Automatic strapping and packing machine and strapping and packing technology thereof

A tape-mounted and automatic technology, applied in the direction of automatic control of packaging, parts of bundling machinery, packaging, etc., can solve the problems of high-speed connection, damage, and easy scratching of the automatic production line of glass sheet production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

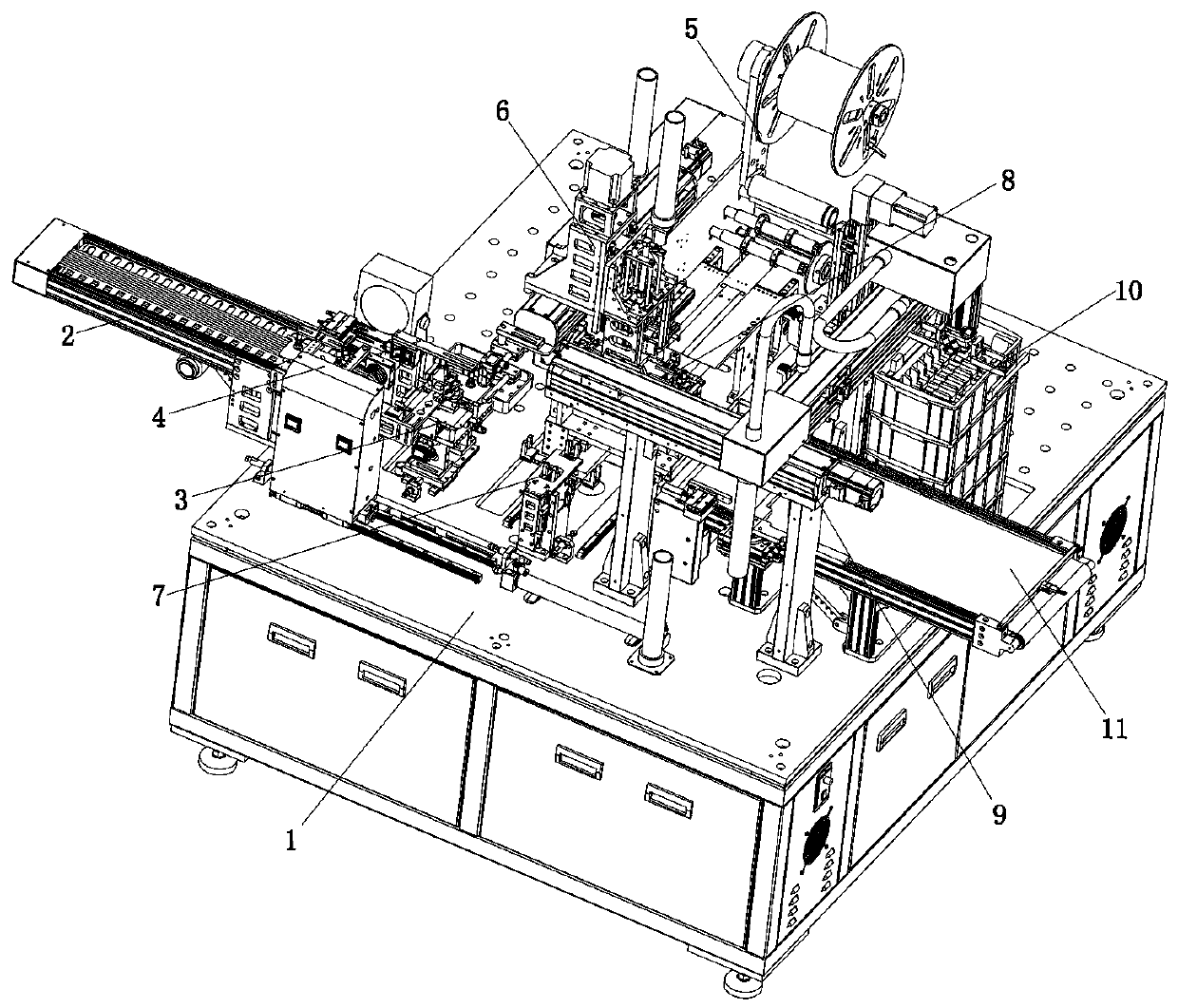

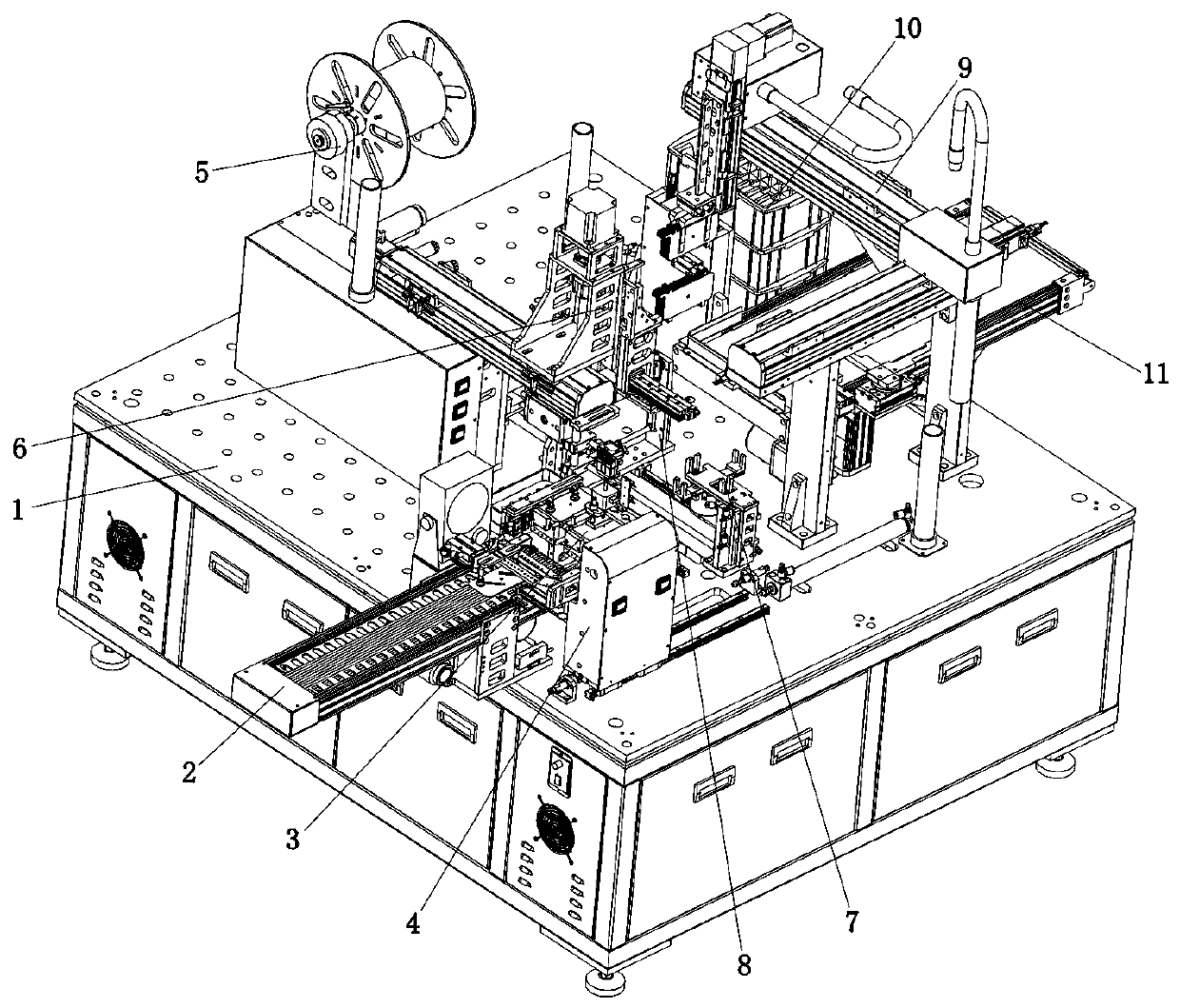

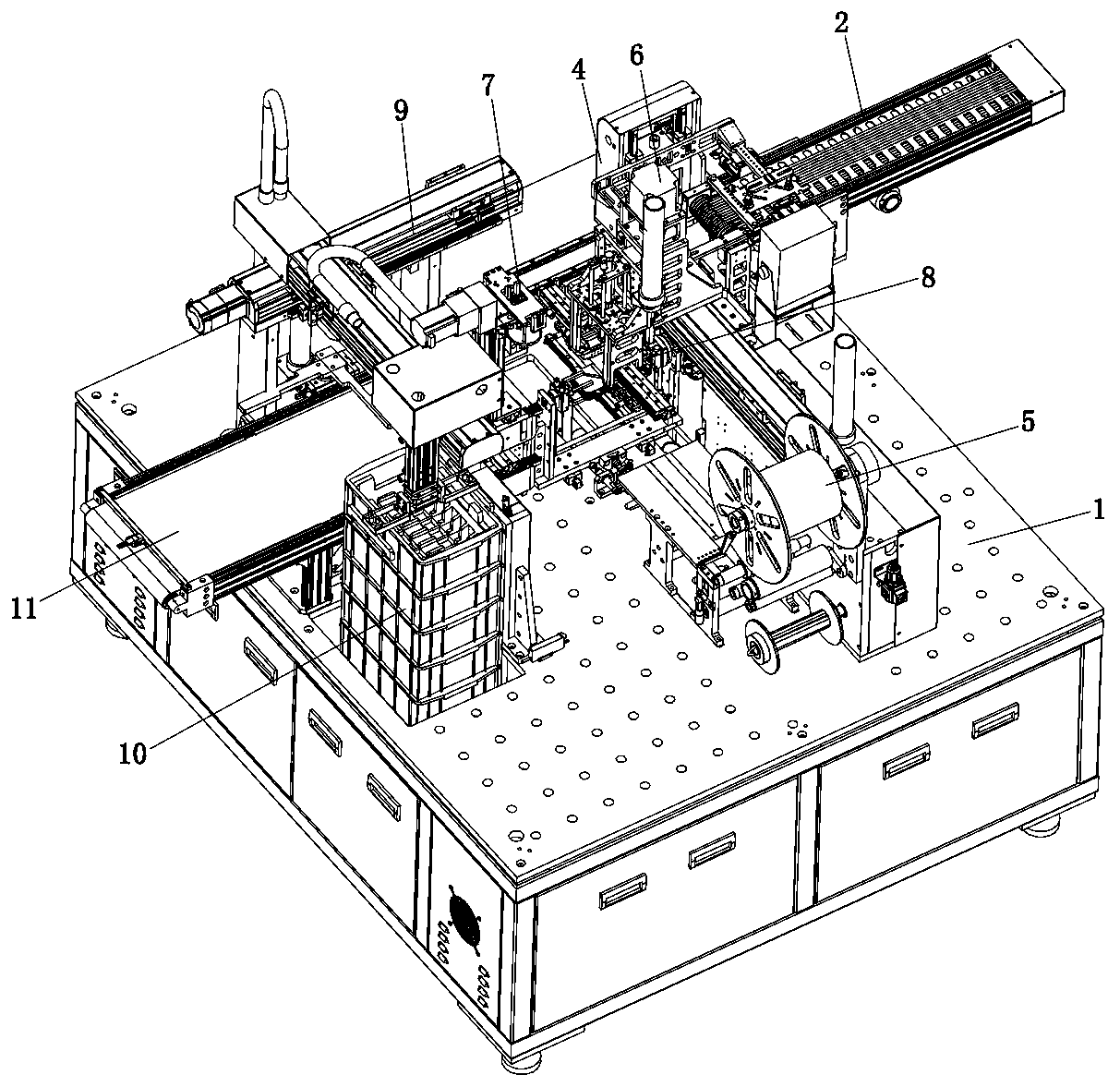

[0049] The present invention will be further described below in conjunction with accompanying drawing:

[0050] like Figure 1 to Figure 18 As shown, the technical scheme adopted by the present invention is as follows: an automatic strapping cartoning machine, comprising a frame 1, a feed belt 2 and a discharge belt 11, and the feed belt 2 and the discharge belt 11 are arranged on the machine along a straight line. On both sides of frame 1, the single glass sheets to be stacked and boxed are conveyed towards frame 1 through the feed belt 2, and also include the transfer detection platform 3, the linkage feeding manipulator 4, the lamination platform 7, and the sheet picking platform. And the rotating mechanism 8, the tape-out and strapping mechanism, the bundle-taking and unloading manipulator 9 and the material box 10, wherein the above-mentioned transfer detection platform 3 is arranged on the frame 1, and is located at the end of the feed belt 2, and the linkage The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com