Beneficiation process for fine-particle-embedded silicate type iron oxide ore

A technology of iron oxide ore and silicate, applied in the improvement of process efficiency, chemical instruments and methods, magnetic separation, etc., can solve the problems of complex process, low quality of iron ore concentrate, high energy consumption, and promote the growth of aggregation. , Enhance the effect of magnetic separation and reduce the energy consumption of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

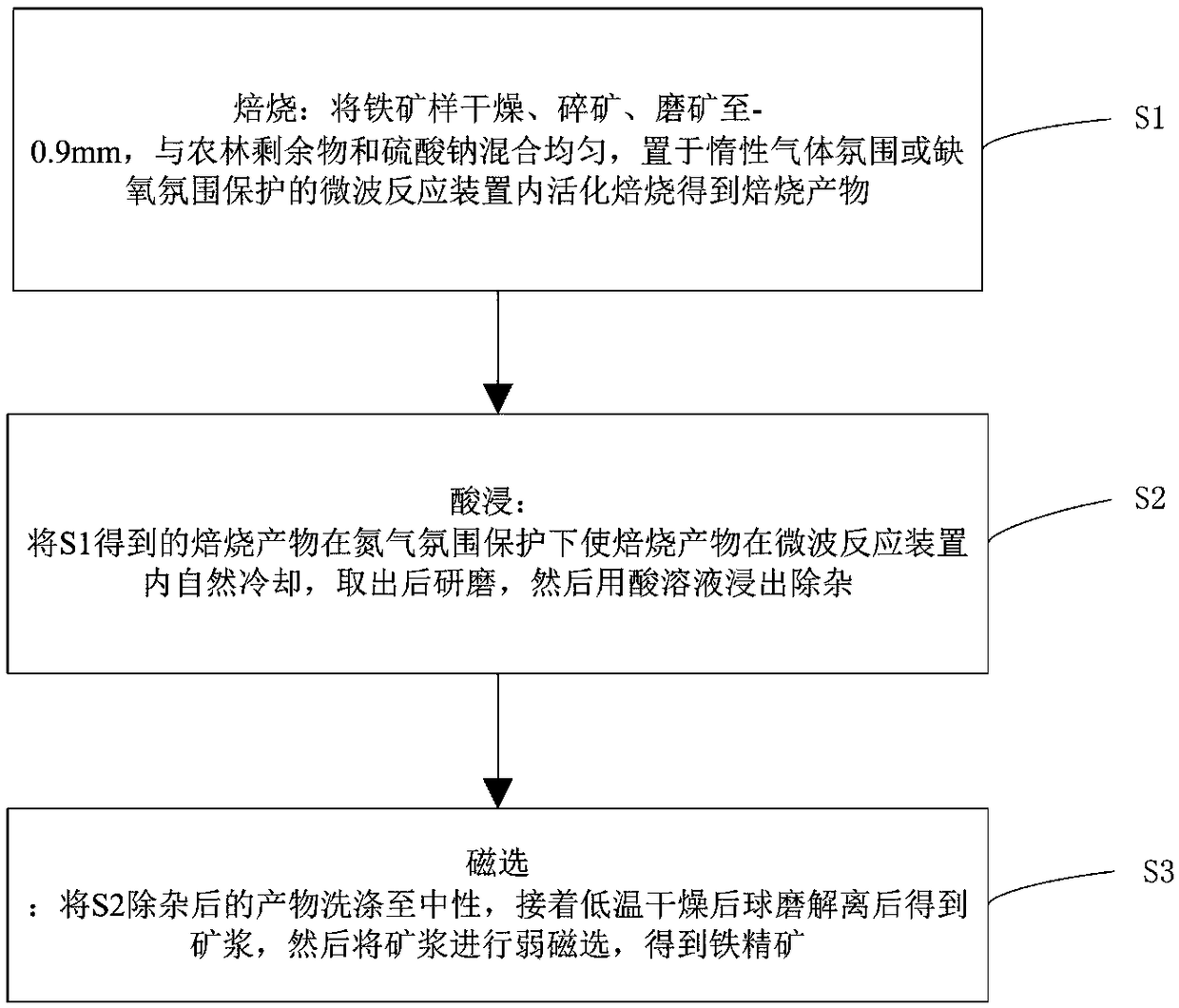

[0045] A beneficiation process for fine-grained silicate-type iron oxide ore, comprising the following steps:

[0046] S1. Roasting: 100 parts of iron ore samples are dried, crushed and ground to 0.25 mm by weight, mixed evenly with 5 parts of agricultural and forestry residues and 5 parts of sodium sulfate, and placed in a microwave protected by an inert gas atmosphere or an oxygen-deficient atmosphere. Reaction in the reaction device, the heating rate is set to 40°C, the target temperature of roasting is 200°C, the holding time is 30min, and the roasted product is obtained by activation roasting;

[0047] S2. Acid leaching: The roasted product obtained in S1 is cooled naturally in a microwave reaction device under the protection of nitrogen atmosphere, taken out and ground to 0.25mm, and then the solid-to-liquid ratio is 10:1 at 60°C with a concentration of 0.7mol / L sulfuric acid solution was dissolved for 5min to obtain the product after impurity removal;

[0048] S3. Mag...

Embodiment 2

[0051] A beneficiation process for fine-grained silicate-type iron oxide ore, comprising the following steps:

[0052] S1. Roasting: 100 parts of iron ore samples are dried, crushed and ground to 0.25 mm by weight, mixed evenly with 5 parts of agricultural and forestry residues and 5 parts of sodium sulfate, and placed in a microwave protected by an inert gas atmosphere or an oxygen-deficient atmosphere. Reaction in the reaction device, the heating rate is set to 40°C, the target temperature of roasting is 200°C, the holding time is 30min, and the roasted product is obtained by activation roasting;

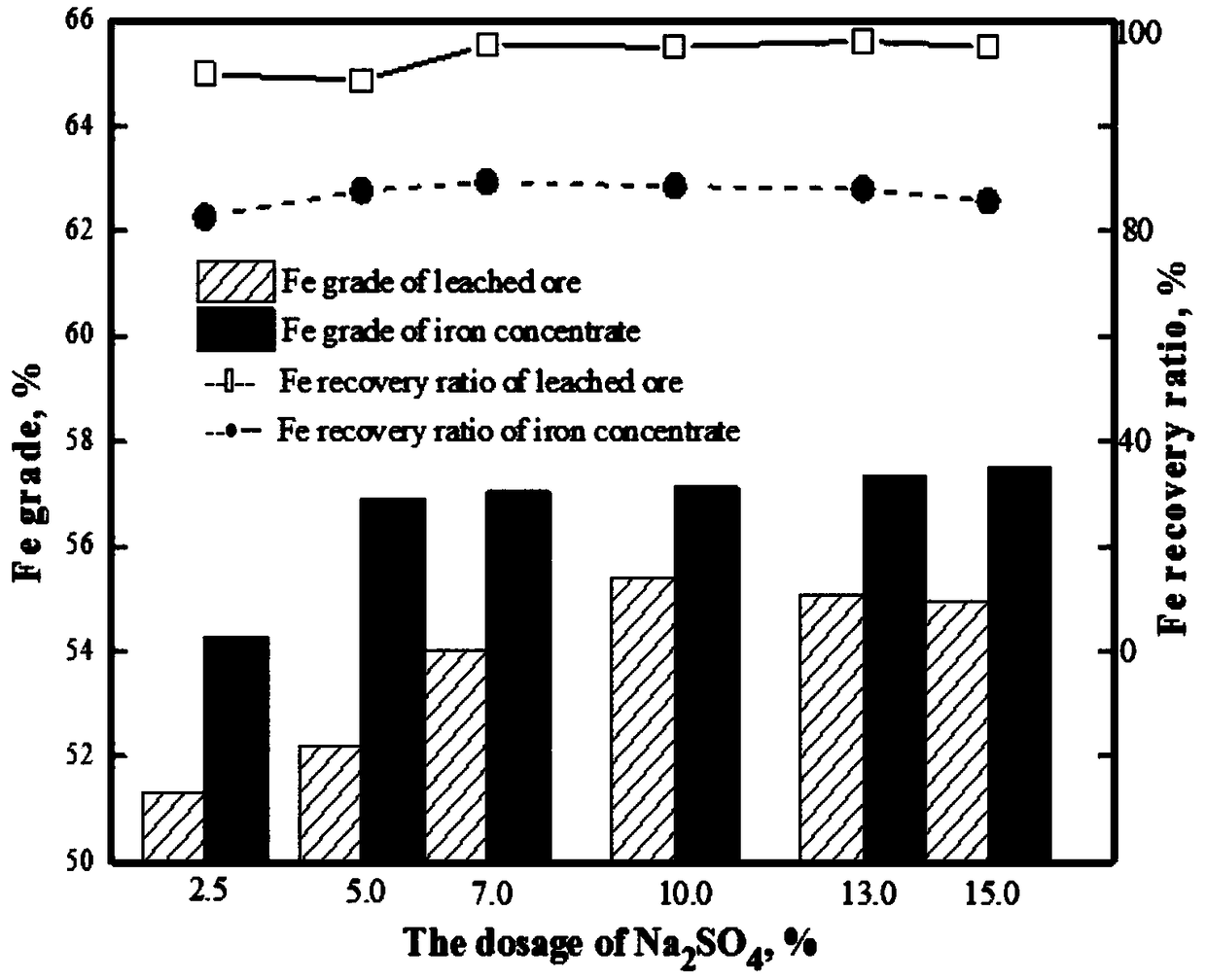

[0053] S2. Acid leaching: The roasted product obtained in S1 is cooled naturally in a microwave reaction device under the protection of nitrogen atmosphere, taken out and ground to 0.25mm, and then the solid-to-liquid ratio is 10:1 at 60°C with a concentration of 0.7mol / L sulfuric acid solution was stripped for 20min to obtain the product after the impurity removal, the iron grad...

Embodiment 3

[0056] A beneficiation process for fine-grained silicate-type iron oxide ore, comprising the following steps:

[0057] S1. Roasting: 100 parts of iron ore samples are dried, crushed and ground to 0.25 mm by weight, mixed evenly with 5 parts of agricultural and forestry residues and 5 parts of sodium sulfate, and placed in a microwave protected by an inert gas atmosphere or an oxygen-deficient atmosphere. Reaction in the reaction device, the heating rate is set to 40°C, the target temperature of roasting is 200°C, the holding time is 30min, and the roasted product is obtained by activation roasting;

[0058] S2, acid leaching: the roasted product obtained in S1 is cooled naturally in a microwave reaction device under the protection of nitrogen atmosphere, taken out, ground to 0.25mm, and then the concentration is 2.0mol at 60°C according to the solid-to-liquid ratio of 10:1 / L sulfuric acid solution was stripped for 5min to obtain the product after the impurity removal, the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com