Method and device for improving beneficiability of niobium mineral in niobium-containing tailings

A technology for minerals and tailings, applied in the field of microbial pretreatment of niobium-containing tailings, can solve the problems of low recovery rate and low grade, and achieve the effect of easy floating and improving the difference of floatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

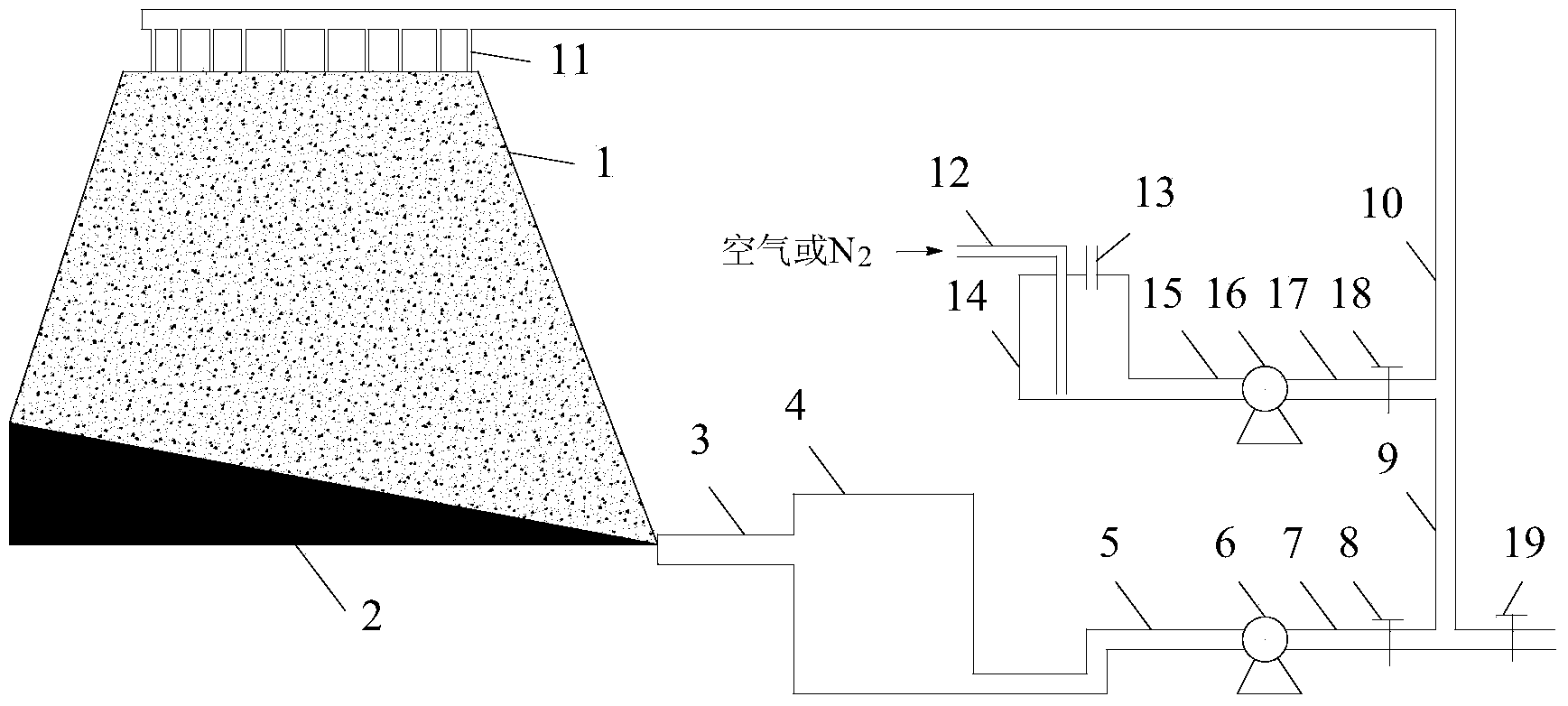

[0022] figure 1 It is an illustration of a device for recovering niobium minerals from niobium-containing tailings. The device includes: ore pile 1, acid-resistant slope foundation 2, pipeline 3, liquid collection tank 4, pipeline 5, liquid delivery pump 6, pipeline 7, Valve 8, pipeline 9, pipeline 10, spray pipe 11, gas pipeline 12, gas pipeline 13, medium storage tank 14, pipeline 15, liquid delivery pump 16, pipeline 17, valve 18 and valve 19.

[0023] (1) Surface modification of niobium minerals

[0024] Pile the niobium-containing complex tailings to be processed on the impermeable, acid-resistant slope foundation 2 to form an ore pile 1, install a spray pipe 11 on the surface of the ore pile 1, and build a liquid collection pool 4 at a lower position to collect leachate. First add Thiobacillus ferrooxidans ( Thiobacillus ferrooxidans ) medium and Thiobacillus ferrooxidans, each liter of medium contains (NH 4 ) 2 SO 4 0.15g, K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com