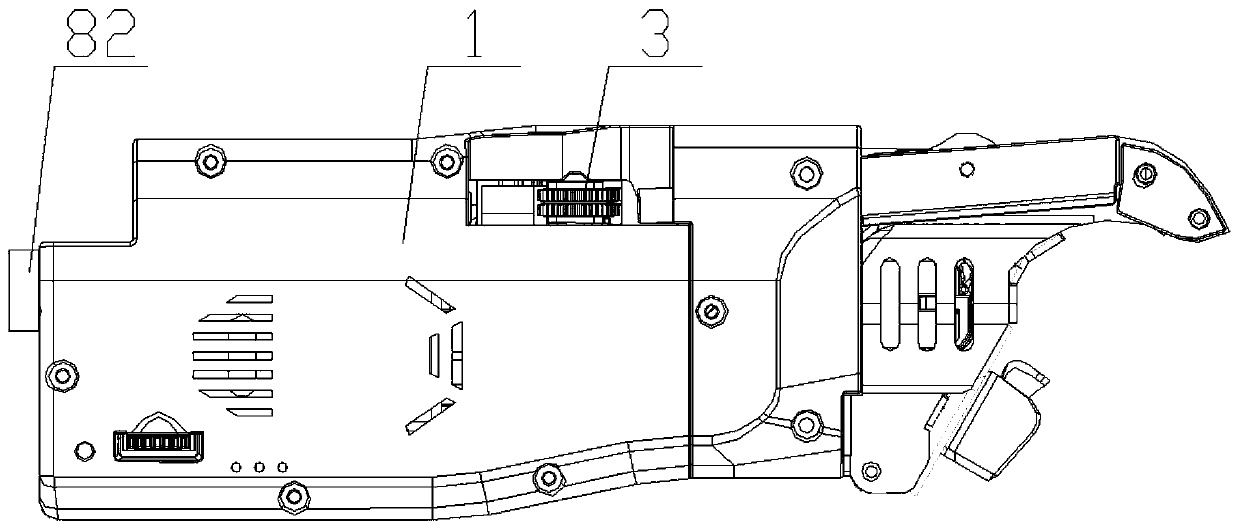

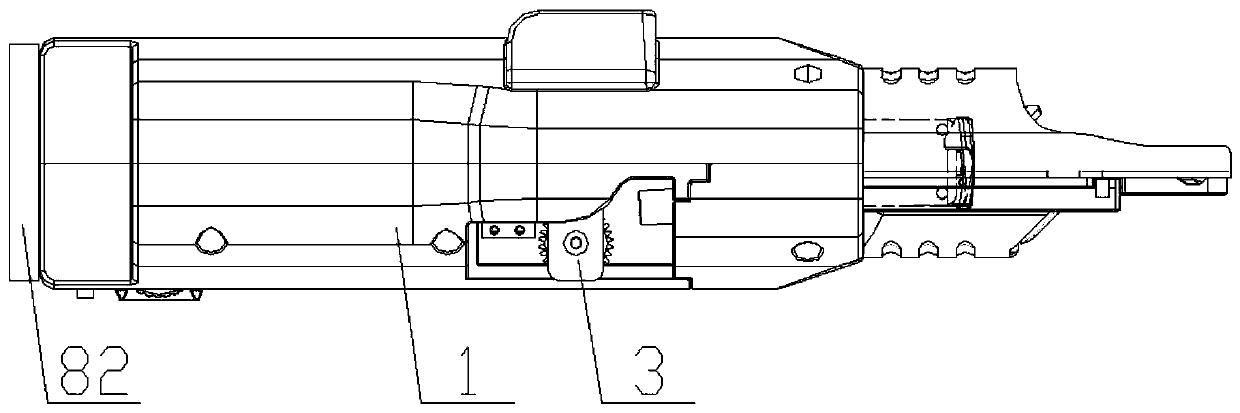

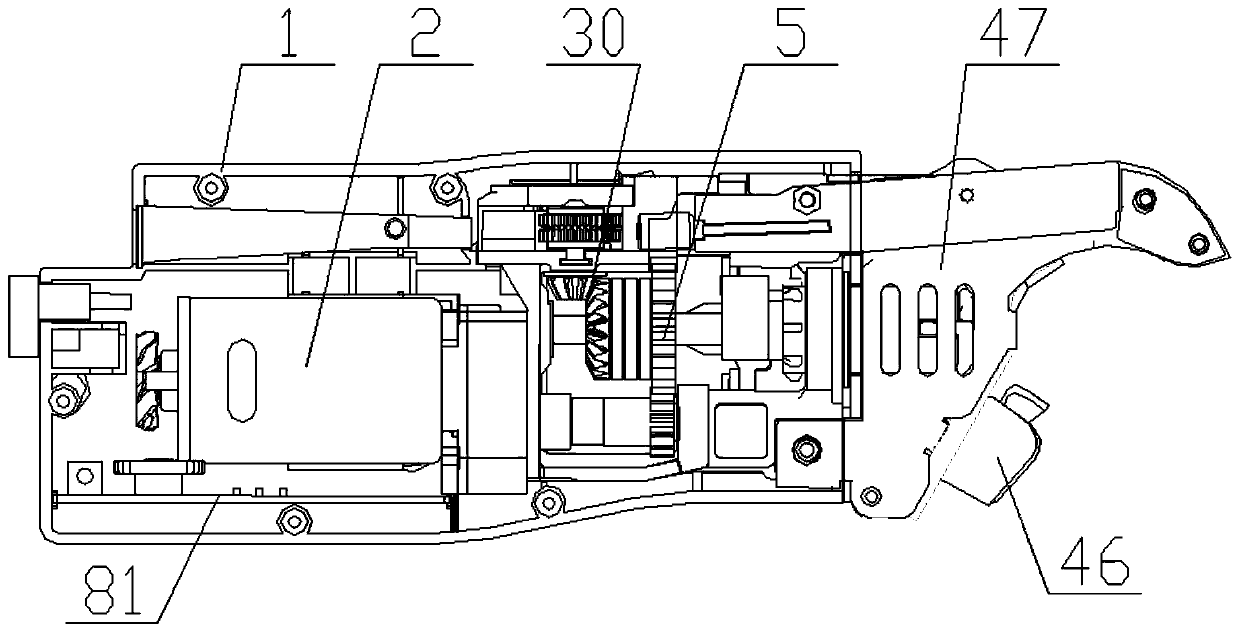

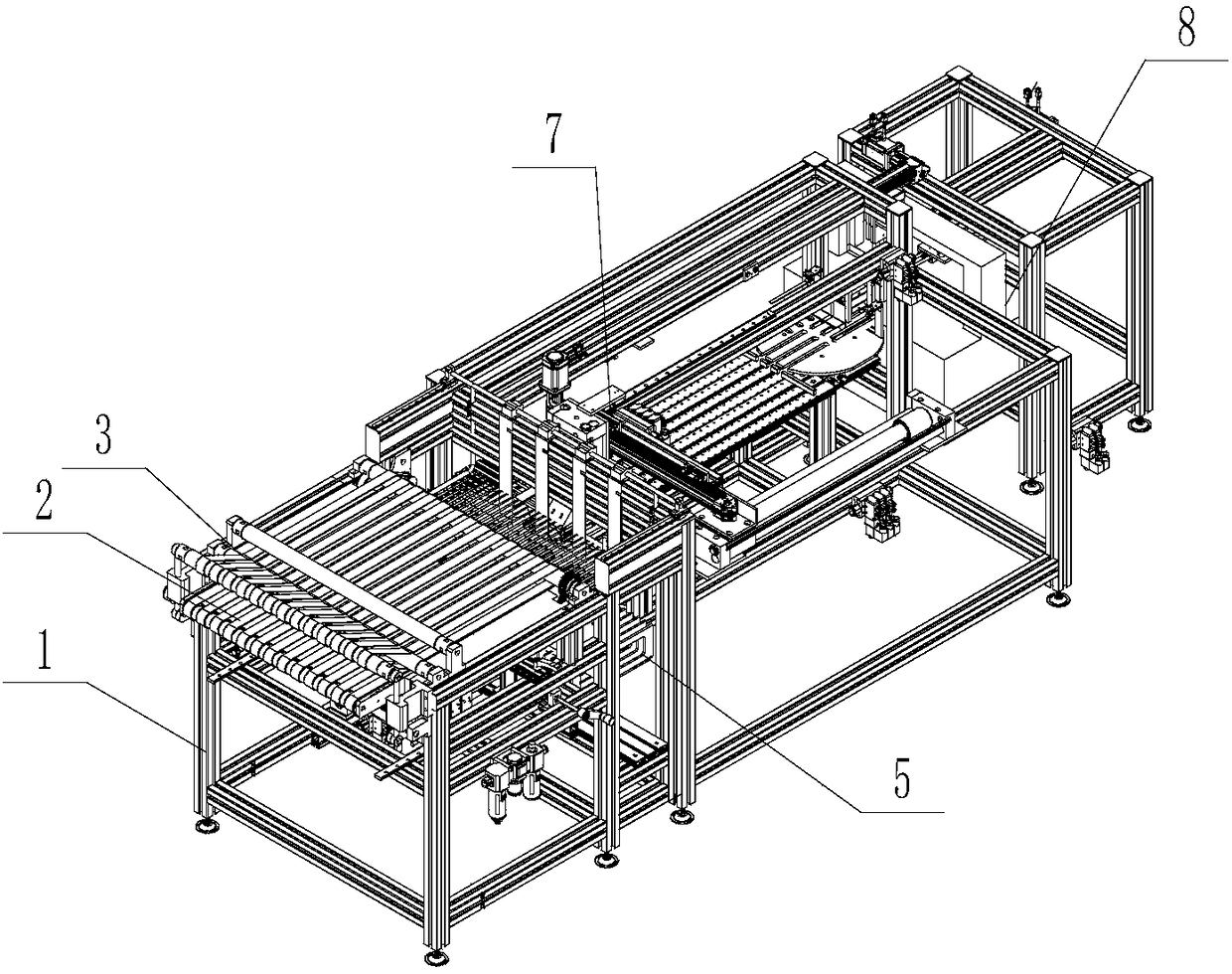

Communication type no-handheld steel bar strapping machine and steel bar strapping automation equipment

PendingCN111576888AQuality assuranceReduce volumeClosed circuit television systemsBuilding material handlingStrappingElectric machinery

The invention discloses a communication type no-handheld steel bar strapping machine and steel bar strapping automation equipment. The communication type no-handheld steel bar strapping machine comprises a machine shell, a main control unit, a motor, a wire feeding mechanism, a wire twisting mechanism and a cutting-off mechanism, wherein the machine shell is in a long strip type shape without a handheld portion, the motor is arranged inside the machine shell, and the wire feeding mechanism, the wire twisting mechanism and the cutting-off mechanism are all arranged inside the machine shell in the length direction of the machine shell to make the steel bar strapping machine be long in size only in the length direction. The communication type no-handheld steel bar strapping machine is small in structural volume and is suitable for performing steel bar strapping work in some relatively narrow areas in which plate face steel bars and vertical face steel bars intersect and steel bar combination sites where inner layer and outer layer steel bar nets exist, and the quality of steel bar strapping in these special sites is guaranteed; and meanwhile, the steel bar strapping automation equipment realized on account of the communication type no-handheld steel bar strapping machine can be suitable for automation strapping of various steel bar combinations and has the advantage of being highin steel bar strapping efficiency and quality.

Owner:GUANGDONG SHUNDE HUAYAN ELECTRONICS TECH CO LTD

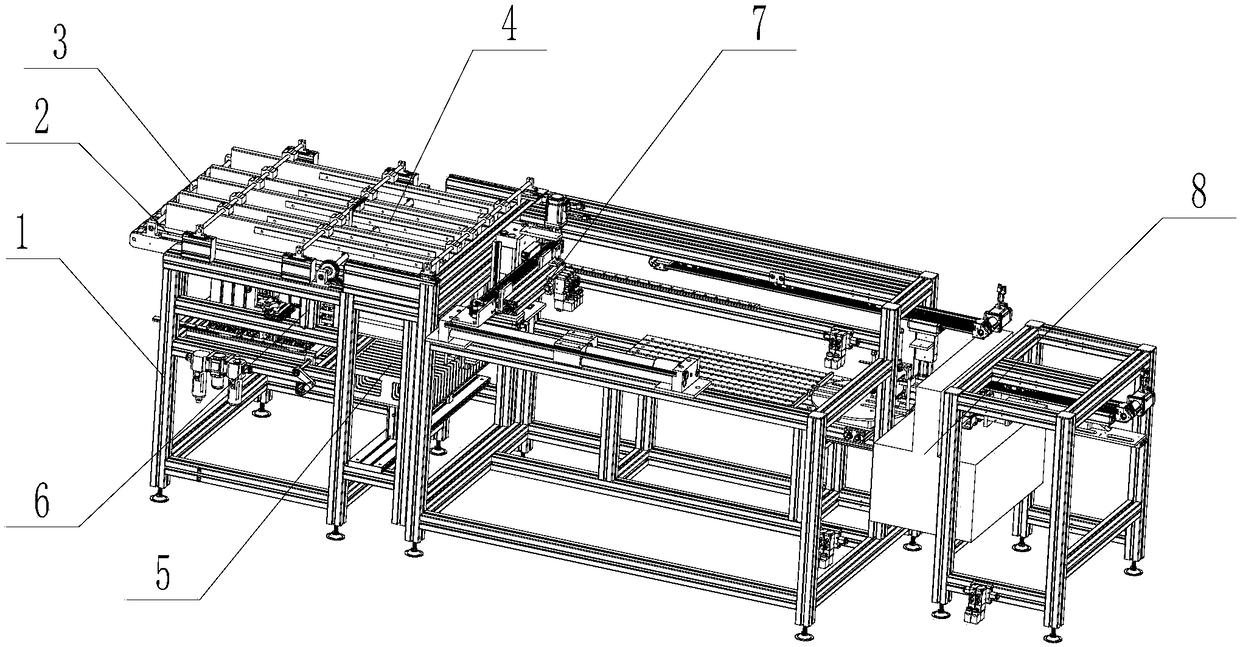

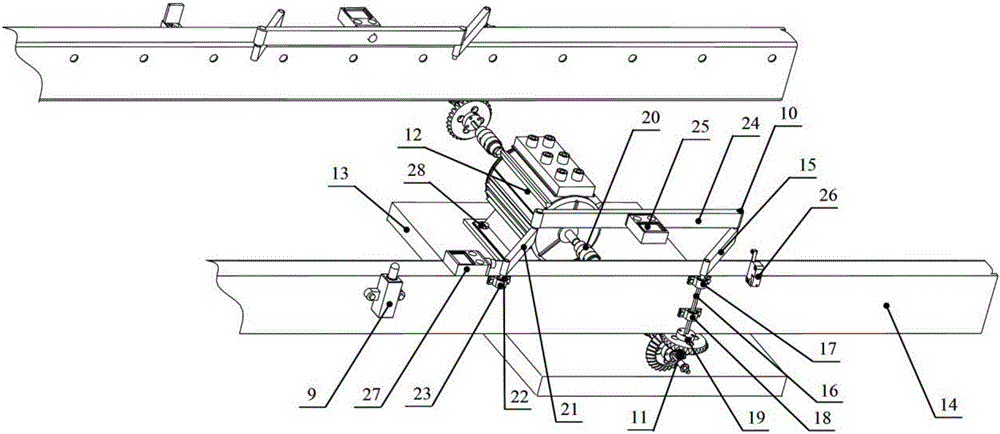

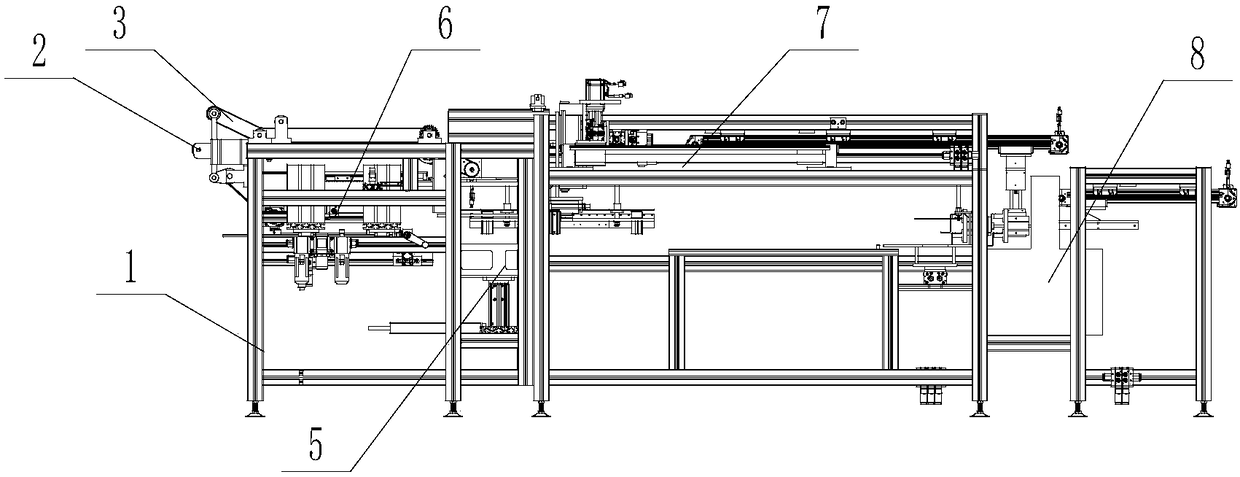

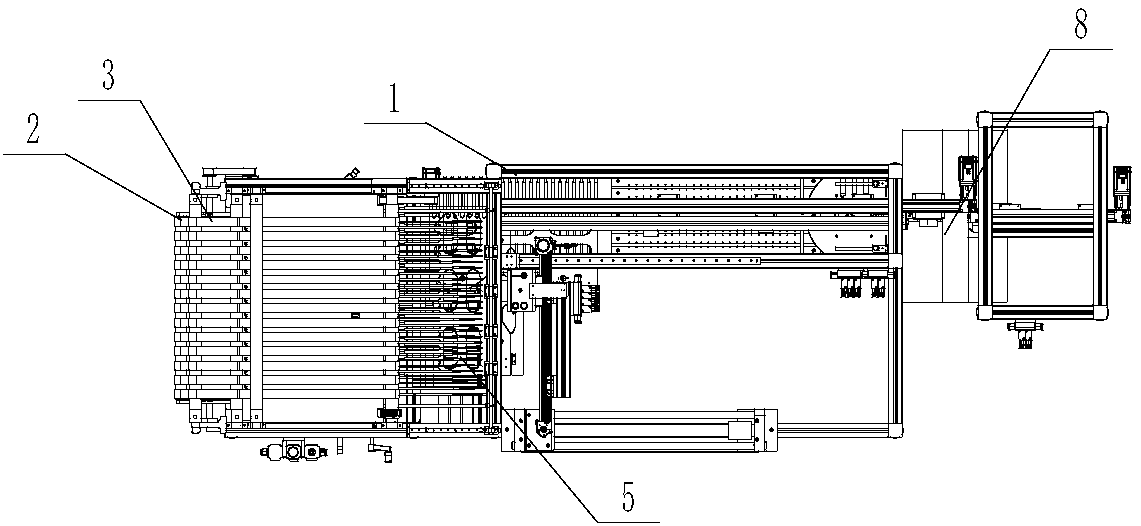

High-speed intelligent plastic bag arranging and bundling mechanism

ActiveCN108545237AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingPlastic recyclingEngineeringPlastic bag

The invention discloses a high-speed intelligent plastic bag arranging and bundling mechanism. The high-speed intelligent plastic bag arranging and bundling mechanism comprises a whole rack, a feedingconveying module, a guiding module, a falling groove module, a reciprocating pushing blocking rod module, a transferring module and a bundling module, and the feeding conveying module, the guiding module, a way-separation baffle module, the falling groove module, the reciprocating pushing blocking rod module, the transferring module and the bundling module are all arranged on the whole rack. Plastic bags can be automatically bundled, the bundling efficiency is high, and the labor cost is low; the high-speed intelligent plastic bag arranging and bundling mechanism can be adjusted to adapt to automatic bundling of the plastic bags of different widths, lengths and thicknesses, and the application range is wide; and unqualified products can be detected and removed, and the removing efficiencyis high.

Owner:浙江创派智能科技有限公司

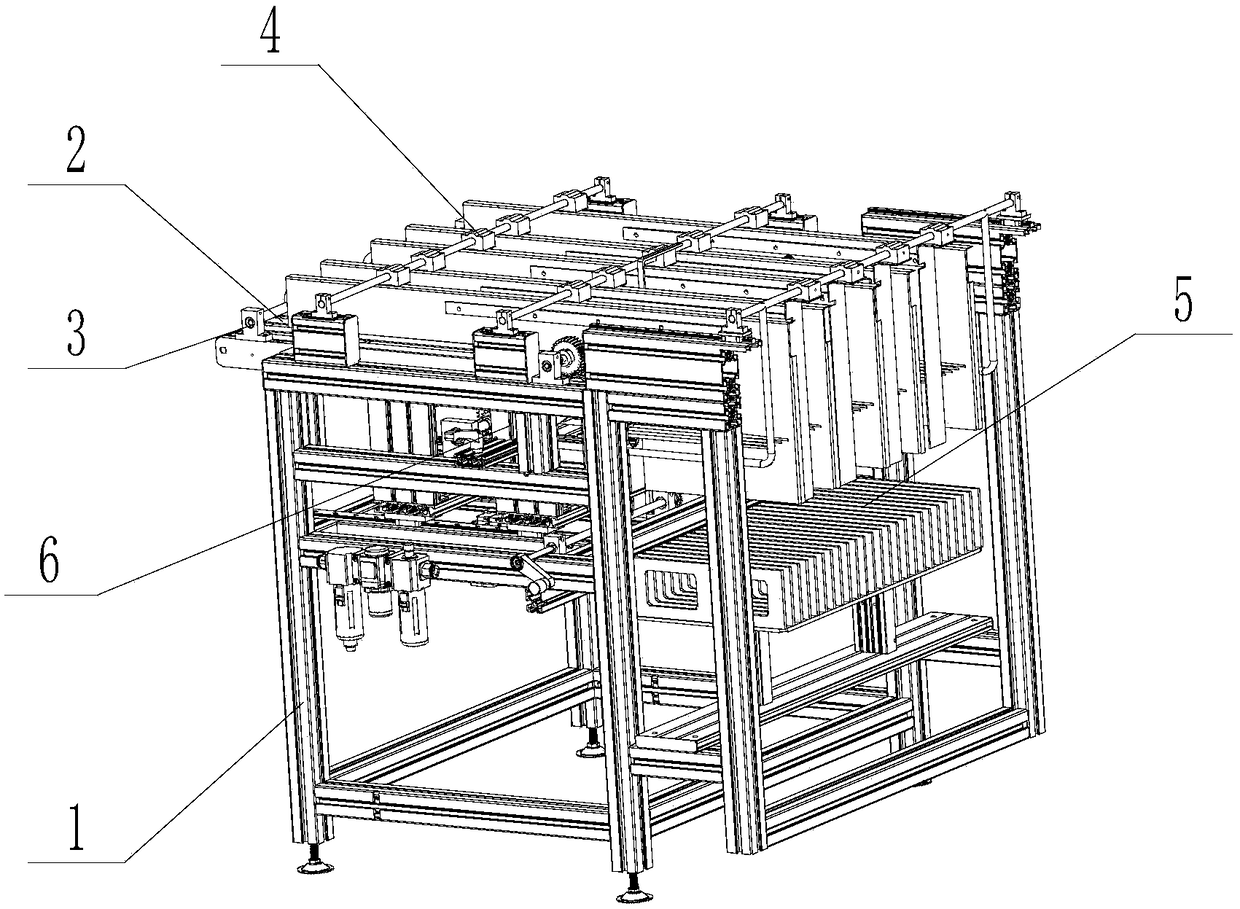

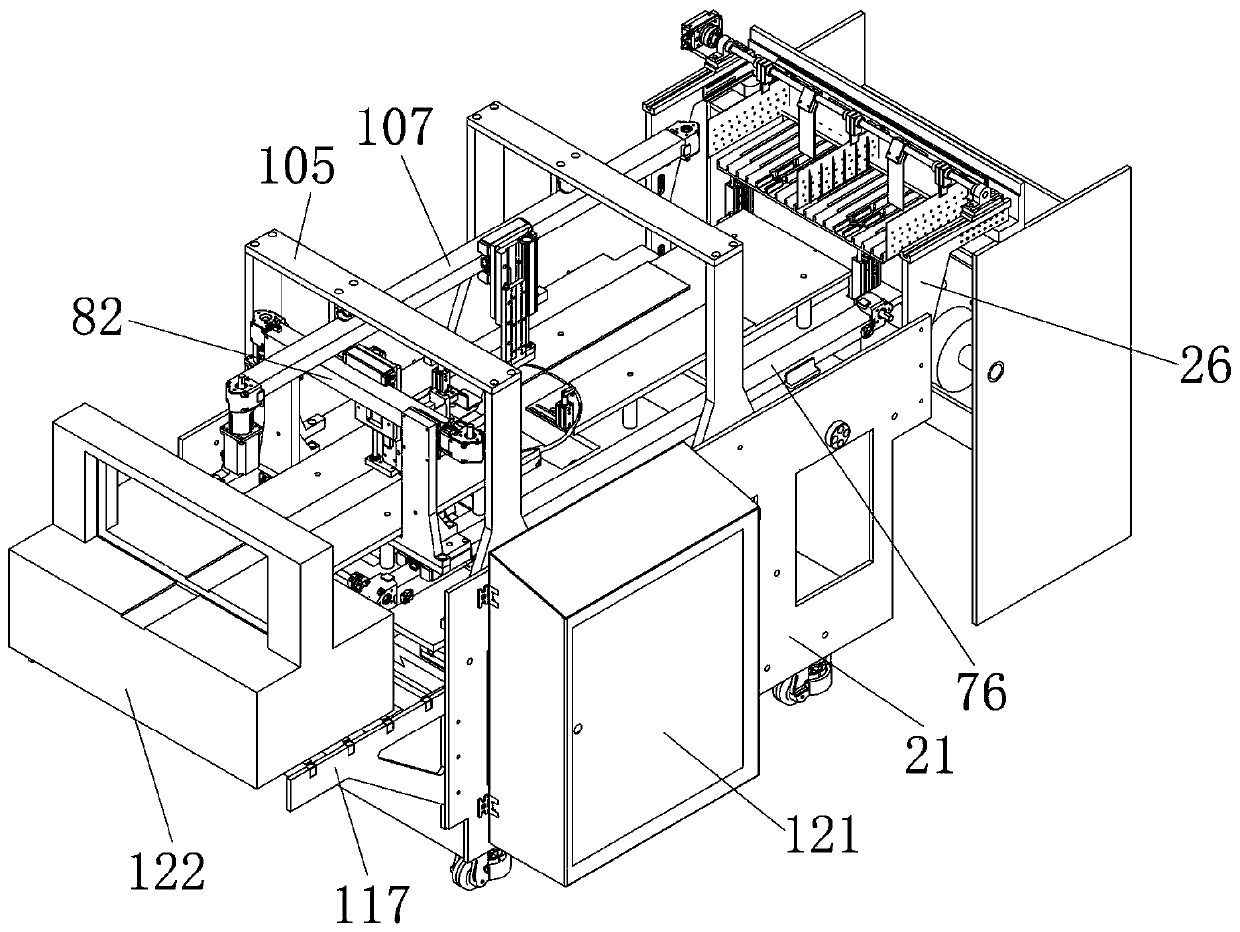

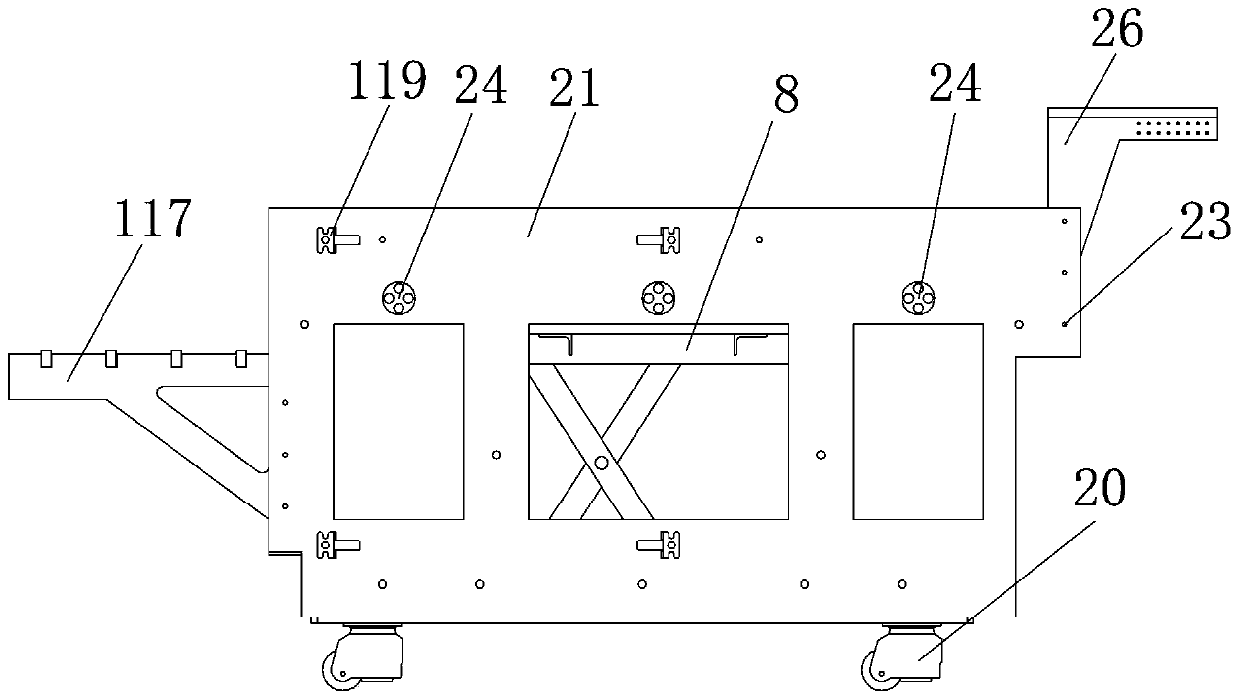

Full-automatic plastic bag arranging and binding system

PendingCN109850230AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingBundling machine detailsTransfer mechanismPlastic bag

The invention discloses a full-automatic plastic bag arranging and binding system, and belongs to the technical field of packing bag binding. The full-automatic plastic bag arranging and binding system comprises a main body frame, a material groove mechanism, a towing fork material blocking mechanism, a clamping mechanism, a transferring mechanism, a material pushing mechanism, a binding machine and an electric control cabinet, and the material groove mechanism, the towing fork material blocking mechanism, the clamping mechanism, the transferring mechanism, the material pushing mechanism, thebinding machine and the electric control cabinet are arranged on the main body frame. According to the full-automatic plastic bag arranging and binding system, a sliding groove, a swinging air cylinder, a first transmission shaft, a material blocking sliding block and a material blocking plate cooperate with one another so that the length of a material groove plate can be changed to adapt to binding of plastic bags with different lengths; the first transmission shaft, a positioning sliding block and a separation plate cooperate with one another so that the width of the material groove plate can be changed to adapt to binding of plastic bags with different widths; and by means of the full-automatic plastic bag arranging and binding system, continuous falling of the plastic bags can be realized, in the binding process, a bag making machine does not need to pause to wait for binding of the plastic bags, and the movement of a clamping jaw air cylinder in any direction can be further realized so that the plastic bags in different directions can be conveniently clamped.

Owner:浙江创派智能科技有限公司

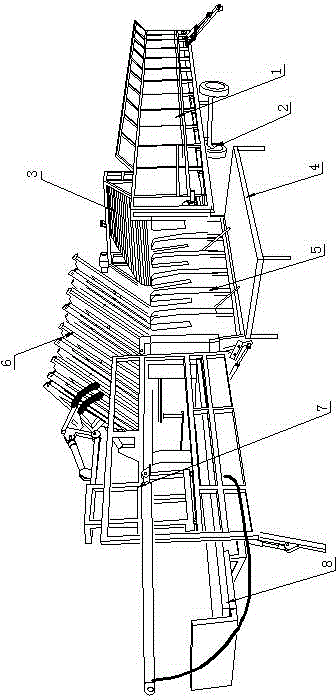

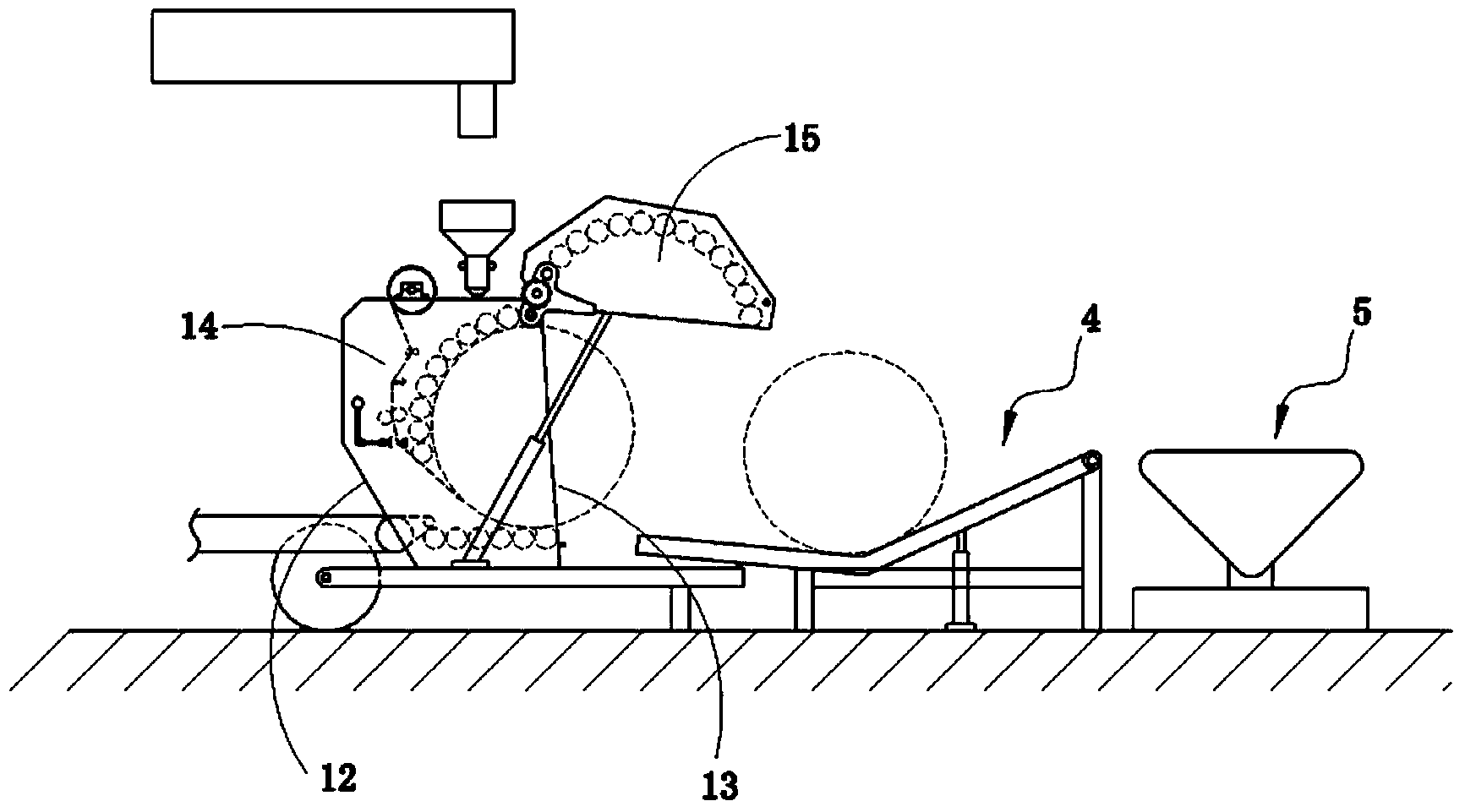

Self-walking type scattered reed conveying, bundling and cutting integrated machine

InactiveCN104081950AImprove bundling efficiencyReduce manufacturing costBalingButt jointUltimate tensile strength

The invention provides a self-walking type scattered reed conveying, bundling and cutting integrated machine which comprises a conveying machine, a bundling and cutting machine and an operating room. The conveying machine comprises a rack, walking wheels, a drive device and a conveying device. The conveying device comprises a conveying belt and a reed pressing rotating cage. Both the conveying belt and the reed pressing rotating cage are connected with the drive device respectively. The bundling and cutting machine comprises a rack, a reed pushing plate, a reed pressing frame and a drive mechanism. The rack is provided with a rectangular bundling platform, the reed pushing plate moves back and forth on the bundling platform through the drive mechanism, and the reed pressing frame rises and falls through the drive mechanism. The output end of the conveying belt of the conveying machine is flush with and in butt joint with the input end of the bundling platform of the bundling and cutting machine. The operating room is located on the rear portion of the bundling and cutting machine. By means of the self-walking type scattered reed conveying, bundling and cutting integrated machine, fully mechanical operation in the whole process of reed conveying, bundling and cutting is achieved, line production is achieved, workshop sections are conducted in a tightly linked up mode, bundling efficiency is improved remarkably, production cost is greatly lowered, labor intensity is obviously relieved, and working conditions are completely improved.

Owner:奥斯曼·托克荪

Full-automatic binding machine for nylon cable binding belts

PendingCN110002026AAutomate bundling operationsImprove bundling efficiencyBinding material applicationBundling machine detailsMechanical engineeringBinding efficiency

The invention relates to the technical field of binding belt binding, in particular to a full-automatic binding machine for nylon cable binding belts. The full-automatic binding machine comprises a machine frame, a sorting mechanism, a moving mechanism and a binding mechanism, wherein the sorting mechanism, the moving mechanism and the binding mechanism are arranged on the machine frame, the sorting mechanism is used for integrating the multiple nylon cable binding belts scattered outside into a pile shape, the moving mechanism is used for transferring the stacked nylon cable binding belts which are integrated by the sorting mechanism to the binding mechanism, the binding mechanism is used for binding the stacked nylon wire binding belts conveyed by the moving mechanism together through the binding belts outside, and the moving mechanism is used for moving the bundle-shaped nylon wire binding belts which are bundled together by the moving mechanism. The automatic binding operation of the scattered nylon cable binding belts is realized, a worker does not need to manually bind the scattered nylon cable binding belts together, the binding efficiency of the nylon wire binding belts isimproved, and the capacity requirement of modern production is met.

Owner:DONGGUAN TONGYI MACHINE

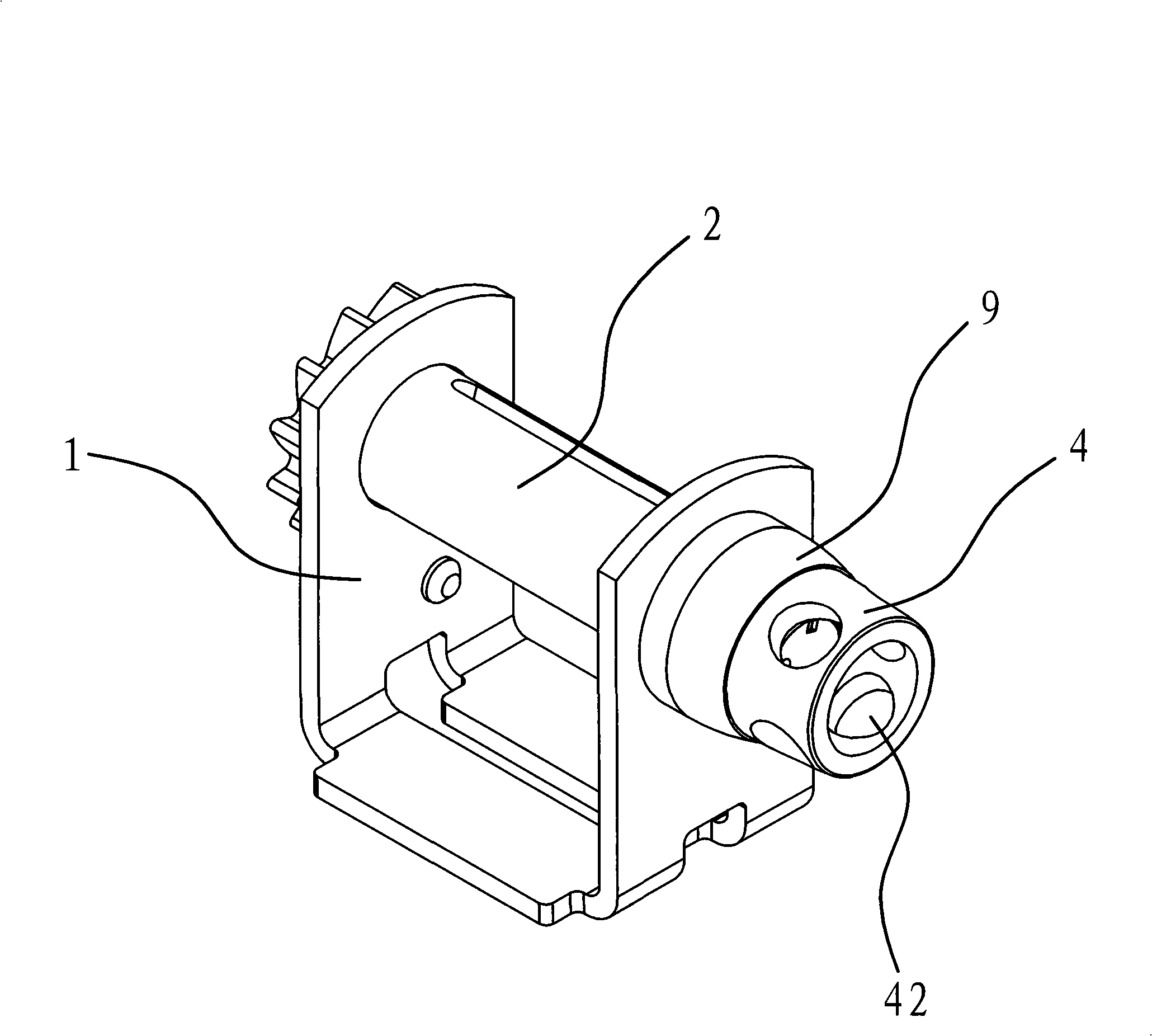

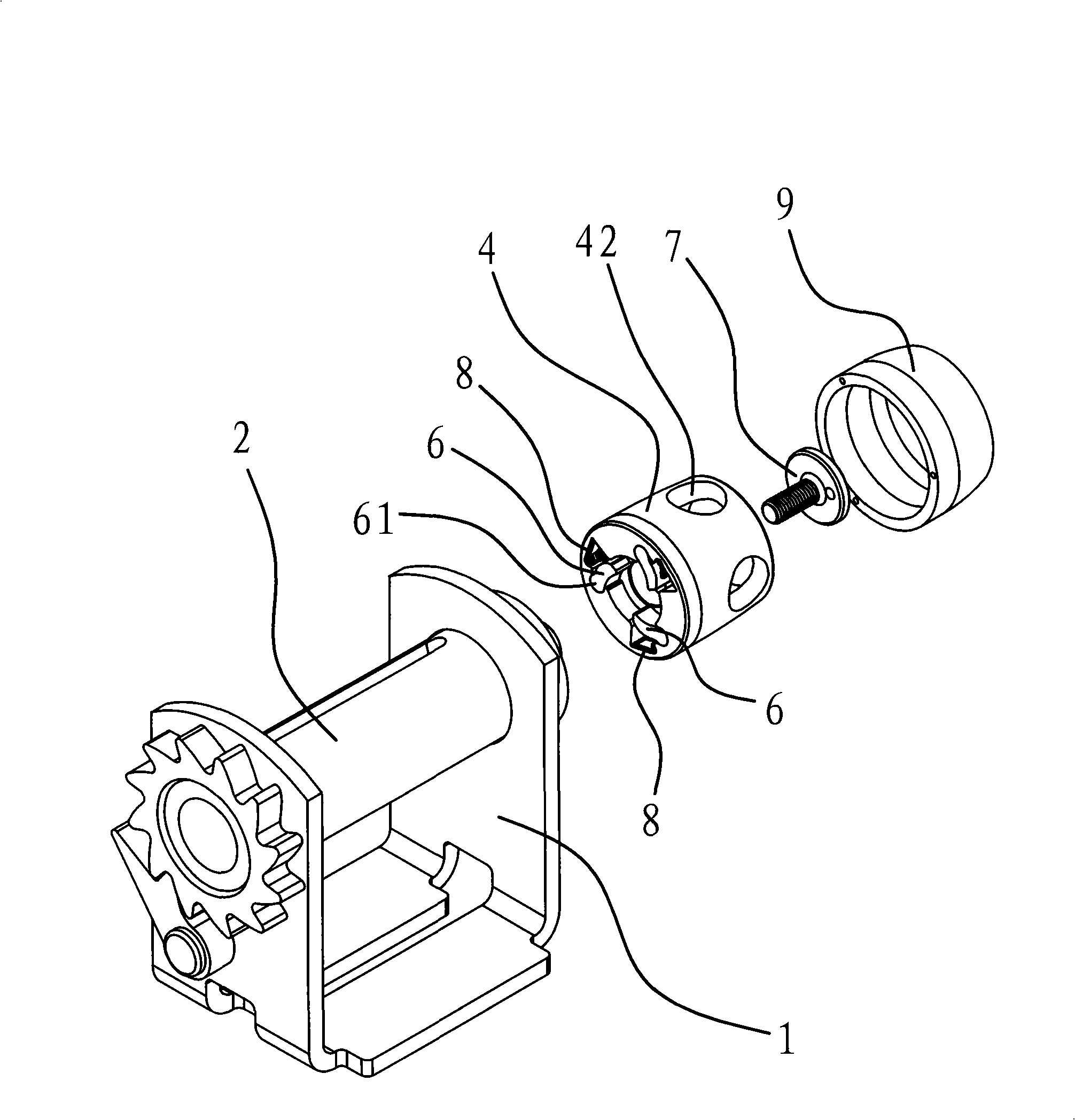

Automatic winding and unwinding device for winch

ActiveCN101274606AEasy to useImprove bundling efficiencyGearingLoad securingEngineeringConductor Coil

The invention provides a self-rendering device of a winch, which pertains to the technical field of machinery. The self-rendering device of the winch solves the problems of the inconvenient use of the rendering device and the low binding efficiency, etc. of the present winches. The self-rendering device of the winch is arranged at the bracket position of the winch and is interconnected with the rotating shaft of the winch; the device comprises a ratchet wheel, a pawl and a cylinder; the ratchet wheel is interconnected with the rotating shaft of the winch; the pawl is arranged on the bracket and imbedded on the ratchet wheel; a transmission mechanism which can drive the ratchet wheel to rotate uniaxially is arranged between the piston rod of the cylinder and the ratchet wheel. The self-rendering device of the winch has the advantages of convenient operation and comparatively high binding efficiency, etc.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

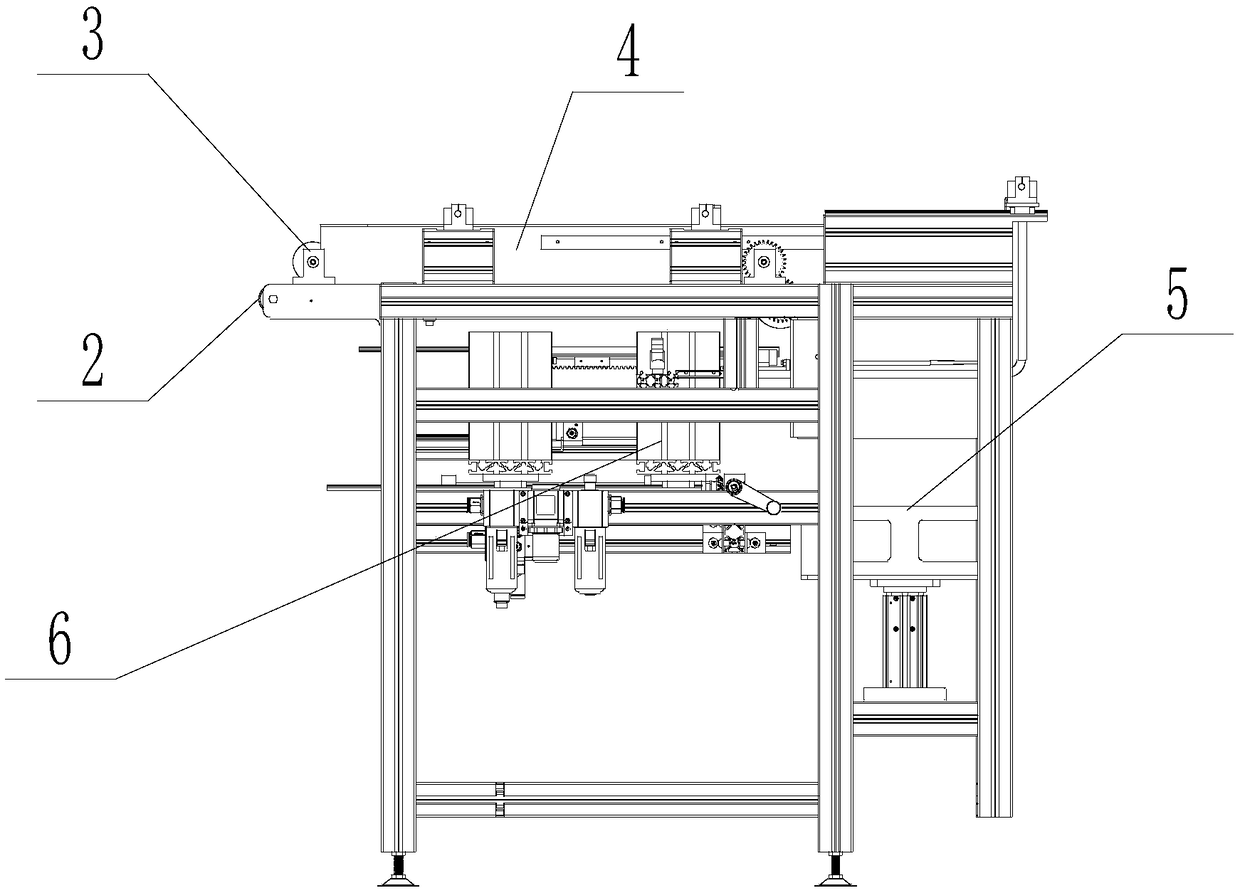

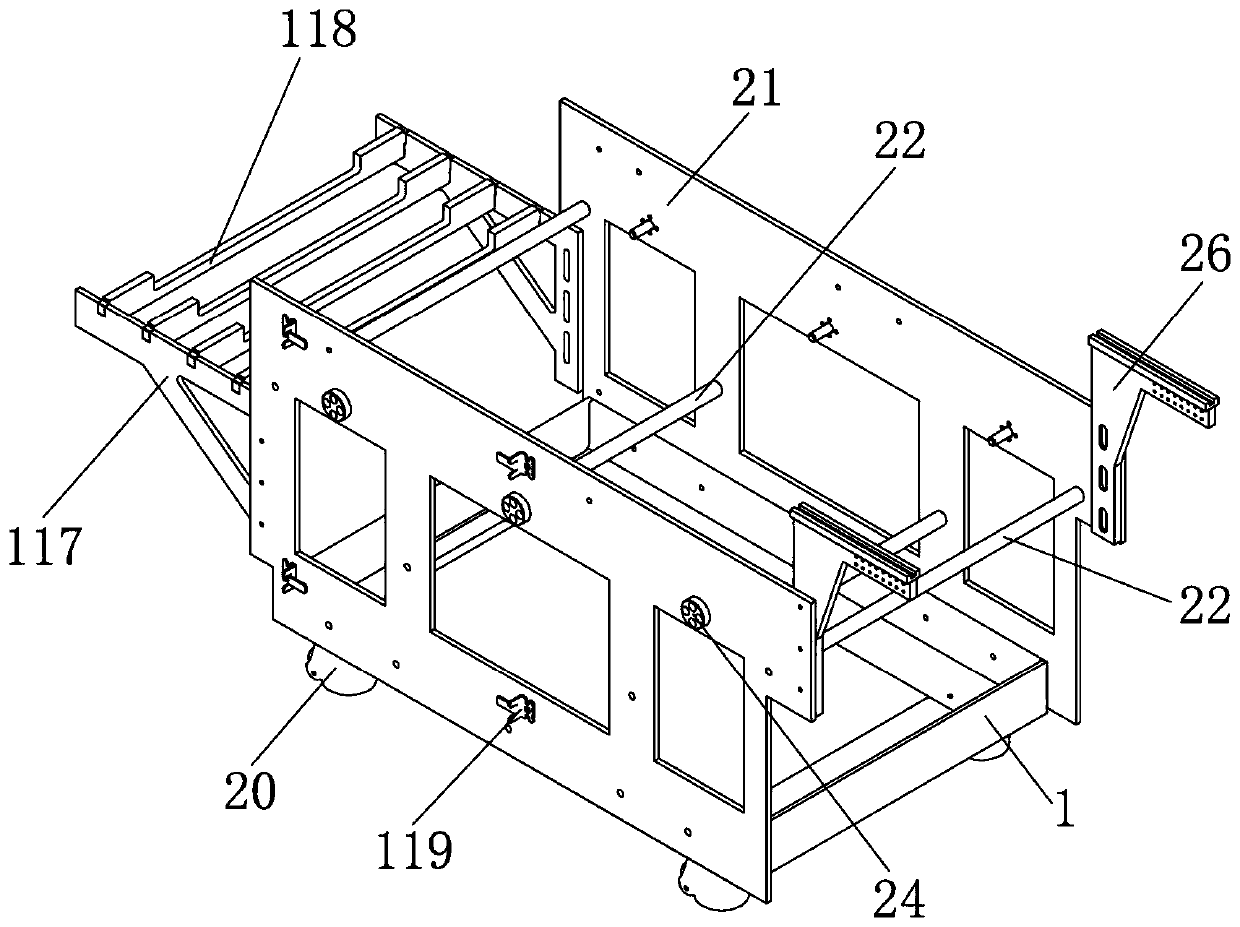

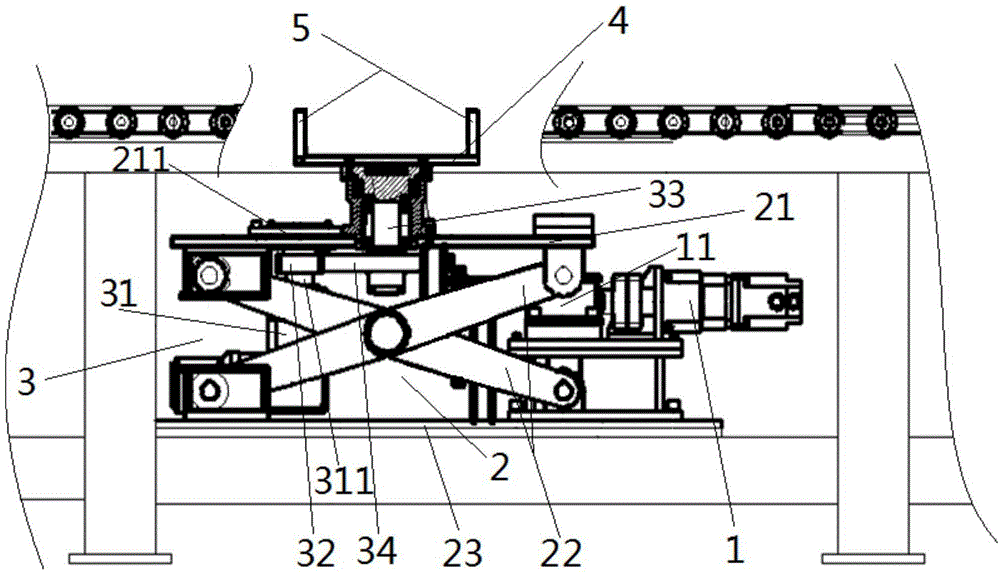

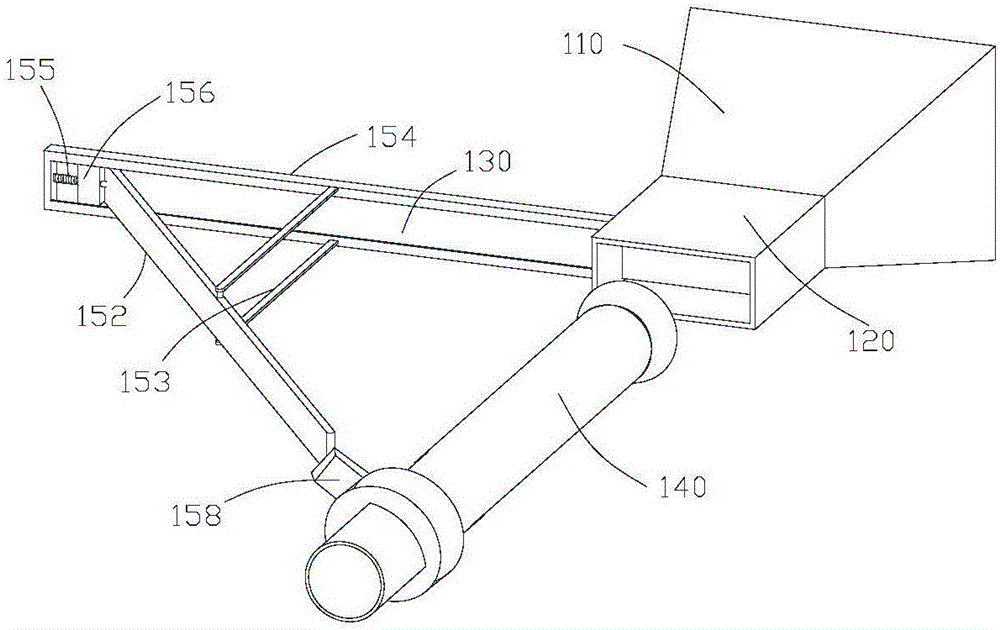

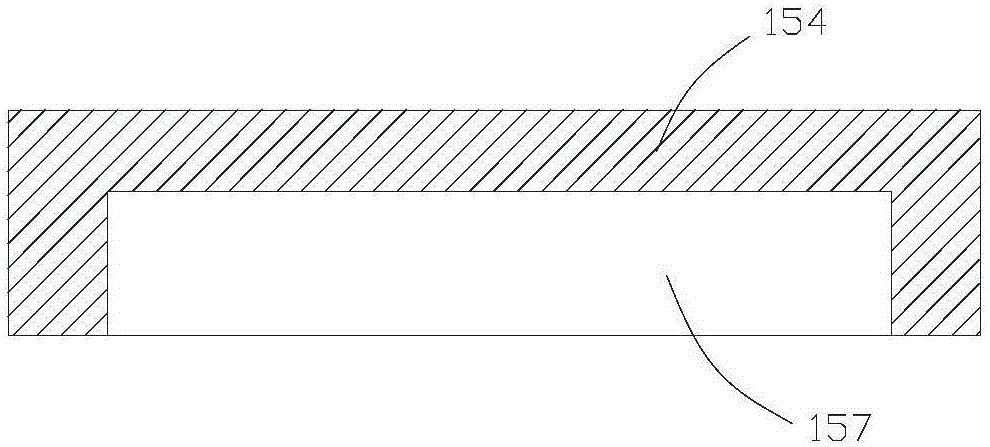

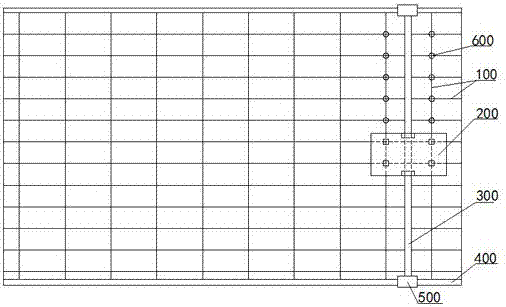

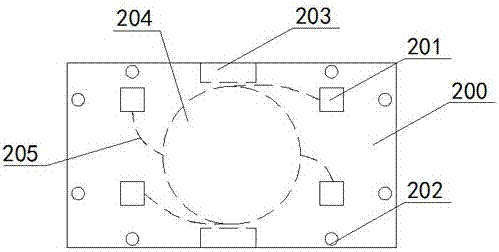

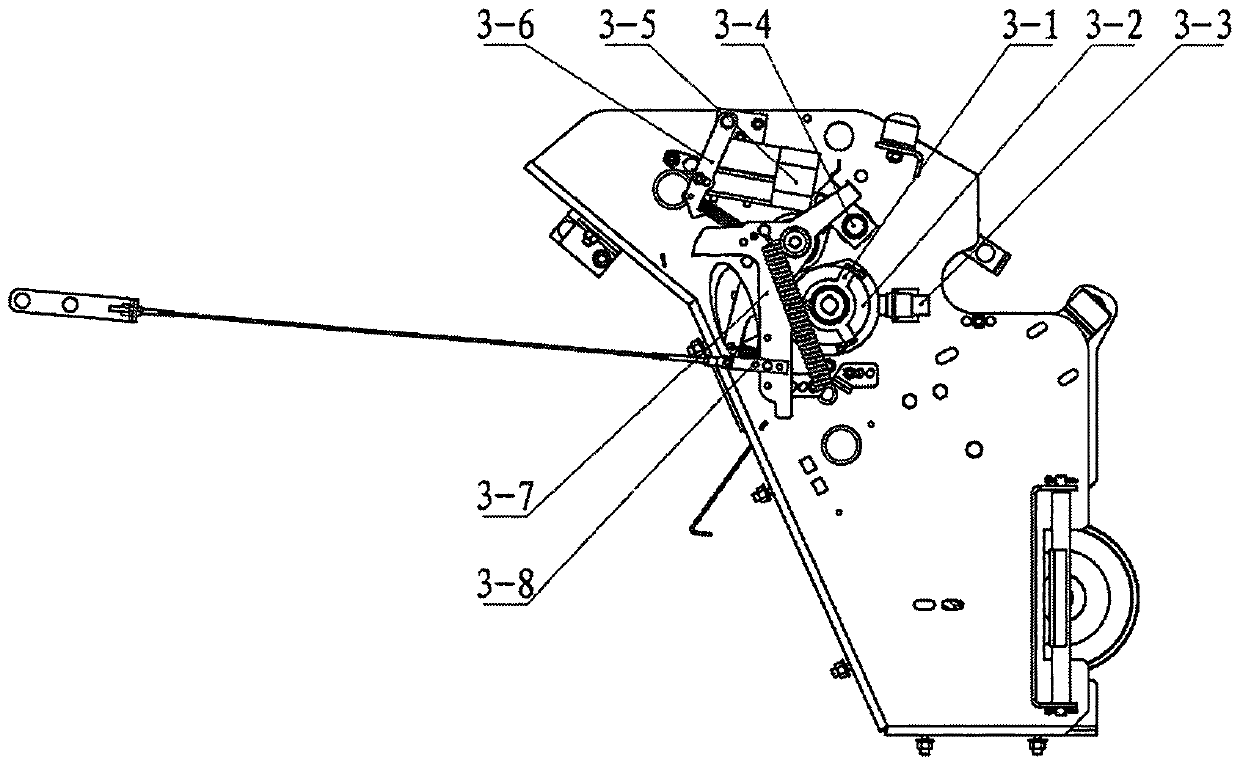

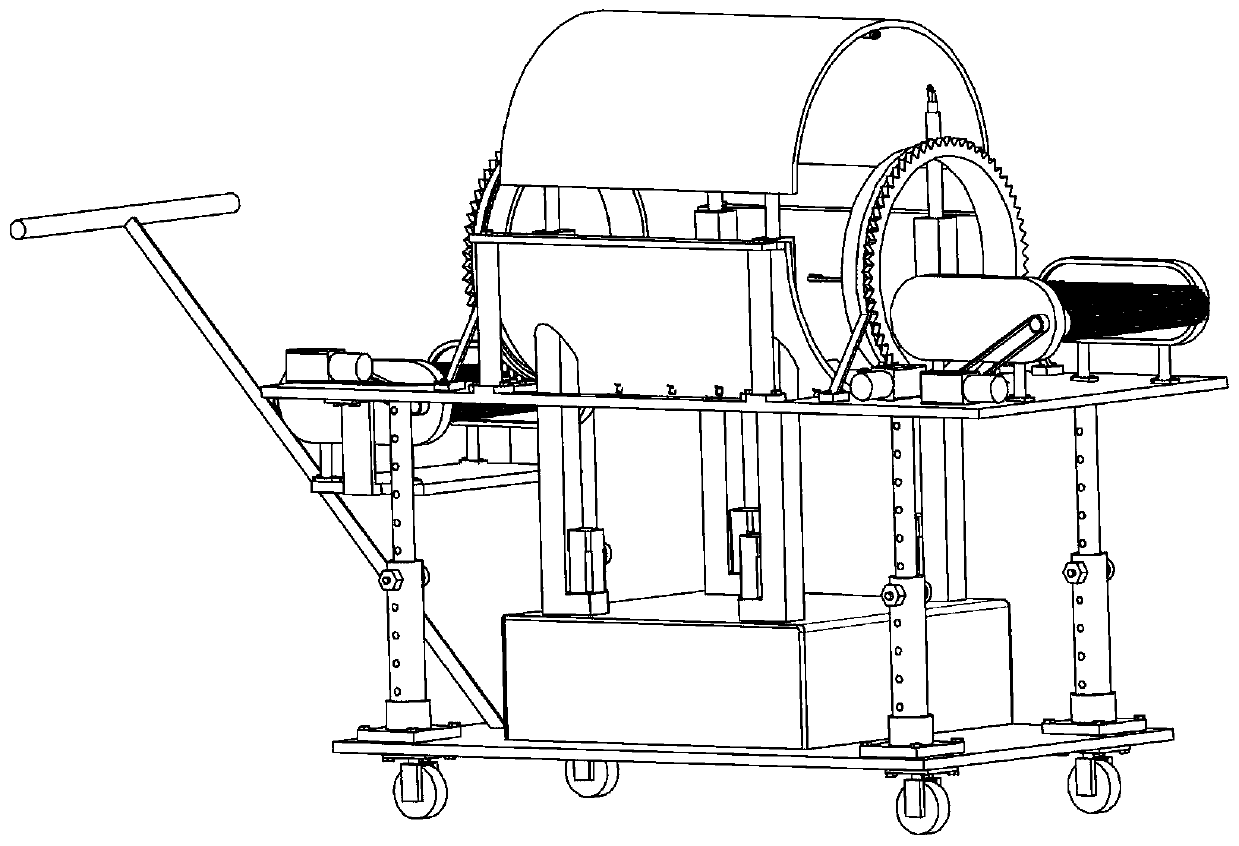

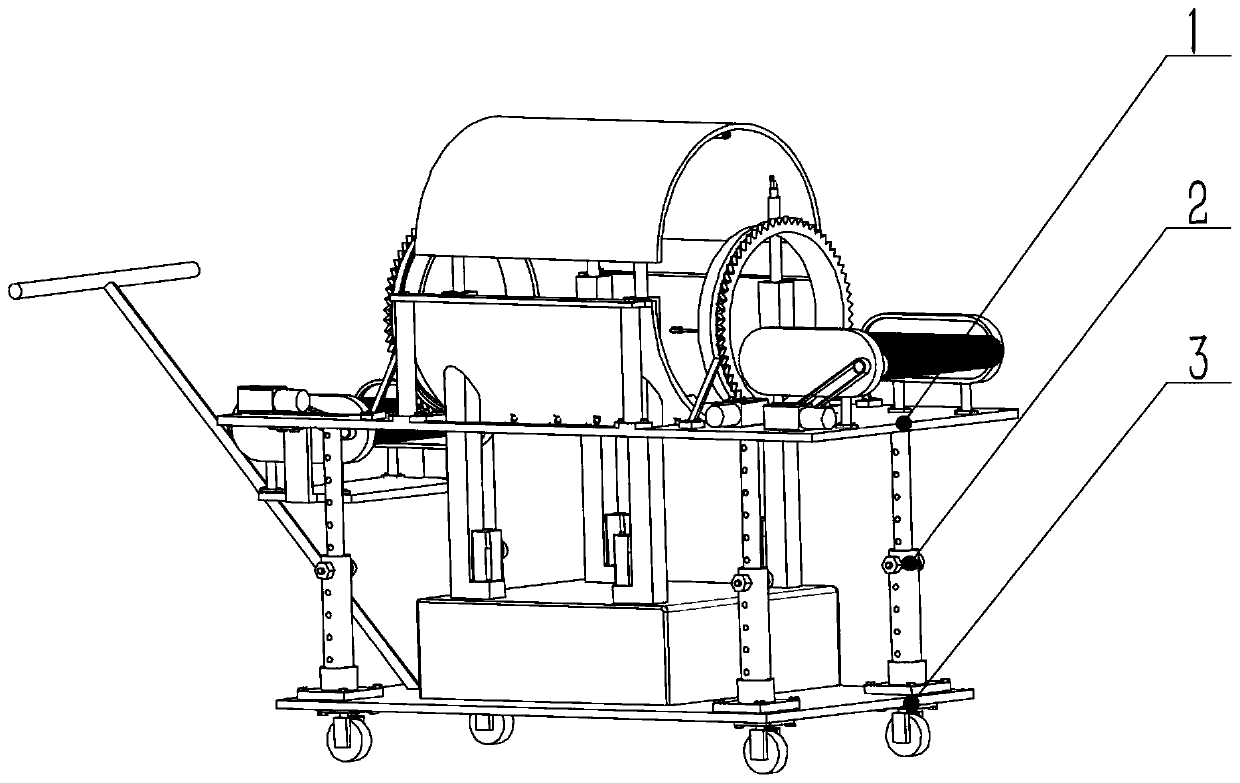

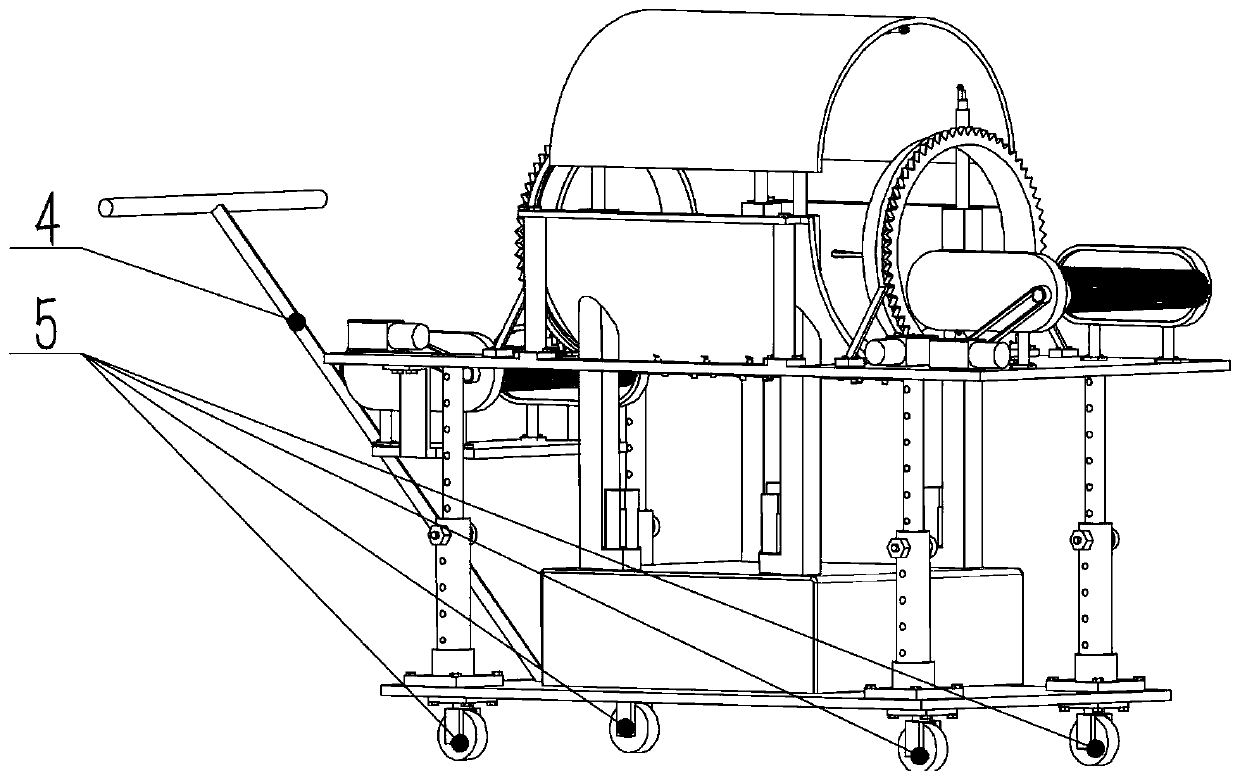

Device used for assisting bi-directional bundling of aluminum ingot stack automatic bundling machine

InactiveCN104890914ASolve the problem of bundlingImprove bundling efficiencyBundling machine detailsElectric machineryEngineering

In order to solve the problems that in the prior art, when a manual semi-automatic bundling manner is adopted for bundling aluminum ingots, the efficiency is low, and the labor cost is high, or a fully automatic bundling device can only perform bundling in a single direction, the invention provides a device used for assisting bi-directional bundling of an aluminum ingot stack automatic bundling machine, comprising a lifting machine, a diagonal bracing, a rotating mechanism, a top plate and a support; the lifting machine is arranged below an upper seat plate of the diagonal bracing; the support is arranged on the top plate; the rotating mechanism comprises a motor, a driving gear, a supporting shaft and a driven gear; the supporting shaft penetrates through the upper seat plate of the diagonal bracing and is fixedly connected with the top plate; the device used for assisting bi-directional bundling of the aluminum ingot stack automatic bundling machine is arranged below a transmission chain at the packaging position of an aluminum ingot continuous casting production line. When the device is used for bundling aluminum ingot stacks, the aluminum ingot stacks can be in bi-directional bundling at bundling positions, so that the bundling efficiency is improved, and the labor cost and the equipment cost are reduced.

Owner:兰州爱赛特机电科技有限公司 +1

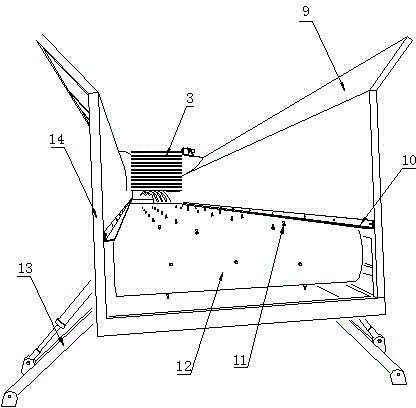

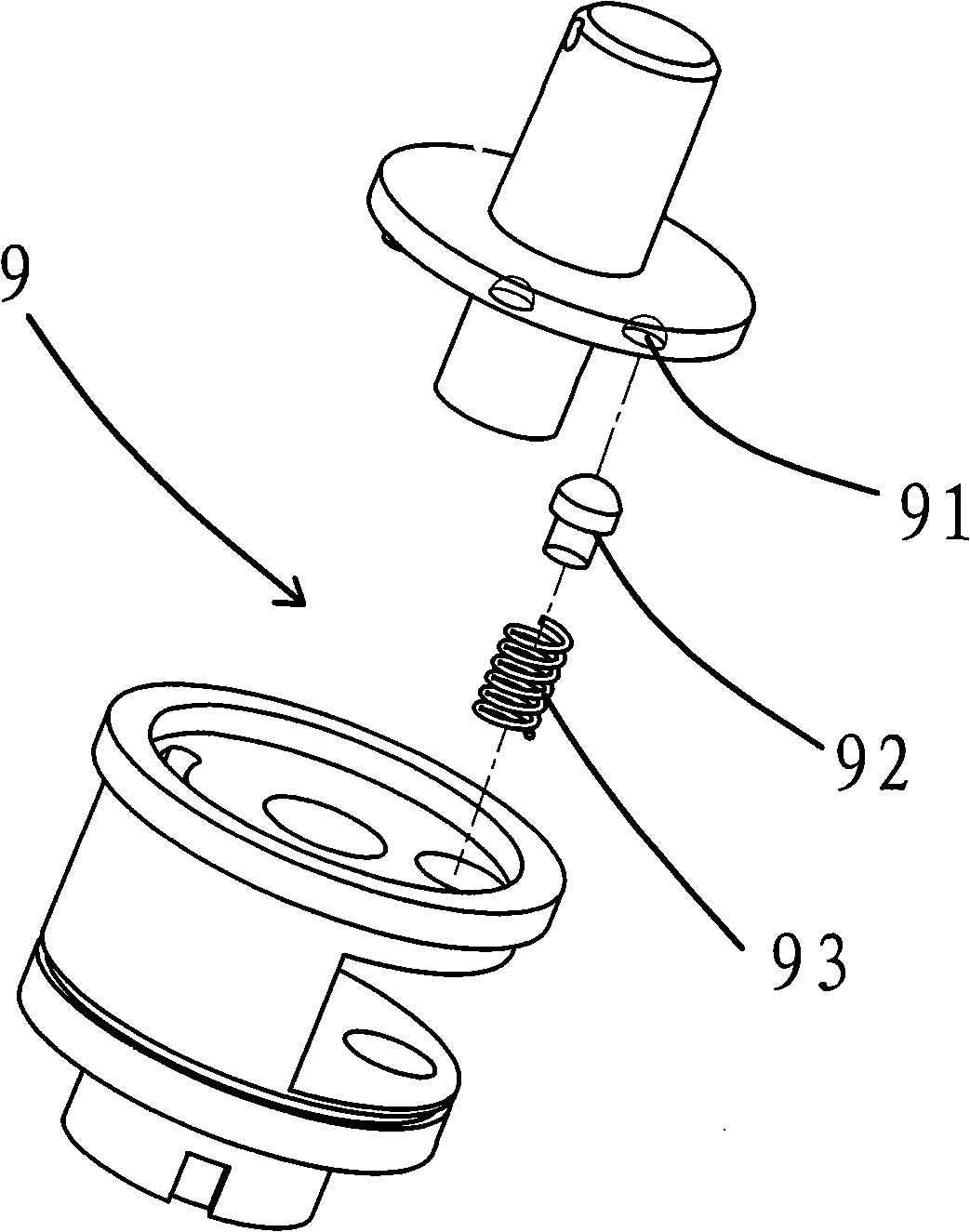

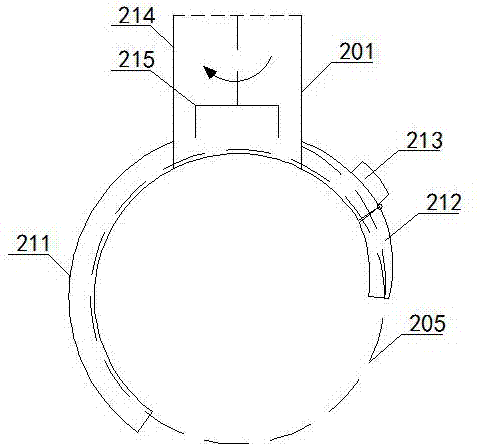

Crab automatic bundling auxiliary device

ActiveCN105799967AQuick fixImprove bundling efficiencyPackaging foodstuffsBundling machine detailsProcess equipmentElectrical and Electronics engineering

The invention provides a crab automatic bundling auxiliary device and belongs to the field of crab processing equipment.The crab automatic bundling auxiliary device comprises a discharging mechanism and a positioning mechanism for fixing crab legs.The discharging mechanism comprises a hopper, a material channel and a baffle.The hopper is installed at the top of the material channel, the material channel is vertically arranged, and the baffle is installed in the material channel and used for controlling the material channel to be unblocked or blocked.The positioning mechanism is located below a discharging port of the material channel and used for receiving crabs falling off the position of the discharging port and fixing the crab legs.The auxiliary device is simple and reasonable in structure, convenient to process and manufacture, low in manufacturing cost and convenient to install and use.The crab automatic bundling auxiliary device can fix the crab quickly, does not damage workers in the fixing process, does not damage crab claws, improves crab bundling efficiency, and is safe, reliable and convenient to use.

Owner:YANCHENG INST OF TECH

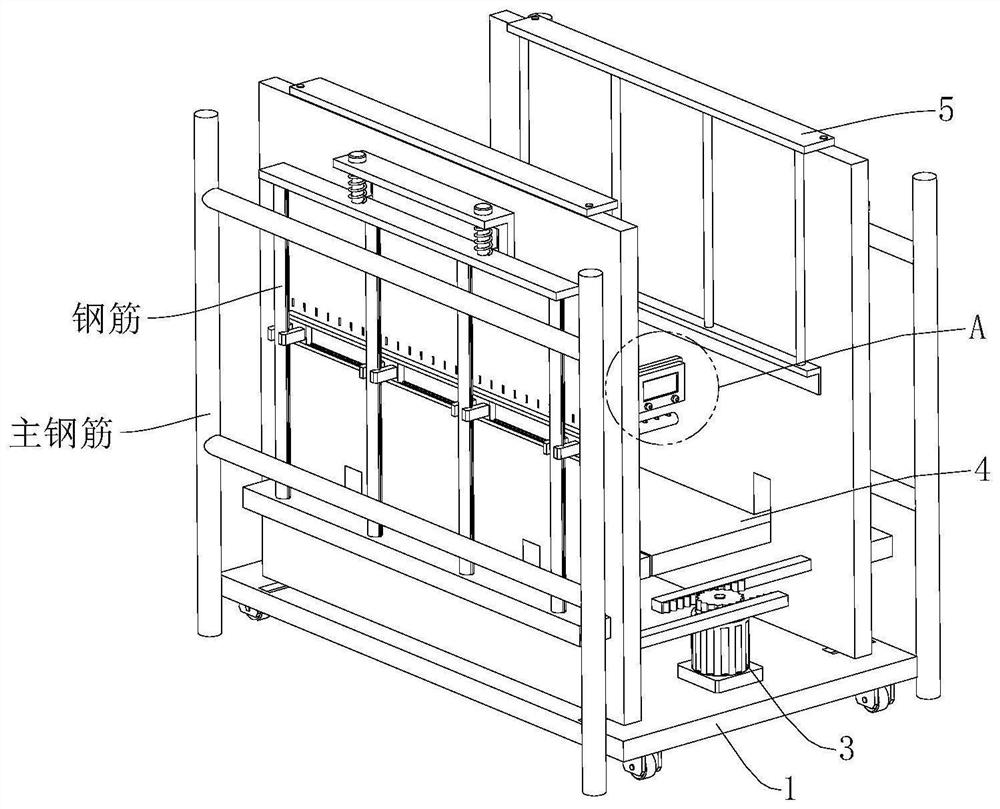

Control system of pre-embedded reinforcement binding device in concrete

PendingCN107165417AImprove bundling efficiencyReduce labor costsBuilding material handlingControl systemMesh reinforcement

The invention discloses a control system of a pre-embedded reinforcement binding device in concrete and belongs to the field of buildings. The control system of the pre-embedded reinforcement binding device in the concrete comprises a primary-setting modeling module, a position regulatory and control module, a feeding and thread-cutting module, a binding module and a control module. According to the control system of the pre-embedded reinforcement binding device in the concrete, binding for a reinforcing mesh can be automatically completed, the multiple disadvantages that in the binding process of an existing reinforcement, binding which fully relies on human power are overcome, reinforcement binding before concrete casting is competed through the intelligent device, the overall binding process is automatically completed, and workers are prevented from constructing under an exposure environment.

Owner:成都智诚利合科技有限公司

Method for forming single heat sealing joint on binding plastic film in plastic sealing pre-binding procedure

The invention discloses a method for forming a single heat sealing joint on a binding plastic film in a plastic sealing pre-binding procedure. The method comprises steps as follows: A, arrangement of a plastic film on a rack: the binding plastic film roll is mounted and positioned on a plastic film rack, and the plastic film is wound around a tensioning mechanism and sequentially passes through an upper correction roller, a film limiting assembly, a lower correction roller and a guide roller to be positioned on a waste film rack; B, correcting, aligning, pushing and forming: a bank note stack is driven to move horizontally by a bank note pushing device, and the plastic film is driven to move to be pack-shaped; C, pressurizing, binding, film pressing, wrapping, adhesion and cutting: an embedded pressure head is vertically pressed downwards by a linear drive mechanism, a bank note bundle is formed, the loose plastic film is tensioned by the aid of a floating positioning structure of the embedded pressure head and a rolling matching structure of a pressure roller, and a sealing and cutting device presses downwards to drive the plastic film to perform wrapping, heat adhesion and cutting, so that a binding belt ring is separated from a belt strip; D, leading out of the heat sealing joint and outputting of the bank note bundle: the waste film rack is driven to rotate, so that the heat sealing joint is pulled out of a binding work area, and the waste film rack is braked.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

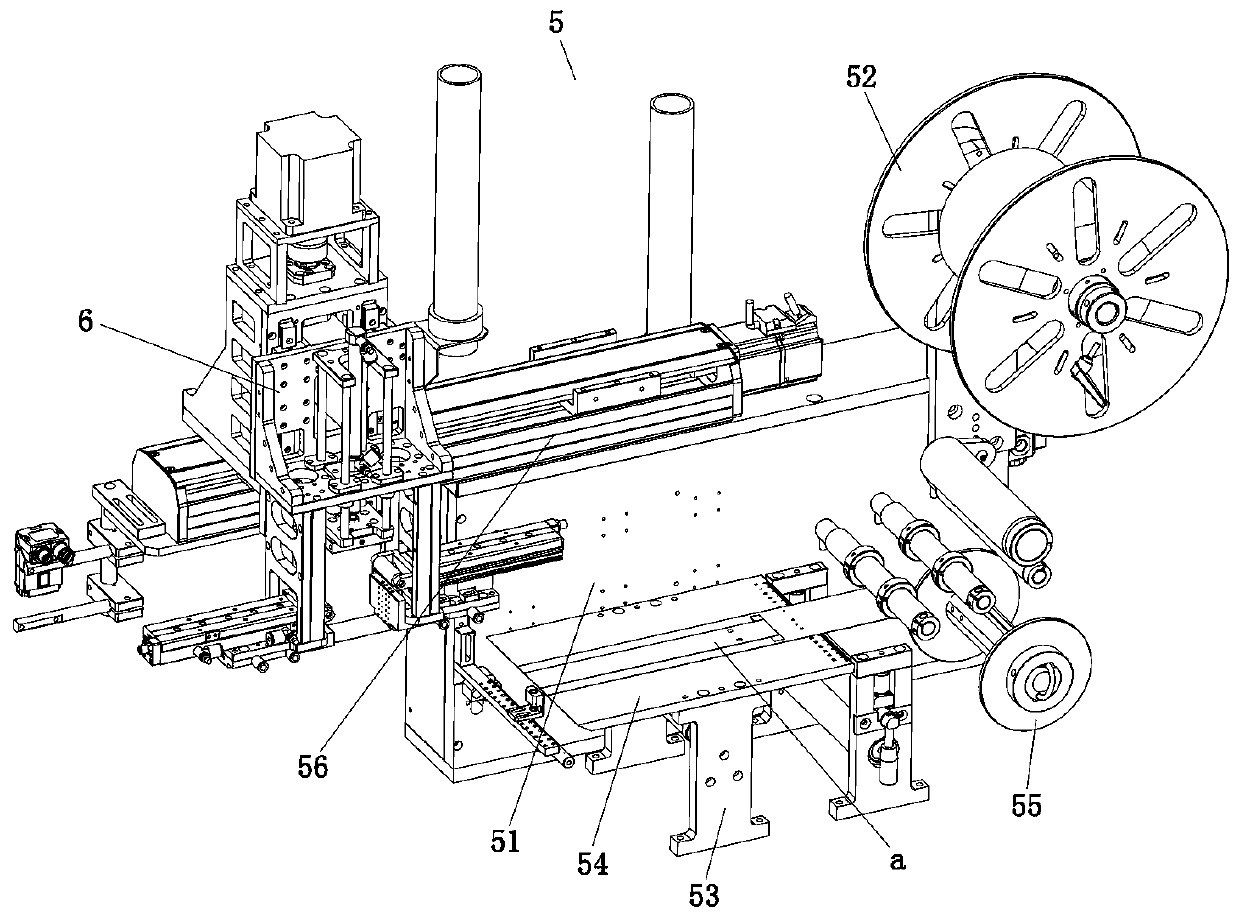

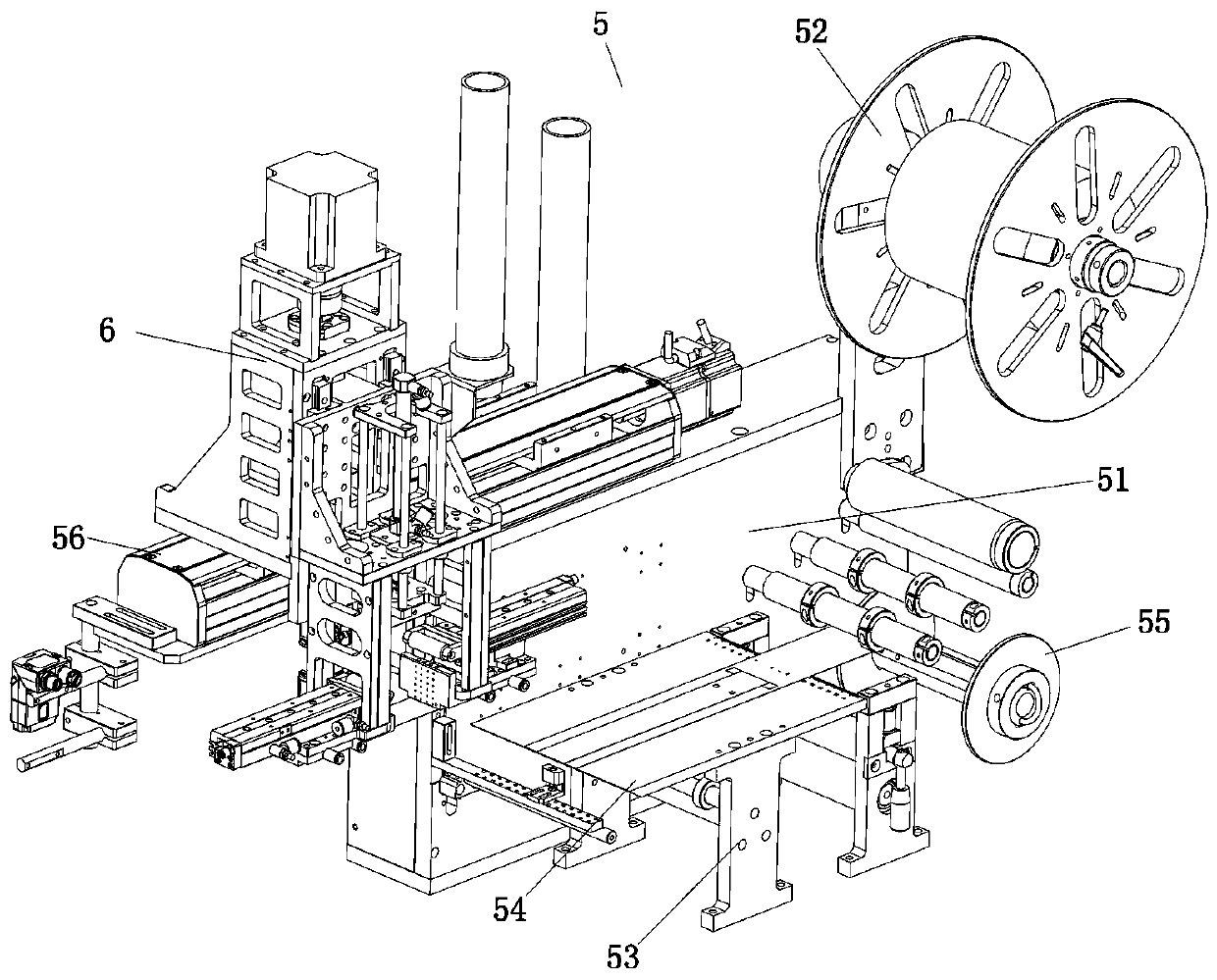

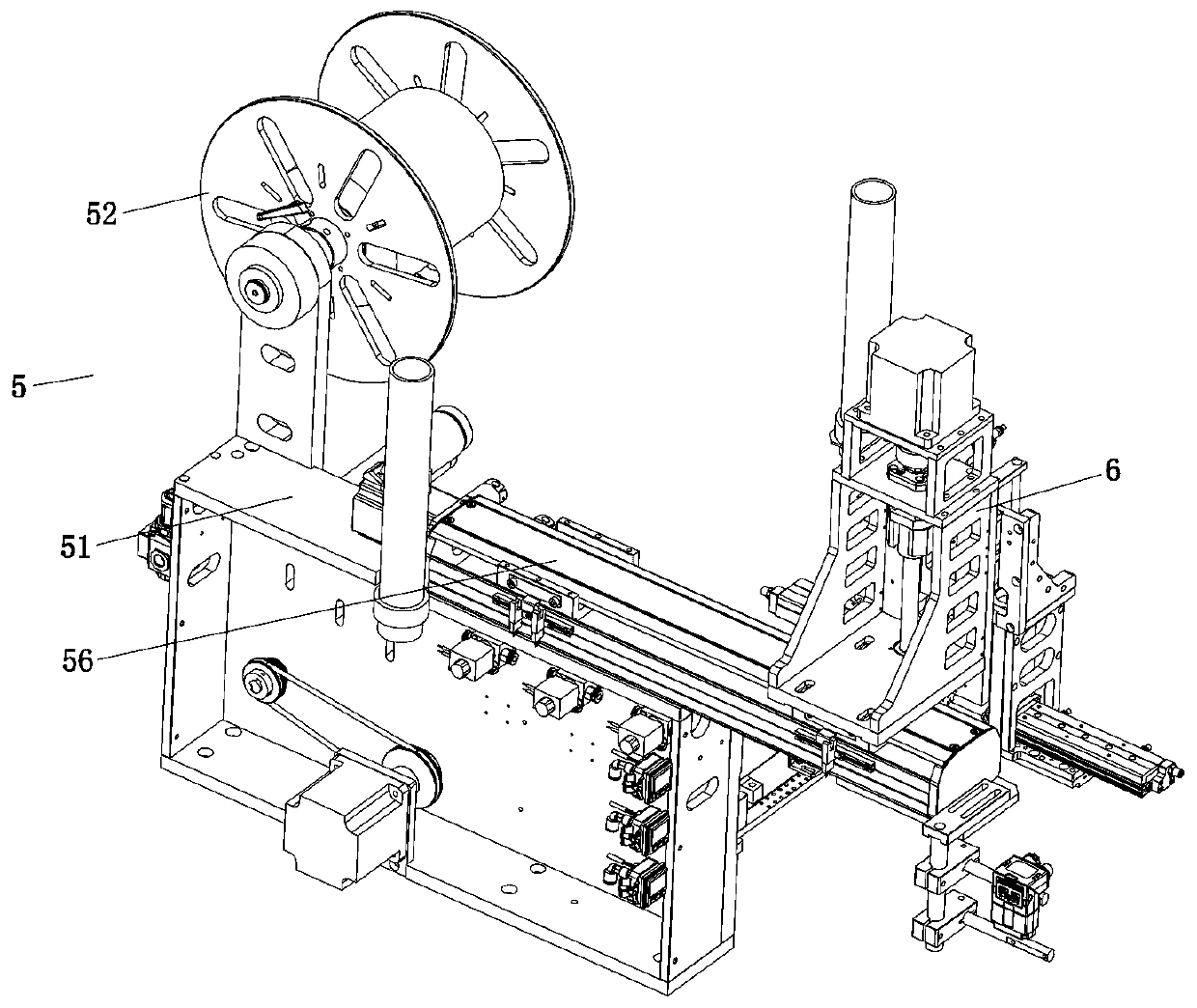

High speed continuous plastic bag strapping machine

ActiveCN108945577AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingBundling machine detailsPlastic bagEngineering

The invention discloses a high speed continuous plastic bag strapping machine. The high speed continuous plastic bag strapping machine comprises an integral rack, a supporting bottom plate at the discharge port of a bag maker, a separated baffle plate module, a blanking slot module, a reciprocating material pushing pin module, a transfer module and a strapping module. The supporting bottom plate at the discharge port of the bag maker, the separated baffle plate module, the blanking slot module, the reciprocating material pushing pin module, the transfer module and the strapping module are arranged on the integral rack. The high speed continuous plastic bag strapping machine disclosed by the invention can strap plastic bags automatically, is high in strapping efficiency and low in labor cost, and can be adjusted to be suitable for strapping the plastic bags different in width, length and thickness automatically, so that the high speed continuous plastic bag strapping machine is wide inapplication range; the high speed continuous plastic bag strapping machine can detect and remove unqualified products, and is high in removal efficiency. The high speed continuous plastic bag strapping machine disclosed by the invention can directly fit the outlet of the bag maker. The plastic bags at the outlet of the bag maker enter into a blanking slot to be accumulated, conveyed and strapped,so that the integral strapping step is canceled.

Owner:浙江创派智能科技有限公司

Full-automatic round-bundle silage bundling unit

InactiveCN104221622AImprove bundling efficiencyImprove baling qualityFeeding-stuffBalingTransfer mechanismUltimate tensile strength

The invention relates to feed bundling machinery, in particular to a full-automatic round-bundle silage bundling unit. The full-automatic round-bundle silage bundling unit comprises a controller, a silage device, a bundling machine, a conveying belt and a material bundle packaging device for receiving material bundles from the bundling machine and packaging the material bundles, wherein a transferring mechanism is arranged between the material bundle packaging device and the bundling machine and is used for bearing the material bundles output from an outlet of a material bundle forming chamber and transferring the material bundles to the material bundle packaging device; a third power source of the material bundle packaging device adopts an adjustable double-speed motor, so that the production efficiency is improved. Compared with the prior art, the full-automatic round-bundle silage bundling unit has the advantages that 1, the bundling efficiency is improved; 2, one operator can easily operate the full-automatic round-bundle silage bundling unit; 3, the labor intensity is alleviated, and the bundling quality is greatly improved.

Owner:郑伟伦

Flat binding and stable conveying equipment of air conditioner heat insulating pipes

InactiveCN108357990AImprove bundling efficiencyThermal insulationPipe protection by thermal insulationDrive motorEngineering

Owner:朱文祥

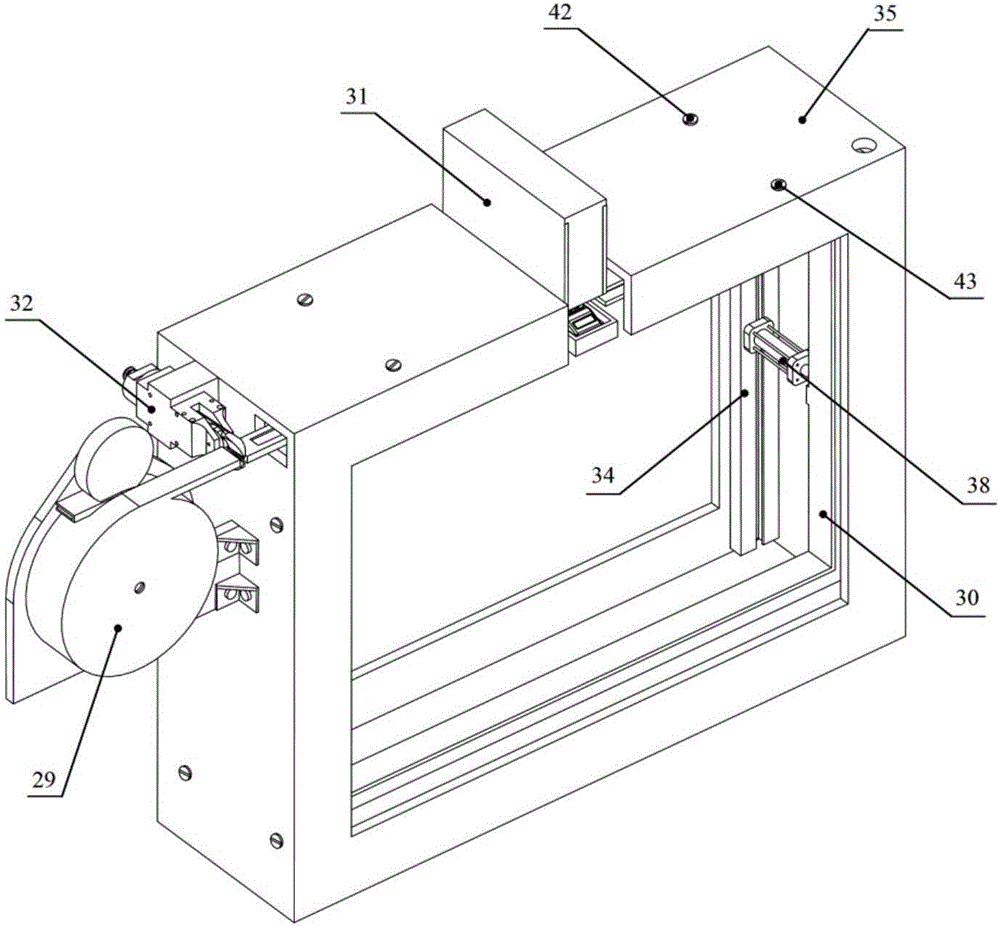

Automatic glass laminated sheet binding and wrapping device and binding and wrapping technology thereof

PendingCN109515806AReduce collisionsImprove bundling efficiencyBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses an automatic glass laminated sheet binding and wrapping device and a binding and wrapping technology thereof. A tape discharging assembly and a binding assembly are included. When the tape discharging assembly outwards pulls material tape to pass through a peeling plate, adhesive tape adhering to the material tape is peeled to the peeling plate, wherein the material tape towhich the adhesive tape adheres is wound around a tape wheel. A linear module is arranged at the upper portion of a tape discharging support plate, and the binding assembly is connected to the linearmodule in a sliding manner. Two tape absorbing plates of the binding assembly adsorb and fix the adhesive tape from the peeling plate. The tape absorbing plates drive the adhesive tape and move downwards, laminated glass upwards slides from the interior of the binding space, and a downward pressing component is used for pressing the bundled adhesive tape from the upper portion. Two side pressingcomponents roll and fix the adhesive tape along the laminated glass surface. According to the automatic glass laminated sheet binding and wrapping device and the binding and wrapping technology thereof, membranes are stacked and stored into a whole in a centralized manner, and the collision situations of membranes between adjacent glass sheets and the membranes between the glass sheets and outer objects are effectively reduced. The binding assembly is used for automatically finishing the bundling and wrapping actions of the adhesive tape along the four sides of the laminated glass, and the binding efficiency and quality are greatly improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Automatic cross-shaped strapping machine for envelopes and cards

The invention discloses an automatic cross-shaped strapping machine for envelopes and cards. The automatic cross-shaped strapping machine comprises a rack, a first conveyor line, a first strapping assembly, an intermediate rotary conveyor line, a second strapping assembly, a second conveyor line and a control cabinet. The rack comprises a supporting frame and a flatly-arranged top plate arranged at the top of the supporting frame. The first conveyor line is arranged at the left end of the middle of the supporting frame, and the intermediate rotary conveyor line is arranged in the middle of thesupporting frame and located on the right side of a first blocking air cylinder. The second conveyor line is arranged at the right end of the middle of the supporting frame, and the control cabinet is arranged on the upper surface of the flatly-arranged top plate and internally provided with a first strapping controller, a second strapping controller and a human-computer interface. According to the automatic cross-shaped strapping machine for the envelopes and the cards, design is reasonable, the structure is simple, and the extremely high promotional value is achieved; and the automatic cross-shaped strapping machine can automatically conduct cross-shaped strapping on products, thus industrial automation can be achieved, worker labor force is relieved, and the strapping efficiency of theproducts is improved.

Owner:广州坤林自动化科技有限公司

Working method of rapid bundling device for reinforcing steel bars a building

InactiveCN112593707AAdjust the sliding distancePrecise adjustment of sliding distanceBuilding material handlingArchitectural engineeringRebar

The invention relates to the technical field of building construction, in particular to a working method of a rapid bundling device for reinforcing steel bars for a building. The rapid bundling devicecomprises a bottom plate, a controller, an external expansion mechanism, a longitudinal adjusting mechanism and transverse adjusting mechanisms; the external expansion mechanism comprises a driving assembly and two vertical plates; the longitudinal adjusting mechanism is arranged at the top of the bottom plate and is used for adjusting the installation heights of the reinforcing steel bars; the longitudinal adjusting mechanism comprises a jacking assembly and two limiting assemblies; the transverse adjusting mechanisms are arranged on the outer walls of the vertical plates and are used for adjusting the installation distances of the reinforcing steel bars; each transverse adjusting mechanism comprises two sliding rails, two locking assemblies and a plurality of clamping assemblies; and the driving assembly and the jacking assembly are electrically connected with the controller. According to the rapid bundling device and method for the reinforcing steel bars for the building as well asthe method, construction errors can be effectively avoided, the installation heights can be rapidly adjusted, the horizontal distances between the reinforcing steel bars can be accurately adjusted after the reinforcing steel bars are clamped, meanwhile, manual adjustment is not needed, time and labor are saved, and withdrawing is convenient after bundling.

Owner:赵桂荣

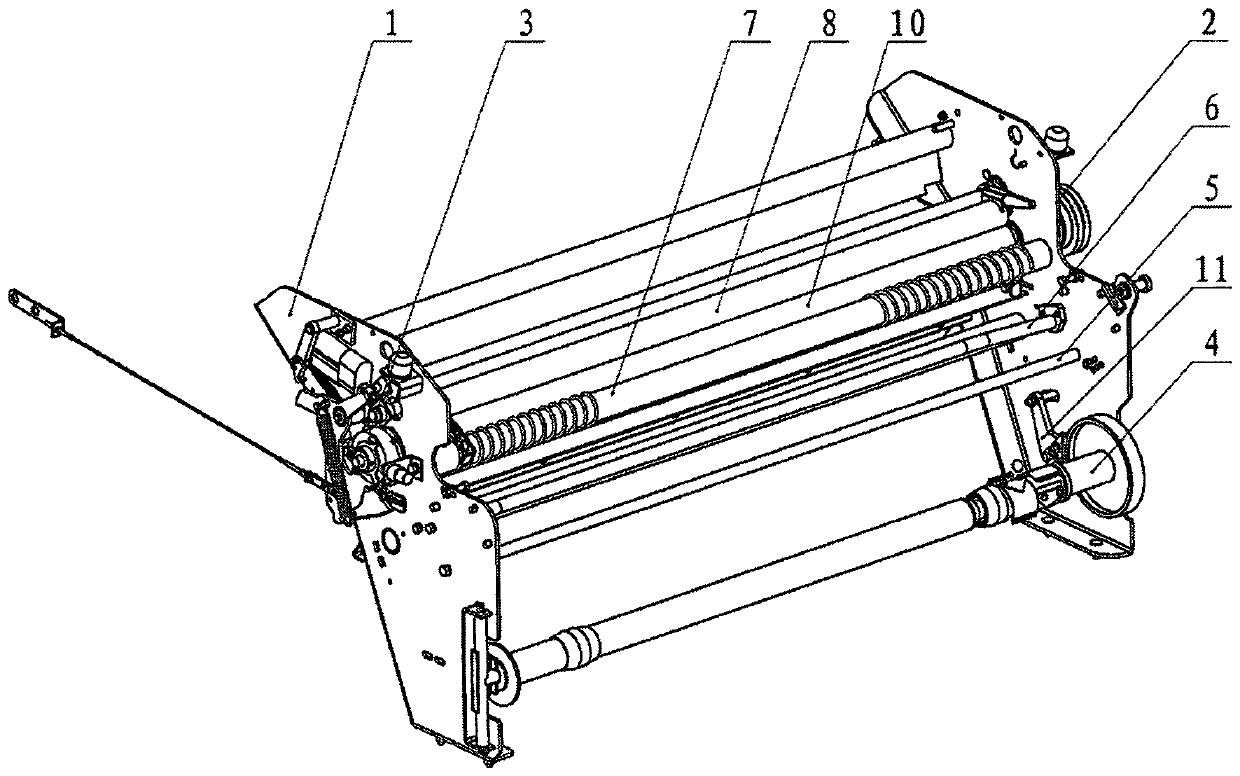

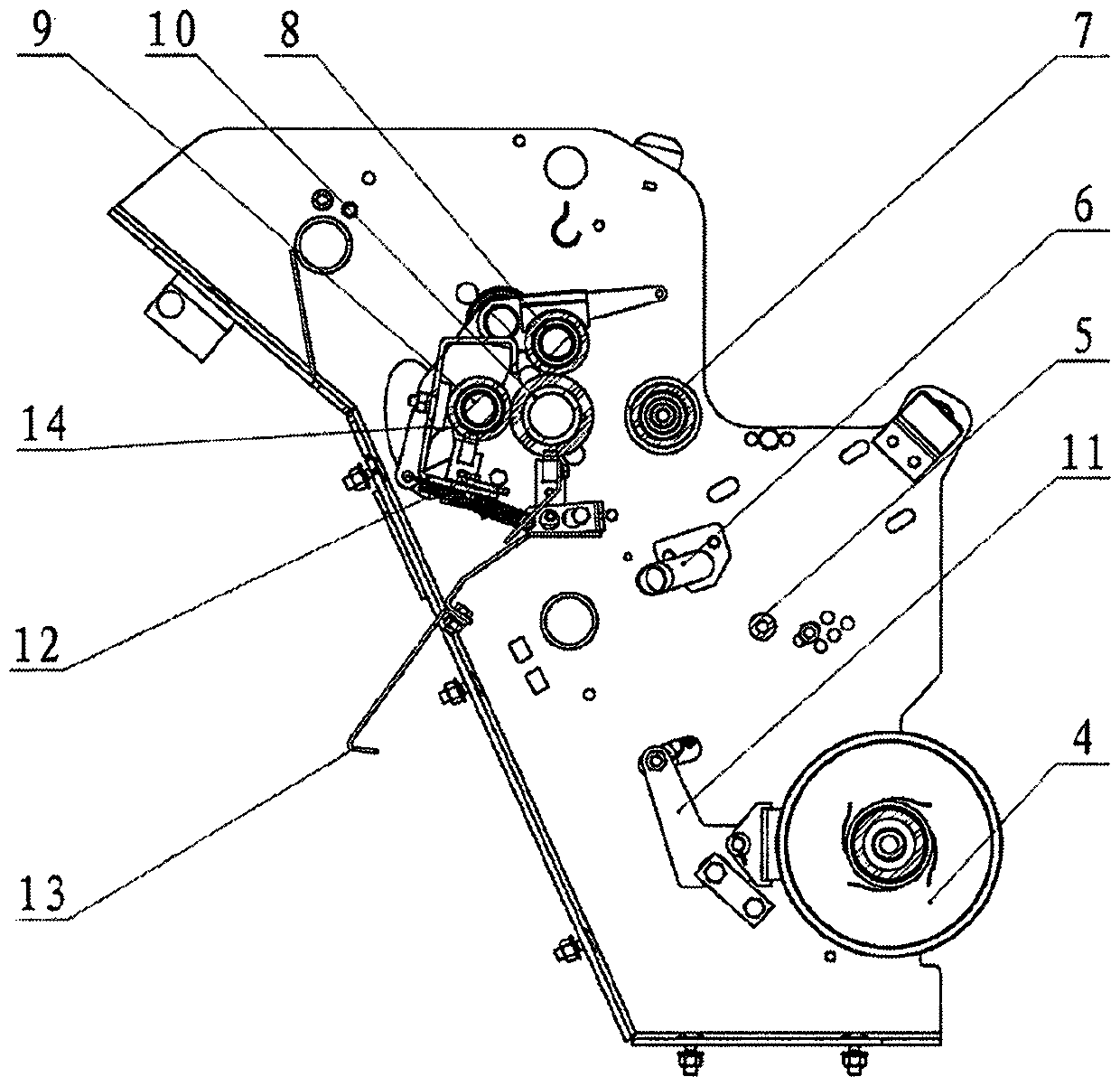

Net winding device of round baler

PendingCN111201902ANovel and reasonable designConstant frictional resistanceBalingAgricultural engineeringAnimal husbandry

The invention discloses a net winding device of a round baler, and belongs to the technical field of agriculture and animal husbandry machinery. The net winding device mainly comprises a net winding device frame, a driving belt pulley, a net winding quantity control mechanism, a net feeding mechanism, a support shaft I, a support shaft II, a net stretching roller, a compression roller I, a compression roller II, a net feeding rubber roller, a net roll brake device, a net cutting knife, a guide plate, a net cutting knife rest and the like. The net winding device has the advantages that the netwinding device is used for the round baler, and is in a working mode that the number of turns of the rubber roller is electronically counted and a net is started to be cut by an electric push rod, accordingly, the number of turns of net winding can be conveniently adjusted, and the reliability is high; and constant frictional resistance can be continuously provided for net rolls by the net feedingmechanism and the net roll brake device and cannot be changed along with the diameters of the net rolls, electromagnetic brakes can guarantee that a silk screen is difficult to loosen when the net iscut, and accordingly, the baling efficiency and the baling reliability of the round baler can be improved.

Owner:内蒙古华德新技术有限公司 +2

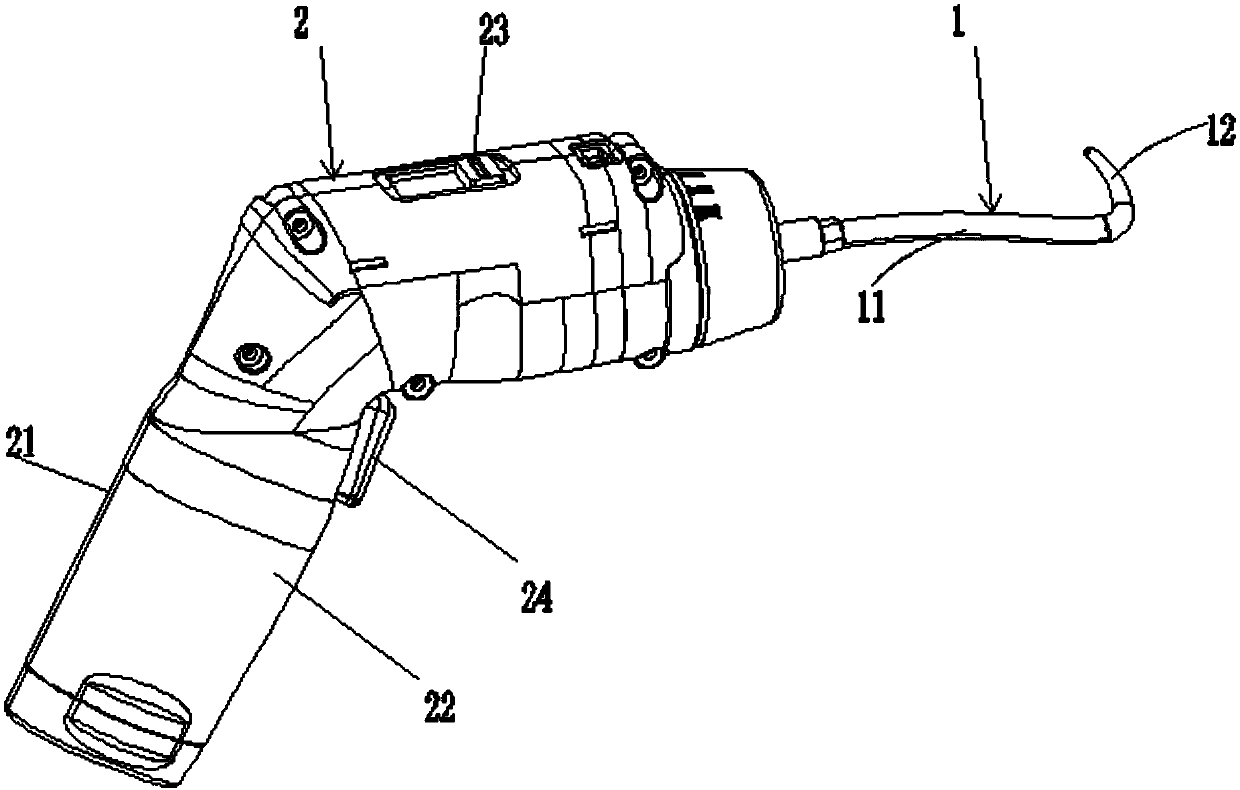

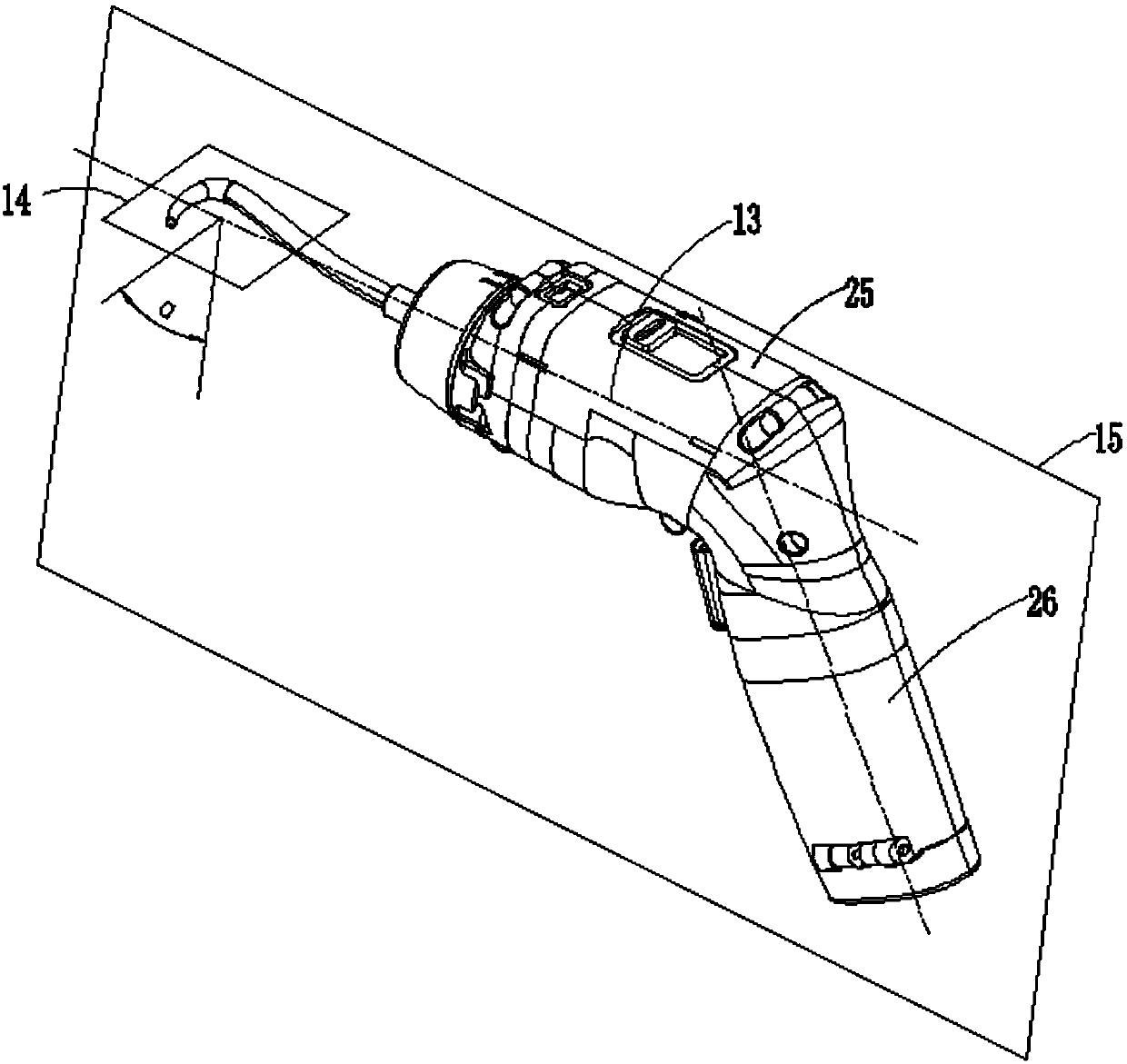

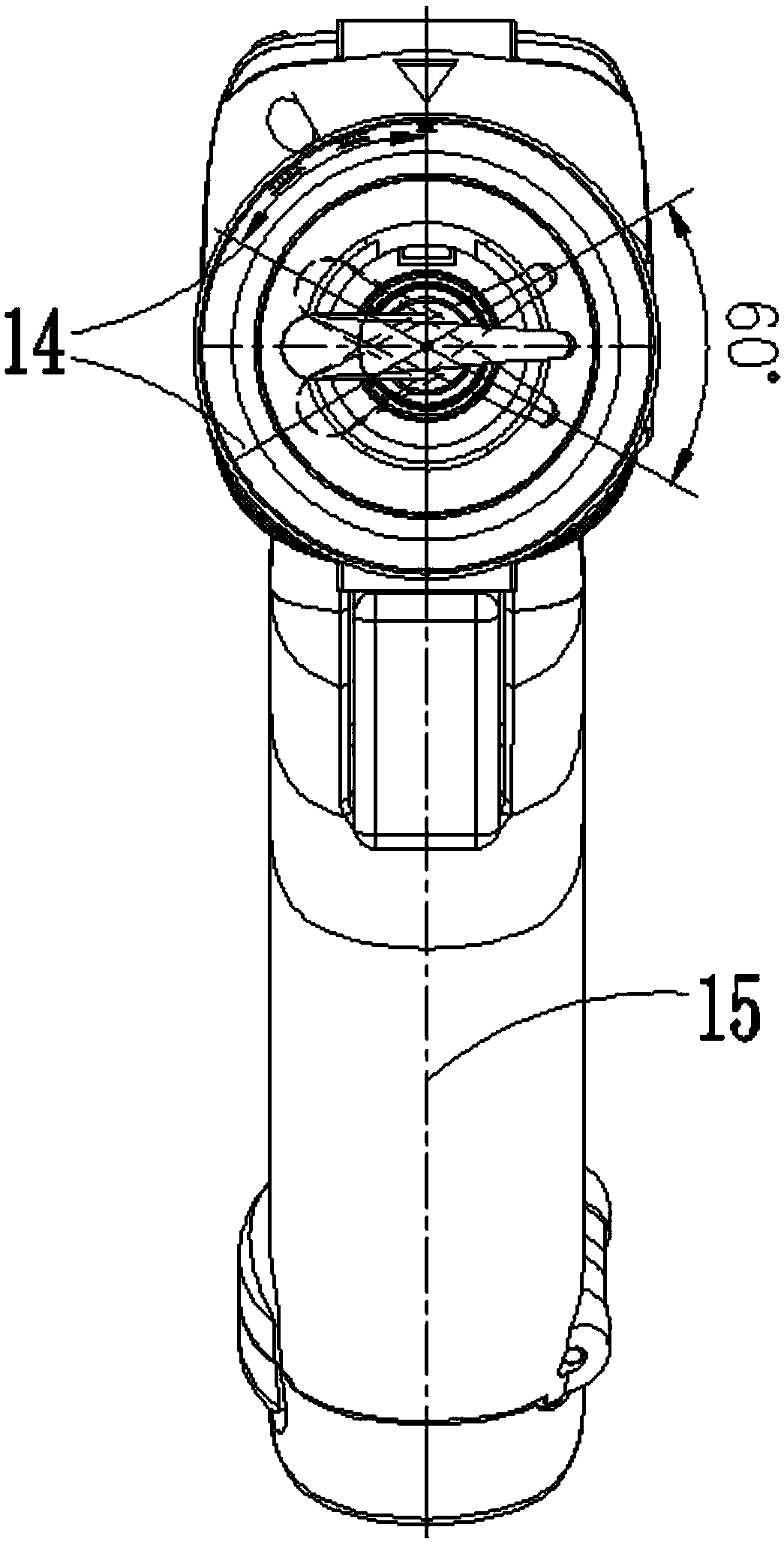

Steel bar binding machine

PendingCN111140017ACompact structureReduce weightBuilding material handlingSteel barMechanical engineering

The invention discloses a steel bar binding machine. The steel bar binding machine comprises a shell, a working head, a power mechanism, a signal acquisition unit and a control unit, wherein the working head is used for twisting joint of steel wires, and the working head comprises a body part extending out of the shell in a first extending direction and a working part arranged at the end, far awayfrom the shell, of the body part; the working part has a second extending direction different from the first extending direction, and the body part defines a first axis in the first extending direction; the power mechanism is used for driving the working head to rotate around the first axis; the signal acquisition unit is used for acquiring a signal representing the twisting joint state of the steel wires; and the control unit is electrically connected with the power mechanism and the signal acquisition unit, and the control unit is used for controlling the working head to stop rotating underthe condition that the signal acquisition unit acquires a signal indicating that the steel wires finish twisting joint. With the steel bar binding machine, the operation convenience can be improved and the working condition adaptability is higher.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Full-automatic multifunctional bander

The invention discloses a full-automatic multifunctional bander. The full-automatic multifunctional bander comprises a carrying mechanism, a moving mechanism, a conveying mechanism, a forming mechanism and a rope winding mechanism. The carrying mechanism comprises a carrying plate, a telescopic rod set and a frame supporting plate. The moving mechanism comprises a control rod and universal wheel sets. The conveying mechanism comprises a first motor, a first belt, a second motor, a second belt, a first conveying belt shaft group, a first conveying belt, a honeycomb conveying group, a second conveying belt shaft group, a second conveying belt, a first protective cover group, a second protective cover group and a protective cover supporting seat. The forming mechanism comprises an upper guardplate, a lower guard plate, an electric cylinder group, a battery box, a limiting switch and a pressure sensor. The rope winding mechanism comprises a first pinion, a third motor, a first rack wheel,a first gear stand, a first rope storage box, a second rope storage box, a second rack wheel, a second gear stand, a second pinion and a fourth motor. Compared with the prior art, the full-automaticmultifunctional bander has the advantages that the banding efficiency of straw-type crops is improved, and a large quantity of manpower and material resources are saved.

Owner:江苏华丰铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com