Method for promoting growth of ferronickel alloy particles in process of producing ferronickel from laterite-nickel ore

A technology of lateritic nickel ore and nickel-iron alloy, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The low-grade laterite nickel ore powder composition of this embodiment contains Ni 0.82%, Fe9.67%, MgO 31.49%, SiO 2 37.37%, Al 2 o 3 1.89%;

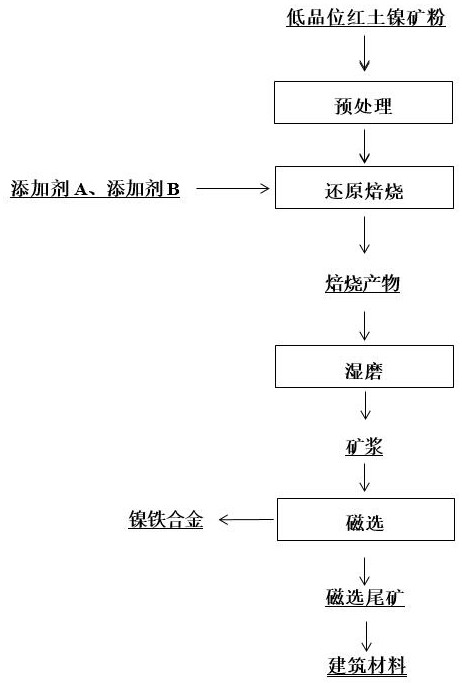

[0021] A method for promoting the growth of nickel-iron alloy particles in the process of producing ferronickel from laterite nickel ore (see figure 1 ),Specific steps are as follows:

[0022] (1) Low-grade lateritic nickel ore and additive A (blast furnace nickel-iron) were dried and crushed to a particle size of -0.074mm, accounting for more than 80%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder and additive powder A (blast furnace nickel iron powder);

[0023] (2) Combine low-grade laterite nickel ore powder, reducing agent (anthracite powder), additive powder A (blast furnace nickel-iron powder) and additive B (Na 2 CO 3 ) mixed evenly, heated to 1200°C at a uniform speed and subjected to high-temperature reduction roasting for 85 minutes to obtain roasted ore, whic...

Embodiment 2

[0026] Embodiment 2: The low-grade laterite nickel ore powder composition of this embodiment contains Ni 0.8%, Fe9.7%, MgO 31.5%, SiO 2 37.4%, Al 2 o 3 1.9%;

[0027] A method for promoting the growth of nickel-iron alloy particles in the process of producing ferronickel from laterite nickel ore (see figure 1 ),Specific steps are as follows:

[0028] (1) Low-grade lateritic nickel ore and additive A (blast furnace nickel-iron) were dried and crushed to a particle size of -0.074mm, accounting for more than 80%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder and additive powder A (blast furnace nickel iron powder);

[0029] (2) Combine low-grade lateritic nickel ore powder, reducing agent (coke), additive powder A (blast furnace ferronickel powder) and additive B (Na 2 CO 3 ) mixed evenly, heated to 1250°C at a uniform speed and subjected to high-temperature reduction roasting for 70 minutes to obtain roasted ore, which was naturally c...

Embodiment 3

[0032] Embodiment 3: The low-grade laterite nickel ore powder composition of this embodiment contains Ni 1.1%, Fe9.4%, MgO 28.7%, SiO 2 35.6%, Al 2 o 3 2.0%;

[0033] A method for promoting the growth of nickel-iron alloy particles in the process of producing ferronickel from laterite nickel ore (see figure 1 ),Specific steps are as follows:

[0034] (1) Low-grade laterite nickel ore and additive A (electric furnace nickel-iron) were dried and crushed and ground to a particle size of -0.074mm, accounting for more than 80%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder and additive powder A (electric furnace nickel iron powder);

[0035] (2) Combine low-grade lateritic nickel ore powder, reducing agent (graphite powder), additive powder A (electric furnace nickel-iron powder) and additive B (Na 2 CO 3 ) mixed evenly, heated to 1230°C at a uniform speed and subjected to high-temperature reduction roasting for 90 minutes to obtain roas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com