Disinfection equipment for disinfection supply room

A technology for disinfection equipment and supply rooms, which is applied in the direction of sanitary equipment for toilets, disinfection, and water supply equipment, etc. It can solve the problems of reducing the performance of the device, affecting the effect of disinfection, and difficult equipment cleaning, so as to increase stability and improve disinfection. effect, reducing the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

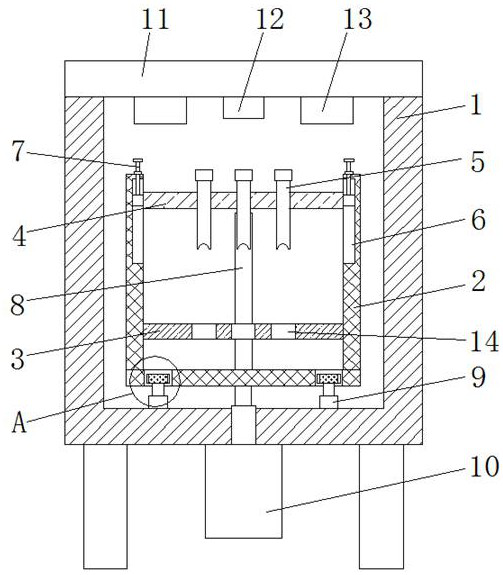

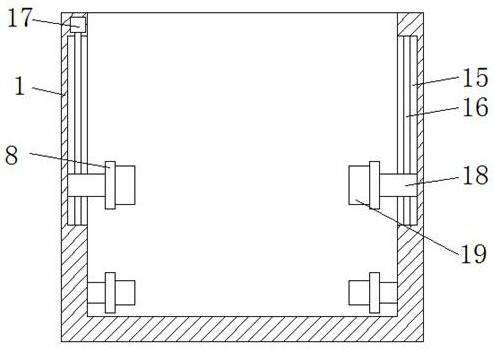

[0031] see Figure 1 to Figure 6 , the present invention provides a technical solution for disinfection equipment for disinfection supply rooms: a disinfection equipment for disinfection supply rooms, including a device main body 1, a placement frame 2 is arranged inside the device body 1, and the interior of the placement frame 2 is close to the lower end A partition 3 is installed at a fixed position, and a cover plate 4 is provided on the inside of the shelf 2 near the upper end, and the cover plate 4 is located directly above the partition 3, and movable slots are opened on the inside of the main body 1 near both sides. 15. A rotating rod 16 is installed inside the movable groove 15, and one end of the rotating rod 16 is fixedly connected with a motor 17. The outer surface of the rotating rod 16 is threaded with a moving plate 18, and the moving plate 18 is slidably installed inside the movable groove 15. A brush 19 is provided at a position corresponding to the moving pla...

Embodiment 2

[0036] Such as Figure 5 with Image 6 As shown, in the case that other parts are the same as in Embodiment 1, the difference between this embodiment and Embodiment 1 is that: the inner surface of the placement frame 2 is provided with a chute 6 near the front and rear ends, and the inside of the chute 6 slides Side plates 24 are installed, and the two side plates 24 are fixedly installed on the two end faces of the cover plate 4 respectively, and the upper end faces of the side plates 24 are fixedly equipped with the adjusting rod 7, and the outer surface of the adjusting rod 7 is screwed with the rotating plate 20 , the lower end surface of the rotating plate 20 is fixedly equipped with a sleeve 25, the sleeve 25 is threadedly mounted on the inside of the placement frame 2 near the upper end, and the sleeve 25 is threaded with the adjusting rod 7, and the upper end of the adjusting rod 7 extends to The outside of the placement frame 2 is fixedly installed with an operation ...

Embodiment 3

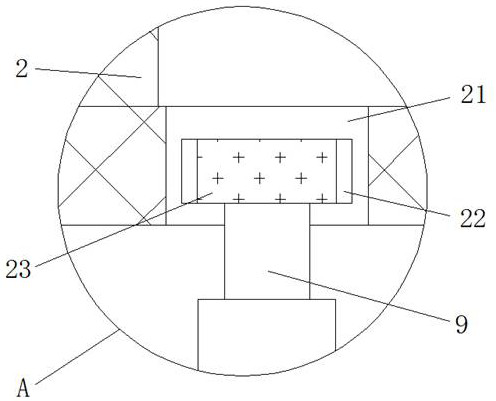

[0041] Such as figure 1 with image 3 As shown, in the case that other parts are all the same as in Embodiment 1, the difference between this embodiment and Embodiment 1 is that a fixed plate 21 is fixedly installed on the lower end surface of the placement frame 2 near the outside, and the lower end surface of the fixed plate 21 An annular groove 22 is opened, and a limiting plate 23 is installed in rotation inside the annular groove 22 , and an electric push rod 9 is fixedly connected between the lower end surface of the limiting plate 23 and the equipment main body 1 .

[0042] The middle position of the outer surface of the lower end of the placement frame 2 is fixedly connected with a motor 10 through a telescopic rod, and two electric push rods 9 are symmetrical about the motor 10 .

[0043] Working principle: the motor 10 drives the placement frame 2 to rotate, and the rotation of the placement frame 2 prompts the limit plate 23 to rotate inside the annular groove 22 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com