Patents

Literature

124 results about "Iron sulphur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduction sulfur-fixing bath smelting method and device of low-sulfur lead-containing secondary material and iron-rich heavy metal solid waste

InactiveCN102965510AEliminate pollutionClean and efficient recyclingProcess efficiency improvementMelting tankSlag

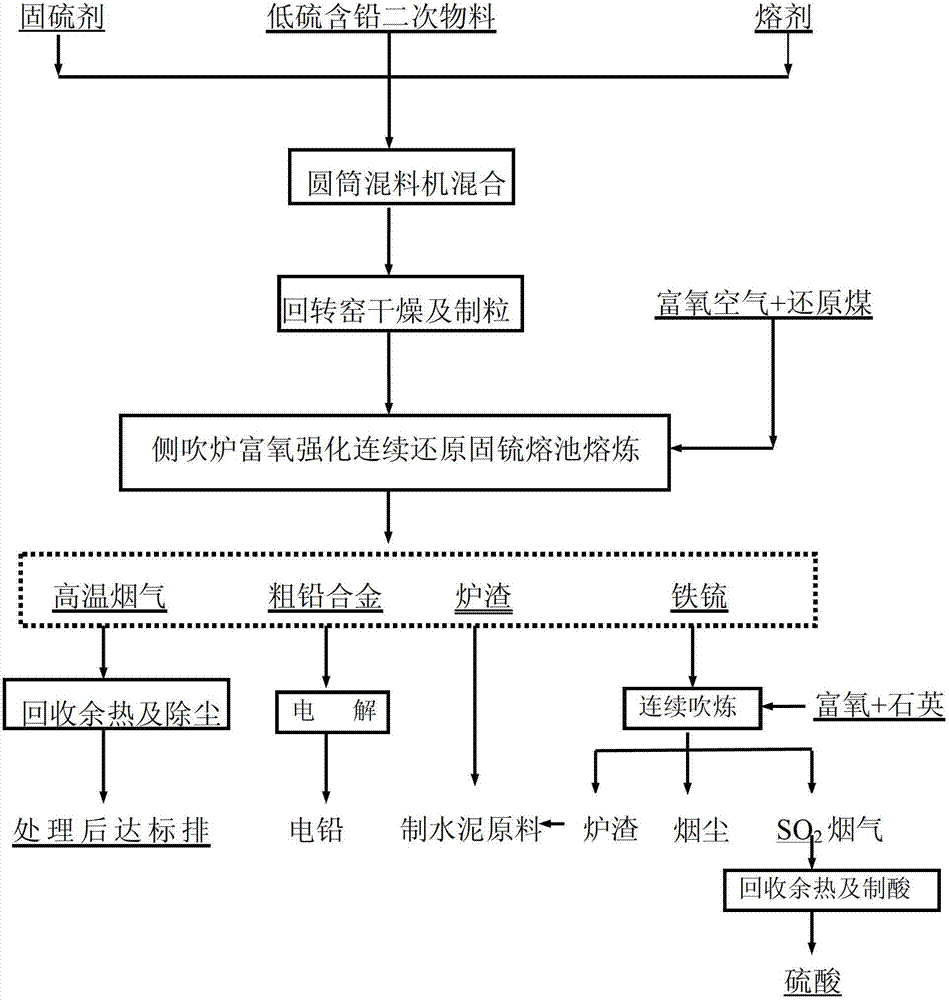

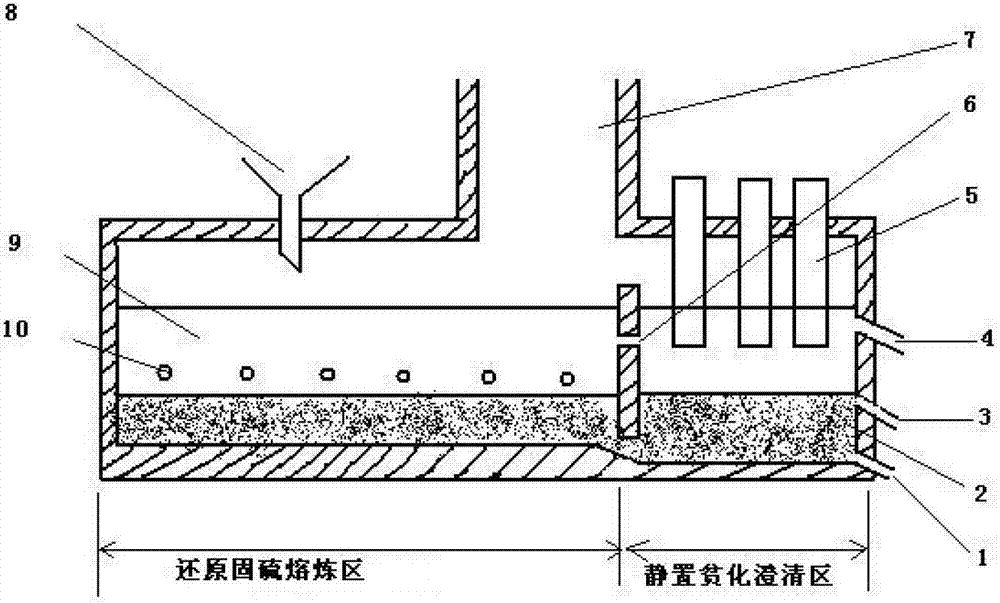

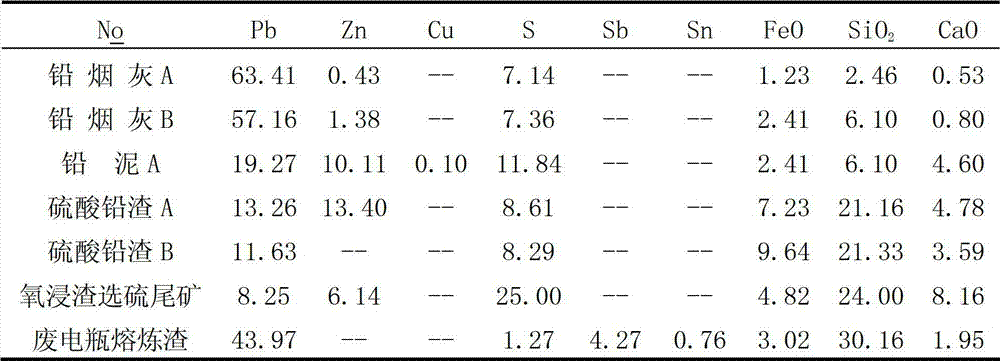

The invention discloses a reduction sulfur-fixing bath smelting method and device of a low-sulfur lead-containing secondary material and iron-rich heavy metal solid waste. The reduction sulfur-fixing bath smelting method comprises the steps of: with iron-rich heavy metal solid waste as a sulphur-fixing agent and smokeless conny as a reducing agent, firstly, fully uniformly mixing raw materials such as the low-sulfur lead-containing secondary material with the sulphur-fixing agent and a solvent, drying and pelleting, then continuously adding a mixed pelleted material and the reducing coal (fuel) into an oxygen side-blowing bath smelting furnace for reduction sulphur-fixing smelting, further producing lead bullion, iron sulphur and sulphur-containing slag in one step under the condition that no sulfur dioxide is generated. According to the method, sulphur in the raw materials is fixed in the sulphur-containing slag and iron sulphur, so that low-concentration sulfur dioxide pollution is thoroughly eliminated, valuable elements such as iron, gold, silver, tin, antimony and bismuth in the sulphur-fixing agent are recycled with high efficiency at low cost, and continuous cleaning smelting of the low-sulfur lead-containing secondary material and continuous harmless treatment of the iron-rich heavy metal solid waste are realized. The reduction sulphur-fixing bath smelting method has the advantages of changing harmful substances into beneficial substances, recycling waste materials, and being simple in process, environmental-friendly, and low in cost, and has important significance for continuous clean smelting of the low-sulfur lead-containing secondary material and the treatment and recycling of the heavy metal solid waste.

Owner:CENT SOUTH UNIV

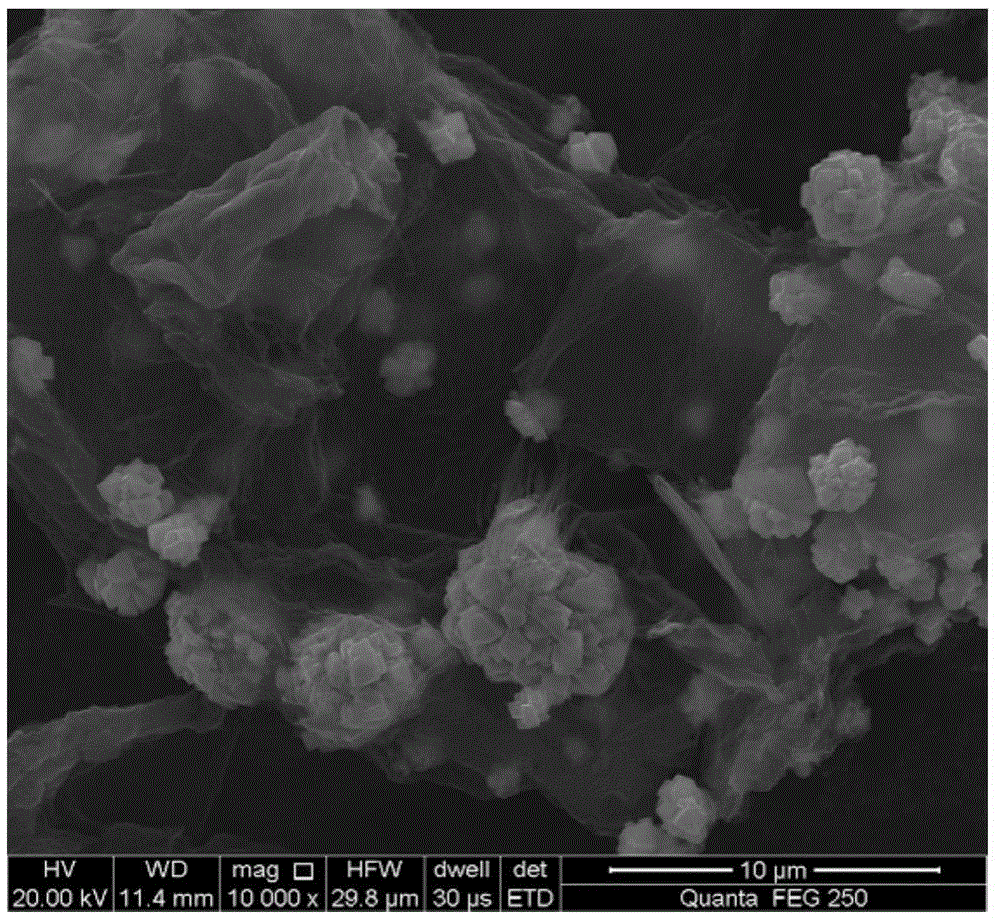

Iron diselenide/sulfur-doped graphene anode composite material for sodium-ion battery and preparation method of iron diselenide/sulfur-doped graphene anode composite material

ActiveCN105390674AAvoid irregular topographyAvoid reunionCell electrodesSecondary cellsSe elementMaterials science

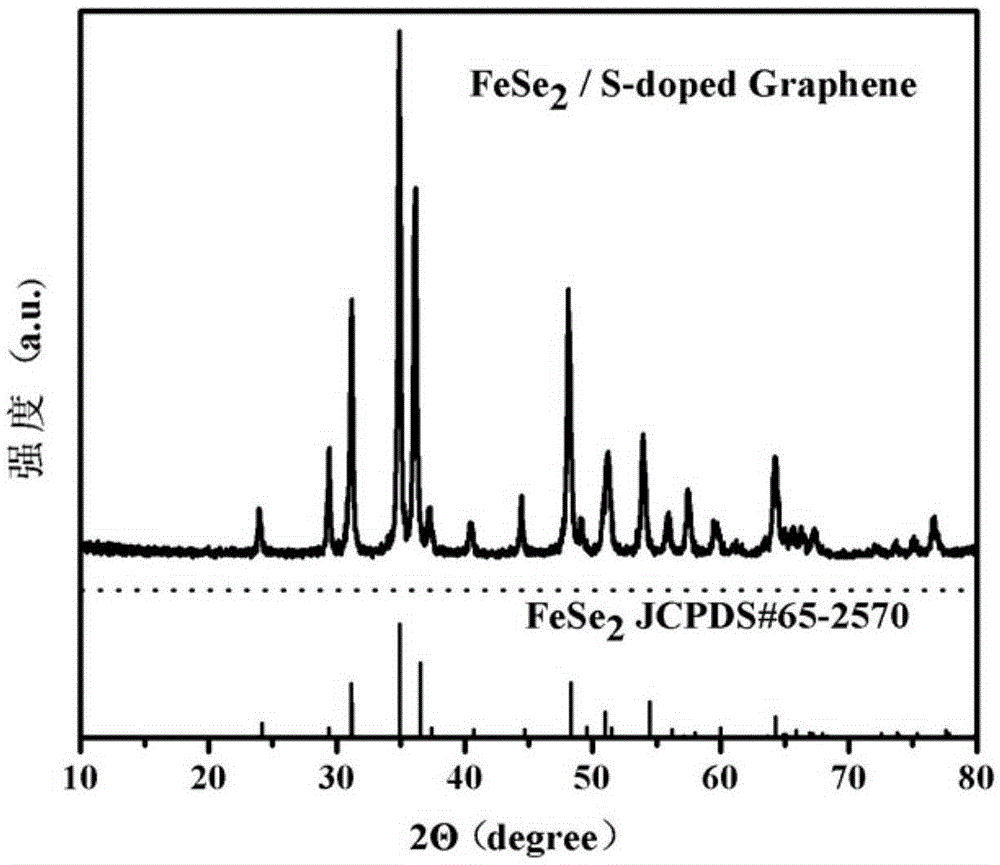

The invention discloses an iron diselenide / sulfur-doped graphene anode composite material for a sodium-ion battery and a preparation method of the iron diselenide / sulfur-doped graphene anode composite material. The preparation method comprises the following steps: dissolving a sulfur source, a selenium-containing inorganic matter, an iron-containing inorganic salt and citric acid or sodium citrate into a graphene oxide solution; dropwise adding hydrazine hydrate to form a light black solution, adding the light black solution to a hydrothermal reaction kettle for reaction, and naturally cooling the product after the reaction is ended; and carrying out repeated washing, suction filtration and drying on a reaction sediment with distilled water and absolute ethyl alcohol, so as to obtain the iron diselenide / sulfur-doped graphene composite material. According to the iron diselenide / sulfur-doped graphene composite material prepared by the method, iron diselenide nano-particles are evenly distributed on the surface of the sulfur-doped graphene and the iron diselenide / sulfur-doped graphene composite material has excellent electrochemical properties as a sodium-ion battery anode material. The iron diselenide / sulfur-doped graphene anode composite material is prepared by a simple hydrothermal process; synchronous sulfur doping, graphene oxide reduction and graphene oxide and iron diselenide recombination can be achieved; and the iron diselenide / sulfur-doped graphene anode composite material is simple in preparation technology and low in cost, and has a wide industrial application prospect.

Owner:CENT SOUTH UNIV

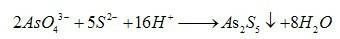

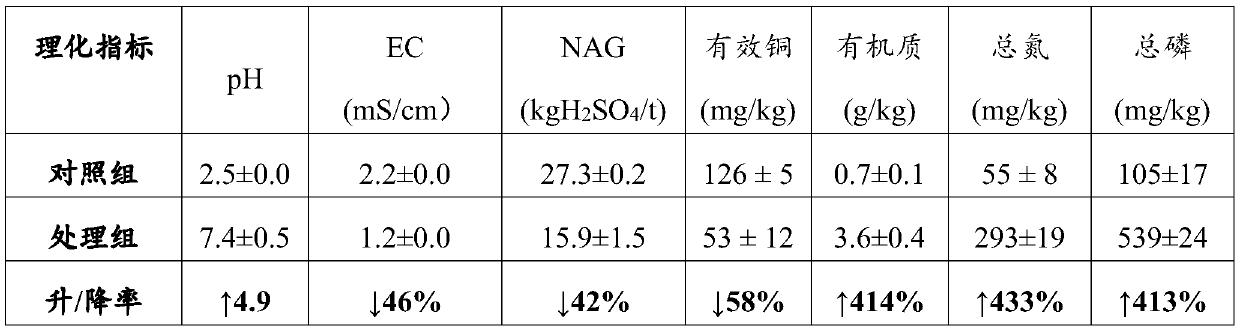

Arsenic-resistant bacteria and method for performing oxidation treatment on high-arsenic gold concentrate by using same

InactiveCN101993835AReduce consumptionEfficient recyclingBacteriaMicroorganism based processesIron sulphurOxidative treatment

The invention relates to a method for treating high-arsenic gold concentrate, which belongs to the technical field of metallurgy. Arsenic-resistant bacteria of the invention are arsenic-resistant thiobacillus ferrooxidant (CCTCCCNO: M2010072) which are obtained by breeding and domesticating thiobacillus ferrooxidant-containing high-arsenic gold concentrate acid mine pit water. The method for treating the high-arsenic gold concentrate by using the arsenic-resistant bacteria comprises the steps of expanding and culturing the bacteria, performing paste mixing on the high-arsenic gold concentrate, performing bacterial oxidation treatment, acidizing to remove arsenic, cyaniding to extract gold, recovering the arsenic and the like. Compared with the conventional method for pretreating high-arsenic gold ore, the method for treating the high-arsenic gold concentrate has the advantages of efficiently recovering noble metal gold, recycling the side product, namely arsenic, solving the environmental problem of high arsenic content of sewage and waste residues subjected to the bacterial oxidation process treatment, reducing the consumption of a cyaniding medicament, increasing the gold-extracting ratio of the high-arsenic gold concentrate and contributing to the environmental protection and the sustainable development of the huge-reserve high-arsenic gold concentrate in China.

Owner:威远川奇生工科技有限责任公司 +1

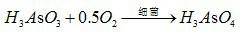

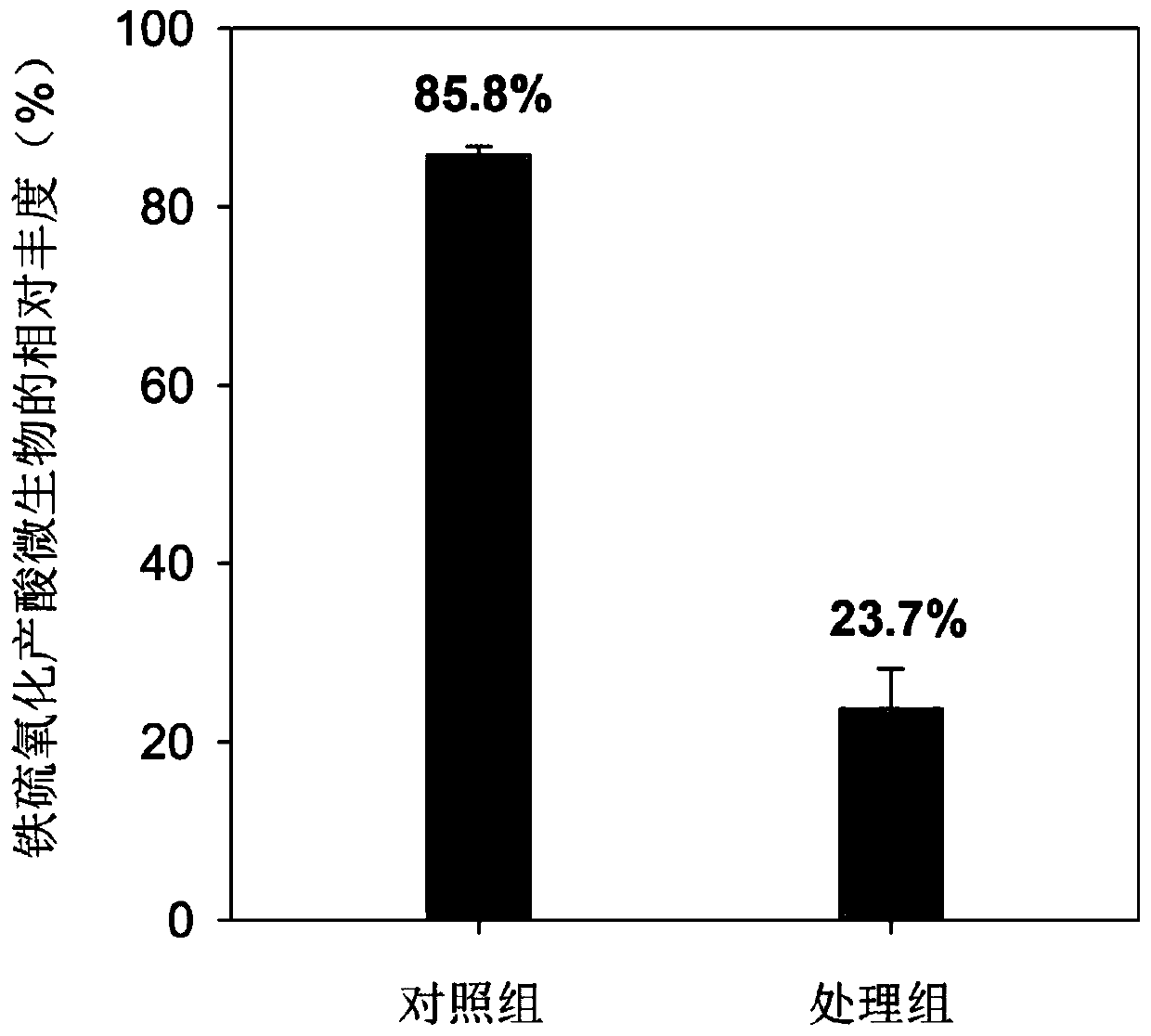

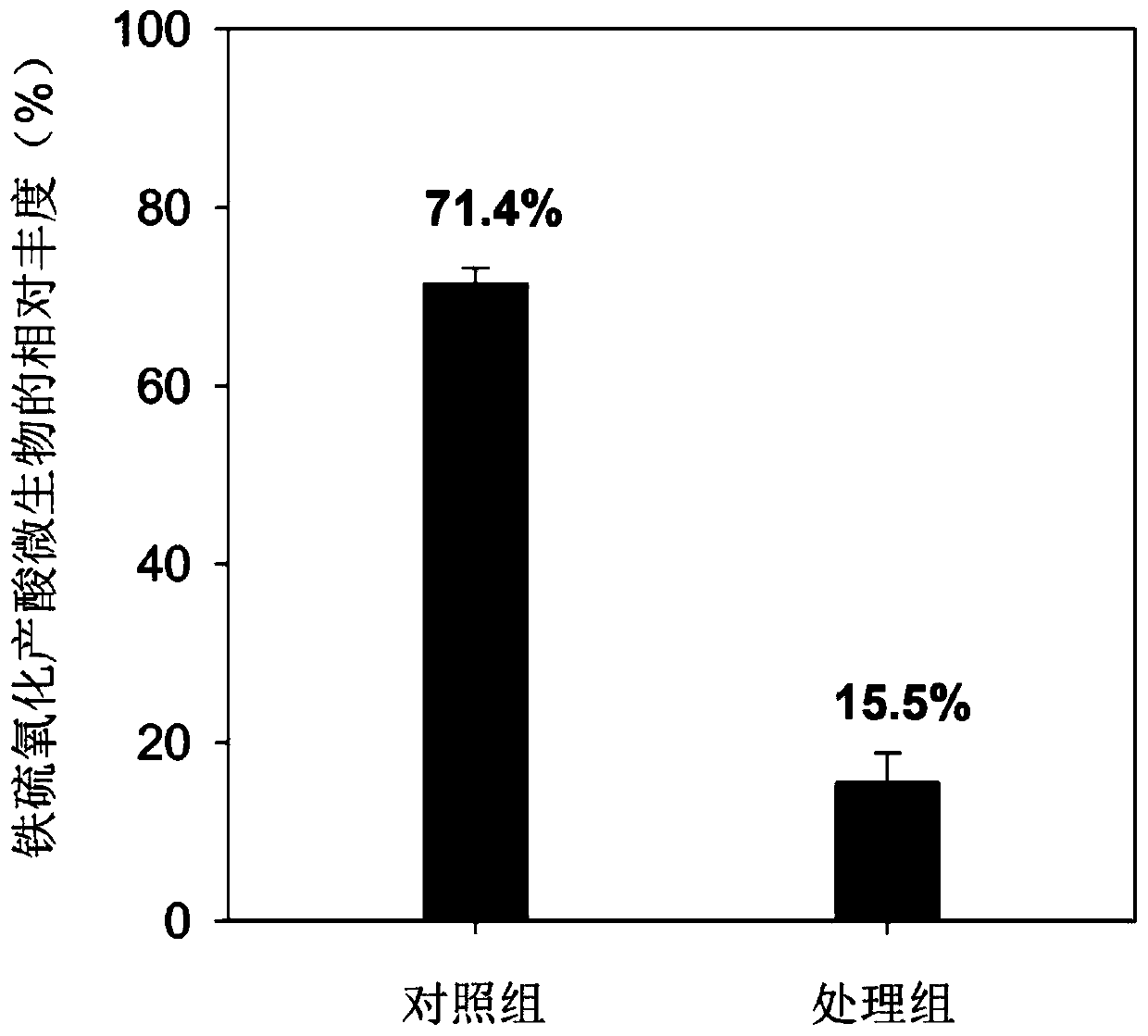

Improvement method of extremely acidified mine soil

PendingCN110860554AReduced Acidogenic PotentialInhibitory activityCalcareous fertilisersOther chemical processesMicrobial agentMetallic sulfide

Belonging to the technical field of contaminated soil remediation, the invention particularly relates to an improvement method of extremely acidified mine soil. The method utilizes an improving agentand a microbial agent to change the microbial community structure of soil, especially reduce the relative abundance of iron-sulfur oxidation acid production microorganisms and inhibit metal sulfide from oxidizing and producing acid. The improving agent can be utilized for adsorption, chelation, complexing and immobilization of heavy metal ions and reduction of the biological toxicity, thus reducing the diffusion and leakage of heavy metal ions to surrounding soil or water. The improvement method provided by the invention has the advantages of low investment cost, good acidification control andheavy metal stabilization effect, substantial increase of nutrient content, no destruction of the soil structure, and easy implementation.

Owner:SHAOGUAN TAOLIN GREEN TECH

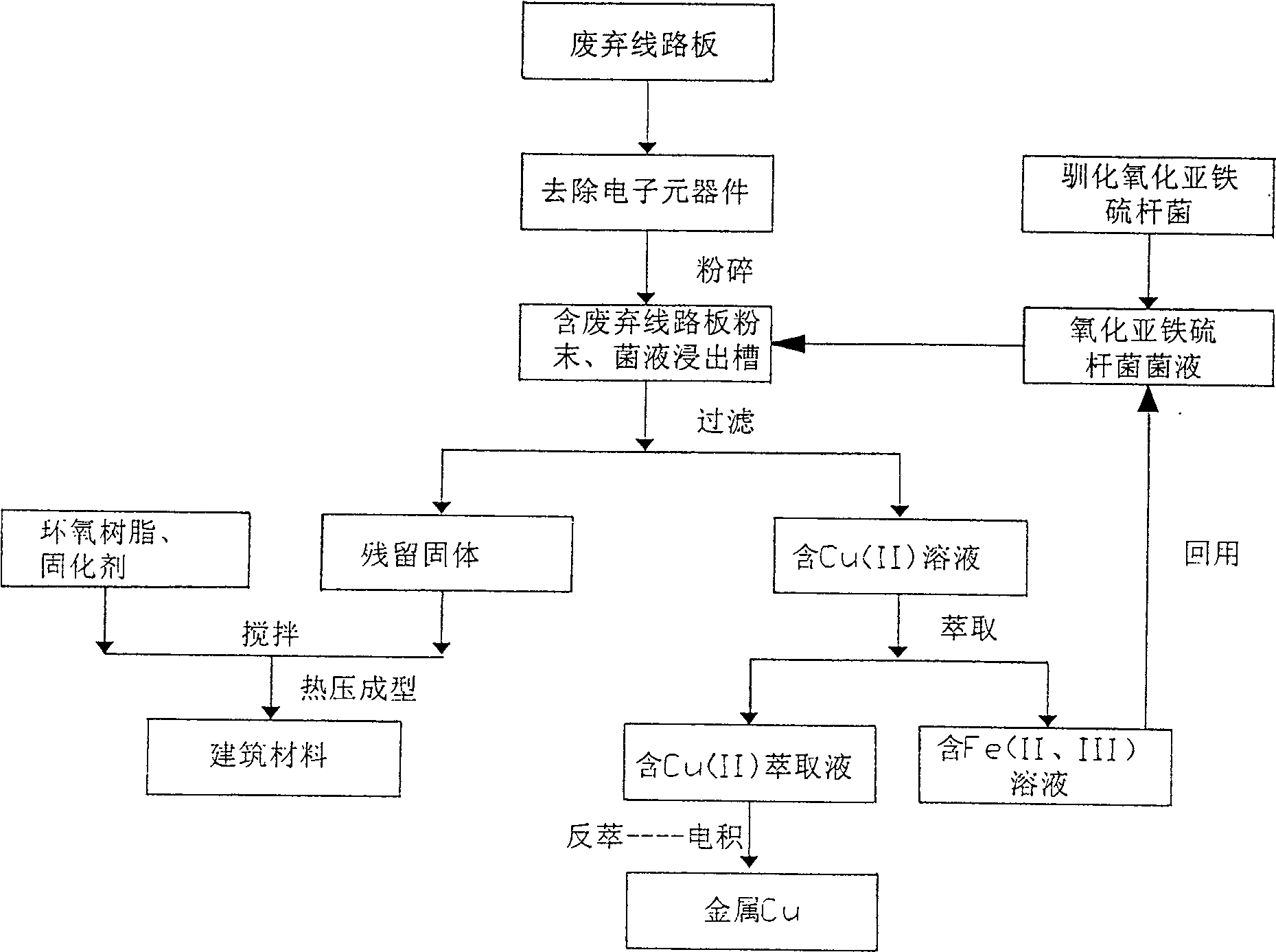

Comprehensive resources treatment method of waste circuit board

InactiveCN100510126CHigh recovery rateRealize cleaner productionPhotography auxillary processesBacteriaThiobacillusWastewater

The invention relates to a method that combines microbial, metallurgical, material and other technologies to extract metallic copper from waste circuit boards and comprehensively utilize other remaining materials. This invention draws on the principles of microbial hydrometallurgy, uses Thiobacillus ferrooxidans and the like to leaching and recovering the metallic Cu in the waste circuit boards, and at the same time recycles the residual solids after leaching the Cu, achieving a completely comprehensive resource utilization of the waste circuit boards. deal with. This method realizes full resource treatment of waste circuit boards, does not discharge waste water, waste residue or waste gas to the environment, realizes clean production in the whole process, has the characteristics of low investment, low cost, high metal recovery rate, no pollution, green ecology, etc. Advantages: It has good social, economic and environmental benefits.

Owner:NANJING UNIV

Denitrification functional filler, and filler ball, filling method and applications thereof

InactiveCN111137973AReduce productionStable pHWater treatment compoundsWater contaminantsBiological activated carbonSludge

The invention provides a denitrification functional filler, which comprises the following components in percentage by mass: 30-50% of an iron-carbon filler, 20-40% of scrap iron, 20-40% of sulfur and5-20% of biological active carbon. According to the invention, by using a novel autotrophic denitrification process of iron and sulfur, sludge production is low, the pH stability of a water body is maintained through a sulfur-iron coupling effect, and the problems of iron-based surface inert film generation and sulfur autotrophy alkalinity consumption in iron autotrophy are reduced; and the oxidation-reduction property of a biological active carbon functional group, and the conductivity, the high specific surface area and the biological activity of the main body are synchronously utilized, sothat the biomass in the system is improved, the denitrification efficiency of the system is improved, and finally the aims of reducing the operation cost and meeting the water quality requirement areachieved.

Owner:清上(苏州)环境科技有限公司

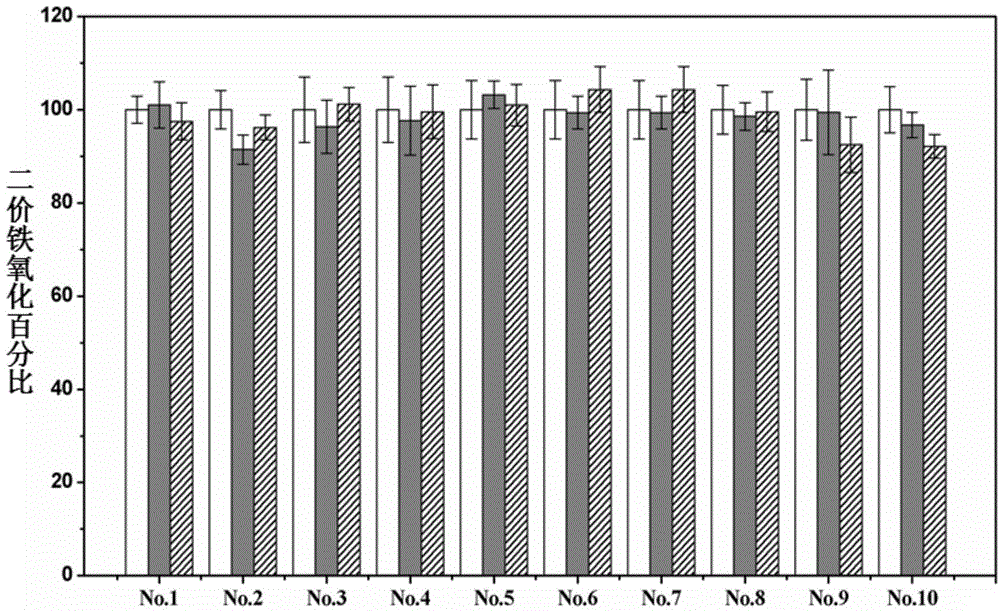

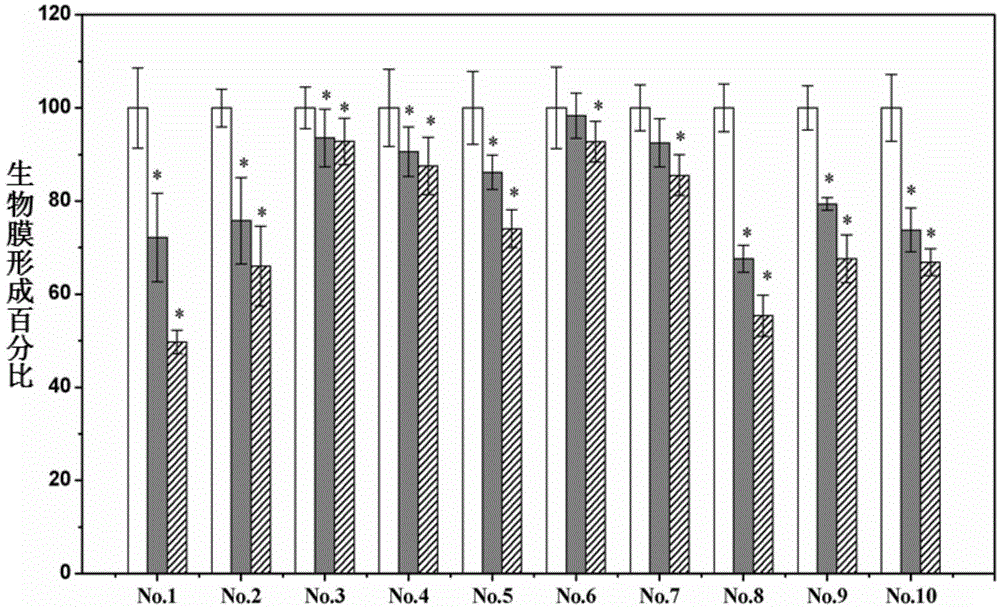

Acyl-homoserine lactone compound and application thereof in environmental protection

ActiveCN106146378AEasy to makeNo secondary pollutionBiocideOrganic chemistryThiobacillus ferrooxidansHigh concentration

As existence of acidophilic thiobacillus ferrooxidans on surface of metal sulfide ore in the form of a bio-membrane, dissolution-out of the metal is greatly improved, thereby forming acidic pit water in high concentration of heavy metal ions and further causing serious environment pollution. The invention discloses a compound which can inhibit formation of bio-membrane of the acidophilic thiobacillus ferrooxidans. The compound, without influence on normal growth of the acidophilic thiobacillus ferrooxidans, can inhibit the formation of the bio-membrane of the acidophilic thiobacillus ferrooxidans, thus reducing the erosion speed of the acidophilic thiobacillus ferrooxidans on the metal sulfide ore and significantly reducing generation of acidic heavy metal pit water in a sulfide mining area. Compared with a bactericide or an antibacterial agent for treating acidic heavy metal pit water pollution, the ecologic toxicity on environment of the compound is reduced to minimum during the treatment on the acidic heavy metal pit water pollution. The acidophilic thiobacillus ferrooxidans is free of drug resistance caused by the bactericide or the antibacterial agent.

Owner:LANZHOU UNIVERSITY

Desulphurization of ferrous materials using glass cullet

InactiveUS20050066772A1Easy to replaceBlast furnace componentsBlast furnace detailsEvaporationIron sulphur

The invention relates to a method for the preparation of a sodium-based reactive desulphurizing agent for use in molten ferrous materials. The source of sodium in the reactive desulphurizing agent is a glass cullet, a composition comprising of at least Na2O and SiO2. In a second embodiment of the invention, the glass cullet reactive desulphurizing agent also comprises of an alkali or an alkaline material or other materials, such as oxides of calcium, aluminum and magnesium. Preferred raw materials for the oxides of calcium, aluminum and magnesium are, respectively, lime, alumina and dolomite. The premixed solid reactive desulphurizing agent is brought in contact with the molten ferrous material, allowing the desulphurization or the double replacement of the iron sulphur to take place and produce a ferrous oxide. The sodium in the reactive desulphurizing agent is rendered resistant to combustion or evaporation on contact with the molten ferrous materials by the flux activity of the silica. A metallic solid, such as aluminum, is introduced into the molten ferrous material to complete the reduction of the ferrous oxide.

Owner:FLORES MORALES JOSE IGNACIO +1

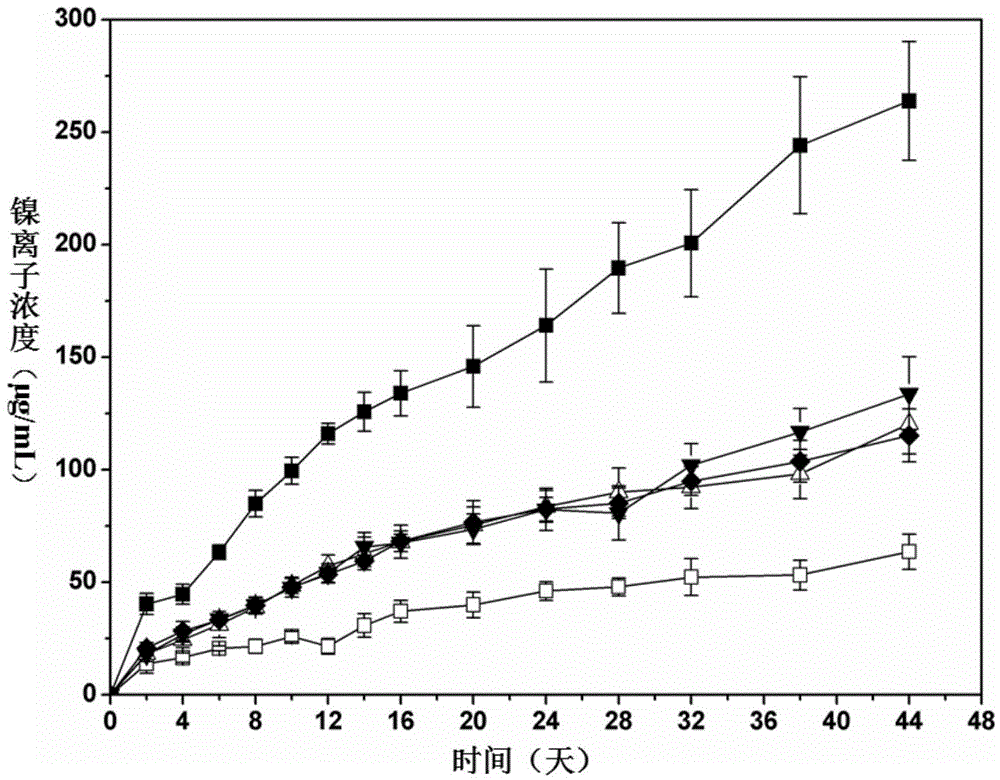

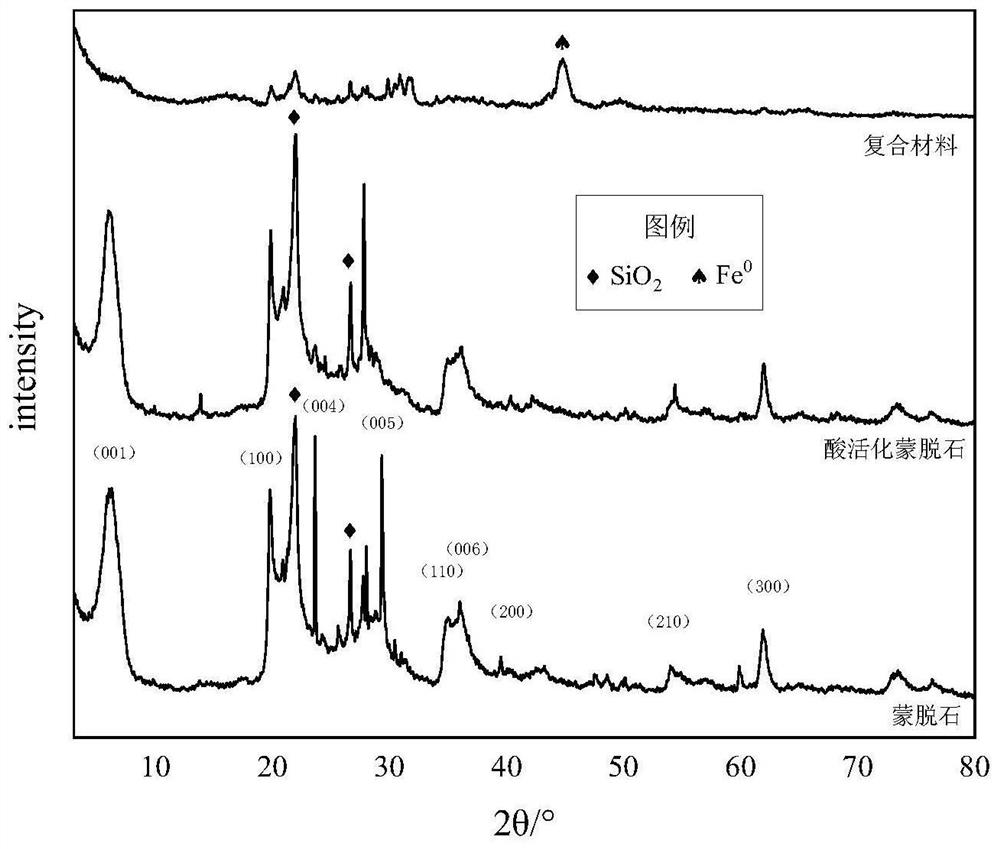

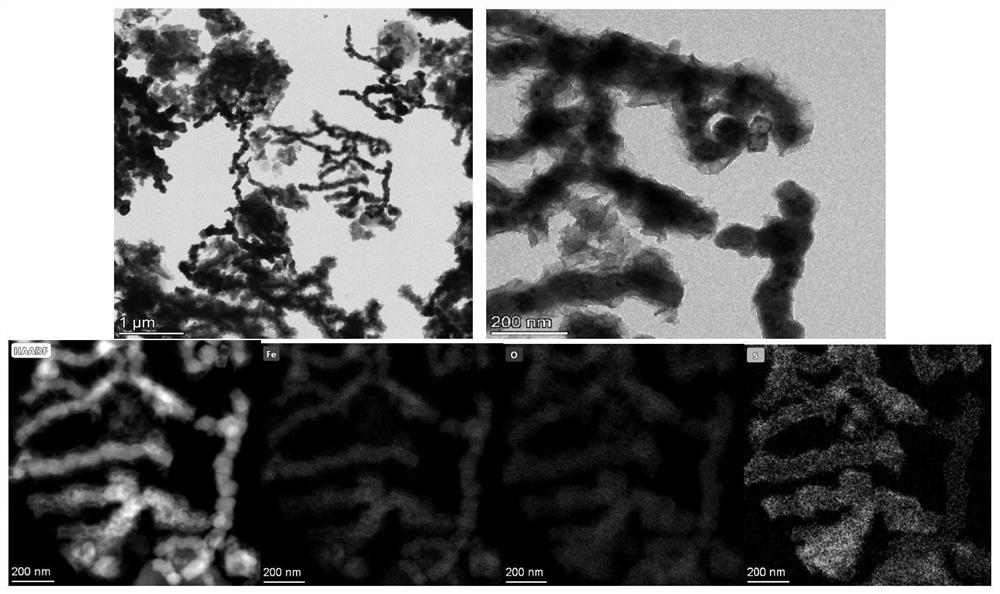

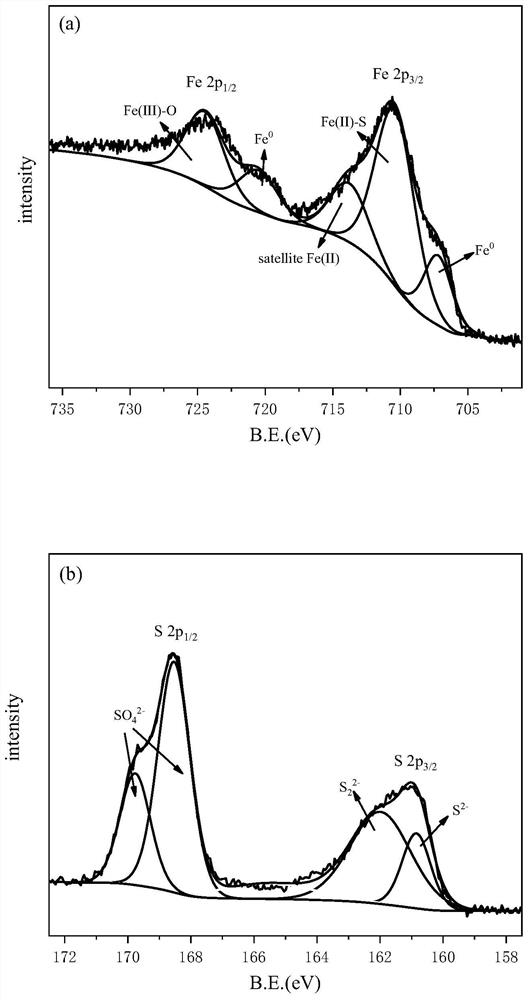

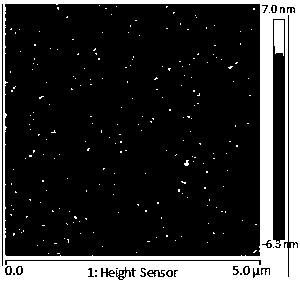

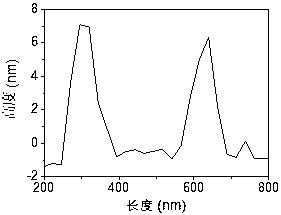

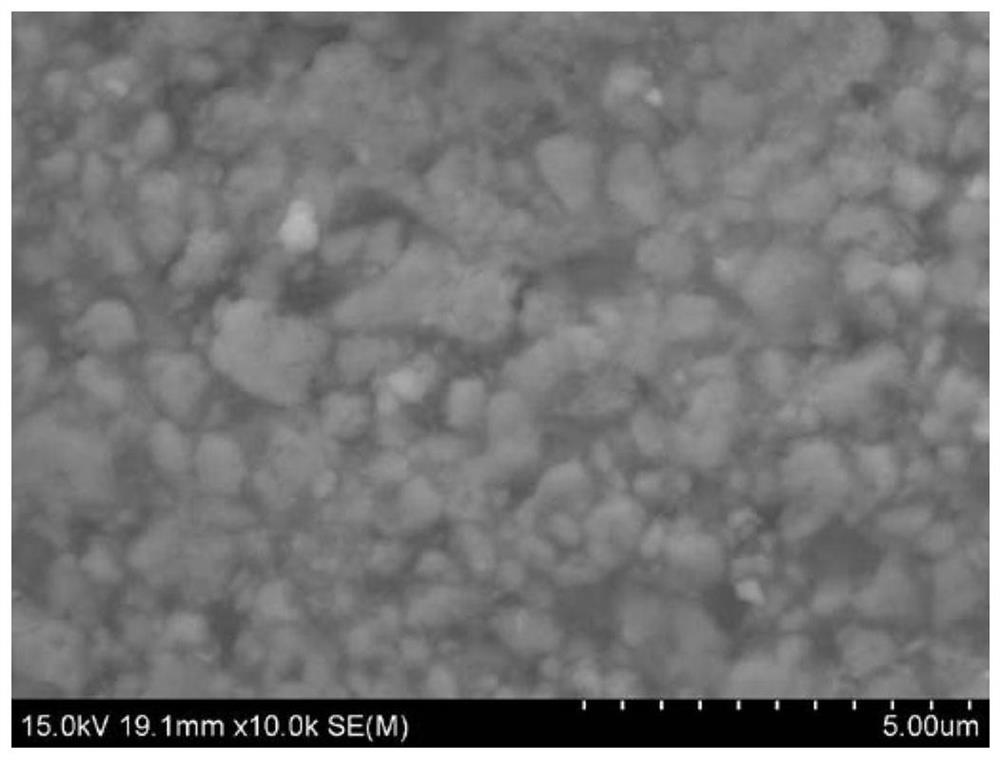

Vulcanized nano zero-valent iron-acid activated montmorillonite composite material, and preparation method and application thereof

ActiveCN111718719AIncrease speedImprove reduction efficiencyOrganic fertilisersSoil conditioning compositionsIn situ remediationMontmorillonite

The invention discloses a vulcanized nano zero-valent iron-acid activated montmorillonite composite material, and a preparation method and application thereof. The composite material is composed of spherical particles with nano zero-valent iron as a core and ferrous sulfide as a shell, is of a nano long-chain structure, has uniformly distributed and highly dispersed iron and sulfur elements, and has typical structural characteristics of silicate and zero-valent iron. The vulcanized nano zero-valent iron-acid activated montmorillonite composite material prepared by the invention is simple in raw material components, green, pollution-free and low in cost; and the product is convenient to transport and store. The prepared vulcanized nano zero-valent iron-acid activated montmorillonite composite material can be applied to in-situ remediation of soil polluted by various alkaline Cr (VI), the process is simple and rapid, the applicability is good, and the remediation effect is good.

Owner:CENT SOUTH UNIV

Method for safe production of rice soil mildly and moderately polluted by heavy metals

ActiveUS20200337255A1Promote safe productionReduced activityPlantingAlkali orthophosphate fertiliserSulphur reducing bacteriaSoil science

The present invention discloses a method for safe production of rice on soil mildly and moderately polluted by heavy metals. The method includes applying a passivator before transplanting rice seedlings to reduce activity of heavy metals in soil, and then spraying a foliar barrier from the peak tillering stage to the booting stage of rice and at the filling stage of rice; the passivator includes bentonite, gypsum powder, lime, a biochar, an iron-based biochar, a slow-release iron-based biochar, an iron-sulfur-silicon composite biochar, a heavy metal cadmium passivator and a cadmium-arsenic synchronous passivator for activating sulfur reducing bacteria in paddy soil; and the foliar barrier includes an acid silica sol, a selenium-silicon composite sol, a cerium composite silica sol, a ferrous modified selenium sol. The method can also include applying a nitrate nitrogen fertilizer at the seedling stage of rice, and / or applying a phosphorus potassium fertilizer at the tillering stage of rice.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Method for efficiently preparing sulphur-doped hollow carbon spheres

InactiveCN105293468ARealize continuous preparationImprove efficiencyMaterial nanotechnologyPeristaltic pumpPtru catalyst

The invention relates to a method for efficiently preparing sulphur-doped hollow carbon spheres. The method for efficiently preparing the sulphur-doped hollow carbon spheres comprises the following steps: firstly weighing a catalyst and a sulphur source, and mixing the catalyst with the sulphur source, wherein the catalyst is ferric acetylacetonate, the sulphur source is carbon disulfide, and the concentration of the catalyst in the sulphur source is 1-0.025g / ml; introducing the mixture into a tubular furnace, wherein temperature of the tubular furnace is 600-1350 DEG C; introducing inert gas as a carrier gas, inputting a reaction solution into an ejector inside the tubular furnace by virtue of a peristaltic pump, then spraying into a high-temperature region of the tubular furnace, and collecting products at the tail of the tubular furnace, so that carbon-coated iron nano core-shell particles are obtained; and putting the obtained carbon-coated iron nano core-shell particles into the mixed solution of hydrochloric acid and nitric acid, heating to 60-100 DEG C, carrying out magnetic stirring, filtering the obtained mixed liquor, adding deionized water for washing until filtrate is neutral, and immediately drying, so that the sulphur-doped hollow carbon spheres with high specific surface areas are obtained. The method for efficiently preparing the sulphur-doped hollow carbon spheres is easy to operate, simple in after-treatment, and applicable to industrial production.

Owner:SHANGHAI INST OF TECH

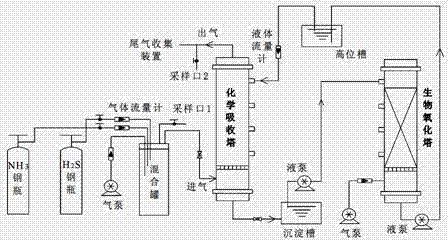

Method for biologically removing hydrogen sulfide and ammonia gas by steel sulfuric acid pickling waste liquor

InactiveCN103585870ARealize resourcesRealize closed loopDispersed particle separationAir quality improvementIron sulphurNutrient solution

The invention relates to a method for biologically removing hydrogen sulfide and ammonia gas by steel sulfuric acid pickling waste liquor. The method comprises the following steps: filling filler subjected to culture and biofilm hanging by acidithiobacillus ferrooxidan thiobacillus in a biological oxidation tower, and carrying out acid pickling on divalent iron in the acid pickling waste liquor divalent iron so as to oxidize the divalent iron by the acidithiobacillus ferrooxidan thiobacillus to form ferric ion; removing the ammonia gas from a biological oxidation solution in a chemical absorption tower by means of the acidic absorption effect, oxidizing hydrogen sulfite by using the soluble ferric iron, reducing the soluble ferric iron into the divalent iron, converting the hydrogen sulfite into a simple substance, and converting the ammonia gas into ammonium radicals; and regenerating a reducing solution by adding a nutrient solution and recycling the reducing solution to a biological power. The method disclosed by the invention has the advantages that a nitrogen source is provided for microorganisms in the process of removing the ammonia gas and the hydrogen sulfide, the divalent iron is regenerated while the hydrogen sulfide is removed by oxidizing the ferric iron in the acid pickling waste liquor, thus the purposes of treating the wastes with wastes and recycling the wastes are achieved, and remarkable economic benefit and environmental benefit are realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

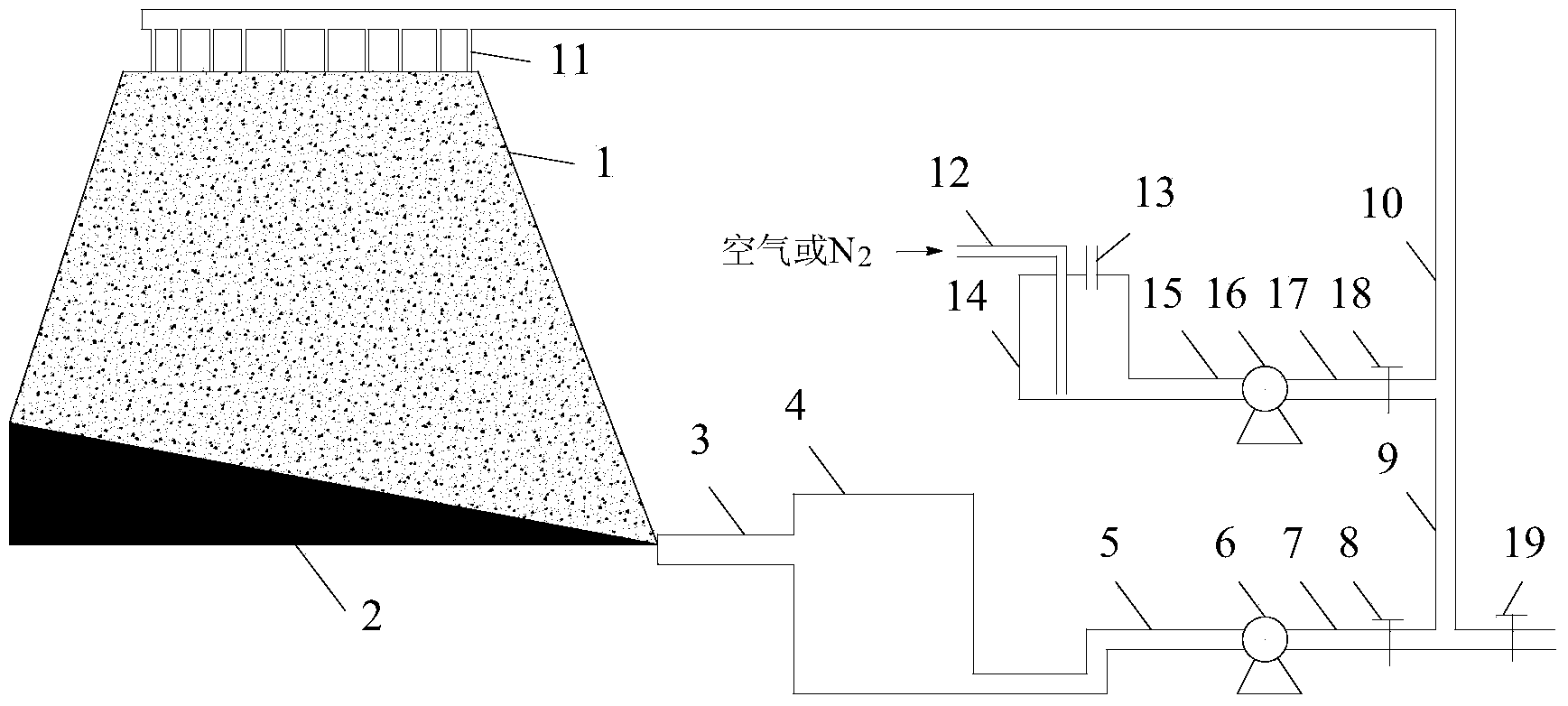

Method and device for improving beneficiability of niobium mineral in niobium-containing tailings

ActiveCN103834806AHigh recovery rateRaise the gradeFlotationProcess efficiency improvementNiobiumMagnetite

The invention provides a method and a device for improving beneficiability of a niobium mineral in niobium-containing tailings. The method comprises the following steps: spraying a culture solution containing ferrous oxide thiobacilli to a niobium-containing tailing heap, wherein the ferrous oxide thiobacilli can oxidize Fe<2+> on the surface of the niobium mineral in the niobium-containing tailings into Fe<3+> so as to be dissolved out, thereby changing the category and density of particles on the surface of the mineral and improving the floatability difference between the niobium mineral and other minerals in the niobium-containing tailings; reducing Fe<3+> on the surface of hematite or magnetite into Fe<2+> ions so as to be dissolved out by using iron-reducing bacteria; meanwhile enabling Fe<2+> to rapidly form a sulfide precipitate on the surface of hematite or magnetite in the presence of sulfate reducing bacteria or Na2S, thereby improving the floatation difference between the hematite or magnetite and the niobium mineral. By using the method, the recovery rate and grade of the niobium mineral in the niobium-containing tailings can be improved, meanwhile the environmental pollution and the use of chemical agents such as an inhibitor and a regulator in a floatation process can be reduced; the method has high social benefits.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

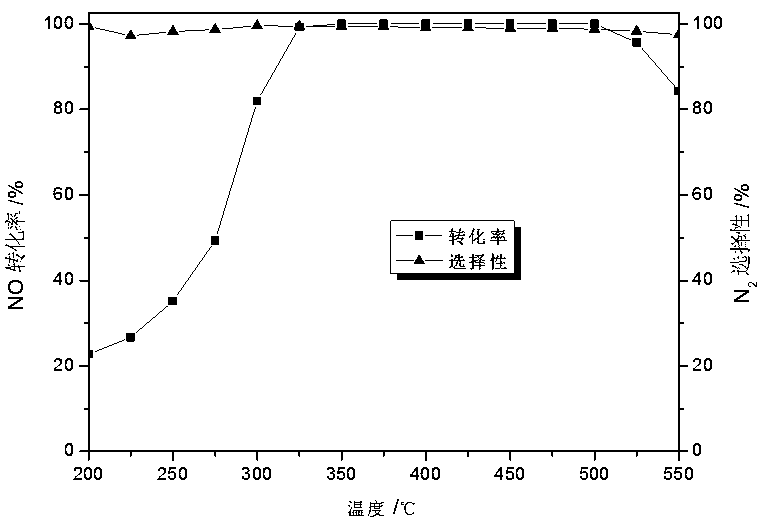

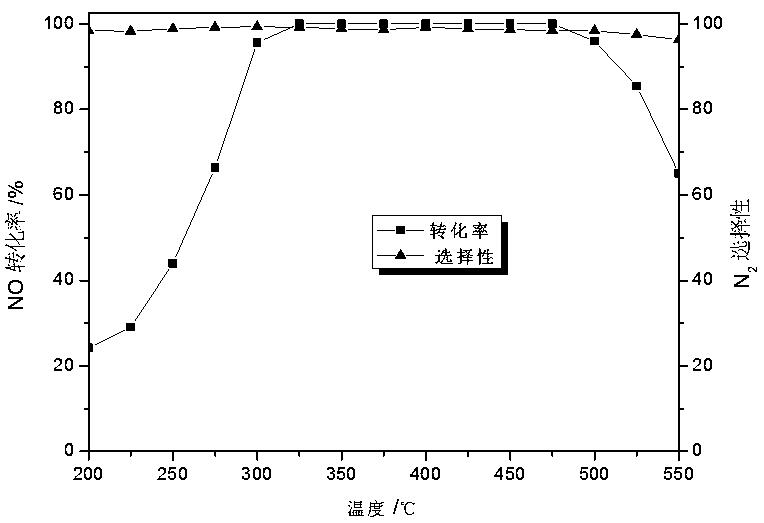

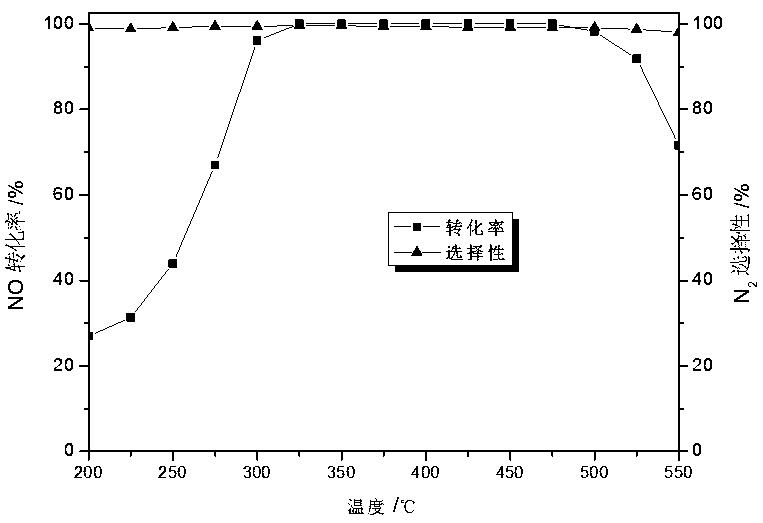

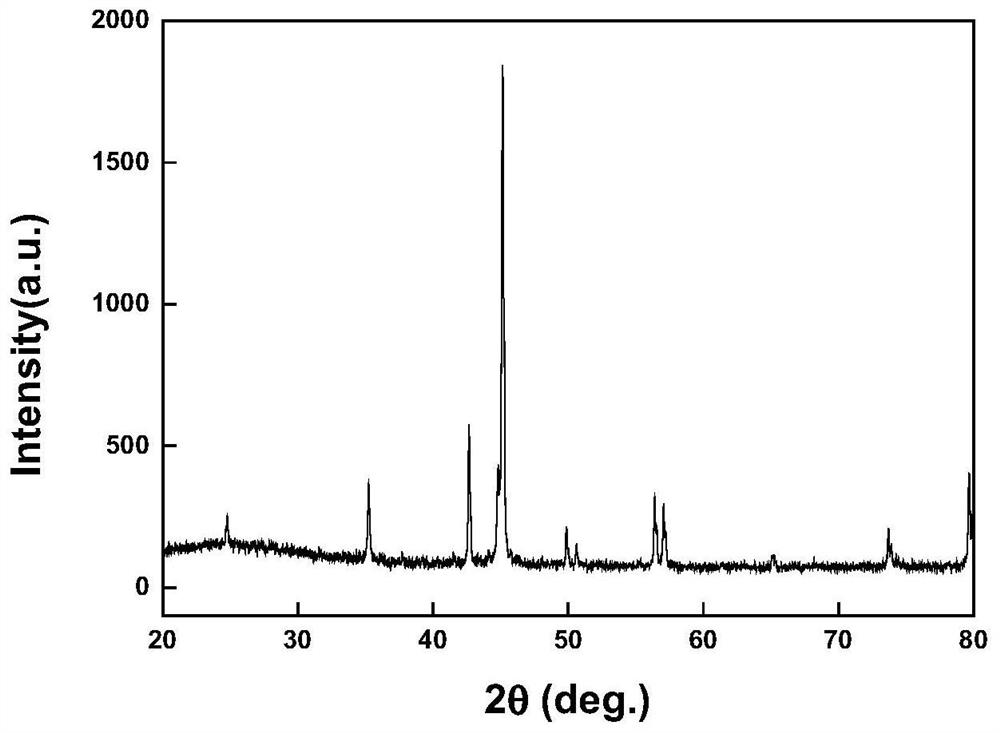

Novel method for preparing iron-sulfur-titanium-based NH<3>-SCR denitrification catalyst

ActiveCN109012703AHigh activityPrevent oxidationGas treatmentPhysical/chemical process catalystsFlue gasPrecipitation

The invention discloses a novel method for preparing an iron-sulfur-titanium-based NH<3>-SCR flue gas denitrification catalyst by utilizing the high-temperature pyrohydrolysis of acidic iron titaniumsulfate solution. The preparation method for the iron-sulfur-titanium-based catalyst is as follows: firstly, titanyl sulfate and ferric sulfate are utilized to for preparinge different concentrationsof titanium iron solutions; secondly, under certain temperature and pH, the titanium iron solutions undergoare subjected hydrolytic precipitation for a certain time; and finally, hydrolysates are filtered by suction, dried and roasted. According to the invention, by regulating preparation conditions, a novel high-activity iron-sulfur-titanium-based catalyst can be obtained. The catalyst appears asan anatase type TiO<2> crystal structure, iron exists in a Fe-O-Ti chemical bond structure form, and the sulfur element appears as plus 6 valence. In an activity test, under high space velocity (60000h<-1>), within a range from 325 DEG C to 500 DEG C, the NO conversion rate can reach 90 percent or moreabove, N2 selectivity can reach 98 percent or moreabove, and therefore the iron-sulfur-titanium-based NH<3>-SCR denitrification catalyst has a great potential to replace the V-W(Mo)-Ti catalytic system which is widely used at present, and can be applied to the denitrification of stationary sources with coal-fired industrial power plants as a representative.

Owner:SICHUAN UNIV

Desulphurization of ferrous materials using sodium silicate

The invention relates to a method for the preparation of a sodium-based reactive desulphurizing agent for use in molten ferrous materials. The sodium in the reactive desulphurizing agent is a sodium silicate, a composition comprising of Na2O and SiO2. In a second embodiment of the invention, the sodium silicate reactive desulphurizing agent also comprises of an alkali or an alkaline material or other materials, such as oxides of calcium, aluminum and magnesium. Preferred raw materials for the oxides of calcium, aluminum and magnesium are, respectively, lime, alumina and dolomite. The premixed solid reactive desulphurizing agent is brought in contact with the molten ferrous material, allowing the desulphurization or the double replacement of the iron sulphur to take place and produce a ferrous oxide. The sodium in the reactive desulphurizing agent is rendered resistant to combustion or evaporation on contact with the molten ferrous materials by the flux activity of the silica. A metallic solid, such as aluminum, is introduced into the molten ferrous material to complete the reduction of the ferrous oxide.

Owner:FLORES MORALES JOSE IGNACIO +1

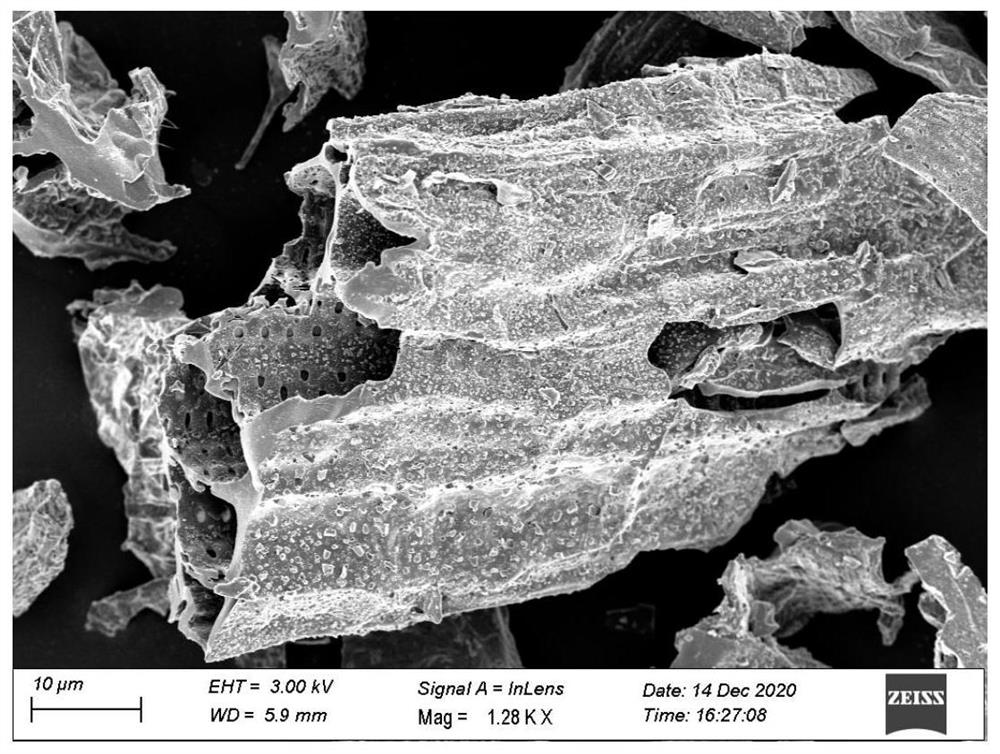

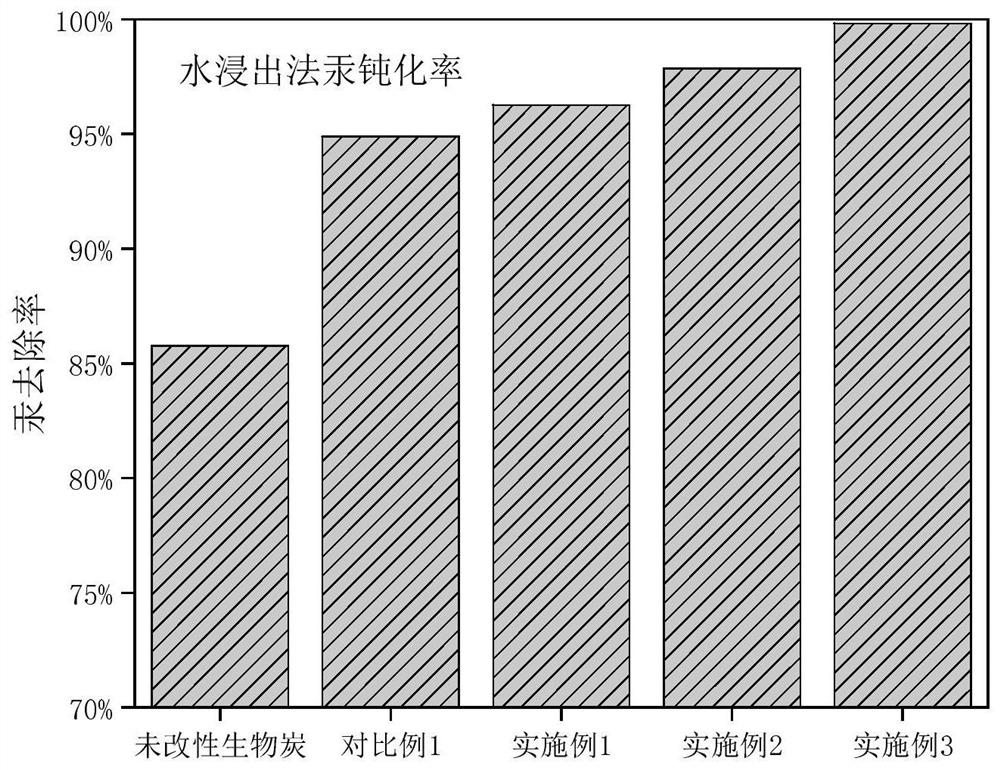

Passivator for repairing mercury-polluted soil as well as preparation method and application thereof

ActiveCN112852430ALarge specific surface areaWide variety of sourcesContaminated soil reclamationOrganic fertilisersSoil scienceCarbonization

The invention discloses a passivator for repairing mercury-polluted soil as well as preparation and application thereof. According to an iron-sulfur-selenium loaded biochar material disclosed by the invention, ferrous sulfide and sodium selenite are taken as central substances, shaddock peel biochar subjected to anoxic high-temperature carbonization is taken as a carrier, and a method of loading iron-sulfur-selenium on biochar is adopted, so that the passivator for repairing mercury-polluted soil is prepared. The synthesized passivation material is added into mercury-polluted soil according to a certain proportion, standing is conducted for 30 days, the highest removal rate of TCLP and water leaching mercury in the mercury-polluted soil can reach 99% or above, and the exchangeable state, the carbonate binding state and the amorphous iron-manganese oxidation state in the soil are obviously converted into the organic binding state and the residue state. The iron-sulfur-selenium biochar material disclosed by the invention is simple in preparation process and low in cost, and can effectively reduce the mobility and bioavailability of mercury in soil.

Owner:CENT SOUTH UNIV

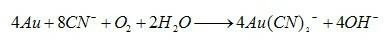

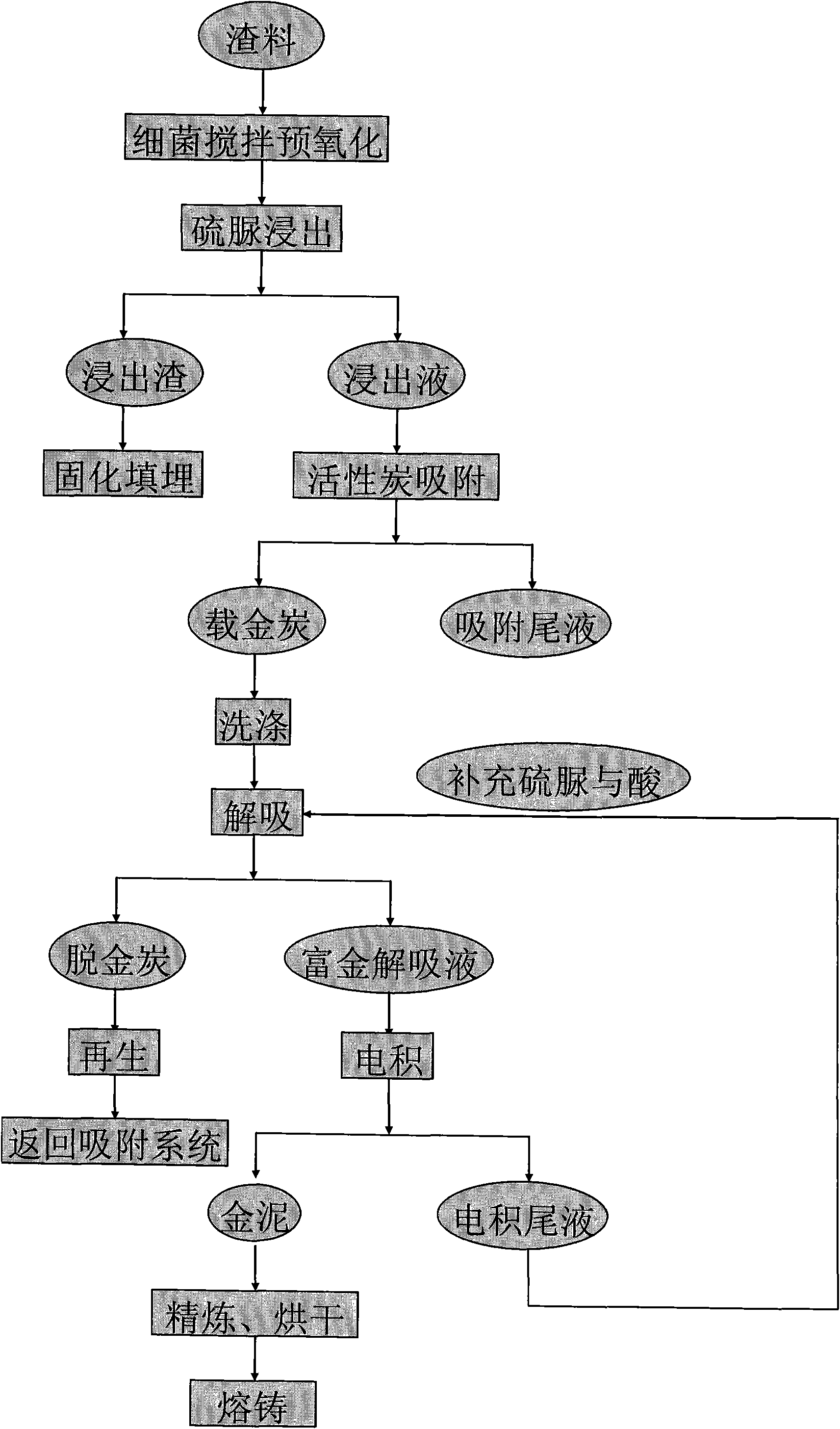

Method for leaching low-grade gold in high-arsenic sulfur concentrate acid-making cinder by microorganism preoxidation

The invention relates to a method for leaching low-grade gold in high-arsenic sulfur concentrate acid-making cinder by microorganism preoxidation, which has the main contents that bacterium preoxidation is utilized to leach the gold in the high-arsenic sulfur concentrate acid-making cinder, and the technology has the core that by taking various microorganisms, such as Thiobacillus ferrooxidans, sulfolobus and the like, under an acid condition, carbonate, sulfide, irony matter and part of silicate packing the gold are unpacked through oxygen in air, and are oxidized into sulfate, subsulphate or arsenate to achieve the goal of exposing the gold. After the gold is exposed, by taking the dilute sulphuric acid solution of thiourea as a leaching agent, under normal temperature and normal pressure, agitation leaching is carried out on pre-oxidized slag under the condition that the pH value is 1.3-1.8; 70-85 percent of gold is leached, and after solid-liquid separation is ended, a gold-contained solution can be extracted by using a traditional gold extraction process. The method of thiourea gold leaching after bacterium preoxidation has the characteristics that the toxicity is low; the solution in which the gold is removed is easy to treat, can be recycled, and can be produced by using a pollution discharge-free process flow; the gold and silver dissolution velocity is high; and the solution is not sensitive to the harmful impurities of base metals (Cu, As, Sb and Pb).

Owner:湖南布鲁斯凯碳资产管理有限公司

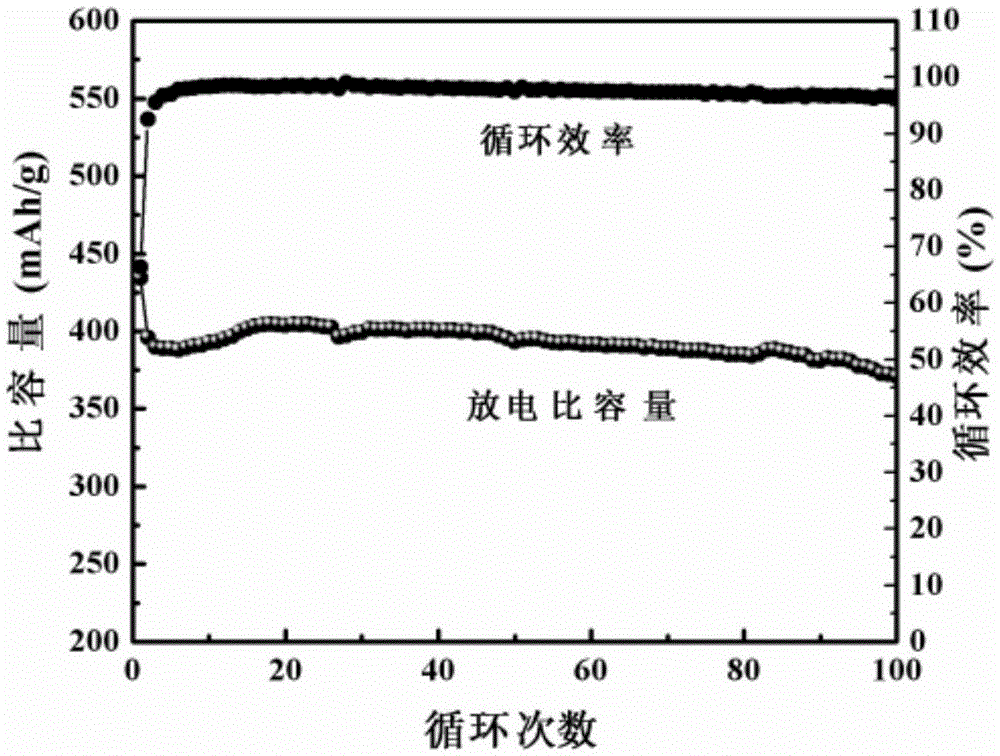

Preparation method of iron-sulfur negative electrode material for lithium battery

InactiveCN108878844AHigh crystallinityImprove conductivityCell electrodesSecondary cellsVolume expansionCarbon nitrogen

The invention discloses a preparation method of an iron-sulfur negative electrode material for a lithium battery. The method comprises the following steps of preparing a high-performance iron-sulfur compound at a proper vulcanization sintering temperature by adopting ferrite hollow spheres with a special micro-nano structure, so that the iron-sulfur compound with relatively high crystallinity canbe obtained, and a lithium-storage reaction is facilitated; through carbon-nitrogen compounding, the conductivity of the active substance is improved; and in addition, a cavity between a nitrogen-doped carbon layer and the iron-sulfur compound provides an effective space for volume expansion in an active substrate intercalation / de-intercalation lithium process, so that pulverization agglomerationof the iron-sulfur compound is prevented.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Iron-sulfur cluster and apoferritin complex and preparation method and application thereof

ActiveCN107790185AImprove the hydrogen production performance of water splittingGood biocompatibilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionFerritin complexWater soluble

The invention discloses an iron-sulfur cluster and apoferritin complex and a preparation method and application thereof; the iron-sulfur cluster and apoferritin complex includes apoferritin and a ruthenium compound and iron-sulfur cluster catalyst loaded therein, wherein the ruthenium compound has an entrapment ratio of 5-15% and the iron-sulfur cluster catalyst has an entrapment ratio of 10-30%.The photosensitizer ruthenium compound and water-insoluble iron-sulfur cluster catalyst molecules are functionally assembled in a protein molecule by means of non-covalent assembly, a working environment in nature is provided for the iron-sulfur cluster catalyst, and an aqueous photo-driven hydrogen production system is constructed; wide application of the iron-sulfur cluster catalyst catalytic system in an aqueous solution is achieved; the system has good stability; when the system is applied to hydrogen production by photocatalytic decomposition, the use of ascorbic acid as a proton source and electron sacrificial donor under light condition enables hydrogen production efficiency of the system to be enhanced.

Owner:NANJING UNIV

Compound bacterium for leaching of manganese slag

InactiveCN103243049AImprove purification effectBacteriaMicroorganism based processesThiobacillus ferrooxidansSlag

The invention aims at providing a compound bacterium for leaching of manganese slag, that is, the manganese slag is treated by using the compound bacterium comprising thiobacillus ferrooxidans, thiobacillus thiooxidans and leptospirillums ferrooxidans, and thus the quality of leachate is improved and the manganese slag is comprehensively utilized. Metal ions in the manganese slag can be efficiently leached by pre-leachate, and manganese leachate can be well purified by using pre-leached slag. Meanwhile, a method matched with the bacterium comprises preparation of the pre-leachate, process of leaching the manganese slag by using the prepared pre-leachate, and subsequent treating process of the leachate. The quality of the prepared treated solution can meet the requirement of preparing industrial grade manganese sulfate, manganese carbonate and electrolyte manganese.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method for promoting biological column leaching of poor chalcocite

ActiveCN110863117AImprove leaching efficiencyRich reservesProcess efficiency improvementIron sulphurEnvironmental chemistry

The invention discloses a method for promoting biological column leaching of poor chalcocite, particularly discloses a method for synergistically promoting biological column leaching of the poor chalcocite based on foreign intervention of compound sulfur oxidizing bacteria and the pyrite, and belongs to the technical field of bioengineering. 9K-chalcocite composite medium is used as a leaching solution, by adding a certain proportion of the pyrite and introducing a foreign compound sulfur oxidizing bacteria, various biochemical reactions in the leaching process are controlled, iron and sulfurmetabolism are promoted in the leaching process, and formation of an iron / sulfur passivation film is reduced; and the biological effect in the leaching process is strengthened by adding the compound sulfur oxidizing bacteria in batches, so as to make the copper ions leaching rate increase by 33.9%. The method is easy and convenient to operate, economical and reasonable, and is suitable for large-scale application of similar bioleaching processes.

Owner:JIANGNAN UNIV

Supercritical CO2 fluid cooperative biological in-situ leaching uranium mining method

The invention discloses a Supercritical CO2 fluid cooperative biological in-situ leaching uranium mining method. First, a uranium ore is pre-acid-leached by injecting organic weak acid citric acid into an ore layer, metal uranium is dissolved from mineral by using a method that a functional group of the citric acid forms a compound and chelate with metal uranium ions, then acclimated thiobacillusferrooxidans is injected into an acidified ore body as an oxidizing agent, Fe2+ in ore is oxidized to Fe3+, then Fe3+ is used to oxidize U4+ insoluble to acid soluble U6+, and finally a highly solubleuranyl carbonate complex is formed with an injected supercritical CO2 fluid. Therefore the concentration of the metal uranium in a leaching solution and the leaching efficiency of the metal uranium are improved, the leaching time is shortened, no side effect exerts on the environment, meanwhile, the use of citric acid can further reduce the precipitation of calcium, magnesium, iron and the like in the leaching solution, and the contact area between a leaching agent and the uranium ore in the subsequent leaching process is increased, so that continuous carrying out of a leaching reaction is facilitated.

Owner:NANHUA UNIV

Preparation method of platinum-rhodium alloy

The invention provides a preparation method of a platinum-rhodium alloy. The platinum-rhodium alloy is prepared from the following components in percentage by weight: less than 2.5% of iron, 0.020-0.060% of sulfur, less than or equal to 0.5% of silicon, 28.0-34.0% of platinum and the balance of rhodium; the preparation method of the platinum-rhodium alloy is characterized by comprising the following three steps: firstly, charging and vacuumizing; secondly, after the charged materials are completely melted, controlling the temperature within the range of 1300-1700 DEG C, refining and adding a deoxidizing agent; and finally, adding a sulfide so that the sulfur content in the platinum-rhodium alloy is within the range of 0.050-0.060%. The preparation method of the platinum-rhodium alloy has the advantages that the properties of the platinum-rhodium alloy are improved, and when the platinum-rhodium alloy is applied to the field of temperature sensors as the basic material of a thermocouple, the platinum-rhodium alloy is stable in properties and more advantageous to the accuracy of temperature detection, and therefore, the measurement accuracy can be improved.

Owner:李家波

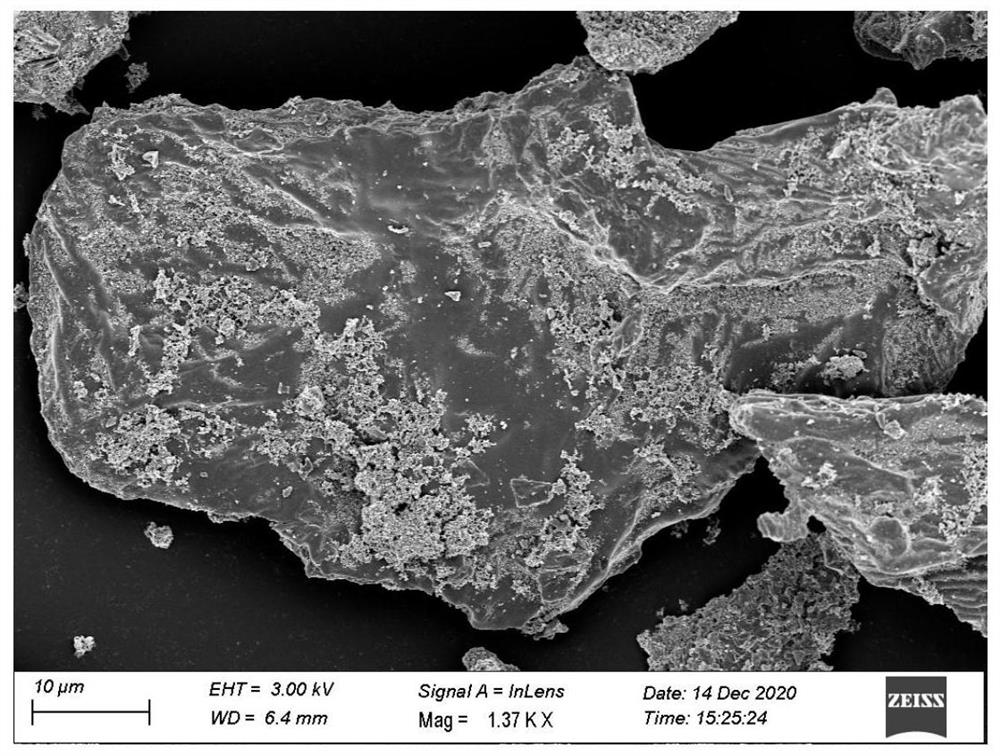

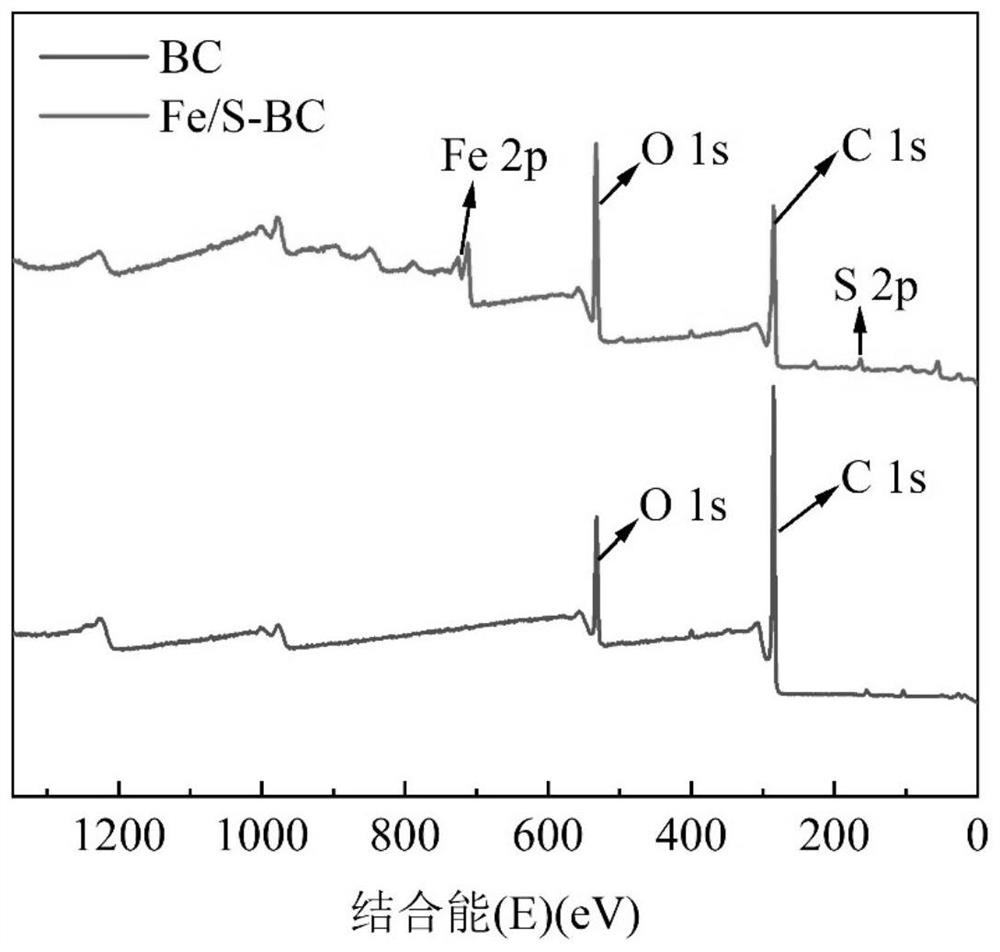

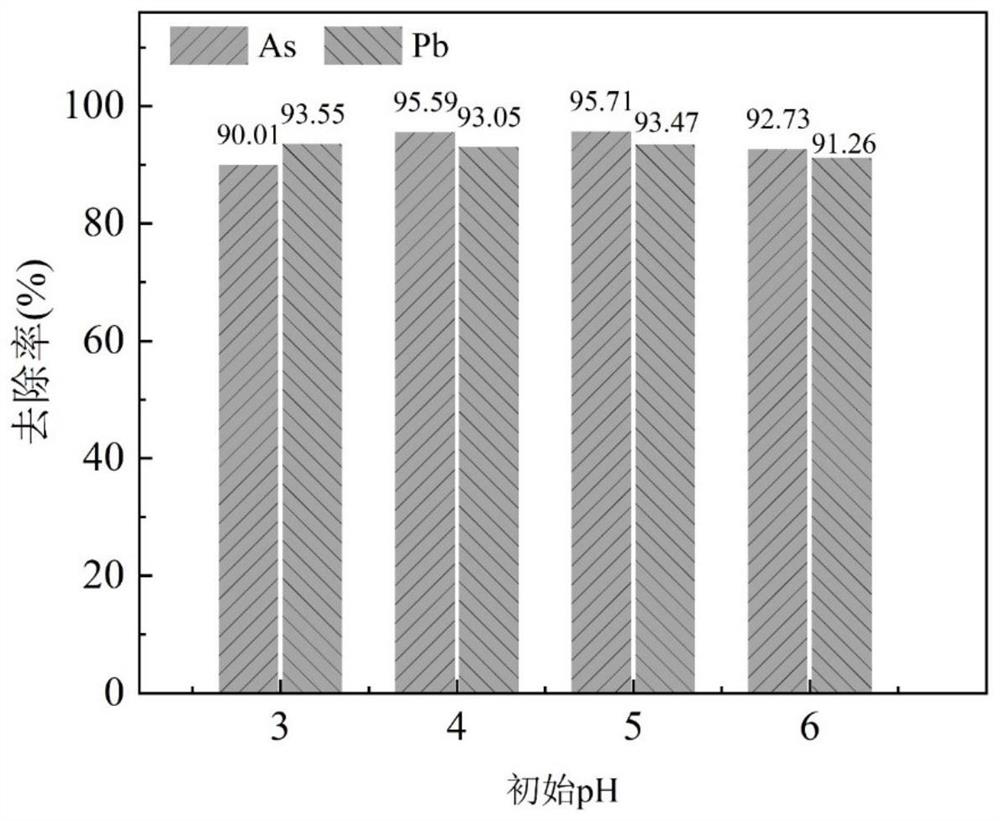

Preparation and application of iron-sulfur co-doped biochar material for simultaneously removing lead-arsenic combined pollution

PendingCN113856621AEfficient removalEasy to operateOther chemical processesWater contaminantsIndustrial waste waterFreeze-drying

The invention relates to preparation and application of an iron-sulfur co-doped biochar material for simultaneously removing arsenic-lead combined pollution. The iron-sulfur co-doped biochar material is prepared by the following steps of: performing magnetic stirring on straw powder and turbid liquid containing ferrous sulfate and sodium thiosulfate according to a solid-to-liquid ratio of (7-12) g: 100mL for 10-36 hours; fully mixing the materials; performing freeze drying; and performing pyrolysis at 250-450 DEG C for 1-3 hours. The molar ratio of the ferrous sulfate to sodium thiosulfate in the turbid liquid is (0.7-2): 1. The iron-sulfur co-doped biochar can efficiently adsorb arsenic and lead in a combined polluted water body at the same time, the optimal removal rate of As (III) within 24 hours reaches 96% or above, and the removal rate of Pb (II) reaches 93% or above; and the removal rates of As (III) and Pb (II) can be kept above 90% under the condition that the pH is 3-6. The iron-sulfur co-doped biochar is obtained through one-time calcination after raw material impregnation, operation is easy, and the arsenic and lead removal effect is remarkable; and the iron-sulfur co-doped biochar has practical significance in treatment of industrial wastewater subjected to arsenic-lead combined pollution.

Owner:GUANGDONG UNIV OF TECH

Autotrophic and heterotrophic compound ore-leaching flora FIM-Z4 and application thereof

ActiveCN105199990AImprove leaching rateImprove leaching reaction kineticsBacteriaMicroorganism based processesLeaching rateAcidithiobacillus thiooxidans

The invention discloses autotrophic and heterotrophic compound ore-leaching flora FIM-Z4 and application thereof and provides a mixed culture FIM-Z4 of acidithiobacillus ferrooxidans, acidithiobacillus thiooxidans and acidiphiliu acidophilum; the preservation number of the mixed culture FIM-Z4 is CGMCC No.11190. Through synergistic effect, the leaching reaction kinetics is improved obviously, the reaction speed is increased, the leaching period is shortened, and the leaching rate and leaching yield of metal (copper and nickel) ions in target ore are increased. The heterotrophic compound ore-leaching flora FIM-Z4 is a compatible whole, and the population ecology keeps relatively stable in a long-term domestication process. The heterotrophic compound ore-leaching flora FIM-Z4 is applied to biological metallurgy and has a better leaching effect on copper ions in low-grade copper sulphide ore and nickel ions in low-grade nickel ore.

Owner:FUJIAN INST OF MICROBIOLOGY

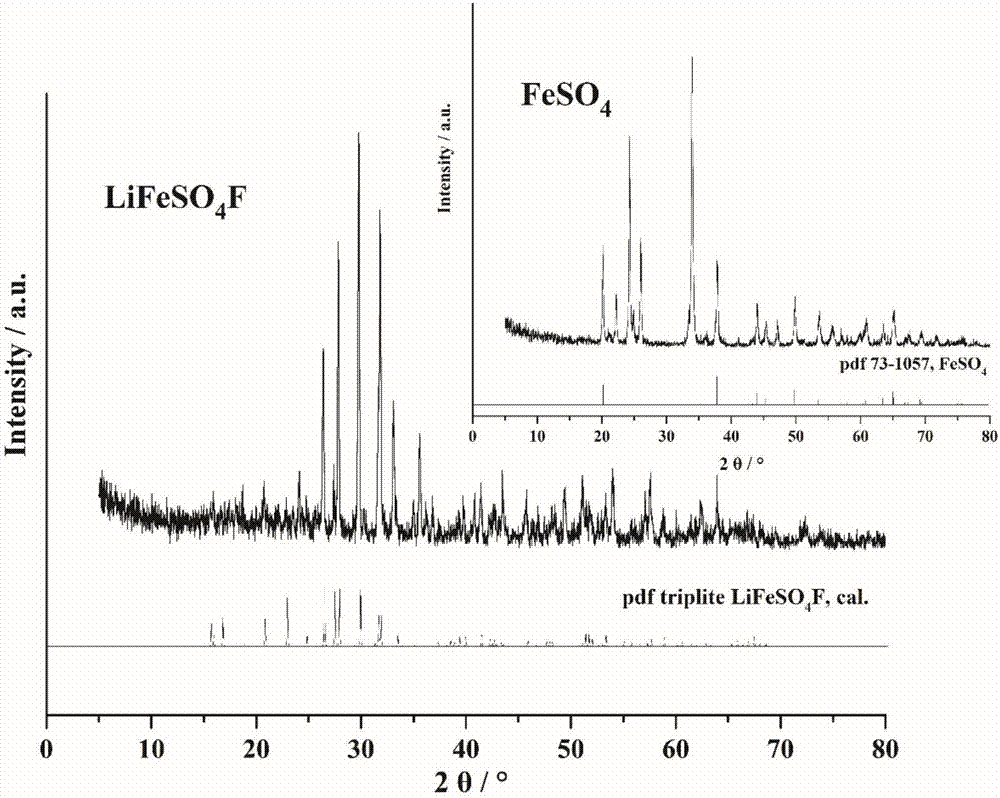

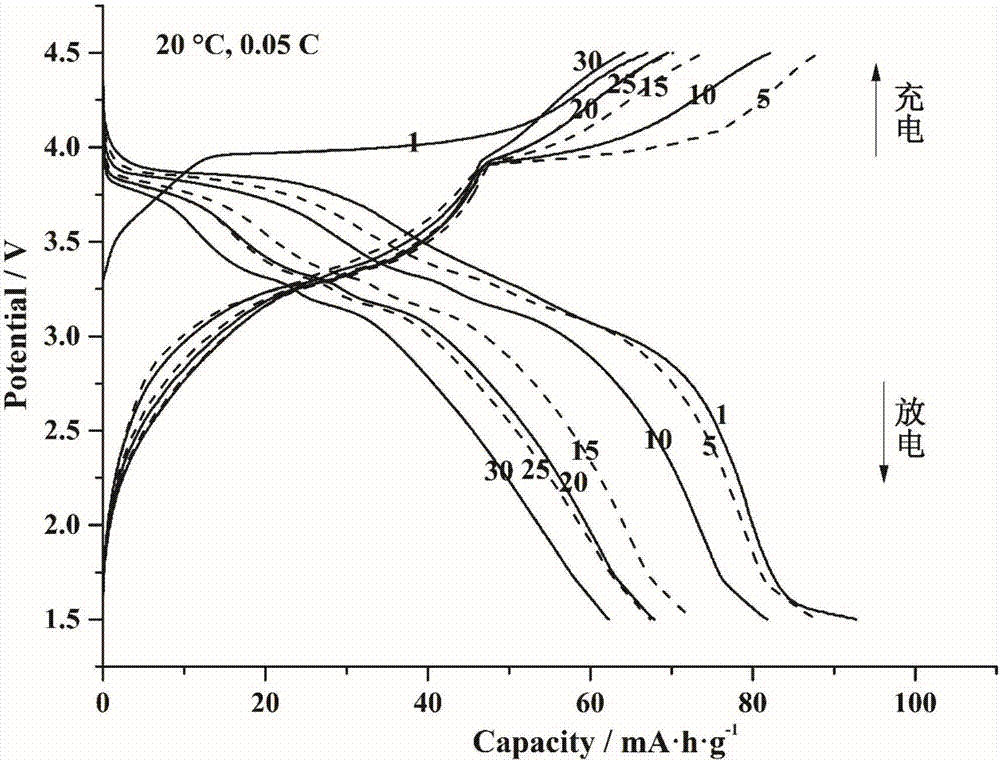

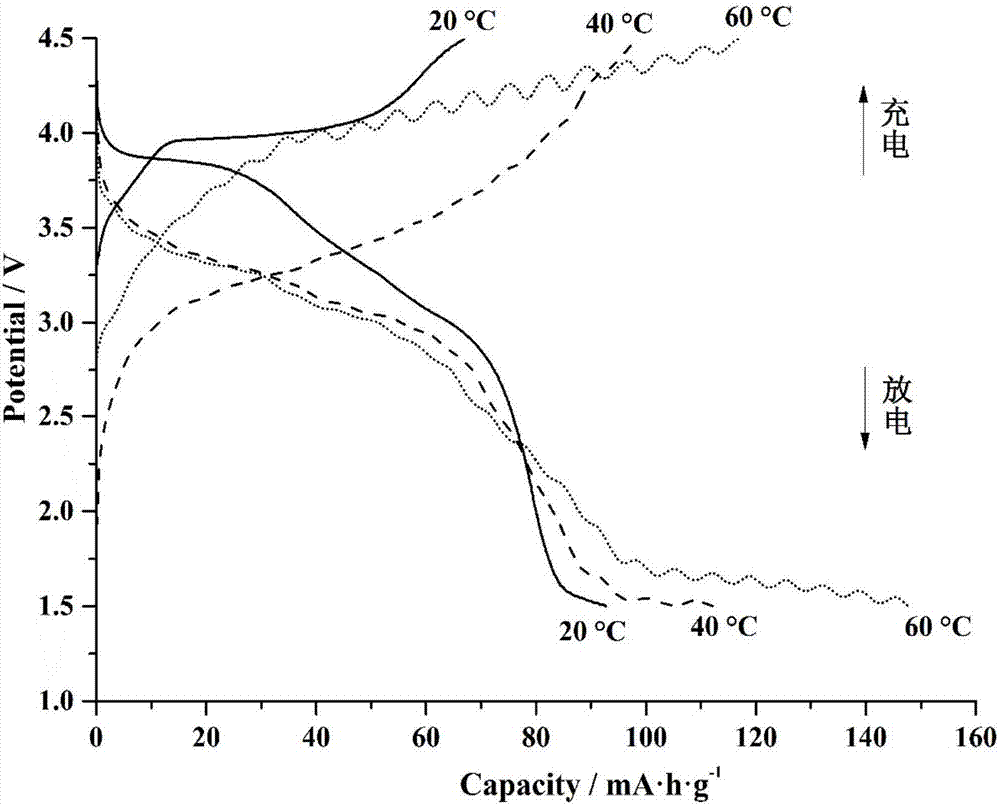

Preparation method of phase-change type LiFeSO4F cell material stable at high temperature, electrode plate, and usage of lithium ion cell

ActiveCN107230779AImprove cycle stabilityImprove discharge capacityCell electrodesSecondary cells servicing/maintenanceLithiumSulfur

The invention provides a preparation method of a phase-change type LiFeSO4F cell material stable at high temperature, an electrode plate, and usage of a lithium ion cell. The preparation method of the cell material comprises the following steps of first, weighing one of the followings according to a stoichiometric ratio of FeSO4: i. iron source and sulfur source, and ii. iron-sulfur source, grinding and mixing, and calcining in an inert gas for 1-2 hours at 380-400 DEG C, so as to obtain FeSO4 pure phase powder; second, preparing LiFeSO4F powder: weighing, according to a stoichiometric ratio of LiFeSO4F, ferrous sulfate powder and lithium fluoride powder prepared in the first step, grinding to obtain Li-Fe-S-O-F precursor powder, wherein the molar mass of the lithium fluoride powder is 1-1.05 times that of the ferrous sulfate; and third, calcining mixed powder obtained in the second step in the inert gas for 0.75-2.25 hours at 450-500 DEG C, so as to obtain LiFeSO4F pure phase powder. In charging and discharging of the cell material prepared by the method, phase change from LiFeSO4F of a Triplite structure to LiFeSO4F(1-x)(OH)x of a Tavorite structure occurs, an obvious -3.2V voltage platform is formed, and cycle stability of charging and discharging at 20-60 DEG C is high.

Owner:WUHAN UNIV OF TECH

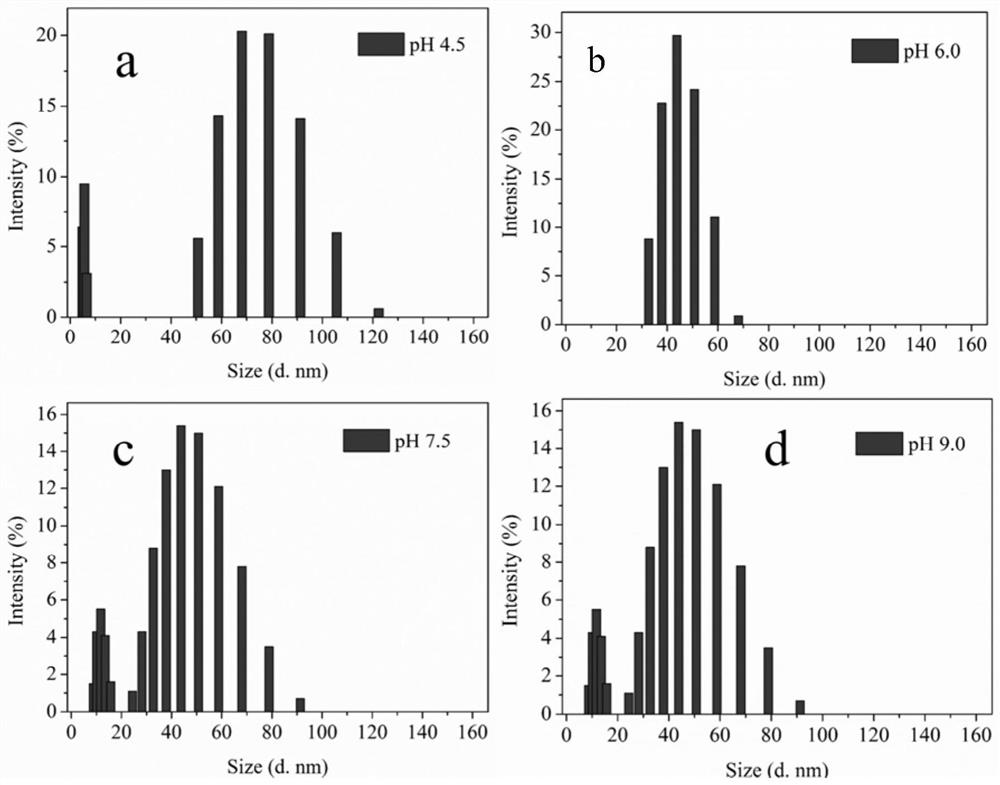

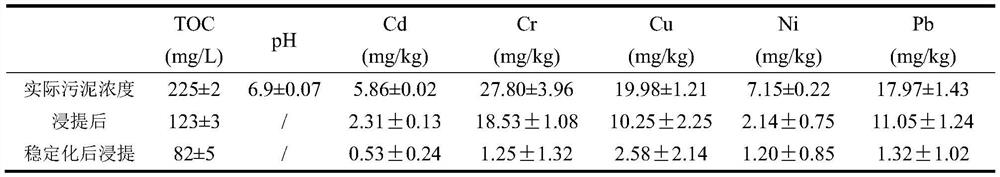

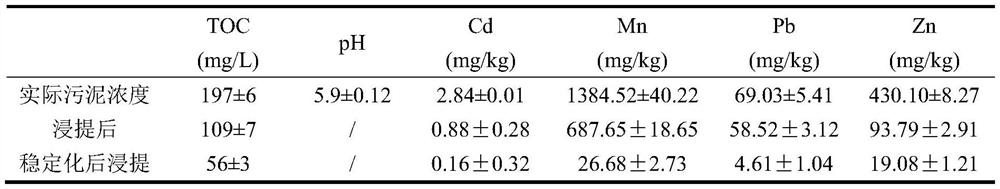

Reductive iron-sulfur mixed colloid as well as preparation method and application thereof

InactiveCN111620530AImprove stabilityPotential for good practice applicationSludge treatmentWater contaminantsProcess equipmentIron sulphur

The invention discloses a reductive iron-sulfur mixed colloid as well as a preparation method and application thereof. The colloid comprises a water-soluble organic polymer compound and a ferrous sulfide compound; the water-soluble organic polymer compound is one or two of polyacrylate and polymethacrylate. The reductive iron-sulfur mixed colloid provided by the invention has high passivation rateon heavy metals in sludge under different pH and organic matter conditions, and the passivation effect is remarkable and long-lasting. The preparation method disclosed by the invention is simple, practical, convenient and easy to implement, simple in process equipment requirement, green in process flow, free of secondary pollution, wide in raw material cost source and low in price, can be used for efficiently passivating polluted heavy metal sludge, and has good market application potential.

Owner:NANJING NORMAL UNIVERSITY

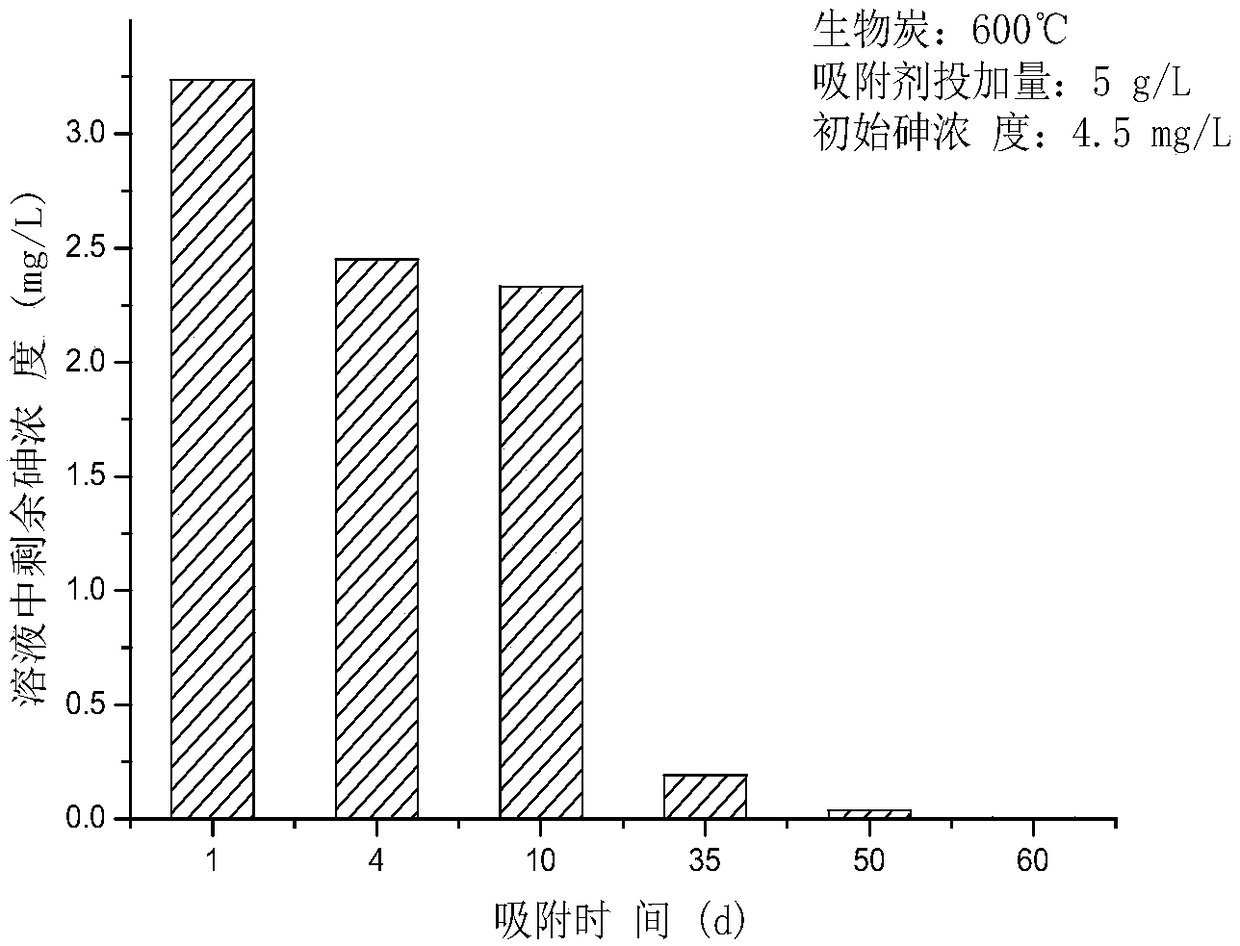

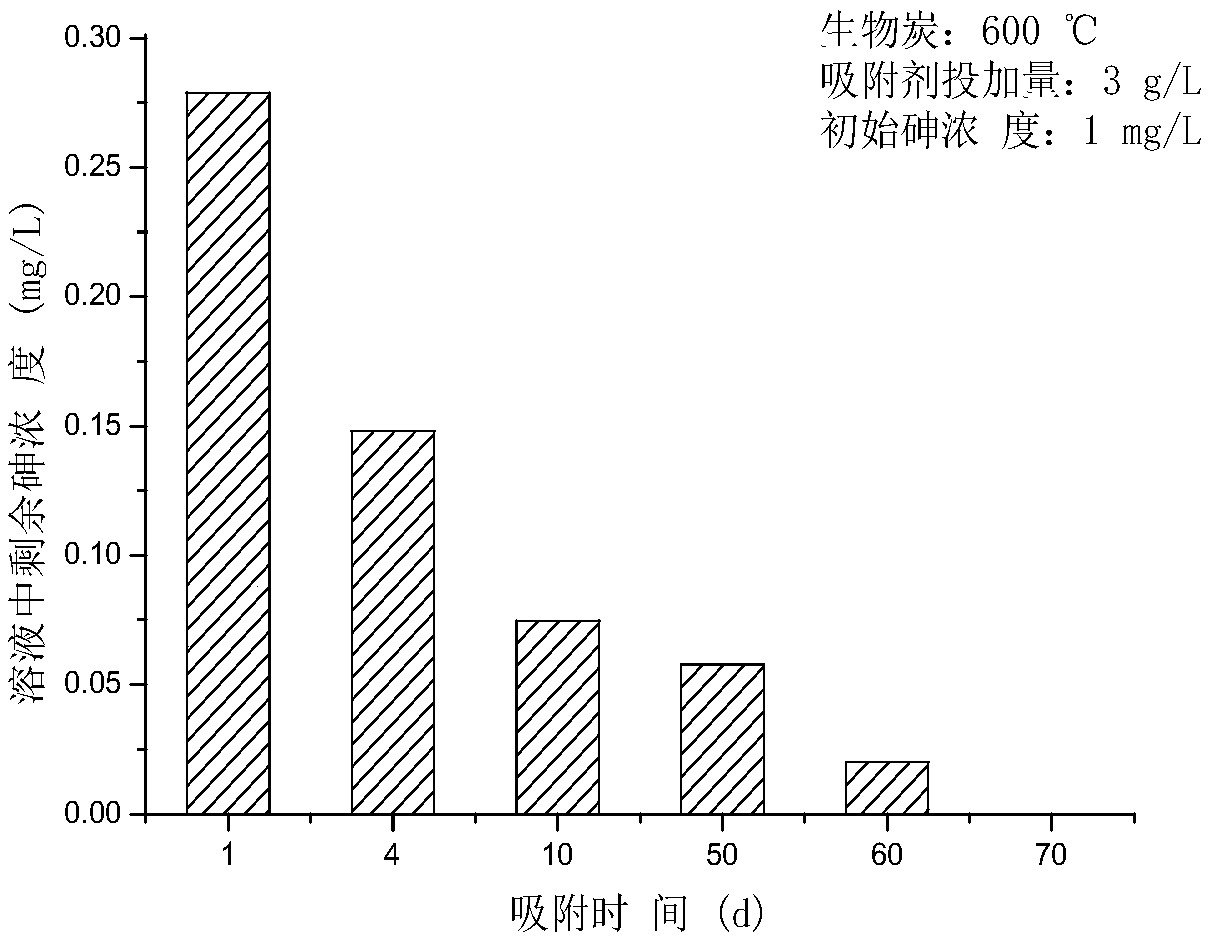

Preparation method and application of a kind of hydroxy iron sulfate sludge-based biochar

ActiveCN106179201BRealize resource utilizationAchieve reductionOther chemical processesWater contaminantsIron sulfateSludge

The invention provides a method for preparing hydroxy ferric sulfate slurry-based charcoal. The method comprises the following steps: (1) adjusting the pH value of a conventional municipal sludge solution with sulfuric acid to separate internal iron in sludge; (2) inoculating acidithiobacillus ferrooxidans into the sludge, wherein hydroxyl ferric sulfate sludge is formed from the acidithiobacillus ferrooxidans by utilizing the internal iron in the sludge; (3) dehydrating the hydroxyl ferric sulfate sludge, and drying; and (4) grinding and screening the dried sludge, and pyrolyzing the screened sludge in N2 protection. The hydroxy ferric sulfate slurry-based charcoal formed by pyrolysis contains schwertmannite which has an efficient and specific adsorbing effect on arsenic. The hydroxy ferric sulfate slurry-based charcoal has the advantages that hydroxyl ferric sulfate is generated by utilizing internal iron in sludge, and cost is reduced; the prepared hydroxy ferric sulfate slurry-based charcoal can be used for efficiently specifically adsorbing arsenic in sludge, so that the sludge resource is utilized, and a novel arsenic adsorbent is provided.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

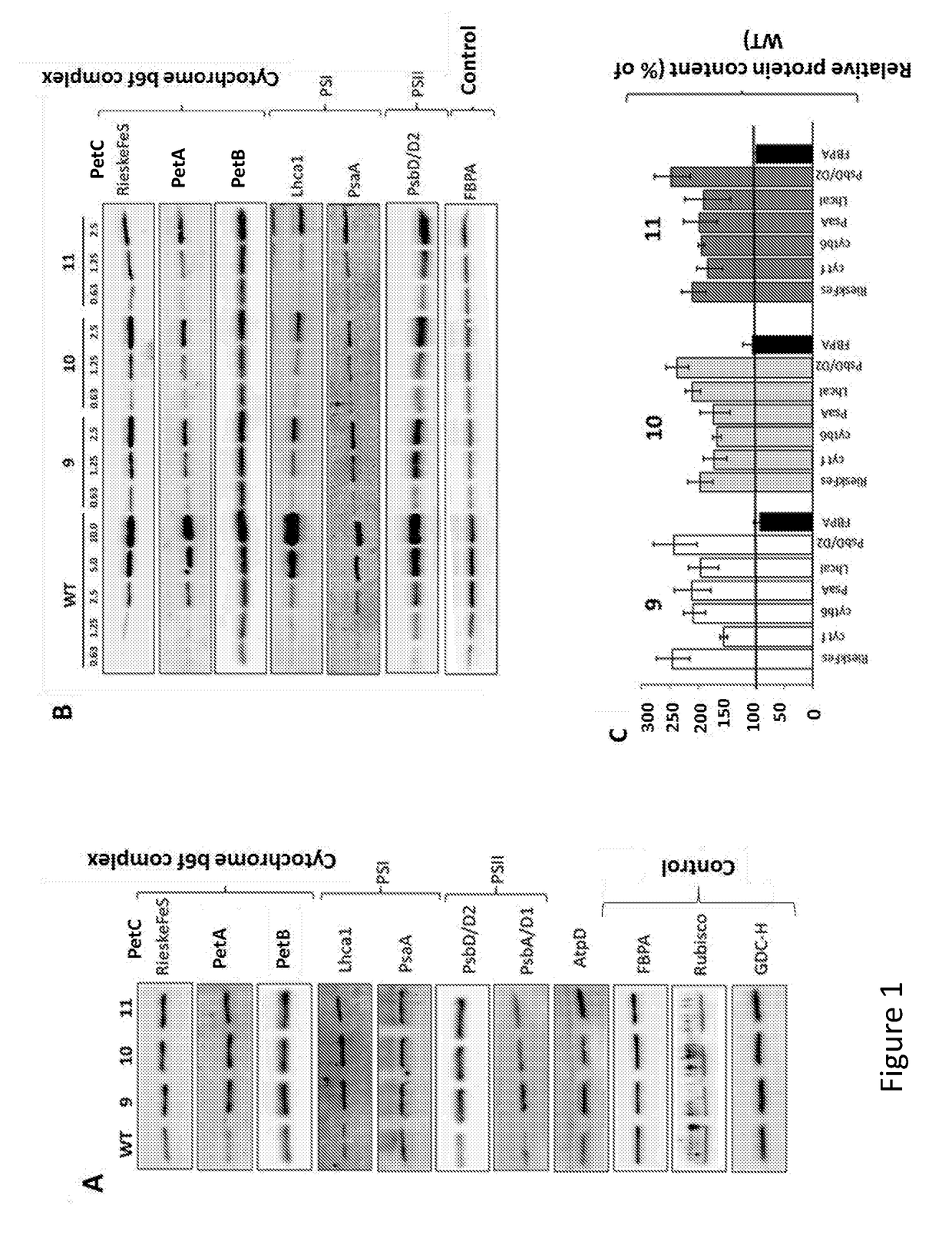

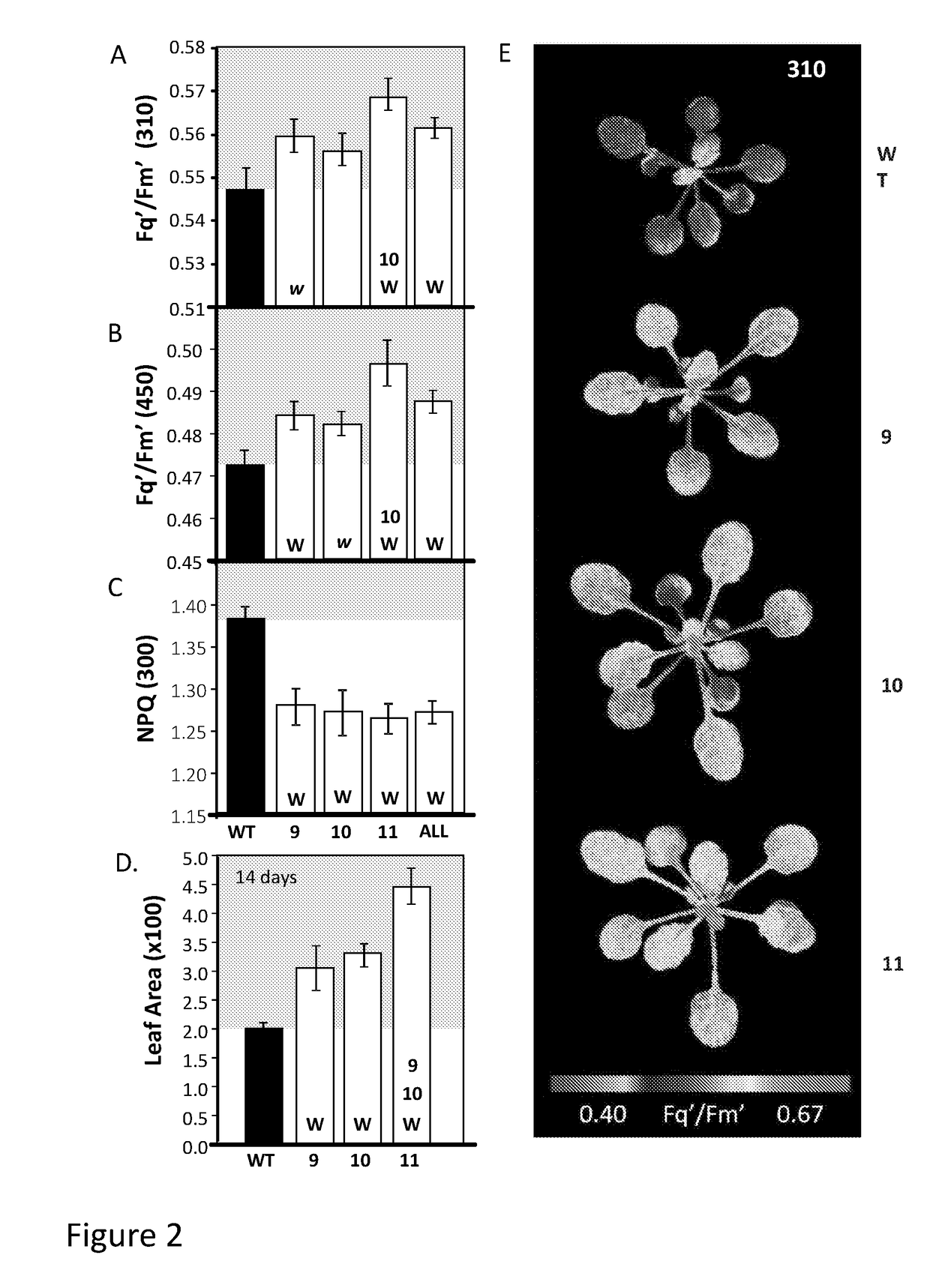

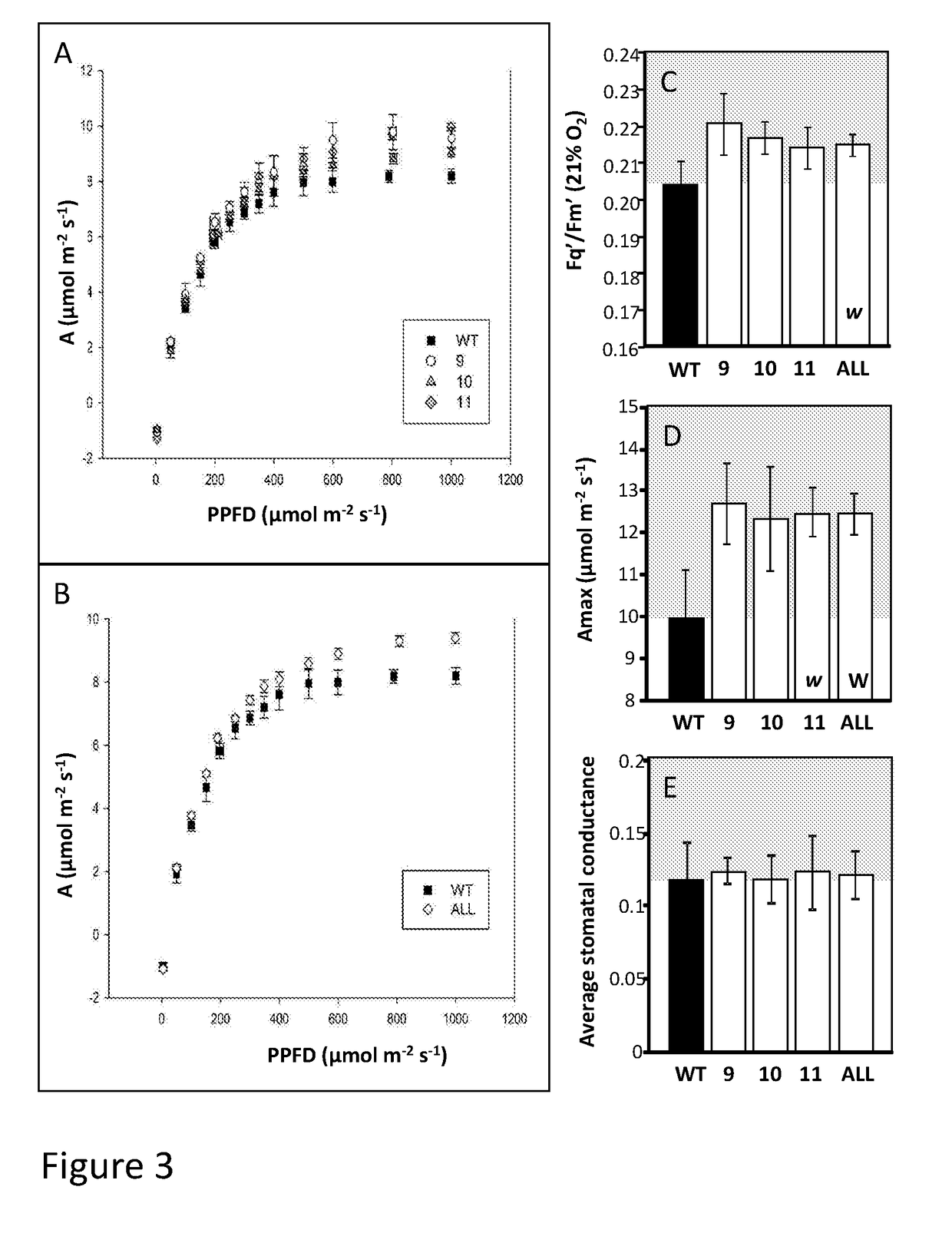

Enhancing Photosynthesis

ActiveUS20190062774A1Increase ratingsIncrease planting yieldClimate change adaptationPlant peptidesIron sulphurTransgene

Certain embodiments of the present invention relate to methods and products for enhancing the rate of photosynthesis in a plant. In addition, certain embodiments relate to transgenic plants and progeny thereof which comprise an exogenous Rieske Iron Sulphur protein.

Owner:UNIV OF ESSEX ENTERPRISES

Preparation method and application of spherical nano iron-sulfur composite material

ActiveCN112479341AImprove performanceImprove efficiencyWater contaminantsContaminated soil reclamationPhenolic content in teaFerrous salts

The invention discloses a preparation method and application of a spherical nano iron-sulfur composite material, and the preparation method comprises the following steps: dissolving a ferrite in a hydrochloric acid solution at room temperature, introducing nitrogen, adding a Na2S solution under a stirring condition, carrying out a reaction, then adding tea polyphenol, continuously conducting stirring, and carrying out a reaction to obtain black particles; and carrying out post-treatment to obtain the spherical nano iron-sulfur composite material. The molar ratio of Na2S to the ferrite is 5:1 to 1:1; and the molar ratio of the tea polyphenol to the ferrite is 1:2 to 2:1. The spherical iron-sulfur composite material activated persulfate has the advantages of high electron transport speed, high persulfate activation efficiency, high oxidation capacity of generated active free radicals, high persulfate utilization rate and the like, and has a wide application prospect in the aspect of remediation of organic contaminated soil and water bodies.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com