Patents

Literature

63results about How to "Reduce collisions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

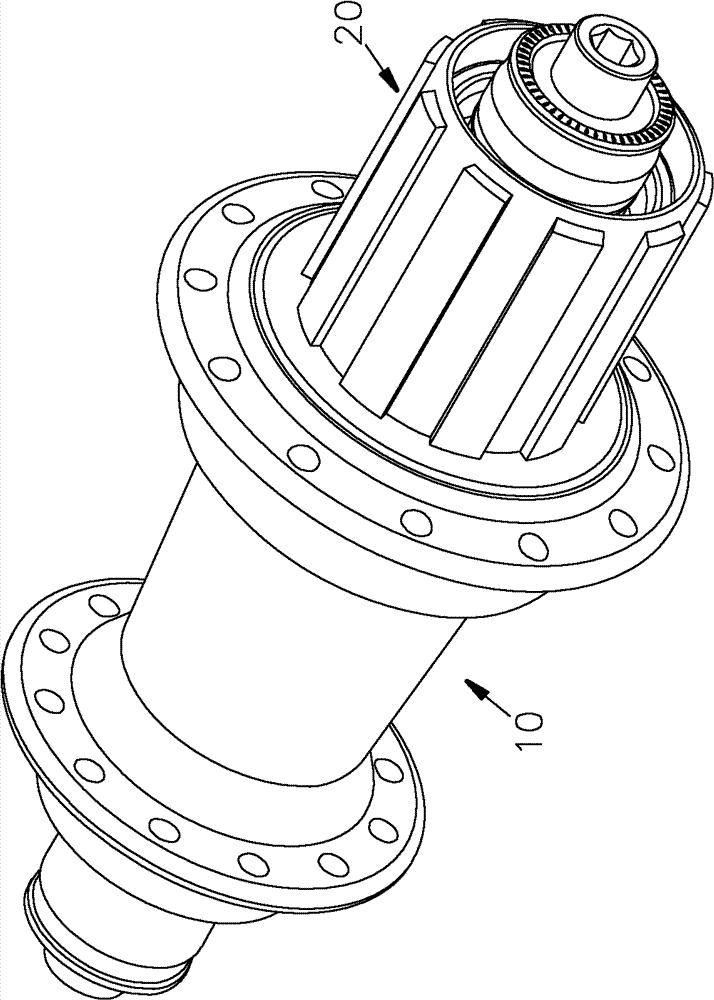

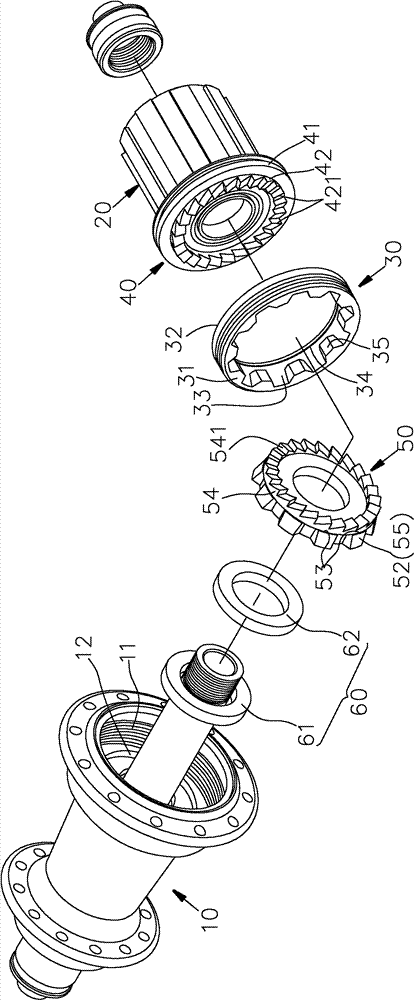

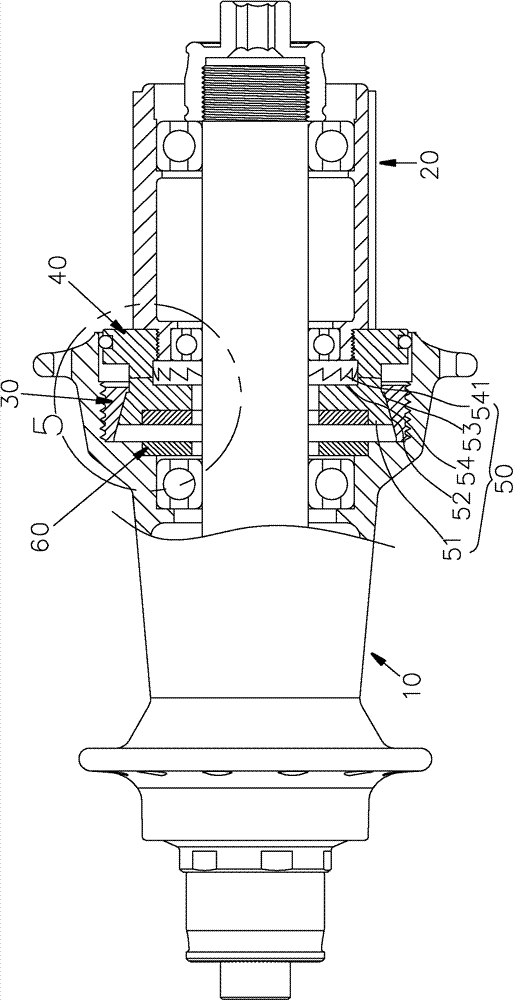

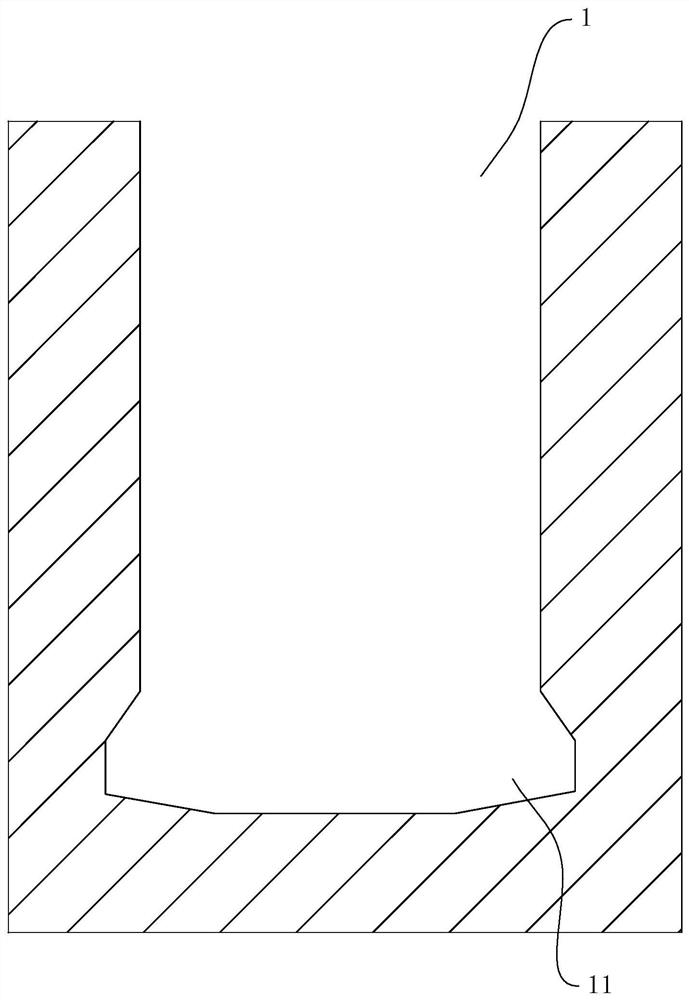

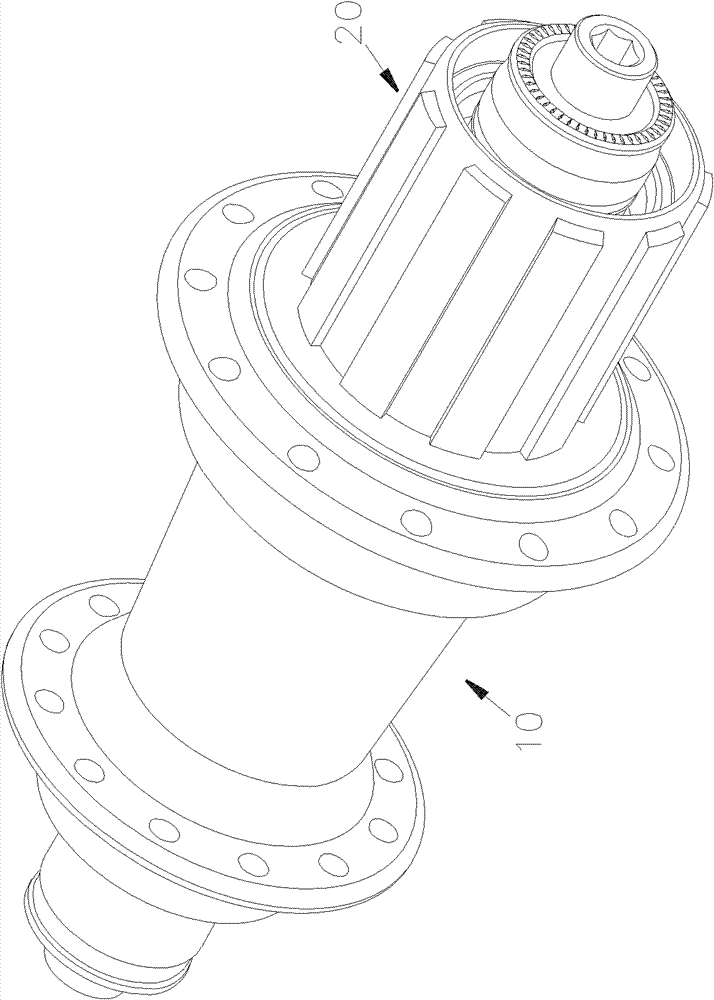

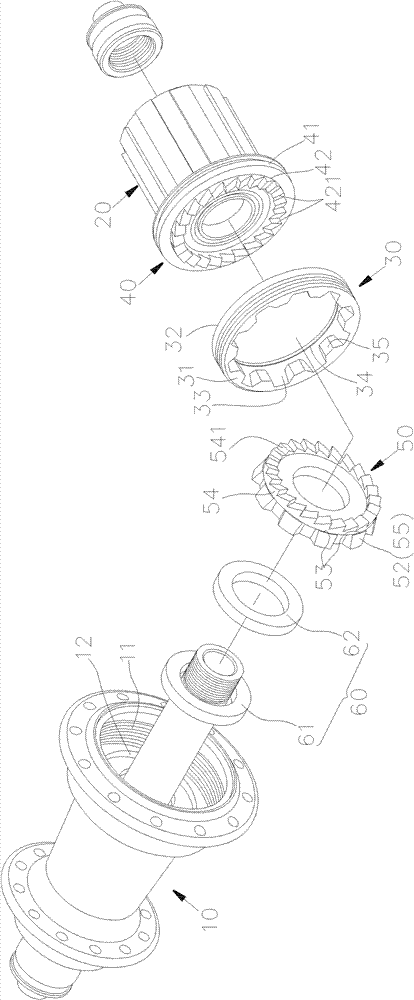

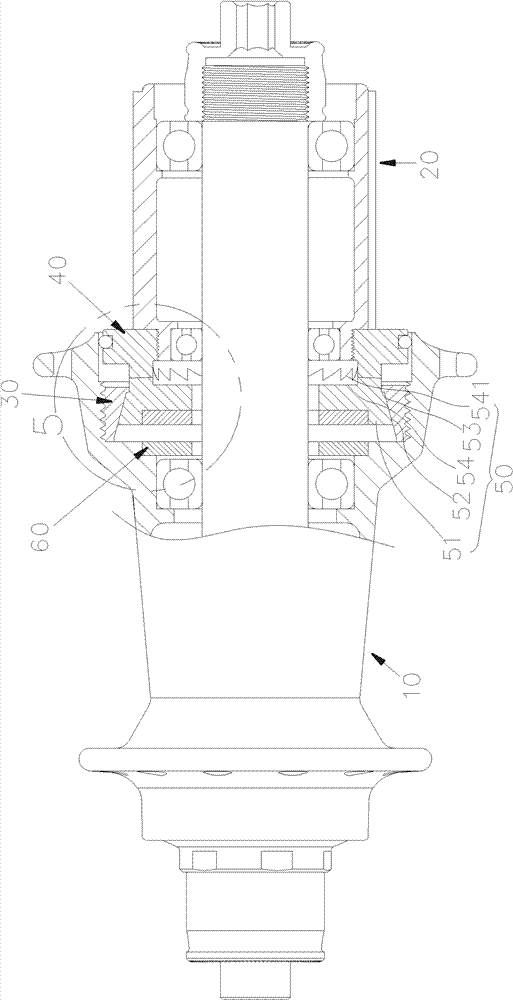

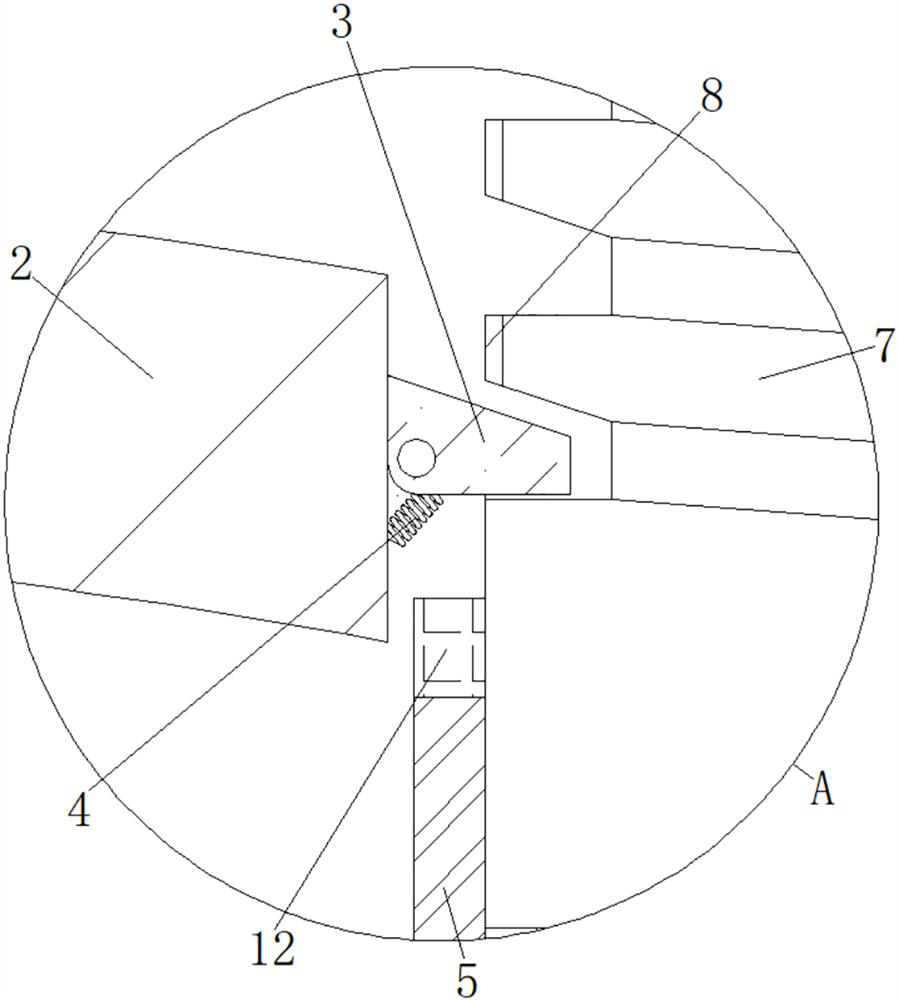

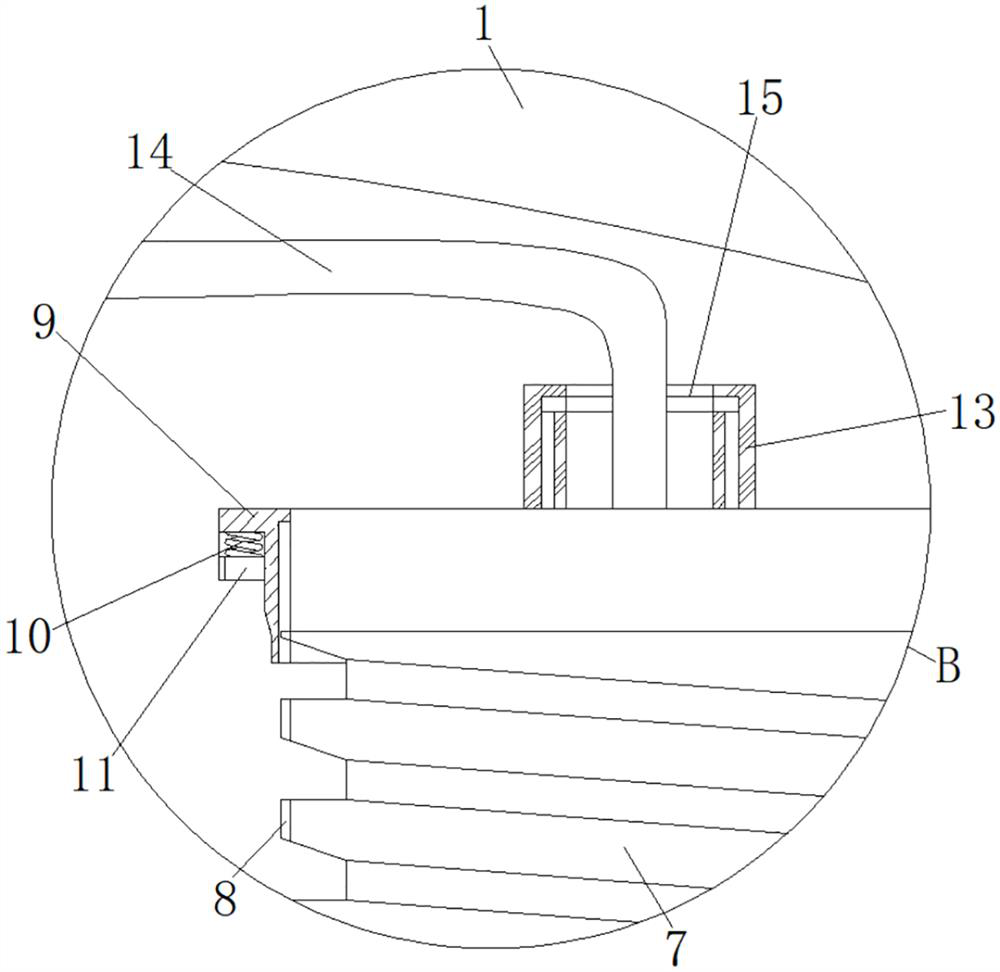

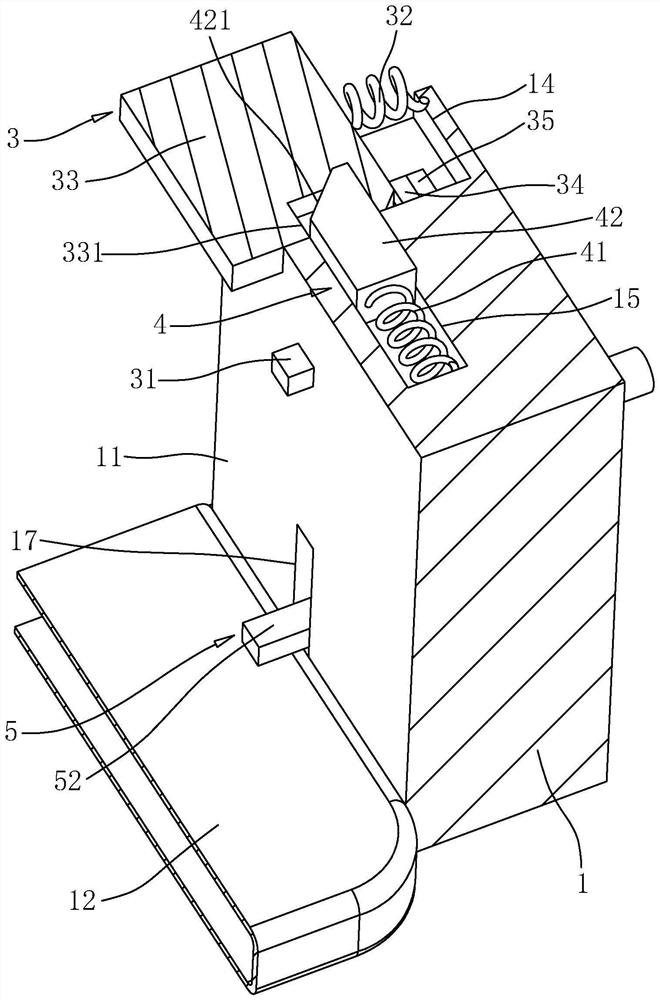

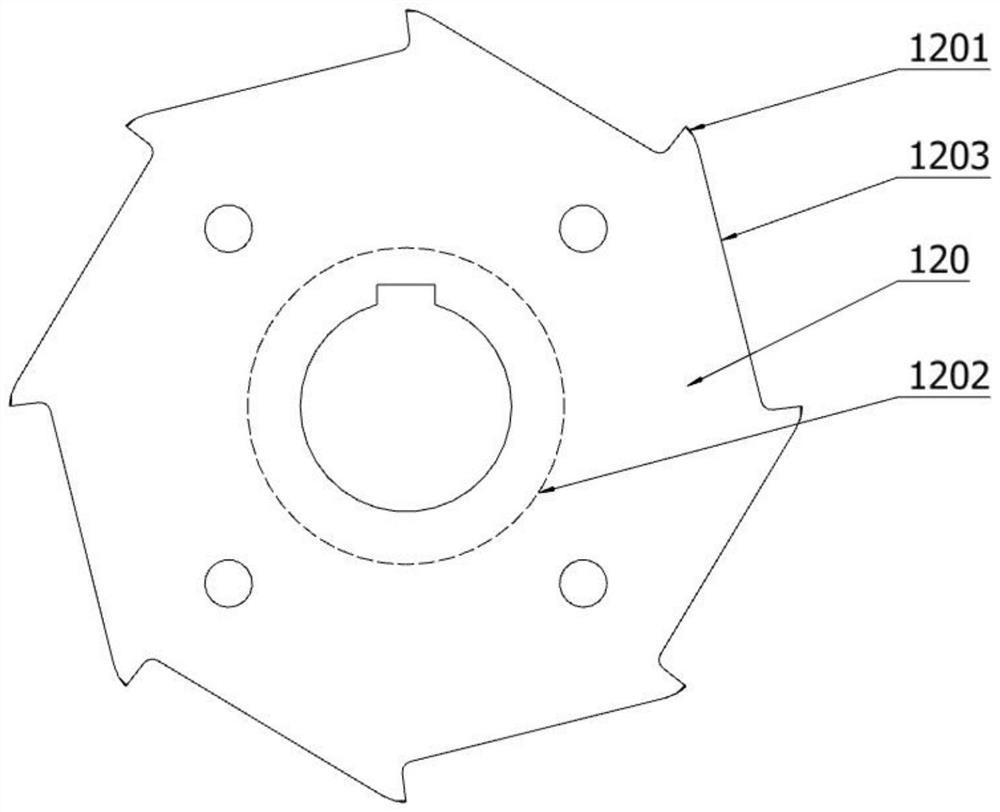

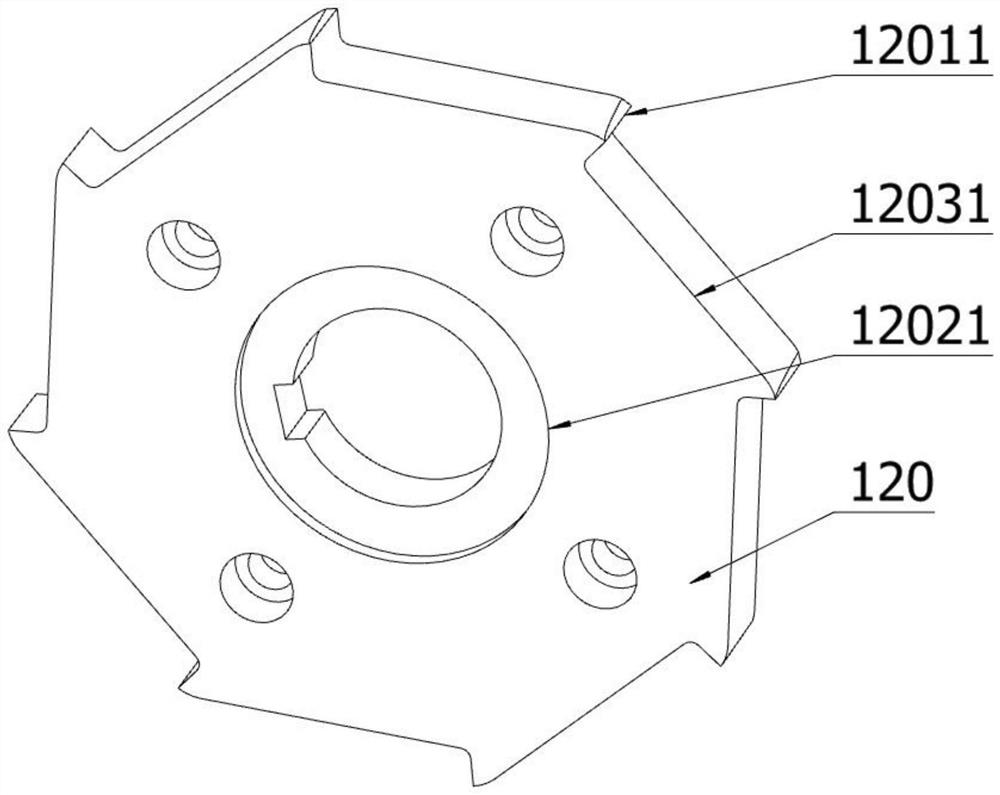

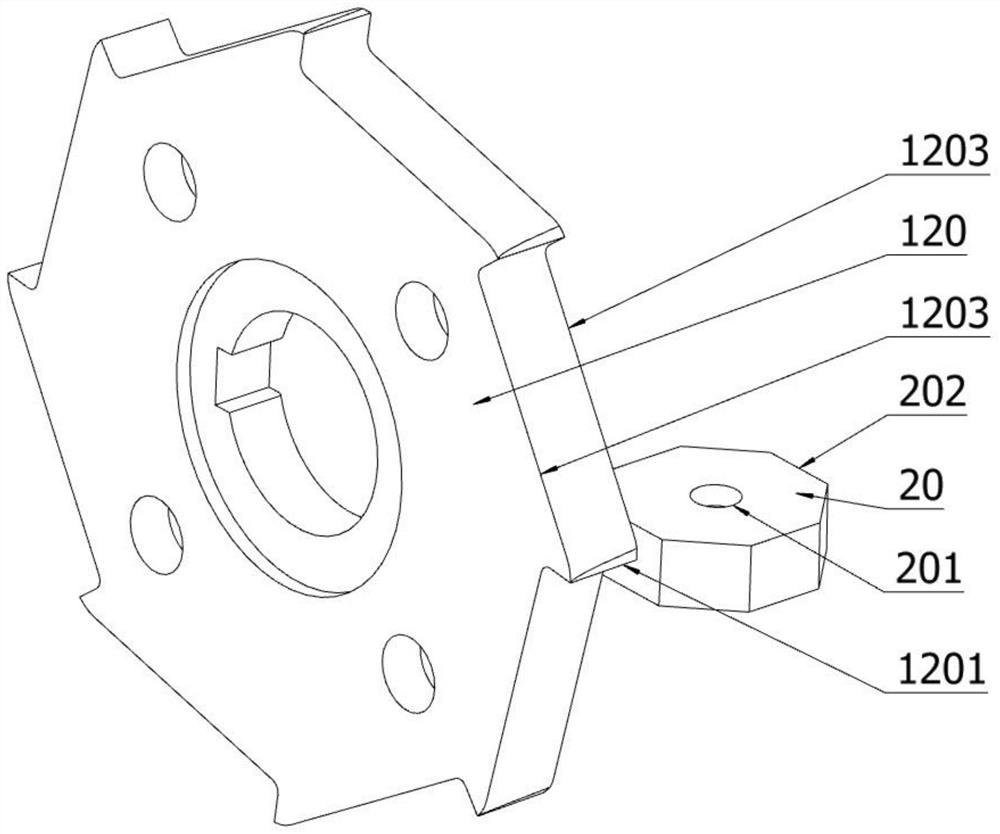

Ratchet wheel of wheel hub of bicycle

The invention mainly provides a ratchet wheel of a wheel hub of a bicycle. The ratchet wheel is arranged between a first wheel hub base and a sleeve base and comprises a blocking ring which is arranged inside the wheel bub base fixedly, a driven base, a conical surface, a blocking portion and a magnetic group; wherein an inclined cone inner hole and a blocking edge are arranged on the blocking ring, a driving base is arranged between the wheel hub base and the sleeve base, and a plurality of first ratchet teeth are arranged on a one side end face of the driving base, which faces towards an axial ring inside the wheel hub base; the driven base is arranged inside the inclined cone inner hole and corresponds to a driving group, the external diameter of the conical surface can be matched with the inclined cone inner hole, the blocking portion can be blocked by the blocking edge in one direction, a driven base ring is provided with a plurality of second ratchet teeth which can be meshed with the first ratchet teeth, and the magnetic group is arranged between the driven base and the wheel hub base and provided with a first magnetic part and a second magnetic part, which are respectively arranged inside the wheel hub base and on the driven base and are in a mutual exclusion state. Thus, the inclined cone inner hole which is in an inclined cone shape and the conical surface design are adopted, the friction force is reduced, the restoring speed of the driven base is increased, and the sensitivity of a ratchet wheel group is improved further.

Owner:KUNSHAN HENRY METAL TECH

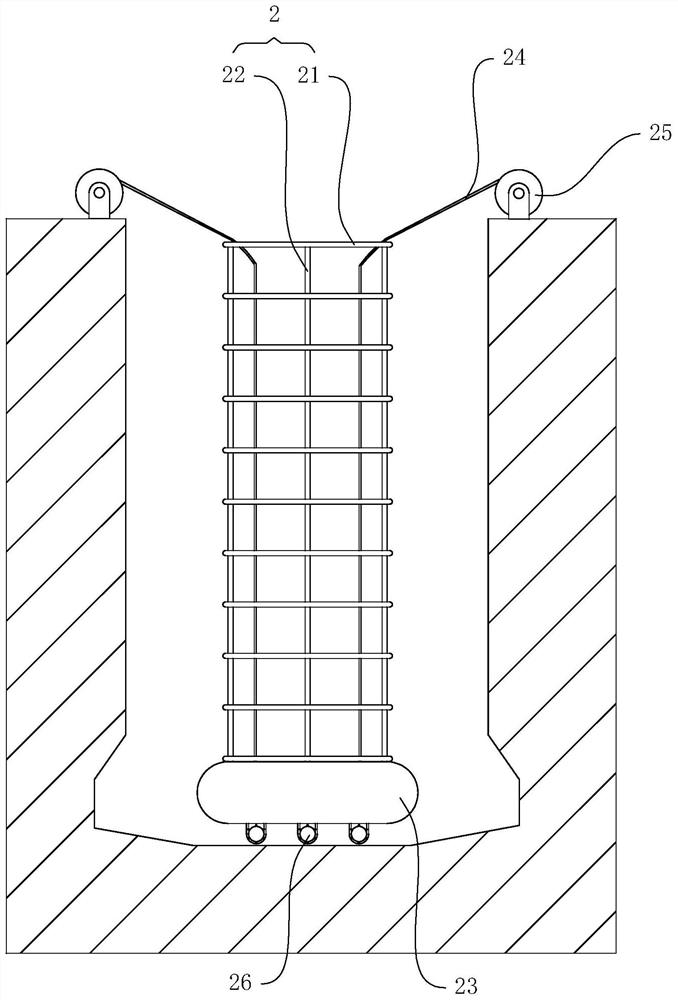

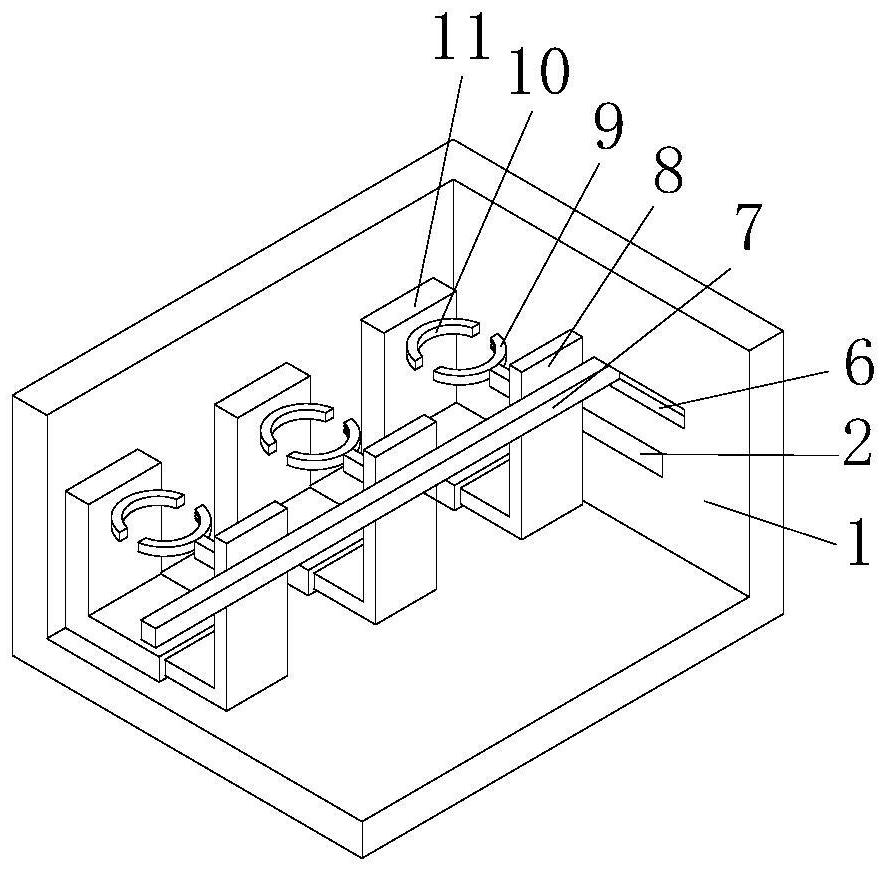

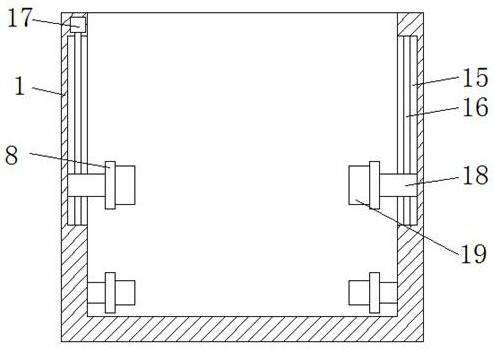

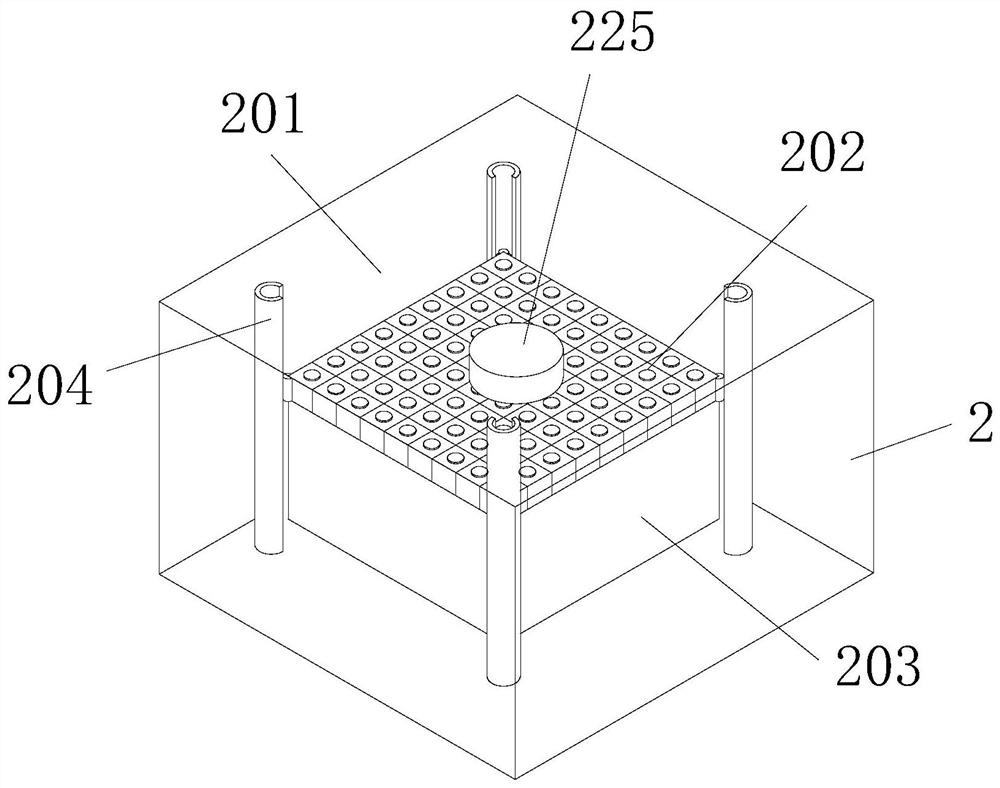

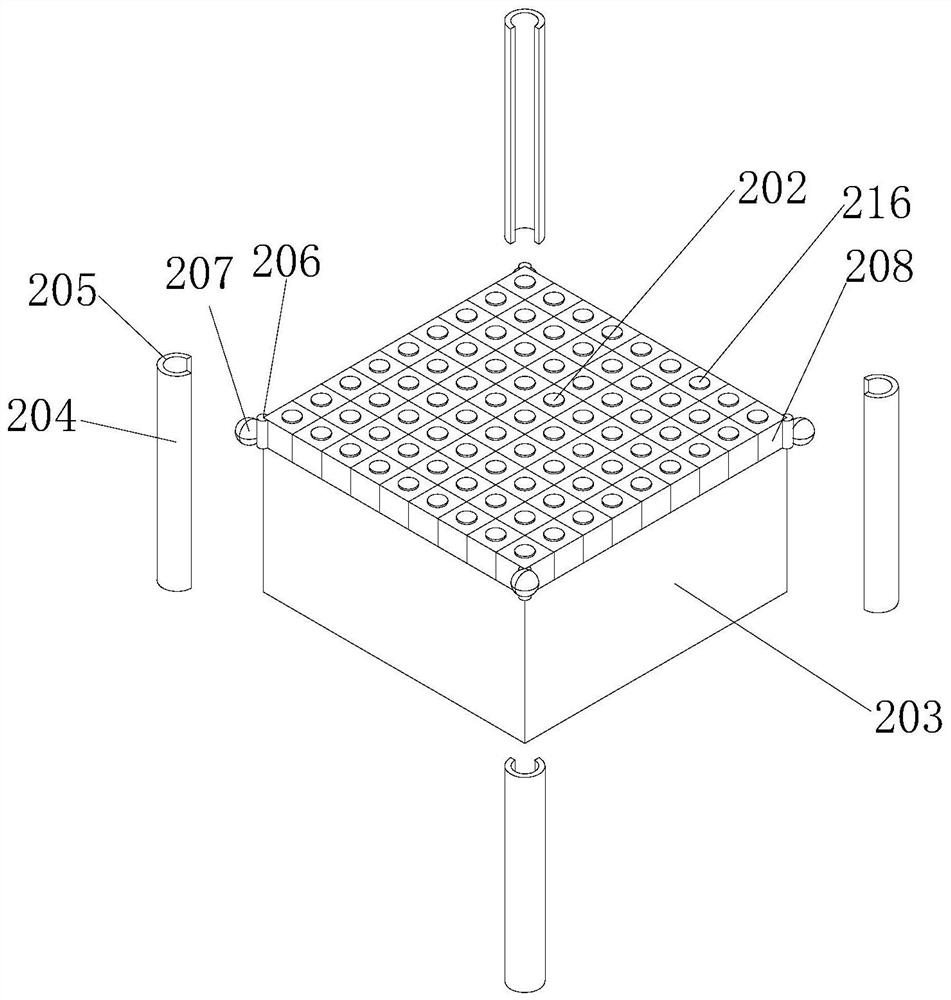

Construction method of single-pipe grouting bottom-expanding cast-in-place pile

The invention relates to a construction method of a single-pipe grouting bottom-expanding cast-in-place pile, and belongs to the field of cast-in-place piles. The construction method comprises the following steps that 1, a spiral pile machine is used for drilling a foundation to form a pile hole, meanwhile, wall protection slurry is poured, after a drill bit reaches a preset position, a drill rodis lifted, the bottom of the pile hole is expanded, and a pile bottom expanding part is formed; 2, the pile hole is cleaned; 3, a reinforcement cage is placed into the pile hole, and the bottom of thereinforcement cage is inserted into the pile bottom expanding part; 4, a first guide mechanism and a second guide mechanism are installed at the position, close to the pile hole, of the ground and the top of the reinforcement cage correspondingly, and a pouring guide pipe is inserted into the pile hole through the first guide mechanism and the second guide mechanism; and 5, a concrete pump is connected to the top of the pouring guide pipe, and pile forming concrete slurry is poured into the pouring guide pipe. The construction method has the effect of keeping the pouring guide pipe stable when being put down.

Owner:湖北中南岩土工程有限公司

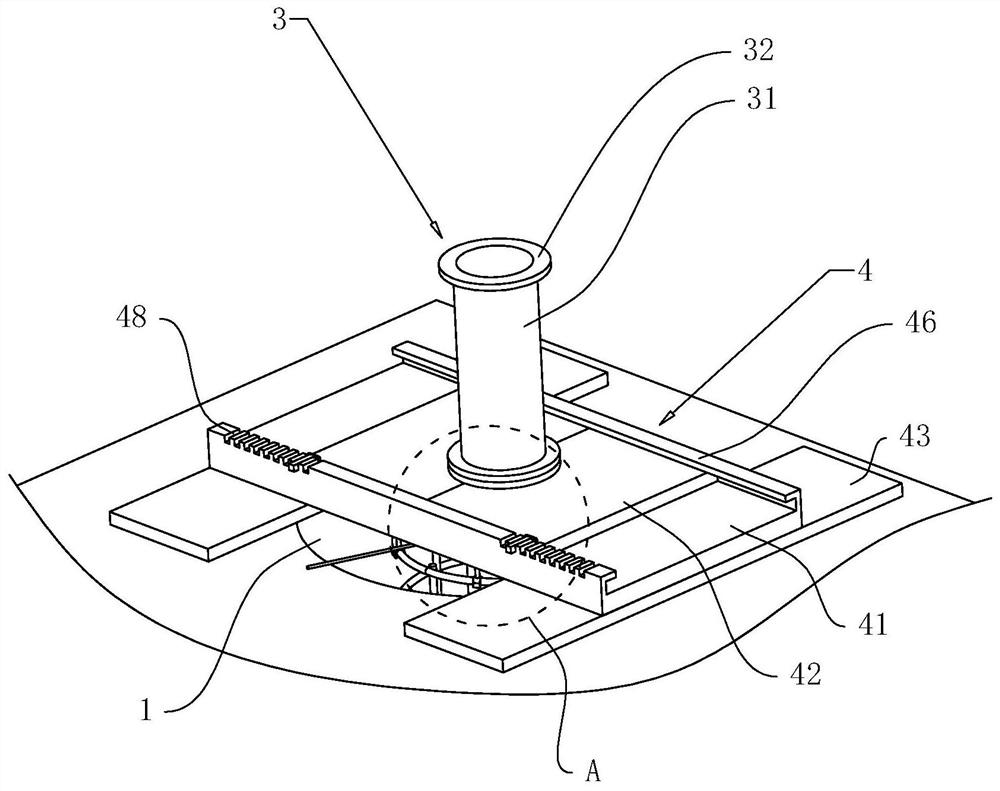

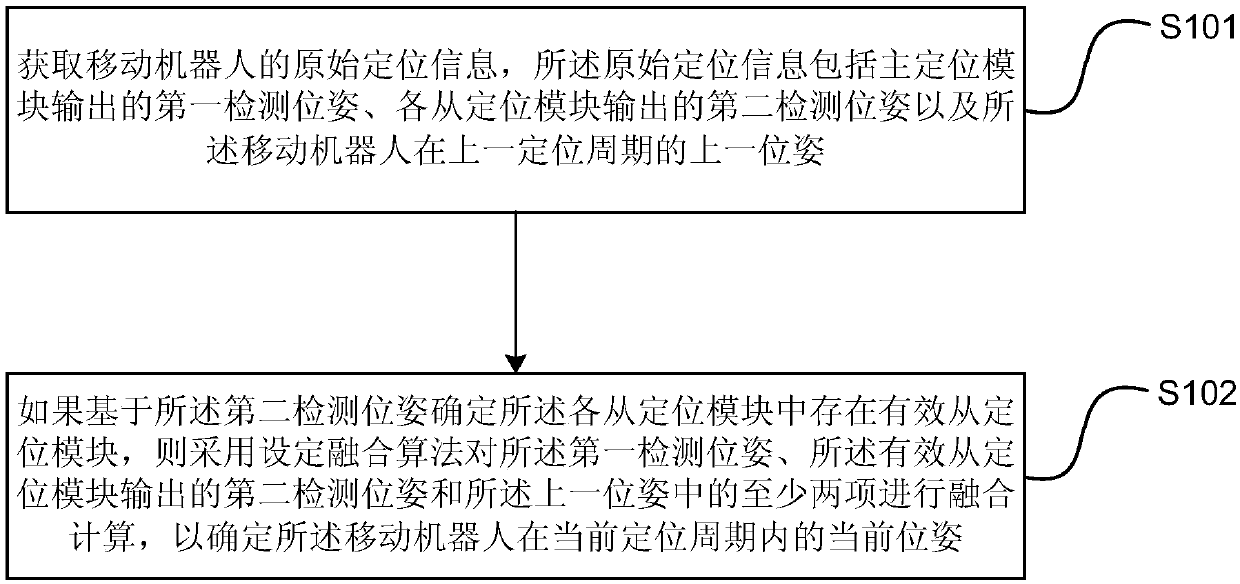

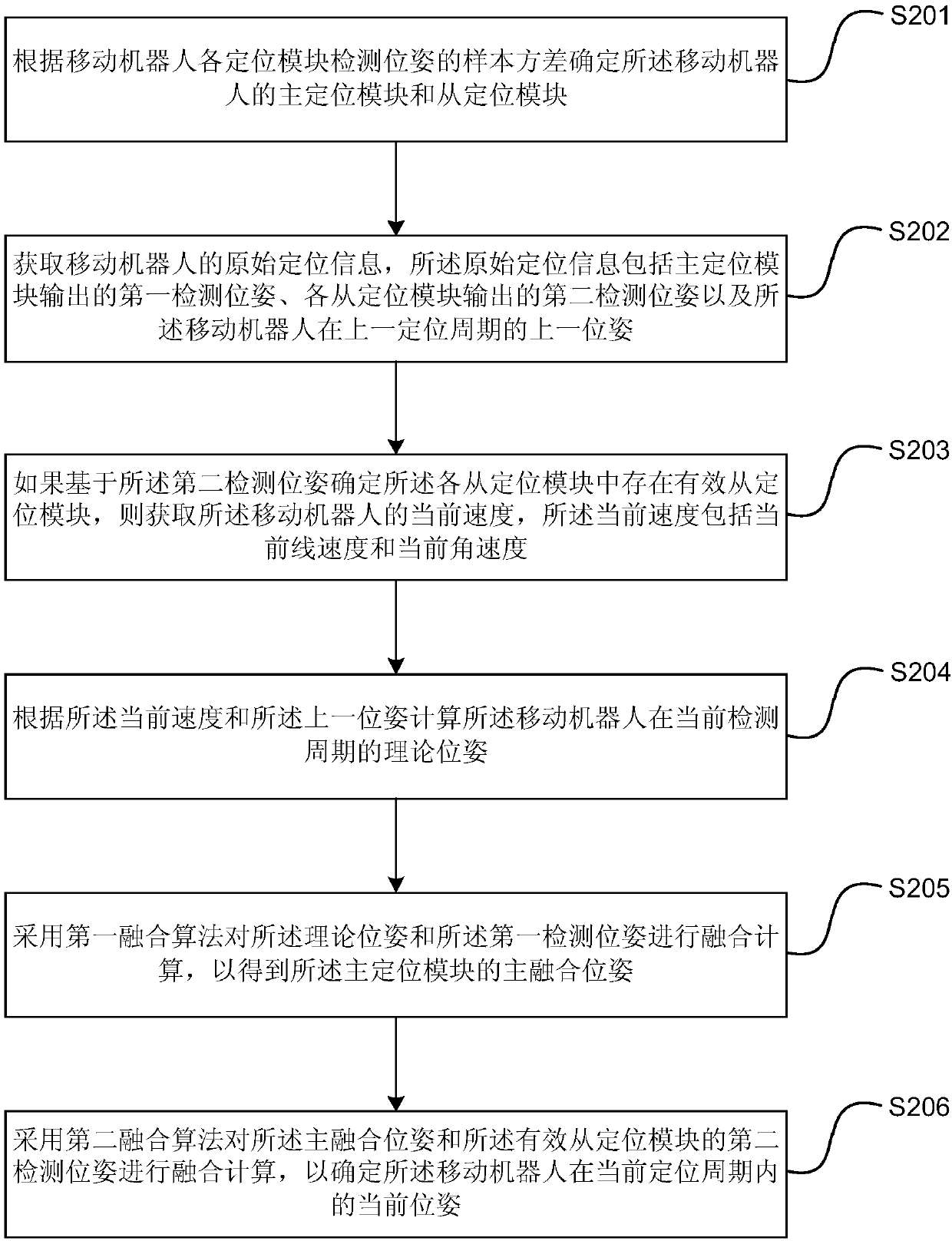

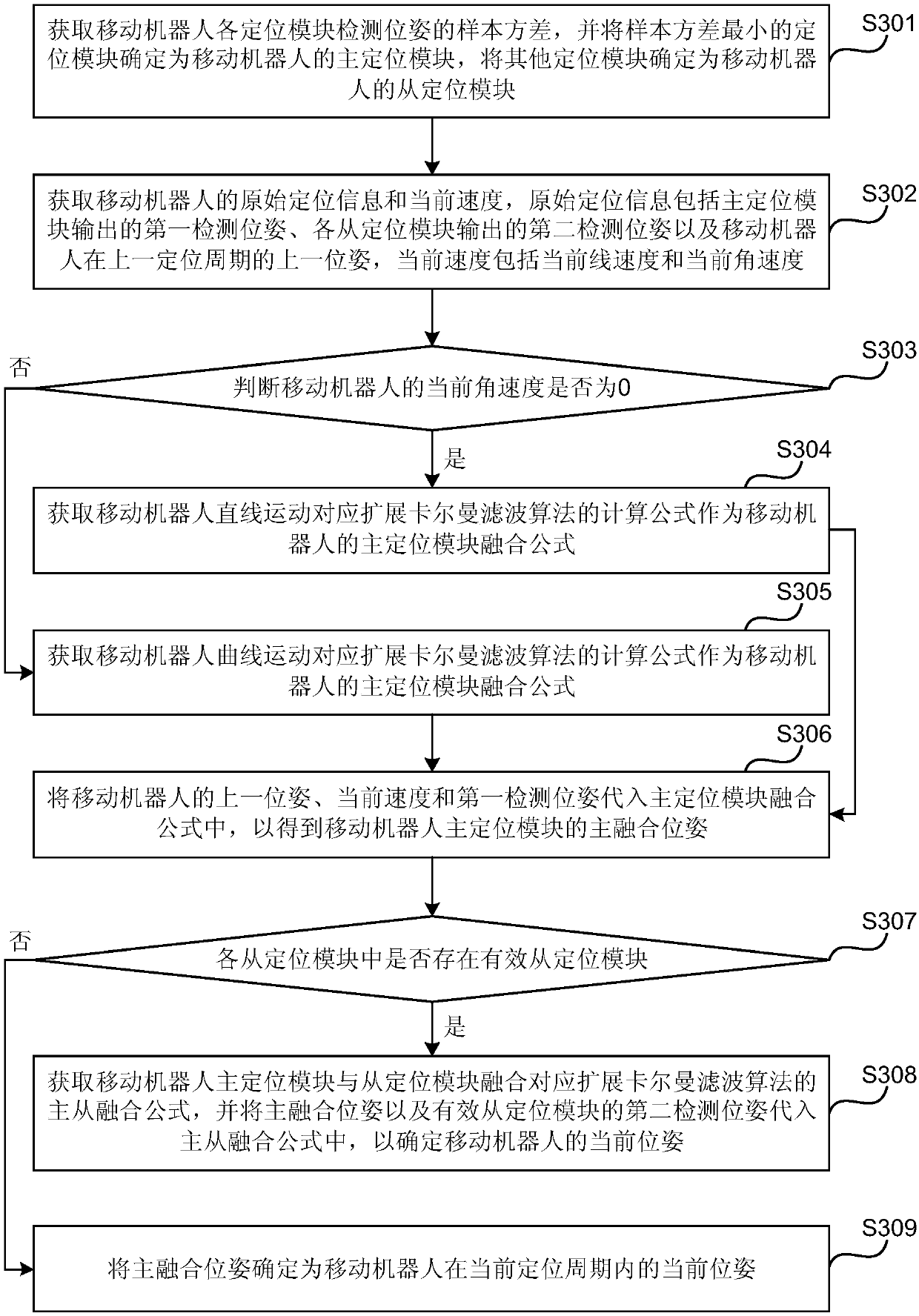

Positioning method and positioning device of mobile robot, mobile robot and storage medium

ActiveCN107782304AReduce positioning errorsHigh positioning accuracyNavigational calculation instrumentsCharacter and pattern recognitionComputer moduleComputer vision

The invention discloses a poisoning method and a positioning device of a mobile robot, a mobile robot and a storage medium. The method comprises the following steps: acquiring the original positioninginformation of the mobile robot, wherein the original positioning information includes a first detection pose output by a main positioning module, second detection poses output by each slave positioning module, and a last pose of the mobile robot in the last positioning cycle; performing fusion calculation on the first detection pose, second detection poses output by valid slave positioning modules and the last pose by adopting a set fusion algorithm if existence of the valid slave positioning modules in the slave positioning modules is determined based on the second detection poses, so as todetermine the current pose of the mobile robot in the current positioning cycle. According to the embodiment of the invention, by adopting the technical scheme, the positioning error of the mobile robot can be reduced, and the positioning precision of the mobile terminal and the navigation accuracy of the mobile terminal are improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

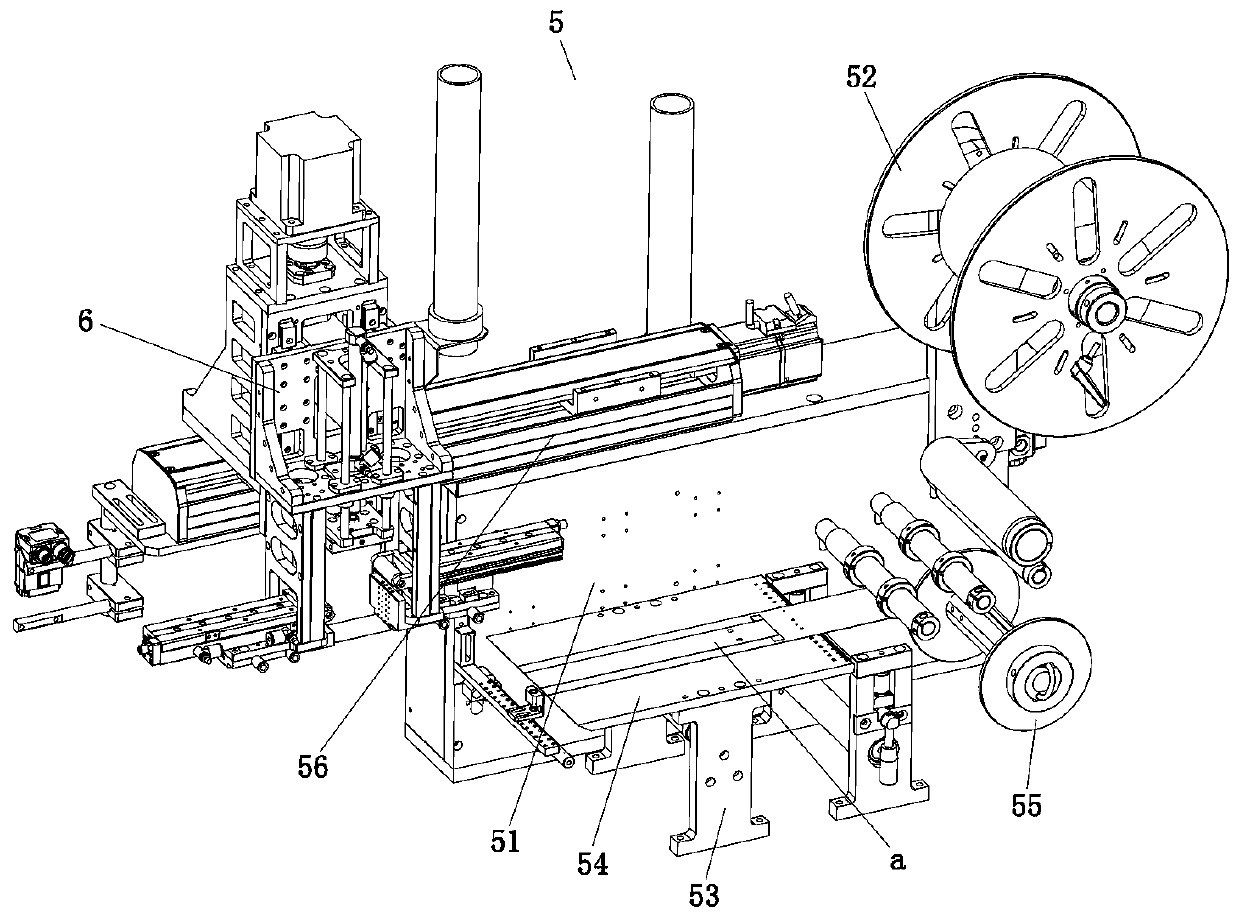

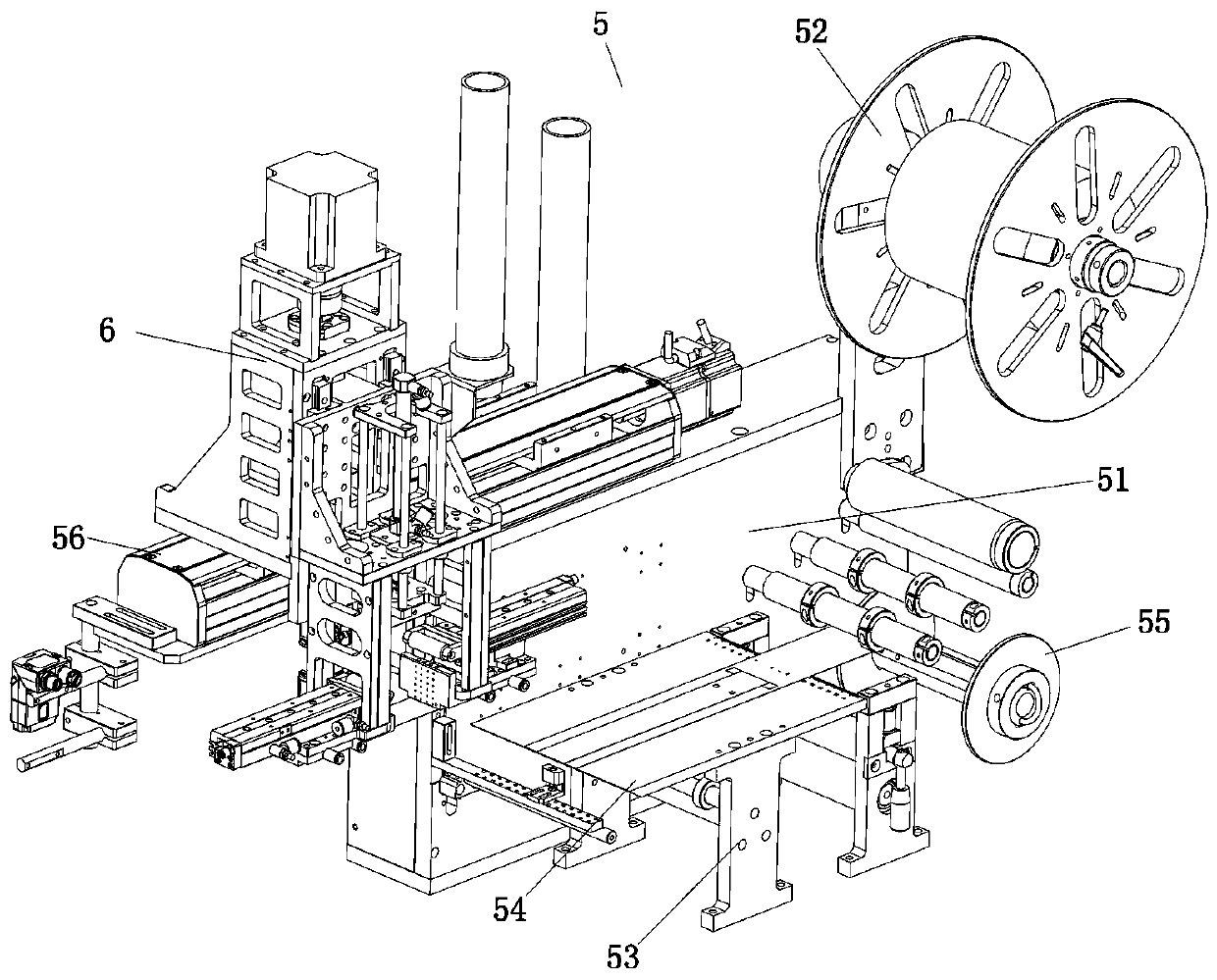

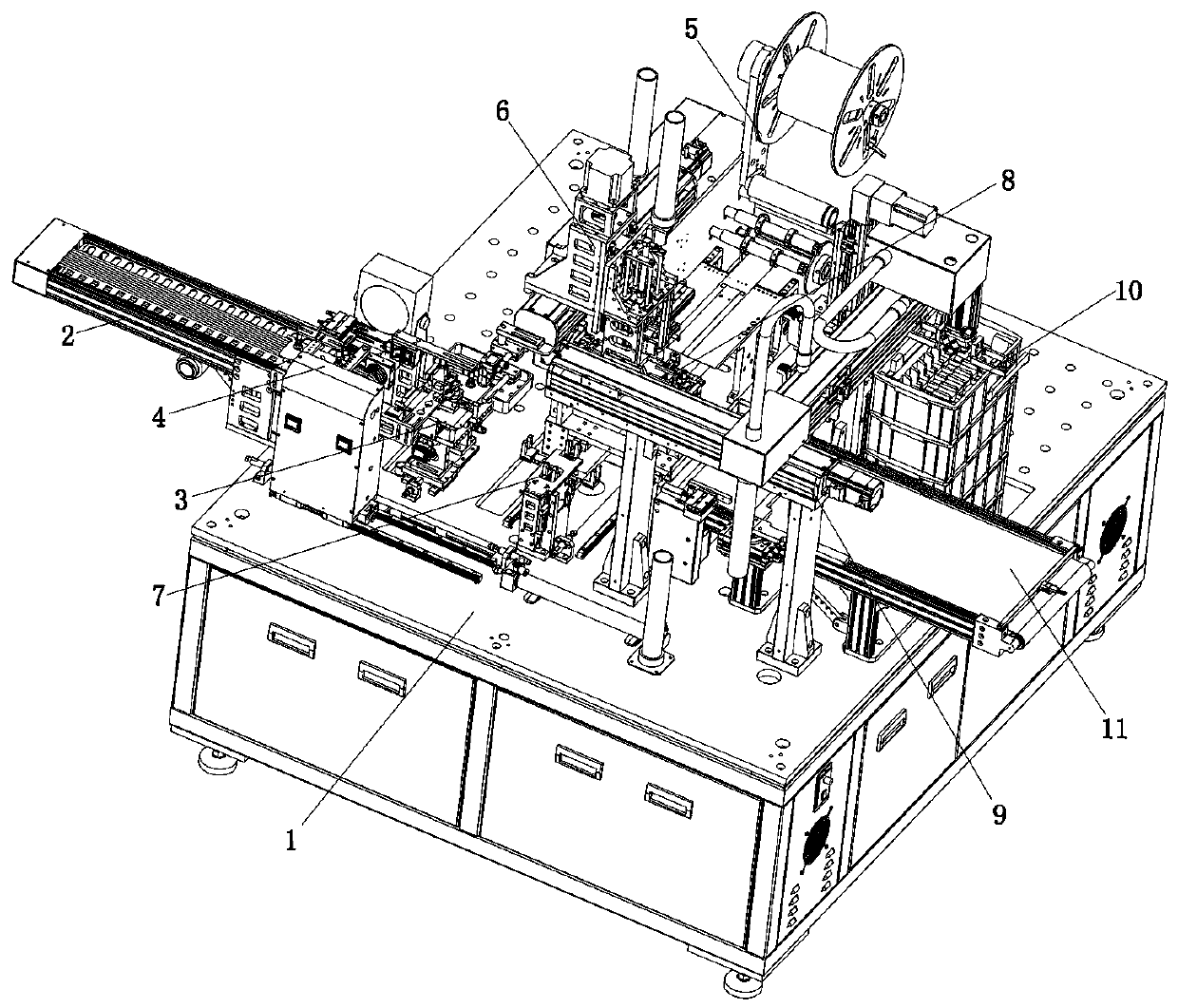

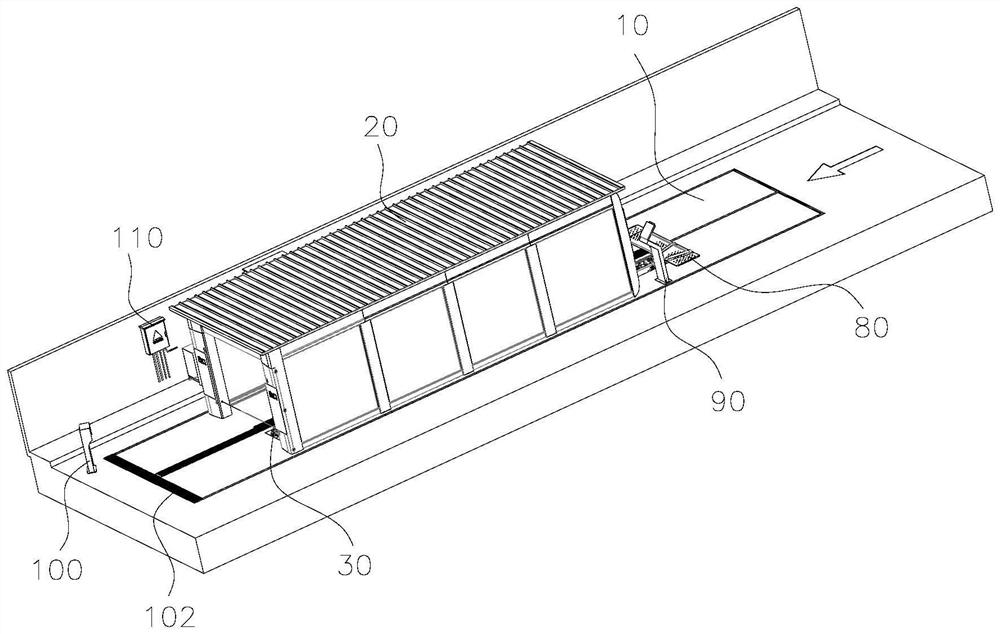

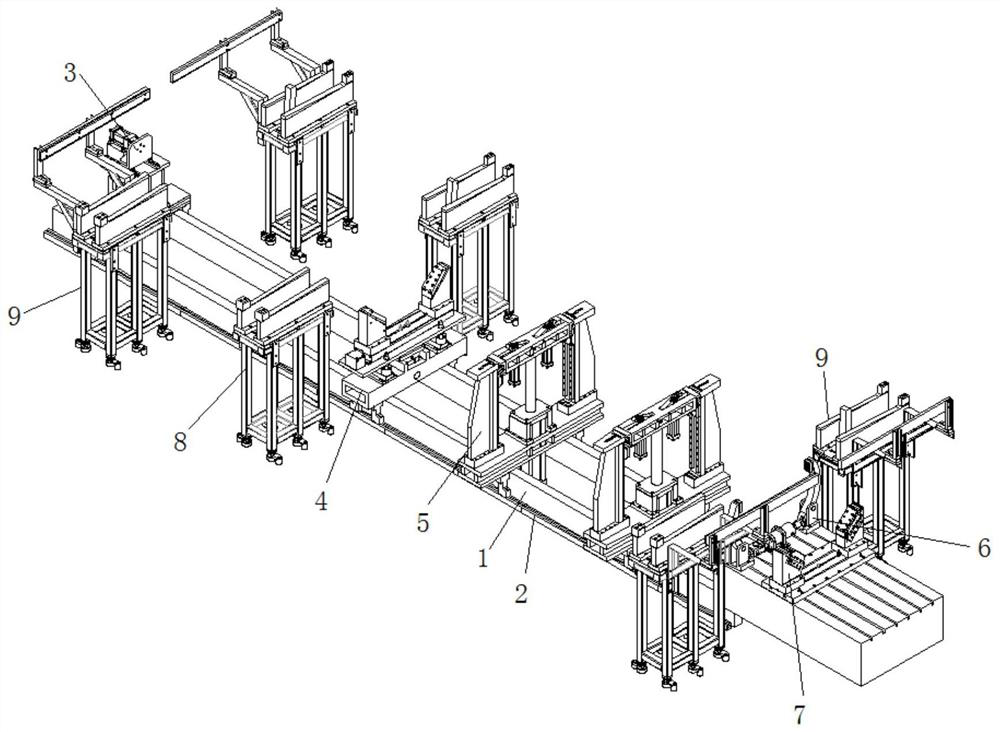

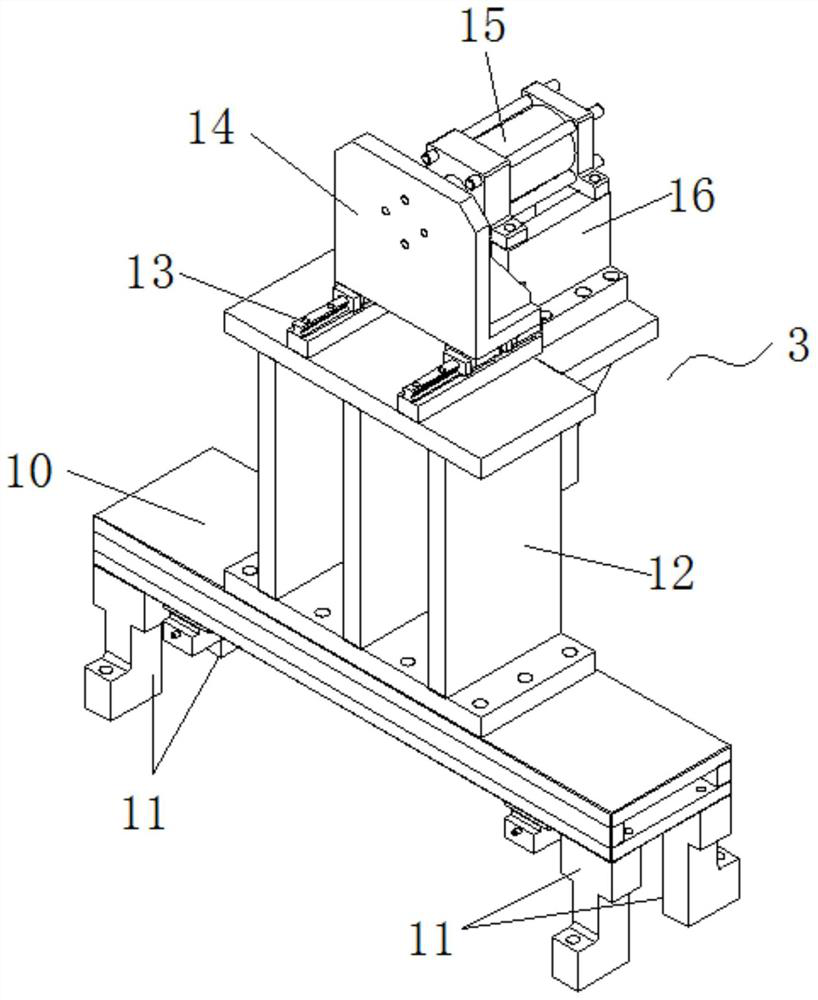

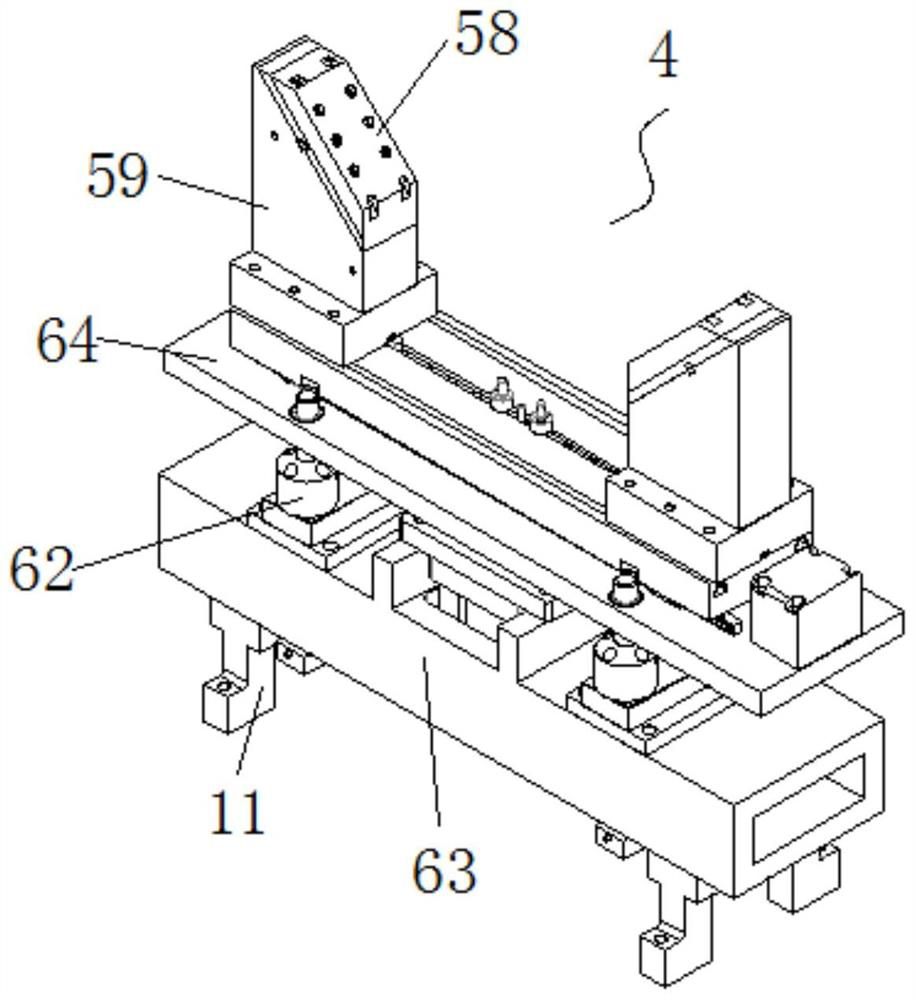

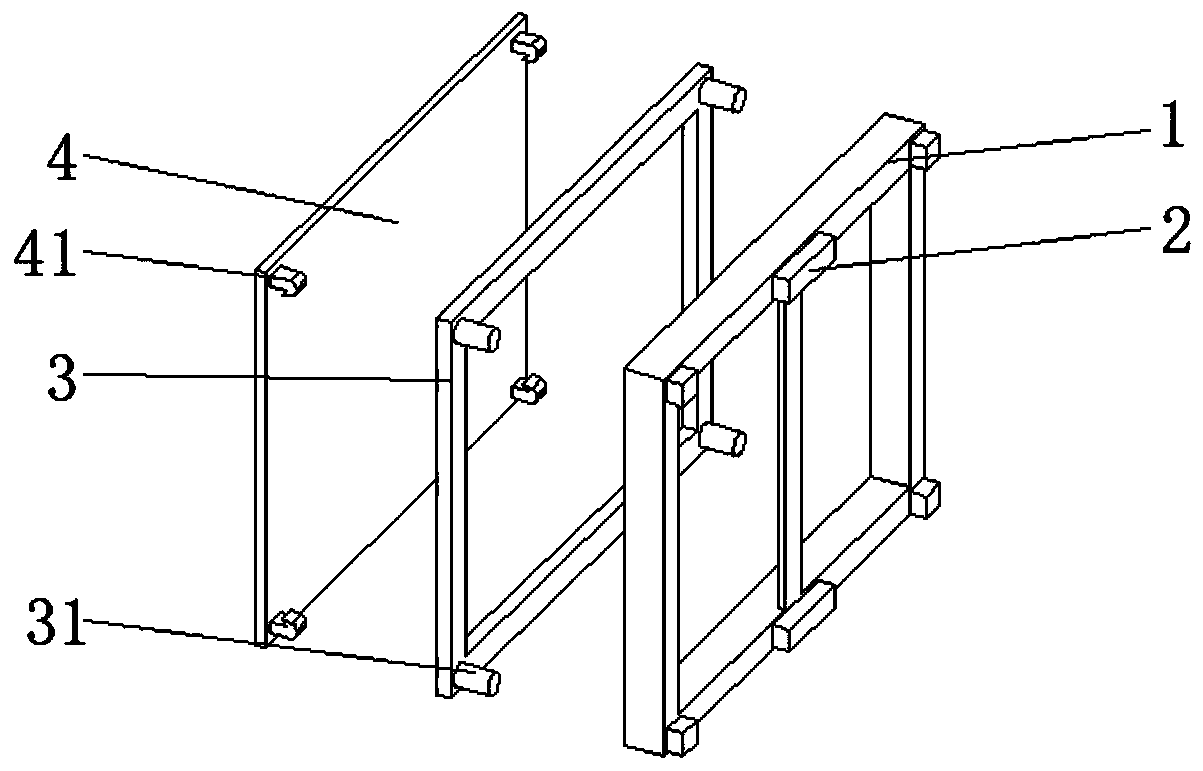

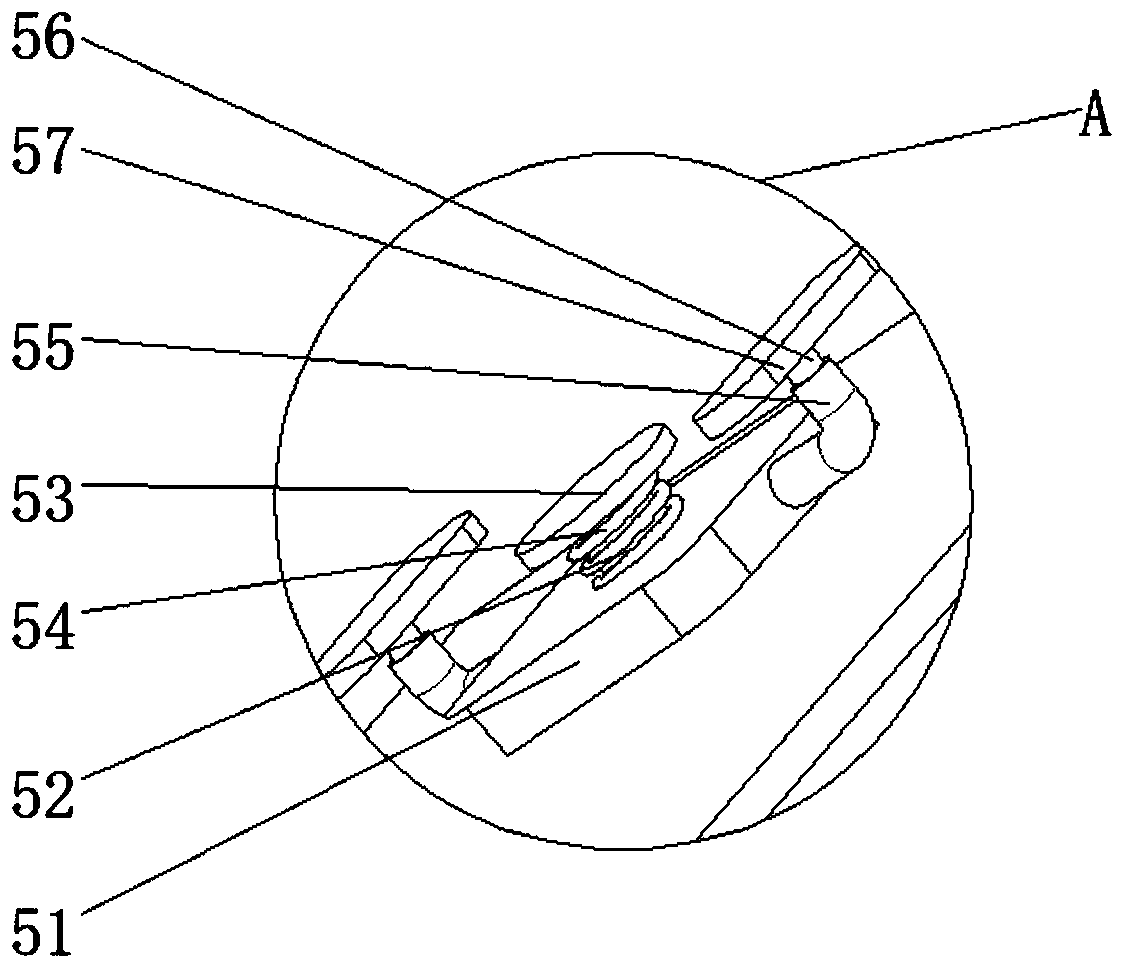

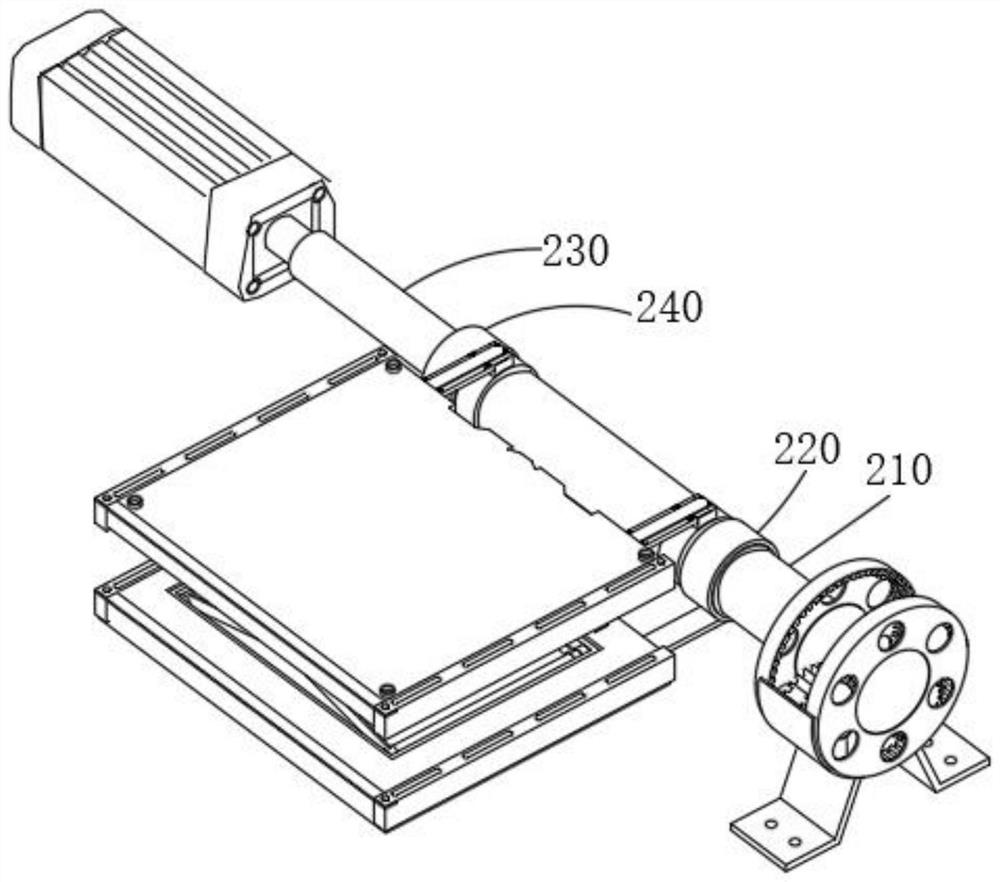

Automatic glass laminated sheet binding and wrapping device and binding and wrapping technology thereof

PendingCN109515806AReduce collisionsImprove bundling efficiencyBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses an automatic glass laminated sheet binding and wrapping device and a binding and wrapping technology thereof. A tape discharging assembly and a binding assembly are included. When the tape discharging assembly outwards pulls material tape to pass through a peeling plate, adhesive tape adhering to the material tape is peeled to the peeling plate, wherein the material tape towhich the adhesive tape adheres is wound around a tape wheel. A linear module is arranged at the upper portion of a tape discharging support plate, and the binding assembly is connected to the linearmodule in a sliding manner. Two tape absorbing plates of the binding assembly adsorb and fix the adhesive tape from the peeling plate. The tape absorbing plates drive the adhesive tape and move downwards, laminated glass upwards slides from the interior of the binding space, and a downward pressing component is used for pressing the bundled adhesive tape from the upper portion. Two side pressingcomponents roll and fix the adhesive tape along the laminated glass surface. According to the automatic glass laminated sheet binding and wrapping device and the binding and wrapping technology thereof, membranes are stacked and stored into a whole in a centralized manner, and the collision situations of membranes between adjacent glass sheets and the membranes between the glass sheets and outer objects are effectively reduced. The binding assembly is used for automatically finishing the bundling and wrapping actions of the adhesive tape along the four sides of the laminated glass, and the binding efficiency and quality are greatly improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

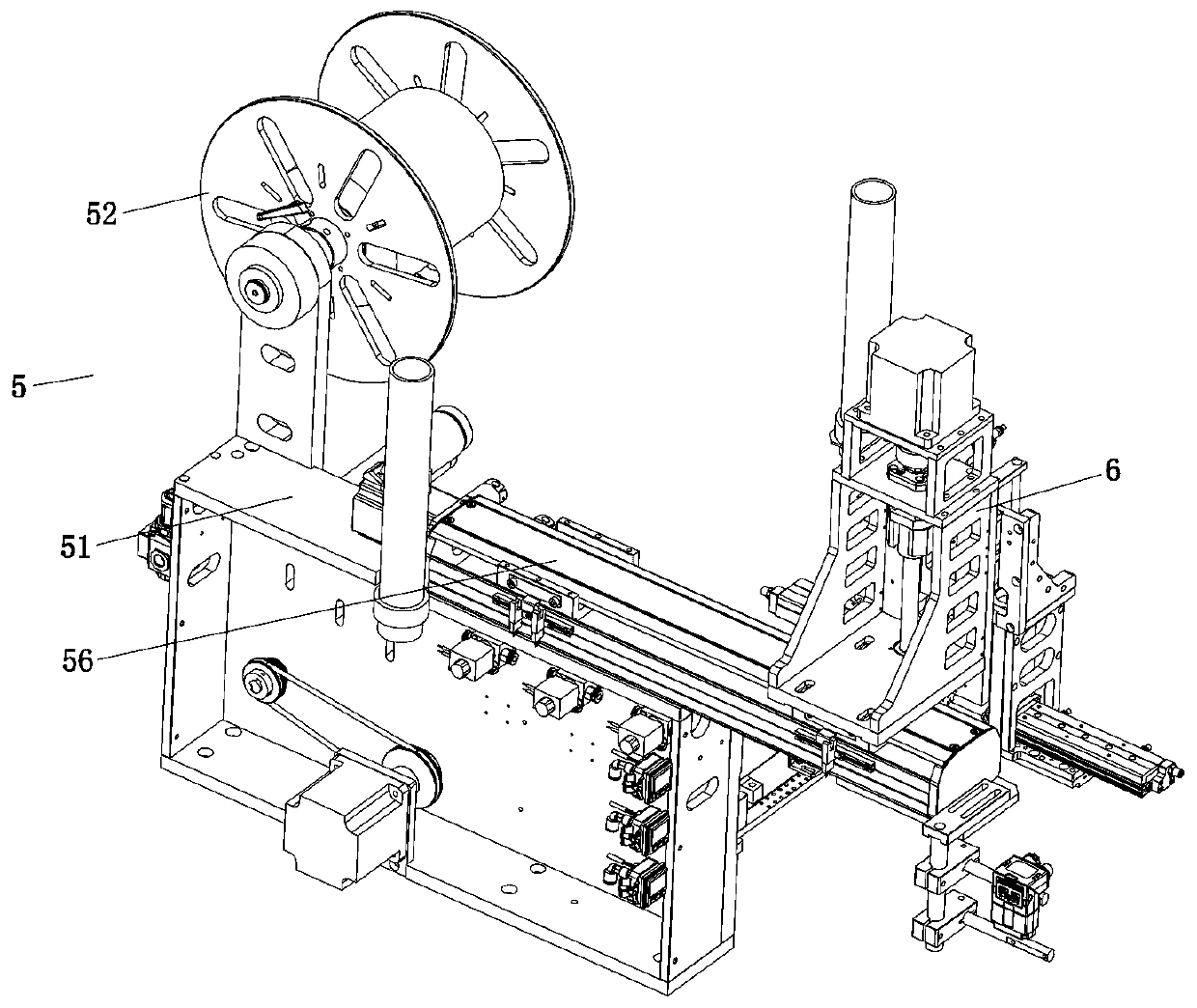

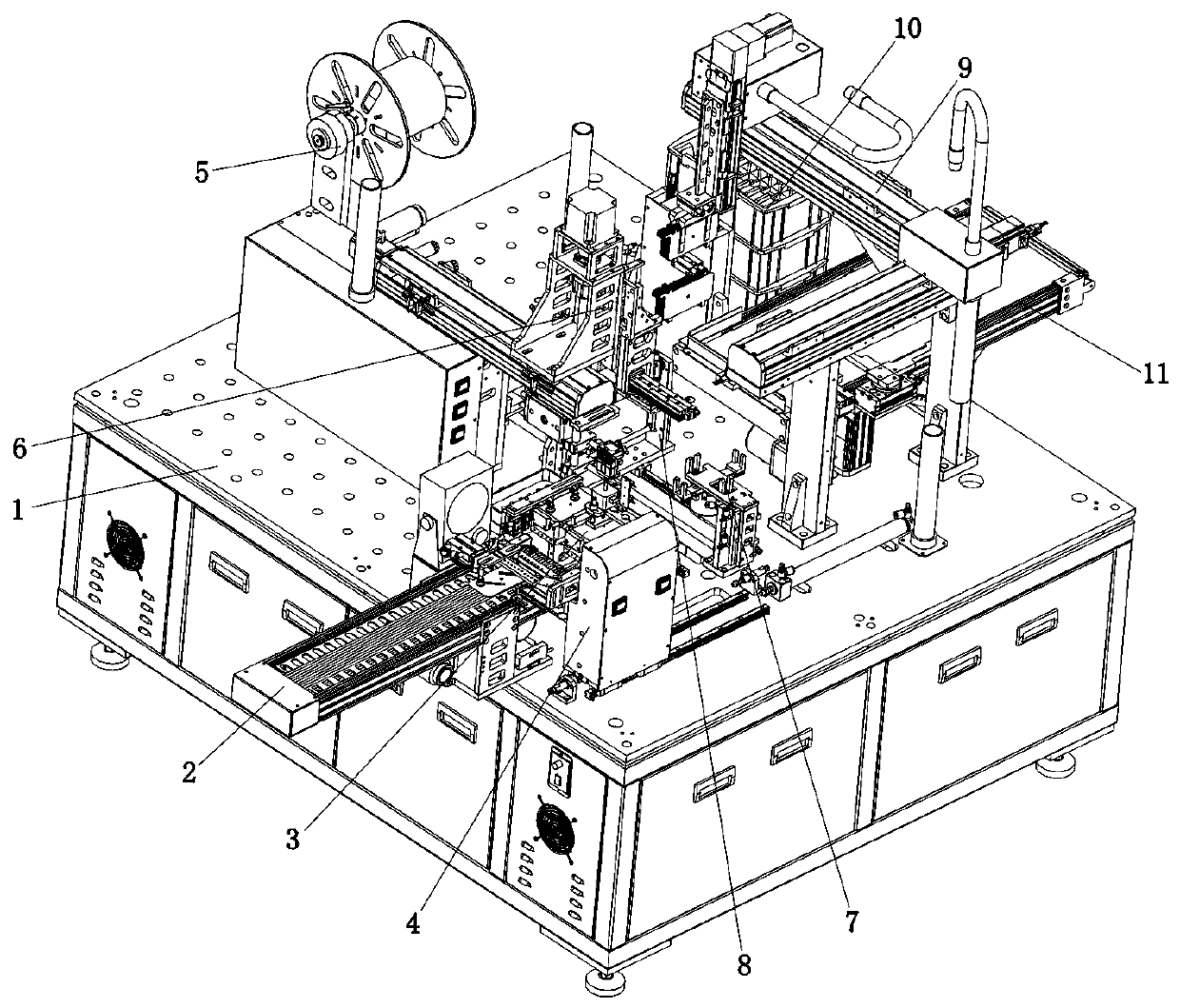

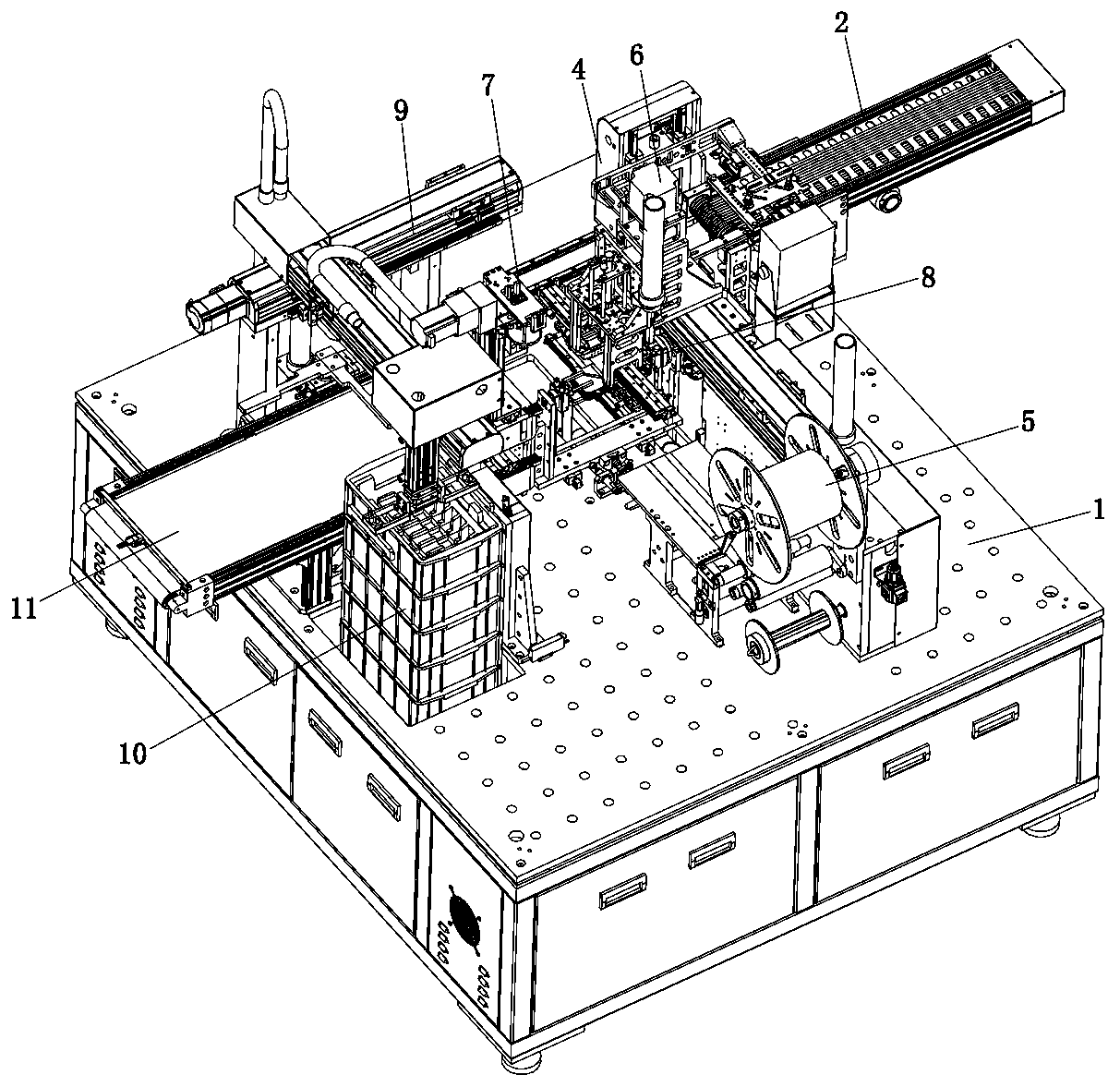

Automatic strapping and packing machine and strapping and packing technology thereof

PendingCN109533442ARealize centralized storageImprove storage efficiencyPackaging automatic controlShock-sensitive articlesStrappingEngineering

The invention discloses an automatic strapping and packing machine and a strapping and packing technology thereof. The automatic strapping and packing machine comprises a transit detection platform, alinkage feeding mechanical arm, sheet stacking platforms, sheet picking and rotating mechanisms, belting and strapping mechanism, bundle picking and blanking mechanical arms and a stock box; the transit detection platform is arranged on a rack, the linkage feeding mechanical arm is arranged on the front side of the transit detection platform, and two sets of stock suction assemblies are arrangedon the linkage feeding mechanical arm at intervals; the sheet stacking platforms are arranged on the right side of the transit detection platform at intervals; the sheet picking and rotating mechanisms are arranged on the rear sides of the sheet stacking platforms, and stacked glass sheets in the sheet stacking platform are clamped and picked out by the sheet picking and rotating mechanisms and rotate to the vertical direction; the belting and strapping mechanisms are arranged on the side portions of the sheet picking and rotating mechanisms; the bundle picking and blanking mechanical arms are arranged on the right sides of the sheet picking and rotating mechanisms. The automatic strapping and packing machine effectively reduces membrane material collision between the adjacent glass sheets and membrane material collision between the glass sheets and external objects, effectively achieves concentrated storage of the glass sheets, and greatly improves the storage efficiency of the glasssheets.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

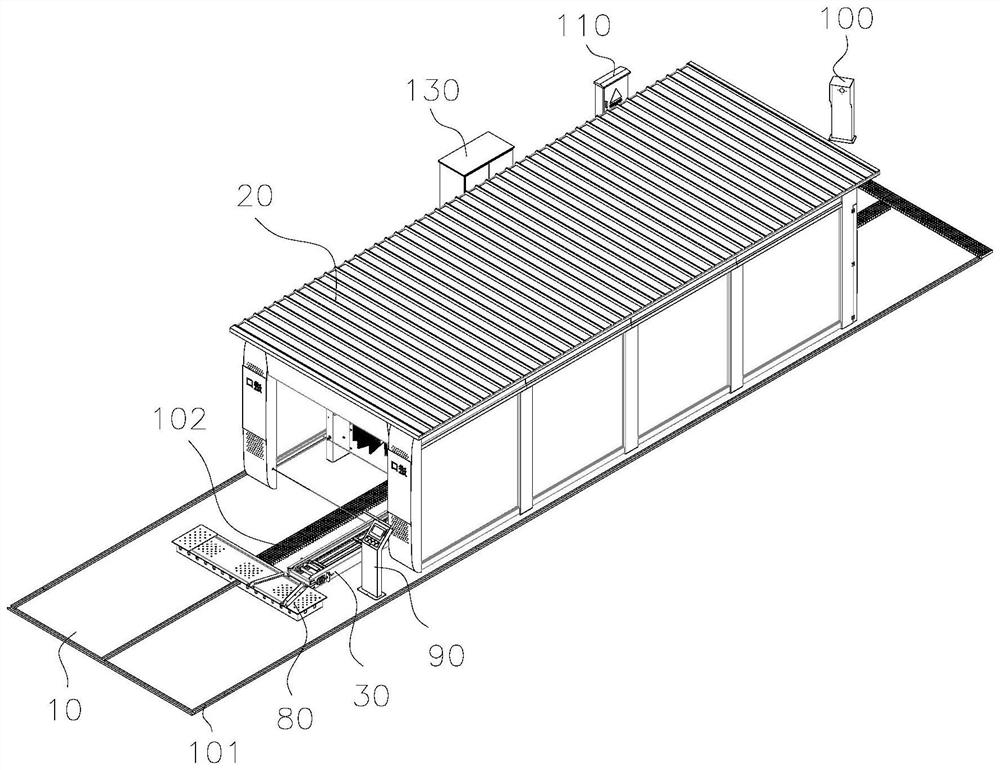

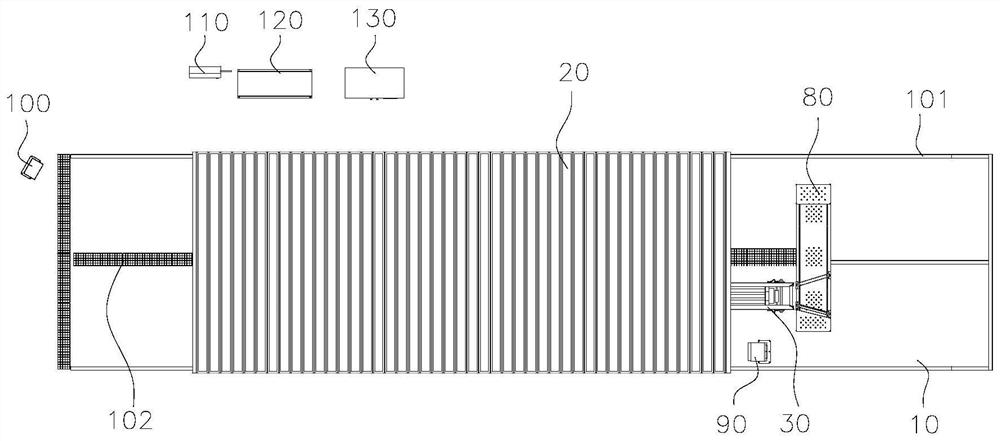

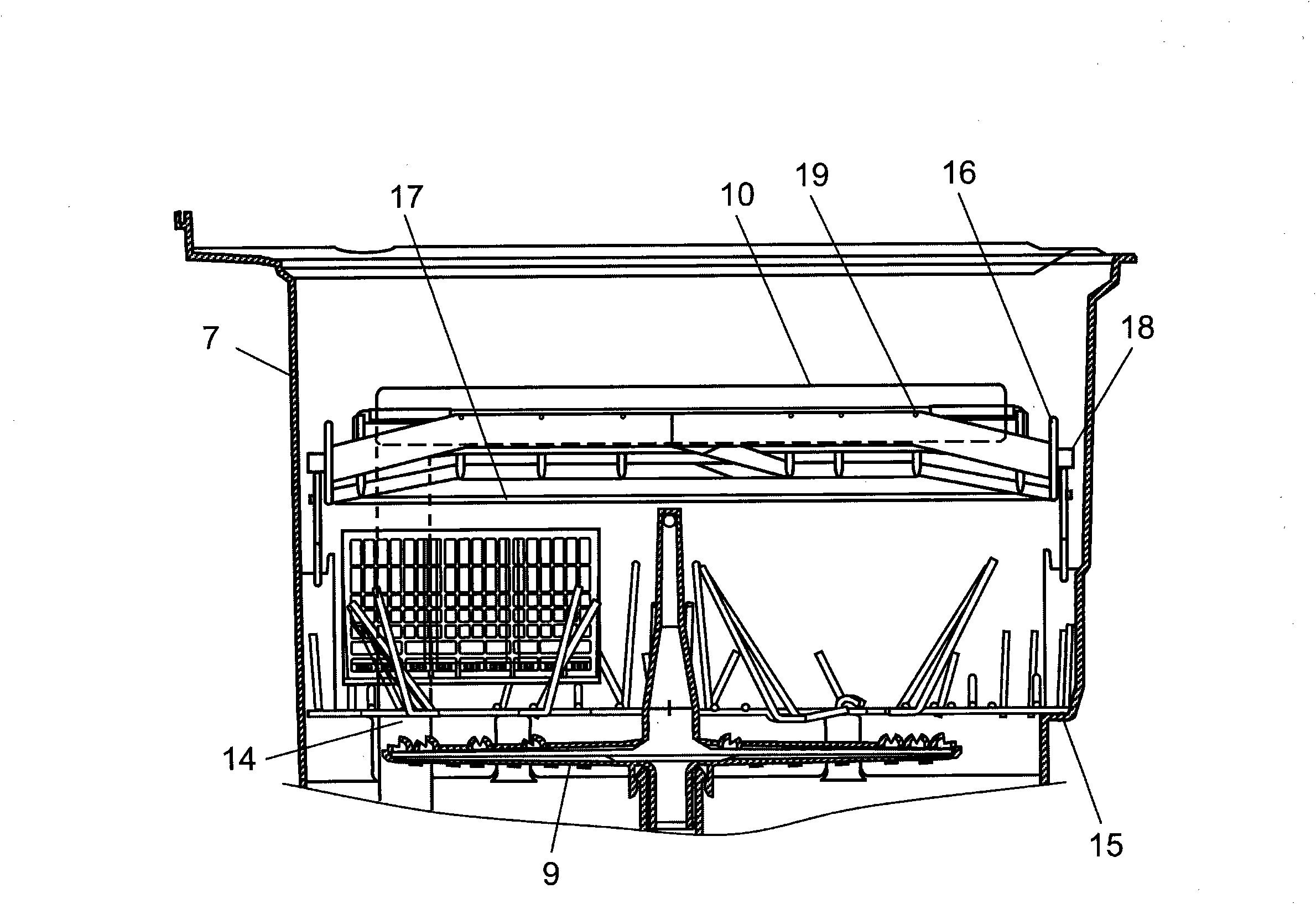

Tunnel type car washer capable of automatically identifying car

PendingCN114312681AReduce collisionsReduce lossesCleaning apparatus for vehicle exteriorsStructural engineeringWasher

The invention discloses a tunnel type car washing machine capable of automatically recognizing a car, and aims to solve the problems that an existing car washing machine is poor in practicability, cannot uniformly clean and blow-dry different types of cars, is difficult to clean dead corners of the cars, is poor in integration and high in operation difficulty, and needs staffs to guard. Comprising two driving bottom plates which are horizontally arranged and a tunnel type car washing room which is erected on the middle sections of the two driving bottom plates, one driving bottom plate is provided with a single-rail car dragging chain, and a guide mechanism is arranged at a car washing inlet; the tunnel type washing room is internally provided with a top brush; the side brushes are symmetrically arranged; the hub cleaning mechanisms are symmetrically arranged; a pipeline waterway; a swing air-drying mechanism; an intelligent vehicle identification terminal is arranged at the vehicle washing entrance, and an exit camera is arranged at the vehicle washing exit. The method is especially suitable for automatically identifying the vehicle and only washing the vehicle, and has high social use value and application prospect.

Owner:中石化易捷澳托猫有限公司

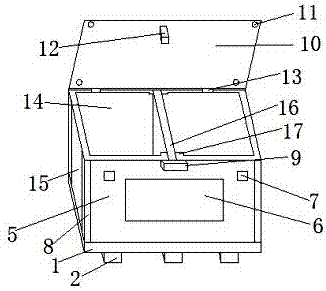

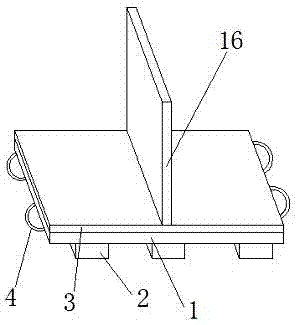

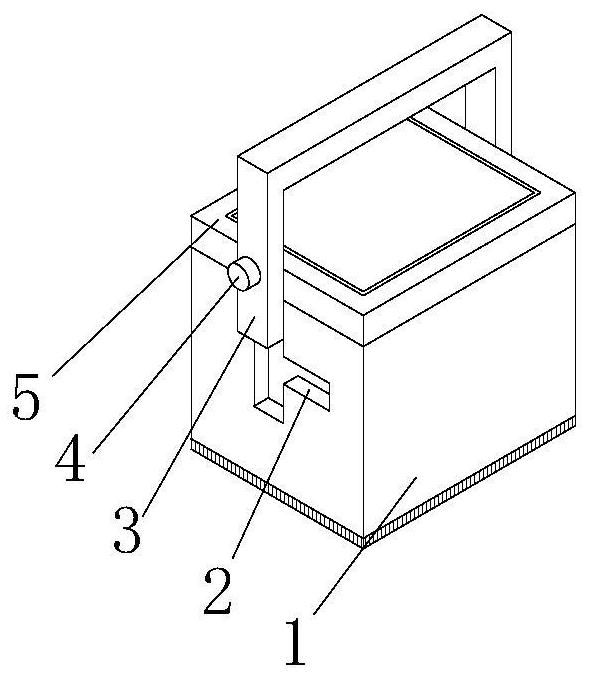

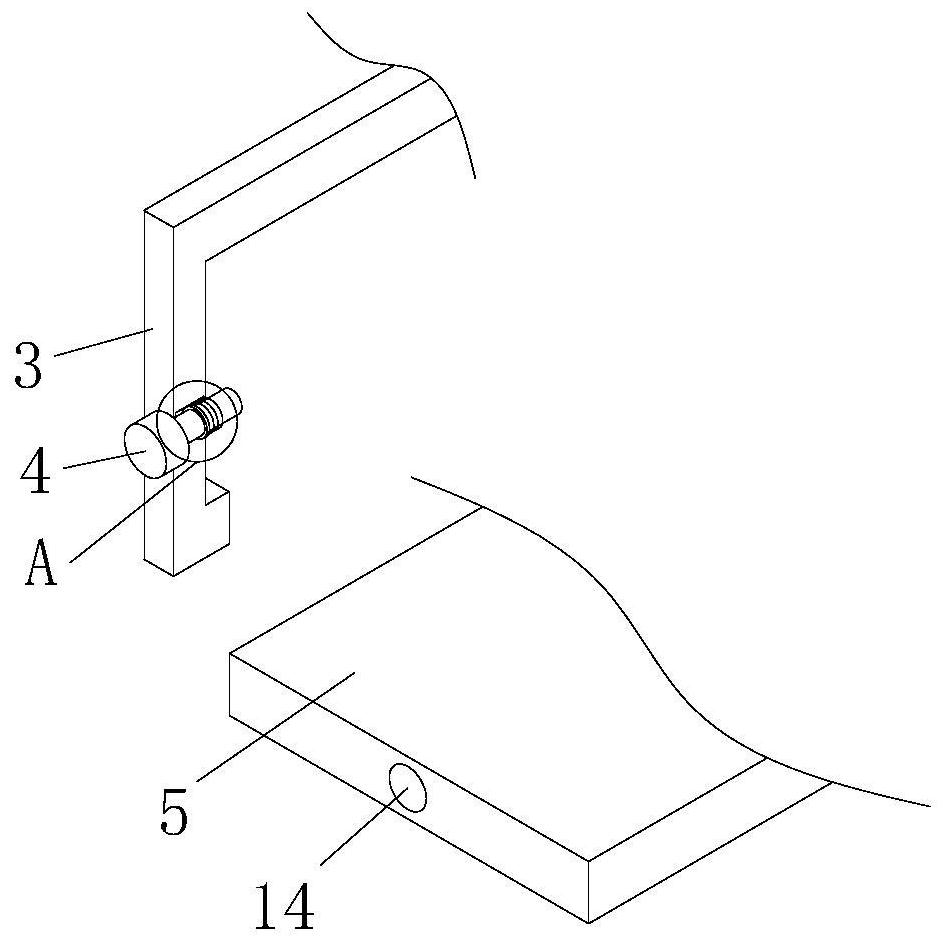

Chemical packaging box for moisture protection

The invention discloses a chemical packaging box for moisture protection. The chemical packaging box comprises a bottom plate, a box cover and a partition, wherein the lower end of the bottom plate is equipped with a supporting block; a rubber cushion is arranged on the outer surface of the bottom plate; lifting rings are arranged at the two ends of the bottom plate; a danger label plate and a sealing plate are arranged on the outer surface of a splicing plate I; a lock body is arranged above the danger label plate; a threaded hole is formed in the outer surface of the box cover; a lock tongue is arranged at one side of the threaded hole; and a partition slot is formed in one end of the partition. According to the chemical packaging box for moisture protection disclosed by the invention, the rubber cushion, the lifting rings, the sealing plate and the lock body are arranged for sealing a gap of a bottom plate connected part to prevent water intake, and a packaging box can be conveniently lifted; and meanwhile, the seam of each splicing plate is sealed to prevent the inner part of the box from being moisturized, and therefore, the occurrence of a condition that objects in the box are scattered as the box cover is opened after screws are loosened can be prevented, different working conditions are adapted, and a better using prospect is brought.

Owner:SUZHOU SHUYUE CARBON ADSORBENT CO LTD

Chemical liquid product sample inspection device

ActiveCN112722542AAchieve clamping and fixingEasy to storeRemovable lids/coversContainers to prevent mechanical damageLiquid productStructural engineering

The invention relates to the technical field of chemical engineering, and discloses a chemical liquid product sample inspection device which comprises a box body. A box cover is rotatably connected to the top of the box body, fixing holes are formed in the left side and the right side of the box cover, moving grooves are formed in the left side and the right side of the box body, the moving grooves are in a transverse T shape, and a holding rod is slidably connected to the interior of each moving groove. According to the chemical liquid product sample inspection device, the holding rods rotate forwards at vertical grooves and transverse grooves of the moving grooves, so that the holding rods move forwards in the transverse grooves of the moving grooves, the holding rods move forwards to drive moving plates to move forwards to stretch second tension springs, meanwhile, reduction is achieved to a certain extent, and the situation that when the device is moved by a worker, an internal sample bottle topples over, so that corrosive liquid in the sample bottle flows out to injure the body of the worker is avoided.

Owner:江西瑞思博新材料有限公司

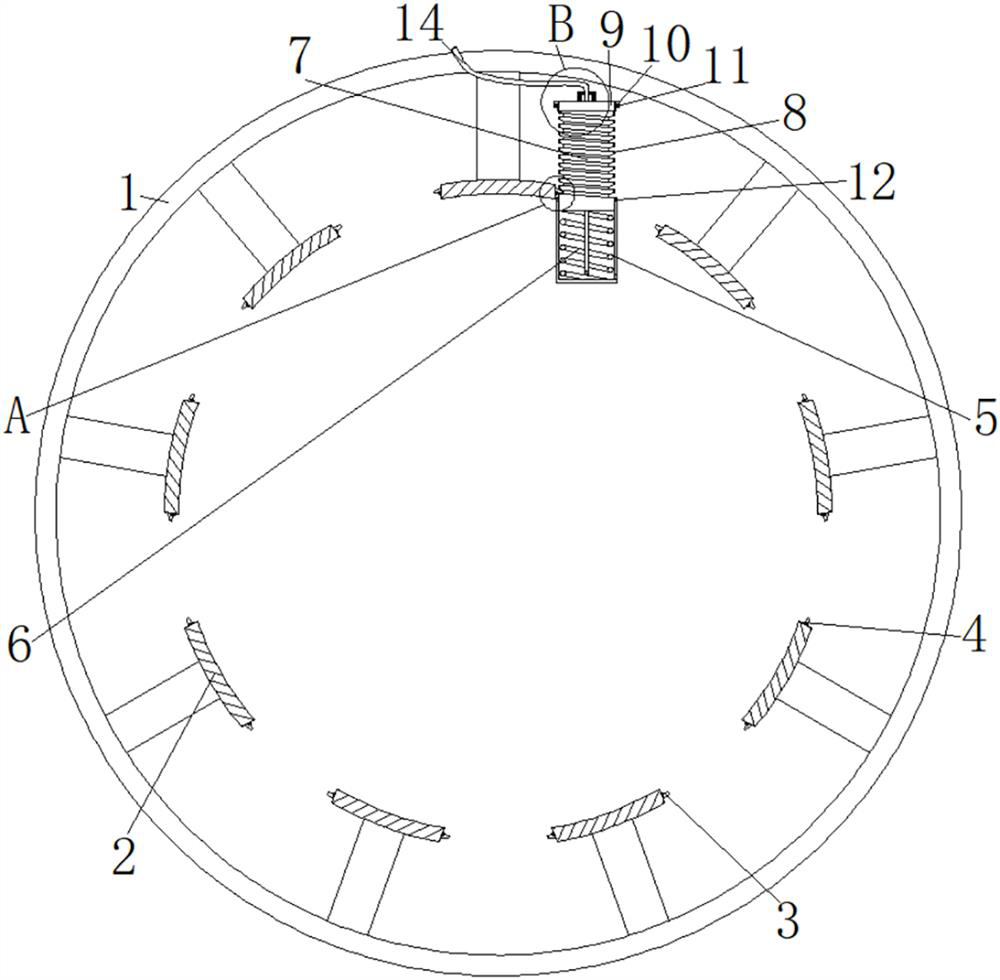

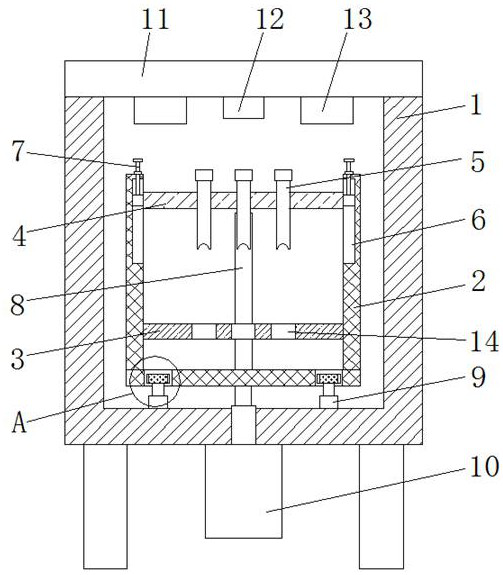

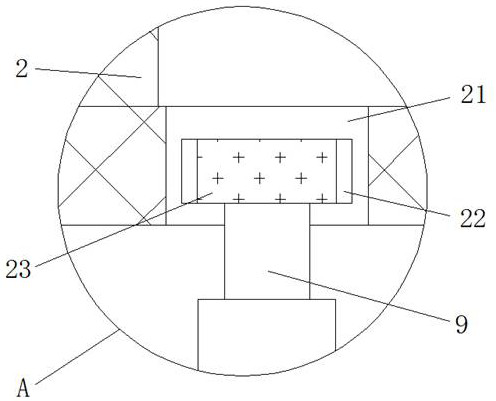

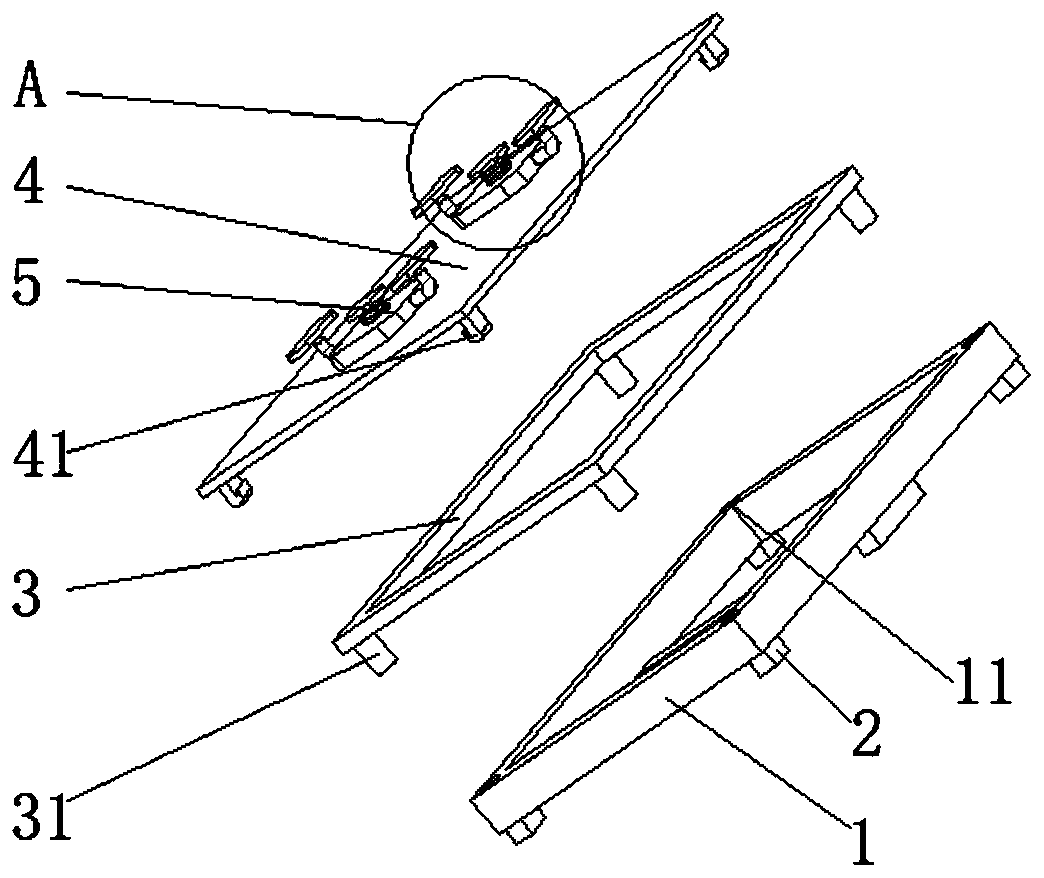

ratchet for bicycle hub

The invention mainly provides a ratchet wheel of a wheel hub of a bicycle. The ratchet wheel is arranged between a first wheel hub base and a sleeve base and comprises a blocking ring which is arranged inside the wheel bub base fixedly, a driven base, a conical surface, a blocking portion and a magnetic group; wherein an inclined cone inner hole and a blocking edge are arranged on the blocking ring, a driving base is arranged between the wheel hub base and the sleeve base, and a plurality of first ratchet teeth are arranged on a one side end face of the driving base, which faces towards an axial ring inside the wheel hub base; the driven base is arranged inside the inclined cone inner hole and corresponds to a driving group, the external diameter of the conical surface can be matched with the inclined cone inner hole, the blocking portion can be blocked by the blocking edge in one direction, a driven base ring is provided with a plurality of second ratchet teeth which can be meshed with the first ratchet teeth, and the magnetic group is arranged between the driven base and the wheel hub base and provided with a first magnetic part and a second magnetic part, which are respectively arranged inside the wheel hub base and on the driven base and are in a mutual exclusion state. Thus, the inclined cone inner hole which is in an inclined cone shape and the conical surface design are adopted, the friction force is reduced, the restoring speed of the driven base is increased, and the sensitivity of a ratchet wheel group is improved further.

Owner:KUNSHAN HENRY METAL TECH

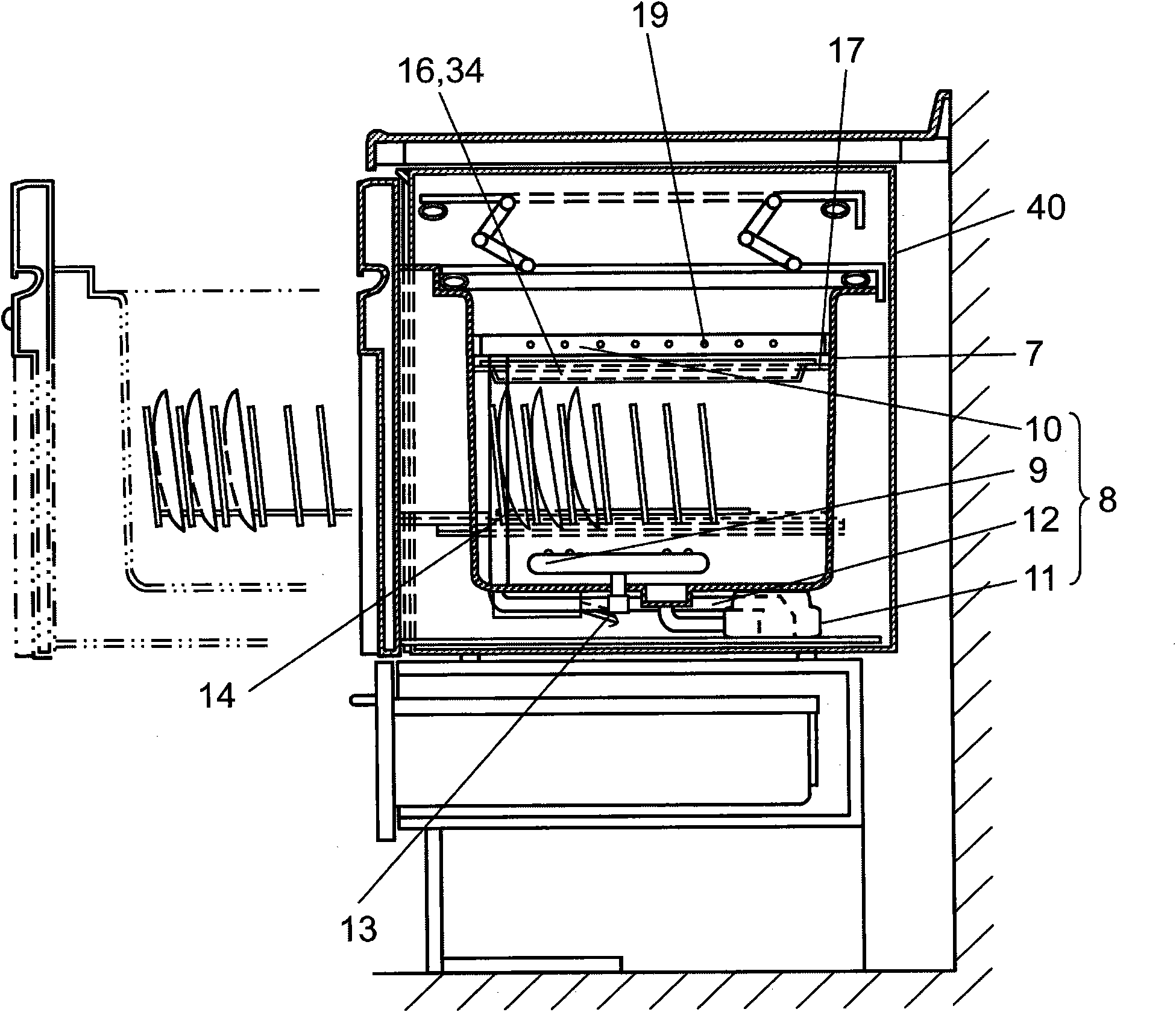

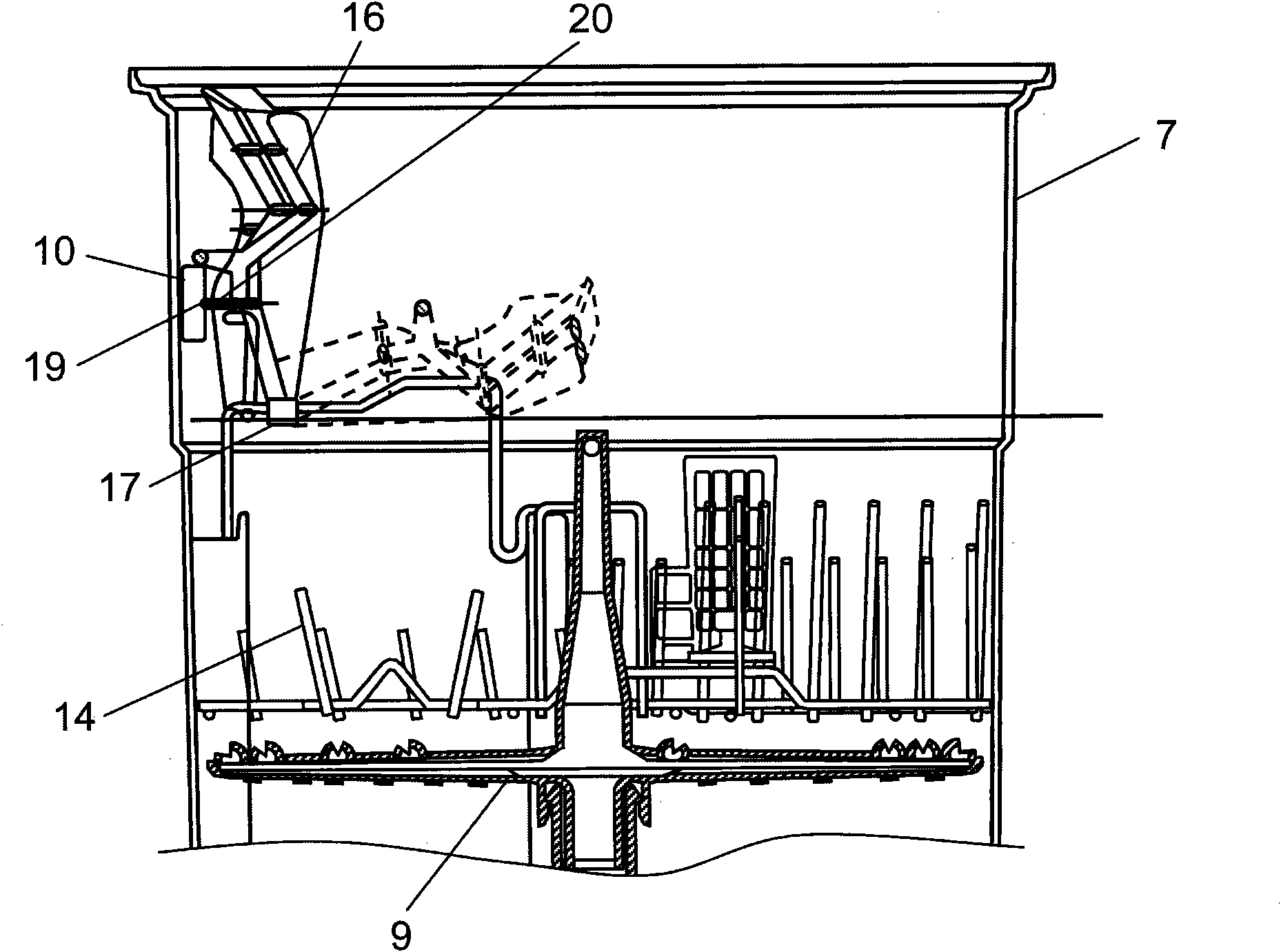

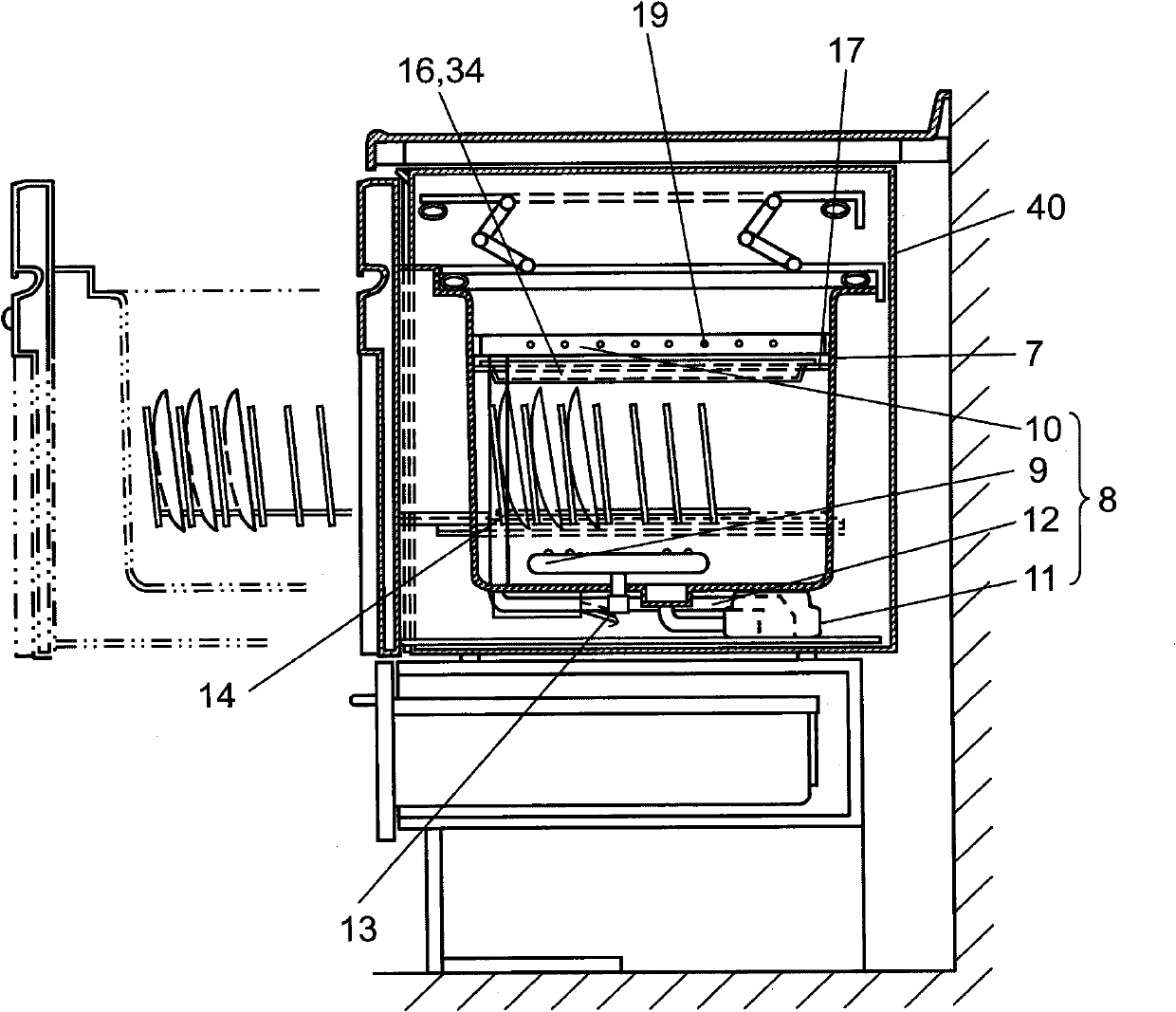

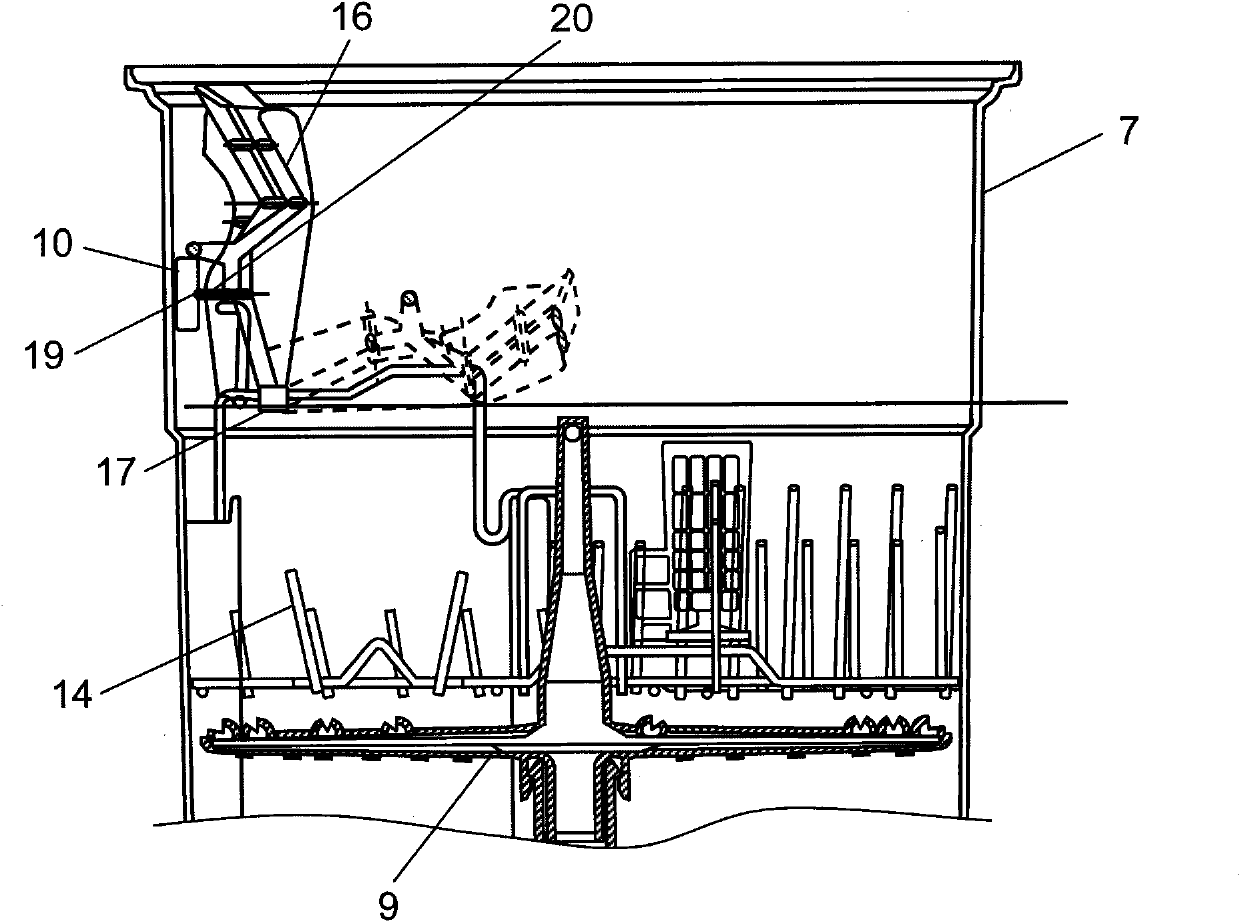

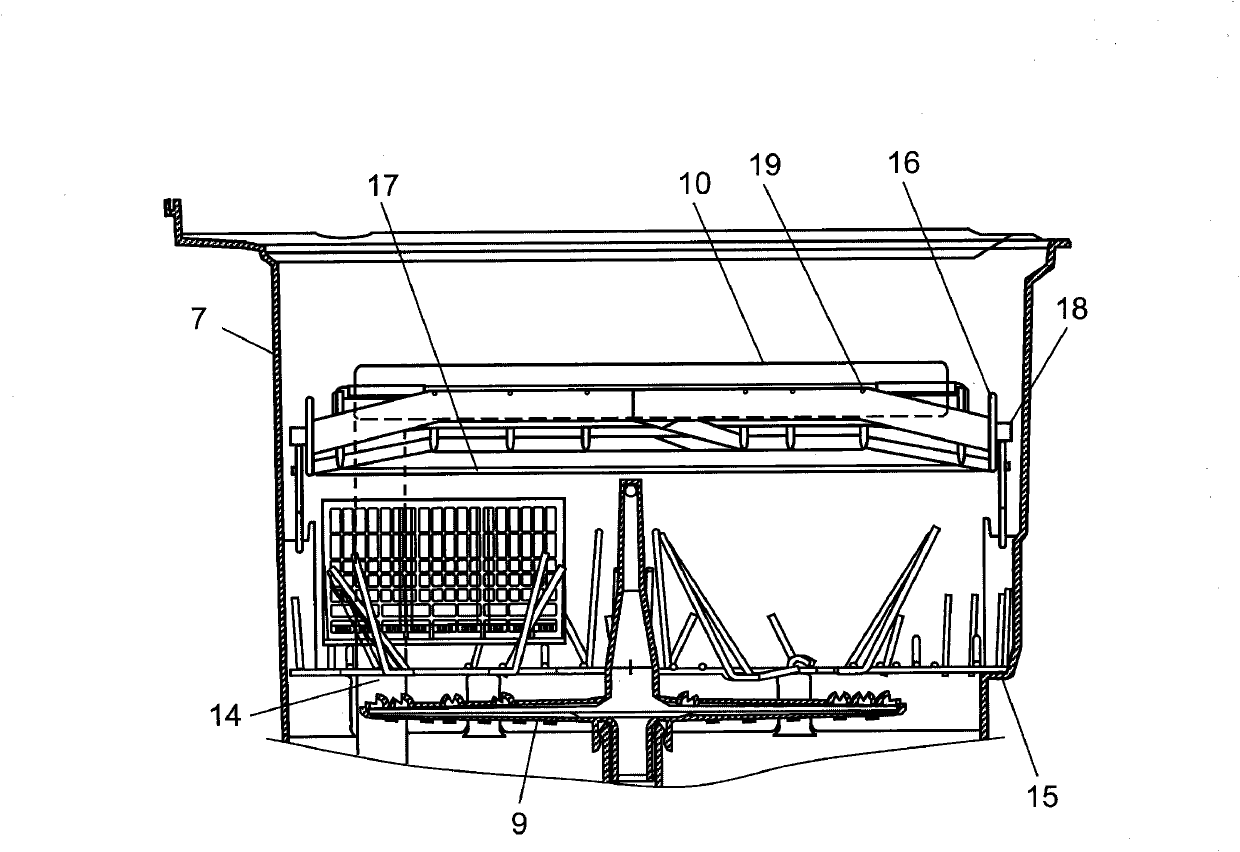

Tableware washer

ActiveCN102028442AReduce noiseEasy to cleanTableware washing/rinsing machine detailsEngineeringPush out

The present invention provides a tableware washer which comprises the following components: a housing; a cleaning trough which is equipped in the housing with a mode that the cleaning trough can be pushed out freely; an upper tableware basket and a lower tableware basket which are equipped in the cleaning trough and eject cleaning water to the cleaning object from a plurality of spray holes. The upper tableware basket is configured to a state that the upper tableware is movable in the cleaning trough. The plurality of spray holes of the upper cleaning part are opened and closed according to the position of the upper tableware basket. Under the subcutaneously vertical condition of the upper tableware basket, lockage members of the spray holes of the upper tableware basket are closely arranged on the plurality of the spray holes of the upper cleaning part.

Owner:PANASONIC CORP

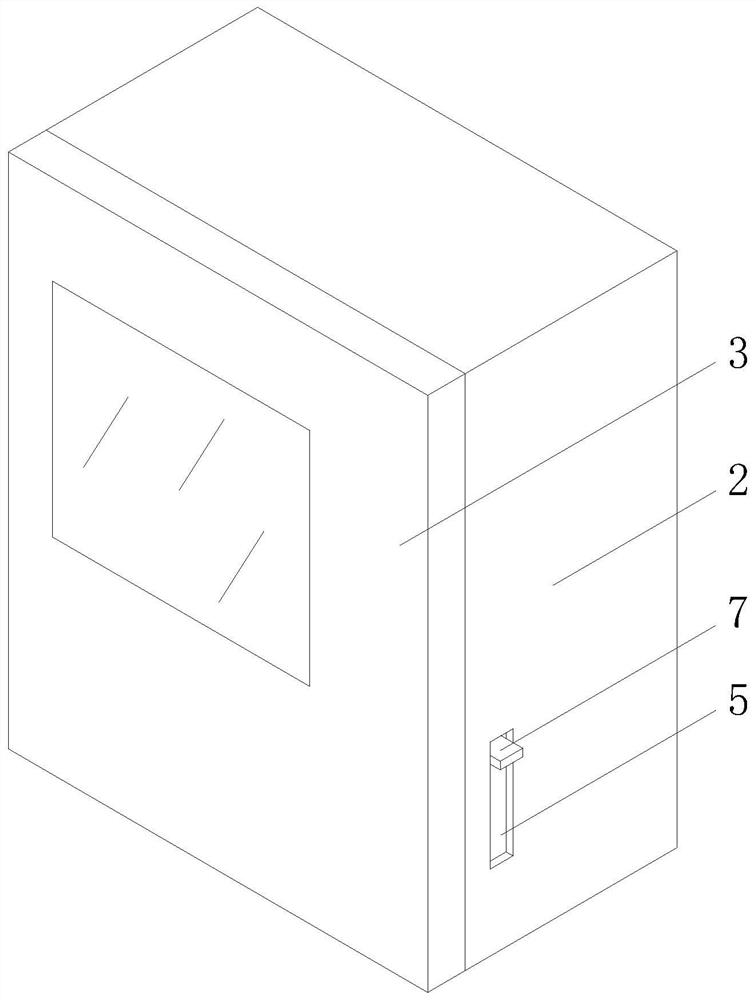

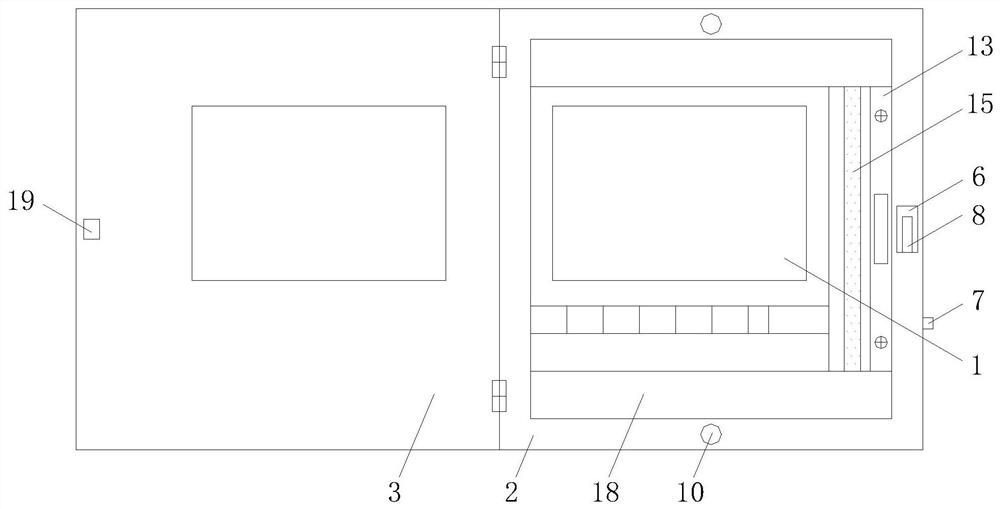

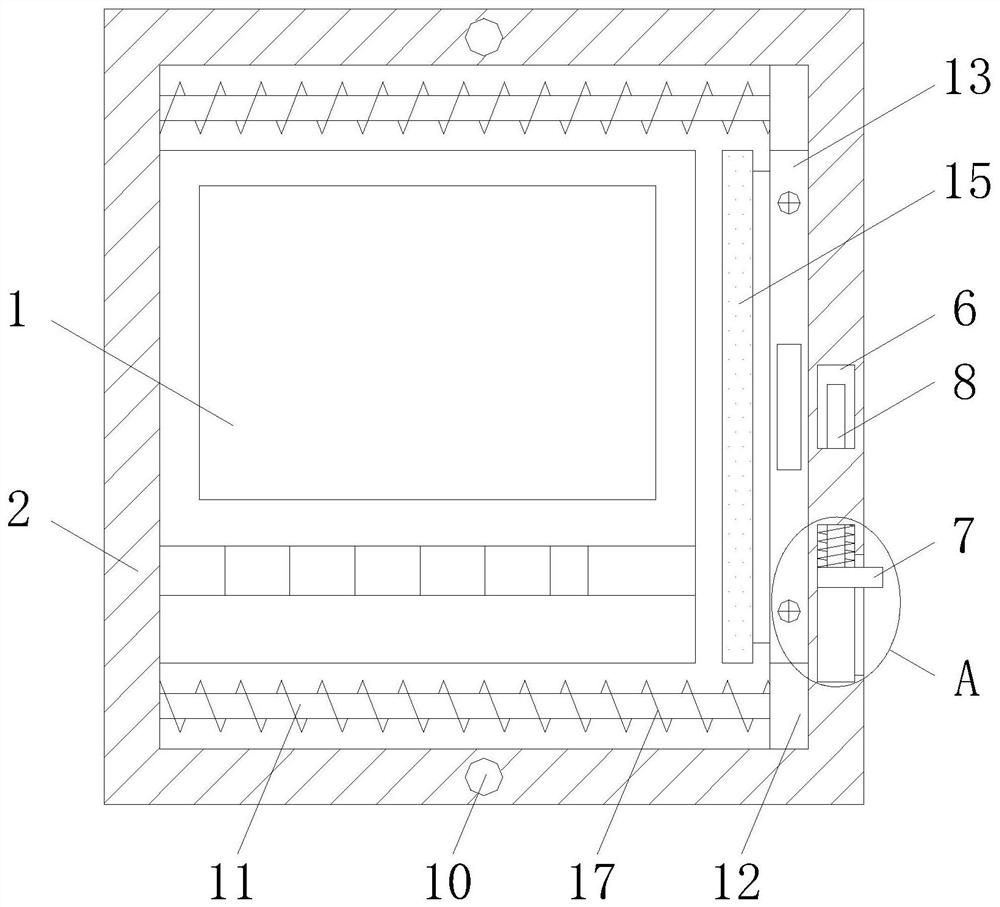

Electronic panel and manufacturing method thereof

InactiveCN112839460AReduce collisionsLess damageCasings/cabinets/drawers detailsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses an electronic panel and a manufacturing method of the electronic panel, the electronic panel comprises an electronic panel body, the outer surface of the electronic panel body is provided with a protection assembly, the protection assembly is composed of a protection box, a protection cover, a groove, a square hole, a connecting groove, a push plate, an insertion rod, a first spring, mounting holes and a limiting sleeve, and the number of the mounting holes is two. A cleaning assembly is arranged in the protection box, and the cleaning assembly is composed of two supporting plates, two sliding blocks, a supporting frame, a connecting plate, a cleaning sponge, a pushing block, two second springs and two baffles. The electronic panel body can be protected by arranging the protection cover and the protection box, the situation that the electronic panel body is collided in the using process can be reduced, the situation that the electronic panel body is damaged due to collision can be reduced, and the service life of the electronic panel body is prolonged. The position of the protection cover can be fixed by inserting the insertion rod into the limiting sleeve.

Owner:苏州普提勒新材料科技有限公司

Lithium ion dry stirring process

InactiveCN107910503ARelieve pressureReduce collisionsCell electrodesSecondary cellsLithiumPhysical chemistry

A lithium ion dry stirring process comprises the following steps of selecting 94-97 parts of active substance, 1-3 parts of conductive agent and 2-4 parts of binding agent powder according to parts bymass, adding the constituents into a stirring barrel, and performing uniform mixing to obtain powder particles, wherein the active substance is graphite; vacuumizing the stirring barrel so that the stirring barrel is in a vacuum state, adding a solvent into the stirring barrel at the first time, wetting the powder particles so that the solvent is absorbed onto surfaces of the powder particles, simultaneously stirring the powder particles to form a large shearing effect, and fully and uniformly mixing and wetting the powder particles to form a particle agglomeration body; adding the solvent into the stirring barrel at the second time, continuously maintaining stirring operation, and dispersing the particle agglomeration body under the shearing effect generated by stirring to form paste sothat the conductive agent is uniformly distributed; and adding the solvent into the stirring barrel at the third time, simultaneously maintaining stirring operation, diluting the paste, and adjustingviscosity of the paste. By the lithium ion dry stirring process, the molecule friction force of the powder particles during the kneading process is effectively reduced, and the heat energy generated by the kneading process is reduced.

Owner:GUANGDONG ORRITT NEW ENERGY EQUIP TECH CO LTD

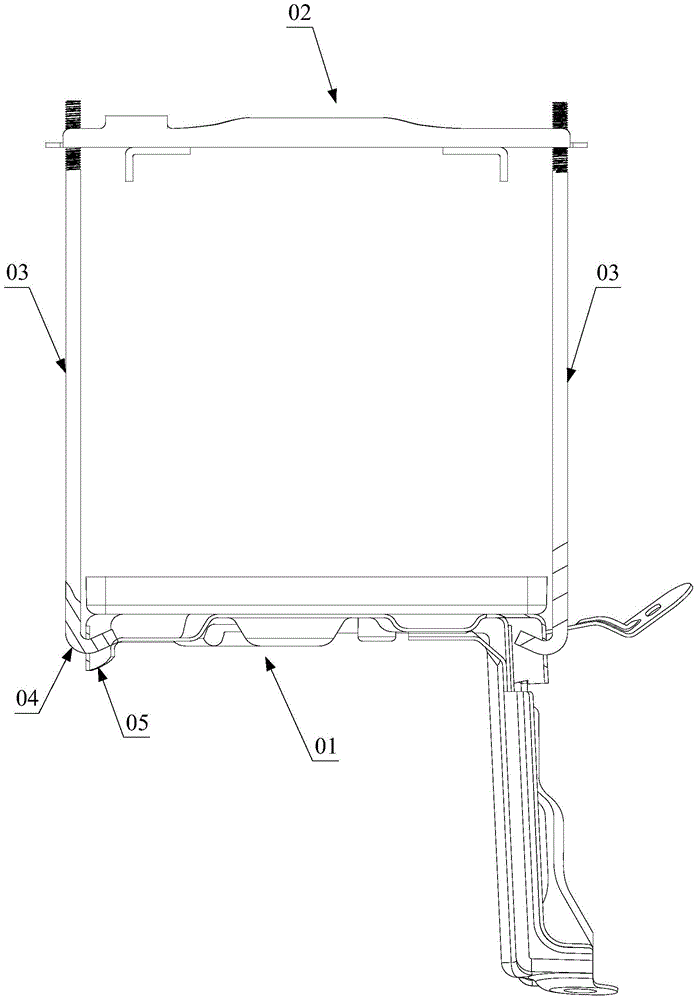

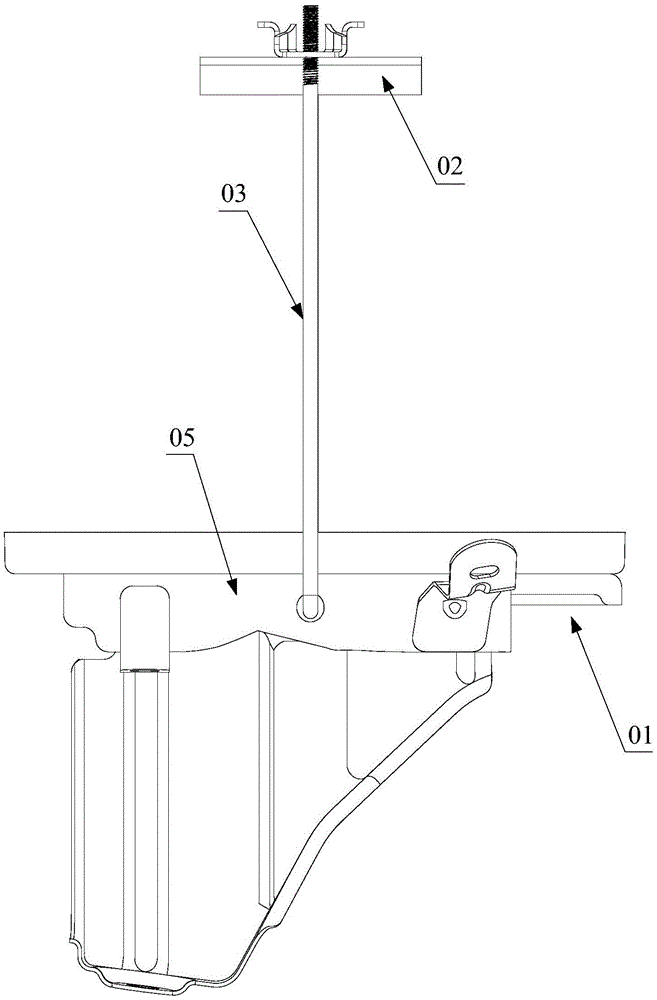

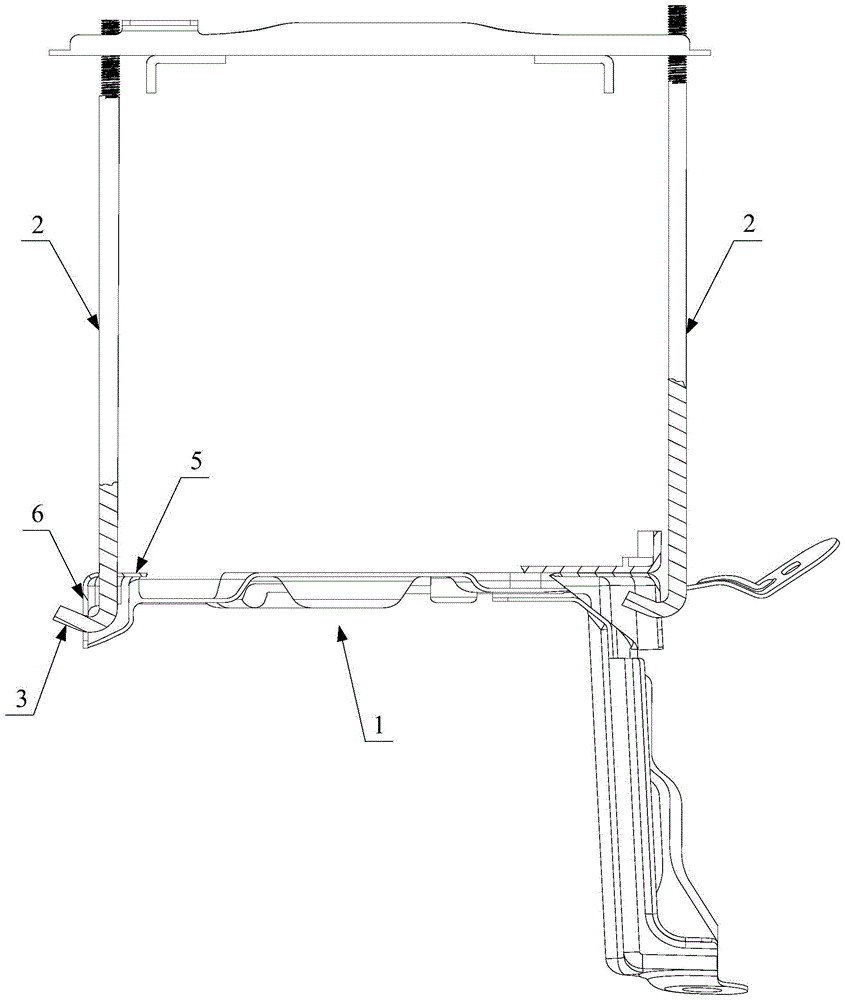

Vehicle and storage battery installing bracket thereof

InactiveCN105459782AIncrease the gapImprove performanceElectric propulsion mountingAir filterEngineering

The invention discloses a storage battery installing bracket. The storage battery installing bracket comprises a bottom plate assembly provided with side walls and pull rods provided with hooks. The bending portions of the hooks extend from the inner sides of the side walls to the outer sides of the side walls, so that the bottom plate assembly is connected with the pull rods. According to the storage battery installing bracket, the hooking direction of the hooks and the bottom plate assembly is changed, and the mode of hooking from the outer side to the inner side is improved to the mode of hooking from the inner side to the outer side; accordingly, the clearance of the pull rods and an air filter is enlarged, the situation of collisions between the pull rods and the air filter in the driving process can be decreased even avoided, the noise is reduced, and the performance of a whole vehicle is improved significantly. The invention further provides the vehicle provided with the storage battery installing bracket.

Owner:力帆科技(集团)股份有限公司

Winding machine for intelligent motor machining

ActiveCN114726171AImprove product qualityWinding lastsElectric machinesManufacturing dynamo-electric machinesWinding machineElectric machinery

The invention relates to the technical field of coil winding, and discloses a winding machine for intelligent motor processing, which comprises a stator, a framework plate is fixedly connected to the inner side of the stator in the circumferential direction, a fixing plate is hinged to the part, close to the middle of the stator, of the framework plate in the circumferential direction, and a fixing spring is fixedly connected to the side, away from the stator, of the fixing plate. Through a wire outlet sleeve rod arranged on the inner side of a wire outlet sleeve and a sliding ring connected with one end, close to a stator, of the wire outlet sleeve rod, when a framework plate and the wire outlet sleeve move relatively, a fixed plate slides in a threaded groove in the outer side of the wire outlet sleeve rod, and the outer side face of the fixed plate pushes the wire outlet sleeve rod to move towards the inner side of the wire outlet sleeve at a constant speed; in the winding process of the secondary return stroke, the sliding ring enables the wire outlet sleeve rod and the fixing plate not to slide relative to each other, so that the effect of continuous winding is achieved, and winding is more uniform.

Owner:扬州市新港电机有限公司

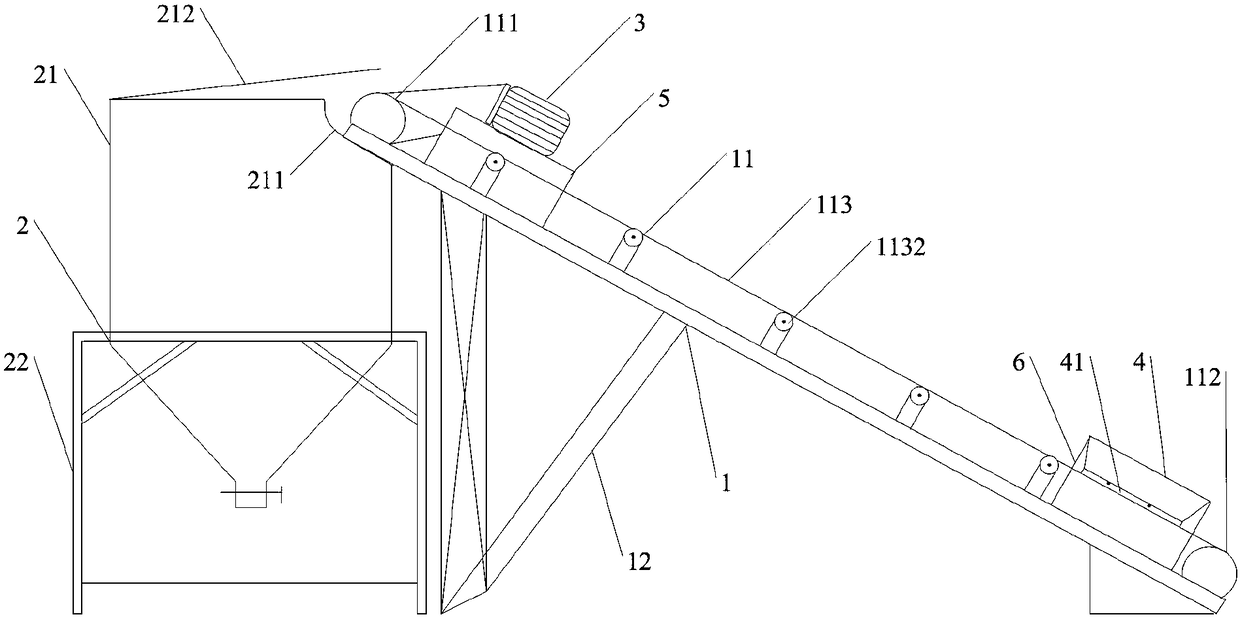

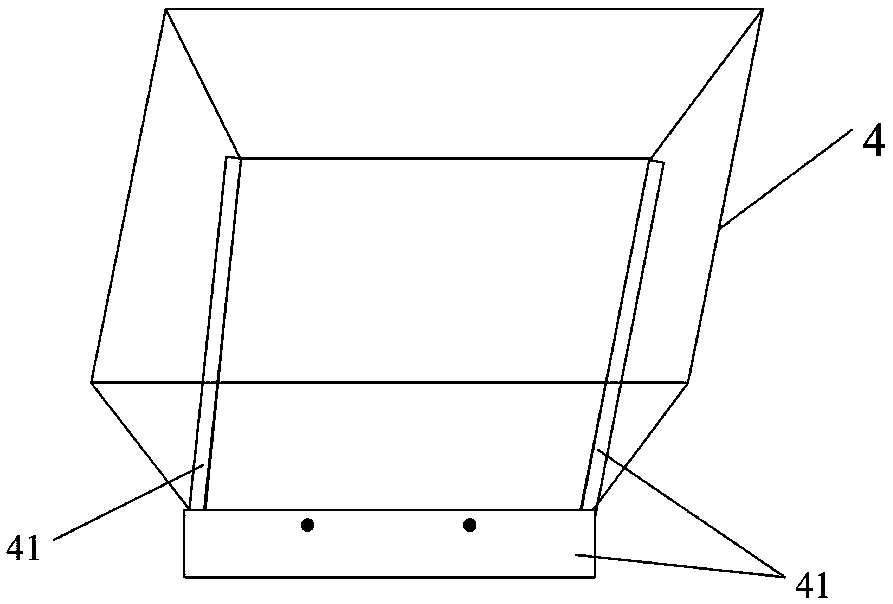

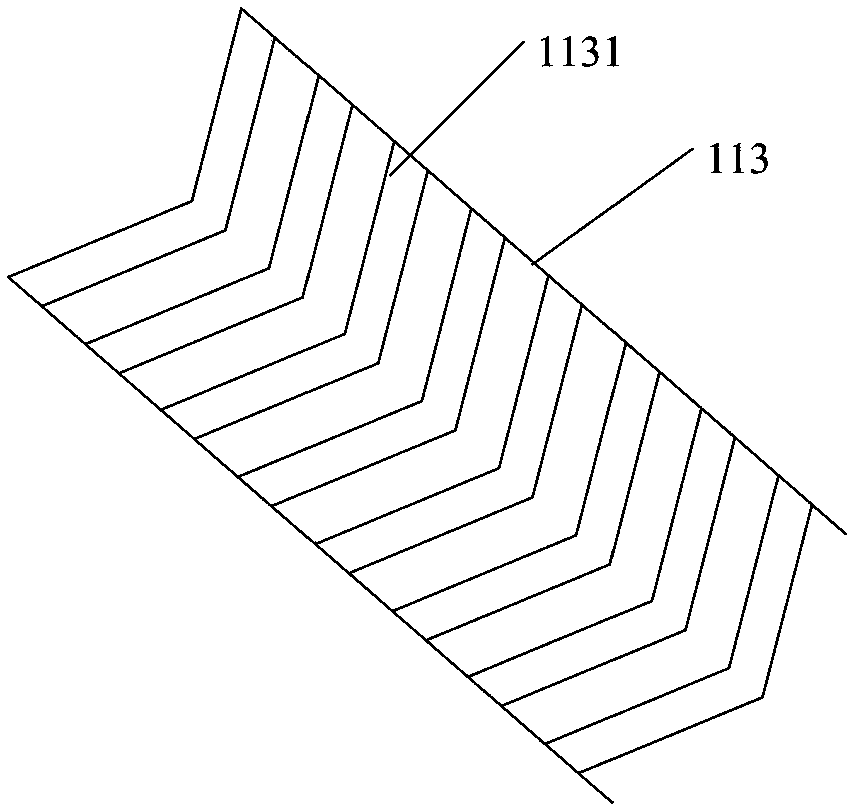

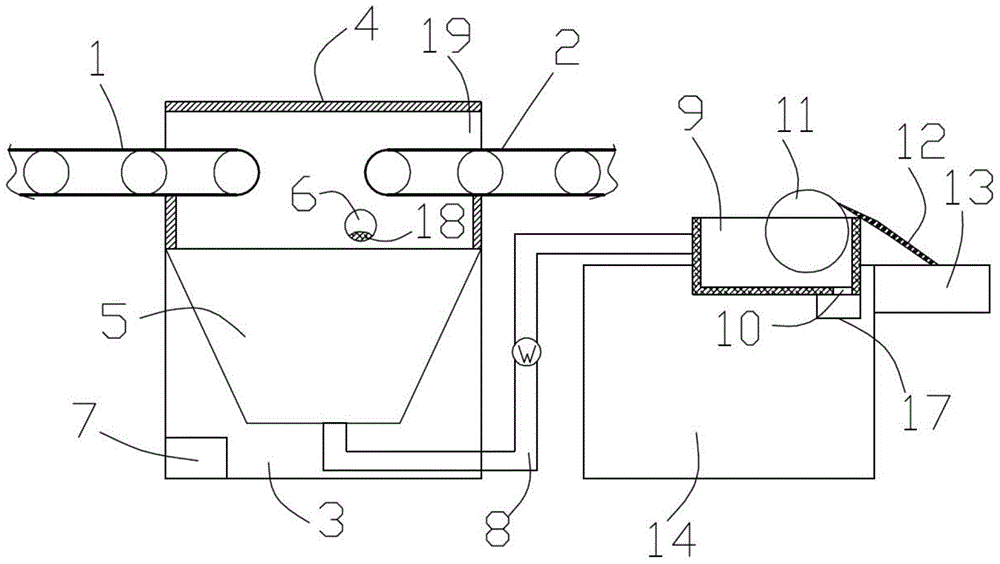

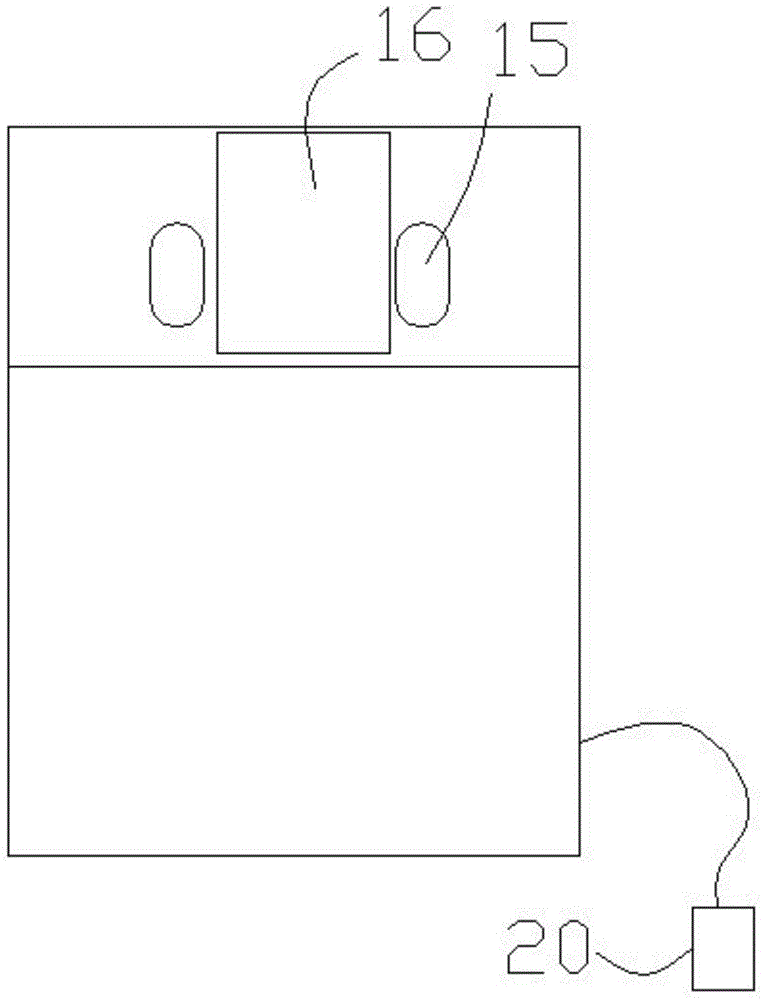

Plastic particle conveying mechanism

The invention discloses a plastic particle conveying mechanism. The plastic particle conveying mechanism comprises a particle conveying device and a particle collecting device, wherein the particle conveying device comprises a belt type conveyor and a first support frame; the belt type conveyor is provided with one end, connected with the particle collecting device, of a driving roller; the belt type conveyor is provided with one end, close to the ground, of a turnabout roller and is provided with a material receiver; the side surface, close to the turnabout roller, of the material receiver and the two side surfaces adjacent to the side surface are provided with side bars; the surface of a conveyor belt is provided with a line-folded bulge; the sharp end direction of the line-folded bulgeis opposite to the motion direction of the conveyor belt; a support roller is arranged under the conveyor belt; the particle collecting device comprises a hopper and a second support frame; and the second support frame is used for supporting the hopper. Through the plastic particle conveying mechanism disclosed by the invention, the collision situation of the plastic particles is reduced, so thatthe quality of the plastic particles is improved.

Owner:湖南登科材料科技有限公司

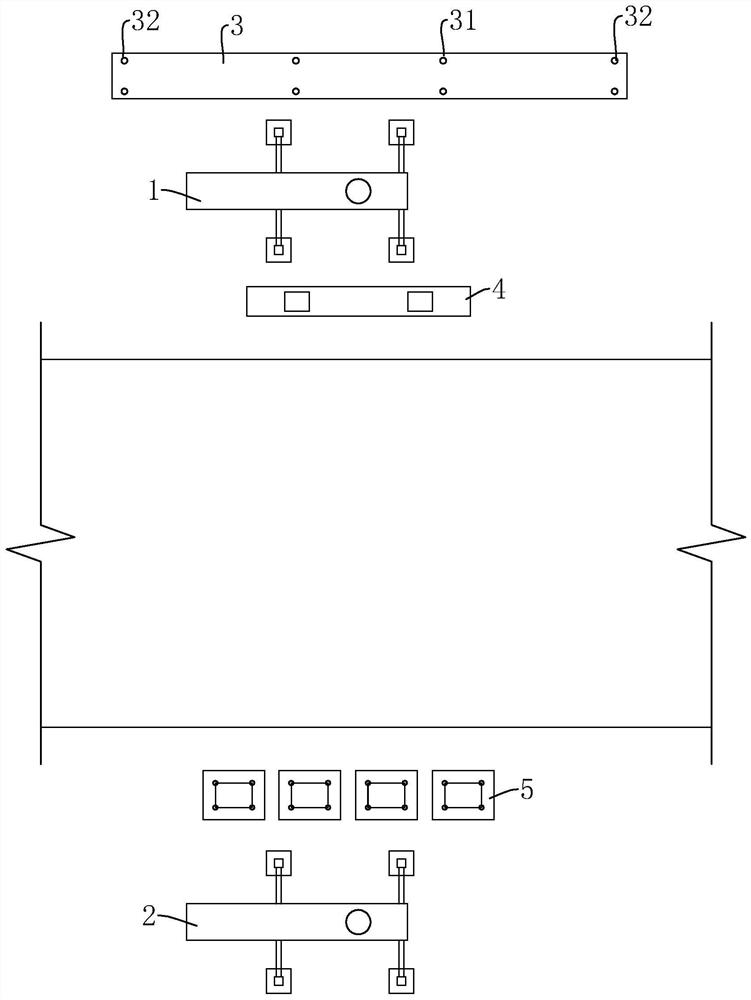

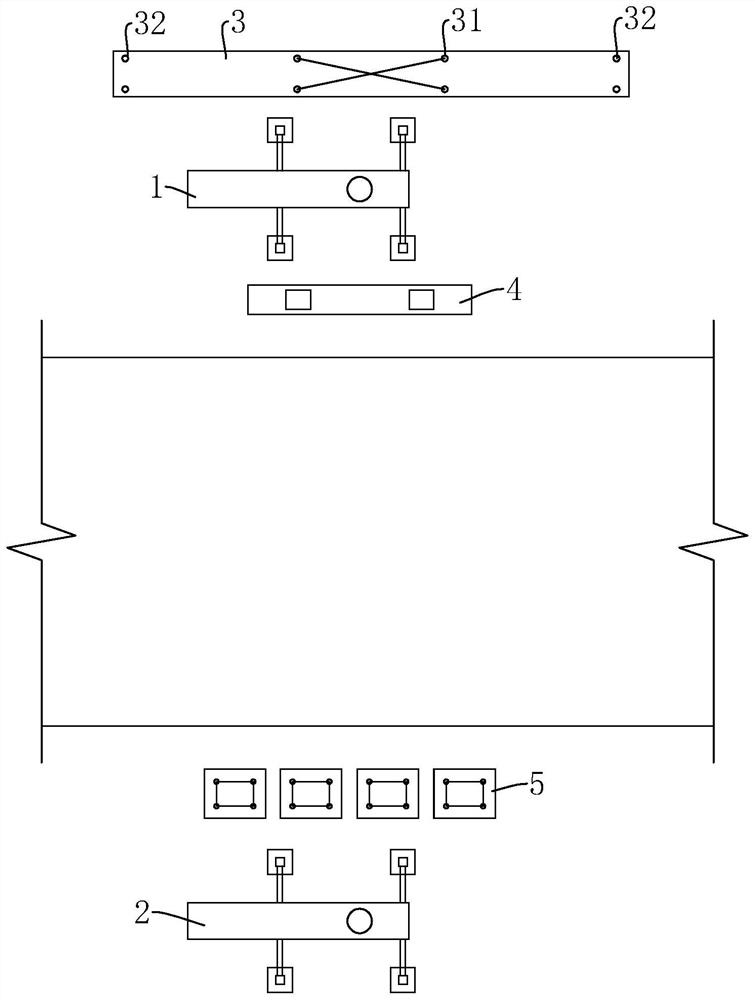

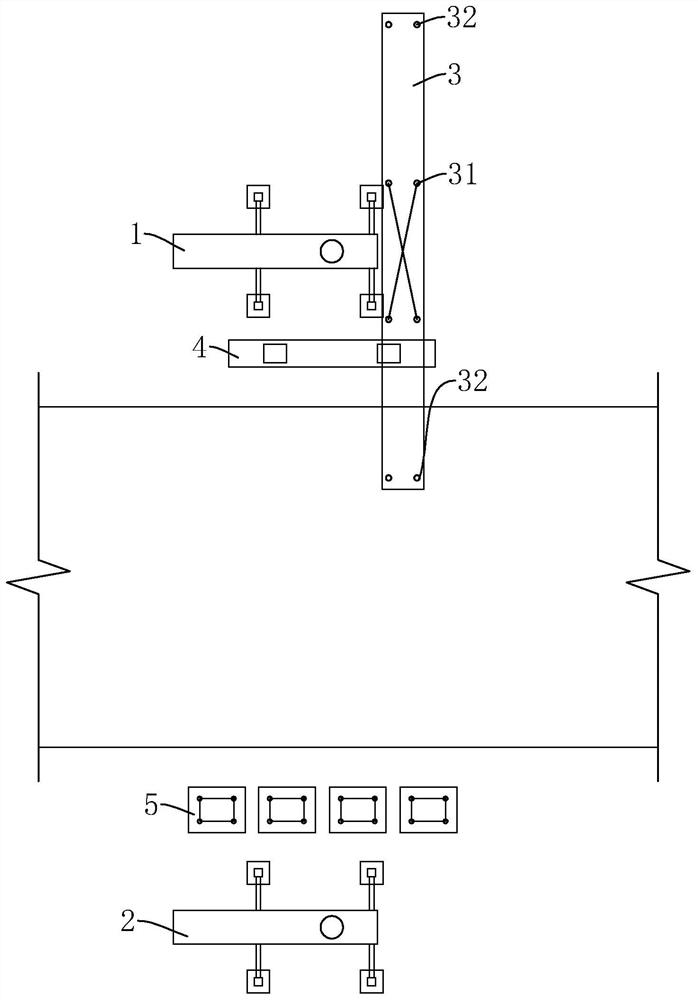

Hoisting method

PendingCN114368695AImprove securityReduce collisionsBridge erection/assemblyCranesControl theoryReliability engineering

The hoisting method comprises the following steps that a, a first crane, a second crane, a steel beam component, a first temporary supporting frame body and a second temporary supporting frame body are arranged; b, the positions and the number of lifting lugs are arranged, and a first set of lifting lugs and a second set of lifting lugs are arranged; c, the first crane lifts the steel beam component through a first set of lifting lugs till the first crane translates to the limit working radius of the first crane, and the steel beam component temporarily falls on a first temporary supporting frame body; d, a second crane is buckled to one second set of lifting lugs, the first crane and the second crane are matched with each other, so that the first crane and the first set of lifting lugs are separated, and the first crane is buckled to the other second set of lifting lugs; and e, the first crane and the second crane synchronously hoist the steel beam component. And the hoisting system is converted, so that the specification of a selected crane is greatly reduced, and a large amount of crane cost is saved.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD +1

Disinfection equipment for disinfection supply room

InactiveCN112023085AImprove disinfection effectImprove stabilityLavatory sanitoryChemicalsStructural engineeringBrush

Owner:日照市岚山区人民医院

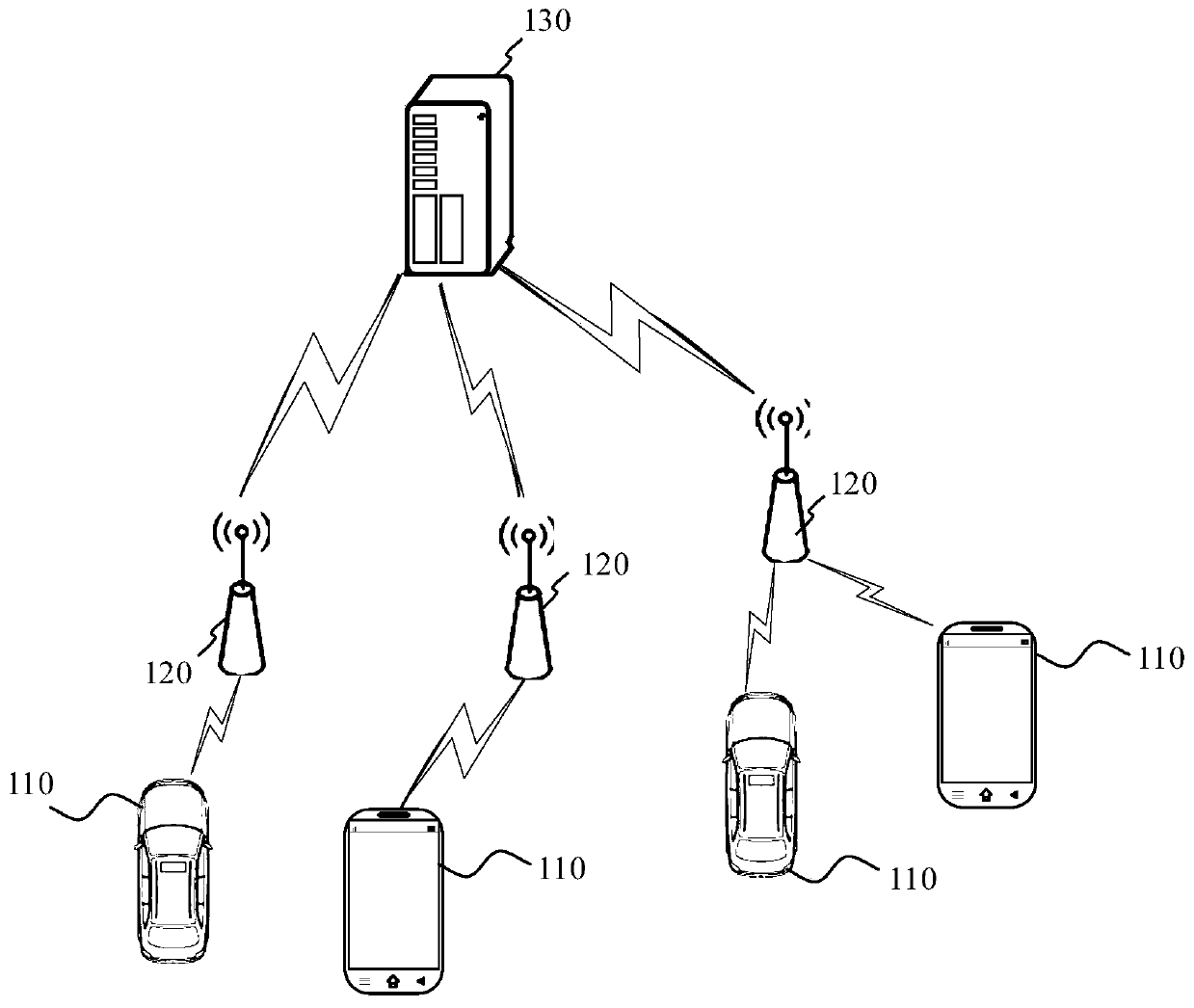

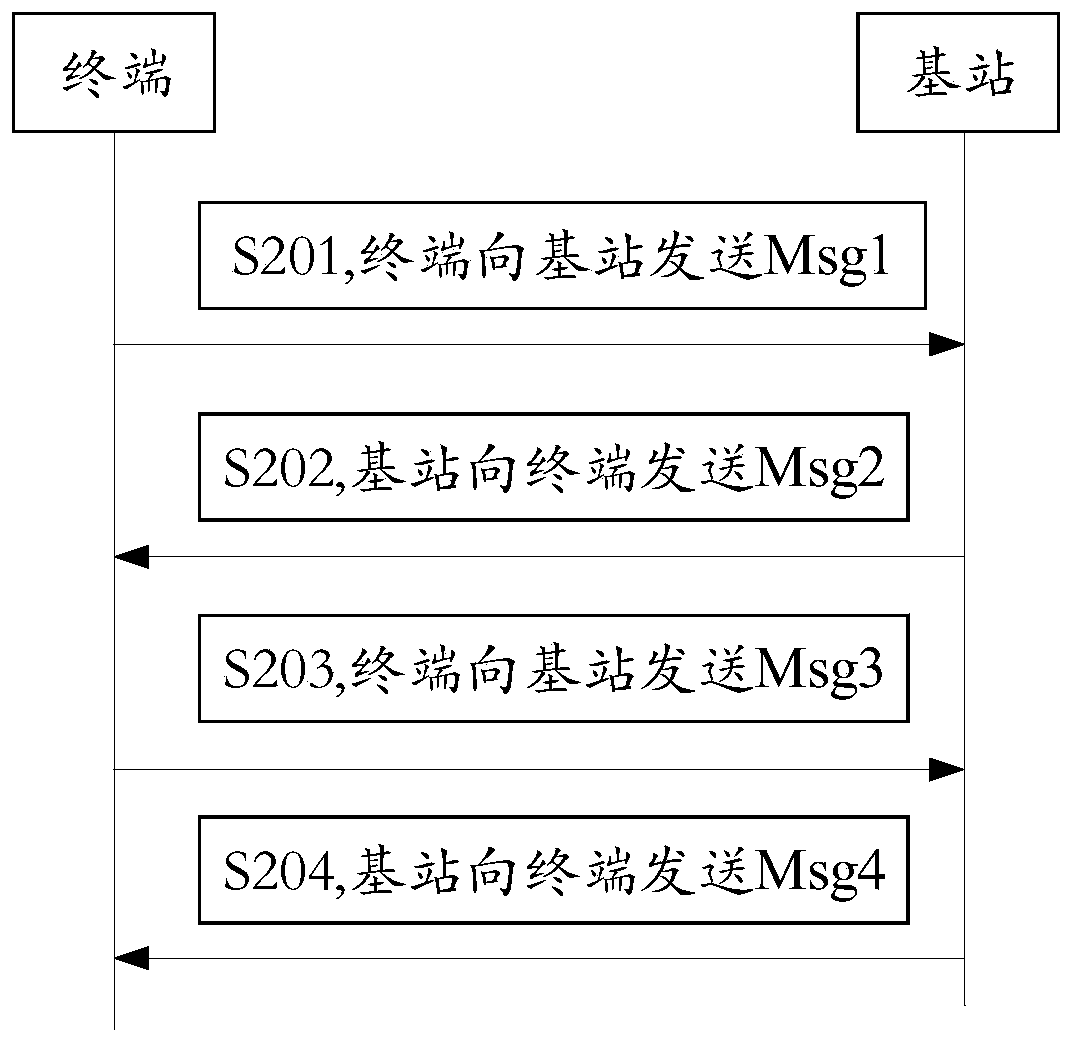

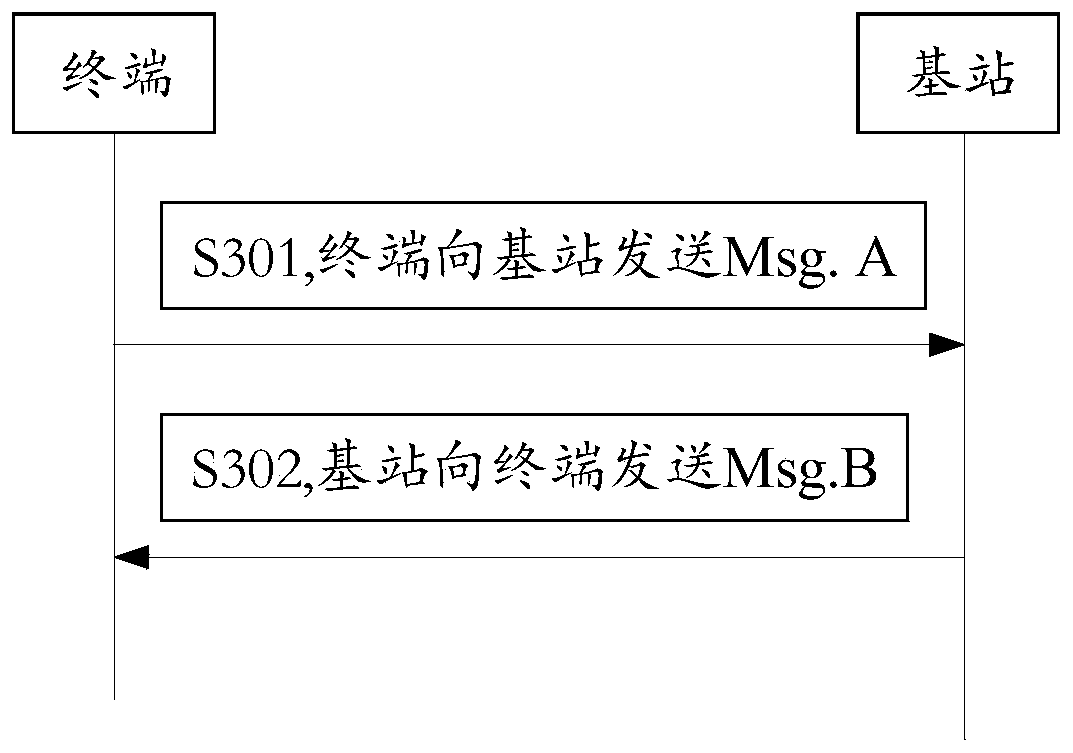

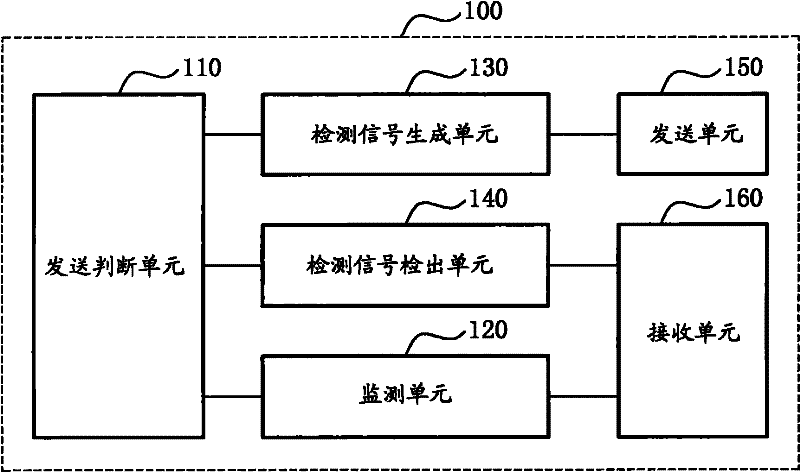

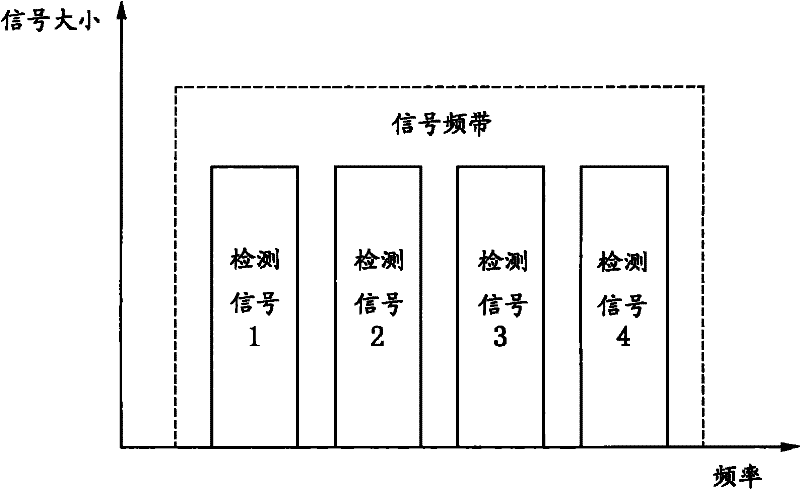

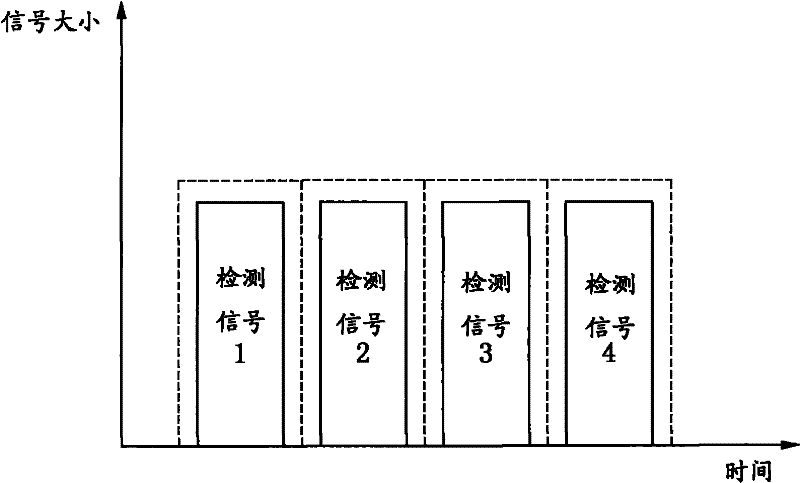

HARQ feedback method, device, and readable storage medium

PendingCN110679104AImprove feedback efficiencyReduce collisionsError prevention/detection by using return channelSignal allocationReal-time computingBase station

The invention discloses an HARQ feedback method, and belongs to the technical field of wireless communication. The method is executed by a base station. The method comprises following step: after first random access information (Msg.A) emitted by at least one terminal is received, returning second random access information (Msg.B) to at least one terminal, wherein Msg.B is used to indicate feedback parameters of all HARQ feedback terminals of at least one terminal; the HARQ feedback resources of all HARQ feedback terminals are different; and based on the HARQ feedback resources of all retransmission terminals, the base station receives HARQ feedbacks aiming at Msg.B from all retransmission terminals. The base station returns Msg.B, which indicates the feedback parameters of all HARQ feedback terminals, to at least one terminal to reduce the collision situation that terminals, which need to carry out HARQ feedback, use a same HARQ feedback resource, and thus the Msg.B feedback efficiency of the terminals is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Manual cleaning equipment

InactiveCN104690026AReduce collisionsImprove product qualityCleaning using liquidsHigh pressureHigh pressure water

The invention discloses manual cleaning equipment. The manual cleaning equipment comprises a left conveying belt and a right conveying belt, a cleaning bench is arranged between the left conveying belt and the right conveying belt, a cleaning cover is arranged on the upper portion of the cleaning bench, a cleaning sink is arranged in the cleaning bench, and a high-pressure cleaning gun is arranged in the cleaning sink and is connected with a high-pressure water pump. The bottom of the cleaning sink is connected with one side of a filtering sink through a pipeline, a water outlet is formed in the other side of the filtering sink, a magnetic roller way is arranged in the filtering sink and is abutted to one end of a scraping plate, the other end of the scraping plate is arranged in a collecting tank, the filtering sink is arranged in a recovery sink, two operation openings are formed in one side of the cleaning cover, and a sight window is arranged between the two operation openings. The manual cleaning equipment is convenient to use, good in cleaning effect, energy saving and environment friendly.

Owner:苏州烨灿设备科技有限公司

Supporting component for building frame structure beam construction

ActiveCN113668901AReduce poor stabilityReduce collisionsLifting framesBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a supporting component for building frame structure beam construction. The supporting component comprises a bottom beam, wherein a rail is arranged on the bottom beam, and a pushing mechanism and lifting mechanisms are arranged on the rail at intervals; the multiple lifting mechanisms are used for lifting or falling a workpiece for height adjustment; and the pushing mechanism is used for adjusting the horizontal position of the workpiece. The supporting component is used for reducing the situation that when a crane is used for hoisting a structure beam in the construction process, the structure beam shakes due to inertia of the crane and collides with surrounding structural parts, and the situation that the stability of the structure beam is poor due to collision is further reduced.

Owner:广州市筑智建筑科技有限公司 +1

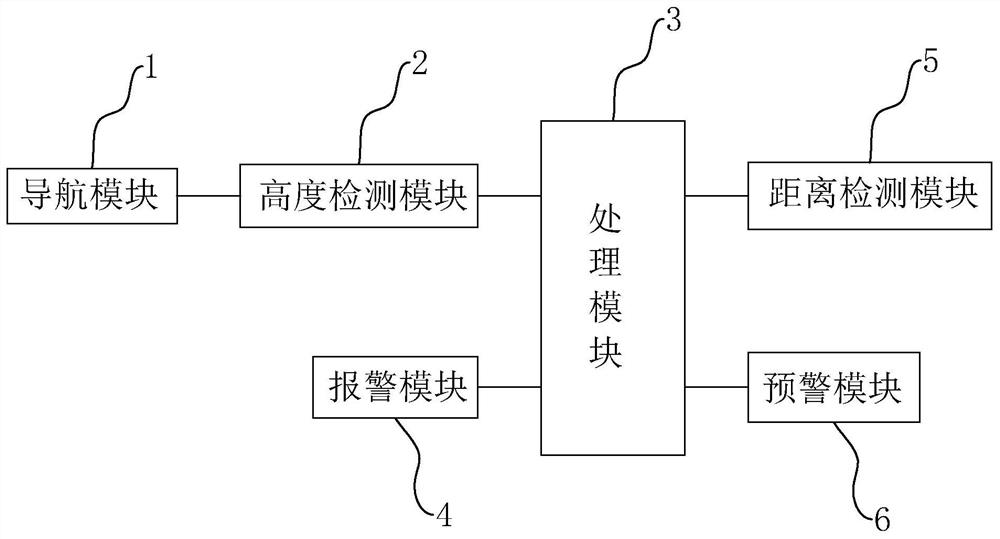

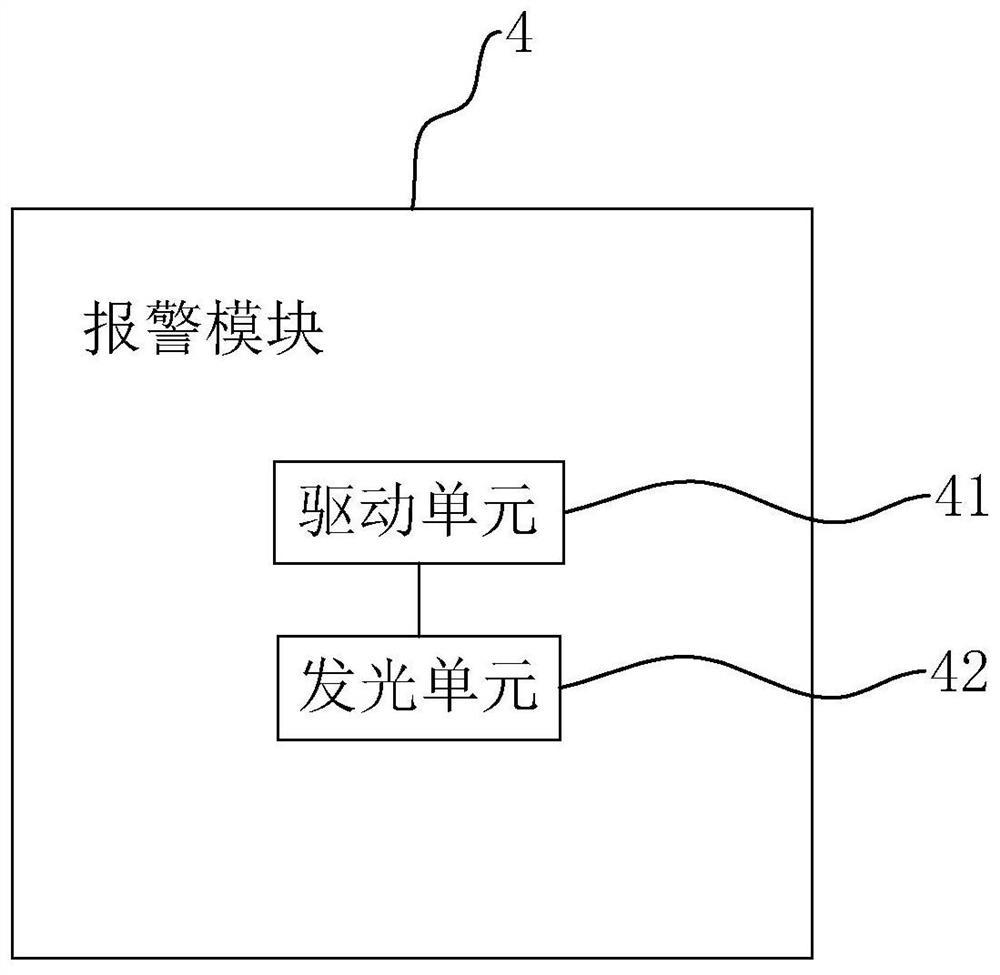

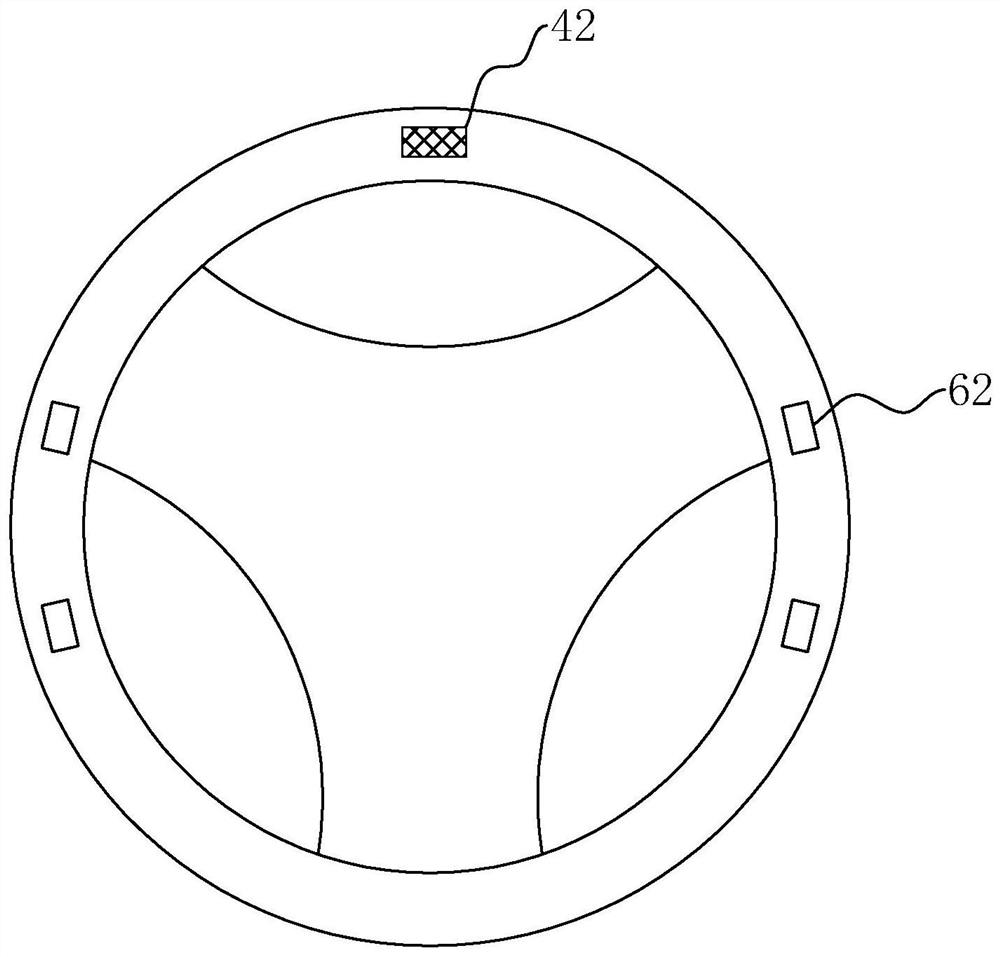

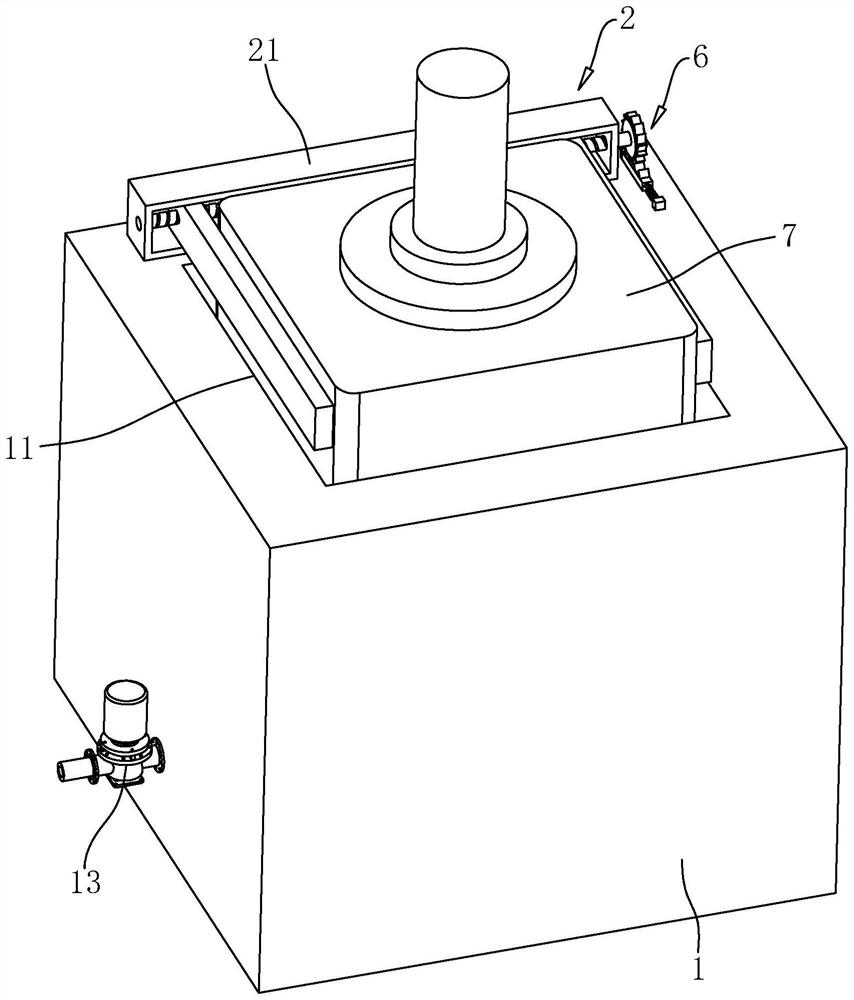

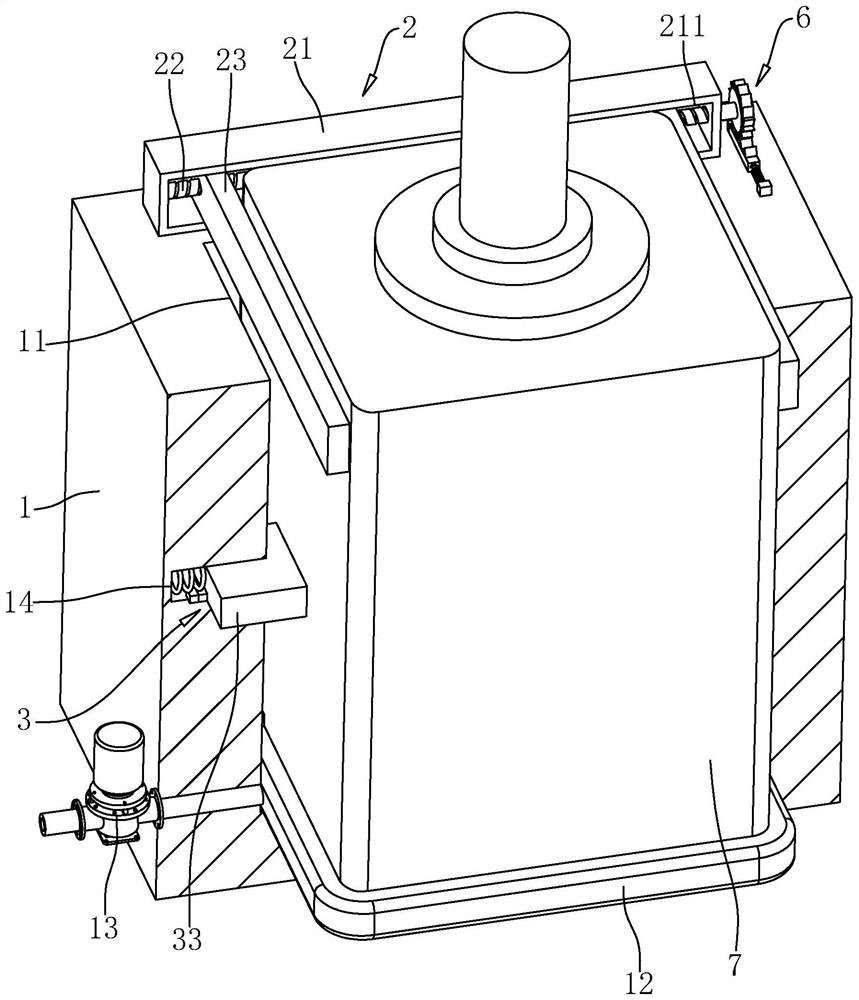

Obstacle detection system for vehicles

InactiveCN112197784AReduce collisionsReduce reroutingInstruments for road network navigationUsing subsonic/sonic/ultrasonic vibration meansSteering wheelTransport engineering

The invention relates to an obstacle detection system for vehicles, and belongs to the field of vehicle safety. The system comprises a navigation module used for positioning and navigating a vehicle and outputting tunnel information; a height detection module used for receiving the tunnel information, being started in response to the tunnel information and detecting the height of a tunnel in frontof the vehicle; a processing module used for comparing the tunnel height with the vehicle height, and outputting an alarm signal if the tunnel height is smaller than the vehicle height; and an alarmmodule used for receiving the alarm signal and giving an alarm in a steering wheel light-emitting mode. The method has the effects of reducing the collision between the vehicle and the tunnel and improving the driving safety.

Owner:SHENZHEN DOWCAUSE TECH

Fixing equipment for motor detection

ActiveCN114217100AImprove the problem of easy damageReduce collisionsMeasurement instrument housingDynamo-electric machine testingMotor testingElectric machine

The invention relates to the field of motor testing, in particular to fixing equipment for motor detection, which comprises a fixing plate, a fixing groove for placing a motor is formed in the end face of the fixing plate, and a locking part for locking the motor is mounted on the end face, on the same side as the fixing groove, of the fixing plate. An inflatable cushion arranged below the motor is fixedly connected to the inner bottom face of the fixing groove, and an air draft pump communicating with the inflatable cushion is fixedly connected to the fixing plate. The problem that the motor is easy to damage is solved.

Owner:无锡市世源电机有限公司

Contention-based data communication apparatus and method

InactiveCN102056323AWaste minimizationReduce collisionsNetwork data managementComputer scienceCommunicator device

Owner:ELECTRONICS & TELECOMM RES INST

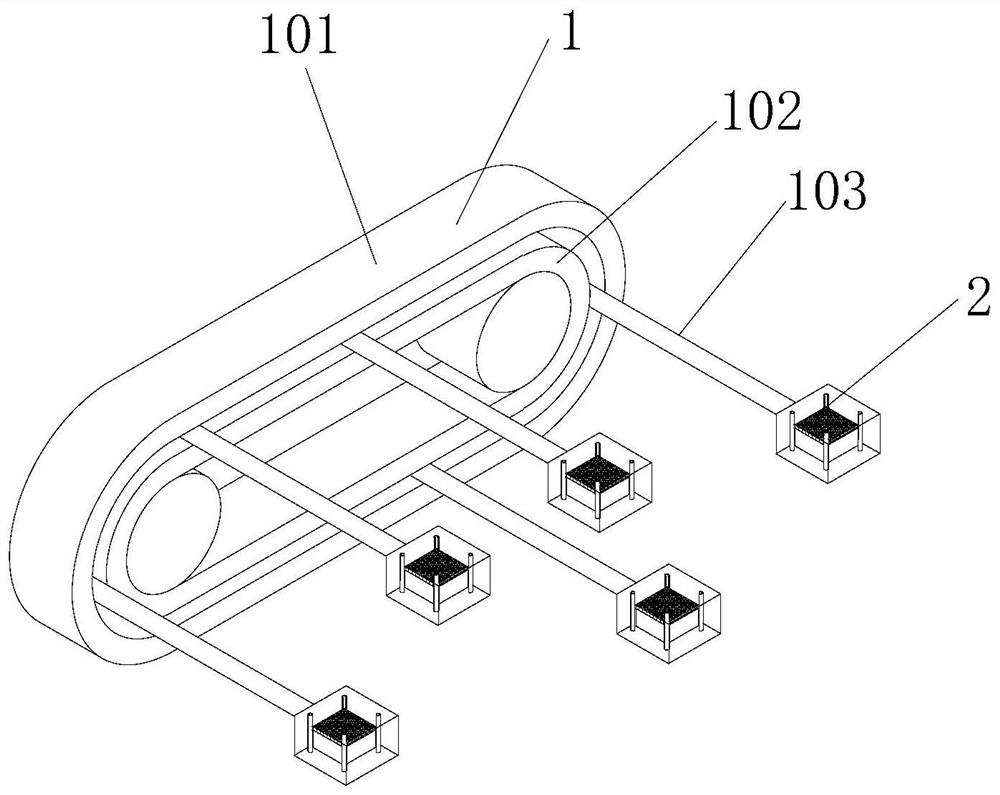

A simulation platform for an integrated exhibition hall with lighting simulation

ActiveCN111214047BEasy to watchImprove viewing angleShow cabinetsLighting elementsEngineeringComputer science

The invention discloses a simulation stand with a light simulation function for an integrated exhibition hall. The simulation stand relates to the technical field of simulation stands, and comprises an annular stand, a conveying belt and rotating rods, wherein the simulation stand can move along the conveying belt by means of the rotating rod. Since exhibition stands in THE integrated exhibition hall are numerous, if each exhibition stand is placed at a position suitable for visitors to watch, a huge space needs to be occupied, and spaces above and below the exhibition stands cannot be used and are wasted after the exhibition stands are placed. By changing a placement mode of the exhibition stands into a mobile mode, the exhibition stand needs to be watched is moved to the front position suitable for watching along the conveying belt by means of the rotating rods when a certain exhibition stand needs to be watched, and the simulation stand which is not watched by people is moved to anupper position or a lower position, thereby guaranteeing the space utilization rate in the exhibition hall.

Owner:SHANGHAI FINEKITE EXHIBITION ENG

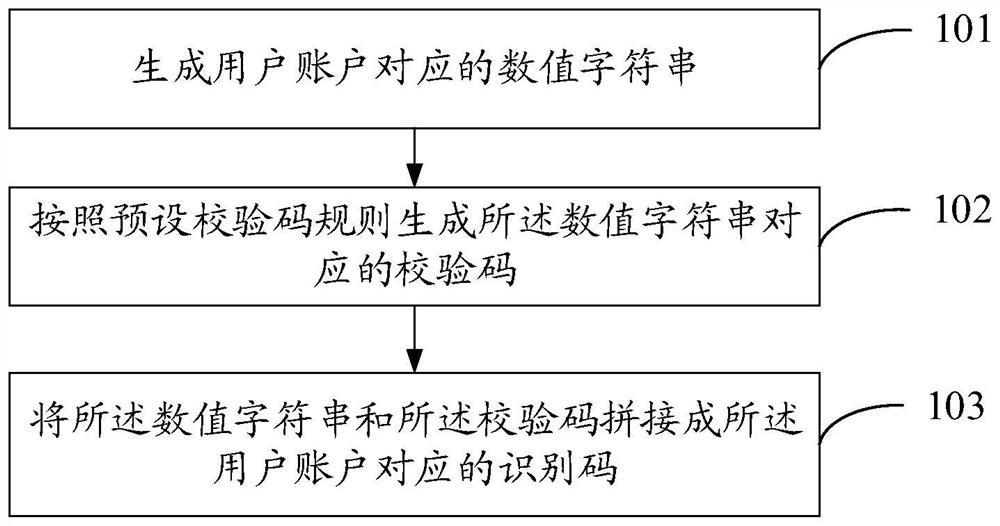

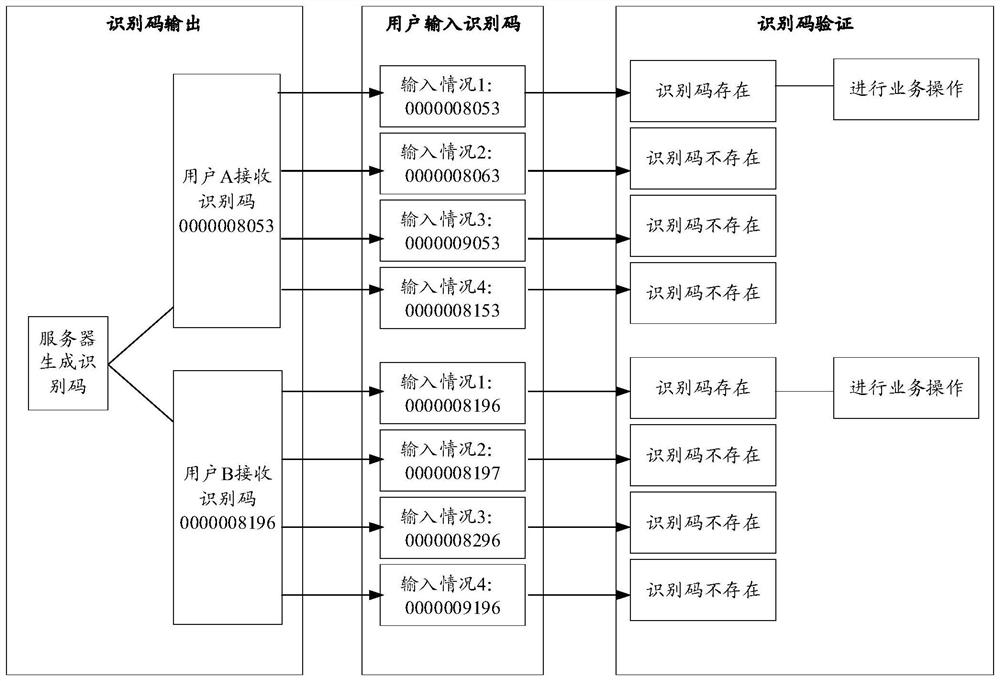

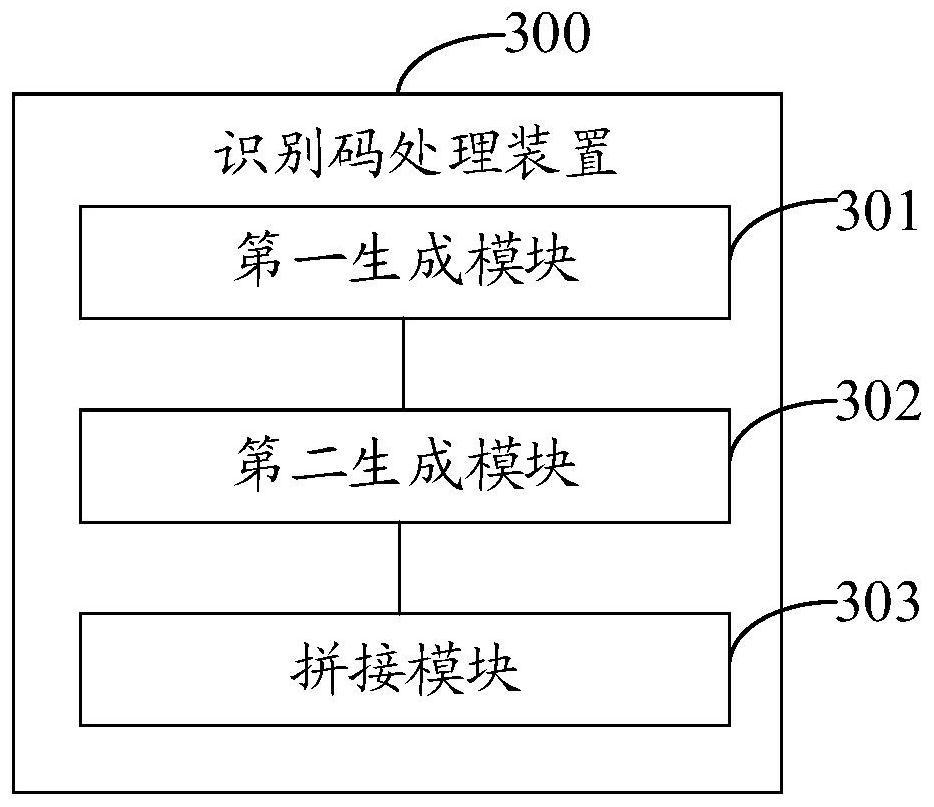

Identification code processing method and device

The invention provides an identification code processing method and device. The method comprises the steps: generating a numerical character string corresponding to a user account, enabling the digitof the numerical character string to be N, enabling N to be an integer greater than 1, and enabling the numerical character strings corresponding to different user accounts to be different; generatingcheck codes corresponding to the numeric character strings according to a preset check code rule, wherein the check codes corresponding to different numeric character strings are different; and splicing the numerical character string and the check code into an identification code corresponding to the user account. Through the identification code processing method provided by the invention, the occurrence of number collision caused by user input errors can be reduced.

Owner:MASHANG CONSUMER FINANCE CO LTD

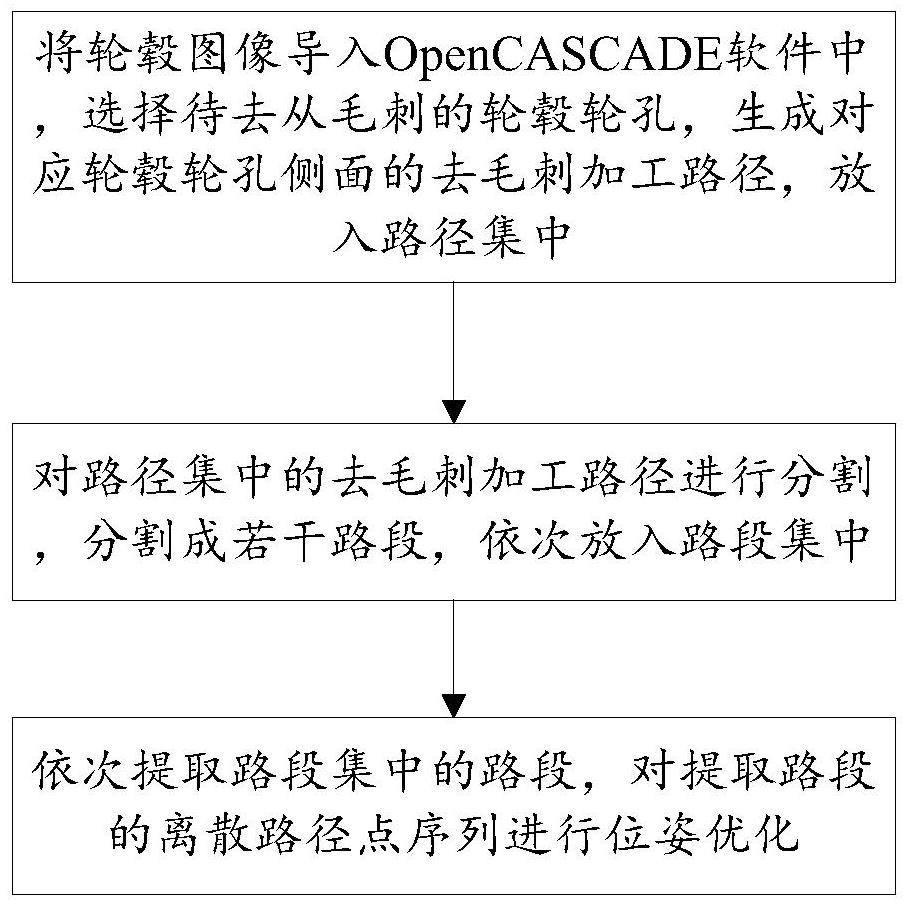

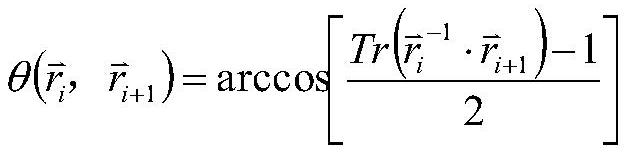

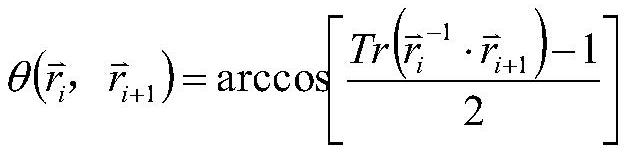

Robot path generation method for hub hole deburring machining

PendingCN114310941AImprove fitReduce collisionsProgramme-controlled manipulatorInternal combustion piston enginesStructural engineeringAlgorithm

The invention discloses a robot path generation method for hub wheel hole deburring machining, which comprises the following steps: S1, importing a hub image into OpenCASCADE software, selecting a hub wheel hole to be deburred, generating a deburring machining path corresponding to the side surface of the hub wheel hole, and putting the deburring machining path into a path set {P}; s2, a deburring machining path in the path set {P} is segmented into a plurality of road sections, and the road sections are sequentially put into a road section set {Pn}; and S3, sequentially extracting road sections in the road section set {Pn}, and performing pose optimization on the discrete waypoint sequence of the extracted road sections. By means of the path optimization method, the finally obtained hub hole side face machining points can be well attached to the surface of the model, the posture transition is smooth, the number of the machining points is relatively small, in addition, the poses of the path points (machining points) are optimized, and the situation that an end executor of a robot collides with the machining face is greatly reduced.

Owner:哈尔滨工业大学芜湖机器人产业技术研究院

Pruning device and using method

PendingCN113510203AReduce replacementReduce collisionsProfiling/shaping machinesShearing machinesStructural engineeringMachining

The invention discloses a pair of rolling scissors, and relates to the technical field of machining. In the application, the rolling scissors comprise a body, a clamping part and a cutting part, wherein the body is used for being connected with a control device; the clamping part is connected with the body, and the clamping part is used for being attached to a part; and the cutting part is connected with the body, and the cutting part is used for cutting materials. The rolling scissors are used for preventing the problems that when a punch is used for cutting redundant steel wire ends at two sides of a fence mesh, the occupied area of the punch is very large, time and labor are wasted after a cutting edge is damaged during cutting of the punch, and the machining efficiency is affected.

Owner:苏州云刚智能科技有限公司

Tableware washer

ActiveCN102028442BReduce noiseEasy to cleanTableware washing/rinsing machine detailsEngineeringPush out

The present invention provides a tableware washer which comprises the following components: a housing; a cleaning trough which is equipped in the housing with a mode that the cleaning trough can be pushed out freely; an upper tableware basket and a lower tableware basket which are equipped in the cleaning trough and eject cleaning water to the cleaning object from a plurality of spray holes. The upper tableware basket is configured to a state that the upper tableware is movable in the cleaning trough. The plurality of spray holes of the upper cleaning part are opened and closed according to the position of the upper tableware basket.

Owner:PANASONIC CORP

Multi-grid double-glass photovoltaic cell structure

PendingCN110995139AReduce quad pressureReduce collisionsPhotovoltaicsPhotovoltaic energy generationDust controlMechanical engineering

The invention provides a multi-grid double-glass photovoltaic cell structure, and relates to the technical field of double-glass assemblies. The structure comprises a shell. A movable adjusting structure is fixedly mounted at the bottom of the shell. A dust removal structure is fixedly mounted on one side of the outer surface of the shell. The dust removal structure comprises a heat dissipation frame. A heat dissipation fan is fixedly mounted on one side of the outer surface of the heat dissipation frame. Heat dissipation holes are formed in the outer surface of the heat dissipation frame. A mounting frame is fixedly mounted on one side of the outer surface of the shell, a pull handle is fixedly mounted at the top of the shell, a dustproof plate is fixedly mounted on the front surface of the shell, a connecting terminal is fixedly mounted on the back surface of the shell, and a control panel is fixedly mounted on the front surface of the shell and located above the dustproof plate. According to the invention, through arranging the POE small strips, 70 * 10mm POE small strips are cushioned at four corners of the upper frame and two sides of the middle bus bar, so that the pressure on four sides of the assembly is reduced, fragments and corner bubbles are improved, the sizes of the small strips are determined through multiple experiments on the basis of the layout of the existingassembly, and the sizes of the POE small strips are in a positive fit state.

Owner:盐城天合国能光伏科技有限公司

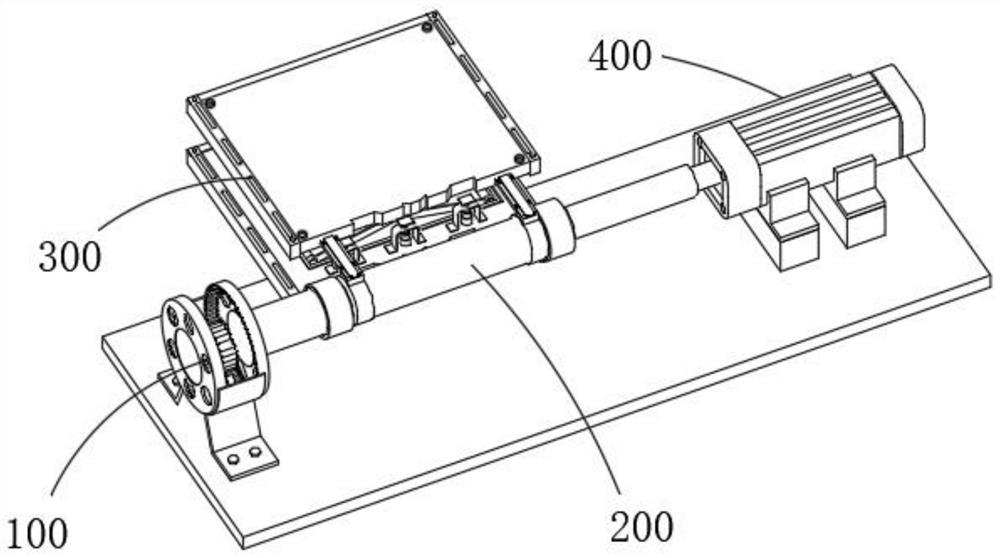

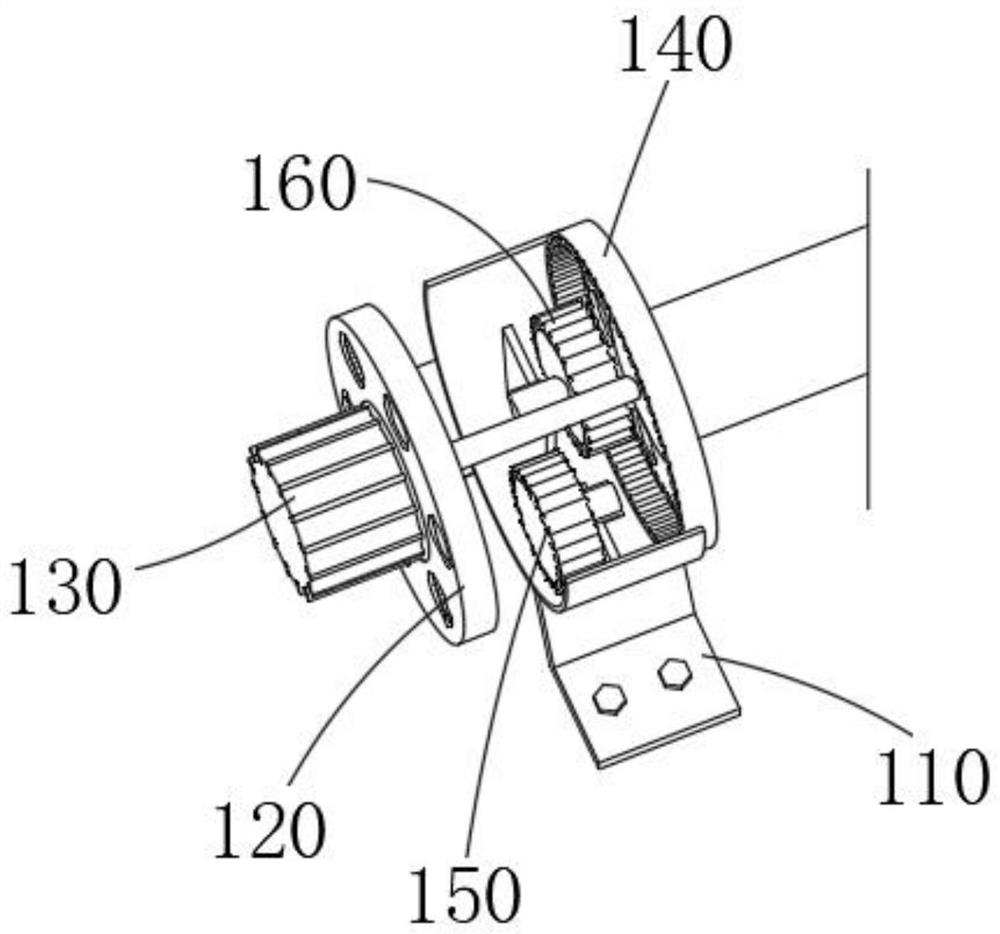

A counter-position turning device for electric vehicle parts processing

ActiveCN113172383BEasy alignmentEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesElectric carsElectric vehicle

The invention discloses a counter-position flipping device for processing electric vehicle accessories, which comprises a driving device, a rotating mechanism, a lifting device and a clamping device. The driving device includes a support frame and a turntable fixed on one side of the support frame. The driving source outside the first turntable, the second turntable fixed on the other side of the support frame, the first rotating tooth installed inside the support frame, and the second rotating tooth installed inside the support frame. The rotating mechanism is installed at one end of the drive device, The lifting device is installed on the side of the rotating mechanism, the clamping device is arranged on the front end of the rotating mechanism, and the rotating mechanism includes short rotating shafts installed on the two outer ends of the turntable. In the present invention, by providing a driving device, the short shaft and the long shaft can be rotated in two directions or in the same direction, which facilitates alignment of the fixed platform and the limit platform after rotation, so that the staff can carry out the work on the workpiece installed on the platform. Operations such as welding.

Owner:徐州海瑞电动车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com