Patents

Literature

40results about How to "Heating controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

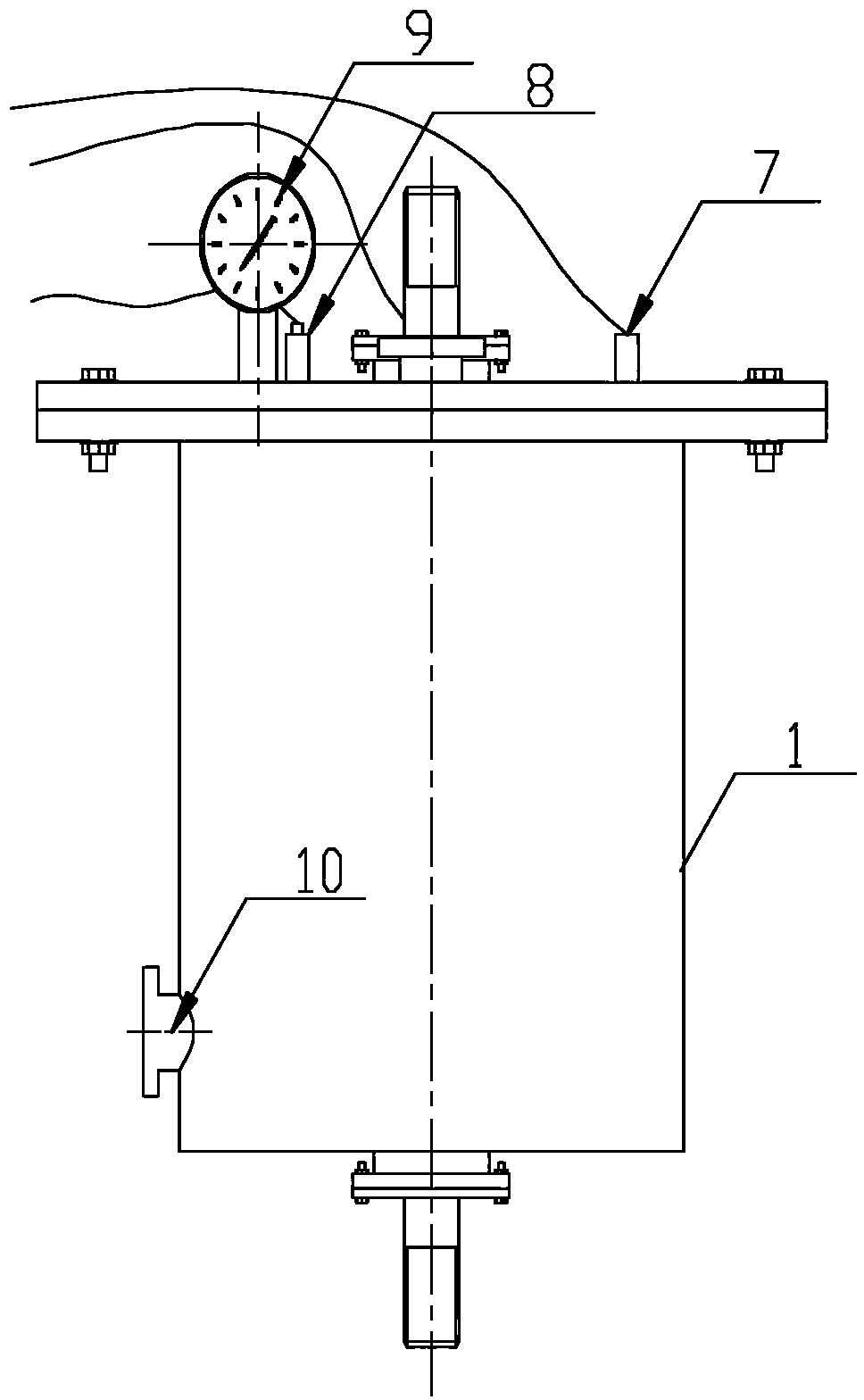

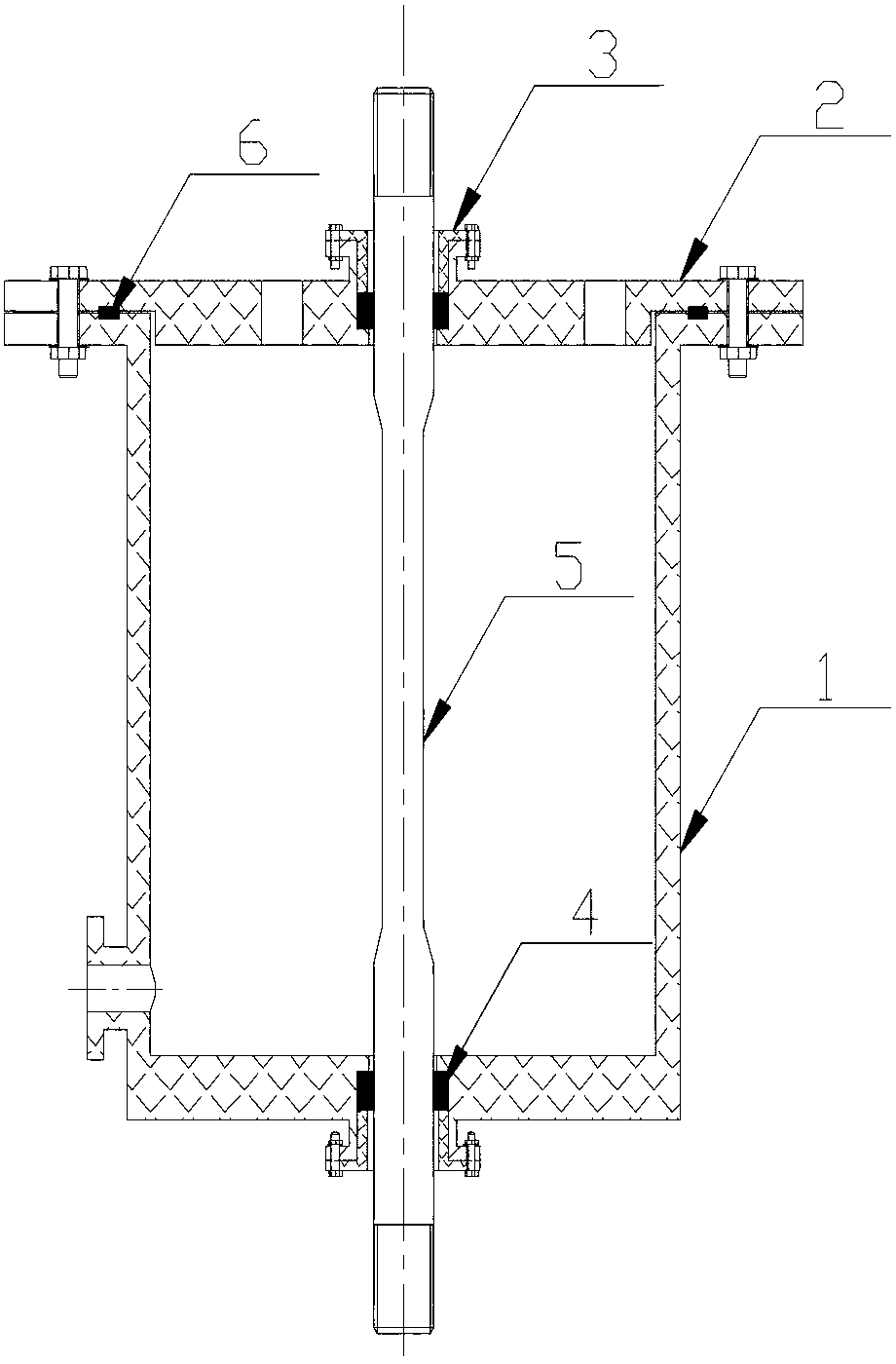

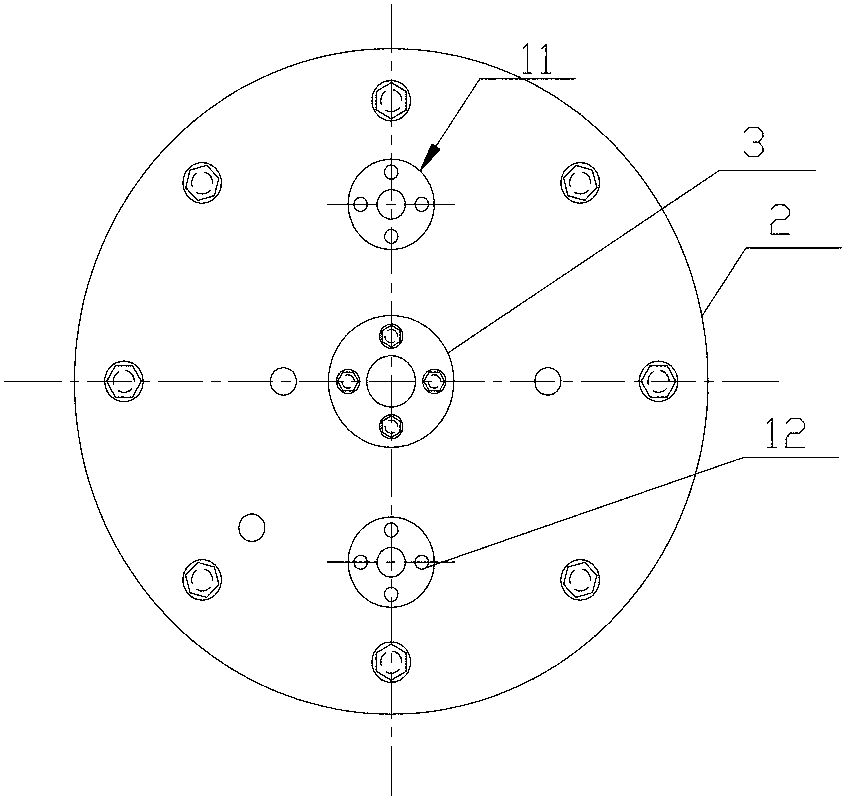

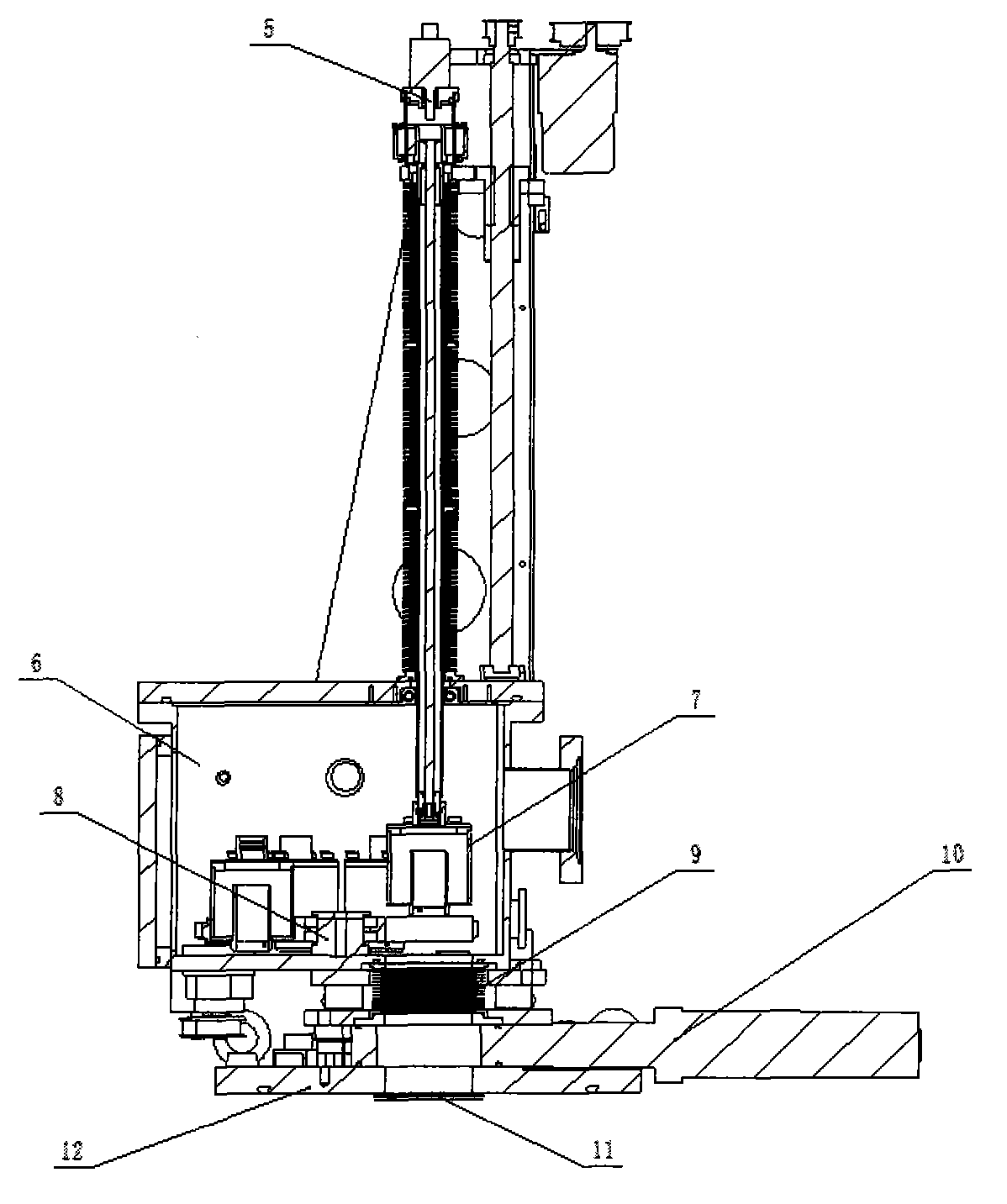

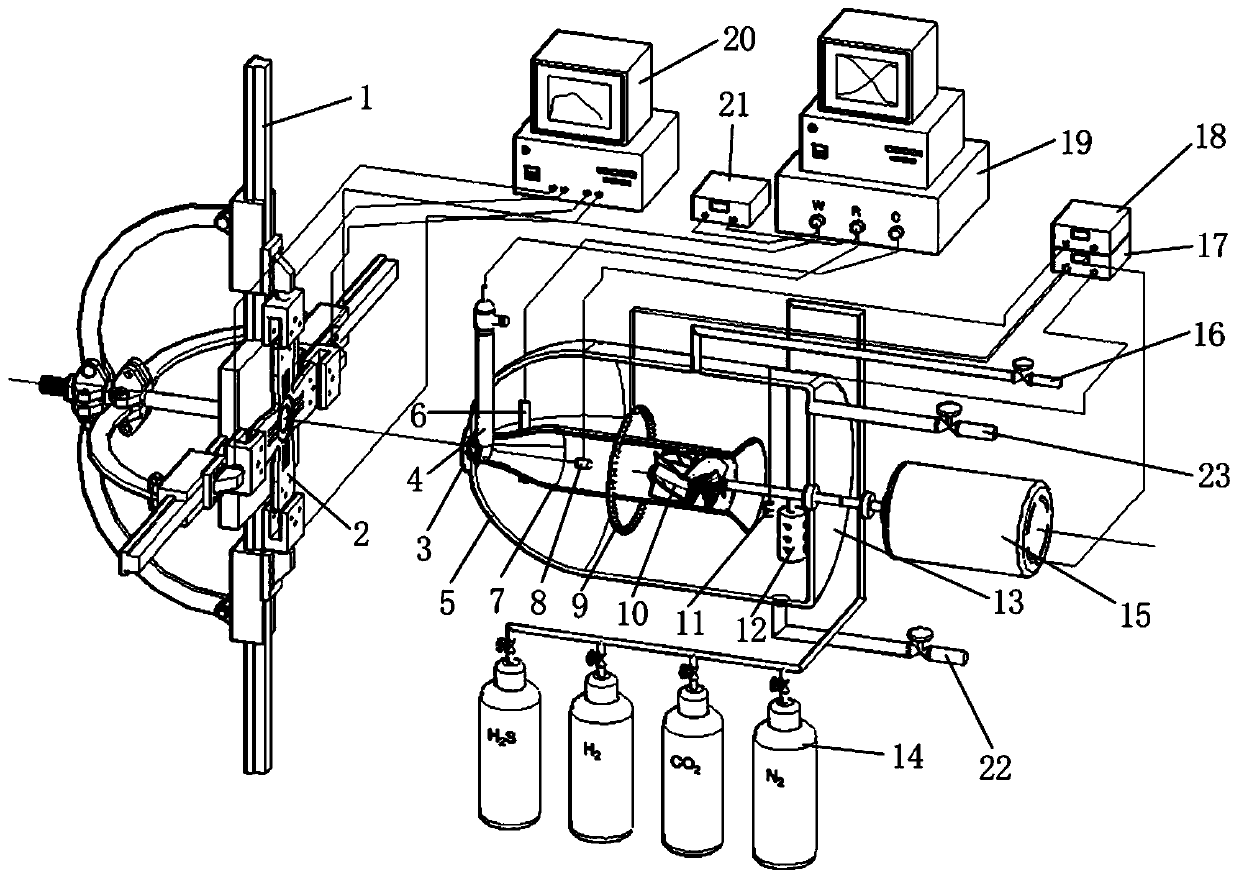

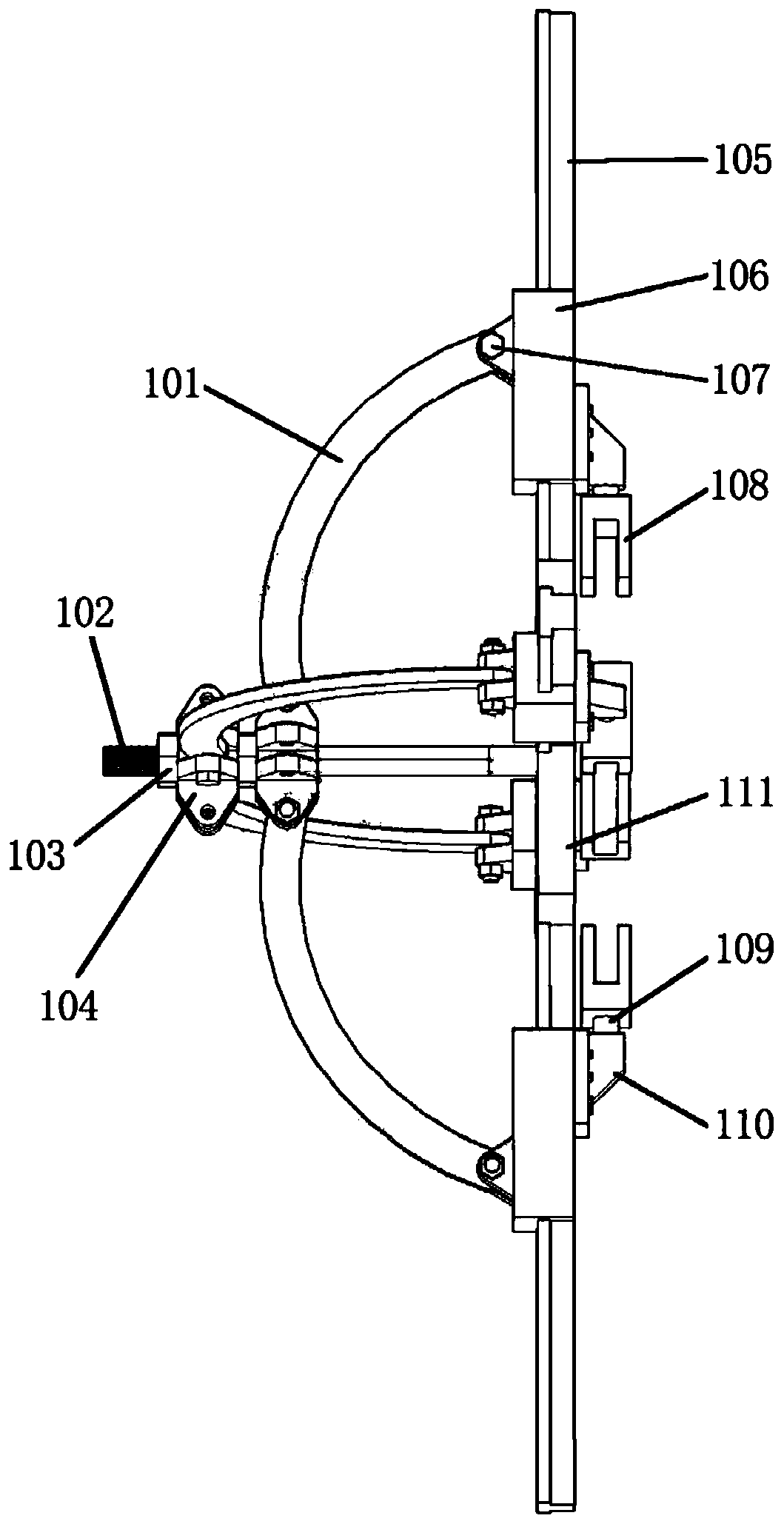

High temperature high pressure acoustic emission electrochemistry simulation experiment apparatus capable of loading stress

InactiveCN103226091AConvenient researchAffect accuracyMaterial analysis using acoustic emission techniquesWeather/light/corrosion resistanceAcoustic emissionEngineering

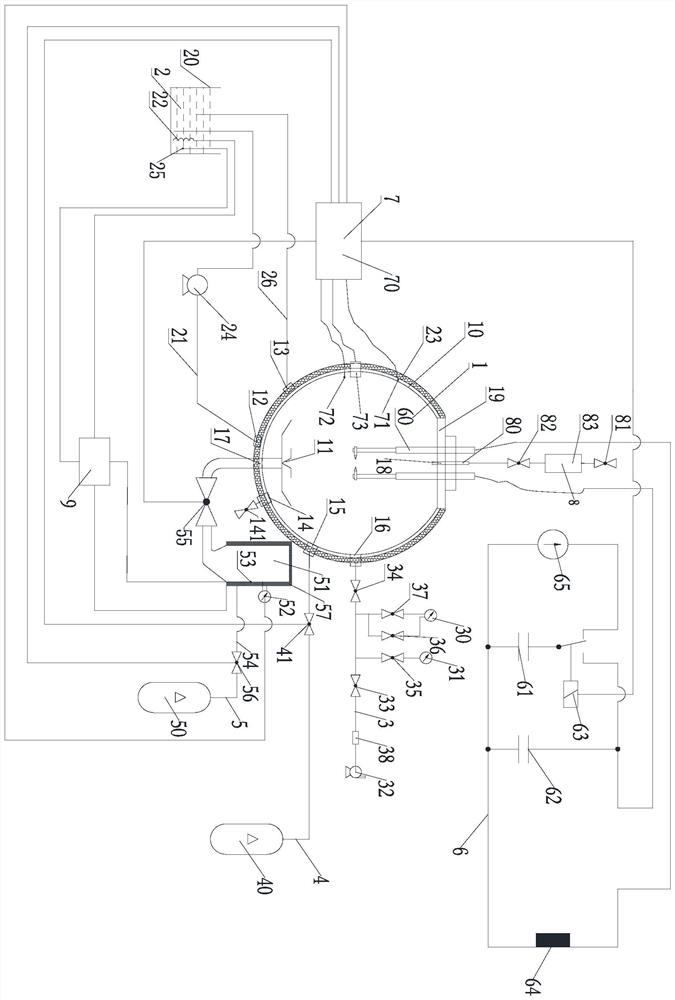

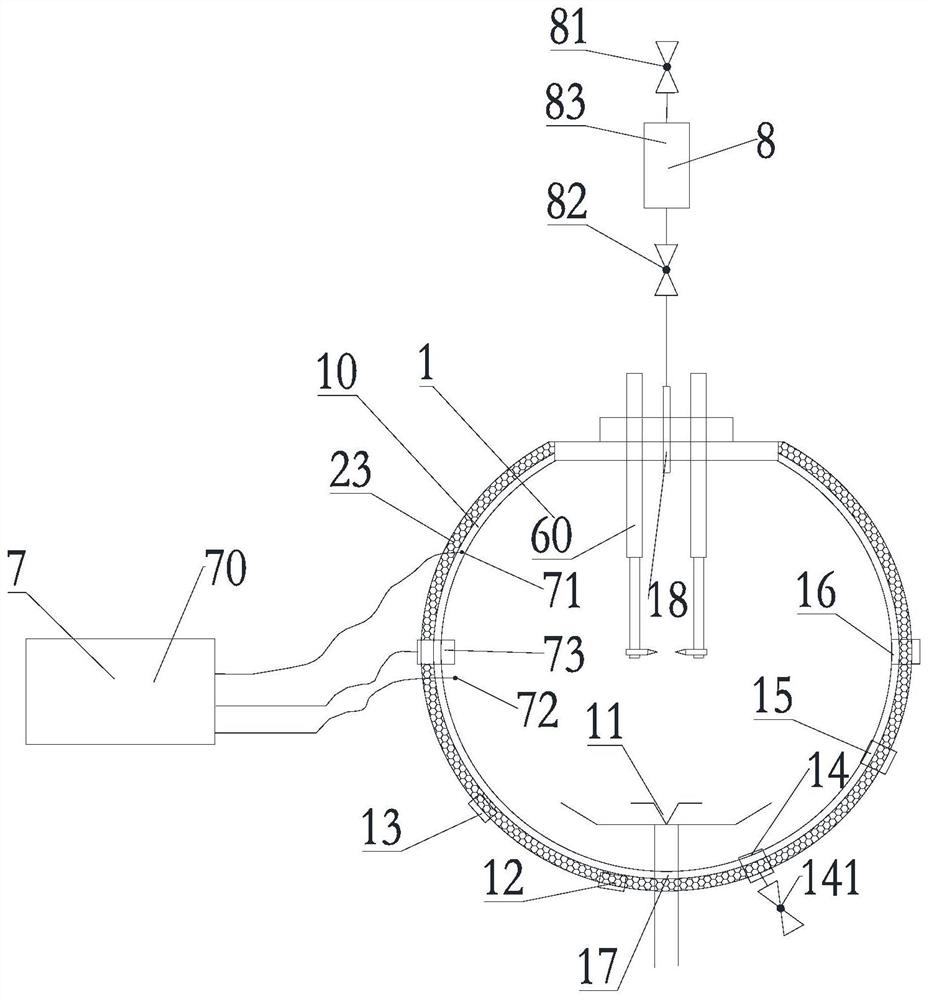

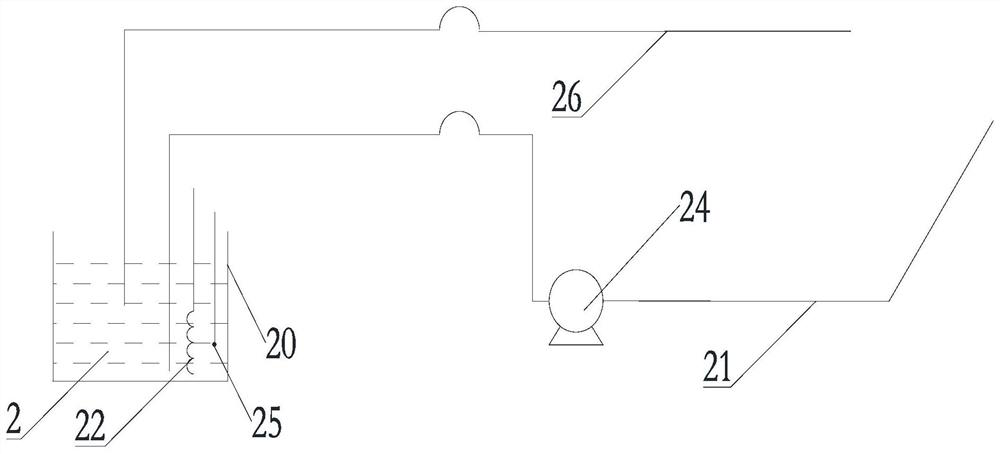

The invention provides a high temperature high pressure acoustic emission electrochemistry simulation experiment apparatus capable of loading stress. The apparatus comprises: a pressure kettle, wherein the pressure kettle is provided with an inner cavity, and a specimen is arranged inside the inner cavity; stretching test systems installed on both ends of the specimen, wherein the tension test system stretches the specimen, tests and obtains tension and a strain signal of the specimen; a solution circulation inflation system connected with the inner cavity of the pressure kettle and provided for providing a solution required by an experiment for the pressure kettle; acoustic emission probes arranged on both ends of the specimen and provided for testing an acoustic signal of the specimen; an electrochemistry test system connected with the specimen and the pressure kettle, and provided for applying polarization current on the specimen to carry out polarization, testing and obtaining an electrochemistry signal; and a data collector for collecting the simultaneously measured strain signal, the electrochemistry signal and the acoustic emission signal. With the present invention, controllable pressurizing, controllable heating and controllable inflation can be performed, and an actual working condition of the on-site material is well simulated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

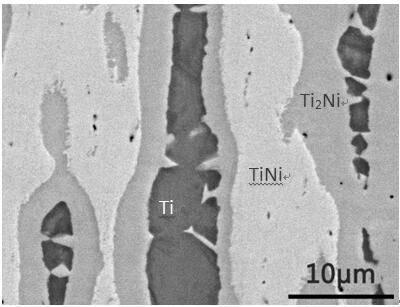

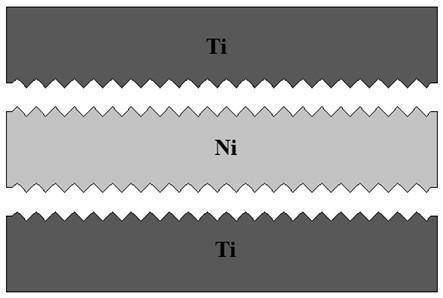

Enhanced TiNi layered composite material and preparation method thereof

ActiveCN110293717AEffective control generationGood mechanical propertiesLamination ancillary operationsLaminationTitaniumPre treatment

The invention discloses an enhanced TiNi layered composite material and a preparation method thereof, and belongs to the field of processing of special material composite technology. By aiming at theproblems of poor mechanical properties of the existing Ti / Ni layered composite material, pure titanium and pure nickel are used as raw materials; titanium plates and pure nickel plates are respectively subjected to surface pretreatment; then, the placement is performed in an alternate laminated sequence in a mode of Ti / Ni / Ti; through the subsequent rolling compounding and heat treatment processes,the Ti / Ni layered composite material with excellent mechanical property is prepared. The preparation process is simple; the cost is low; the mechanical property is excellent.

Owner:JINCHUAN GROUP LIMITED

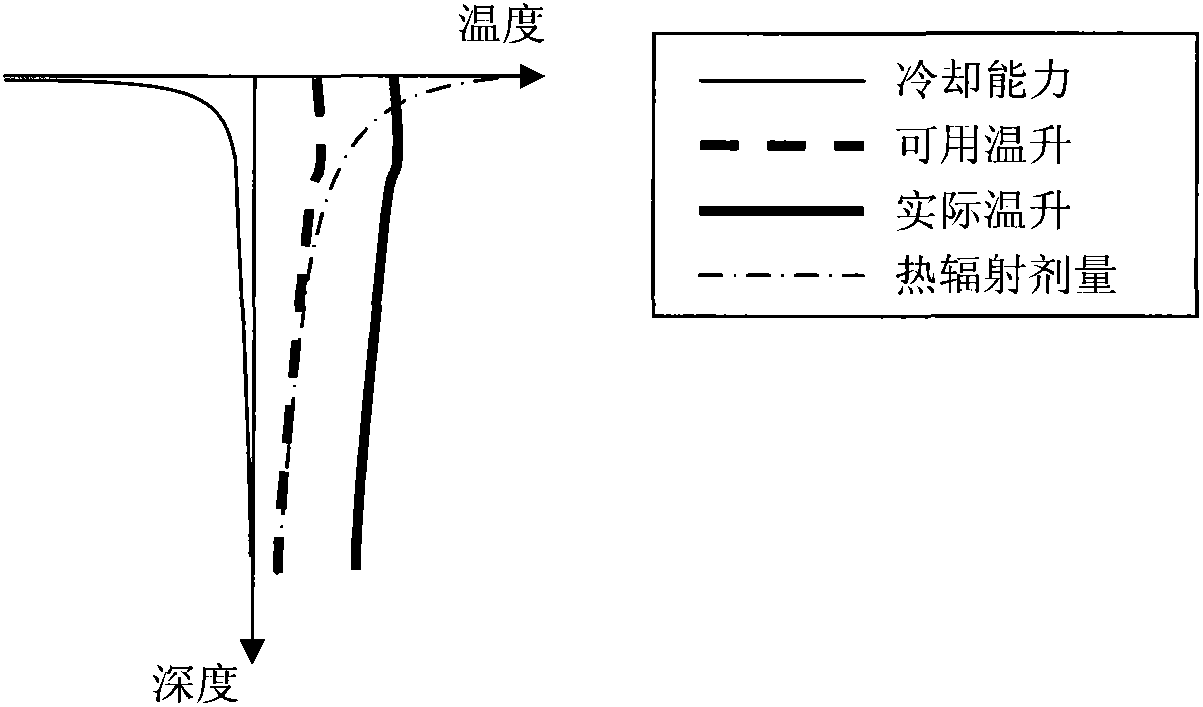

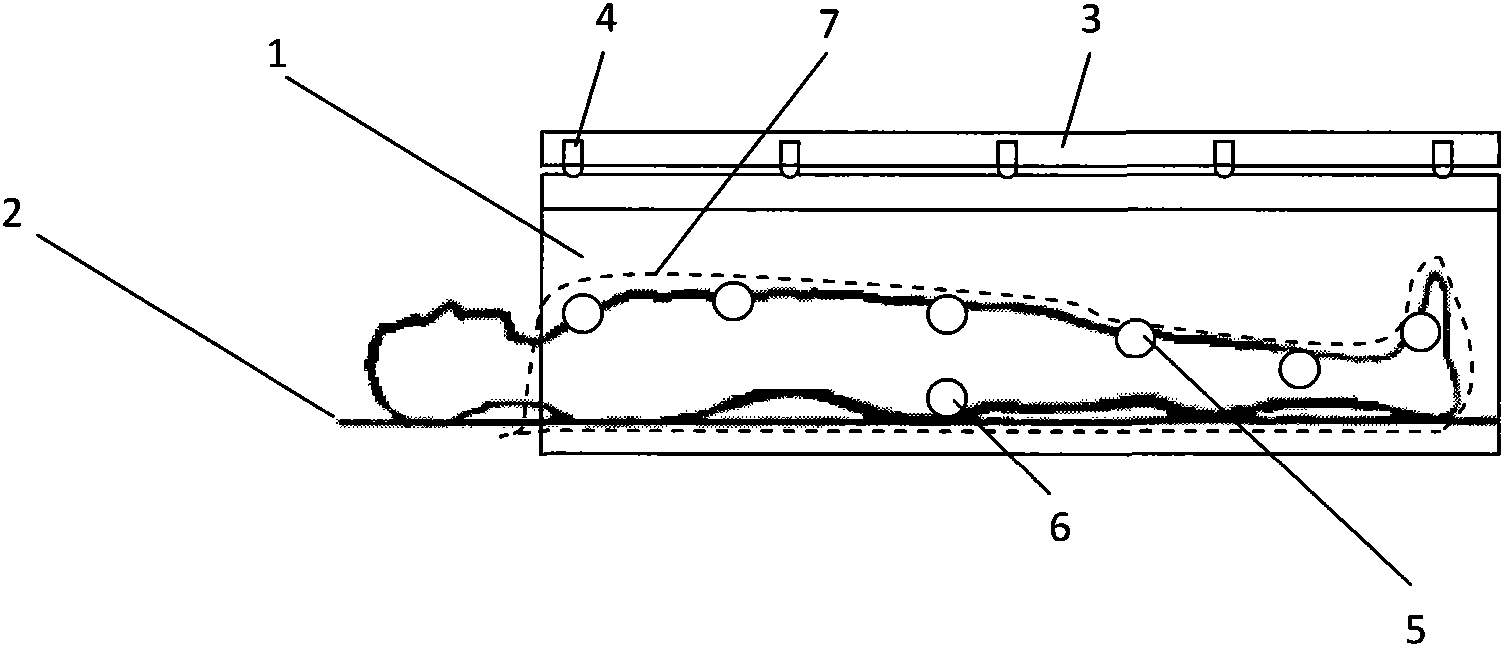

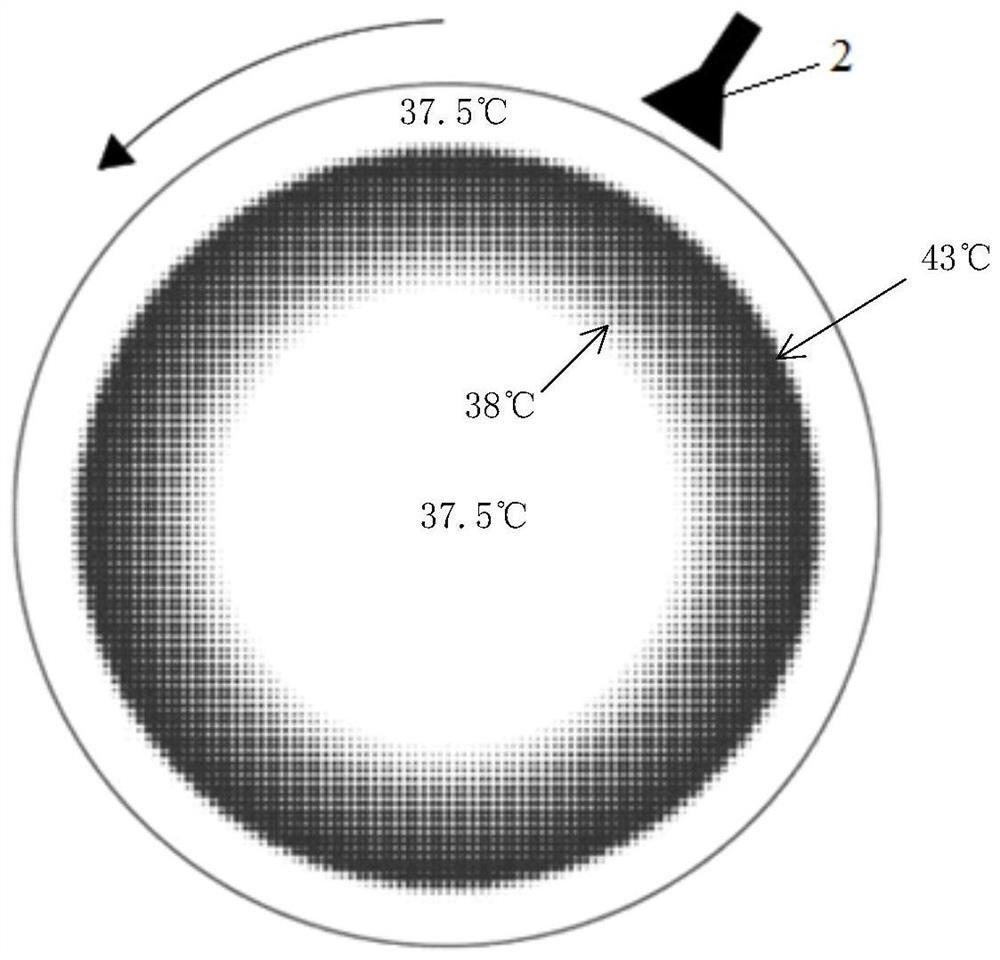

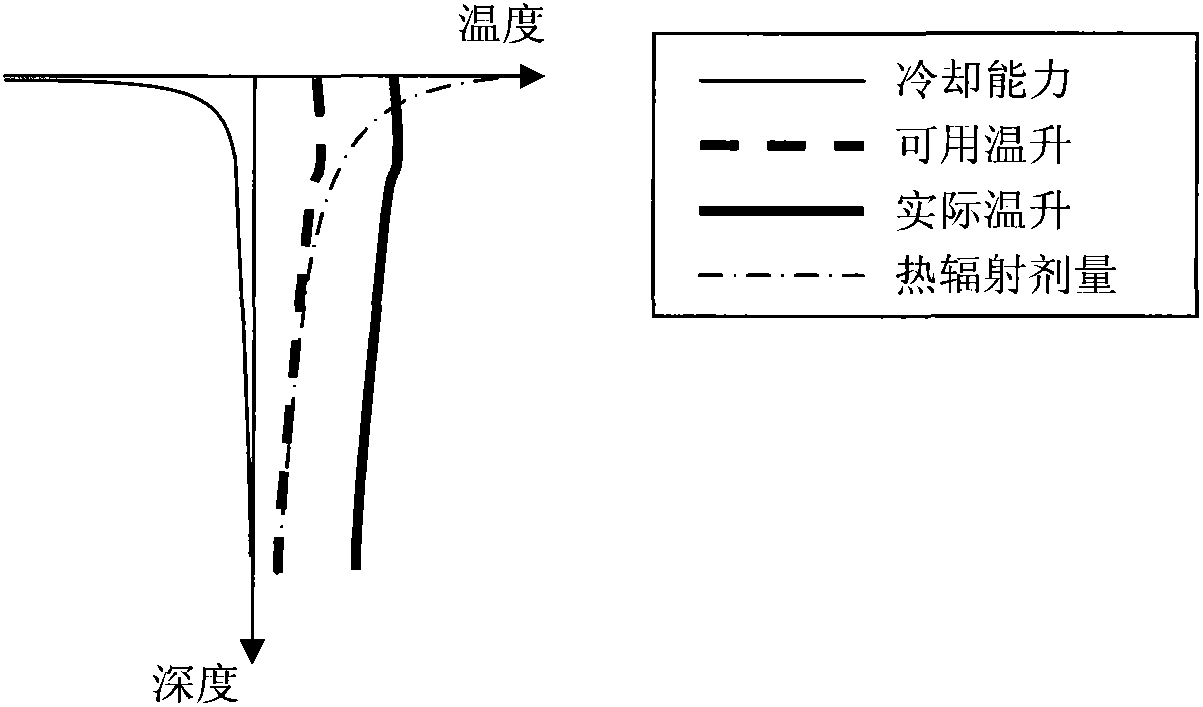

Surface-cooling non-invasive radiation whole-body thermocuring method

The invention relates to a surface-cooling non-invasive radiation whole-body thermocuring method, in particular to a non-invasive radiation whole-body thermocuring method by introducing a large amount of radiation power into the deep issues of human bodies quickly through surface-cooling technology to prevent surfaces from being burned and increase radiation power. In the method, a radiation heating system is combined with a surface-cooling system, so that low-attenuation electromagnetic radiation on the surfaces is taken away, and high dose of infrared, microwaves, radio frequency and energyradiation of electromagnetic wave probes of each frequency range are radiated to the deep parts of the human bodies for heating to realize the non-invasive radiation whole-body thermocuring. The method breaks through the technical route that improvement is performed through aspects of a heating mode, heat source control and the like in the prior art technically, introduces ultralow-temperature cooling for the first time to offset the local radiation of the surfaces and prevent overheating and empyrosis; simultaneously, the non-invasive radiation whole-body thermocuring is performed by utilizing a deep radiation heating source so as to improve power which can be accepted by organisms and prevent the surfaces from being burned substantially.

Owner:TSINGHUA UNIV

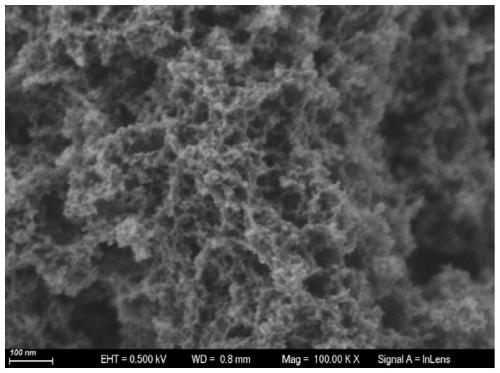

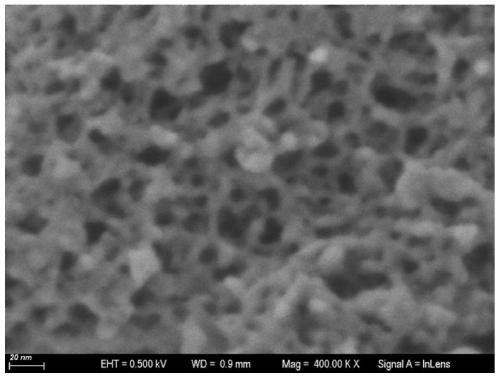

Fast preparation method of silicon dioxide aerogel

The invention provides a fast preparation method of silicon dioxide aerogel. According to the method, tetraethyl orthosilicate is used as a silicon source; low-concentration organic weak acid is added for catalyzed hydrolysis reaction; then, the condensation polymerization reaction and the hydrophobic modification of the gel are completed in one step through reasonably controlling the addition quantity of the nitrogen-containing silane, the dripping speed and the reaction time; the addition of basic catalysts is not needed; the consumption of a great number of replacement solvents in the general post hydrophobic modification method is avoided; waste liquid is not generated; the preparation period is greatly shortened; the process cost is reduced; the industrial production is easy; meanwhile, the prepared silicon dioxide aerogel product has excellent performance.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST +1

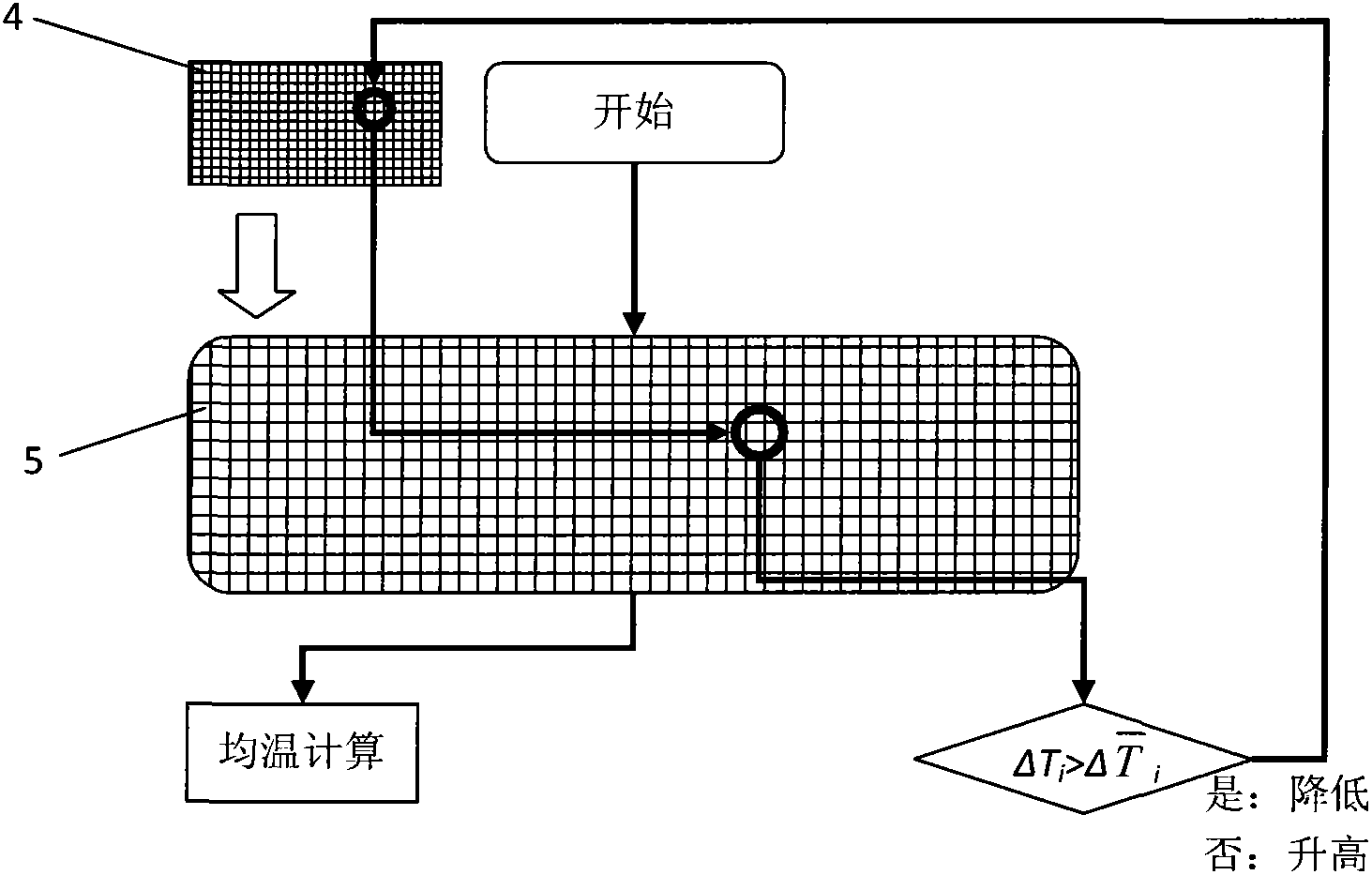

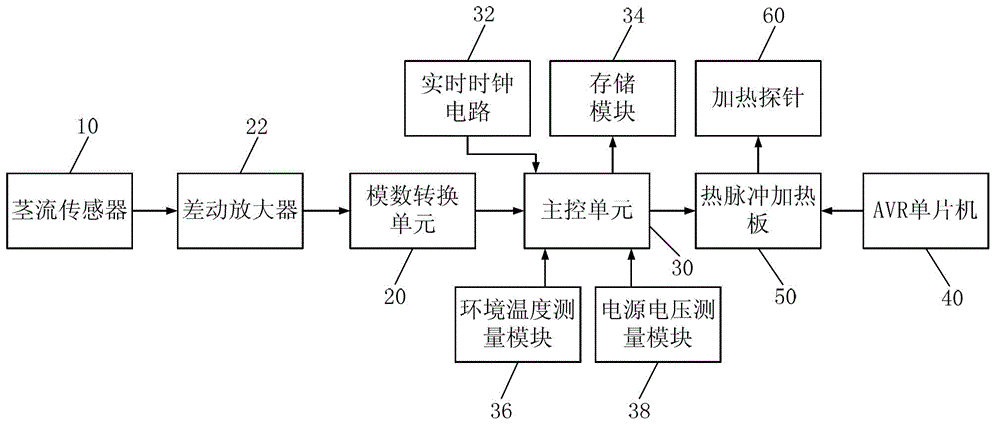

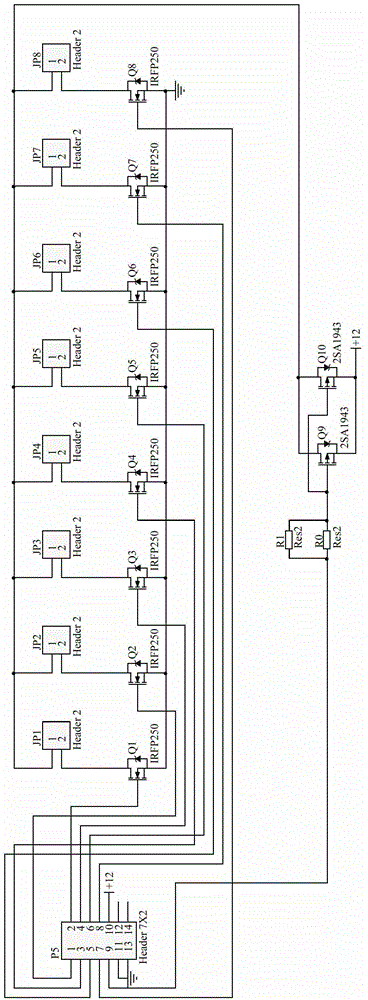

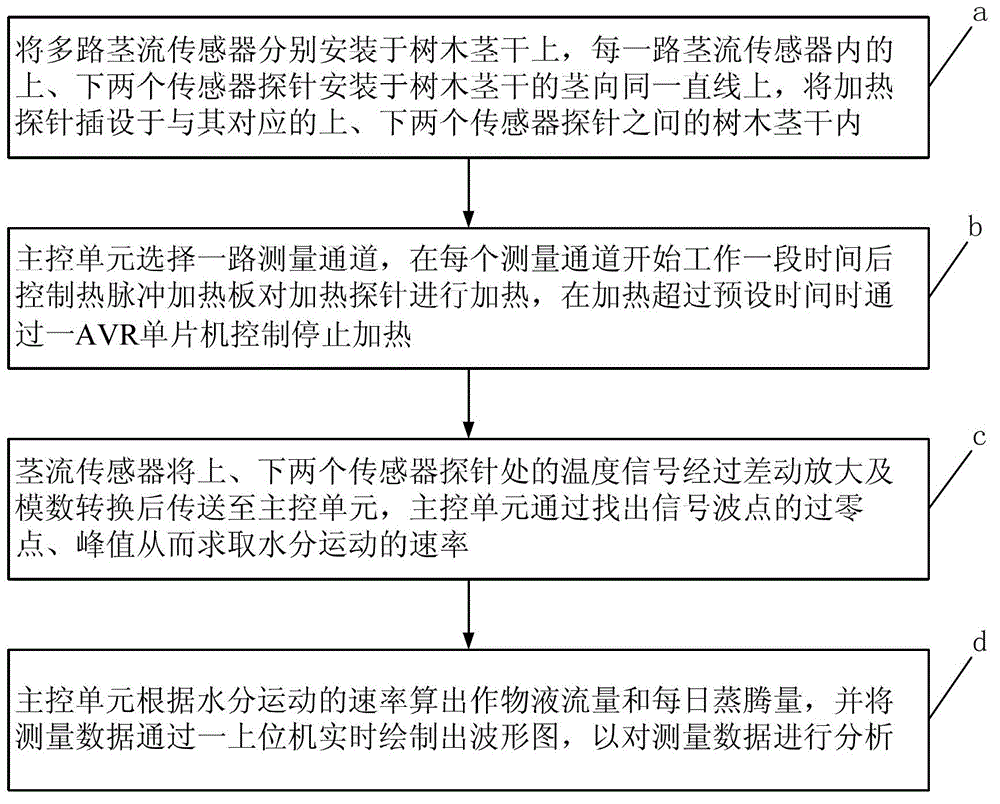

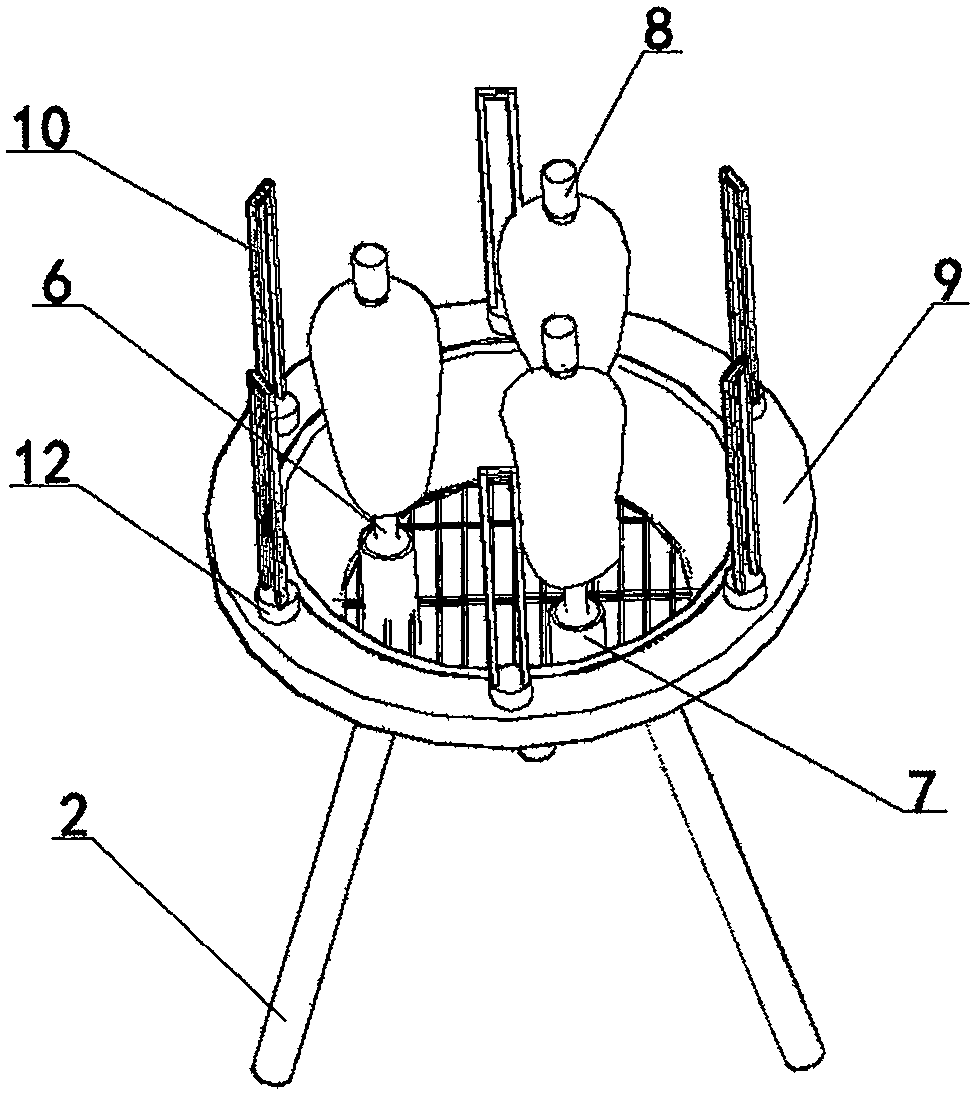

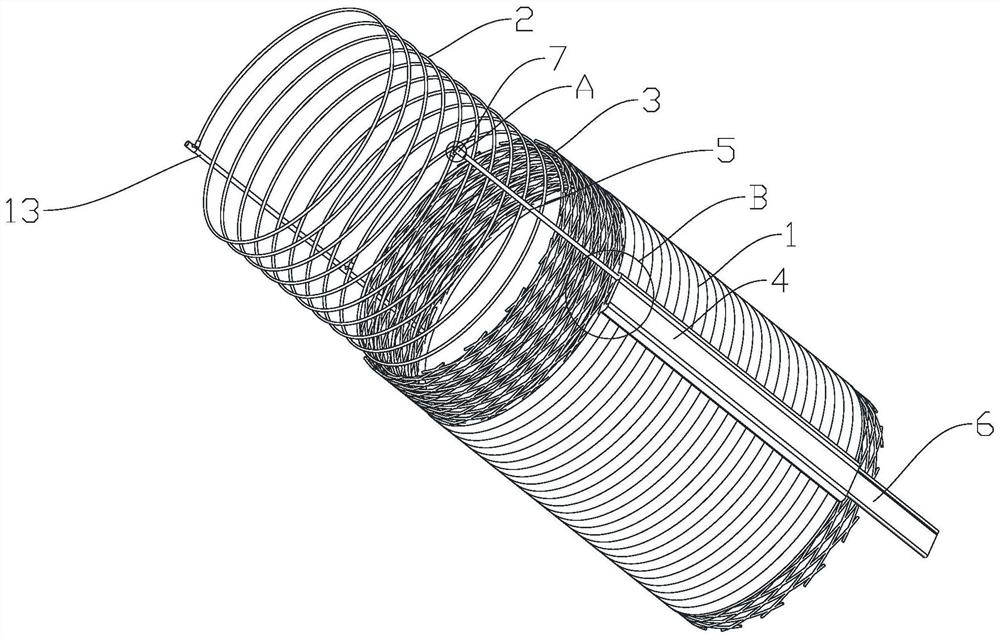

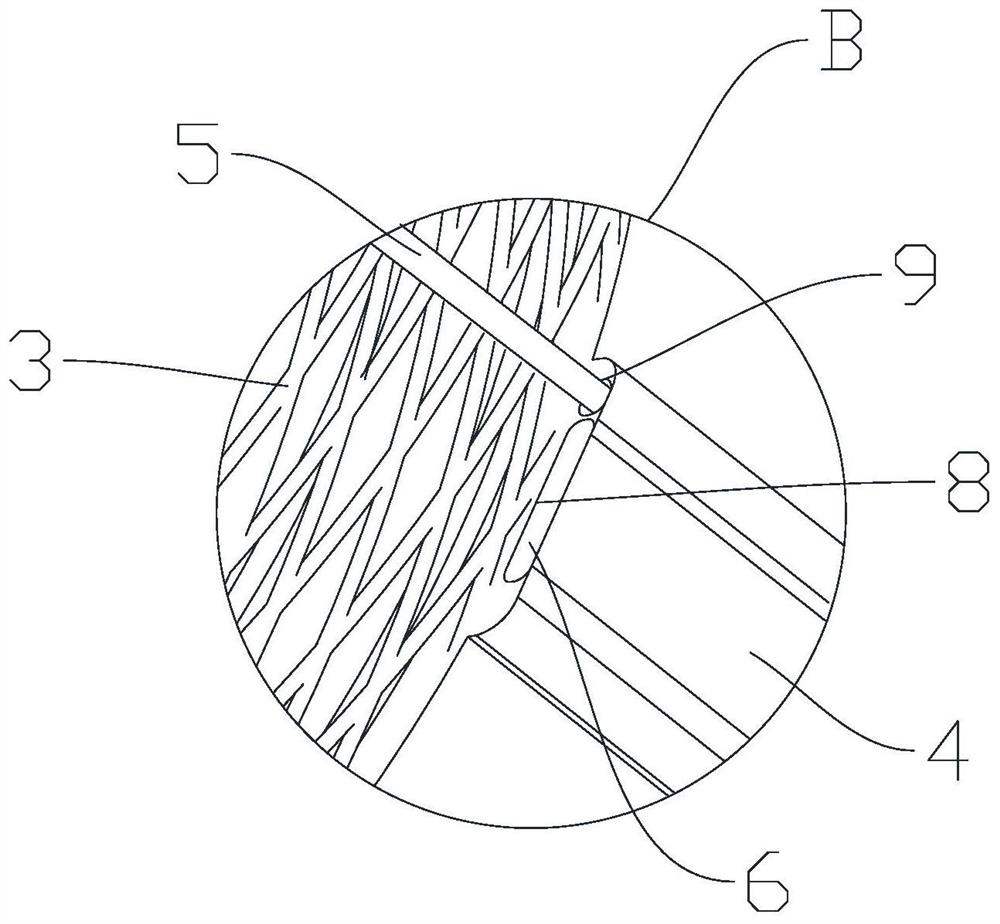

Tree heat pulse transpiration determinator and measuring method thereof

InactiveCN103149243AFlexible heating timeHeating controllableMaterial analysis by electric/magnetic meansMicrocontrollerThermal transpiration

The invention relates to the field of plant transpiration detection, and specifically discloses a tree heat pulse transpiration determinator and a measuring method thereof. The tree heat pulse transpiration determinator comprises multiple ways of stem flow sensors, an analog-digital conversion unit which is electrically connected with the stem flow sensors, a main control unit which is electrically connected with the analog-digital conversion unit, as well as an AVR (automatic voltage regulation) singlechip, wherein the main control unit and the AVR singlechip are respectively electrically connected with a heat pulse heating plate, and the heat pulse heating plate is respectively electrically connected with heating probes which are arranged corresponding to the multiple ways of stem flow sensors. The tree heat pulse transpiration determinator and the measuring method provided by the invention have the advantages that the power dissipation is low, the heat pulse heating time is flexible, the tree transpiration can be obtained by direct measurement, and the accuracy of measuring data is greatly improved.

Owner:NORTHWEST A & F UNIV

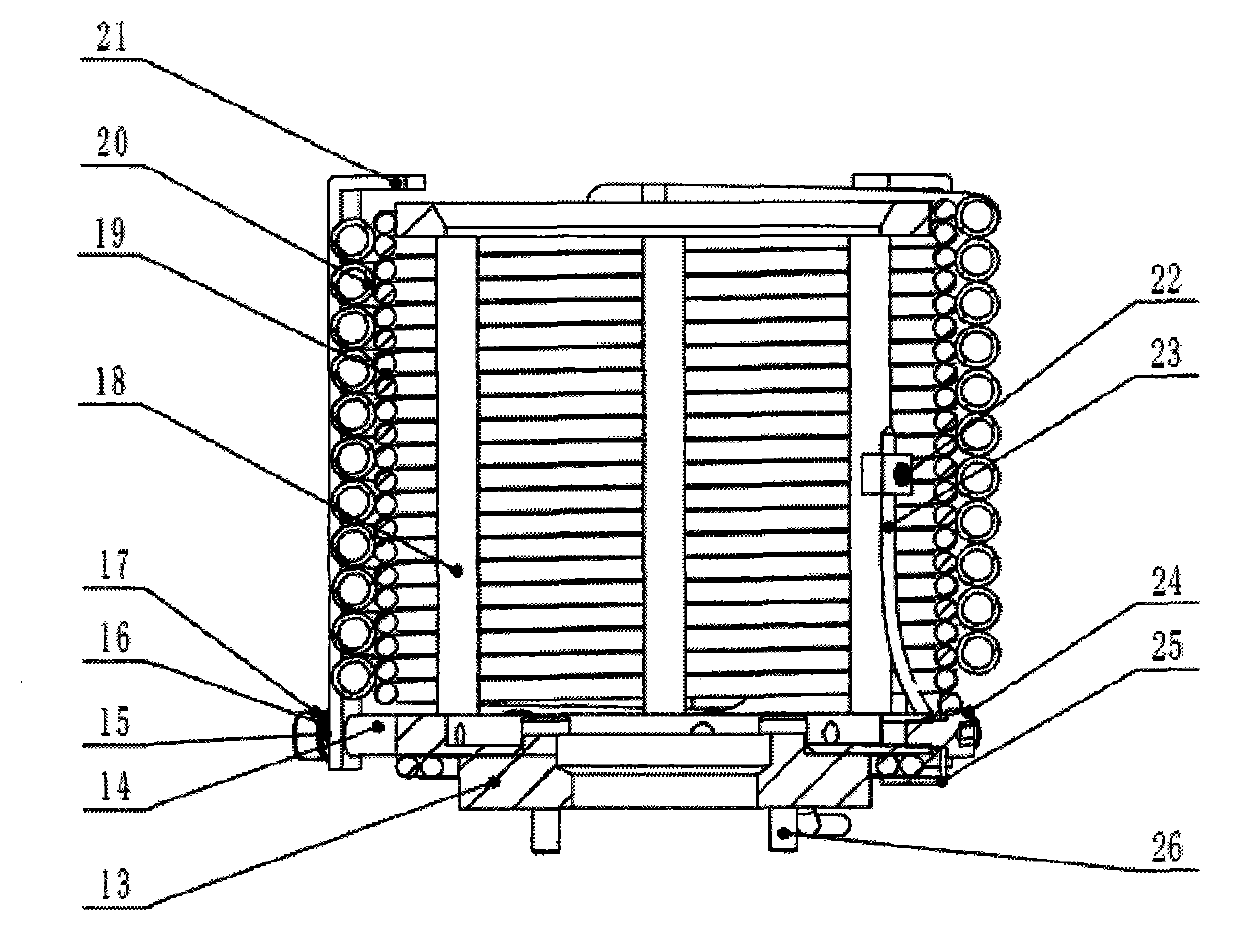

Vacuum refueling horizontal linear evaporation source

InactiveCN103966552AConvenient evaporation temperature and evaporation rateReduce volumeVacuum evaporation coatingSputtering coatingNonmetalEngineering

The invention relates to a vacuum refueling horizontal linear evaporation source. The evaporation source employs horizontal linear down-blowing evaporation, has evaporation width of 300 mm and is applicable to evaporation of nonmetal elements with a sublimation temperature of lower than 2500 DEG C. The vacuum refueling horizontal linear evaporation source has the advantages of a small size, a simple structure, low manufacturing cost, capacity of realizing on-line continuous supply or replacing of raw materials, multi-point and controllable heating of raw materials, etc.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

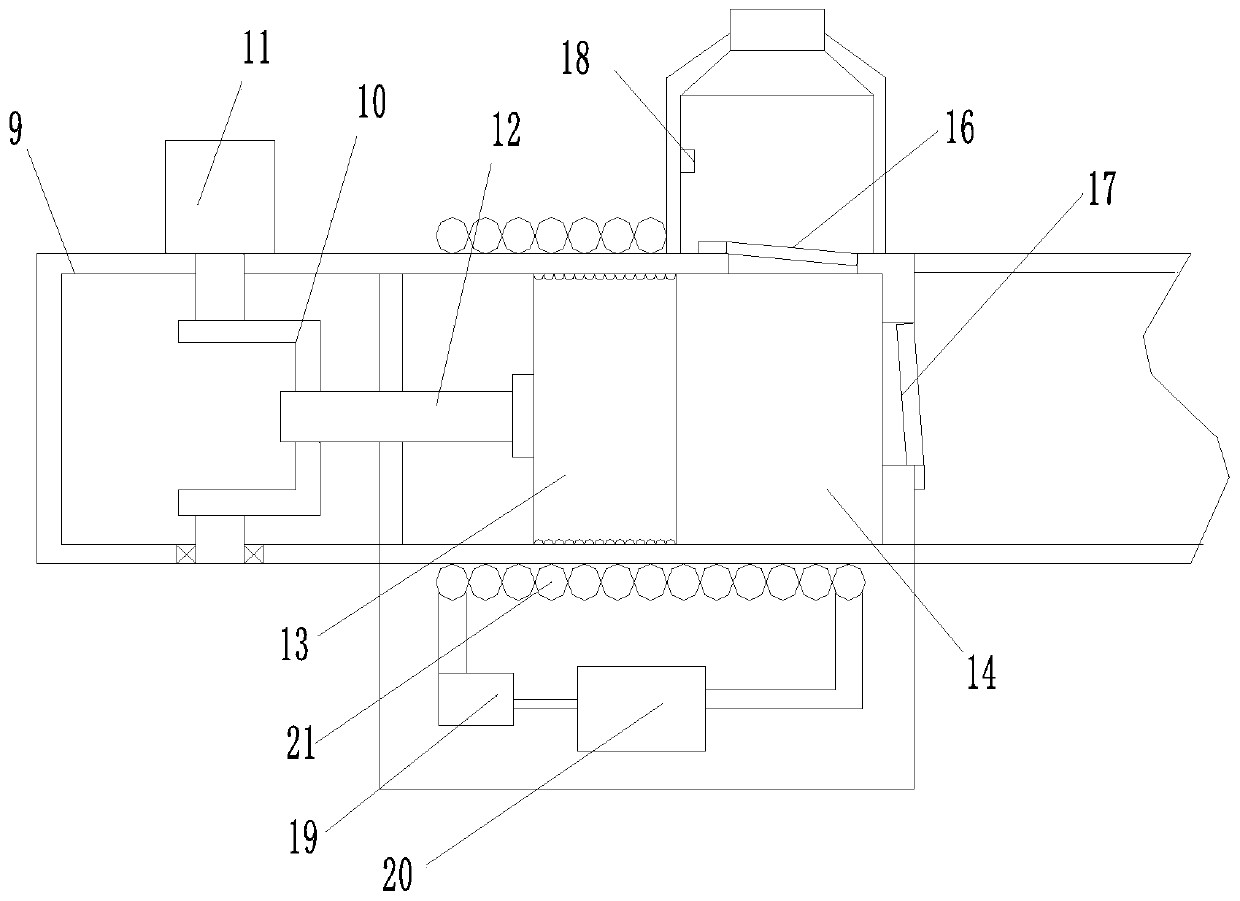

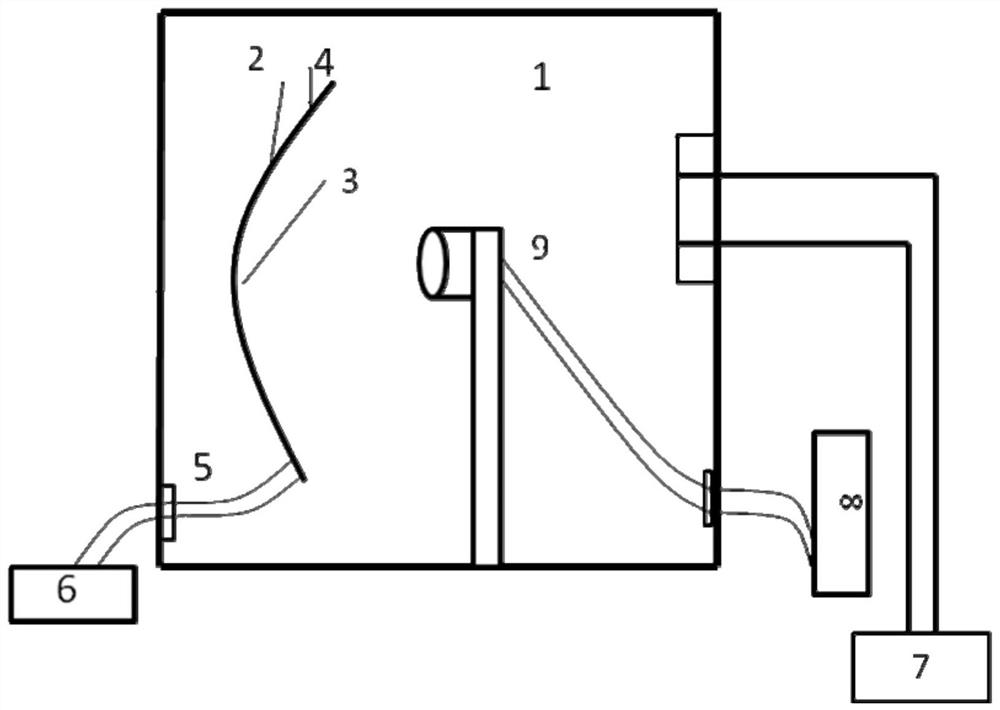

Minimum ignition energy testing device

PendingCN112461890AExplosive test reasonableTroubleshoot sampling issuesMaterial exposibilityDust explosionHeating system

The invention discloses a minimum ignition energy testing device which is characterized by comprising an explosion cavity, a heating system, a vacuumizing system, a gas supply system, a powder spraying system, an ignition system, a data acquisition system, a controller and a sample injection system, wherein the heating system, the vacuumizing system, the gas supply system, the powder spraying system, the ignition system, the data acquisition system and the sample injection system are all connected with the explosion cavity, the heating system and the powder spraying system are both connected with the controller, and the ignition system, the gas supply system and the powder spraying system are all connected with the data acquisition system. According to the invention, tests of different temperatures, ignition time, ignition energy, combustible mixture ratio and the like can be carried out, so that a basis is provided for industrial production dust explosion accident prevention; the problems of liquid sample loading and steam preparation are solved, and meanwhile, different proportions of inflammable steam and dust mixtures can be configured, so that the explosive test of the liquidsteam and dust mixtures is more reasonable.

Owner:GUANGZHOU SPECIAL MECHANICAL & ELECTRICAL EQUIP INSPECTION & RES INST

Modification method for improving saline tolerance of acrylic acid macromolecule water uptake resin

InactiveCN101402702AImprove salt toleranceIncrease salt water absorption rateWater bathsAmmonium peroxydisulfate

The invention relates to a modification method for improving the salt tolerance of a crylic acid macromolecule absorbent resin. The modification method for improving the salt tolerance of the crylic acid macromolecule absorbent resin is characterized by comprising the following steps: 1) according to the parts of all component raw materials by weight as follows: 90 portions to 140 portions of n-hexane, 30 portions to 50 portions of coconut oil diethanolamide, 20 portions to 40 portions of crylic acid, 5 portions to 12 portions of sodium hydroxide, 3 portions to 15 portions of calcium chloride, 0.03 portion to 1 portion of N, N'- methylene bisacrylamide, 0.05 portion to 1 portion of ammonium peroxydisulfate and 32 portions to 100 portions of water, raw materials are selected; 2) water is respectively mixed with the sodium hydroxide and the calcium chloride so as to obtain sodium hydroxide solution and calcium chloride solution; and 3) all raw materials are added into a reaction kettle with a water bath, the water bath temperature is risen to 70 DEG C to 80 DEG C, the raw materials are stirred for 4 hours to 6 hours at the temperature for reaction, finally a reaction product is taken out; and after being dried, the reaction product is the modified crylic acid macromolecule absorbent resin. The method can evidently improve the salt tolerance of the crylic acid macromolecule absorbent resin and has low production cost.

Owner:WUHAN UNIV OF TECH

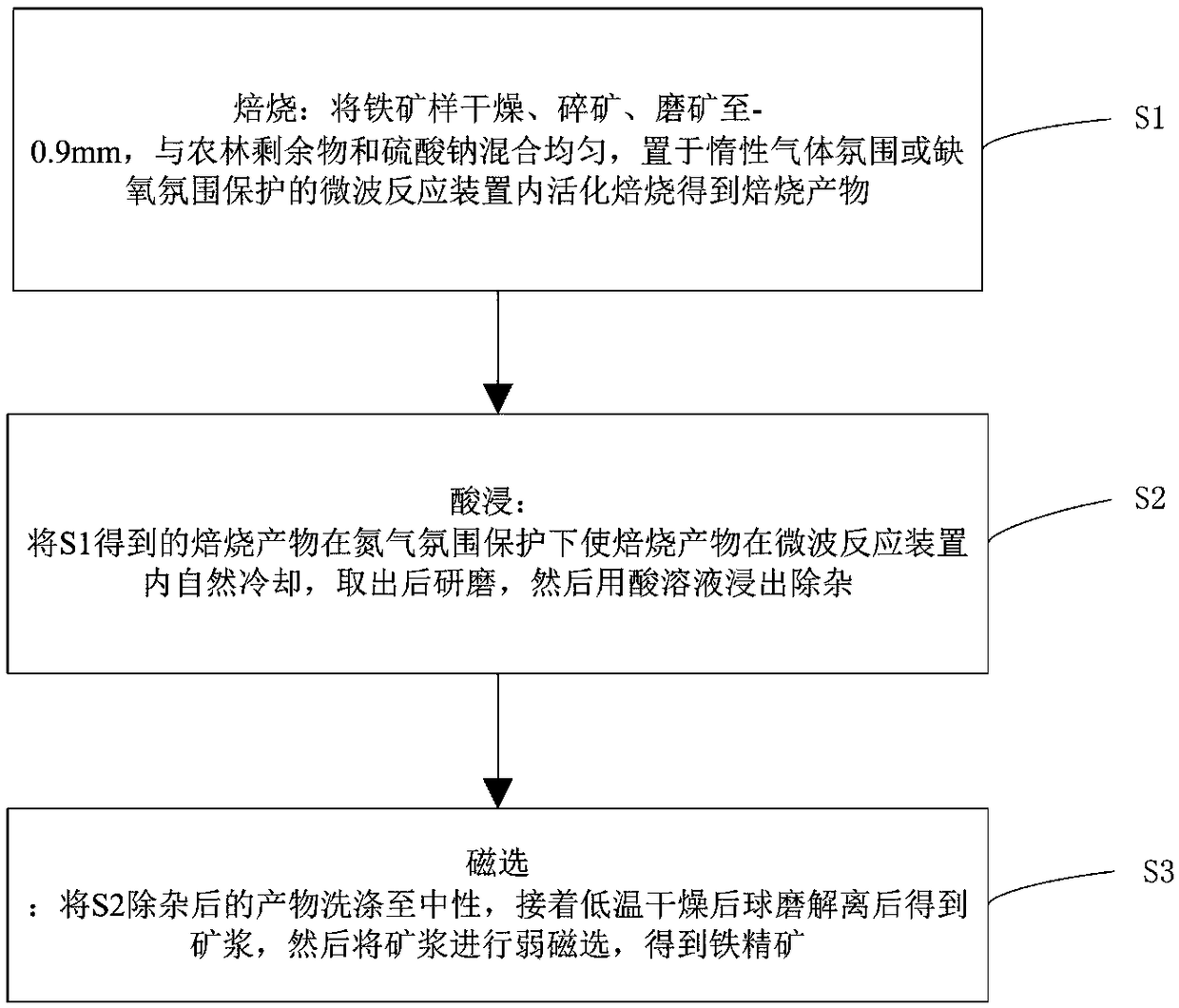

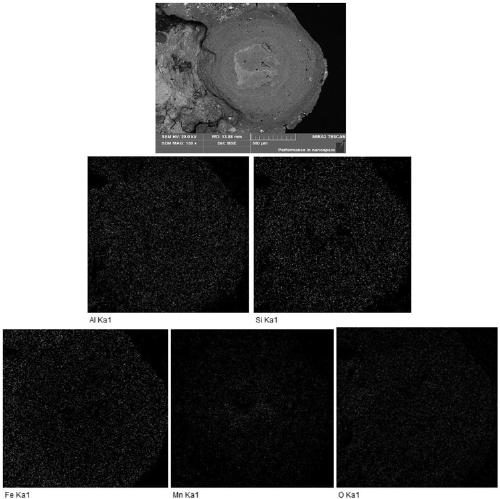

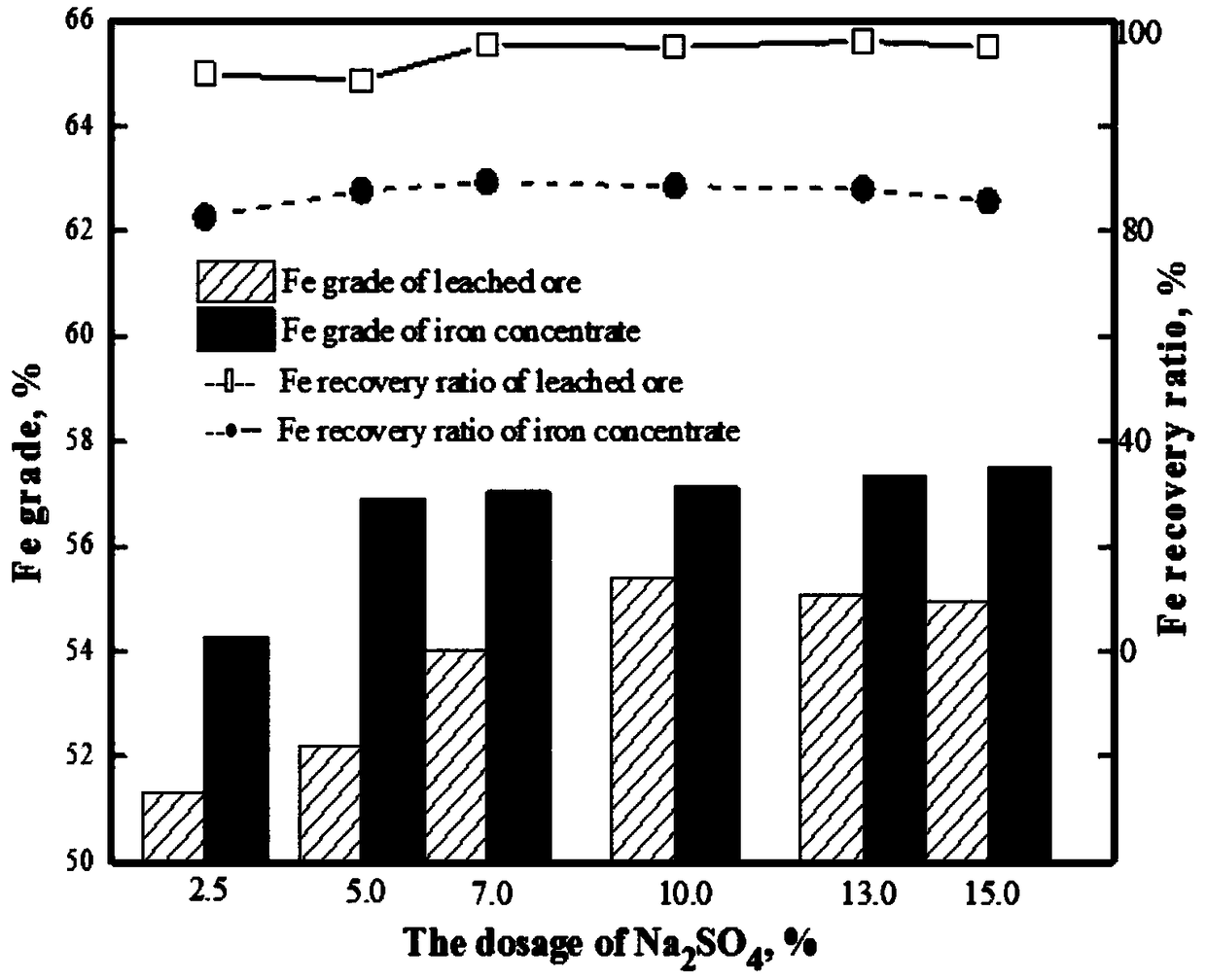

Beneficiation process for fine-particle-embedded silicate type iron oxide ore

InactiveCN108993770APromote aggregation and growthGood acid solubilityMagnetic separationProcess efficiency improvementBiological activationSodium sulfate

The invention discloses a beneficiation process for fine-particle-embedded silicate type iron oxide ore. According to the beneficiation process, agriculture and forestry residues and sodium sulfate are adopted as activating and roasting additives, microwave is used as a heating heat source, the magnetic property of the iron ore is enhanced efficiently with lowenergy consumption, the micro-particle-embedded silicate type gangue minerals can generate activation in the roasting process and react with the sodium sulfate to generate an acid-soluble substance, and then the coarse separation of the gangue minerals and the iron minerals is realized through an acid dissolving process; and in addition, due to addition of the sodium sulfate in the roasting process, the growth of the iron ore particles can be promoted, the ore grinding process is improved, and the magnetic separation index is strengthened. The process can effectively solve the problems that the iron grade in the fine-grain silicate type iron ore is low, the monomer dissociation is difficult, the roasting energy consumption is high and the like, and the process has the advantages of being simple in technological process, wide in auxiliary raw material source, low in cost, easy to control reaction and the like, and can be used for solving the problems of difficulty in dissociation, poor product quality and the like caused byother silicate micro-particle embedding.

Owner:HUNAN AGRICULTURAL UNIV +1

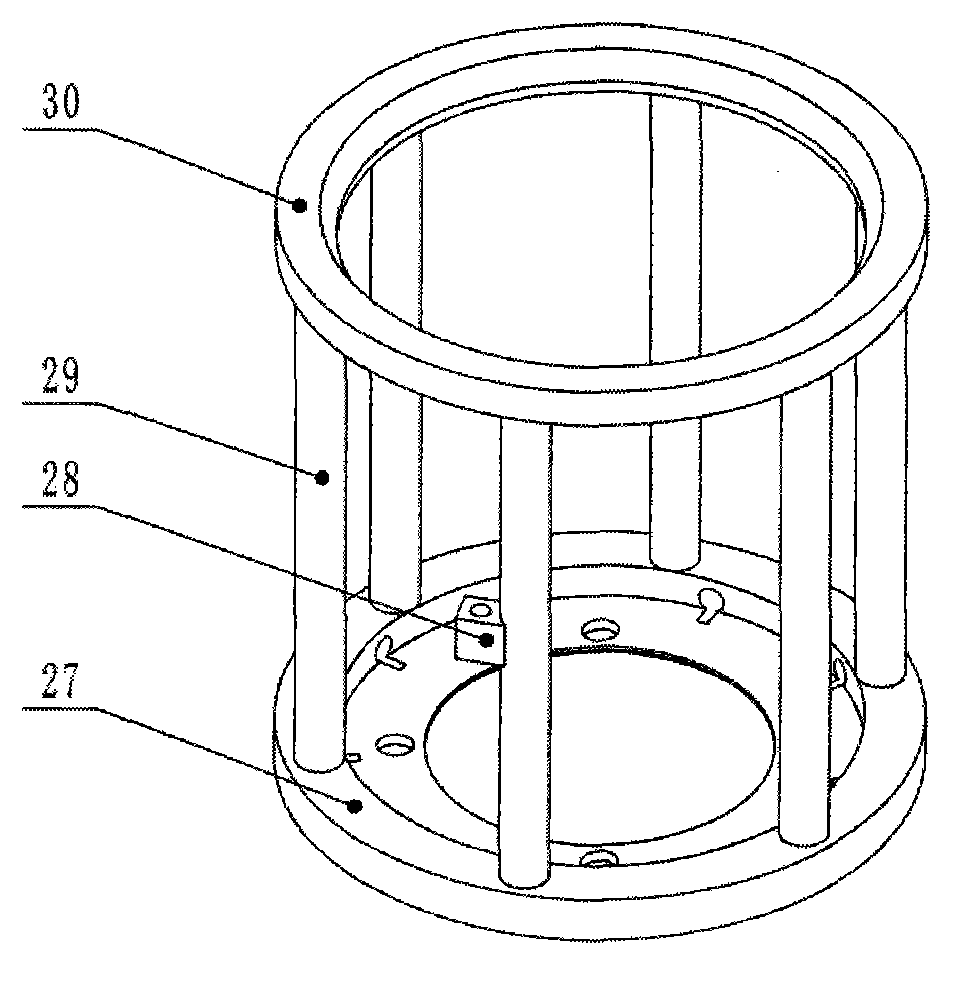

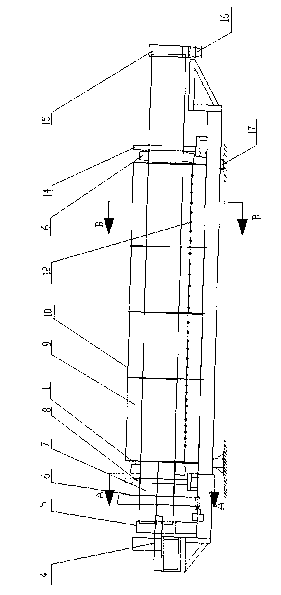

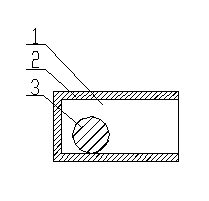

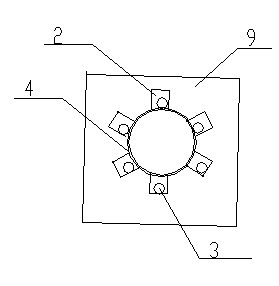

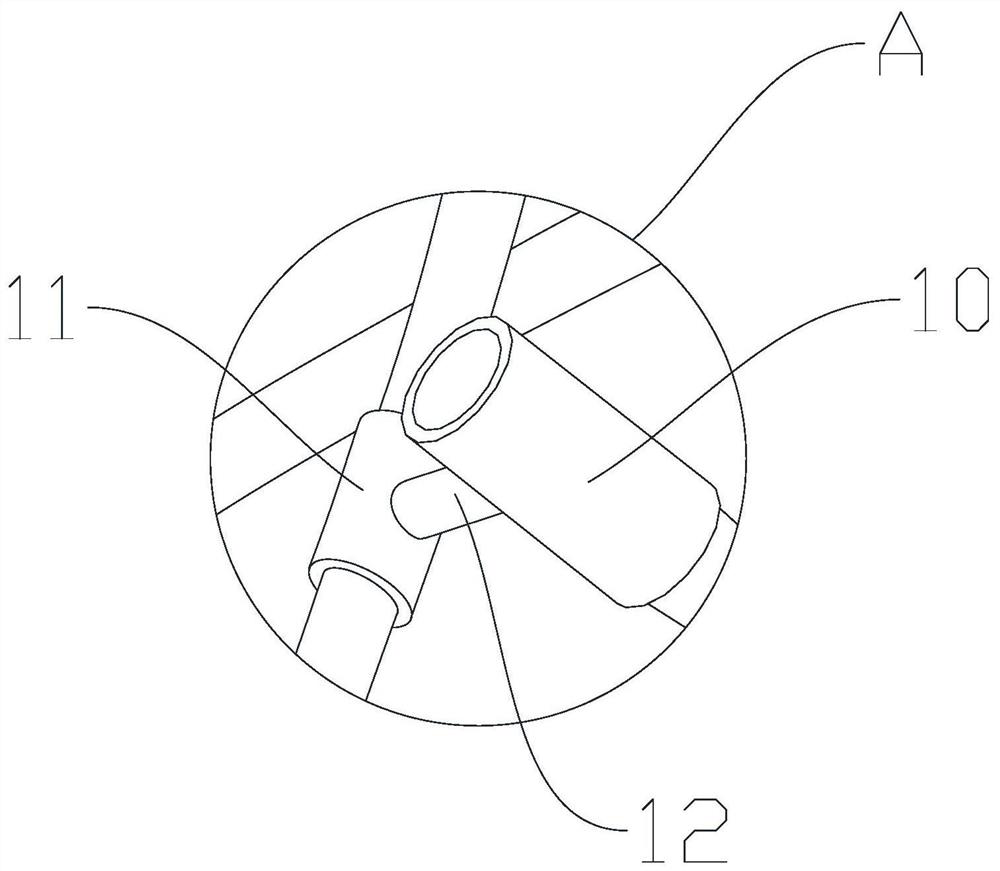

Percussive device of rotary kiln

InactiveCN103105056AHeating is fully controllableHeating controllableRotary drum furnacesEngineeringHeating furnace

The invention relates to a percussive device of a rotary kiln. The percussive device of the rotary kiln comprises a hollow cavity and a ball body, the ball body is flexibly arranged inside the hollow cavity, one end of the hollow cavity is fixed in the external wall of a heating furnace barrel of the rotary kiln, the ball body and the external wall of the heating furnace barrel of the rotary kiln are in a spaced percussive state, the hollow cavity is polyhedron-shaped, or cylinder-shaped or cage-shaped, and the hollow cavity is vertically fixed on the external wall of the heating furnace barrel of the rotary kiln. The percussive device of the rotary kiln enables materials to leave the internal wall of the heating furnace barrel quickly, and ensures that material heating inside the heating furnace barrel is completely controllable, and therefore bonding and scorch of the materials in the inner wall of the heating furnace barrel are avoided, and quality and yield coefficient of calcined products are guaranteed, and meanwhile service life of the rotary kiln is prolonged, and production cost of the products is reduced.

Owner:TAIXING SMELTING PLANT

Transformer for reservation type water heater

InactiveCN101814364AHeating controllableIncrease heating rateFluid heatersTransformersHeating timeTransformer

The invention provides a transformer for a reservation type water heater. The transformer is provided with a plurality of voltage positions; an output end of each position is connected to a corresponding heating rod; the plurality of positions can be superimposed in use; and each voltage position corresponds to a heating time range which is calculated by a central computer controller according to factors such as actual environmental temperature. Each time the water heater is reserved to heat, the water heater can automatically select one voltage position for heating according to an input preparation time, cuts off a power supply when heating to the required position, and displays a prompt for completing heating at a remote control end simultaneously; after confirmation, the transformer can cut off all heating circuits automatically; and otherwise, the water heater enters a constant temperature protection mode. The invention has the advantages of adopting a multi-level heating direct-heating transformer, connecting the tail end of the transformer to an electric heating rod directly for heating water, improving the heating efficiency, along with easy control, high speed and convenience.

Owner:蔡建林

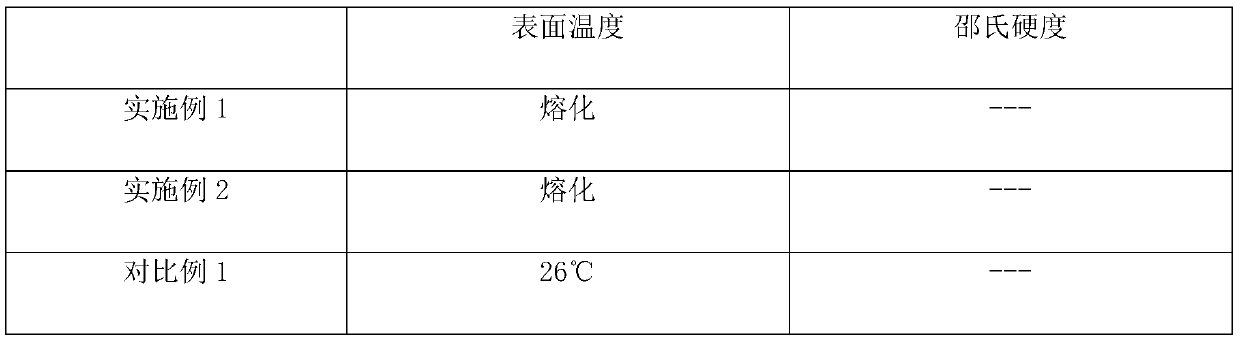

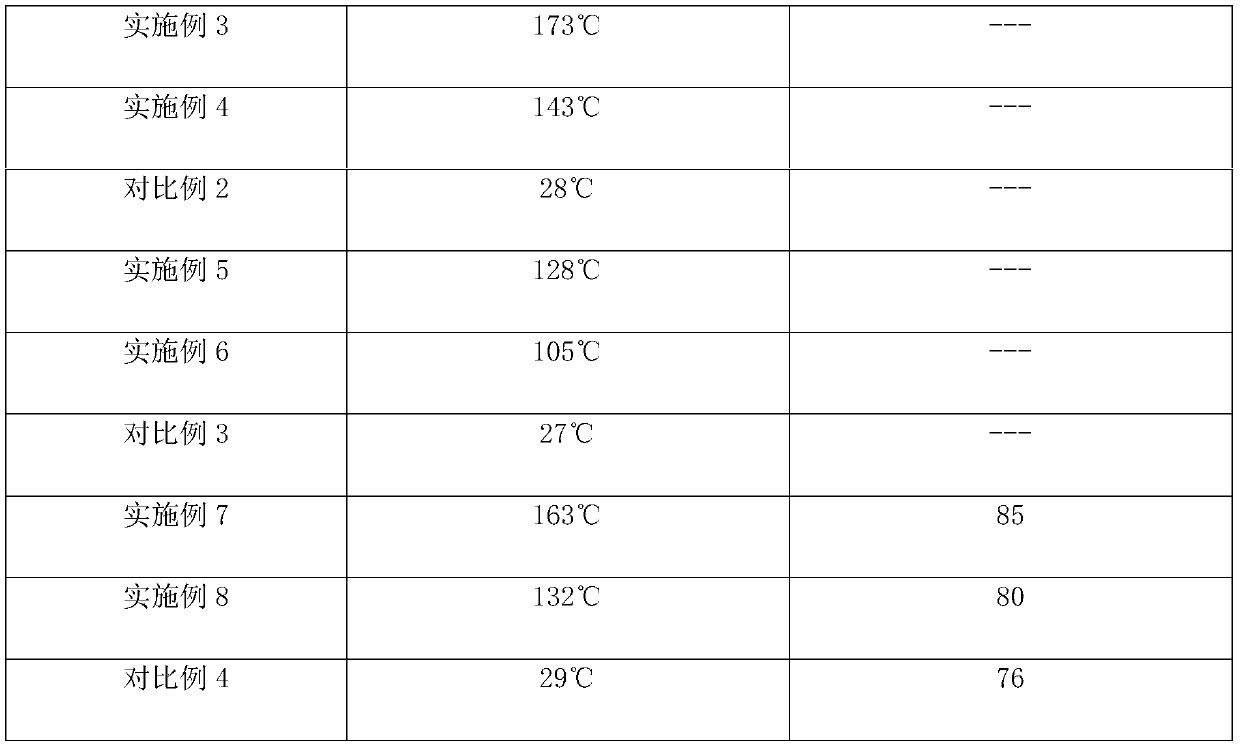

A method for efficiently heating polymers using microwaves

The invention discloses a method for efficiently heating a macromolecular polymer by microwave. The method comprises adding a small amount of a dielectric loss ceramic material with high microwave absorbing efficiency into a macromolecular polymer or its monomer or its oligomer so that the traditional low dielectric loss microwave transparent macromolecular polymer unable to heat with microwave and its monomer and oligomer can be rapidly heated under the action of microwave. The method realizes fast, controllable and uniform heating of the macromolecular polymer and its monomer and oligomer, improves production efficiency, improves product quality, reduces energy consumption and increases the automatic control easiness. The used microwave-sensitive additive is a ceramic material with high microwave absorbing properties and satisfies fast heating requirements under the condition of a small use ratio of 0.1-5% based on the macromolecular polymer volume. The method produces small influence on polymer performances and has a wide application range.

Owner:BAMSTONE NEW MATERIAL TECH (WUHAN) CO LTD

Electromagnetic heating rotary kiln with function of controlling reducing atmosphere

ActiveCN110836599AAvoid severe corrosionExtended service lifeRotary drum furnacesControl systemEngineering

The invention discloses an electromagnetic heating rotary kiln with the function of controlling reducing atmosphere, and belongs to the field of rotary kilns. The electromagnetic heating rotary kiln comprises a feeding portion, a main kiln portion and a discharging portion. The feeding portion and the discharging portion are in sealed connection to a front port and a rear port of the correspondingmain kiln portion correspondingly. The main kiln portion comprises a core resisting to high-temperature oxidization, a rear-end gas conveying device and a front-end tail gas exhaust device. The coreis made of a Cr-Ni-Mo-W-Fe-Si alloy material. The left portion of the core is lower than the right portion of the core, and a protection cover is arranged on the outer side of the core. A gap is reserved between the core and the protection cover, and an electromagnetic induction heating structure is arranged in the gap. The electromagnetic induction heating structure generates vortexes on the electric conduction core to emit heat, the heat is transmitted to materials turning over in the core, reduction gas is controllably input from the left end of the core through the rear-end gas conveying device under the action of a control system, and then tail gas generated after reacting in the whole core is controllably exhausted from the rear end of the core through the front-end tail gas exhaustdevice under the action of the control system.

Owner:上海江竑环保科技有限公司

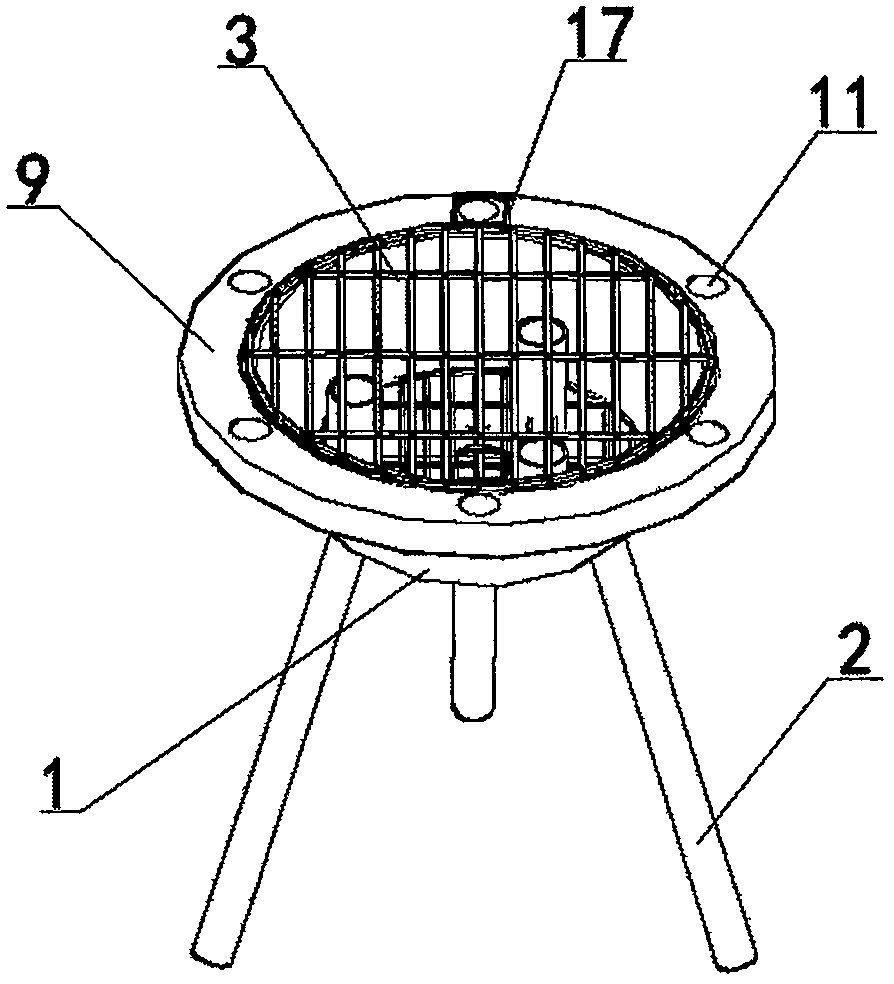

Household picnic barbecue oven with three barbecue modes

InactiveCN107713798AHeating controllableHeating evenlyFood scienceUltimate tensile strengthGrilled food

The invention relates to a barbecue oven for family picnics with three barbecue modes, comprising a furnace body, three furnace body legs, auxiliary heating components, a grill net, a charcoal net, a storage cylinder, a hanging grill component and three barbecue rods; The furnace body has a hemispherical structure. The auxiliary heating component includes a ring base and six electric heating rods. The electric heating rod includes a U-shaped rod body and a plug that can be used with a two-hole socket. The storage cylinder has six electric heating rod passages, three barbecue rod passages, three outrigger passages and one roasting rod passage arranged along its axial direction. The barbecue oven of the present invention can not only roast some small food materials, but also can barbecue some larger food materials, and the heating of the barbecue oven is more uniform, and the heating intensity can also be adjusted according to the specific conditions of the barbecue food materials.

Owner:陈家龙

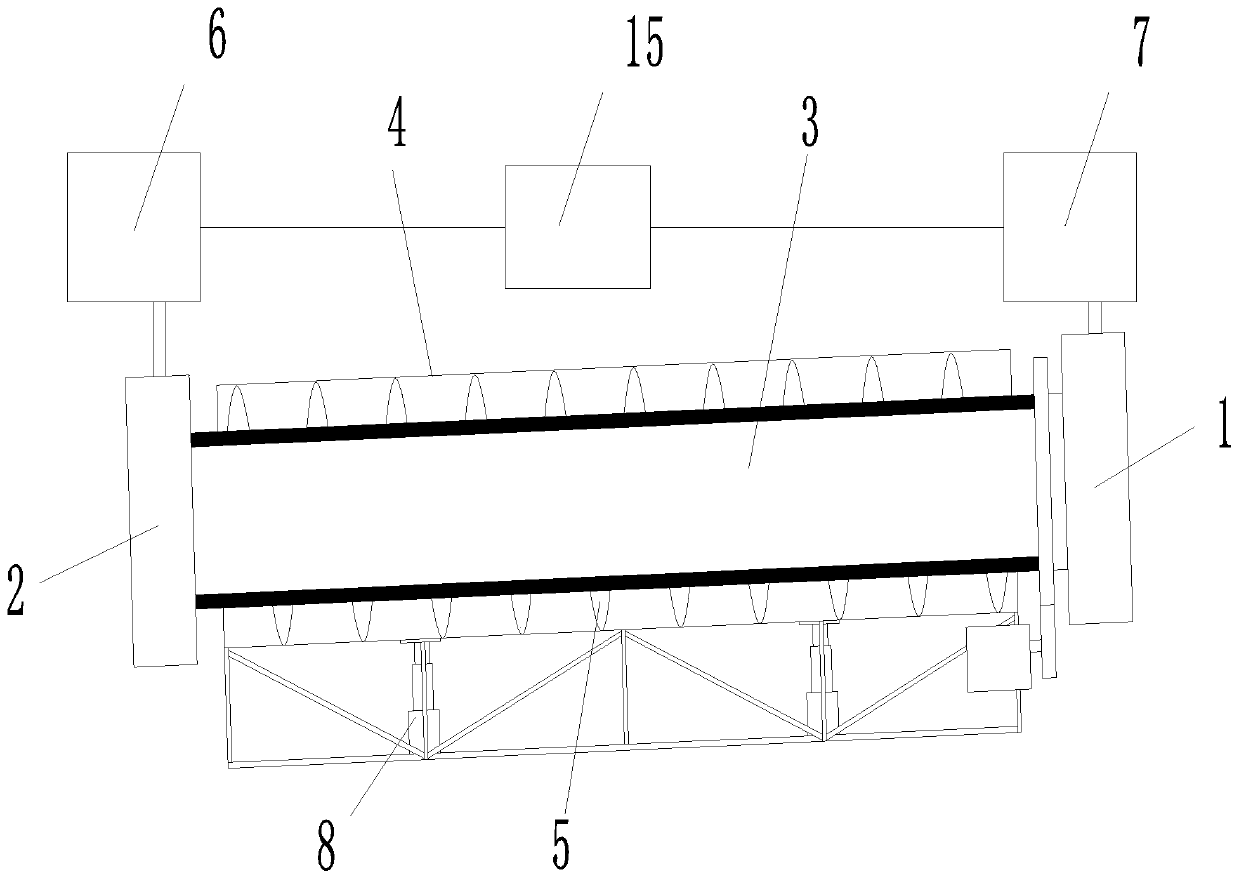

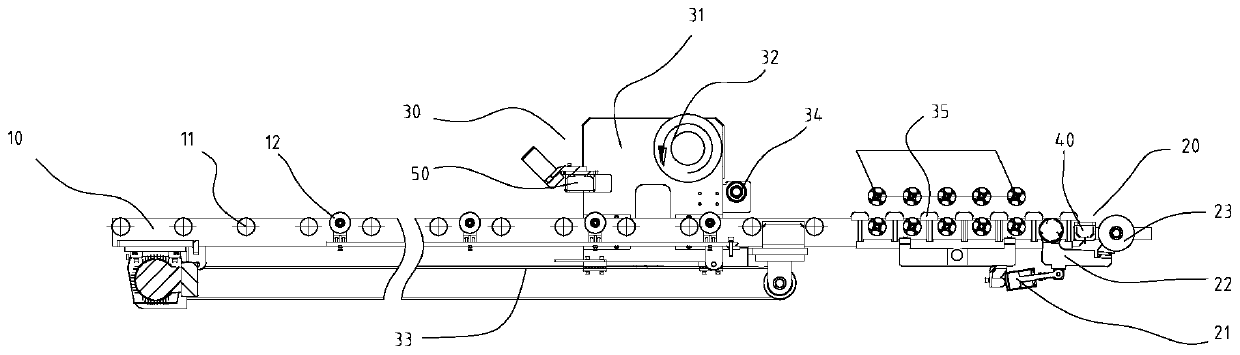

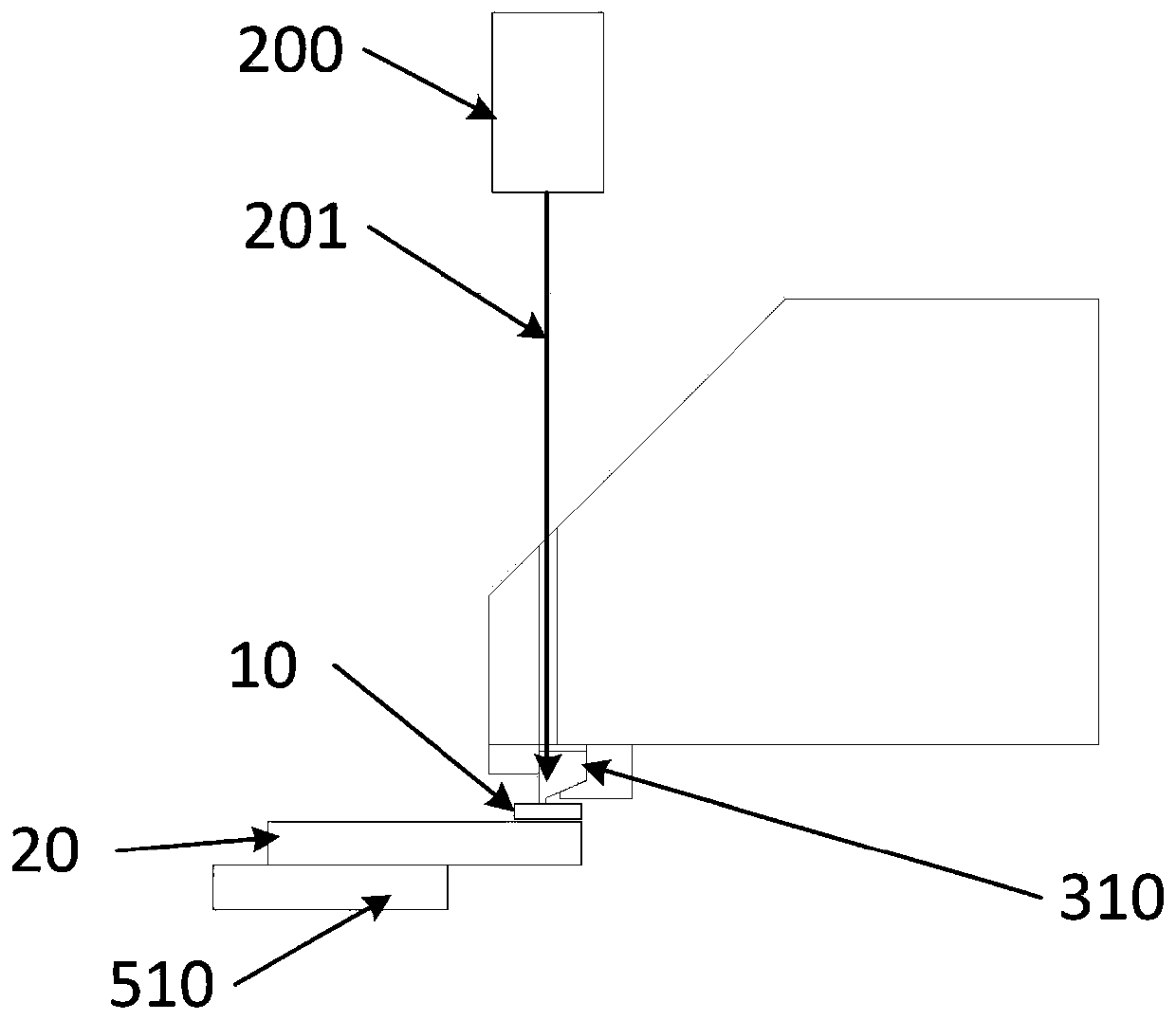

Film tearing system for tread rubber

PendingCN110937201AHeating controllableRealize semi-automatic strippingArticle unpackingEngineeringMechanical engineering

The invention provides a film tearing system for tread rubber. The film tearing system comprises a frame body, a film tearing device, a first heating device and a second heating device; a pressing attaching device is arranged at the first end of the frame body and is used for fixing the first end of the tread rubber; the film tearing device is movably arranged on the frame body, a film tearing roller is arranged on the film tearing device, a to-be-torn preservative film winds around the film tearing roller, and the film tearing device moves from the first end of the frame body to the second end of the frame body; the first heating device is arranged at the first end of the frame body; and the second heating device is arranged on the film tearing device and can heat the second end of the tread rubber under the condition that the film tearing device moves to the second end of the frame body. The second heating device moves along with the film tearing device, the second heating device starts heating when moving above a material tail, and the first heating device can heat the first end of the tread rubber at any time. According to the film tearing system, on the premise that the lengthof the frame body is not increased, the film tearing roller and the second heating device are integrated, so that semi-automatic stripping of the preservative film and simultaneous controllable heating of the front and back edges of the tread rubber are realized.

Owner:MESNAC +1

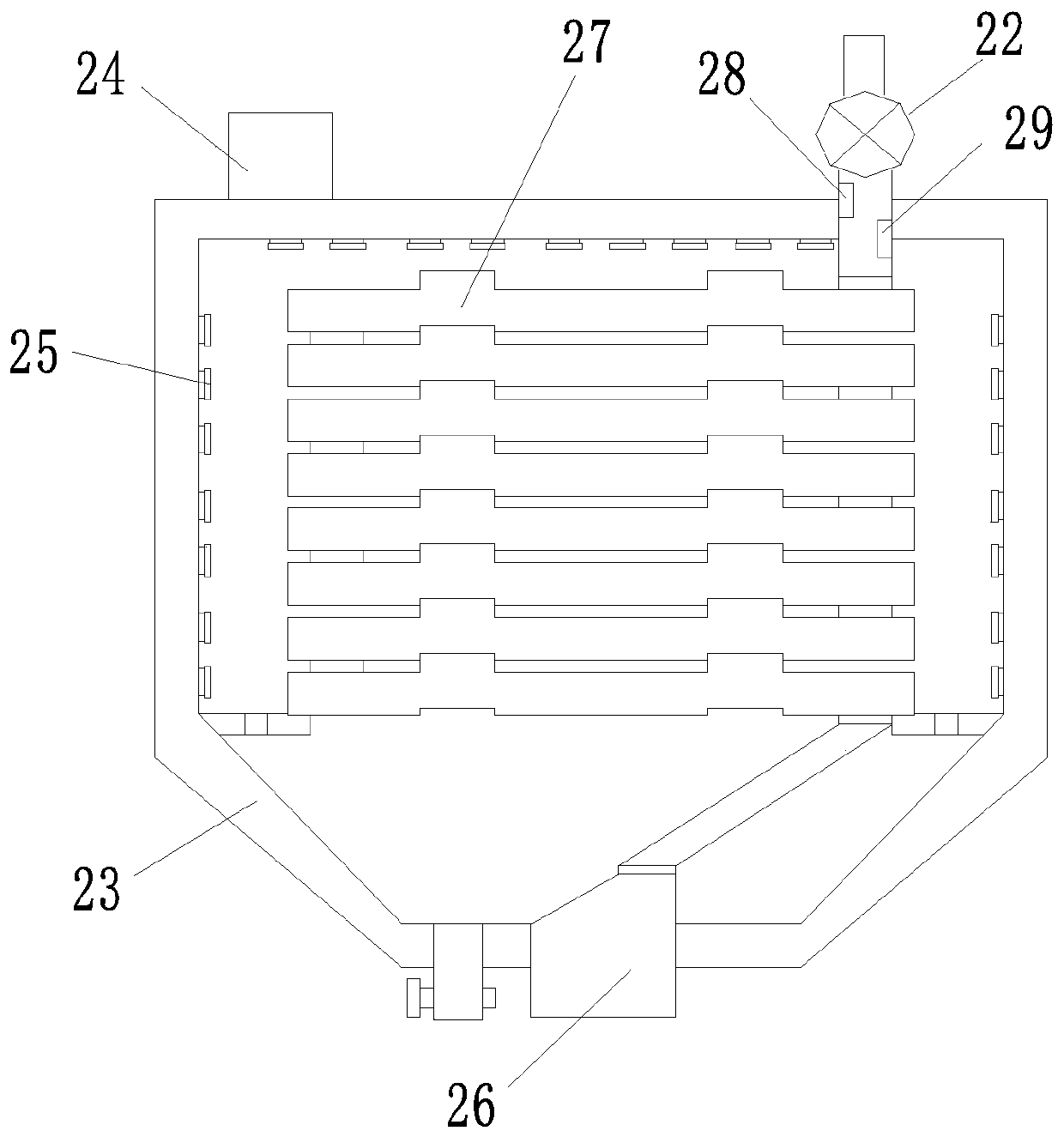

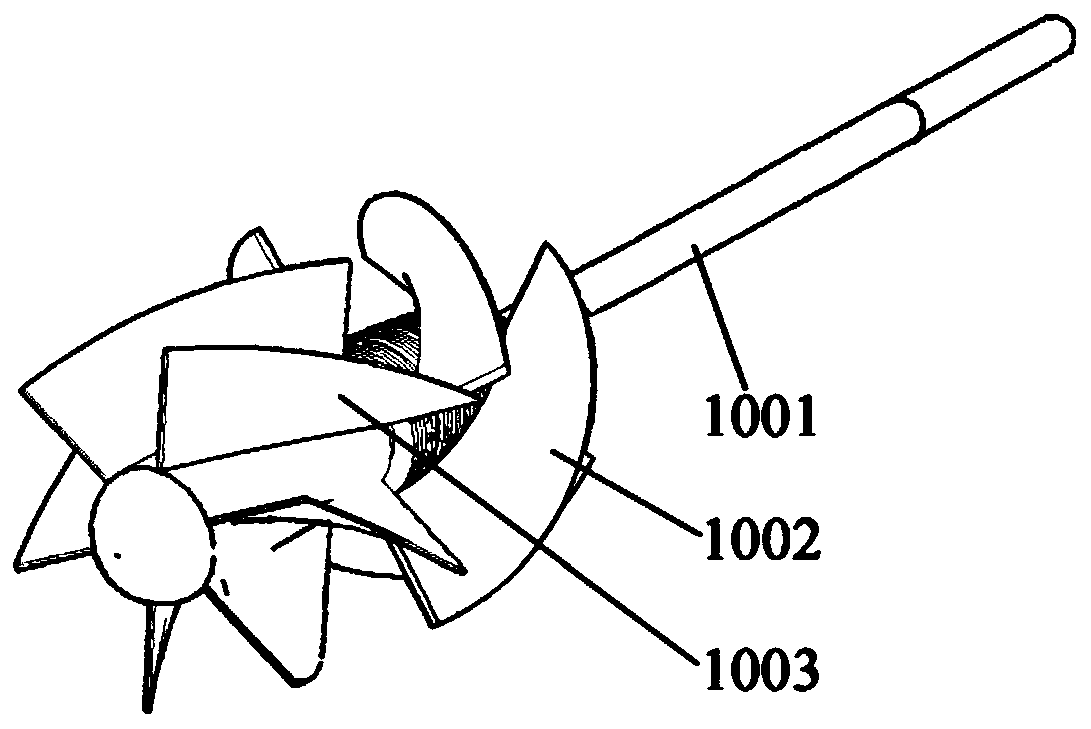

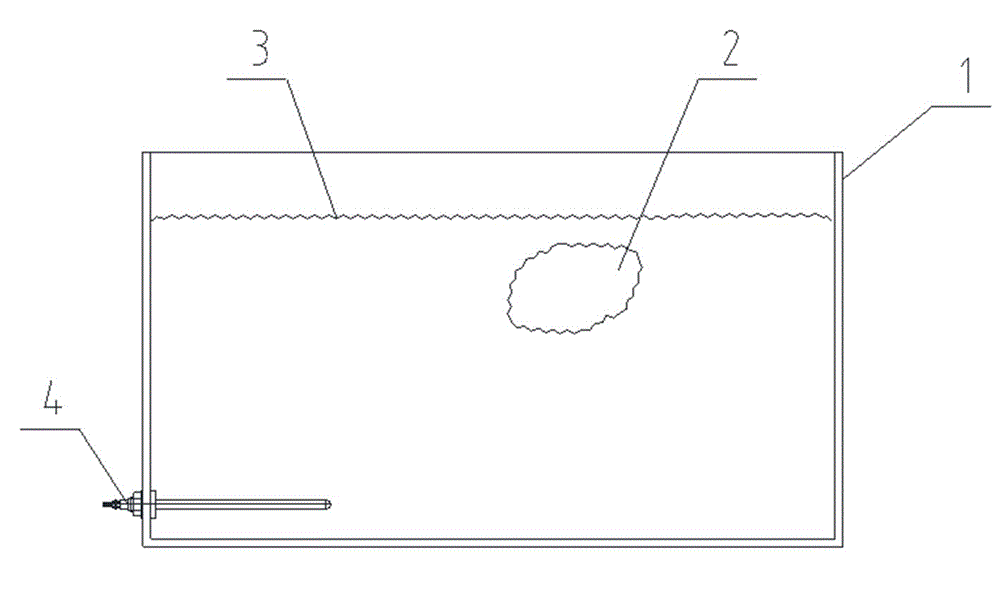

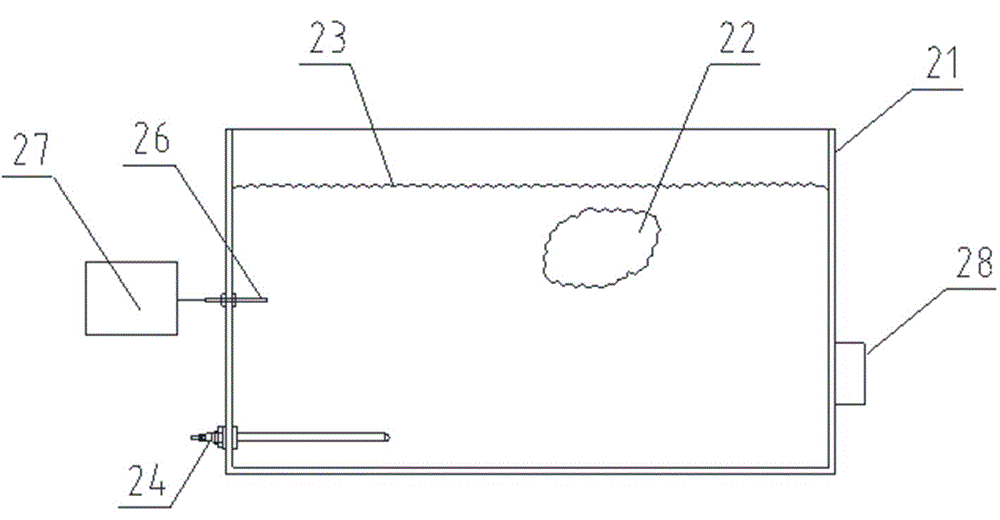

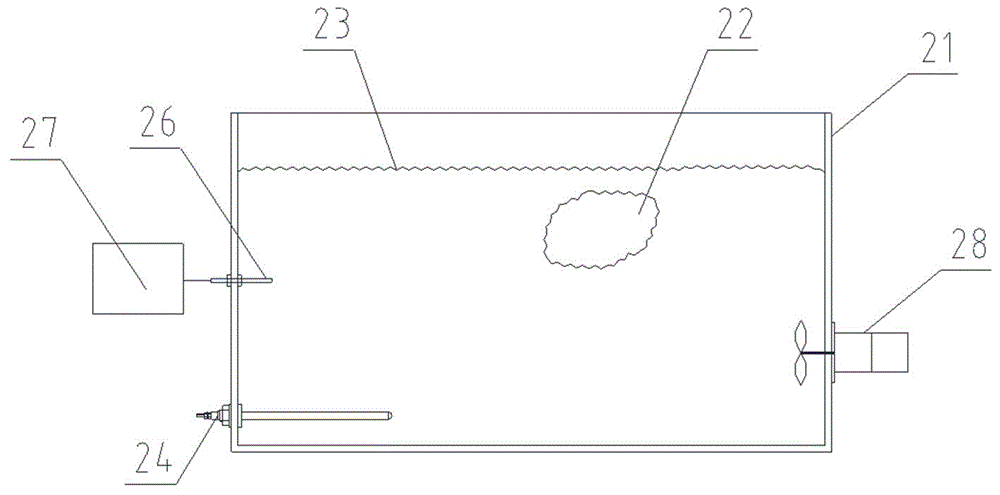

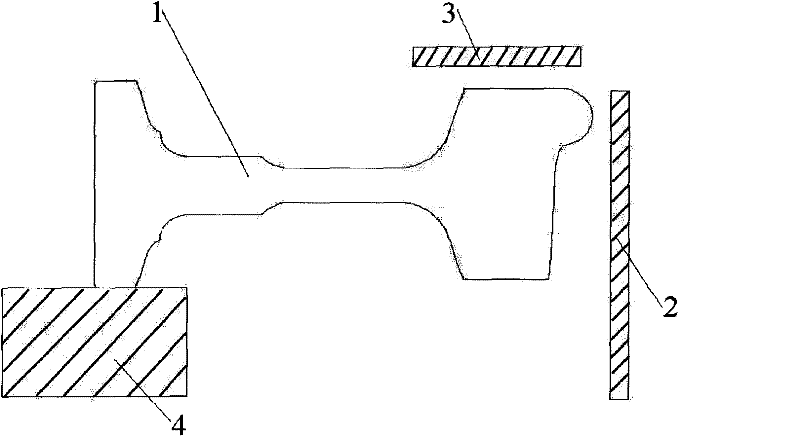

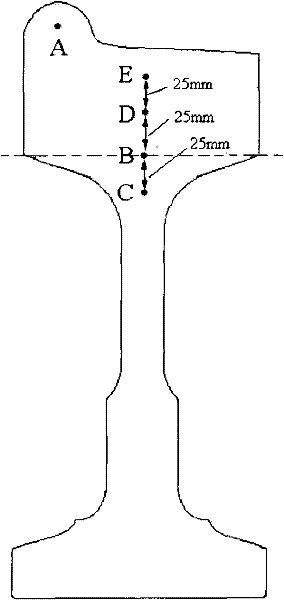

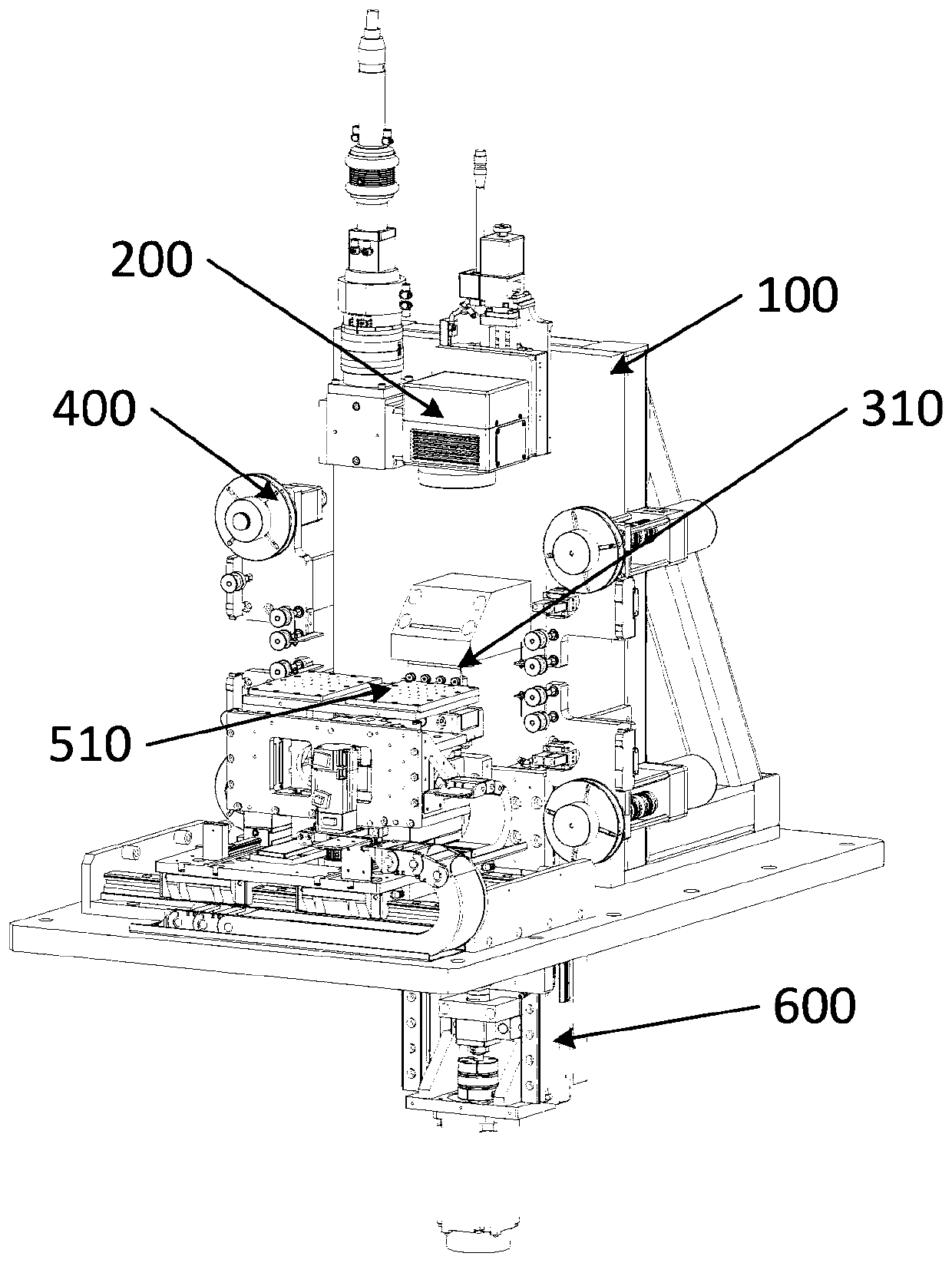

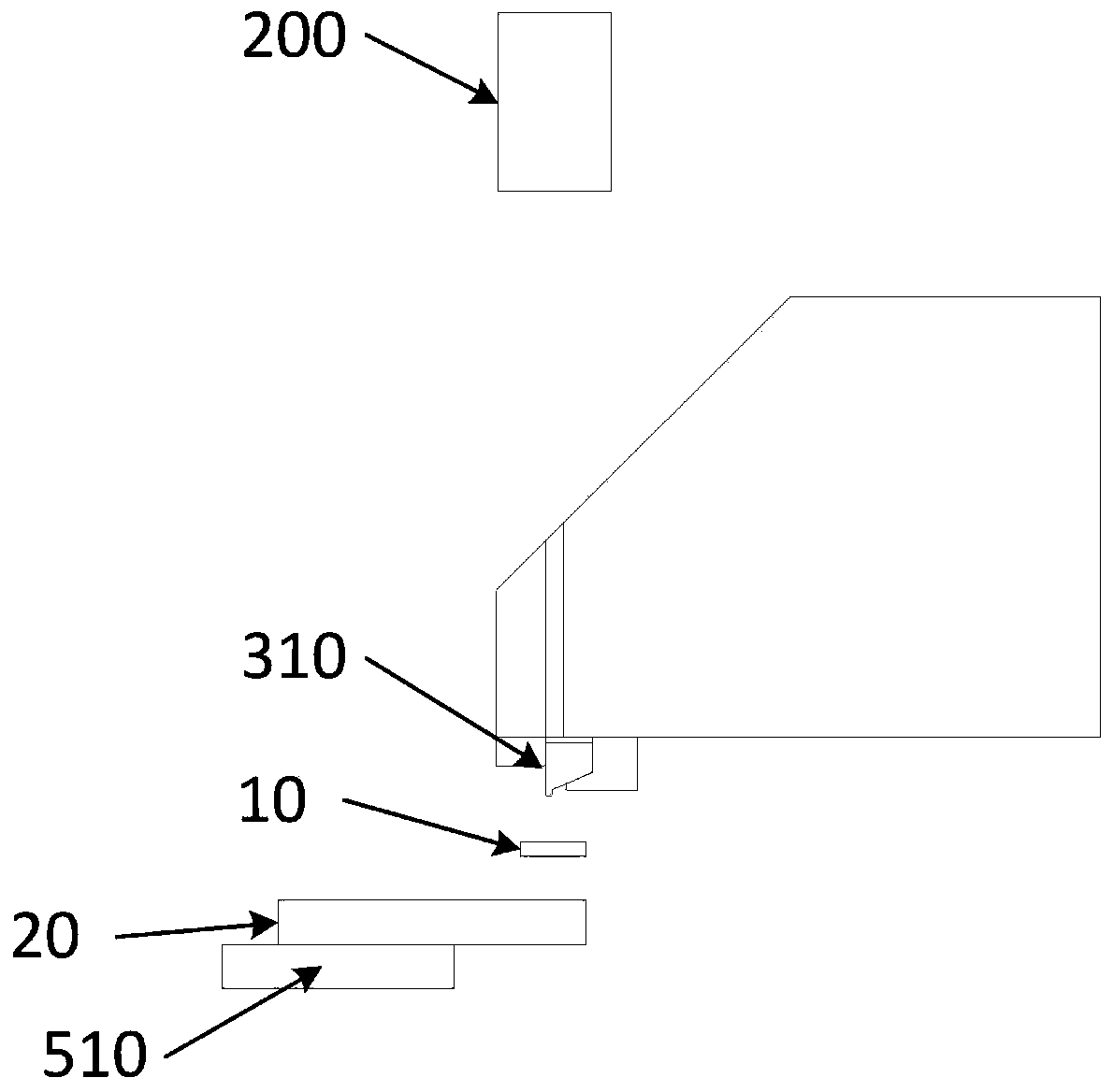

Experimental device and test method for electrochemical corrosion of specimens loaded with bidirectional tensile stress

ActiveCN106769474BHigh simulationTest accurateWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCorrosion reactionControl system

The invention discloses a two-way stretch stress loading sample corrosion electrochemistry experiment device and a testing method. The two-way stretch stress loading sample corrosion electrochemistry experiment device comprises a two-way stretch stress loading mechanism, a cross-shaped sample, a corrosion reaction tank, an electrochemical testing system and a control system, wherein the cross-shaped sample is arranged in a clamp of the two-way stretch stress loading mechanism and can be set to bear different proportions of two-way stress and simulating an actual situation of pipeline work; the corrosion reaction tank is capable of providing multiple component experimental media and working environments. By utilizing the two-way stretch stress loading sample corrosion electrochemistry experiment device and the testing method thereof, disclosed by the invention, a corrosion behavior and a rule of a metal material under various working situations and the two-way stress can be researched and simulated.

Owner:CHANGZHOU UNIV

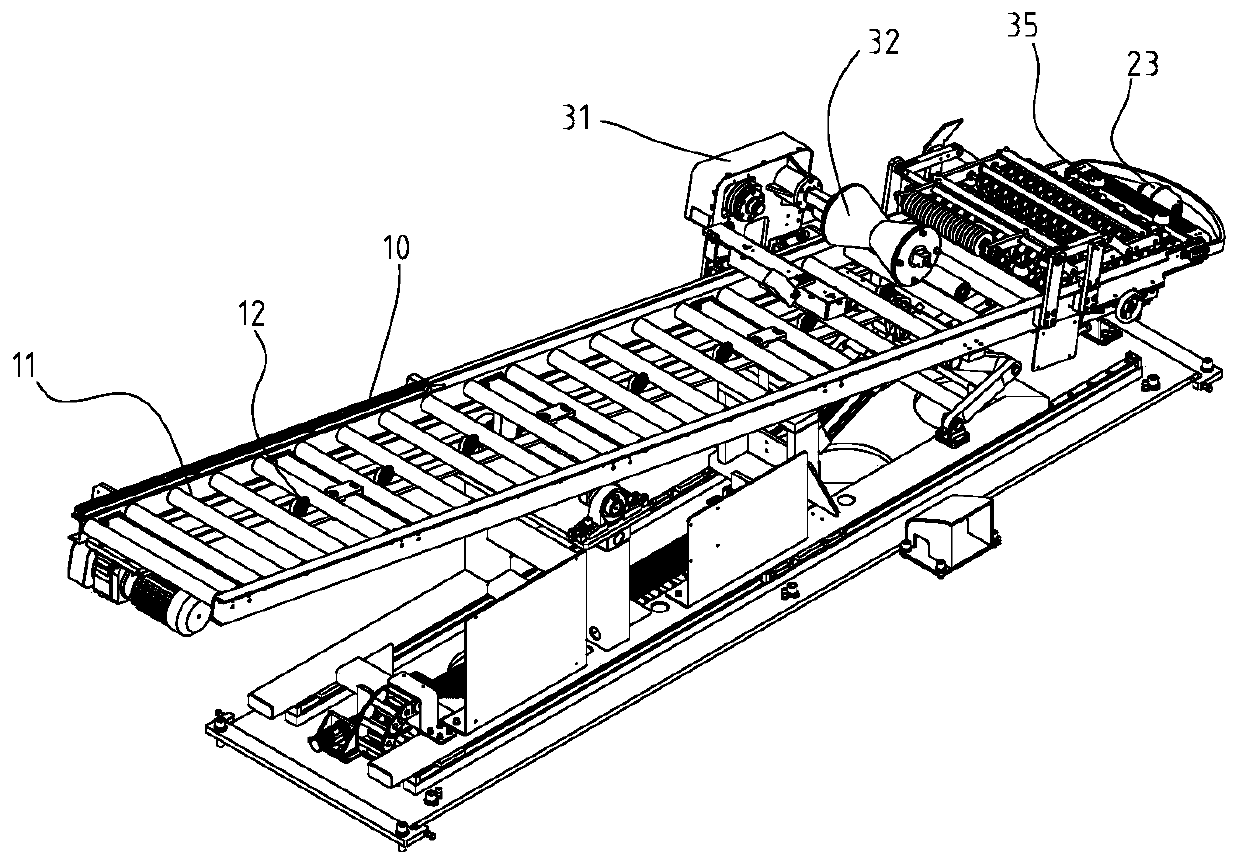

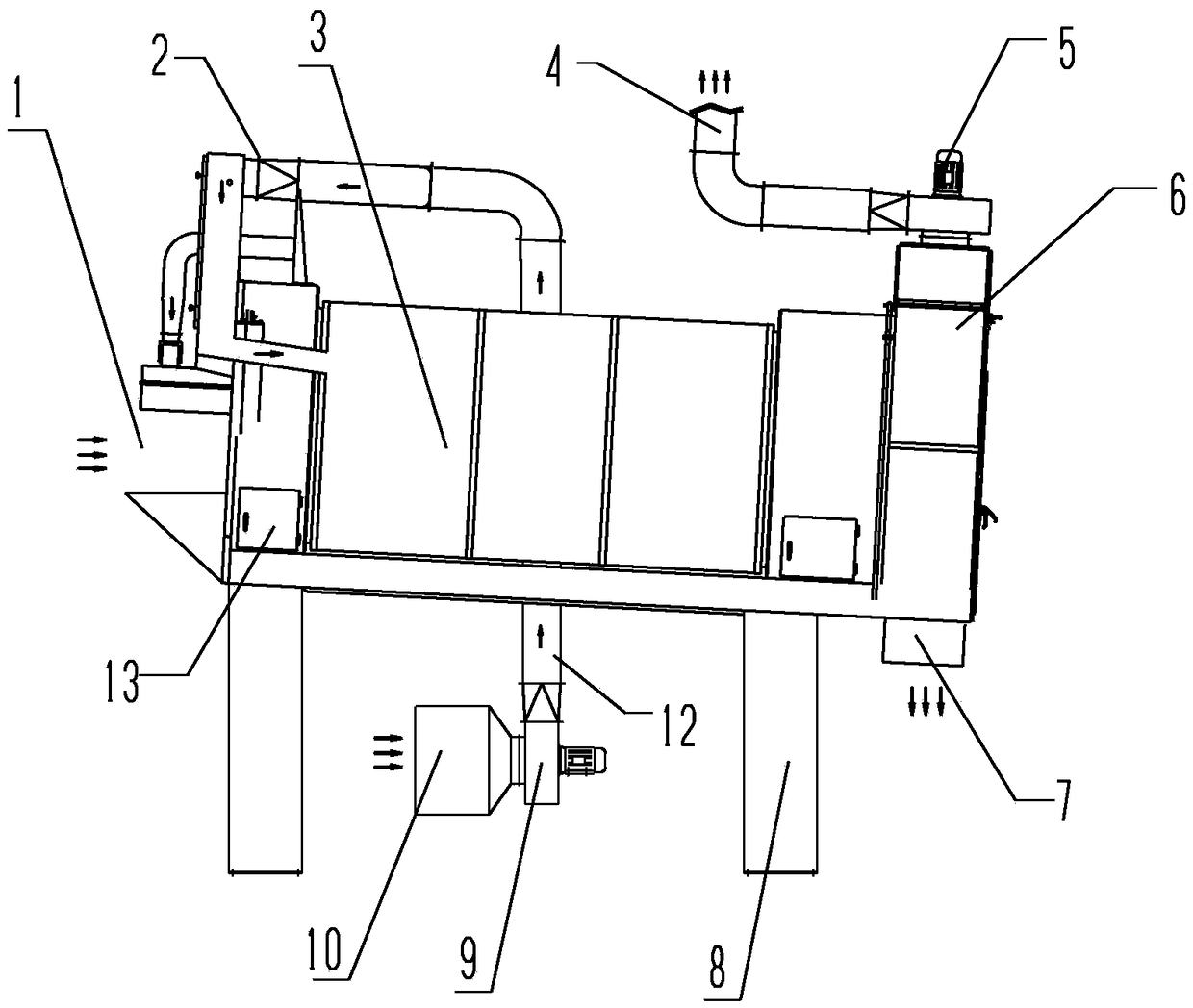

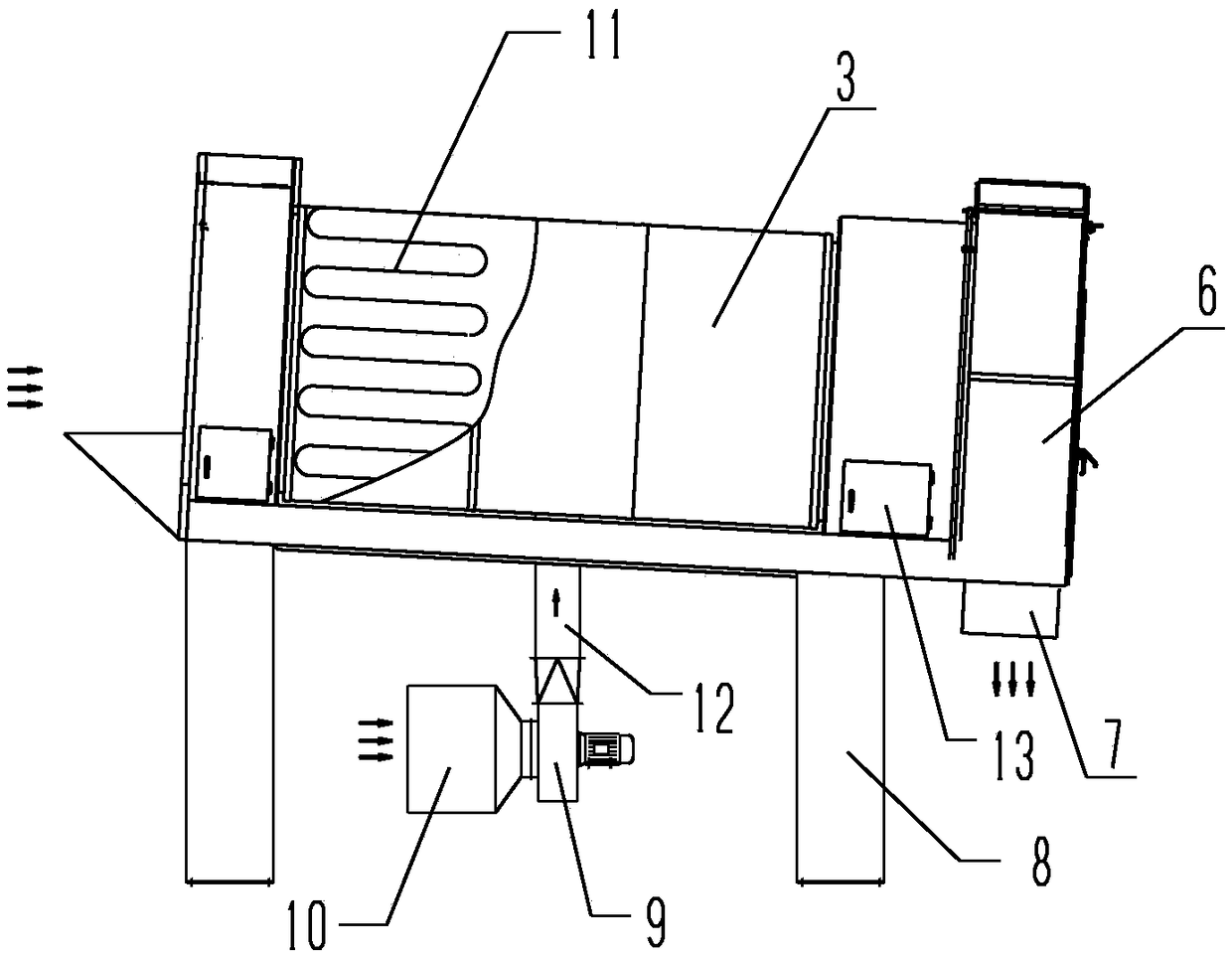

Roller-type tobacco feeding machine with composite-type heating system

InactiveCN109497607AReduce the effects of moistureHeating evenlyCigarette manufacturePulp and paper industryUltimate tensile strength

The invention provides a roller-type tobacco feeding machine with a composite-type heating system. The roller-type tobacco feeding machine comprises a machine frame, a material conveying roller slantwise installed on the machine frame, a transmission device and a hot air circulating system installed on the material conveying roller. The higher side of the material conveying roller is provided witha feeding chamber, and the lower side is provided with a discharging port. A roller wall of the material conveying roller is of a double-layer structure, and a steam heat-radiating tube is arranged in an interlayer. An inlet and an outlet of the steam heat-radiating tube are arranged outside the roller wall. The discharging port of the material conveying roller is provided with a moisture removing chamber. The discharging port is placed at the lower end of the moisture removing chamber, and the upper part of the moisture removing chamber is connected with a moisture removing pipe and a moisture removing fan. The roller-type tobacco feeding machine does not affect material moisture in a heating process, and a material is more uniformly heated, and controlled. A material adhesion quantity of the roller wall is effectively reduced, and labor intensity of an operator is reduced in a maintaining process.

Owner:HUBEI CHINA TOBACCO IND

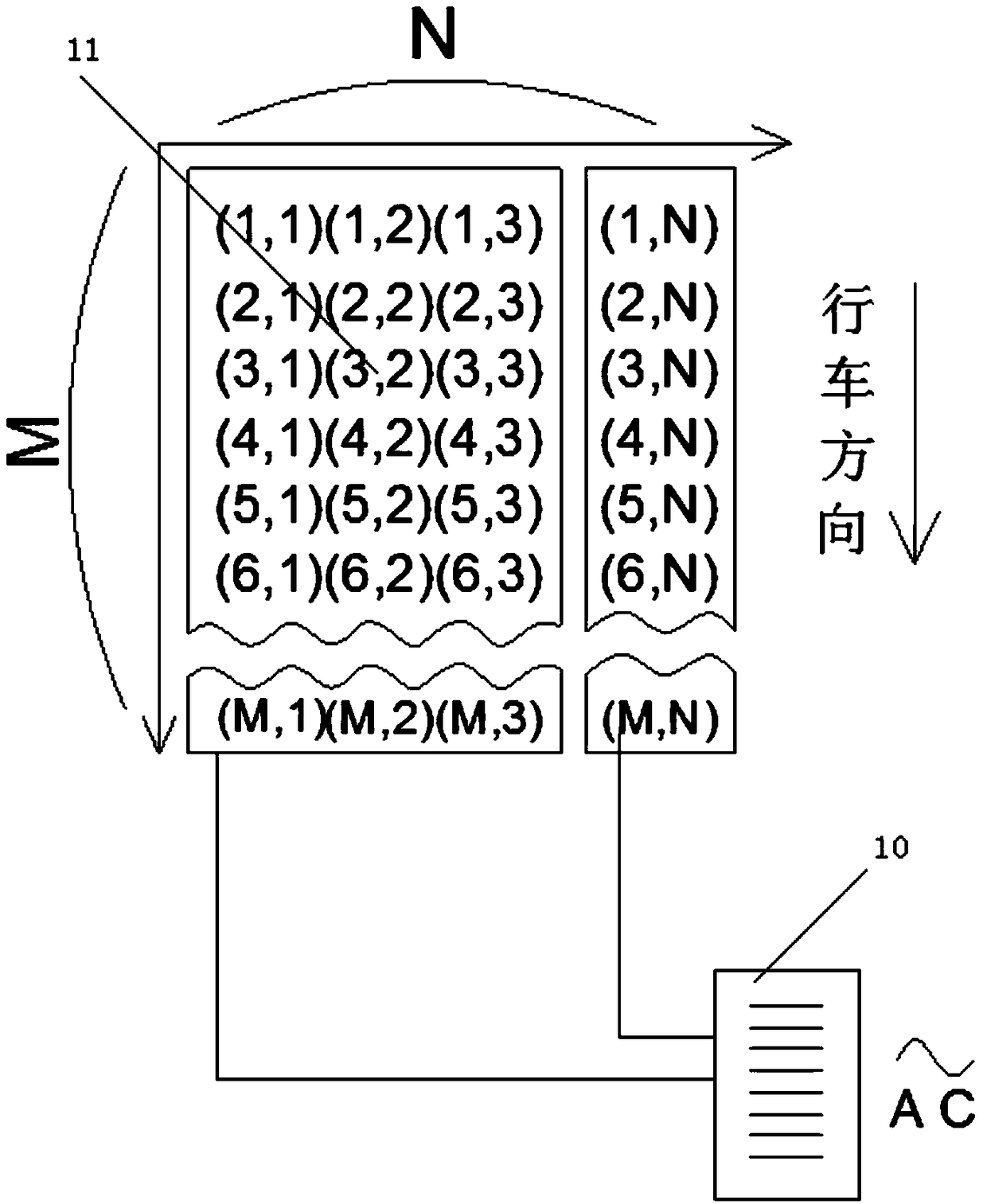

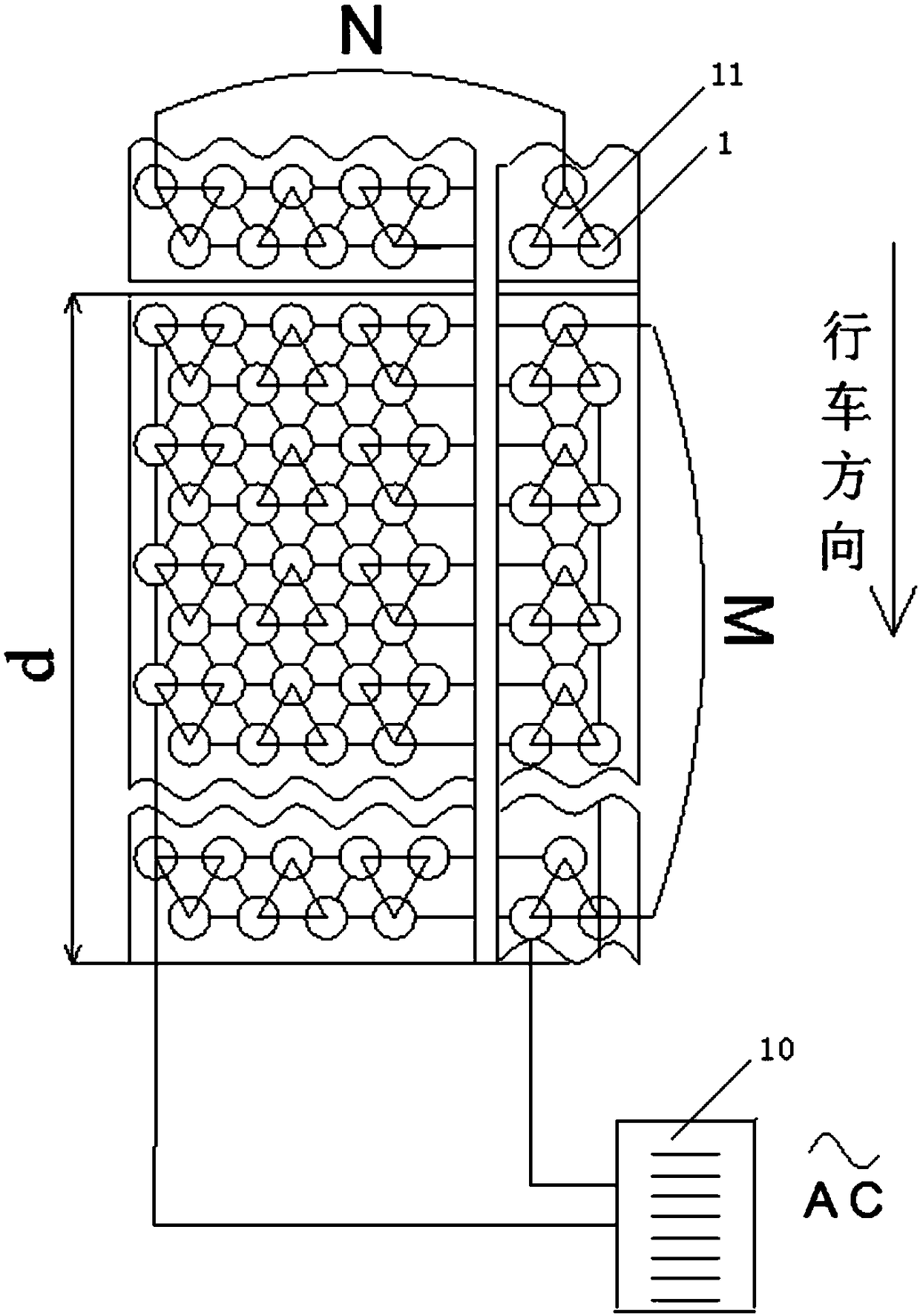

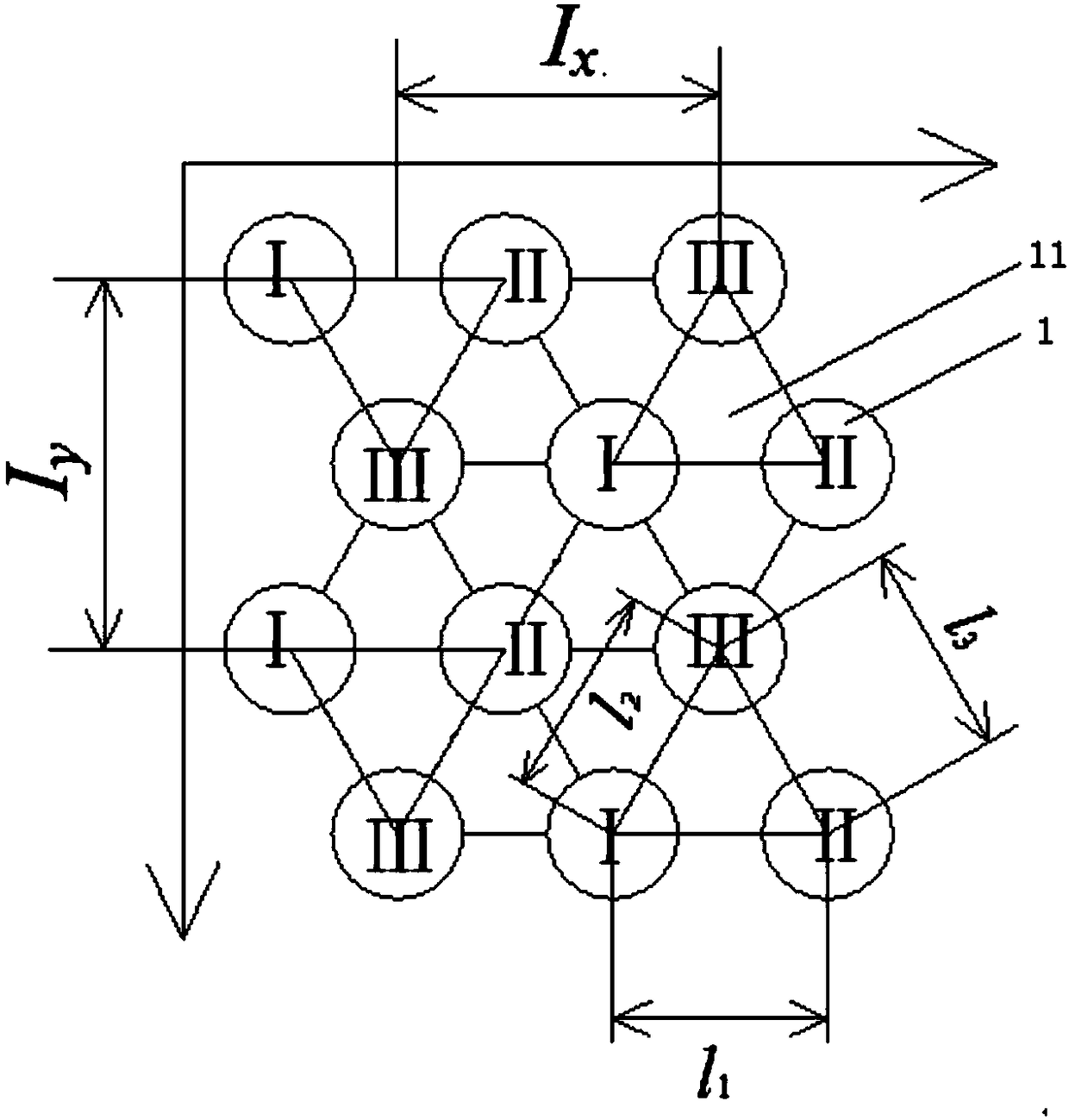

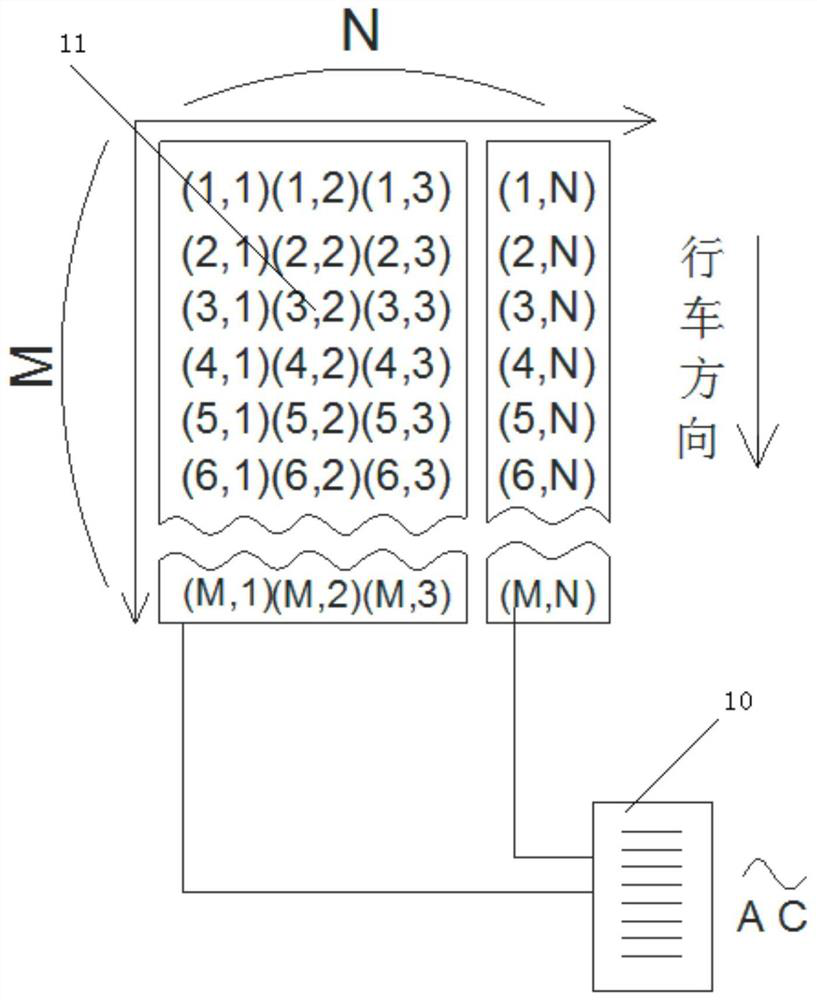

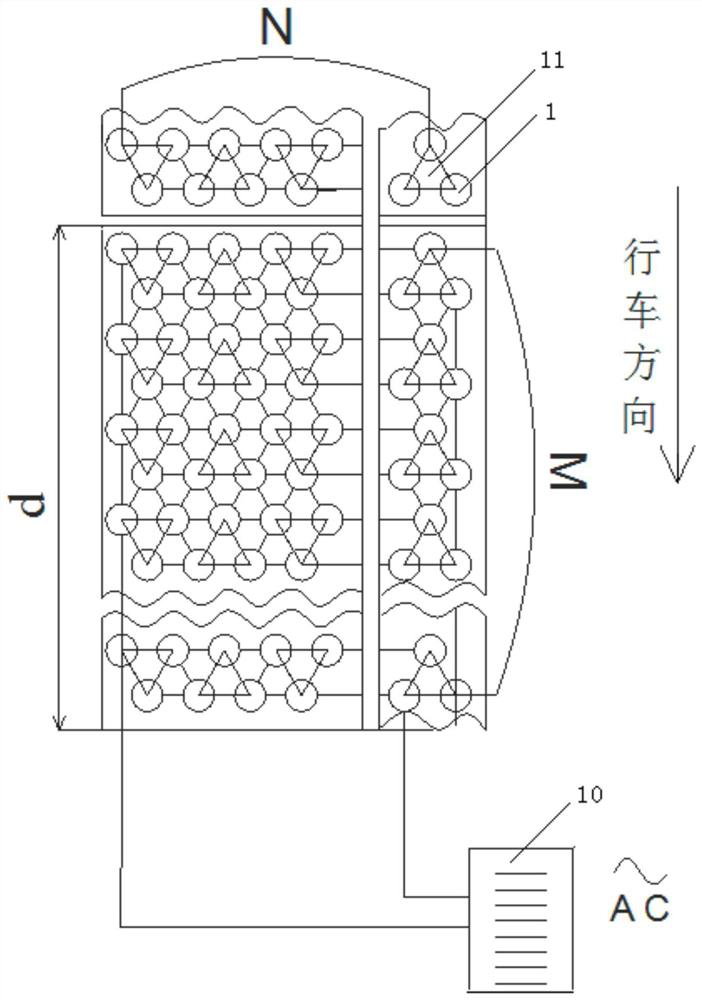

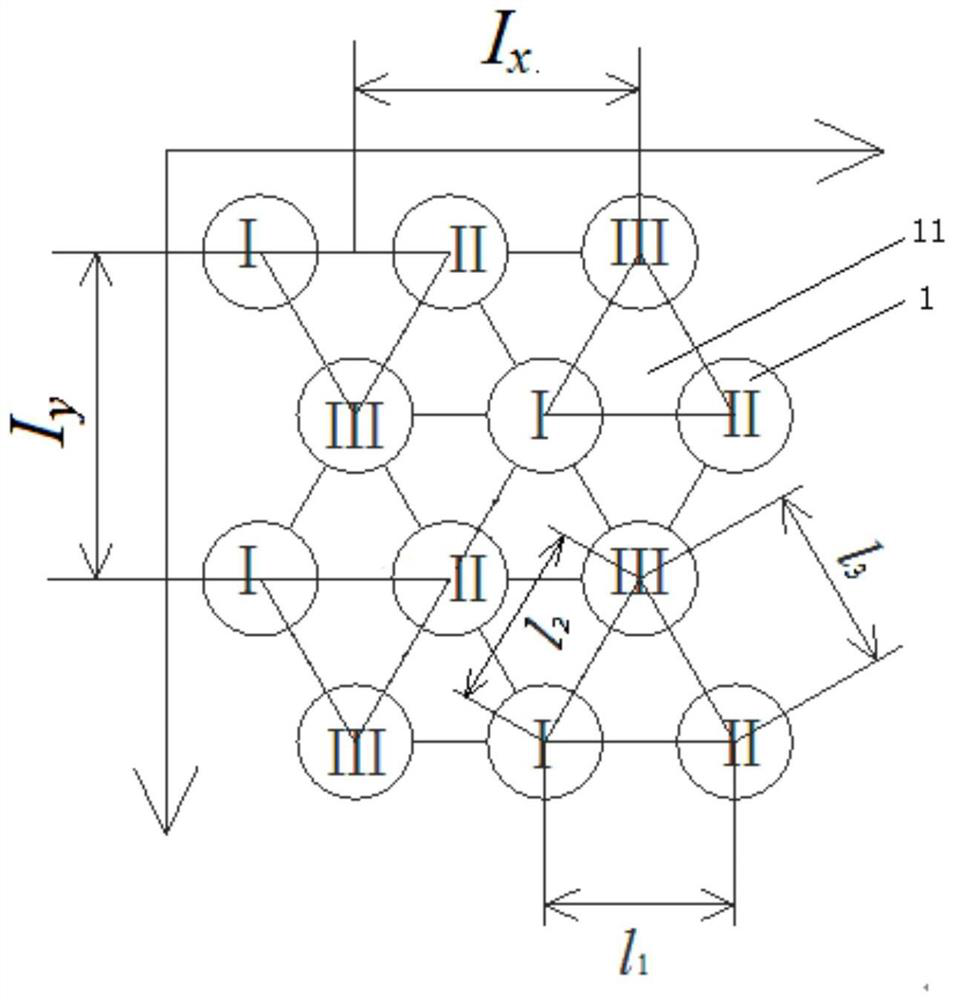

Control method of ice- and snow-melting electrical heating system

ActiveCN108200676AExtend your lifeUniform heat transferPaving detailsInduction heating controlElectricitySnow melting

The invention discloses a control method of an ice- and snow-melting electrical heating system. The control method comprises the following construction steps of (1) arranging according to horizontal telescopic gaps of a road surface and a bridge surface, and dividing the road surface and the bridge surface into a plurality of heating regions, wherein the distance among the horizontal telescopic gaps is d, and the value range of the d is 8-12 meters; (2) arranging a plurality of electromagnetic heating units in each heating region in a rectangular array way, wherein the line numbers of the electromagnetic heating units are 1, 2 until M, the row numbers of the electromagnetic heating units are 1, 2 until N, the line number is perpendicular to a travelling direction and is numbered accordingto a sequence from left to right and small to large, the row number is numbered according to a sequence from small to large along the travelling direction, the electromagnetic heating system is provided with S electromagnetic heating units, and S is equal to M by N; and (3) allowing that each electromagnetic heating unit comprises a first electromagnetic heating device, a second electromagnetic heating device and a third electromagnetic heating device which are arranged in a triangular shape. The control method of the ice- and snow-melting electrical heating system can be favorably applied under various conditions, and a road is enabled to be safe and smooth.

Owner:HEFEI UNIV OF TECH

Energy-saving food cooking equipment

InactiveCN104522440AFast heating rateAvoid overheatingFood preparationProcess engineeringConvective heat transfer

The invention discloses energy-saving food cooking equipment which comprises a container, a constant temperature control system and a stirring device, wherein the constant temperature control system is used for heating water, maintaining the cooking temperature and controlling the operation of the stirring device. According to the energy-saving food cooking equipment disclosed by the invention, at the heating stage, convective heat transfer is increased, so that the food temperature reaches the cooking temperature as soon as possible. Moreover, at the temperature maintaining and cooking stage, due to the optimized combination of constant temperature control and stirring, the food temperature is always maintained nearby the cooking temperature, and lots of energy can be saved under the condition that the cooking temperature of the food is guaranteed.

Owner:邱于正

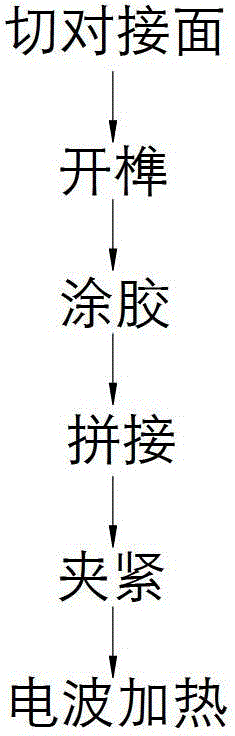

A method of manufacturing a framed door

A production method of a multi-frame door includes the steps of A, selecting four solid-wood door frames, processing the end of each solid-wood door frame to obtain 45-degree chamfers with ends which form butt ends; B, making mutually matching mortises and tenons on the butt ends of the two adjacent solid-wood door frames; C, coating the surface of each tenon and the inner wall of each mortise with white emulsion; D, inserting the tenons on the butt ends of the two adjacent solid-wood door frames into the mortises; E, placing the assembled rectangular frame into a fixture; F, placing the clamped solid-wood door frame into a radio frequency heater, heating by electric wave to solidify the white emulsion which adhere the tenons and the mortises, thus obtaining the multi-frame door. The method has the advantages that the production process of the multi-frame door is simplified, production efficiency of the multi-frame door can be improved, and assembly precision is improved; the white emulsion is solidified by radio frequency heating; the method compared to the traditional heating and solidifying method is high in heating speed, even in heating, easy for control of the heating process and the like.

Owner:河南索菲亚家居有限责任公司

A kind of rapid preparation method of silica airgel

The invention provides a fast preparation method of silicon dioxide aerogel. According to the method, tetraethyl orthosilicate is used as a silicon source; low-concentration organic weak acid is added for catalyzed hydrolysis reaction; then, the condensation polymerization reaction and the hydrophobic modification of the gel are completed in one step through reasonably controlling the addition quantity of the nitrogen-containing silane, the dripping speed and the reaction time; the addition of basic catalysts is not needed; the consumption of a great number of replacement solvents in the general post hydrophobic modification method is avoided; waste liquid is not generated; the preparation period is greatly shortened; the process cost is reduced; the industrial production is easy; meanwhile, the prepared silicon dioxide aerogel product has excellent performance.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST +1

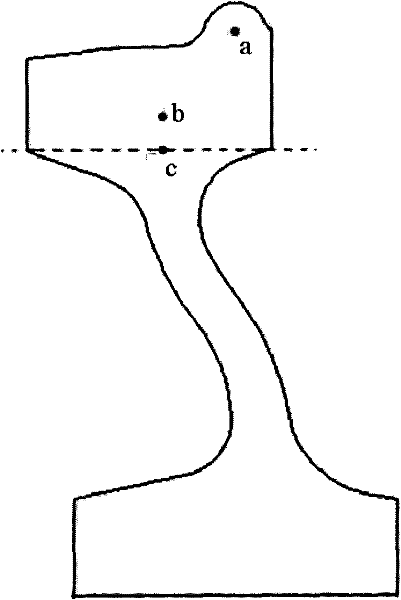

Railway wheel heat treatment heating furnace and heat treatment process thereof

ActiveCN101818239BHigh strengthImprove toughnessIncreasing energy efficiencyFurnace typesEnvironmental resistanceHigh intensity

The invention discloses a railway wheel heat treatment heating furnace. An induction heating device therein has the structure that the periphery of the tread of a railway wheel is provided with an induction heating coil, the corresponding positions of the inner side surface of the rim of the railway wheel and the inner side surface of the rim to a transition area are respectively provided with aninduction heating compensation coil. The invention also discloses a heat treatment process thereof of the heat treatment heating furnace. The above technical scheme realizes the technical target of high strength and high toughness of the rim as well as low strength and high toughness of a wheel disk. The two-phase region has high heating speed and short austenite temperature region, is favorable for evenly refining crystalline grains and improves rim toughness. The invention can realize quick heating of the wheel rim position, and the wheel disk position temperate is below Ac3 while the rim position is totally austenitized. The invention has the advantages of quick starting, high heating speed, easy control of temperature, high heating efficiency, favorable technical repeatability, favorable workpiece surface quality, environmental protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

A method for vacuum flexible heating of curved glass

ActiveCN108545955BQuality assuranceHeating evenlyOhmic-resistance heating detailsCoatingsTemperature controlThermal spraying

The invention belongs to the field of electrical heating, and particularly relates to a method for vacuum flexible heating of bent glass. By adopting the characteristic that various special-shaped glass can be attached to a flexible heating film or a flexible heating jacket to be subjected to curving heating, so that high-temperature coating on large bent glass can no longer be limited by shapes or sizes. Flexible heating has the advantages that the uniform and controllable heating can be realized, the problems in other heating methods that the heating is nonuniform and the temperature controlis inaccurate are solved, and the high-temperature coating quality is ensured. The method further has the following beneficial effect that the used device and method can be applied to other coating equipment such as electronic beam evaporation and thermal spraying, and can also be used for performing vacuum heat treatment on a film grown on a substrate in situ.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Bonding device and bonding method

PendingCN110648933ASolve the problem of large thermal impactHeating evenlySolid-state devicesSemiconductor/solid-state device manufacturingChip on filmThermodynamics

The invention relates to the field of bonding technology for display panel processing, specifically to a bonding device and a bonding method. The bonding device comprises a laser, a pressure head, a first buffer material fixing mechanism, a fixing platform and a pressing mechanism, wherein the fixing platform comprises a fixing assembly for fixing a product, and the pressure head is made of a material with light transmission performance and heat conductivity. Compared with the prior art, the invention has the following beneficial effects: the bonding device and the bonding method are designedto overcome the problem that a traditional heating mode is large in heat influence; and through heat dissipation of the pressure head, the temperature of a chip on film, a buffer material and other peripheral components is comprehensively reduced, ACF heating is not affected, and ACF heating is more uniform.

Owner:SHENZHEN HANHE INTELLIGENT MFG CO LTD

Optical auxiliary induction heating self-crucible single crystal growth device and application thereof

InactiveCN111962143AAccelerated corrosionReduce total usageBy pulling from meltCrucibleSingle crystal

The invention relates to an optical auxiliary induction heating self-crucible single crystal growth device and an application thereof. A self-crucible is formed by combining discrete copper pipes filled with circulating water, a high-power optical heat source is used for heating to form a liquid pool, and controllable and clean melting starting of a melt is realized. Resistance heating or opticalheat source heating is selected to form a rear hot temperature zone to achieve crystal growth temperature gradient control, and traditional crystal growth technologies such as a pulling method and anedge-defined film-fed growth method are used for controllable and efficient growth of single crystals. According to the invention, a precious metal crucible is prevented from being used as a crystal growth container, precious metal loss is effectively overcome, and crystal growth cost is reduced. Crystal growth can be carried out in various atmospheres, and improvement of crystal quality and regulation and control of physical properties are facilitated. The problems that a solid-liquid interface needs to be maintained by surface tension and large-size crystals are difficult to grow in a pure optical floating zone method are solved. Optical heating is adopted, melting starting of raw materials is achieved, and the defects of impurity pollution, inclusion and the like caused by melting starting of graphite rods, metal rods and the like are avoided.

Owner:SHANDONG UNIV

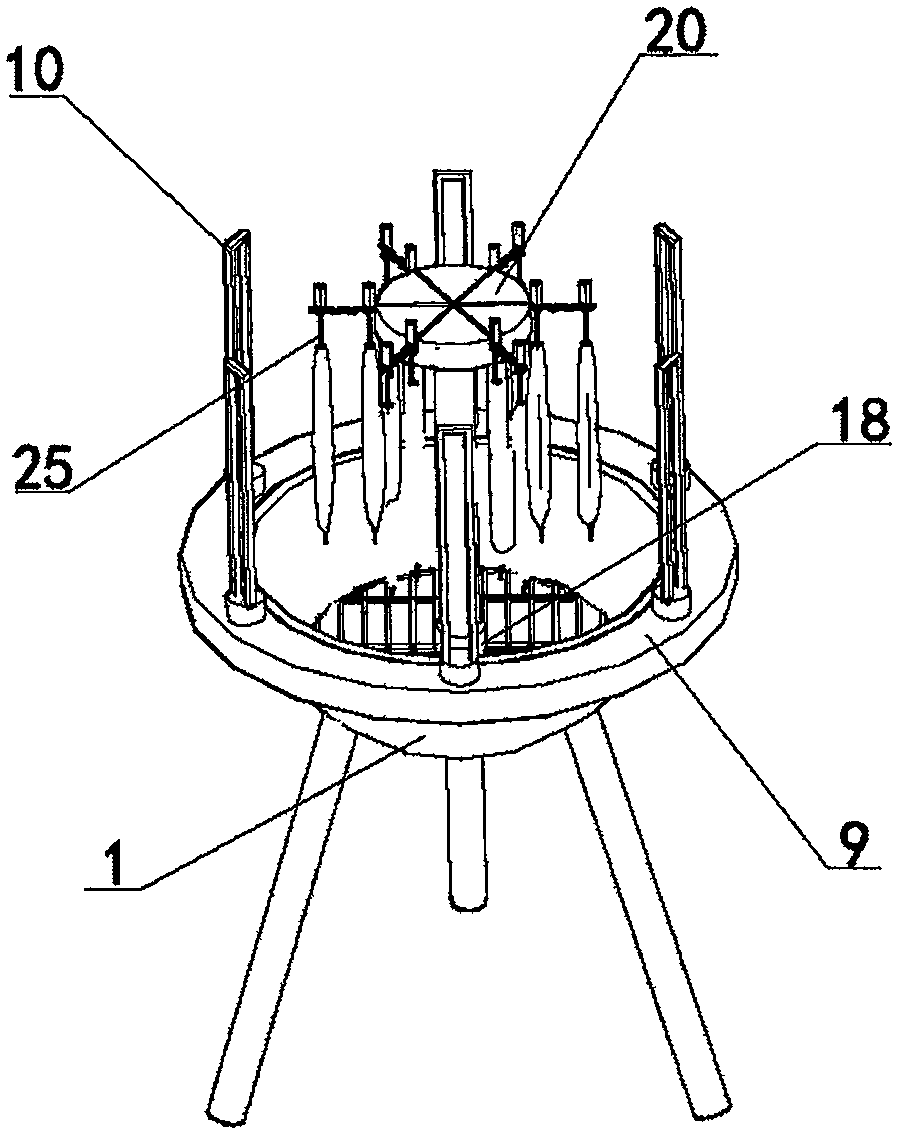

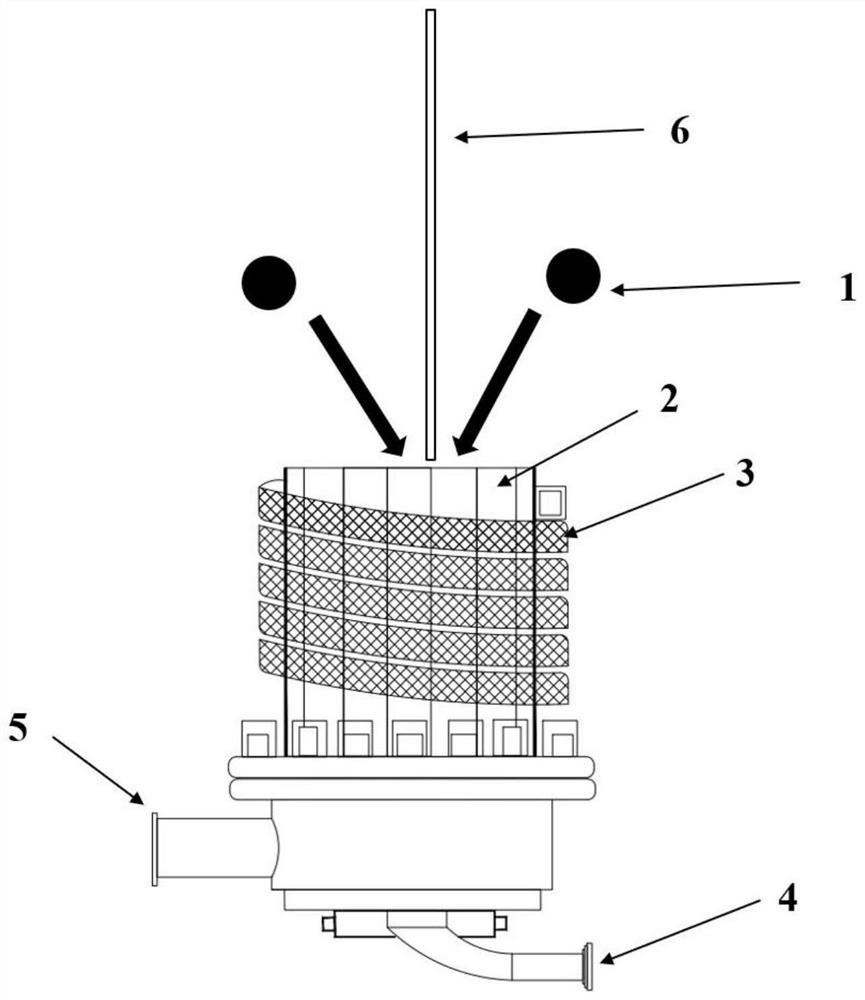

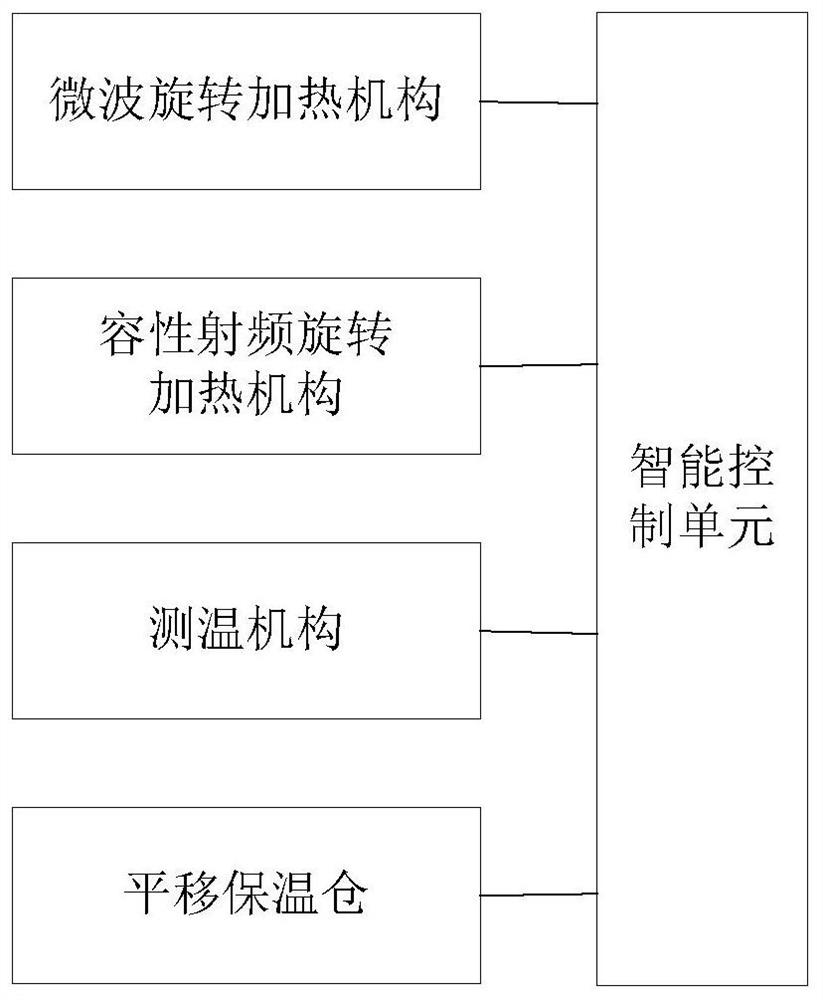

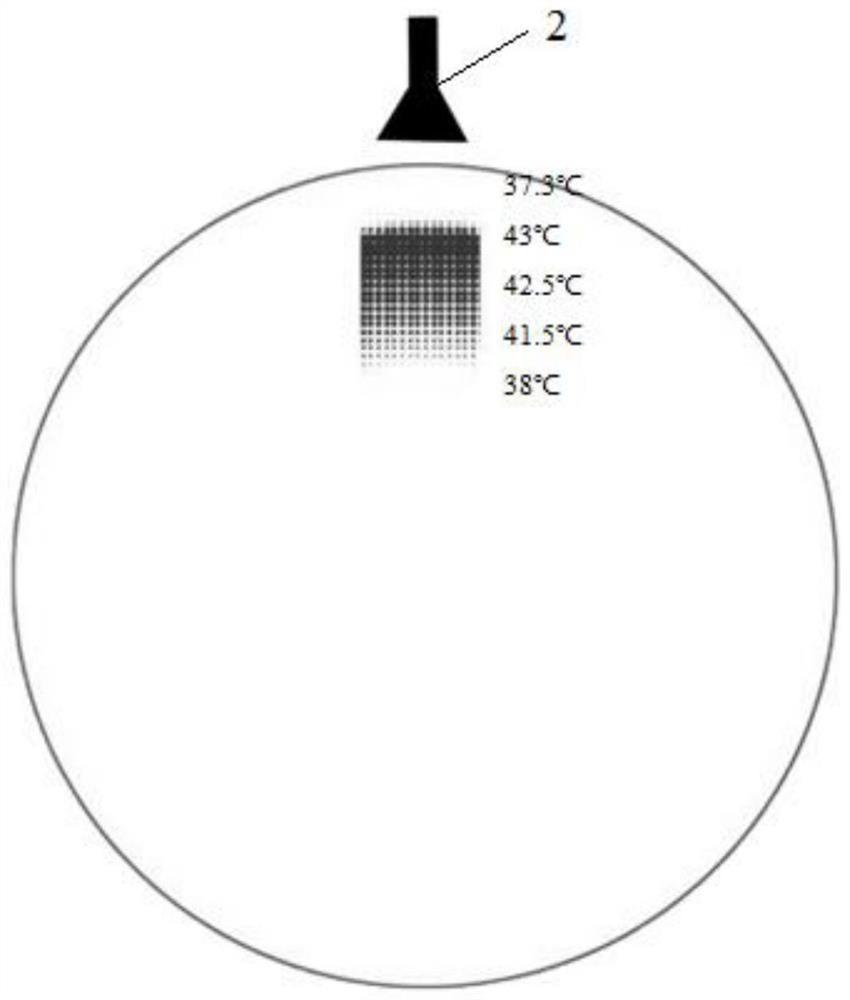

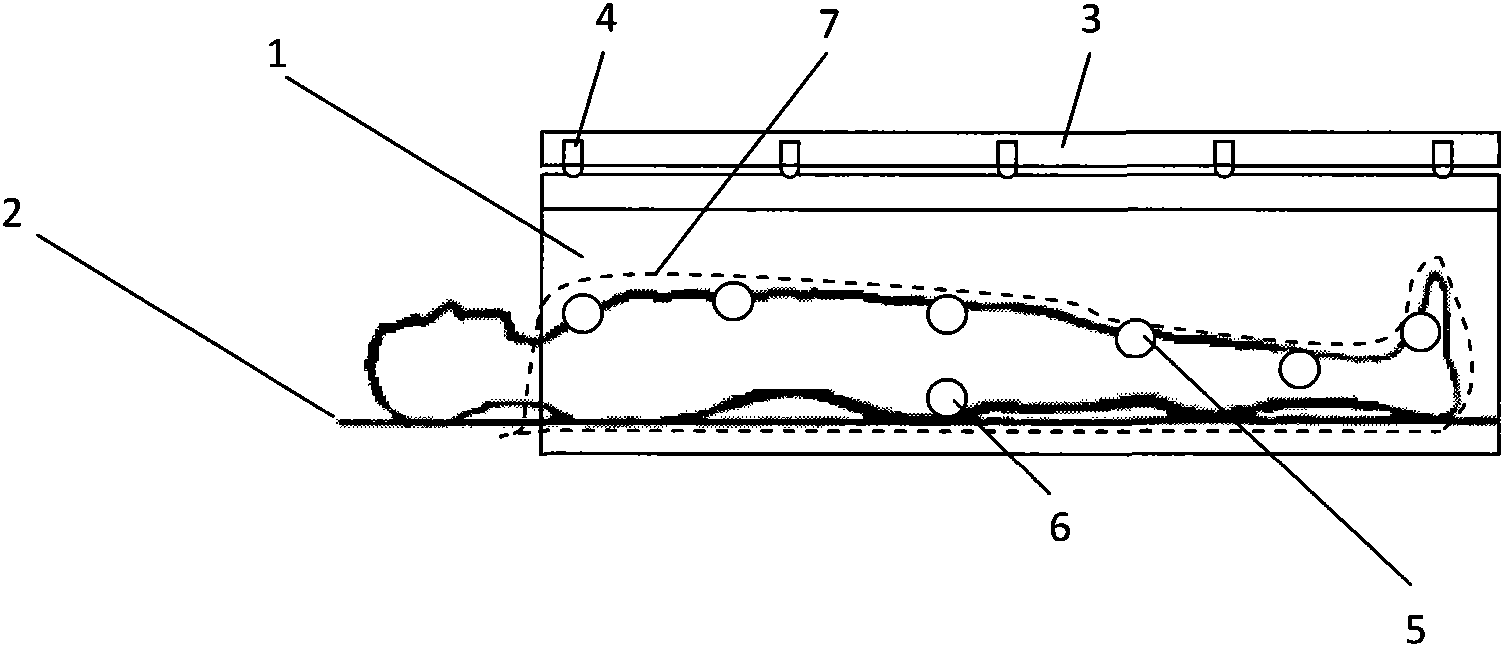

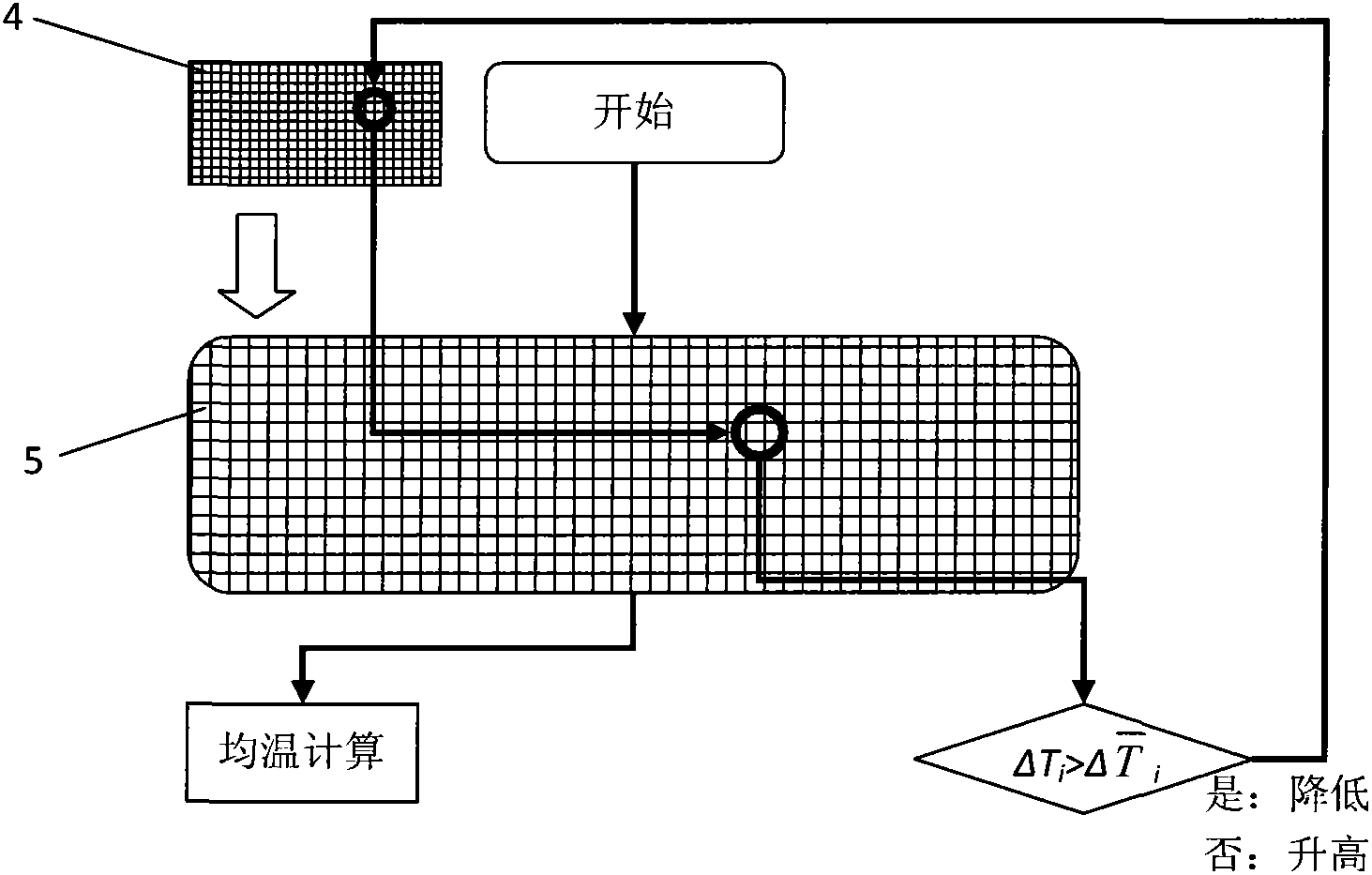

Microwave and radio frequency cooperative rotation global radiation hyperthermia system

ActiveCN111603684BNo damageHeating evenlyMicrowave therapyMeasurements using NMR imaging systemsControl cellEngineering

The invention discloses a microwave and radio frequency cooperative rotation global irradiation hyperthermia system, which comprises an intelligent control unit, a microwave rotary heating mechanism connected with the intelligent control unit, a capacitive radio frequency rotary heating mechanism, and a temperature measuring mechanism; The rotating heating mechanism and the capacitive radio frequency rotating heating mechanism rotate and irradiate the heating area around the human body heat treatment area for heating in different areas, and complement each other with deep and shallow layered diathermy to realize uniform heating of various tissues in the human body heat treatment area; The obtained internal temperature data of the human body is used as a reference system, and it cooperates with nuclear magnetic thermal imaging technology to perform non-invasive real-time and accurate temperature measurement in the body, to achieve precise temperature control, and to achieve accurate high fever and scalding in the whole area.

Owner:尚圣杰

A control method for ice and snow melting electric heating system

ActiveCN108200676BExtend your lifeUniform heat transferPaving detailsInduction heating controlEngineeringRoad surface

Owner:HEFEI UNIV OF TECH

Surface-cooling non-invasive radiation whole-body thermocuring method

The invention relates to a surface-cooling non-invasive radiation whole-body thermocuring method, in particular to a non-invasive radiation whole-body thermocuring method by introducing a large amount of radiation power into the deep issues of human bodies quickly through surface-cooling technology to prevent surfaces from being burned and increase radiation power. In the method, a radiation heating system is combined with a surface-cooling system, so that low-attenuation electromagnetic radiation on the surfaces is taken away, and high dose of infrared, microwaves, radio frequency and energyradiation of electromagnetic wave probes of each frequency range are radiated to the deep parts of the human bodies for heating to realize the non-invasive radiation whole-body thermocuring. The method breaks through the technical route that improvement is performed through aspects of a heating mode, heat source control and the like in the prior art technically, introduces ultralow-temperature cooling for the first time to offset the local radiation of the surfaces and prevent overheating and empyrosis; simultaneously, the non-invasive radiation whole-body thermocuring is performed by utilizing a deep radiation heating source so as to improve power which can be accepted by organisms and prevent the surfaces from being burned substantially.

Owner:TSINGHUA UNIV

Modification method for improving saline tolerance of acrylic acid macromolecule water uptake resin

InactiveCN101402702BImprove salt toleranceIncrease salt water absorption rateWater bathsAmmonium peroxydisulfate

The invention relates to a modification method for improving the salt tolerance of a crylic acid macromolecule absorbent resin. The modification method for improving the salt tolerance of the crylic acid macromolecule absorbent resin is characterized by comprising the following steps: 1) according to the parts of all component raw materials by weight as follows: 90 portions to 140 portions of n-hexane, 30 portions to 50 portions of coconut oil diethanolamide, 20 portions to 40 portions of crylic acid, 5 portions to 12 portions of sodium hydroxide, 3 portions to 15 portions of calcium chloride, 0.03 portion to 1 portion of N, N'- methylene bisacrylamide, 0.05 portion to 1 portion of ammonium peroxydisulfate and 32 portions to 100 portions of water, raw materials are selected; 2) water is respectively mixed with the sodium hydroxide and the calcium chloride so as to obtain sodium hydroxide solution and calcium chloride solution; and 3) all raw materials are added into a reaction kettle with a water bath, the water bath temperature is risen to 70 DEG C to 80 DEG C, the raw materials are stirred for 4 hours to 6 hours at the temperature for reaction, finally a reaction product is taken out; and after being dried, the reaction product is the modified crylic acid macromolecule absorbent resin. The method can evidently improve the salt tolerance of the crylic acid macromolecule absorbent resin and has low production cost.

Owner:WUHAN UNIV OF TECH

Carbon fiber heating pipe

ActiveCN112867188AReduce the disc radiusEasy to storeOhmic-resistance heating detailsHeating element shapesFiberCarbon fibers

Owner:南京奎道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com