Passivator for repairing mercury-polluted soil as well as preparation method and application thereof

A technology of soil passivation and passivating agent, which is applied in the field of mercury-contaminated soil remediation, can solve the problems of selenium-contaminated soil and low risk of mercury secondary release, and achieve the effect of wide sources, favorable reuse and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

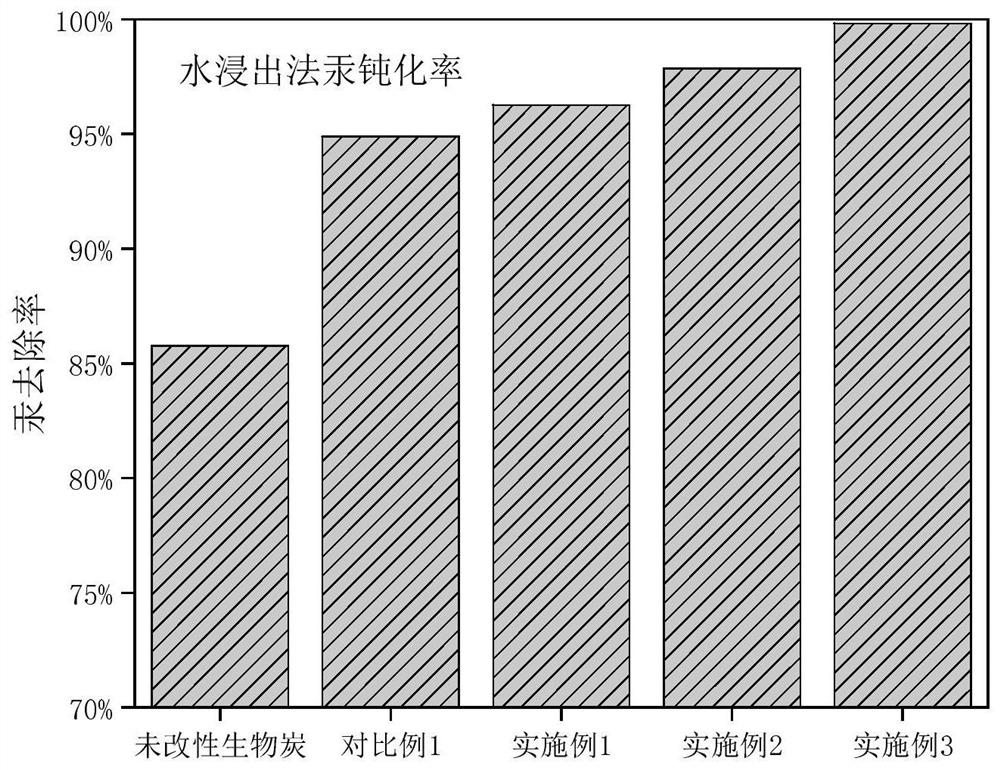

Embodiment 1

[0042] In the preparation process of the soil passivation agent described in this example, the ratio of sodium selenite to ferrous sulfide-loaded biochar is 0.051mmol: 5g, and the preparation process is as follows:

[0043] (1) After washing the pomelo peel with deionized water for 3 times, put it in an oven at 105°C and dry it for 1 day; grind it with a mortar for 10 minutes to make the particle size pass through a 10-mesh sieve.

[0044] (3) Put the dried and ground pomelo peel in a 200ml aluminum box, the volume of the aluminum box is Cover it, put it into the muffle furnace, set the heating rate to 300°C / h, the carbonization temperature to 600°C, and the holding time to 2h.

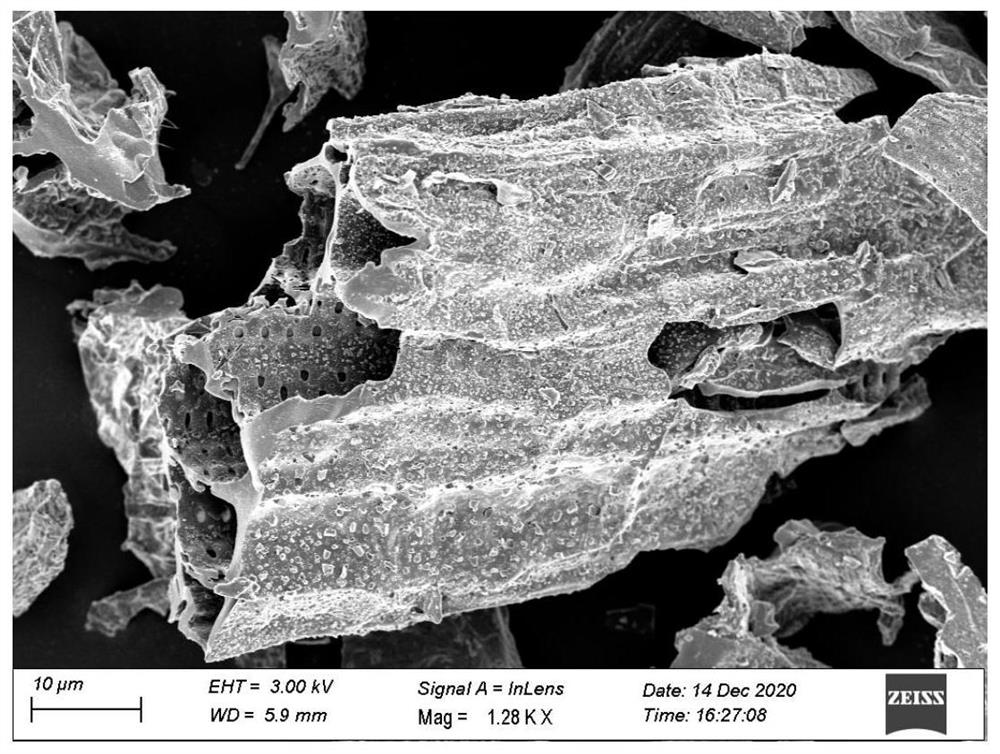

[0045](4) Take 20 g of the biochar produced in step (3) and place it in 200 ml of 0.045 mol / L ferrous solution, and stir at a speed of 800 rpm for 12 h, and the gas atmosphere is nitrogen. After 24 hours, 200 ml of 0.045 mol sodium sulfide solution was added dropwise within 10 minutes, reacted for 5...

Embodiment 2

[0049] In the preparation process of the soil passivation agent described in this example, the ratio of sodium selenite to ferrous sulfide-loaded biochar is 0.506mmol: 5g, and the preparation process is as follows:

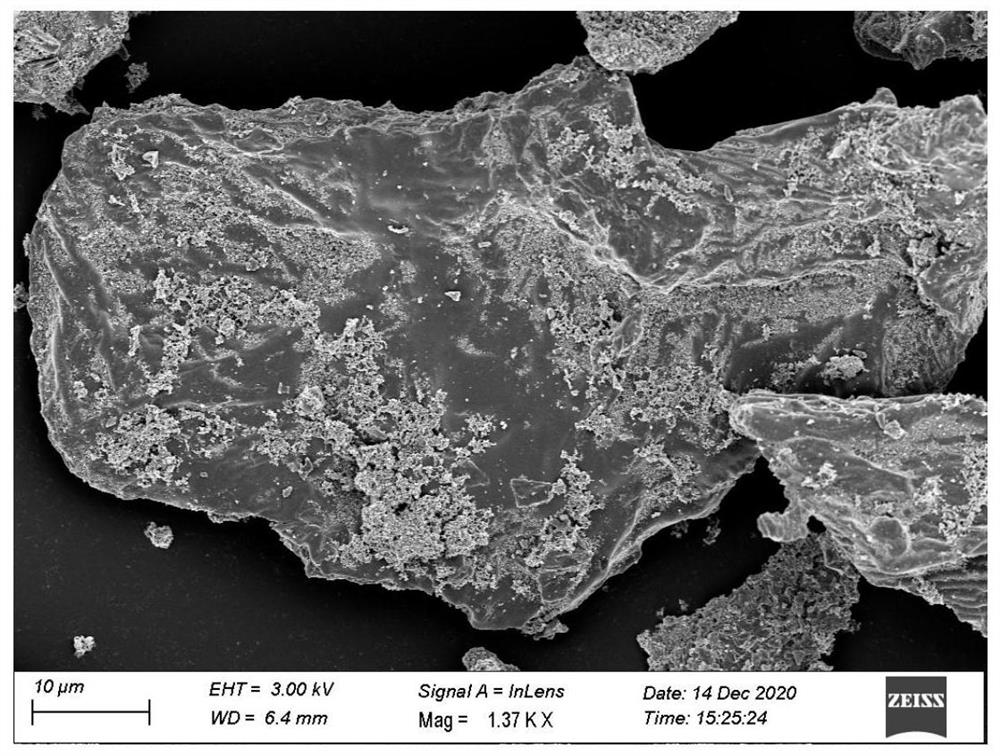

[0050] Other conditions are the same as in Example 1, except that during step (5), 5 g of ferrous sulfide loaded biochar will be placed in the sodium selenite solution of 1000ml 0.506mmol / L, and stirred at a speed of 800rpm for 24h, gas The atmosphere is nitrogen. Be the product of Example 2 after freeze-drying.

Embodiment 3

[0052] In the preparation process of the soil passivation agent described in this example, the ratio of sodium selenite to ferrous sulfide-loaded biochar is 5.06mmol: 5g, and the preparation process is as follows:

[0053] Other conditions are the same as in Example 1, except that during step (5), the ferrous sulfide loaded biochar 5g will be placed in the sodium selenite solution of 1000ml 5.06mmol / L, and stirred at a speed of 800rpm for 24h, gas The atmosphere is nitrogen. Be the product of Example 3 after freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com